Abstract

This review article presents an in-depth examination of research and development in the fields of rehabilitation, assistive technologies, and humanoid robots. It focuses on parallel robots designed for human body joints with three degrees of freedom, specifically the neck, shoulder, wrist, hip, and ankle. A systematic search was conducted across multiple databases, including Scopus, Web of Science, PubMed, IEEE Xplore, ScienceDirect, the Directory of Open Access Journals, and the ASME Journal. This systematic review offers an updated overview of advancements in the field from 2012 to 2023. After applying exclusion criteria, 93 papers were selected for in-depth review. This cohort included 13 articles focusing on the neck joint, 19 on the shoulder joint, 22 on the wrist joint, 9 on the hip joint, and 30 on the ankle joint. The article discusses the timeline and advancements of parallel robots, covering technology readiness levels (TRLs), design, the number of degrees of freedom, kinematics structure, workspace assessment, functional capabilities, performance evaluation methods, and material selection for the development of parallel robotics. It also examines critical technological challenges and future prospects in rehabilitation, assistance, and humanoid robots.

1. Introduction

Rehabilitation and assistance for human body joints play crucial roles in people’s health, well-being, and quality of life. These activities are essential for helping individuals recover or improve their functionality, mobility, and autonomy following injuries, surgeries, or diseases affecting the joints. In recent years, technological advances have opened up new possibilities in the use of parallel robots in the fields of rehabilitation, assistive technologies, and humanoid systems. These robotic systems are specifically designed to facilitate the recovery of motor and functional skills. Featuring a parallel mechanical structure, these robots offer greater precision, stability, and adaptability to meet the individual rehabilitation or assistance needs of patients.

Rehabilitation technologies aid in the recovery or improvement of motor function after an injury or illness. Utilizing parallel robots in rehabilitation enables specialists to help patients regain strength and mobility in affected joints more rapidly and efficiently than traditional therapeutic methods. The scope of these technologies includes rehabilitation devices for patients with head and neck injuries [1,2,3,4]; pediatric rehabilitation devices for the arm [5]; wearable rehabilitation devices for the arm [6]; exoskeletons for the arms of patients with stroke and spinal cord injuries [7]; and devices specifically designed for wrist [8,9,10], ankle [11,12,13,14,15,16], and foot rehabilitation [17].

Parallel robots in assistive devices help individuals carry out activities of daily life, thereby providing greater autonomy and independence. Examples include prostheses designed to offer functional mobility by replacing missing limbs in amputees [18], as well as shoulder disarticulation arm prostheses [19,20], wrist prostheses [21], and disarticulated hip prostheses [22].

The integration of humanoid robots into medical rehabilitation and assistance offers exciting opportunities. These include personalized therapy, precise motivation and tracking, assisted mobility, and the objective assessment of patients’ progress.

Parallel robots have advanced significantly in the fields of architectural [23] and mathematical modeling, particularly in kinematic [24,25,26] and dynamic analyses [27]. These robots can move at high speeds due to their lightweight and simple structural design [28]. They are also highly rigid, making them ideal for tasks requiring substantial force or pressure [29]. Their high-precision design minimizes unwanted movements and vibrations [30]. Furthermore, they can support heavier loads [31,32] and offer better positioning accuracy due to their high rigidity and low weight, which ensure minimal deformation [33]. Utilizing sensor technology and control algorithms, these parallel robots can automatically adjust to meet each patient’s specific needs, whether for rehabilitation or assistance, thus delivering a highly personalized experience.

However, there is a gap in the current literature concerning the use of parallel robots in the fields of rehabilitation, assistance, and humanoid systems. This review aims to address this gap by summarizing the available evidence on the utilization of parallel robots.

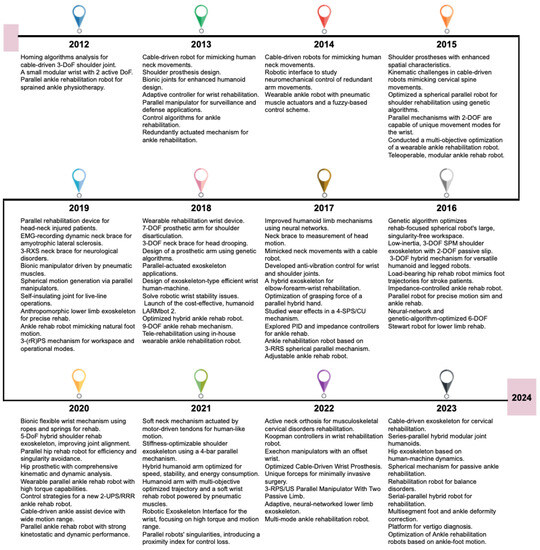

Therefore, this article aims to review the state of parallel robot technology as applied to rehabilitation, assistance, and humanoid systems, focusing on joints with three degrees of freedom in the human body: the neck, shoulder, wrist, hip, and ankle. Initially, the search strategy, inclusion and exclusion criteria, quality assessment, and data extraction methods are defined. Subsequently, the search results are presented, along with a detailed description of the biomechanics of the joints, parallel robots, and applications in the medical field. The article then discusses the timeline and advancements of parallel robots between 2012 and 2023 and examines the technology readiness levels (TRLs), design, number of degrees of freedom, kinematics structure, workspace assessment, functional capabilities, performance methods, and material selection in the development of parallel robotics, as well as the critical technological challenges and future prospects in rehabilitation, assistance, and humanoids. Finally, conclusions are presented.

2. Methodology

2.1. Search Strategy

Before initiating the search, a research question was formulated: “Are there parallel robots designed for rehabilitation, assistance, and humanoid applications that target joints such as the neck, shoulder, wrist, hip, and ankle?” This question helped focus the search for pertinent information. Subsequently, several databases were identified for the search, including Scopus, Web of Science, PubMed, IEEE Xplore, ScienceDirect, the Directory of Open Access Journals (DOAJ), and the ASME Journal. Following this, search terms were determined, incorporating keywords related to the topic such as “parallel robot and neck”, “parallel robot and shoulder”, “parallel robot and hip”, “parallel robot and wrist”, and “parallel robot and ankle”.

2.2. Inclusion Criteria

The search was conducted from 2012 to 2023, and articles were selected based on the following inclusion criteria:

- Articles in English that discuss parallel robots for the rehabilitation of the neck, shoulder, wrist, hip, and ankle.

- Articles in English that discuss parallel robots for assistance related to the neck, shoulder, wrist, hip, and ankle.

- Articles in English that discuss parallel robots for humanoid applications focusing on the neck, shoulder, wrist, hip, and ankle.

- Parallel robots with three or more degrees of freedom.

- Articles discussing parallel robots at either the conceptual or prototype level of technological development.

2.3. Exclusion Criteria

The article search, conducted between 2012 and 2023, was performed based on the following exclusion criteria:

- Articles that do not discuss parallel robots.

- Articles unrelated to rehabilitation involving parallel robots.

- Articles unrelated to assistance involving parallel robots.

- Articles unrelated to humanoid applications involving parallel robots.

2.4. Quality Assessment

Articles were identified and selected based on their relevance to the research question. Initially, the titles and abstracts were reviewed to determine if they met the inclusion criteria. Subsequently, the content of each article was thoroughly read. The quality of the selected articles was then evaluated based on the reputation and trustworthiness of the scientific journals in which they were published.

2.5. Data Extraction

Data from the selected articles were synthesized to answer the research question. This involved conducting an analysis of various factors concerning the development of parallel robots, including the year of publication, country of development, type of rehabilitation targeted at specific joints, level of technological maturity, types of mechanisms, degrees of freedom, types of movement, types of actuators, kinematic models, and simulation tools used.

2.6. Search Performance

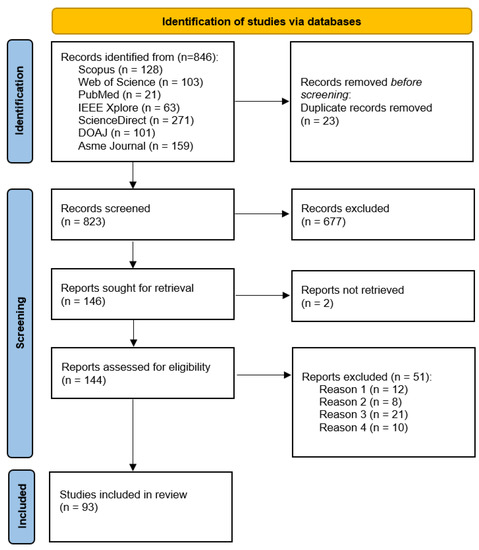

The search yielded a total of 846 articles: Scopus contributed 128, Web of Science 103, PubMed 21, IEEE Xplore 63, ScienceDirect 271, DOAJ 101, and ASME Journal 159. After eliminating 23 duplicate articles, 823 articles remained. Following the application of the exclusion criteria, 93 papers were selected for review. These included 13 articles related to the neck joint, 19 related to the shoulder joint, 22 related to the wrist joint, 9 related to the hip joint, and 30 related to the ankle joint, as illustrated in Figure 1.

Figure 1.

PRISMA flow diagram illustrating the application of inclusion and exclusion criteria to studies selected from 2012 to 2023, focusing on the shoulder, neck, wrist, hip, and ankle joints.

2.7. Systematic Review

The 93 selected articles were analyzed and categorized by joint type: neck, shoulder, wrist, hip, and ankle. Key aspects such as the year of publication, country of origin, type of rehabilitation targeted by joint, mechanism type, degrees of freedom, types of movement, type of actuator, mathematical models, and simulation tools were considered.

3. Biomechanics of the Human Joints

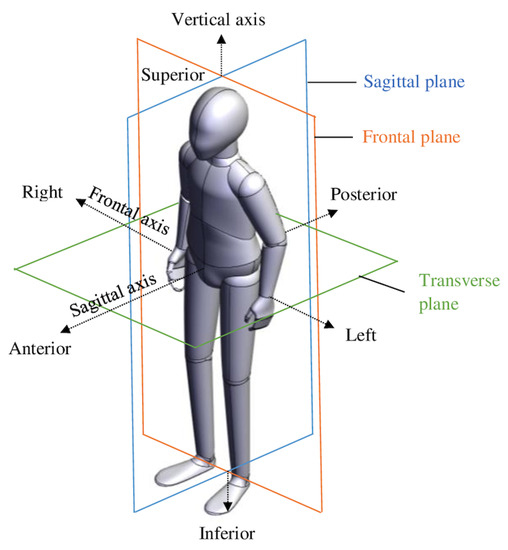

The relationship between the planes, axes, and ranges of motion in human joints is fundamental to understanding how joints function. These concepts are interrelated and play roles in describing and analyzing joint movement. Planes and axes of motion serve as useful tools for describing the directions and orientations of movements in the human body. The three primary planes, sagittal, frontal, and transverse, are associated with the frontal, sagittal, and vertical axes, respectively [34], as illustrated in Figure 2.

Figure 2.

Anatomical sagittal, frontal, and transverse planes and vertical, sagittal, and frontal axes.

The range of motion is fundamental to the movement and functionality of the human body. The term “range of motion” refers to the various directions and amplitudes through which a joint or body segment can move. Biomechanics investigates not only how these movements occur but also how they are generated and influenced by factors such as anatomical structure, muscle strength, and external forces. This field of study also encompasses different types of joint movements, including flexion, extension, abduction, adduction, and rotation, describing these movements in three dimensions through a combination of planes and axes.

- Anatomical planes:Sagittal plane (or median plane): Divides the body into left and right halves. Movement in this plane is forward and backward.Frontal plane (or coronal plane): Divides the body into anterior (front) and posterior (back) halves. Movement in this plane is side-to-side.Transverse plane (or axial/horizontal plane): Divides the body into superior (upper) and inferior (lower) halves. Movement in this plane involves rotation.

- Anatomical axes:Sagittal axis (or anteroposterior axis): Extends front to back and is perpendicular to the frontal plane. Movements around this axis include abduction and adduction.Frontal axis (or horizontal axis): Extends side to side and is perpendicular to the sagittal plane. Movements around this axis include flexion and extension.Vertical axis (or longitudinal axis): Extends top to bottom and is perpendicular to the transverse plane. Movements around this axis include internal and external rotation.

- Range of motion of human joints:The range of motion (ROM) varies depending on the specific joint and is influenced by factors such as age, gender, flexibility, and the individual’s physical condition. Table 1 presents the planes and axes of motion, types of motion, and ranges of motion for the neck, shoulder, hip, wrist, and ankle joints [34].

Table 1. Dominant movement, planes, axis, and range of motion (ROM) of the neck, shoulder, hip, wrist, and ankle joints.

Table 1. Dominant movement, planes, axis, and range of motion (ROM) of the neck, shoulder, hip, wrist, and ankle joints.

4. Parallel Robots and Applications in the Medical Field

Parallel robots have had a significant impact on the medical field, finding applications in areas such as rehabilitation, assistance, and humanoids.

- Rehabilitation robots are designed to assist individuals in regaining motor skills, functionality, and strength following injury or illness. Deployed in therapeutic settings, these devices aim to enhance the individual’s physical capabilities and long-term quality of life.

- Assistive robots are created to help individuals perform activities of daily living, such as dressing, running, or walking, when these activities are restricted due to disability or injury. These devices serve as aids to improve the individual’s quality of life, offering autonomy and independence.

- Humanoid robots represent an impressive advancement in technology, designed to mimic and replicate human form and behavior. These robots are built with anatomical features resembling those of humans, including heads, torsos, arms, and legs, enabling them to move and execute tasks in a manner similar to humans.Based on the preceding discussion, it is crucial to initially distinguish between parallel robots and their serial and hybrid counterparts. Following this differentiation, we can then delve into their applications in rehabilitation, assistance, and humanoid contexts, particularly focusing on specific joints like the neck, wrist, shoulder, hip, and ankle.

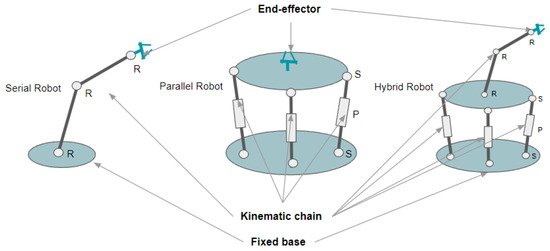

4.1. Distinctions between Serial, Parallel, and Hybrid Robots

Serial robots have links and joints sequentially connected to maneuver the end-effector in relation to a stationary base. Parallel robots, on the other hand, feature several serial chains that link a movable platform to a fixed base using multiple independent kinematic chains. Hybrid robots integrate features from both, blending closed-chain structures with open-chain systems [21]. These distinctions relate directly to the robots’ architectural design and intrinsic structure, as depicted in Figure 3.

Figure 3.

Architectural design of serial, parallel, and hybrid robots.

Parallel robots vary in structure depending on the kinematic chain, which can consist of revolution (R), prismatic (P), universal (U), and spherical (S) type joints. The 3-SPS/S parallel mechanism serves as an example; the “3-SPS” portion of the name indicates the presence of three serial chains, each containing a spherical, prismatic, and then spherical joint. The “S” series chain, although consisting of only one spherical joint, remains parallel to the other three SPS chains [21].

4.2. Parallel Robot for Neck Joint

Studies related to rehabilitation, assistance, and humanoid applications for the neck joint are summarized in Table 2.

4.2.1. Parallel Robot for Neck Rehabilitation

In 2019, Limgampally et al. introduced a wearable therapy device for treating cervical spine injuries. The device used a three-degrees-of-freedom parallel manipulator and was intended for automated, safe operation under therapist supervision. Figure 4a shows the wearable therapeutic device designed to treat patients with head/neck posture disorders. It employs a 3-RPS parallel mechanism consisting of a movable platform (top) and a fixed platform, connected by three similarly designed supporting links. Each link sequentially connects the top and fixed platforms through a revolute joint (R), a prismatic joint (P), and a spherical joint (S), with the prismatic joint being controlled by an electric linear actuator [1]. Zhang et al. also designed a dynamic neck brace used for characterizing head motion in ALS patients while simultaneously recording the surface electromyography (EMG) of neck muscles. The brace measured muscle activation and could supplement self-reported data to assess head drop and disease progression [2].

In 2022, Lozano et al. developed a closed-chain robotic active neck orthosis featuring four degrees of freedom, based on a four-legged Stewart platform configuration. The orthosis employed a robust control strategy with state restrictions, offering an innovative approach to treating neck ailments. The system was tested on selected volunteer subjects and successfully limited the range of motion within a pre-established area based on the patients’ reported range of motion for conditions such as cervicalgia and whiplash syndrome [4].

In 2023, Zhang et al. presented a cable-driven exoskeleton specifically designed for cervical rehabilitation, addressing the urgent need given the increasing prevalence and younger onset of cervical conditions. The research began with an in-depth analysis of the mechanics of neck movement and the specific needs of rehabilitation, setting the foundation for the design criteria and the preliminary sketch of the exoskeleton. Subsequent phases involved kinematic modeling and simulation exercises, which not only confirmed the design’s validity but also provided insights into cable adjustments across different rehabilitation paths [35].

4.2.2. Parallel Robot for Neck Assistance

In 2017, Zhang et al. designed a dynamic neck brace to measure and assist head motion in human users. The device offered accurate measurements of head motion and had the potential to improve the neck’s range of motion for patients with head/neck posture disorders [36].

In 2018, Zhang et al. developed an active neck brace with three degrees of freedom designed to support patients exhibiting symptoms of head drooping. The device allowed for an enhanced range of motion for both the head and neck and reduced muscle activation when assisted by the brace [37].

In 2019, Liu et al. proposed a rigid–flexible parallel mechanism known as the 3-RXS, designed as a neck brace for patients suffering from head drooping symptoms. The mechanism demonstrated excellent rotational performance and could effectively assist in neck flexion, extension, lateral bending, and axial torsion. As shown in Figure 4b, the device was intended for use in various neurological disorders like amyotrophic lateral sclerosis (ALS), Parkinson’s disease (PD), and primary lateral sclerosis (PLS), all of which may lead to head drooping syndrome (HDS). The 3-RXS mechanism facilitated passive neck extension, aiding in the correction of head drooping. The mechanism consisted of a series of links connected to both the top and fixed platforms through a sequence of joints in the following order: revolute joint (R), X-shaped compliant joint (X), and spherical joint (S). This construction was simple and lightweight, enabling smooth flexion/extension, left/right lateral bending, and axial rotational movements [38].

4.2.3. Parallel Robot for Neck Humanoid

In 2013, Gao et al. introduced a cable-driven flexible parallel robot designed to mimic the pitch and roll movements of the human neck. This robot employed three cables and a compression spring to serve as its flexible spine, replicating the motion of the head. Inverse kinematics were addressed using quaternion methods, and workspace analysis was performed under positive cable tension constraints, all validated through simulations [39].

In 2014, Gao et al. compared two different lateral bending models for the compression spring used in their cable-driven parallel robot. The robot aimed to emulate human neck movements by utilizing the spring’s bending motion for inverse kinematics [40]. In a related study, Gao et al. presented a cable-driven flexible parallel robot designed to simulate the motion of a human neck while minimizing motion noise. This robot used three cables and a compression spring, with the spring acting as the cervical spine to support the head-like moving platform and cables functioning as muscles around the human neck. Due to the flexible nature of the compression spring, inverse kinematics were not directly solvable. Cable placements were optimized to reduce actuation force, and workspace analysis was conducted under the constraint of positive cable tension. Simulations validated the efficacy of the inverse kinematics and workspace analysis [41].

In 2015, Jiang et al. presented a cable-driven flexible parallel robot featuring a compression spring as the cervical spine. As with previous models, the flexible nature of the spring meant that the inverse kinematics were not directly solvable. To find possible solutions, statical analysis was incorporated. The cable placements were optimized to reduce actuation force, and workspace analysis was conducted under a positive cable tension constraint [42].

In 2017, Gao et al. introduced another cable-driven parallel robot, this one featuring a flexible spine and four cables designed to mimic human neck movements. The lateral bending motion of the spring facilitated pitch and roll movements, while an included bearing enabled yaw motion. Both inverse kinematics and cable placement optimization were investigated through simulations [43].

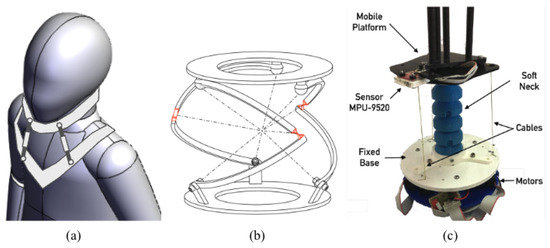

In 2021, Quevedo et al. applied various linear and non-linear models to design a soft neck mechanism with a central soft link actuated by three motor-driven tendons. The force exerted on the individual tendons allowed the neck to perform motions similar to those of a human neck. The cable-driven parallel mechanism, referred to as 3-CDPM and illustrated in Figure 4c, was constructed from flexible materials and activated by cables, causing the upper platform to tilt. The neck was comprised of a base, movable platform, central soft link, tendons (cables), and motors [3].

Figure 4.

Neck joint mechanisms: (a) 3-RPS mechanism by Vellore Institute of Technology, redrawn based on [1]; (b) 3-RXS mechanism by the University of Technology Beijing [38], available under a Creative Commons Attribution License; (c) 3-CDPM mechanism by University Carlos III of Madrid [3], available under a Creative Commons Attribution License.

Table 2.

Parallel robots for rehabilitation, assistance, and humanoids of the neck joint.

Table 2.

Parallel robots for rehabilitation, assistance, and humanoids of the neck joint.

| Author | Year | Country | Device | TRL | Mechanism | DoF | ToM | Actuator | Model | Tool |

|---|---|---|---|---|---|---|---|---|---|---|

| Gao et al. [39] | 2013 | China | NH | 1 | cable-driven | 3 | PR | NS | IK | M |

| Gao et al. [40] | 2014 | China | NH | 2 | cable-driven | 3 | NS | NS | IK | M |

| Gao et al. [41] | 2014 | China | NH | 1 | cable-driven | 3 | NS | NS | IK | M |

| Jiang et al. [42] | 2015 | China | NH | 2 | cable-driven | 3 | NS | NS | IK | M |

| Gao et al. [43] | 2017 | China | NH | 2 | cable-driven | 3 | PR | NS | IK | M |

| Zhang et al. [36] | 2017 | USA | NA | 3 | 3-RRS | 3 | FE, RLB, RLR | NS | FK | M |

| Zhang et al. [37] | 2018 | USA | NA | 3 | 3-RRR | 3 | FE, RLB, RLR | ER | IK | NS |

| Liu et al. [38] | 2019 | China | NA | 3 | 3-RXS | 3 | FE, RLB, RLR | NS | IK | AN |

| Lingampally et al. [1] | 2019 | India | NR | 3 | 3-RPS | 3 | RLR | EL | IK | M |

| Zhang et al. [2] | 2019 | USA | NR | 3 | 3-RRR | 3 | FE, RLB, RLR | ER | D | M |

| Quevedo et al. [3] | 2021 | Spain | NH | 3 | cable-driven | 3 | FE, RLR | ER | IK | M |

| Lozano et al. [4] | 2022 | Mexico | NR | 4 | 4-SPS | 4 | NS | EL | D | M |

| Zhang et al. [35] | 2023 | China | NR | 4 | cable-driven | 3 | FE, RLB, RLR | NS | IK | M |

Abbreviations: NH—neck humanoid, NA—neck assistance, NR—neck rehabilitation, 3-RRS—3 (revolute-revolutespherical), 3-RRR—3 (revolute-revolute-revolute), 3-RXS—3 (revolute-joint X-spherical), 3-RPS—3 (revoluteprismatic-spherical), 4-SPS—4 (spherical-prismatic-spherical), PR—pitch and roll, NS—not specified, FE—flexion–extension, RLB—right–left bending, RLR—right–left rotation, ER—electric rotary, EL—electric linear IK—inverse kinematic, FK—forward kinematic, D—dynamics, M—MATLAB, AN—ANSYS.

4.3. Parallel Robot for Shoulder Joint

Studies related to rehabilitation, assistance, and humanoid applications for the shoulder joint are summarized in Table 3.

4.3.1. Parallel Robot for Shoulder Rehabilitation

In 2014, Klein et al. introduced a novel robotic interface to explore the neuromechanical control of redundant planar arm movements. This device featured a 5R closed-loop pantograph design with a wrist flexion/extension cable-actuated mechanism. The interface’s characteristics, such as motion range, impedance, friction, and dynamics, were discussed. This lightweight, high-force, and low-impedance device enabled research into redundant motor control in humans [44].

In 2015, Enferadi et al. proposed a new spherical parallel robot design for rehabilitation applications. The robot’s full rotational capabilities were highlighted. Dimensional optimization, aimed at maximizing the robot’s workspace, was carried out using genetic algorithms. The robot boasted a relatively large workspace and exhibited precision in its kinematics, Jacobian matrices, and workspace analysis [45].

In 2016, Enferadi et al. presented another spherical parallel robot designed for various applications, including rehabilitation (e.g., TV satellite dishes; tracking systems; solar panels; cameras; telescopes; and the rehabilitation of human joints like the ankle, shoulder, and wrist). The robot allowed for complete rotation around an axis. A genetic algorithm optimized its dimensions to maximize the workspace, which was found to be relatively large and free from singularities—a significant advantage [46]. Hunt et al. introduced a low-inertia shoulder exoskeleton with five degrees of freedom (DoF). The first innovation involved a 3DoF spherical parallel manipulator (SPM), which was designed through a new approach that mechanically coupled certain degrees of freedom to constrain the kinematics. The second innovation was a 2DoF passive slip interface that enhanced system mobility and prevented joint misalignment caused by the user’s glenohumeral joint motion. Motion capture validated the SPM’s kinematics, confirming both its forward and inverse kinematic solutions. Beyond its application for shoulder rehabilitation, the device introduced a novel motion coupling method that was applicable to various parallel architectures. It also showcased the versatility of its passive slip interface in both parallel and serial robotic systems [47].

In 2020, Niketkaliyev et al. shifted the focus to robotic shoulder rehabilitation exoskeletons, which often neglect certain shoulder DoF, leading to discomfort due to joint axis misalignments. They introduced a bio-inspired 5DoF hybrid human–robot mechanism (HRM) that combined serial and parallel manipulators with rigid and cable links. This hybrid mechanism ensured compatibility between human and exoskeleton joint axes and covered the complete range of human shoulder motion in a singularity-free workspace. Numerical simulations and a 3D-printed prototype validated the kinematic model and advantages of the proposed hybrid mechanism [48].

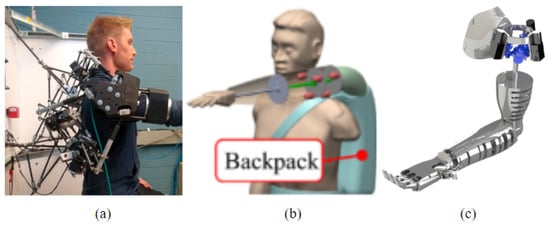

In 2021, Hunt proposed a novel parallel-actuated exoskeleton architecture for rehabilitation. This architecture’s stiffness property could be optimized for specific tasks using a stiffness model and bounded nonlinear multi-objective optimization. Figure 5a shows an exoskeleton designed with a four-bar system in a parallel mechanism, denoted as 4B-SPM. This system allowed individuals to modulate their stiffness attribute to optimize activities, such as augmented lifting or impact absorption for the shoulder [49].

Figure 5.

Shoulder joint mechanisms: (a) 4B-SPM mechanism by Arizona State University [49]; (b) cable-driven mechanism by Chiba University [50]; (c) 3-RRR mechanism by Universidad de Guanajuato [19]. All are available under a Creative Commons Attribution License.

4.3.2. Parallel Robot for Shoulder Assistance

In 2013, Sekine et al. presented a systematic approach to designing a shoulder prosthesis with consideration for force and spatial accessibility. Using measurements from Activities of Daily Living (ADLs), the design process entailed evaluating both force and spatial accessibility, followed by optimization based on kinematic and static models. The optimized parallel mechanism was tailored for specific ADL tasks and various spatial specifications, illustrating the potential for individualized shoulder prosthesis design. Figure 5b depicts an optimized, compact, pneumatic-actuator-driven parallel mechanism for a shoulder prosthetic arm [50].

In 2015, Sekine et al. proposed shoulder prostheses designed for transhumeral and shoulder disarticulation amputees. Accessibility and intrinsic viscoelasticity were the focal points of this study. The paper introduced new mechanisms—specifically, an antagonistic mechanism and a soft backbone—to enhance spatial characteristics and responsiveness to disturbances. The evaluation confirmed increased workspace and disturbance responsiveness for the prosthetic arm [20].

In 2018, Leal-Naranjo et al. introduced a synthesis of a spherical parallel manipulator for a seven-degrees-of-freedom (7DoF) prosthetic human arm. The design objectives included workspace, dexterity, and actuator torques. Optimization was performed using genetic algorithms, culminating in a manipulator that met all performance requirements [51]. Hunt et al. unveiled a new parallel-actuated exoskeleton architecture aimed at offering a superior alternative to serial actuation for augmenting multiple-DoF biological joints. This architecture employed a spherical parallel manipulator (SPM) with three four-bar substructures to control three rotational DoF independently. Variants of the four-bar spherical parallel manipulator (4B-SPM) were presented for shoulder, hip, wrist, and ankle exoskeletons. Three actuation methods for the 4B-SPM were explored, each based on different dynamic performance requirements. This work set the stage for advancements in more effective parallel-actuated exoskeletons as opposed to conventional serial-actuated counterparts [52]. Leal-Naranjo presented a low-cost prosthetic device designed for shoulder disarticulation and featuring seven DoF. The mechanisms for shoulder, elbow, and wrist movements were discussed. Dynamic simulations and experimental evaluations confirmed the device’s functionality and suitability for daily activities [19]. Figure 5c illustrates a shoulder mechanism integrated into an arm prosthesis. This spherical mechanism, configured as a 3-RRR type, allowed for three degrees of freedom with shoulder motions, using compact motors. Given that the shoulder prosthetic supported the entire structure of the device, this is where the highest joint loads developed [19].

4.3.3. Parallel Robot for Shoulder Humanoid

In 2012, Chen et al. presented a novel homing algorithm for a three-degrees-of-freedom (3DoF) parallel spherical joint in a cable-driven parallel robot. The algorithm utilized incremental encoders and limit switches to identify the home posture automatically, implementing decoupling control for each axis. Simulation results affirmed the algorithm’s effectiveness [53]. Both control accuracy and a consistent initial posture are pivotal when evaluating control algorithms. To minimize cumulative errors during control processes or to estimate initial postures, robotic systems need to revert to an approximate home posture.

In 2013, Wang et al. aimed to improve the performance of bionic joints using a five-link parallel mechanism, actuated by two antagonistic artificial pneumatic muscles (PMs). The study examined kinematics, singularity constraints, and joint torque models based on spring-damp dynamics. The joint’s compliance, represented by the angle-to-spring torque ratio, was derived. Energy consumption analysis was conducted considering varying PM lengths. The proposed bionic shoulder and elbow joints exhibited an enhanced angular range and decreased PM contraction, contributing to a more humanoid-like design [54].

In 2016, Alfayad et al. undertook a research initiative focused on developing a three-degrees-of-freedom (3DoF) hybrid mechanism suitable for humanoid robotics. This mechanism catered to various modules in humanoid robots and could also be adapted for other legged robots, such as quadrupeds and hexapods. Utilizing kinematic synthesis, the study proposed a novel hip mechanism that combined one rotary and two linear actuators. This approach accommodated the wide motion ranges of the shoulder module and introduced a new perspective on the contributions of linear actuators in both motion and force generation. The research employed kinematic and geometrical models to optimize the hybrid mechanisms, demonstrating their broad applicability in various robotic systems [55].

In 2017, Jiang et al. focused on developing a new hybrid mechanism for humanoid wrist and shoulder joints. A cable-driven parallel robot platform was developed for experimental study. A dynamic model of the mechanism was formulated, considering the coupling theory of flexible body motion and deformation. A nonlinear control method was applied for anti-vibration control. Both simulations and experimental results validated the feasibility and control scheme of the hybrid mechanism [56].

In 2019, Liu et al. introduced a bionic flexible manipulator driven by pneumatic muscle actuators (PMAs). The study outlined the configuration design based on human physiological mapping, established kinematic models, and employed the Lagrange method for dynamic analysis. A fuzzy torque control algorithm, developed using the computed torque method, showed improved trajectory tracking and accuracy compared to traditional methods [57]. In the same year, Bai et al. provided a comprehensive review of state-of-the-art techniques in spherical motion generation via parallel manipulators or spherical motors. The review covered kinematics, dynamics, design optimization, and emerging applications, offering insights into new research challenges and future developments in the field [58].

In 2021, Wang et al. proposed a multi-objective trajectory planning approach for a 7DoF hybrid humanoid robotic arm. The methodology combined kinematic modeling and optimization to achieve faster transit times, lower energy consumption, and higher stability during point-to-point tasks. Simulation results validated the proposed approach [59].

In 2023, Chen et al. introduced an enhanced design and modeling analysis for a 3DoF series-parallel joint module used in humanoid service robots. This module, inspired by human-like 3DoF joints, employed a cable-driven method. Using the shoulder joint as a model, it could execute various motions like arm abduction, back extension, and lifting. The team designed a shared modular connector for easier assembly and disassembly across modules and a tension amplification mechanism for a more compact design. They also developed a transient torque model and a cross-coupling control framework and conducted kinematics analysis based on the anti-parallelogram principle. Prototyping and tests showed the design’s potential for realistic humanoid shoulder movements, offering a novel concept for humanoid robots [60].

Table 3.

Parallel robots for rehabilitation, assistance, and humanoids of the shoulder joint.

Table 3.

Parallel robots for rehabilitation, assistance, and humanoids of the shoulder joint.

| Author | Year | Country | Device | TRL | Mechanism | DoF | ToM | Actuator | Model | Tool |

|---|---|---|---|---|---|---|---|---|---|---|

| Chen et al. [53] | 2012 | China | SH | 2 | cable-driven | 7 | NS | ER | IK | AD |

| Sekine et al. [50] | 2013 | Japan | SA | 2 | cable-driven | 3 | FE, AA, IER | PL | FK | ADLA |

| Wang et al. [54] | 2013 | China | SH | 2 | 5-PMA | 5 | NS | P | FK | MS |

| Klein et al. [44] | 2014 | UK | SR | 4 | 5R | 3 | NS | E | FK | CAD |

| Sekine et al. [20] | 2015 | Japan | SA | 3 | 3-SPS/P | 3 | NS | PL | FIK | NS |

| Enferadi et al. [45] | 2015 | Iran | SR | 2 | 3-RSS/S | 3 | RP | ER | IK | NS |

| Enferadi et al. [46] | 2016 | Iran | SR | 2 | 3-RSS/S | 3 | NS | ER | IK | NS |

| Hunt et al. [47] | 2016 | USA | SR | 3 | SPM | 3 | NS | EL | FIK | CAD |

| Alfayad et al. [55] | 2016 | France | SH | 3 | 2-UPUR/RU | 2 | PRY | EL | IK | NS |

| Jiang et al. [56] | 2017 | China | SH | 3 | cable-driven | 2 | NS | ER | NS | NS |

| Leal-Naranjo et al. [51] | 2018 | Italy | SA | 3 | 3-RRR | 3 | FE | ER | IK | NS |

| Leal-Naranjo et al. [19] | 2018 | Mexico | SA | 2 | 3-RRR | 3 | FE | ER | IK | AD |

| Hunt et al. [52] | 2018 | USA | SA | 3 | 4B-SPM | 3 | NS | ER | FIK | M |

| Lui et al. [57] | 2019 | China | SH | 3 | 5-PMA | 5 | NS | PL | FIK | M-AD |

| Bai et al. [58] | 2019 | Denmark | SH | 3 | 3-RRR | 3 | RP | ER | FIK | NS |

| Niyetkaliyev et al. [48] | 2020 | Australia | SR | 2 | cable-driven | 3 | AA | NS | IK | CAD |

| Hunt et al. [49] | 2021 | USA | SR | 3 | 4B-SPM | 7 | FE, AA | EL | FIK | NS |

| Wang et al. [59] | 2021 | China | SH | 2 | 5R | 3 | FE, AA, IER | ER | FK | AD |

| Chen et al. [60] | 2023 | China | SH | 4 | cable-driven | 3 | FE, AA, L | ER | IK | NS |

Abbreviations: SR—shoulder rehabilitation, SH—shoulder humanoid, SA—shoulder assistance, 5-PMA—5 pneumatic muscle actuator, NS—not specified, 3-SPS/P—3 (spherical-prismatic-spherical)/1 (prismatic), 3-RSS/S—3 (revolute-spherical-spherical)/spherical, 3-RRR—3 (revolute-revolute-revolute), 4B-SPM—4-bar (spherical parallel manipulator), 5R—5 revolute, FE—flexion–extension, AA—abduction–adduction, IER—internal–external rotation, RP—rotational pure movement, L—lifting, PRY—pitch-roll-yaw, ER—electric rotary, EL—electric linear, PL—pneumatic linear, IK—inverse kinematic, FK—forward kinematic, FIK—forward and inverse kinematic, AD—ADAMS, ADLA—(ADL area) is used to evaluate spatial accessibility, MS—MATLAB-SimMechanics, CAD—Computer-Aided Design, M—MATLAB, M-AD—MATLAB-ADAMS.

4.4. Parallel Robot for Wrist Joint

Studies related to wrist assistance and rehabilitation and humanoid wrist mechanisms are summarized in Table 4.

4.4.1. Parallel Robot for Wrist Rehabilitation

In 2013, Pehlivan et al. developed an adaptive controller for a robotic mechanism designed for the upper-extremity rehabilitation of the wrist. Compared to a proportional-derivative (PD) controller, the model-based adaptive controller improved trajectory tracking. The adaptive controller achieved similar error performance but used significantly lower feedback gains, offering a more compliant interface for patients during rehabilitation sessions [61].

In 2017, Bian et al. introduced an exoskeleton aimed at rehabilitating the elbow, forearm, and wrist motor functions in stroke patients. The EFW Exo II exoskeleton was based on a hybrid mechanism that combined a parallel 2-URR/RRS mechanism with a serial R mechanism. It included adjustable features to accommodate different arm sizes and utilized force sensors to facilitate patient interaction. The exoskeleton provided ranges of motion that met the requirements of activities of daily living [62].

In 2018, Kitano et al. unveiled a wearable wrist rehabilitation training device that utilized a parallel link mechanism. This innovative approach allowed for the training of both translational and rotational wrist joint motions, filling a gap left by previous techniques that did not address translational motion. The device could enable a range of motion that covered approximately 60% of the wrist’s mobility, potentially reducing wrist joint strain [6].

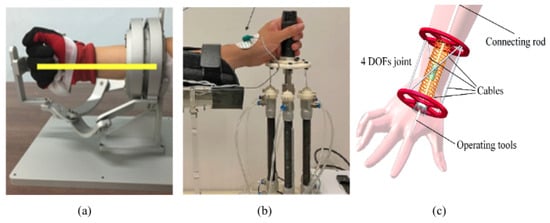

In 2021, Wang et al. introduced a soft parallel robot designed for automated wrist rehabilitation. Figure 6a illustrates the 6-SPS/PS soft parallel robot that employed pneumatic artificial muscles for wrist rehabilitation. This robot merged soft and parallel structures to offer a secure, adaptable, and low-cost personalized rehabilitation solution. Linear actuators, including pneumatic artificial muscles, drove the robot, and an electromyography sensor provided feedback for evaluating rehabilitation progress. Experimental tests confirmed the robot’s efficacy in assisting various wrist motions [63].

In 2022, Goyal et al. developed an impedance controller designed to rehabilitate stroke patients with wrist motor impairments. The controller employed a Koopman-operator-based autodidactic system identification model to predict wrist joint stiffness during different rotational motions. It adjusted the applied force based on the subject’s joint stiffness, utilizing a parallel-structured end-effector robot equipped with biomimetic muscle actuators. The performance of the controller was validated through tests on healthy subjects [64].

In 2023, Li et al. developed a bionic cable-driven mechanism for forearm-wrist rehabilitation. This device mimics human wrist motions with three degrees of freedom, addressing the full range of wrist and forearm actions. Notably, a spring within a parallel mechanism helps counteract cable slack. The system’s design incorporates kinematics and statics for precise movement calculations. Simulations and practical tests confirmed its effectiveness and accuracy for rehabilitation purposes [65]. In the same year, Goyal et al. introduced a robot with a four-link parallel end-effector designed for wrist joint rehabilitation. Using biomimetic muscle actuators (BMAs), the robot had an inherent flexibility, with a fuzzy model developed to recognize the BMAs’ nonlinear characteristics. The system’s stiffness-observer tailored itself to individual subject stiffness, adjusting the robot’s trajectories. An adaptive controller, based on the fuzzy model and stiffness-observer, governed the four BMAs, giving the robot end-effector three rotational degrees of freedom. Initial tests with three healthy individuals confirmed the controller’s effectiveness in guiding the robot while accounting for the compliant and nonlinear nature of the BMAs, even adjusting for higher-stiffness areas within the wrist’s range of motion [66]. In the same year, Goyal et al. developed a trajectory-tracking controller for a wrist rehabilitation robot with three degrees of freedom. They used the Koopman linear system to address the nonlinearity of human–robot interaction, turning state variables into linear approximations of nonlinear systems through Koopman operators. These operators, learned via linear regression, determined the system dynamics for the robot’s trajectory controller. This data-driven method resulted in a clear control-oriented model. Tests with three healthy individuals proved the controller’s effectiveness in guiding the wrist along a set trajectory [67].

4.4.2. Parallel Robot for Wrist Assistance

In 2012, Serracin et al. designed a parallel robot to assist in bone milling surgeries. The robot had two active degrees of freedom and was employed for orientation during bone-milling procedures. The paper outlined the kinematic geometry, discussed workspace optimization, and performed force analysis for jawbone reconstruction. The singularities of the mechanism were analyzed, and the motor selection was justified based on torque requirements. The study also presented simulation results and a prototype using linear motors [68].

In 2018, Lee et al. introduced an over-actuated coaxial spherical parallel mechanism optimized for efficient wrist motion. The mechanism’s rotation axis was aligned with the wrist’s pronation-supination movement. The prototype demonstrated a design that enhanced user comfort and workspace efficiency. Simulation results indicated improved performance compared to similar devices, along with extensive motion coverage [69]. Figure 6b depicts the wrist human–machine interface based on this over-actuated coaxial spherical parallel mechanism. The base was connected to two links that were coaxially coupled, and the rotation axis was specifically designed to align with the wrist’s pronation/supination motion, which has the most extensive operational range of wrist movements [69].

In 2021, Lee et al. proposed a robotic exoskeleton interface (REI) for the wrist, based on a fully actuated coaxial spherical parallel mechanism (CSPM). The CSPM-based interface offered pure rotational motion akin to the human wrist, along with a high torque output and low moving-parts inertia. The device’s torque output and range of motion aligned closely with human capabilities [70].

In 2022, Lopez-Custodio et al. conducted a stiffness analysis of the Exechon hybrid manipulator, which served as a five-axis machine tool. The study included the consideration of an offset wrist in both kinematic and stiffness analyses. A compliance model was formulated and validated against experimental data, offering a more accurate portrayal of the manipulator’s behavior [71]. Sanjuan et al. proposed a cable-driven wrist prosthesis (CDWP) to address challenges related to limb amputation. The anti-parallel-based local transmission index was introduced to optimize the device’s dimensions. The CDWP design aimed to offer both high dexterity and aesthetic appeal to a wide range of patients [72].

4.4.3. Parallel Robot for Wrist Humanoid

In 2013, Chaparro-Altamirano et al. proposed a system utilizing a 3SPS-1S parallel manipulator for surveillance and defense applications. The mechanism incorporated a central leg to increase stiffness and provide three pure rotational degrees of freedom. The study covered inverse kinematics, forward kinematics solved through geometry and neural networks, workspace calculations, parameter optimization, and singularity detection via Jacobian matrix analysis [73].

In 2015, Kong et al. focused on synthesizing two-degrees-of-freedom (DoF) parallel mechanisms (PMs) capable of both spherical translation and sphere-on-sphere rolling modes. They introduced a 2DoF 3-4R overconstrained PM, derived from an existing 5DoF US equivalent PM, to serve as the basis for further developments. The study classified 2DoF 3-4R PMs capable of both identified modes by exploring shared conditions between them [74].

In 2017, Lu et al. conducted a comprehensive study analyzing coordinated grasping kinematics for multi-fingered systems and optimizing grasping force in a parallel hybrid hand. The study included conditions for coordinated grasping and formulas for calculating the displacement, velocity, and acceleration of contact points between the fingers and the object [75].

In 2018, Wu et al. addressed the dynamic stability challenges of a tripod parallel robotic wrist using the monodromy matrix method. The wrist demonstrated uninterrupted end-effector rotation across its orientation workspace, making it suitable for machine tool head tasks like drill point grinding. Stability analysis was conducted using Floquet theory, and stability charts were constructed to identify parametric instabilities [76].

In 2019, He et al. introduced a novel concept of a self-insulating joint design, employing a cable-driven parallel-series (CDPS) mechanism coupled with electrical insulation analysis. This design offered mechanical support and electrical insulation during live-line operations, thus facilitating equipment maintenance without manual intervention or power interruption. Figure 6c depicts the wrist joint of the robotic arm as a CDPS mechanism, featuring a lower and an upper platform in concentric positions for mechanical support. Two concentric shafts in a spring, connected by a universal joint, provided additional structural support. Four cables powered the structure [77].

In 2020, Pang et al. proposed a bionic flexible wrist parallel mechanism that mimicked human wrist joints by using a combination of rope-driven and compression spring-supported hybrid mechanisms. A parallel structure controlled by cables emulated wrist muscles. The inverse kinematics were solved using force and torque balance conditions along with the spring bending equation. MATLAB software was used for analysis, verifying the mechanism’s feasibility for wrist rehabilitation and promoting the development of rehabilitation robots and rope-driven technology [9].

In 2021, Wang et al. proposed a seven-degrees-of-freedom serial–parallel hybrid humanoid robotic arm. The arm’s trajectory planning was optimized for speed, energy consumption, and stability using a multi-objective optimization approach. Simulation results validated the effectiveness of this methodology [59].

In 2022, Bazman et al. introduced a 4DoF parallel forceps mechanism designed for minimally invasive surgery. This mechanism employed a unique center leg to convert thrust into gripping motion. The study included kinematic analysis and workspace assessment and addressed unintended gripper motion. Human-in-the-loop simulations validated the design [78]. Li et al. developed a 3-RPS/US parallel mechanism with two DoF to enhance load-bearing capabilities. The study covered kinematics, Jacobian matrix analysis, workspace calculations, singularity considerations, and static analysis. The potential application of this mechanism in tracking photovoltaic brackets was demonstrated [79].

Figure 6.

Wrist joint mechanisms: (a) 6-SPS/PS mechanism by the University of Macau [63]; (b) 3-CSPM mechanism by Kwangwoon University [69]; (c) 4-CDPS mechanism by Southeast University [77]. All are available under a Creative Commons Attribution License.

Table 4.

Parallel robots for rehabilitation, assistance, and humanoids of the wrist joint.

Table 4.

Parallel robots for rehabilitation, assistance, and humanoids of the wrist joint.

| Author | Year | Country | Device | TRL | Mechanism | DoF | ToM | Actuator | Model | Tool |

|---|---|---|---|---|---|---|---|---|---|---|

| Serracin et al. [68] | 2012 | Spain | WA | 3 | 2-UPS/S | 2 | NS | EL | IK | M |

| Chaparro et al. [73] | 2013 | Mexico | WH | 3 | 3-SPS/S | 3 | RPY | EL | FK | NS |

| Pehlivan et al. [61] | 2013 | USA | WR | 3 | 3-RPS | 2 | FE, AA | PL | FIK | M |

| Kong et al. [74] | 2015 | UK | WH | 2 | 3-4R | 2 | NS | NS | IK | NS |

| Lu et al. [75] | 2017 | China | WH | 3 | 5-SPM | 5 | NS | EL | FIK | NS |

| Bian et al. [62] | 2017 | China | WR | 3 | 2-URR/RRS | 3 | FE, AA | ER | IK | NS |

| Lee et al. [69] | 2018 | South Korea | WA | 3 | 2-RRR | 3 | FE, AA | ER | FIK | NS |

| Kitano et al. [6] | 2018 | Japan | WR | 3 | 3-RRR | 3 | FE, AA, SP | ER | FIK | NS |

| Wu et al. [76] | 2018 | China | WH | 3 | 2-PUU/RPS | 2 | TR | ER, EL | IK | NS |

| He et al. [77] | 2019 | China | WH | 2 | cable-driven | 4 | NS | ER | IK | NS |

| Pang et al. [9] | 2020 | China | WH | 3 | cable-driven | 2 | FE, AA | ER | IK | NS |

| Wang et al. [63] | 2021 | China | WR | 3 | 6-SPS/PS | 3 | FE, AA, SP | PL | FIK | NS |

| Lee et al. [70] | 2021 | Korea | WA | 3 | 2-CSPM | 2 | FE, AA, SP | EL | FIK | NS |

| Wang et al. [59] | 2021 | China | WH | 2 | 3-UPS/S | 2 | FE, SP | EL | FK | AD |

| López et al. [71] | 2022 | UK | WA | 3 | 2-RRRPR/RRPR | 3 | NS | EL | IK | M |

| Goyal et al. [64] | 2022 | Australia | WR | 3 | 3-RPR | 3 | FE, AA, PS | PMA | IK | NS |

| Bazman et al. [78] | 2022 | Turkey | WH | 2 | 3-RSR/UUP | 2 | RPY | NS | FK | MS |

| Sanjuan et al. [72] | 2022 | USA | WA | 2 | cable-driven | 2 | NS | NS | IK | NS |

| Li et al. [79] | 2022 | China | WH | 2 | 3-RPS/US | 2 | NS | EL | IK | NS |

| Li et al. [65] | 2023 | China | WR | 4 | cable-driven | 3 | FE, AA, SP | ER | IK | M |

| Goyal et al. [66] | 2023 | Australia | WR | 4 | 4-BMA | 3 | FE, AA, SP | PL | IK | NS |

| Goyal al. [67] | 2023 | Australia | WR | 4 | 4-BMA | 3 | FE, AA, SP | PL | IK | NS |

Abbreviations: WR—wrist rehabilitation, WA—wrist assistance, WH—wrist humanoid, 2-UPS/S—2 (universal-prismatic-spherical)/1 (spherical), 3-SPS/S—3 (spherical-prismatic-spherical)/1 (spherical), 3-RPS—3 (revolute-prismatic-spherical), 3-4R—3 (4 revolute), 5-SPM—5 (spherical parallel mechanism), 2-URR/RRS—2 (universal-revolute-revolute)/1 (revolute-revolute-spherical), 2-RRR—2 (revolute-revolute-revolute), 3-RRR—3 (revolute-revolute-revolute), 2-PUU/RPS—2 (prismatic-universal-universal)/1 (revolute-prismatic-spherical), 6-SPS/PS—6 (spherical-prismatic-spherical)/1 (prismatic-spherical), 2-CSPM—2 (coaxial spherical parallel mechanism), 3-UPS/S—3 (universal-prismatic-spherical)/1 (spherical), 2-RRRPR/RRPR—2 (revolute-revolute-revolute-prismatic-revolute)/1 (revolute-revolute-prismatic-revolute), 3-RPR—3 (revolute-prismatic-revolute), 3-RSR/UUP—3 (revolute-spherical-revolute)/1 (universal-universal-prismatic), 3-RPR—3 (revolute-prismatic-revolute), 3-UPU—3 (universal-prismatic-universal), 3-RPS/US—3 (revolute-prismatic-spherical)/3 (universal-spherical), 4-BMA—4 (biomimetic actuators) RPY—roll-pitch-yaw, FE—flexion–extension, AA—abduction–adduction, SP—supination–pronation, TRP—translation-rotation-pure, EL—electric linear, PL—pneumatic linear, ER—electric rotary, IK—inverse kinematic, FK—forward kinematic, FIK—forward and inverse kinematic, NS—not specified, M—MATLAB, AD—ADAMS, MS—MATLAB-SimMechanics.

4.5. Parallel Robot for Hip Joint

Studies related to assistance, rehabilitation, and humanoid applications for the hip are summarized in Table 5.

4.5.1. Parallel Robot for Hip Rehabilitation

In 2016, Rastegarpanah et al. investigated a six-degrees-of-freedom parallel robot developed at the University of Birmingham for use in hip rehabilitation for stroke patients. This robot could replicate foot trajectories associated with three types of rehabilitation exercises: hip flexion/extension, ankle dorsiflexion/plantarflexion, and human gait. The study also emphasized the robot’s ability to lift significant loads, indicating its potential for the effective administration of lower-limb rehabilitation exercises [80].

In 2020, Zhang et al. introduced an innovative approach to enhance the performance of a three-degrees-of-freedom parallel mechanism used in hip rehabilitation robots. The objective was to prevent kinematic singularity within the workspace corresponding to human gait and to improve power efficiency. This was achieved by optimizing the geometric parameters of the mechanism and by proposing improved force transmission indices. Optimization was conducted using a multi-objective model and the differential evolution algorithm. The effectiveness of this method was validated by comparing the performance metrics of the optimized mechanism to those of the original model, particularly in terms of Jacobian matrix singularity and output power efficiency [81].

In 2022, Shi et al. explored a serial–parallel lower-limb rehabilitation exoskeleton for its potential to mimic human lower-limb kinematics. To address challenges related to modeling errors and uncertainties, an adaptive control approach was proposed. This approach incorporated sensor data from the parallel mechanism to accurately capture attitude and employed a neural network adaptive controller to compensate for uncertainties and external disturbances. The effectiveness of the dynamic modeling and control system was validated through experimental testing [82].

4.5.2. Parallel Robot for Hip Assistance

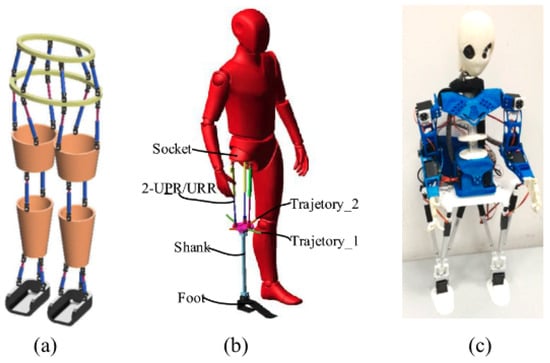

In 2019, Ren et al. designed a wearable lower-limb exoskeleton to assist with medical rehabilitation. Traditional exoskeletons often struggle to precisely replicate natural human limb movements. To address this issue, the researchers developed an innovative anthropomorphic lower-limb exoskeleton based on a series-parallel mechanism. Human lower-limb movements were captured using an optical gait-tracking system. By comparing the simulation results from the series-parallel mechanism with the captured human data, a kinematics matching model was established specifically for the hip joint. The study demonstrated that the proposed model effectively reduced kinematic matching errors in multiple directions. This made the anthropomorphic series-parallel mechanism a significant improvement for tracking human hip joint positions. Figure 7a shows a lower-limb exoskeleton based on the series-parallel mechanism. A 6-SPS parallel mechanism was employed to enhance the pelvis’s capacity to move, thereby providing the lumbar spine joint with six degrees of freedom (DoF) [83].

In 2020, Song et al. focused on aiding amputees in regaining their daily quality of life through the development of a hip prosthetic mechanism, as shown in Figure 7b. Analyzing human hip motion characteristics, they designed a 2-UPR/URR parallel mechanism with a passive limb. The study delved into the inverse kinematics of this mechanism using a closed-loop vector method. A comprehensive analysis of constrained and kinematic Jacobian matrices was conducted, leading to the construction of a 6 × 6 fully populated Jacobian matrix. This matrix aided in evaluating kinematic performance. Additionally, a dynamic model based on the virtual work principle was formulated. Its theoretical solution was compared with numerical simulation results, validating the dynamic model’s efficacy and the accuracy of the inverse kinematics. The prosthetic mechanism exhibited a larger rotating workspace and superior mechanical performance, closely mimicking the range of motion and bearing capacity of the human hip across various gait modes. The torque change during hip flexion and extension aligned well with human hip behavior, affirming the feasibility and dynamic performance of the prosthetic hip mechanism [84].

In 2023, Wang et al. introduced a hip exoskeleton with a distinctive parallel structure that allowed unrestricted walking and resolved misalignment issues. They proposed a model-based controller rooted in a human–machine integrated dynamic model, enhancing the system’s responsiveness to user movements. Unlike most existing exoskeletons, this controller only needed the user’s kinematic data, not interaction force, making the system more compact. Tests showcased the proposed hip exoskeleton’s kinematic compatibility and assistance capabilities [85].

4.5.3. Parallel Robot for Hip Humanoid

In 2017, Jiang et al. addressed challenges related to mimicking the distribution of human muscles in robots actuated by antagonistic pneumatic artificial muscles. They observed that existing control algorithms often fail to replicate natural muscle patterns accurately. To remedy this, the researchers proposed a humanoid lower-limb parallel mechanism with unevenly distributed muscle representation. They analyzed the kinematics and dynamic movements of the bionic hip joint using an observer-based fuzzy adaptive control algorithm. This algorithm considered the overall movement of the joint rather than focusing on individual pneumatic artificial muscles. The parameters were optimized using a neural network, and experimental results confirmed the effectiveness of this method. The study particularly highlighted the importance of muscle roles in trajectory tracking for specific muscle groups [22]. Wang et al. focused on the dynamic performance of a 4-SPS/CU parallel mechanism that included a spherical joint with clearance. They employed Archard’s wear model to analyze the wear properties of the socket. A kinematics model for the spherical joint with clearance was established, and an improved contact force model was introduced. The researchers formulated a dynamic model for the parallel mechanism while taking into account the spherical joint with clearance. Wear analysis involved the decomposition of contact forces and the computation of sliding distances. Simulation results revealed a nonuniform wear depth along the socket surface, which had implications for the mechanism’s performance [86].

In 2018, Russo et al. presented the mechanical design of LARMbot 2, an affordable humanoid robot intended for user-centric applications. LARMbot 2 featured parallel architectures for both the torso and legs, as shown in Figure 7c. The design’s kinematics for its primary components—including legs, torso, and arms—are detailed and compared with the previous version. A prototype was introduced, showcasing the subsystem construction and technical specifications. Experimental results offered insights into the robot’s performance during walking and weight-lifting operations [87].

Figure 7.

Hip joint mechanisms: (a) 6 SPS mechanism by Shangai University [83]; (b)4 RPS mechanism by Jiaotong University [84]; (c)3UPR mechanism by the University of Cassino and Southern Latium [87]. All are available under a Creative Commons Attribution License.

Table 5.

Parallel robots for rehabilitation, assistance, and humanoids of the hip joint.

Table 5.

Parallel robots for rehabilitation, assistance, and humanoids of the hip joint.

| Author | Year | Country | Device | TRL | Mechanism | DoF | ToM | Actuator | Model | Tool |

|---|---|---|---|---|---|---|---|---|---|---|

| Rastegarpanah et al. [80] | 2016 | UK | HR | 4 | 6-UPS | 6 | FE | EL | FK | M |

| Jiang et al. [22] | 2017 | China | HH | 3 | PMA | NS | NS | PL | FIK | NS |

| Wang et al. [86] | 2017 | China | HH | 2 | 4-SPS/CU | 2 | NS | EL | NS | NS |

| Russo et al. [87] | 2018 | Italy | HH | 3 | 4-SPS | 4 | NS | EL | IK | NS |

| Ren et al. [83] | 2019 | China | HA | 3 | 6-SPS | 6 | NS | PL | FIK | NS |

| Zhang et al. [81] | 2020 | China | HR | 3 | 2-UPS/RRR | 3 | FE, AA, IER | EL | FK | NS |

| Song et al. [84] | 2020 | China | HA | 2 | 4-RPS | 3 | NS | NS | FK | NS |

| Shi et al. [82] | 2022 | China | HR | 3 | 2-UPS/RRR | 3 | FE-AA, IER | EL | FIK | NS |

| Wang et al. [85] | 2023 | China | HA | 4 | 2-UPS+S | 2 | IER | EL | IK | NS |

Abbreviations: HR—hip rehabilitation, HA—hip assistance, HH—hip humanoid, 6-UPS—6 (universal-prismatic-spherical), PMA—pneumatic muscle actuator, 4-SPS/CU—4 (spherical-prismatic-spherical)/1 (cylindrical-universal), 3-UPR—3 (universal-prismatic-revolute), 6-SPS—6 (spherical-prismatic-spherical), 2-UPS-RRR—2 (universal-prismatic-spherical)/1 (revolute-revolute-revolute), 4-RPS—4 (revolute-prismatic-spherical), 2-UPS/RRR—2 (universal-prismatic-spherical)/1 (revolute-revolute-revolute), FE—flexion–extension, NS—not specified, AA— abduction–adduction, IER—internal–external rotation, ER—electric rotary, EL—electric linear, PL—pneumatic linear, IK—inverse kinematic, FK—forward kinematic, FIK—forward and inverse kinematic, M—MATLAB.

4.6. Parallel Robot for Ankle Joint

In the realm of scientific exploration concerning parallel robots, it is paramount to emphasize the scarcity of articles related to assistance and humanoids in the current body of literature. Notably, existing studies tend to focus exclusively on ankle rehabilitation, leaving a significant gap in our understanding of the broader landscape of assistance and humanoid interactions.

Parallel ankle rehabilitation devices aim to improve strength and mobility in patients suffering from ankle injuries, such as sprains or fractures. These devices provide controlled resistance and enable precise ankle motion. Studies related to rehabilitation are summarized in Table 6, each of which is described below.

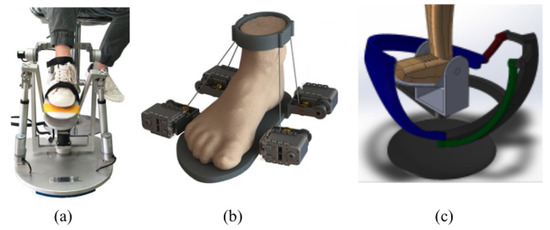

In 2012, Wang et al. introduced a novel parallel ankle rehabilitation robot and determined its efficacy through kinematic analysis and simulations. The results showcased the robot’s versatility under different input scenarios. with single inputs, the robot facilitated a range of ankle movements including dorsiflexion (0–30°), plantar flexion (0–50°), inversion/eversion (0–18°), and adduction/abduction (0–10°), making it suitable for initial ankle rehabilitation training. For double inputs, the robot enabled ankle motions such as dorsiflexion (0–30°), plantar flexion (0–50°), inversion/eversion (0–25°), and adduction/abduction (0–20°), apt for medium-term rehabilitation training. Under three inputs, the robot supported dorsiflexion (0–30°), plantar flexion (0–50°), inversion/eversion (0–40°), and adduction/abduction (0–30°), optimally meeting the needs of comprehensive ankle rehabilitation training. The robot’s design effectively accommodated the full range of motion necessary for normal ankle function and provided a versatile platform for various rehabilitation exercises, thereby aiding patients’ recovery processes [88].

In 2013, Saglia et al. examined the control architecture and experimental outcomes of the Ankle Rehabilitation Robot (ARBOT), aiming to develop effective control algorithms for aiding ankle joint training and rehabilitation, particularly in the presence of musculoskeletal injuries. They utilized a position control approach for patient-passive exercises and an admittance control technique for patient-active exercises, both with and without motion assistance. The design of the control algorithms was informed by an analysis of the rehabilitation protocol, taking into account system dynamics and human–robot interaction. Experimental assessments involving healthy subjects were conducted to evaluate the performance of the proposed control algorithms [89]. In the same year, Wang et al. presented the design of a novel 3-RUS/RRR redundantly actuated parallel mechanism for ankle rehabilitation, based on conceptual design principles. The mechanism facilitated ankle rotational movements in three directions, aligning the mechanism’s center of rotations with the ankle axes. A new actuator redundancy scheme was introduced to enhance system flexibility without compromising inherent advantages. Kinematic attributes such as dexterity, singularity, and stiffness were evaluated using the Jacobian matrix, which was then followed by simulations [90].

In 2014, Jamwal et al. introduced an innovative wearable ankle robot designed for the physical rehabilitation of ankle sprains. Originating from a comprehensive analysis of existing ankle robots, this bioinspired design was adaptable to individuals across different physiological abilities and age groups. The robot was powered by lightweight yet robust pneumatic muscle actuators (PMAs) that emulated skeletal muscles. To address the PMAs’ nonlinear characteristics, a fuzzy-based disturbance observer (FBDO) was employed. Additionally, an adaptive fuzzy logic controller—based on Mamdani inference and augmented with FBDO—managed the transient behavior of the PMAs. This control scheme allowed for the simultaneous control of four parallel actuators, achieving three rotational degrees of freedom. Experimental evaluations were conducted with a neurologically intact subject to maintain active–passive robot–human interaction during predefined trajectory tracking. These trials accounted for unforeseen human interventions, nonlinear and compliant actuators, and the parallel kinematic structure of the ankle robot [91].

In 2015, Jamwal et al. delved into the design, analysis, and optimization of a novel wearable parallel robot aimed at ankle rehabilitation. To confront challenges related to parallel mechanisms, flexible actuators, and ankle rehabilitation constraints, a thorough design analysis was executed. Three design stages—kinematic design, actuation design, and structural design—were meticulously investigated, resulting in six critical performance objectives essential for achieving the design goals. Initially, the optimization focused on single objectives; however, due to conflicting objectives, a simultaneous optimization approach was required. The study employed the nondominated sorting algorithm (NSGA II), based on evolutionary algorithms, for multi-objective optimization. NSGA II outperforms single-objective and preference-based optimization methods, providing more comprehensive design solutions. Furthermore, a fuzzy-based ranking method was introduced to select the ultimate design from NSGA II’s set of nondominated solutions. This methodology is adaptable for various types of parallel robots [92]. In the same year, Valles et al. from Universitat Politécnica de Valencia developed an economical parallel rehabilitation robot, addressing its design, kinematics, dynamics, and control features. Various position and force controllers were examined to ensure precise tracking performance. The robot was equipped with a force-sensor-integrated orthopedic boot designed for ankle exercises targeting injured areas. It supported passive, active-assistive, and active-resistive exercises for dorsi/plantar flexion, inversion, and eversion ankle movements. Orocos, a component-based middleware, offered a modular and configurable control scheme. Integration with Orocos and ROS enabled real-time teleoperation, represented by a CAD model that mirrored the robot’s position. Teleoperated rehabilitation exercises could be conducted using devices like a Wiimote [93].

In 2016, Jamwal et al. developed an ankle rehabilitation robot that employed an interactive training approach based on impedance control. Powered by PMAs, the robot allowed patients to adapt robot-induced motions to their specific limb movements, accommodating for disabilities. Four training modes—position control, zero-impedance control, non-zero-impedance control with high compliance, and non-zero-impedance control with low compliance—were employed to assess the effectiveness of the proposed control scheme. Evaluations involving 10 neurologically intact subjects indicated that increased robotic compliance led to greater participant engagement during training [94]. In the same year, Ruiz-Hidalgo et al. introduced a novel three-degrees-of-freedom (DoF) parallel robot that utilized revolute and spherical joints. The inverse kinematic model incorporate a PID-type controller with tracking capabilities to accurately follow a desired trajectory. Potential applications for this robot include its use as a motion simulator or ankle rehabilitation device. Simulation experiments conducted with a virtual prototype in MD ADAMS software validated the performance of the PID-type controller [95]. Azar et al. introduced an algorithm and an improved rule for controlling a lower-limb rehabilitation system. This system was implemented on a 6DoF Stewart parallel robot. Both impedance control and adaptive control methods were used, and the control parameters were estimated and optimized using artificial neural networks and genetic algorithms. Safety was assured by enabling adaptation under stable conditions. Simulations carried out using MATLAB/SIMULINK demonstrated the effectiveness of this approach when compared to common methods [96].

In 2017, Rosado et al. explored the use of PID controllers for conducting passive rehabilitation exercises. They designed and constructed an ankle rehabilitation prototype that employed a 2-RRSP parallel mechanism. Computer programs for guiding the rehabilitation exercises were developed using open-source software. The prototype facilitated passive exercises that involved path planning and PID control for various ankle movements [97]. Rosado et al. also presented the application of impedance controllers in active rehabilitation exercises. As in the previous study, a parallel ankle rehabilitation prototype using a 2-RRSP mechanism was utilized. They categorized active rehabilitation exercises and user-operation resistance effects into low, medium, and high opposition levels [98]. Du et al. introduced design modeling for a novel 3-RRS spherical parallel mechanism specifically intended for ankle rehabilitation. The study established the kinematics, degree-of-freedom calculations, and inverse kinematics of the mechanism. Multiple inverse solutions were derived, and a forward position analysis method suitable for motor position control was developed. The ankle rehabilitation robot was versatile and applicable in various settings, including homes, hotels, and fitness centers [99]. Zhang et al. highlighted innovative features of a Compliant Ankle Rehabilitation Robot (CARR) that offered an adjustable workspace and torque capacity. The CARR consisted of three rotational degrees of freedom (DoF) and was redundantly actuated by four compliant actuators. Due to the use of a parallel mechanism and compliant actuators, the robot faced the challenge of reconciling conflicting workspace and actuation torque requirements. To address this, the CARR was designed with reconfigurability, allowing it to balance workspace and torque capacity and meet diverse training needs. Theoretical analyses suggested the potential for varying kinematic and dynamic performance by reconfiguring the actuator layout [100].

In 2018, Liao et al. proposed a novel hybrid ankle rehabilitation robot composed of both serial and parallel components. The kinematic performance of this hybrid robot was analyzed, with its parallel part simplified as a constrained 3-PSP mechanism. Mathematical modeling based on screw theory was employed to establish a mathematical model for this component. Inverse kinematics were determined, and factors such as reciprocal twists, Jacobian matrices, and singularities were examined. The study predicted that the workspace of the central point on the moving platform can be expanded while eliminating singularities, making the robot suitable for clinical applications [15]. Rastegarpanah et al. presented a nine-degrees-of-freedom hybrid parallel mechanism designed for ankle rehabilitation, aiming to achieve precise movement in the lower extremities. The methodology for determining stiffness involved calculating the position vectors of each actuator in specific poses using inverse kinematics, thereby obtaining the magnitude and direction of the applied forces. The study leveraged both the stiffness and workspace attributes of parallel robots for ankle rehabilitation. Comparisons were made with standard parallel mechanisms, and the stiffness was evaluated through simulation, which was then compared to a prototype hybrid model in various scenarios [17]. Jamwal et al. investigated the feasibility of a wearable ankle robot for in-home rehabilitation. They began with an analysis of existing technologies and solutions. The complexities of human–robot interactions during rehabilitation were addressed through a fuzzy-logic-based controller designed for ankle treatment. The team proposed visual haptic interfaces to enhance patient engagement and considered web-based communication channels between users and remote physiotherapy staff. The software architecture included patient databases, a graphical user interface, and exercise libraries, thereby ensuring user-friendly operations and offering virtual reality-specific exercises for ankle rehabilitation [101].

In 2019, Wang et al. developed a robot to assist with ankle joint rehabilitation. This robot featured upper and lower platforms connected by a ball–pin pair and driving branches based on an SPS mechanism. Despite having only two degrees of freedom, the upper platform could emulate three types of ankle joint movements. The robot utilized a central ball–pin pair to mimic the natural motions of a patient’s foot and ankle joint, while rigid–flexible hybrid driving systems ensured decoupled dorsiflexion/plantar flexion and varus/valgus movements to minimize the risk of secondary injuries [102]. Naruhmi et al. presented a comprehensive analysis of a reconfigurable 3-(rR)PS metamorphic parallel mechanism, exploring its complete workspace and operational modes. The mechanism consisted of three (rR)PS legs, each having an (rR) joint comprising two perpendicular revolute joints. One axis of the (rR) joint could be continuously reconfigured, leading to three distinct configurations. Algebraic geometry techniques were used to derive constraint equations, and primary decomposition computations were carried out for each configuration. The study revealed that the mechanism could exhibit one or two operational modes, depending on the arrangement of the second axes of the (rR) joints. The work characterized the orientation workspaces for both modes and compared the moving platform’s instantaneous motion along the same trajectories. An identification approach was also introduced for determining which operational mode corresponded to a given mechanism pose, thereby offering a useful tool for trajectory planning [103].