Design and Scaling of Exoskeleton Power Units Considering Load Cycles of Humans

Abstract

1. Introduction

Use Case

2. Materials and Methods

2.1. Definition of Movement

2.2. Arm Model

2.3. Scaling Approach

2.4. Control

2.5. Load Cycle Analysis

2.6. Power Unit Design

2.6.1. Reference Machine

2.6.2. Scaling Approach

2.6.3. Solving

2.6.4. Constraints

2.6.5. Validation

3. Results

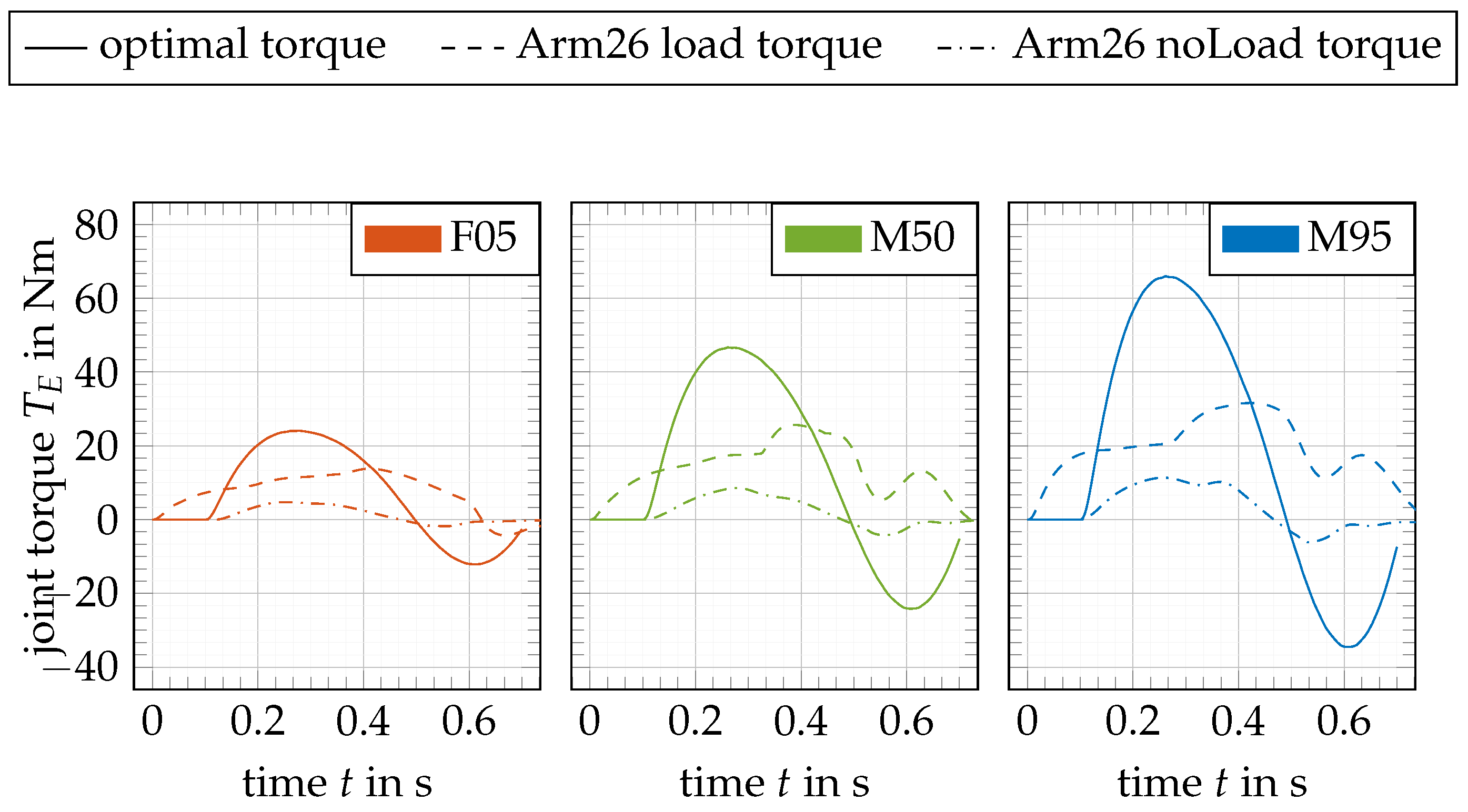

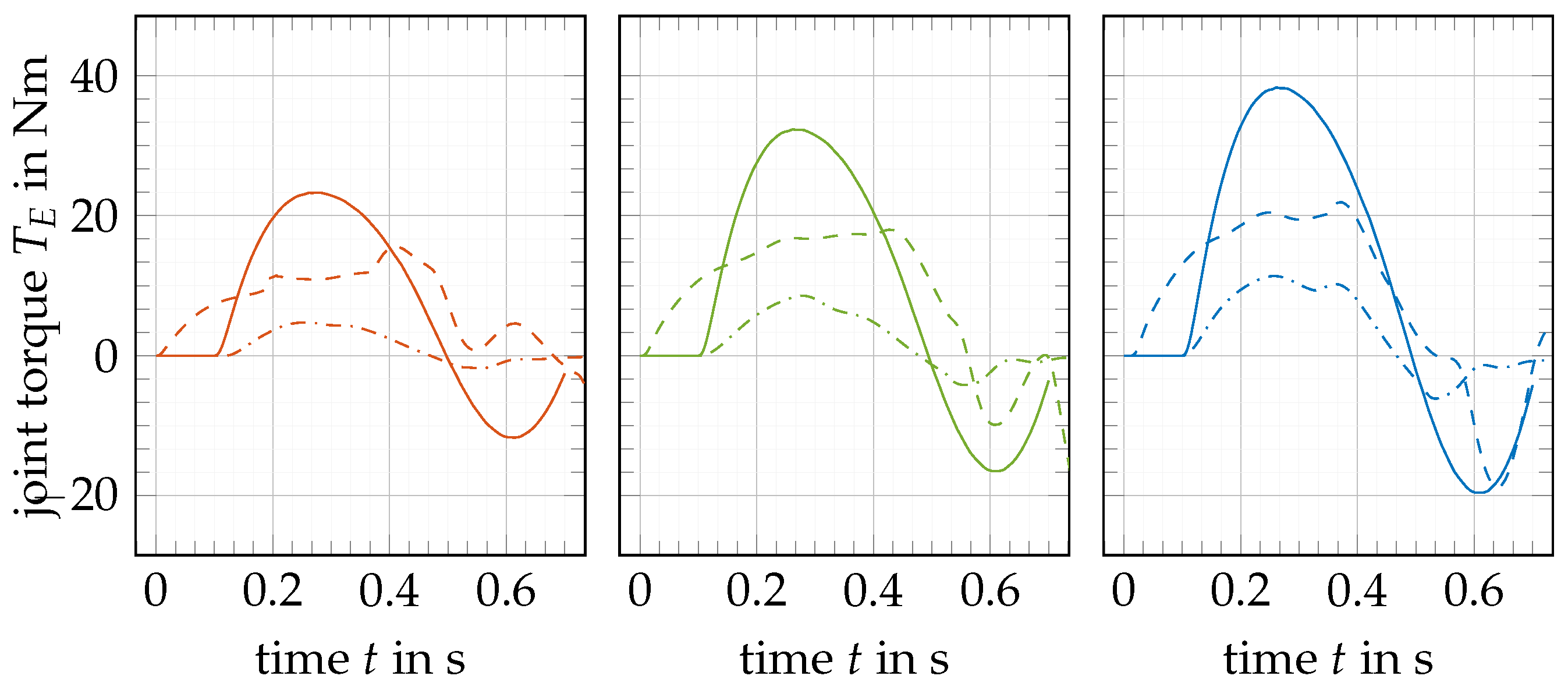

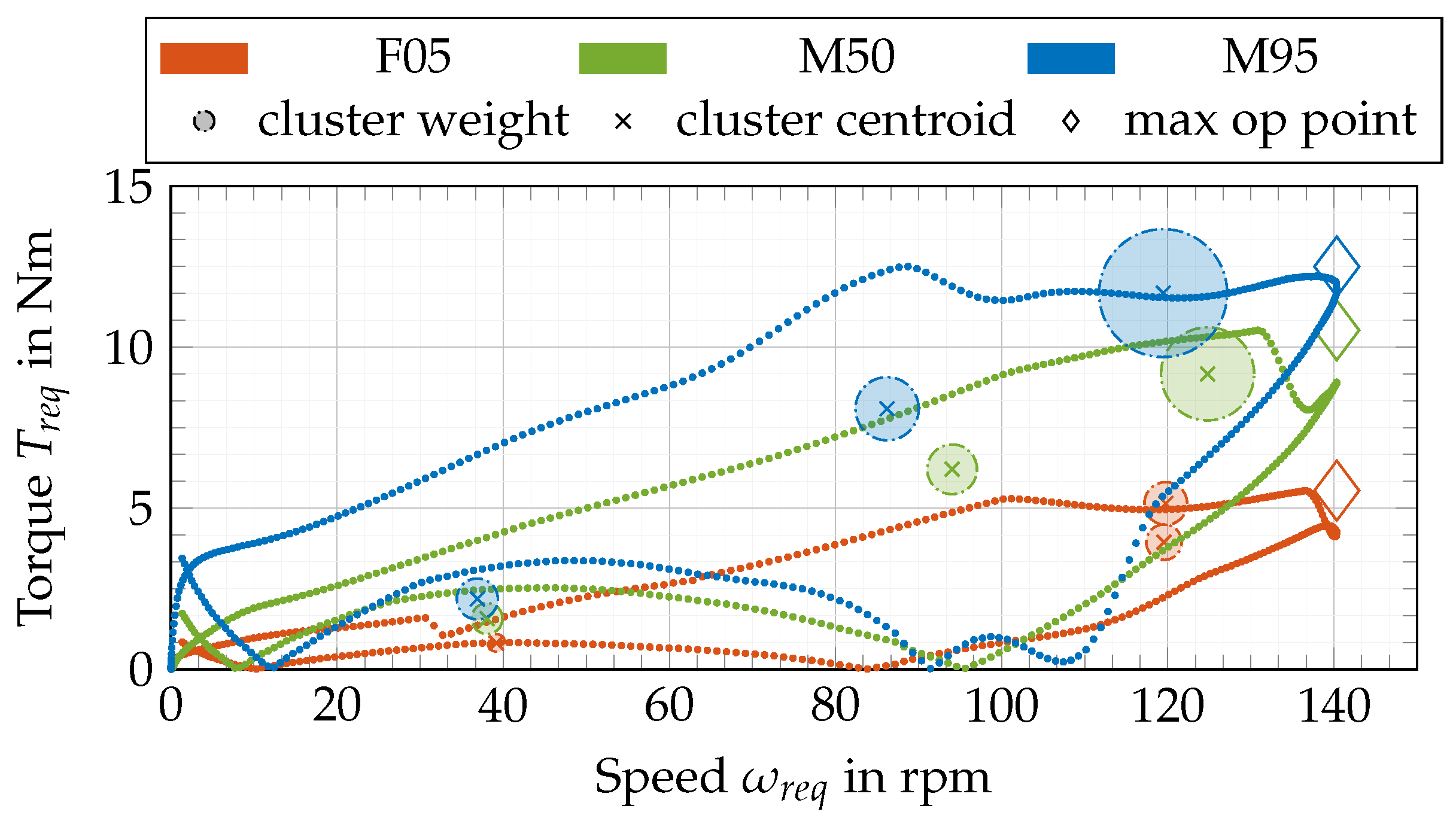

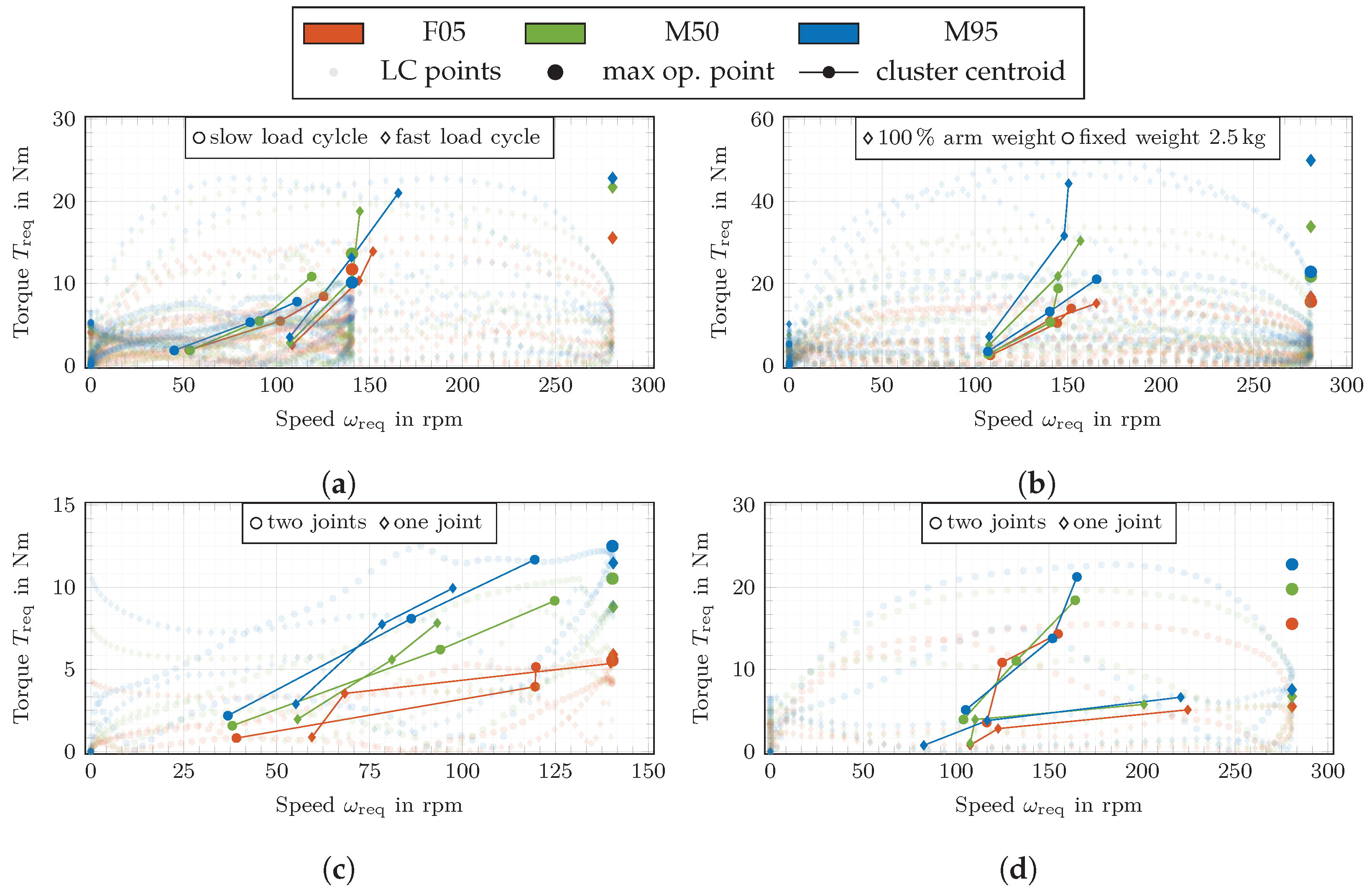

3.1. Influences of Movement

3.2. Influences of Person

3.3. Power Unit Scaling

4. Discussion and Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AFM | Axial Flux Machine |

| EM | Electrical Machine |

| EMG | Muscle Surface Electromyogram |

| exo | Exoskeleton |

| FEM | Finite Element Method |

| HD | Harmonic Drive Gear |

| LC | Load Cycle |

| PCSA | Physiological Cross-sectional Area |

| PU | Power Unit |

| RFM | Radial Flux Machine |

Appendix A. Flexion Movement Load Cycles

References

- Sylla, N.; Bonnet, V.; Colledani, F.; Fraisse, P. Ergonomic contribution of ABLE exoskeleton in automotive industry. Int. J. Ind. Ergon. 2014, 44, 475–481. [Google Scholar] [CrossRef]

- van Engelhoven, L.; Poon, N.; Kazerooni, H.; Barr, A.; Rempel, D.; Harris-Adamson, C. Evaluation of an adjustable support shoulder exoskeleton on static and dynamic overhead tasks. Proc. Hum. Factors Ergon. Soc. Annu. Meet. 2018, 62, 804–808. [Google Scholar] [CrossRef]

- Smets, M. A Field Evaluation of Arm-Support Exoskeletons for Overhead Work Applications in Automotive Assembly. IISE Trans. Occup. Ergon. Hum. Factors 2019, 7, 192–198. [Google Scholar] [CrossRef]

- Gull, M.A.; Bai, S.; Bak, T. A review on design of upper limb exoskeletons. Robotics 2020, 9, 16. [Google Scholar] [CrossRef]

- Shao, Z.F.; Tang, X.; Yi, W. Optimal design of a 3-DOF cable-driven upper arm exoskeleton. Adv. Mech. Eng. 2014, 6, 157096. [Google Scholar] [CrossRef]

- Zhou, L.; Li, Y.; Bai, S. A human-centered design optimization approach for robotic exoskeletons through biomechanical simulation. Robot. Auton. Syst. 2017, 91, 337–347. [Google Scholar] [CrossRef]

- Zoss, A.; Kazerooni, H. Design of an electrically actuated lower extremity exoskeleton. Adv. Robot. 2006, 20, 967–988. [Google Scholar] [CrossRef]

- Toxiri, S.; Calanca, A.; Poliero, T.; Caldwell, D.G.; Ortiz, J. Actuation Requirements for Assistive Exoskeletons: Exploiting Knowledge of Task Dynamics. In Wearable Robotics: Challenges and Trends; Biosystems & Biorobotics; Carrozza, M.C., Micera, S., Pons, J.L., Eds.; Springer: Cham, Switzerland, 2019; Volume 22, pp. 381–385. [Google Scholar] [CrossRef]

- Calanca, A.; Toxiri, S.; Costanzi, D.; Sartori, E.; Vicario, R.; Poliero, T.; Di Natali, C.; Caldwell, D.G.; Fiorini, P.; Ortiz, J. Actuation Selection for Assistive Exoskeletons: Matching Capabilities to Task Requirements. IEEE Trans. Neural Syst. Rehabil. Eng. A Publ. IEEE Eng. Med. Biol. Soc. 2020, 28, 2053–2062. [Google Scholar] [CrossRef]

- Pries, J.; Hofmann, H. Magnetic and thermal scaling of electric machines. Int. J. Veh. Des. 2013, 61, 219. [Google Scholar] [CrossRef]

- Hsieh, K.T.; Kim, B.K. One kind of scaling relations on electromechanical systems. IEEE Trans. Magn. 1997, 33, 240–244. [Google Scholar] [CrossRef]

- Zhou, K.; Ivanco, A.; Filipi, Z.; Hofmann, H. Finite-Element-Based Computationally Efficient Scalable Electric Machine Model Suitable for Electrified Powertrain Simulation and Optimization. IEEE Trans. Ind. Appl. 2015, 51, 4435–4445. [Google Scholar] [CrossRef]

- Stipetic, S.; Zarko, D.; Popescu, M. Scaling laws for synchronous permanent magnet machines. In Proceedings of the 2015 Tenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 31 March–2 April 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1–7. [Google Scholar] [CrossRef]

- Seok, S.; Wang, A.; Otten, D.; Kim, S. Actuator design for high force proprioceptive control in fast legged locomotion. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Vilamoura-Algarve, Portugal, 7–12 October 2012; IEEE: Piscataway, NJ, USA, 2012. [Google Scholar] [CrossRef]

- Wrobel, R.; Mecrow, B. Additive Manufacturing in Construction of Electrical Machines—A Review. In Proceedings of the 2019 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Athens, Greece, 22–23 April 2019; Volume 1, pp. 15–22. [Google Scholar] [CrossRef]

- Tiismus, H.; Kallaste, A.; Vaimann, T.; Rassolkin, A.; Belahcen, A. Technologies for Additive Manufacturing of Electrical Machines. In Proceedings of the 2019 20th International Conference of Young Specialists on Micro/Nanotechnologies and Electron Devices (EDM), Erlagol, Russia, 29 June–3 July 2019; pp. 651–655. [Google Scholar] [CrossRef]

- Kallaste, A.; Vaimann, T.; Rassalkin, A. Additive Design Possibilities of Electrical Machines. In Proceedings of the 2018 IEEE 59th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), Riga, Latvia, 12–13 November 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Huang, J.; Huo, W.; Xu, W.; Mohammed, S.; Amirat, Y. Control of Upper-Limb Power-Assist Exoskeleton Using a Human-Robot Interface Based on Motion Intention Recognition. IEEE Trans. Autom. Sci. Eng. 2015, 12, 1257–1270. [Google Scholar] [CrossRef]

- Yamasaki, H.; Tagami, Y.; Fujisawa, H.; Hoshi, F.; Nagasaki, H. Interaction torque contributes to planar reaching at slow speed. Biomed. Eng. Online 2008, 7, 27. [Google Scholar] [CrossRef]

- Wang, C.; Xiao, Y.; Burdet, E.; Gordon, J.; Schweighofer, N. The duration of reaching movement is longer than predicted by minimum variance. J. Neurophysiol. 2016, 116, 2342–2345. [Google Scholar] [CrossRef]

- Stollenmaier, K.; Ilg, W.; Haeufle, D.F.B. Predicting Perturbed Human Arm Movements in a Neuro-Musculoskeletal Model to Investigate the Muscular Force Response. Front. Bioeng. Biotechnol. 2020, 8, 308. [Google Scholar] [CrossRef]

- Günther, M.; Schmitt, S.; Wank, V. High-frequency oscillations as a consequence of neglected serial damping in Hill-type muscle models. Biol. Cybern. 2007, 97, 63–79. [Google Scholar] [CrossRef]

- Haeufle, D.; Günther, M.; Bayer, A.; Schmitt, S. Hill-type muscle model with serial damping and eccentric force-velocity relation. J. Biomech. 2014, 47, 1531–1536. [Google Scholar] [CrossRef]

- Hammer, M.; Günther, M.; Haeufle, D.; Schmitt, S. Tailoring anatomical muscle paths: A sheath-like solution for muscle routing in musculoskeletal computer models. Math. Biosci. 2019, 311, 68–81. [Google Scholar] [CrossRef] [PubMed]

- Hatze, H. A myocybernetic control model of skeletal muscle. Biol. Cybern. 1977, 25, 103–119. [Google Scholar] [CrossRef]

- Pankoke, S.; Siefert, A. Virtual Simulation of Static and Dynamic Seating Comfort in the Development Process of Automobiles and Automotive Seats: Application of Finite-Element-Occupant-Model CASIMIR; SAE International: Warrendale, PA, USA, 2007. [Google Scholar] [CrossRef]

- Decker, W.; Koya, B.; Pak, W.; Untaroiu, C.D.; Gayzik, F.S. Evaluation of finite element human body models for use in a standardized protocol for pedestrian safety assessment. Traffic Inj. Prev. 2019, 20, S32–S36. [Google Scholar] [CrossRef]

- Pak, W. Development and Validation of Human Body Finite Element Models for Pedestrian Protection. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 2019. [Google Scholar]

- DIN e.V. (publ.) (DIN 33402-2:2005-12, 2005): Ergonomics—Human Body Dimensions, Part 2: Values. 2005. Available online: https://www.beuth.de/en/standard/din-33402-2/84092742 (accessed on 24 August 2022).

- Winter, D.A. Biomechanics and Motor Control of Human Movement; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Handsfield, G.G.; Meyer, C.H.; Hart, J.M.; Abel, M.F.; Blemker, S.S. Relationships of 35 lower limb muscles to height and body mass quantified using MRI. J. Biomech. 2014, 47, 631–638. [Google Scholar] [CrossRef] [PubMed]

- Flash, T.; Hogan, N. The coordination of arm movements: An experimentally confirmed mathematical model. J. Neurosci. 1985, 5, 1688–1703. [Google Scholar] [CrossRef] [PubMed]

- Stollenmaier, K.; Rist, I.S.; Izzi, F.; Haeufle, D.F. Simulating the response of a neuro-musculoskeletal model to assistive forces: Implications for the design of wearables compensating for motor control deficits. In Proceedings of the 2020 8th IEEE RAS/EMBS International Conference for Biomedical Robotics and Biomechatronics (BioRob), New York, NY, USA, 29 November–1 December 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 779–784. [Google Scholar]

- Wierzbicka, M.M.; Wiegner, A.W.; Shahani, B.T. Role of agonist and antagonist muscles in fast arm movements in man. Exp. Brain Res. 1986, 63, 331–340. [Google Scholar] [CrossRef] [PubMed]

- Kistemaker, D.A.; Van Soest, A.K.J.; Bobbert, M.F. Is equilibrium point control feasible for fast goal-directed single-joint movements? J. Neurophysiol. 2006, 95, 2898–2912. [Google Scholar] [CrossRef]

- Gunther, S.; Ulbrich, S.; Hofmann, W. Driving cycle-based design optimization of interior permanent magnet synchronous motor drives for electric vehicle application. In Proceedings of the International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Ischia, Italy, 18–20 June 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 25–30. [Google Scholar] [CrossRef]

- Salameh, M.; Brown, I.P.; Krishnamurthy, M. Fundamental Evaluation of Data Clustering Approaches for Driving Cycle-Based Machine Design Optimization. IEEE Trans. Transp. Electrif. 2019, 5, 1395–1405. [Google Scholar] [CrossRef]

- Selim, S.Z.; Ismail, M.A. K-means-type algorithms: A generalized convergence theorem and characterization of local optimality. IEEE Trans. Pattern Anal. Mach. Intell. 1984, 6, 81–87. [Google Scholar] [CrossRef]

- Waldhof, M.; Echle, A.; Parspour, N. A Novel Drive Train Concept for Personalized Upper Body Exoskeletons with a Multiphase Axial Flux Machine. In Proceedings of the 2019 IEEE International Electric Machines & Drives Conference (IEMDC), San Diego, CA, USA, 12–15 May 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 2160–2166. [Google Scholar] [CrossRef]

- Keller, M.; Müller, S.; Parspour, N. Design of a transverse flux machine as joint drive for an articulated six-axis robot arm. In Proceedings of the 2016 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Capri, Italy, 22–24 June 2016; pp. 849–854. [Google Scholar] [CrossRef]

- Bartlett, H.L.; Lawson, B.E.; Goldfarb, M. Optimal Transmission Ratio Selection for Electric Motor Driven Actuators With Known Output Torque and Motion Trajectories. J. Dyn. Syst. Meas. Control 2017, 139, 43. [Google Scholar] [CrossRef]

- Hanselman, D.C. Brushless Permanent-Magnet Motor Design; McGraw-Hill: New York, NY, USA, 1994. [Google Scholar]

- Gieras, J.F.; Wang, R.J.; Kamper, M.J. Axial Flux Permanent Magnet Brushless Machines, 2nd ed.; Springer: New York, NY, USA, 2008. [Google Scholar]

- Kamper, M.J.; Wang, R.J.; Rossouw, F.G. Analysis and Performance of Axial Flux Permanent-Magnet Machine with Air-Cored Nonoverlapping Concentrated Stator Windings. IEEE Trans. Ind. Appl. 2008, 44, 1495–1504. [Google Scholar] [CrossRef]

- Rosu, M.; Zhou, P.; Lin, D.; Ionel, D.M.; Popescu, M.; Blaabjerg, F.; Rallabandi, V.; Staton, D. Multiphysics Simulation by Design for Electrical Machines, Power Electronics and Drives; IEEE Press Series on Power Engineering; Wiley: Hoboken, NJ, USA, 2018; Volume 66. [Google Scholar]

- Waldhof, M.; Parspour, N. Torque Ripple Minimization in Exoskeleton Drives with Multiphase Electrical Machines by Current Harmonic Injection. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; Volume 1, pp. 2152–2158. [Google Scholar] [CrossRef]

- Maxon-Motor-GmbH. Available online: https://www.maxongroup.de/maxon/view/category/motor?etcc_cu=onsite&etcc_med_onsite=Product&etcc_cmp_onsite=ECXSPEEDProgramm&etcc_plc=Overview-Page-brushless-DC-Motors&etcc_var=[de]#de#_d_&target=filter&filterCategory=ECX (accessed on 21 March 2022).

| Cases | Start to Target Angle [, ] | Mov. Duration | DoF | |||

|---|---|---|---|---|---|---|

| A | [00,00] | to | [−90,−90] | flex. | two joints | |

| B | [−90,−90] | to | [00,00] | ext. | two joints | |

| C | [00,00] | to | [00,−90] | flex. | one joint | |

| D | [00,−90] | to | [00,00] | ext. | one joint | |

| E | [00,00] | to | [−90,−90] | flex. | two joints | |

| F | [−90,−90] | to | [00,00] | ext. | two joints | |

| G | [00,00] | to | [00,−90] | flex. | one joint | |

| H | [00,−90] | to | [00,00] | ext. | one joint | |

| Description | Unit | F05 | M50 | M95 |

|---|---|---|---|---|

| total height lB | 1.535 | 1.750 | 1.855 | |

| total weight mB | 52.000 | 79.000 | 100.000 |

| Parameter | Unit | AM | FEA | PT |

|---|---|---|---|---|

| Torque TAFM | 180.80 | 178.90 | 176.20 | |

| Ind. Voltage Ui | mV/rpm | 1.54 | 1.49 | 1.49 |

| Mass | 156.15 | 156.35 | 157.20 | |

| Efficiency η 1 | % | 62.49 | 62.25 | 61.90 |

| Load Cycle | Person | [g] | [%] | [g] |

|---|---|---|---|---|

| slc | F05 | 2.5 | 33.8 | −46.7 |

| M50 | 2.5 | 43.8 | −44.3 | |

| M95 | 2.5 | 37.9 | −39.6 | |

| F05 | 2.6 | 30.9 | −40.5 | |

| M50 | 3.95 | 49.2 | −25.7 | |

| M95 | 5 | 57.6 | −9.7 | |

| flc | F05 | 2.5 | 51.3 | −32.2 |

| M50 | 2.5 | 67.2 | −15.8 | |

| M95 | 2.5 | 74.2 | 6.8 | |

| F05 | 2.6 | 52.4 | −28.7 | |

| M50 | 3.95 | 73.4 | 14.5 | |

| M95 | 5 | 77.8 | 42.63 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waldhof, M.; Wochner, I.; Stollenmaier, K.; Parspour, N.; Schmitt, S. Design and Scaling of Exoskeleton Power Units Considering Load Cycles of Humans. Robotics 2022, 11, 107. https://doi.org/10.3390/robotics11050107

Waldhof M, Wochner I, Stollenmaier K, Parspour N, Schmitt S. Design and Scaling of Exoskeleton Power Units Considering Load Cycles of Humans. Robotics. 2022; 11(5):107. https://doi.org/10.3390/robotics11050107

Chicago/Turabian StyleWaldhof, Marcel, Isabell Wochner, Katrin Stollenmaier, Nejila Parspour, and Syn Schmitt. 2022. "Design and Scaling of Exoskeleton Power Units Considering Load Cycles of Humans" Robotics 11, no. 5: 107. https://doi.org/10.3390/robotics11050107

APA StyleWaldhof, M., Wochner, I., Stollenmaier, K., Parspour, N., & Schmitt, S. (2022). Design and Scaling of Exoskeleton Power Units Considering Load Cycles of Humans. Robotics, 11(5), 107. https://doi.org/10.3390/robotics11050107