Optimizing Automated Battery Demanufacturing Through Simulation-Based Analysis and Genetic Algorithm

Abstract

1. Introduction

2. Methods

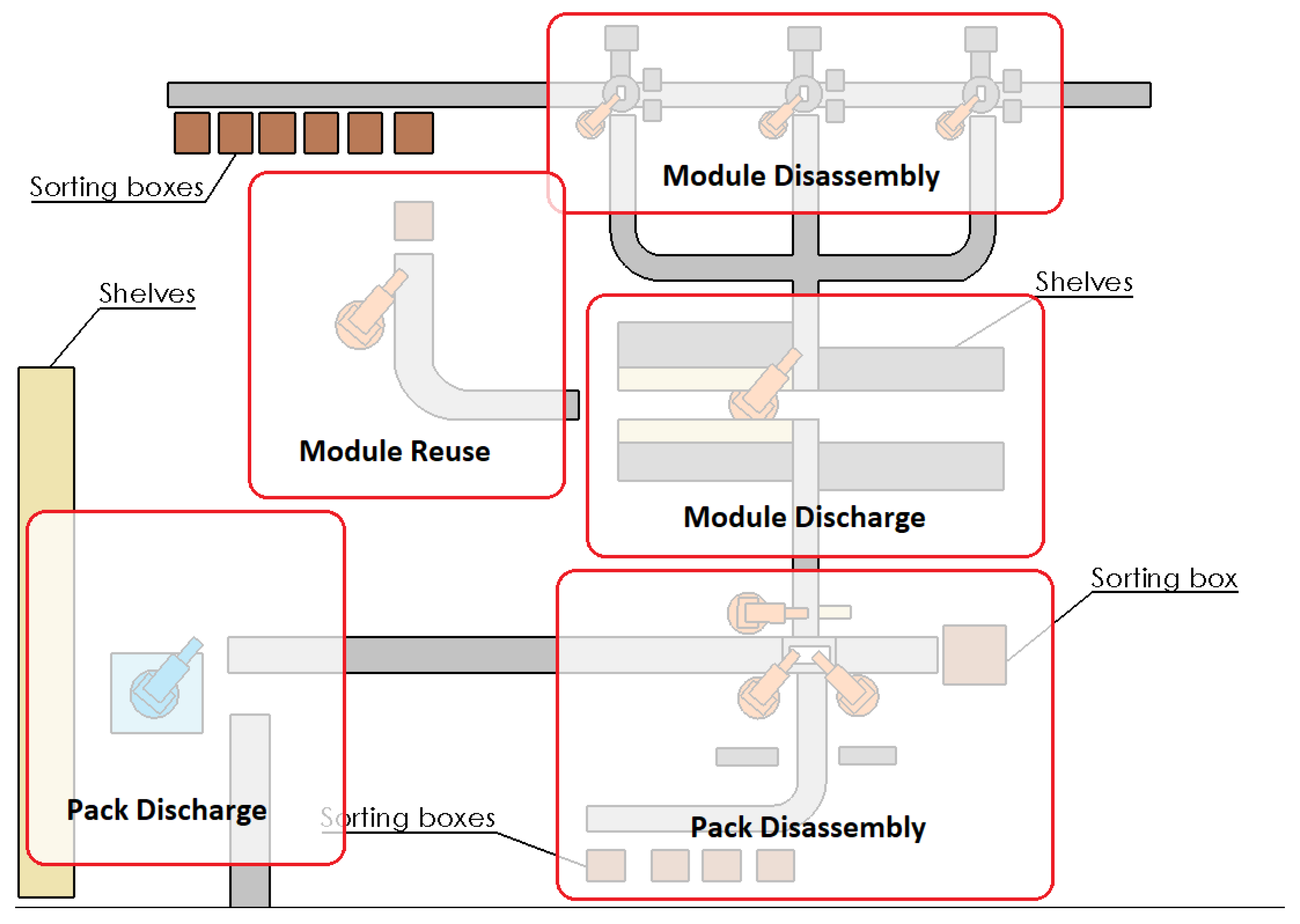

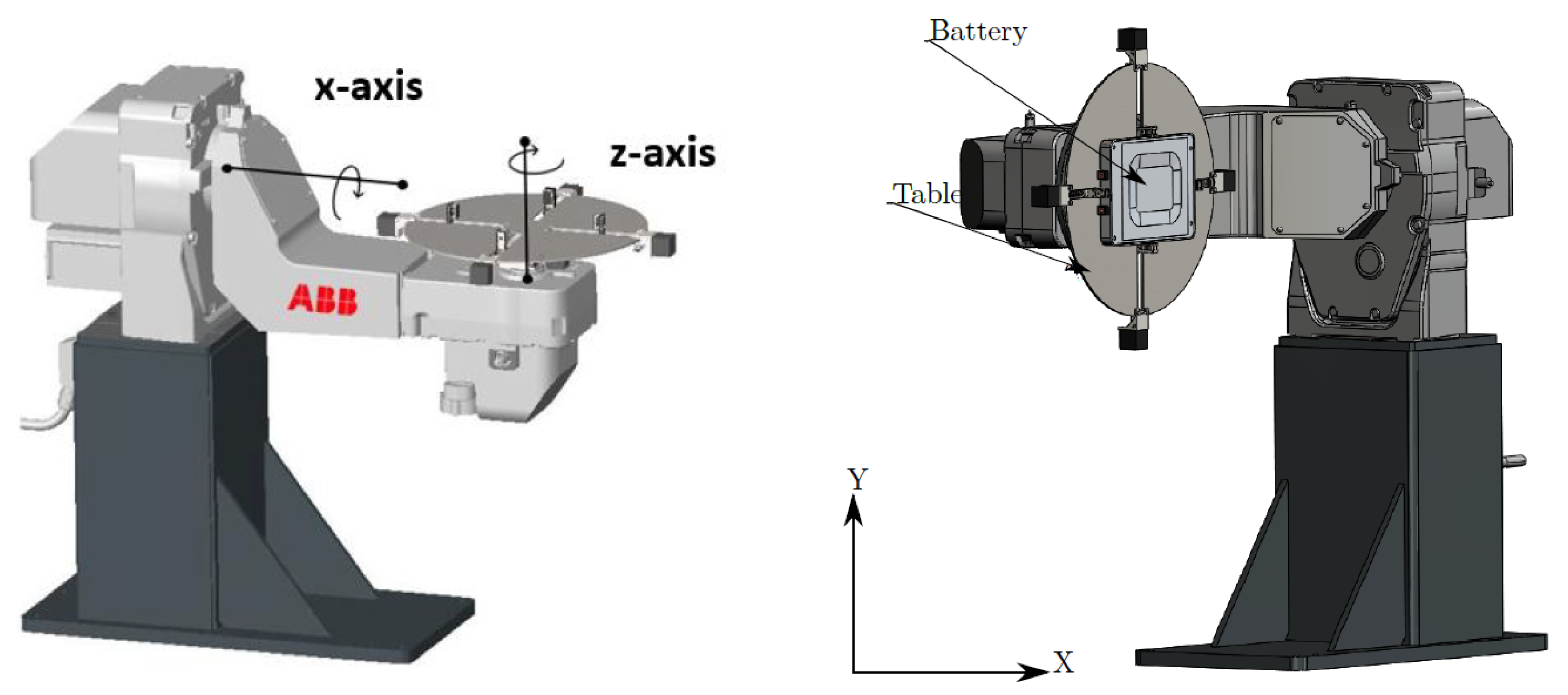

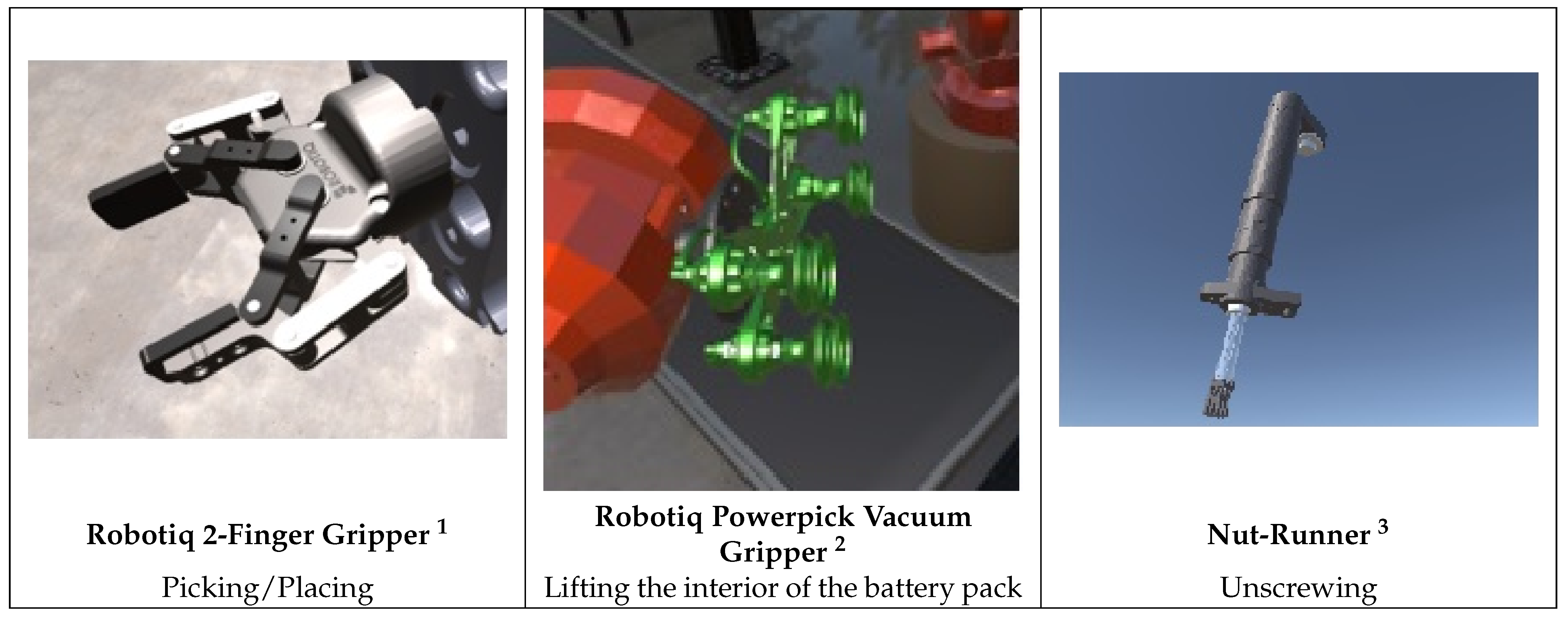

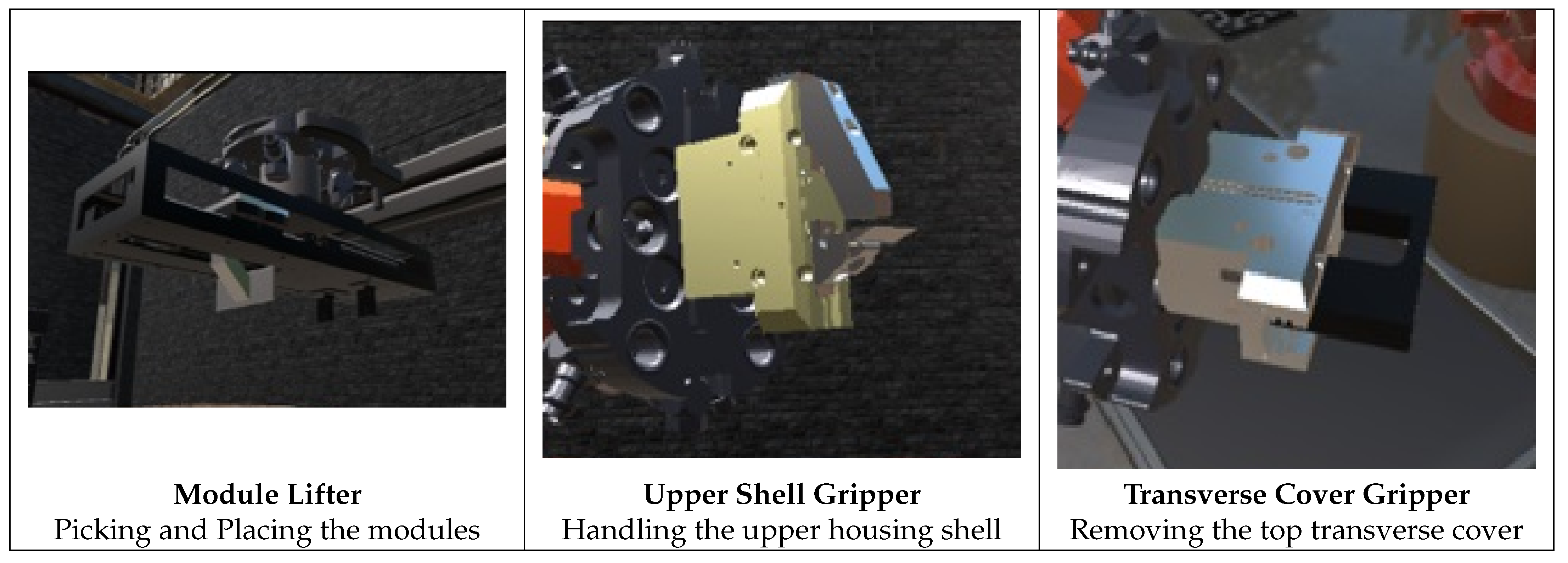

2.1. Robotic Cell Design

2.1.1. Pack Discharge Station

2.1.2. Pack Disassembly Station

2.1.3. Module Characterization and Deep Discharge Station

2.1.4. Module Disassembly Station

2.1.5. Sorting System

2.2. Simulation Environment

2.2.1. 3D Models

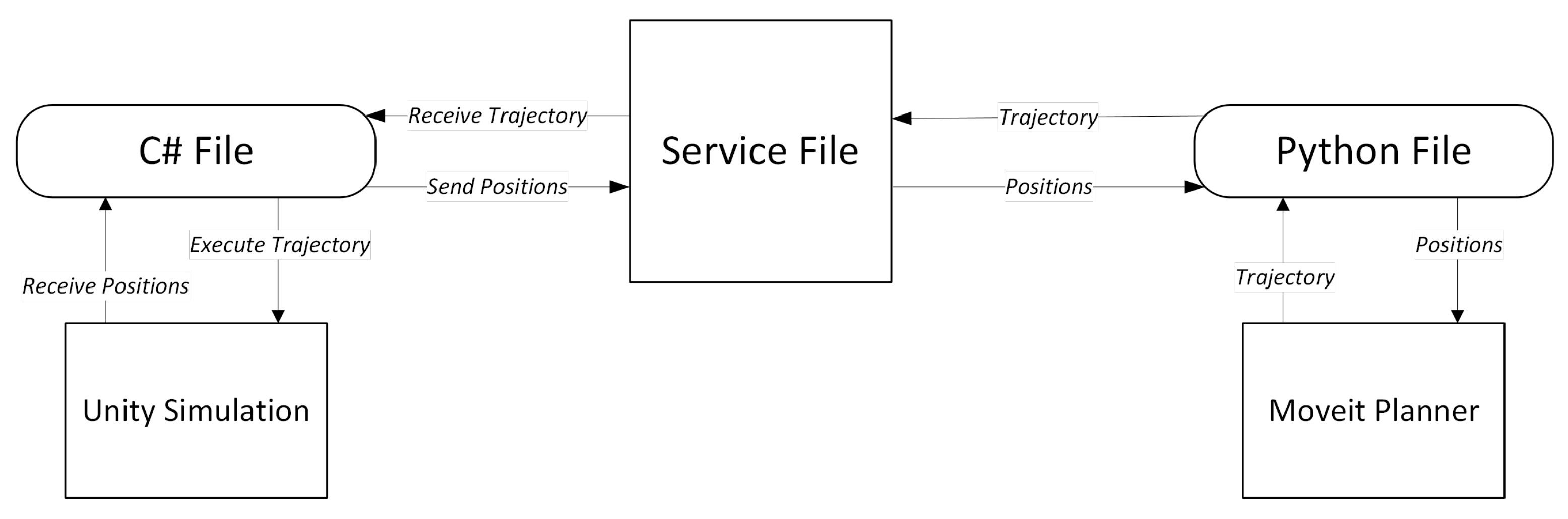

2.2.2. ROS–Unity Communication

2.3. Time Calculation

- High-Precision Timing with “Stopwatch”: For operations where precision is critical, the “Stopwatch” class from the “System.Diagnostics” namespace is utilized. This method allows for high-resolution timing, which is especially useful for capturing variations in operation lengths within complex or rapid sequences of coroutine functions. The stopwatch is started at the beginning of an operation and stopped upon completion, providing an accurate measure of the elapsed time in real-world seconds.

- Real-Time Measurement with “Time.time”: For a broader assessment, Unity’s “Time.time” is employed to measure the time from the start until the end of an operation. This simpler method offers a straightforward way to gauge the duration of longer processes, accurately reflecting real time progression.

2.4. Optimization of Disassembly Sequence Using Genetic Algorithm

3. Case Study and Results

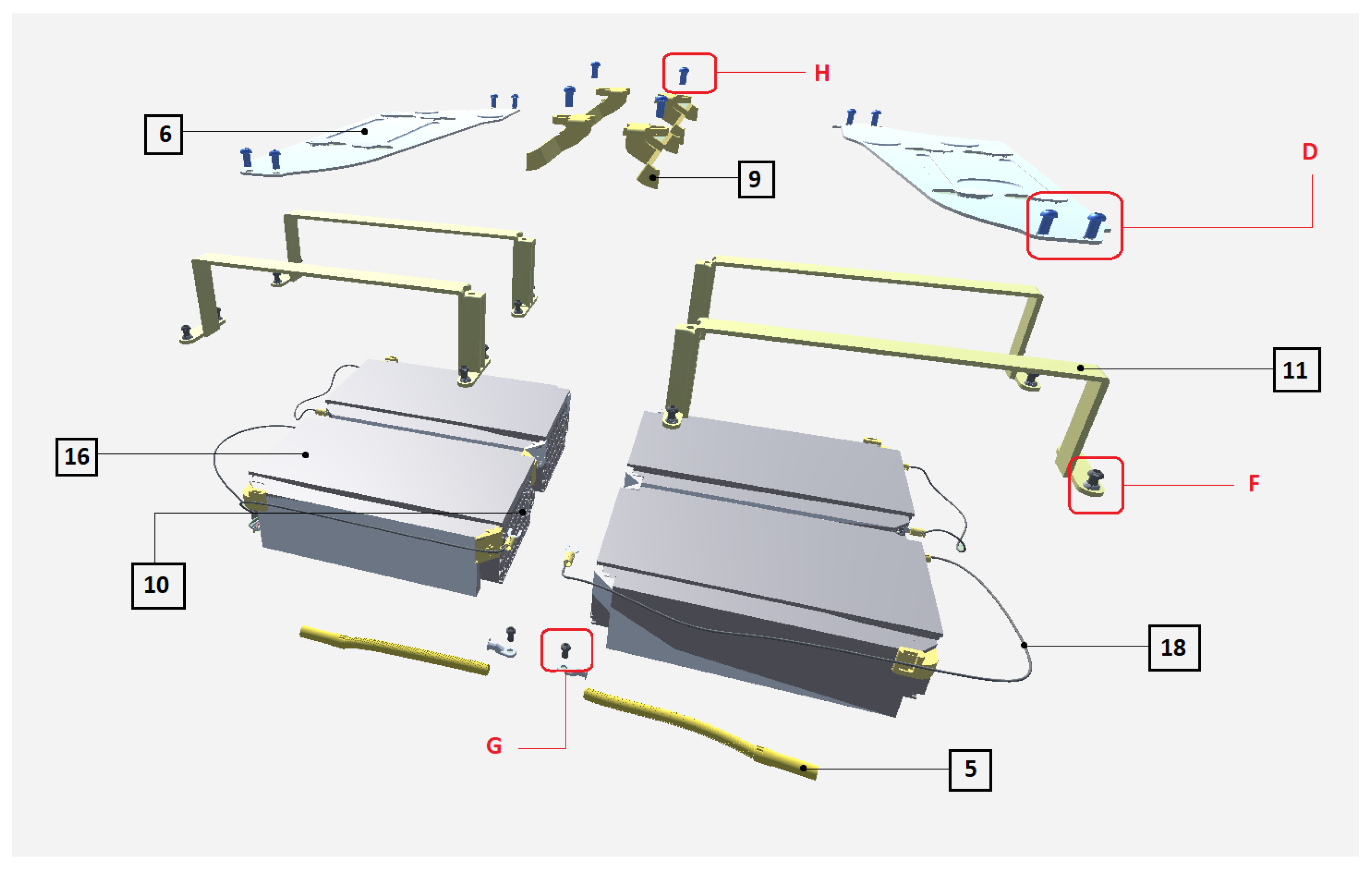

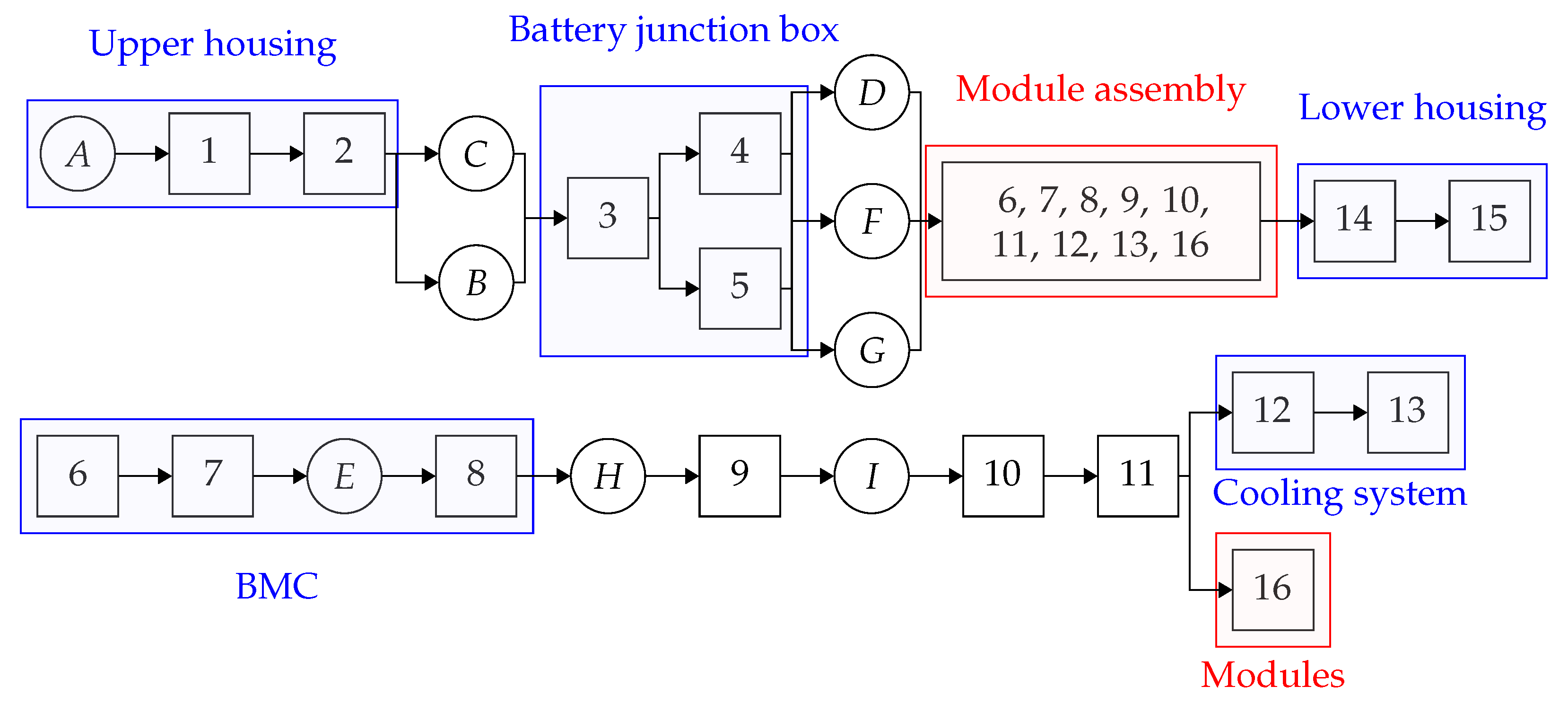

3.1. Description of the Battery Pack and Its Disassembly Process

3.2. Time Estimation for Demanufacturing

- Since transportation of live battery packs is not recommended [24,25], the battery packs are first opened at the collection site and high voltage-cables are disconnected. This step takes care of the glue (if any) used to seal the upper housing shell to the lower housing of the battery pack. Hence, the removal of glue/sealant is not simulated.

- The time needed for the discharging of battery pack to a low voltage and the complete discharge of modules to zero voltage is not considered within the scope of this paper and is conducted simultaneously with the other disassembly operations. Therefore, once the normal operation has started, discharging does not contribute to the overall time calculations of the operations.

- Detection and identification of battery components is not within the scope of this paper. It is assumed that all parts are identified and localized with acceptable confidence at each step of the operation.

- Fasteners of modules are not included in the model of the module and hence not simulated. The time is estimated based on screw removal time.

- The path planning time for robots is not considered as it is less than 1 s and path planning is performed at the same time as other operations.

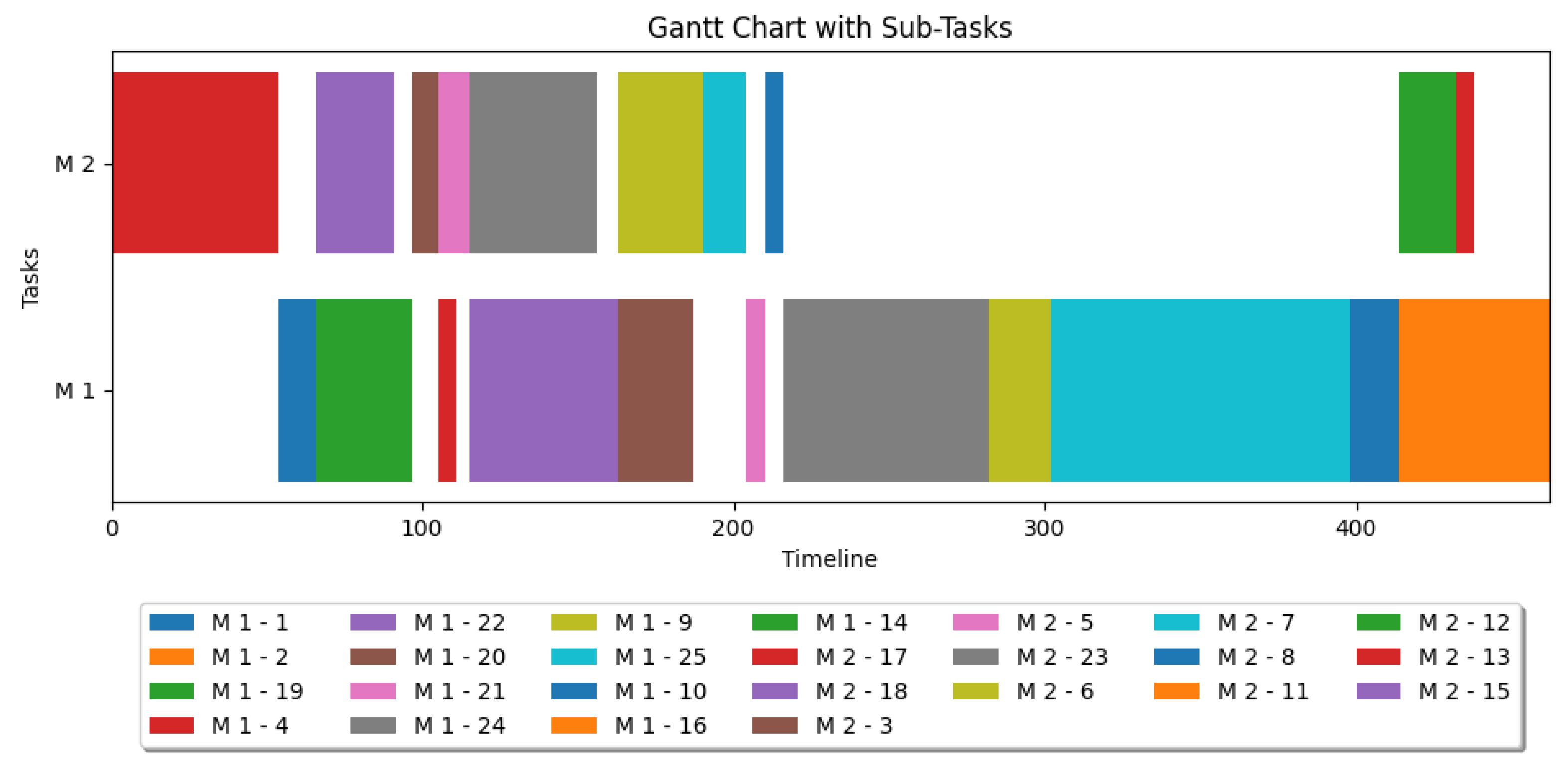

3.3. Genetic Algorithm Optimization

- Jobs (J): 25 disassembly operations (Jobs 0 through 24), representing component and screw removal.

- Processing Time (T): The time required for the machine to complete a job, as calculated and validated by the Unity–ROS simulation (Table 6).

- Chromosomes: The chromosome (solution) is represented by two arrays:

- Job sequence: The GA uses an order-based representation (permutation), where a chromosome is a list of job indices representing the order in which all 25 jobs are processed.

- Machine assignment: The machine dedicated to each job. For this study, the machine assignment is fixed and deterministic, based on a predetermined allocation array rather than being evolved by the algorithm.

- Constraints (C): The component interconnections are defined by the Dependency Matrix (Figure 11), which serves as the core set of precedence constraints.

- Fitness Function (F): The goal is to minimize the total completion time, or Makespan, which is calculated by the internal scheduler using the job sequence and the fixed machine assignments. The fitness function is structured to maximize the inverse of the makespan.

- Generations: 20 generations.

- Population: 6 solutions.

- Selection Method: Softmax transformation to prioritize parents with shorter makespans for reproduction.

- Crossover: The crossover operation employs a modified order-based crossover tailored for sequenced jobs. In this process, elements of the two selected parent sequences are combined to generate two offspring sequences while maintaining job uniqueness. To select contributions, each job element in the parental sequence is assigned a random selection rate (1 or 2). If the rate is 1, the corresponding element from Parent 1 is considered; if the rate is 2, the element from Parent 2 is considered. To prevent invalid solutions due to job duplication, if a selected element is already present in the offspring sequence, that element is systematically removed from the available pool of the parent from which it was selected, guaranteeing that each child solution contains unique genetic material.

- Mutation: A sophisticated mutation function was designed to refine the job sequence by integrating precedence awareness. This process involves randomly selecting two jobs from the sequence, evaluating their precedence relationships, and if both jobs share identical precedence constraints, the one with the later processing time is prioritized and inserted ahead of the one with the earlier processing time. This design ensures that the mutation respects the precedence constraints inherent in the job sequence, allowing the rearrangement of jobs only when resource (machine) allocation is the sole limiting factor.

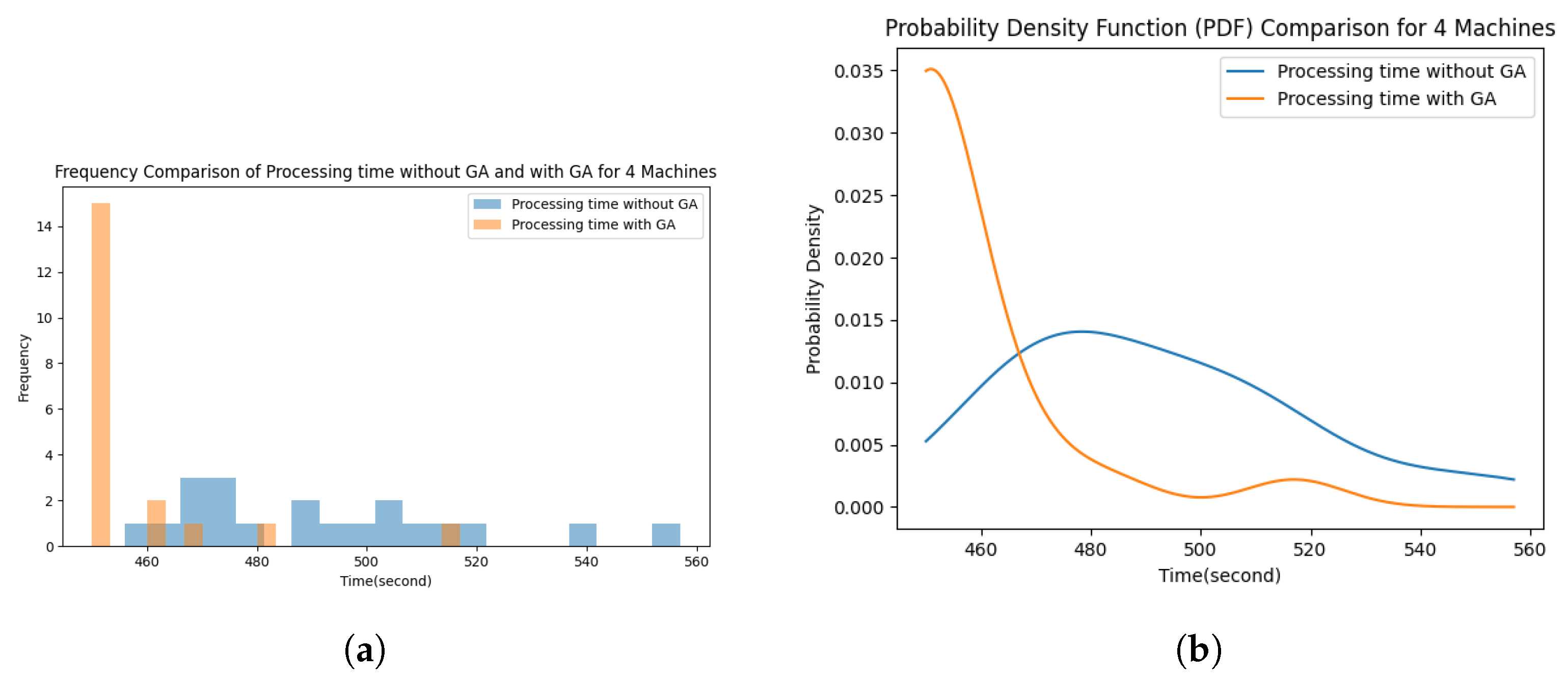

Results of GA Optimization

4. Discussions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EV | Electric Vehicle |

| 3D | Three Dimensional |

| ROS | Robot Operating System |

| VR | Virtual Reality |

| URDF | Unified Robotics Description Format |

| HDRP | High-Definition Rendering Pipeline |

| BEV | Battery Electric Vehicle |

| GA | Genetric Algorithm |

| LIB | Lithium-Ion Battery |

| SoH | State of Health |

| V | Volts |

| ABB | Asea Brown Boveri |

| IRB | Indutrial Robot |

| UR5 | Universal Robot 5 |

| UiA | University of Agder |

| IRBPA | Indutrial Robot Positioner A |

| kWh | Kilowatt-hour |

| GTE | Gran Turismo Electric |

| TCP | Transmission Control Protocol |

| CAD | Computer Aided Design |

| FBX | FilmBox |

| JSSP | Job Shop Scheduling Problem |

| EVB | Electric Vehicle Battery |

| BMC | Battery Management Controller |

| BJB | Battery Junction Box |

| RGB | Red Green Blue |

| NA | Not Applicable |

| RRT | Rapidly Exploring Random Tree |

| TRRT | Transition-Based Rapidly Exploring Random Tree |

References

- Hoener, S.; Mellert, F.T. Offline Programming of Industrial Robots. In Toward the Factory of the Future; Bullinger, H.J., Warnecke, H.J., Eds.; Springer: Berlin/Heidelberg, Germany, 1985; pp. 597–602. [Google Scholar]

- Coronado, E.; Itadera, S.; Ramirez-Alpizar, I.G. Integrating Virtual, Mixed, and Augmented Reality to Human–Robot Interaction Applications Using Game Engines: A Brief Review of Accessible Software Tools and Frameworks. Appl. Sci. 2023, 13, 1292. [Google Scholar] [CrossRef]

- Murhij, Y.; Serebrenny, V. An application to simulate and control industrial robot in virtual reality environment integrated with IR stereo camera sensor. IFAC-PapersOnLine 2019, 52, 203–207. [Google Scholar] [CrossRef]

- Togias, T.; Gkournelos, C.; Angelakis, P.; Michalos, G.; Makris, S. Virtual reality environment for industrial robot control and path design. Procedia CIRP 2021, 100, 133–138. [Google Scholar] [CrossRef]

- Konrad, A. Simulation of Mobile Robots with Unity and Ros: A Case-Study and a Comparison with Gazebo. Master’s Thesis, University West, Trollhättan, Sweden, 2019. [Google Scholar]

- Herrmann, C.; Raatz, A.; Andrew, S.; Schmitt, J. Scenario-based development of disassembly systems for automotive lithium ion battery systems. Adv. Mater. Res. 2014, 907, 391–401. [Google Scholar] [CrossRef]

- Wegener, K.; Andrew, S.; Raatz, A.; Dröder, K.; Herrmann, C. Disassembly of Electric Vehicle Batteries Using the Example of the Audi Q5 Hybrid System. Procedia CIRP 2014, 23, 155–160. [Google Scholar] [CrossRef]

- Wegener, K.; Chen, W.H.; Dietrich, F.; Dröder, K.; Kara, S. Robot Assisted Disassembly for the Recycling of Electric Vehicle Batteries. Procedia CIRP 2015, 29, 716–721. [Google Scholar] [CrossRef]

- Tan, W.J.; Chin, C.M.M.; Garg, A.; Gao, L. A hybrid disassembly framework for disassembly of electric vehicle batteries. Int. J. Energy Res. 2021, 45, 8073–8082. [Google Scholar] [CrossRef]

- Xiao, J.; Jiang, C.; Wang, B. A Review on Dynamic Recycling of Electric Vehicle Battery: Disassembly and Echelon Utilization. Batteries 2023, 9, 57. [Google Scholar] [CrossRef]

- Yin, H.; Xiao, J.; Wang, G. Human-Robot Collaboration Re-Manufacturing for Uncertain Disassembly in Retired Battery Recycling. In Proceedings of the 2022 5th World Conference on Mechanical Engineering and Intelligent Manufacturing (WCMEIM), Ma’anshan, China, 18–20 November 2022; pp. 595–598. [Google Scholar] [CrossRef]

- Li, J.; Barwood, M.; Rahimifard, S. Robotic disassembly for increased recovery of strategically important materials from electrical vehicles. Robot. Comput.-Integr. Manuf. 2018, 50, 203–212. [Google Scholar] [CrossRef]

- Baazouzi, S.; Rist, F.P.; Weeber, M.; Birke, K.P. Optimization of Disassembly Strategies for Electric Vehicle Batteries. Batteries 2021, 7, 74. [Google Scholar] [CrossRef]

- Choux, M.; Marti Bigorra, E.; Tyapin, I. Task Planner for Robotic Disassembly of Electric Vehicle Battery Pack. Metals 2021, 11, 387. [Google Scholar] [CrossRef]

- Blankemeyer, S.; Wiens, D.; Wiese, T.; Raatz, A.; Kara, S. Investigation of the potential for an automated disassembly process of BEV batteries. Procedia CIRP 2021, 98, 559–564. [Google Scholar] [CrossRef]

- Xiao, J.; Terzi, S.; Macchi, M.; Rosa, P. Intelligent disassembly system for end-of-life product using human robot collaboration on a digital twin platform. Procedia CIRP 2025, 136, 654–658. [Google Scholar] [CrossRef]

- Xiao, J.; Huang, K.; Terzi, S.; Bandinelli, R. Towards uncertainty of End-of-Use product recycling: A general screw connection-oriented disassembly analysis. Int. J. Prod. Res. 2025, 1–24. [Google Scholar] [CrossRef]

- Xiao, J.; Anwer, N.; Li, W.; Eynard, B.; Zheng, C. Dynamic Bayesian network-based disassembly sequencing optimization for electric vehicle battery. CIRP J. Manuf. Sci. Technol. 2022, 38, 824–835. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, C.; Zhao, F.; Xiao, H.; Tian, G. An asynchronous parallel disassembly planning based on genetic algorithm. Eur. J. Oper. Res. 2018, 269, 647–660. [Google Scholar] [CrossRef]

- Mattfeld, D.; Bierwirth, C. An efficient genetic algorithm for job shop scheduling with tardiness objectives. Eur. J. Oper. Res. 2004, 155, 616–630. [Google Scholar] [CrossRef]

- Iklassov, Z.; Medvedev, D.; Solozabal Ochoa de Retana, R.; Takac, M. On the Study of Curriculum Learning for Inferring Dispatching Policies on the Job Shop Scheduling. In Proceedings of the IJCAI-23: Thirty-Second International Joint Conference on Artificial Intelligence, Macao, China, 19–25 August 2023; pp. 5350–5358. [Google Scholar] [CrossRef]

- Picon, A.; Ghita, O.; Iriondo, P.M.; Bereciartua, A.; Whelan, P.F. Automation of waste recycling using hyperspectral image analysis. In Proceedings of the 2010 IEEE 15th Conference on Emerging Technologies and Factory Automation (ETFA 2010), Bilbao, Spain, 13–16 September 2010; pp. 1–4. [Google Scholar] [CrossRef]

- Alfaro-Algaba, M.; Ramirez, F.J. Techno-economic and environmental disassembly planning of lithium-ion electric vehicle battery packs for remanufacturing. Resour. Conserv. Recycl. 2020, 154, 104461. [Google Scholar] [CrossRef]

- United Nations. Committee of Experts on the Transport of Dangerous Goods. In Recommendations on the Transport of Dangerous Goods: Model Regulations; United Nations Publications: New York, NY, USA, 2009; Volume 1. [Google Scholar]

- International Air Transport Association (IATA). Dangerous Goods Regulations (DGR), 65th ed.; Guidance for the Transport of Lithium Batteries and Other Hazardous Materials by Air; IATA: Montreal, QC, Canada, 2024. [Google Scholar]

- Bilal, M.T.; Tyapin, I.; Choux, M.M.H. Enhancing object localization accuracy by using multiple camera viewpoints for disassembly systems. In Proceedings of the IECON 2022–48th Annual Conference of the IEEE Industrial Electronics Society, Brussels, Belgium, 17–20 October 2022; pp. 1–6. [Google Scholar]

- Bilal, M.T.; Tyapin, I.; Choux, M.M.H. Fusion of Multiview Images for EV Battery Disassembly. In Proceedings of the 2023 11th International Conference on Control, Mechatronics and Automation (ICCMA), Grimstad, Norway, 1–3 November 2023; pp. 19–24. [Google Scholar]

| Sequence | Task |

|---|---|

| I. | Placement of the packs onto the shelves. |

| II. | Connecting the packs to the discharging system. |

| III. | Disconnecting the packs. |

| IV. | Transport to the pack disassembly location. |

| Sequence | Task |

|---|---|

| I. | Pick and place module on the testing worktable. |

| II. | Pick and place tested modules either on a conveyor or on a discharging shelve. |

| III. | Connect and disconnect module to the discharging system. |

| IV. | Pick and place the discharged modules on a conveyor. |

| Ref. | Denomination | Qty. |

|---|---|---|

| 1/A | Upper housing shell/screw | 1/18 |

| 2 | Upper insulator | 1 |

| 3 | Plug-in cable between BJB and BMC | 1 |

| 4/C | Battery junction box (BJB)/screw | 1/6 |

| 5/B | High voltage cables and connectors/anchor | 1/6 |

| 6/D | Top transverse cover/screw | 2/6 |

| 7 | Plug-in cable BMC | 1 |

| 8/E | Battery management controller (BMC) | 1/1 |

| 9/H | Module connector/screw | 4/12 |

| 10/I | Side module junction/screw | 16/16 |

| 11 | Fastener of module | 32 |

| 12/F | Cooling plate/screw | 4/16 |

| 13/G | Cooling pipe/screw | 2/7 |

| 14 | Lower insulation | 1 |

| 15 | Lower housing shell | 1 |

| 16 | Module | 8 |

| Station | Operation | Simulation | Percentage |

|---|---|---|---|

| (Number of Components) | Time (s) | Time | |

| Pack Disassembly Station | Upper housing screws (18) * | 54 | 6.8 |

| Tool change ** | 5 | 0.6 | |

| Upper housing shell | 12 | 1.5 | |

| Screws of BJB (6) | 31 | 3.9 | |

| Remove connectors (2) | 8 | 1.0 | |

| Remove anchors/cut ties (6) | 25 † | 3.2 | |

| Remove BJB | 6 | 0.8 | |

| Remove cables (2) | 10 | 1.3 | |

| Unscrew transverse cover (8) | 24 | 3.0 | |

| Unscrew cooling plates (16) | 48 ‡ | 6.1 | |

| Unscrew cooling pipes (7) | 41 ‡‡ | 5.2 | |

| Remove subassembly | 19.2 | 2.4 | |

| Remove plates (2) | 27 | 3.4 | |

| Remove BMC, cables, connectors, | 80 | 10.1 | |

| screws (4) | |||

| Remove modules (8) | 48 | 6.1 | |

| Module connector, side module | 66 † | 8.3 | |

| junction screws (22) | |||

| Module Fasteners (32) | 96 † | 12.1 | |

| Total Time | 600.2 (10:00) |

| Station | Operation | Simulation | Percentage |

|---|---|---|---|

| (Number of Components) | Time (s) | Time | |

| Module Disassembly Station | Place modules on shelf | 5 | 0.6 |

| Discharge | 0 ‡‡ | 0 | |

| Place on turntable | 7.5 | 0.9 | |

| Cutting | 100 | 12.6 | |

| Removing cover—UR5 | 24 | 3.0 | |

| Cutting cell connections | 50 | 6.3 | |

| (10 per module) | |||

| Dropping | 4 | 0.5 | |

| Total Time | 190.5 (3:11) |

| Job Number | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| Time (s) | 12 | NA * | 8 | 6 | 10 | 27 | 14 | 6 | 20 | 16 | NA * | 18 | 6 | NA * |

| Job Number | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | |||

| Time (s) | NA * | 48 | 54 | 25 | 31 | 24 | 6 | 48 | 41 | 66 | 96 |

| Number of Machines | 2 Machines | 3 Machines | 4 Machines |

|---|---|---|---|

| Result after 20 generations | 462 s | 456 s | 450 s |

| Percentage improvement comparing with 2 M | 0% | 1.3% | 2.6% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bilal, M.T.; Tian, D.S.; Choux, M.; Jiao, L.; Tyapin, I. Optimizing Automated Battery Demanufacturing Through Simulation-Based Analysis and Genetic Algorithm. Robotics 2025, 14, 156. https://doi.org/10.3390/robotics14110156

Bilal MT, Tian DS, Choux M, Jiao L, Tyapin I. Optimizing Automated Battery Demanufacturing Through Simulation-Based Analysis and Genetic Algorithm. Robotics. 2025; 14(11):156. https://doi.org/10.3390/robotics14110156

Chicago/Turabian StyleBilal, Muhammad Talha, Doris Siyu Tian, Martin Choux, Lei Jiao, and Ilya Tyapin. 2025. "Optimizing Automated Battery Demanufacturing Through Simulation-Based Analysis and Genetic Algorithm" Robotics 14, no. 11: 156. https://doi.org/10.3390/robotics14110156

APA StyleBilal, M. T., Tian, D. S., Choux, M., Jiao, L., & Tyapin, I. (2025). Optimizing Automated Battery Demanufacturing Through Simulation-Based Analysis and Genetic Algorithm. Robotics, 14(11), 156. https://doi.org/10.3390/robotics14110156