1. Introduction

A five-bar mechanism can be used to effectively model a cyclist’s upper and lower leg actuating a conventional crank-driven bicycle [

1]. When restricting the motion and torque at the cyclist’s ankle, the kinematics and dynamics are described with a four-bar model. The ubiquitous four-bar mechanism has four pairs of coordinates defining the locations of its revolute (R) joints for a total of eight design variables. A potential way to improve the performance of a system is to replace its four-bar by a six-bar mechanism. A six-bar mechanism has seven R joints resulting in 14 design parameters. The six-bar performs in a manner that is similar to the four-bar, but has extra design variables that can be used to improve the performance of the mechanism, typically supplying amplification or subtler control over forces and/or displacements. Several recent examples of using the six-bar to provide such design refinement include a furniture hinge mechanism [

2], an adjustable mechanical forming press [

3], a biomimetic leg mechanism [

4], a body guidance mechanism [

5], a hand rehabilitation robot [

6], and a compact bellow globe valve design [

7]. When locking the motion of the ankle, a human pedaling a bicycle is seen as a four-bar loop, with the thigh as a rocking input, the cnemis, or lower leg, as the coupler, and the crank connecting to sprocket and chain as the fully rotating output. With improved performance in mind, the thigh and cnemis can be viewed as two links of a six-bar mechanism instead of two links in a four-bar where, instead of the foot driving the output crank directly, additional links are available between foot and output crank. Two such alternates are the Watt II and the Stephenson III.

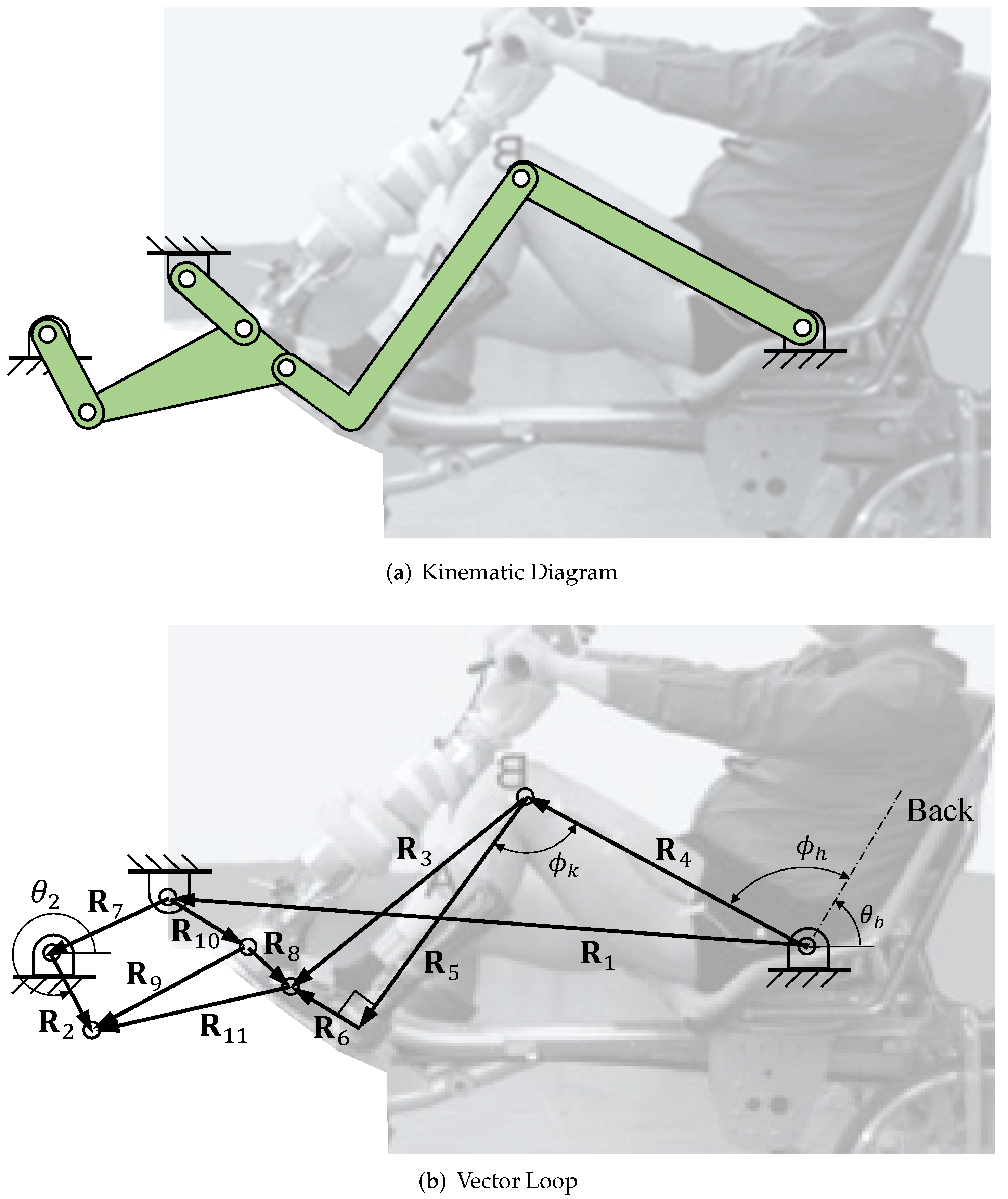

Prior work investigated the Watt II design [

8], referred to therein as the CRT, short for crank-rocker tricycle. That is, the thigh and calf drive a rocker arm that moves a coupler and rotates the output crank. Together, the motion of the legs and the crank-rocker define a pair of connected four-bars as in a Watt II mechanism. The significant change to this work is to consider the leg as pushing on the coupler of a four-bar rather than its output link, producing the CDT or coupler-driven tricycle. The overall architecture resembles that of the Stephenson III. As in the work of Bazler et al. [

8], the focus here is on riders using functional electrical stimulation (FES). Although FES and its use in cycling are reviewed here, that work contains a more detailed examination of these topics.

FES uses low-energy electrical pulses to artificially generate muscle contractions. This stimulation can create movement for individuals who have been paralyzed due to spinal cord injuries (SCI) or other lower-body neurological impairments [

9]. Outcomes include the ability to stand, grasp objects and exercise in people with physically disabling conditions [

10]. FES cycling can be a successful means of exercise and rehabilitation for these patients. A variety of physical and mental health benefits have been observed [

11,

12,

13]. The biomechanical challenges of FES cycling can be observed in the bike race event of the Cybathlon [

14,

15]. The challenges arise as FES cyclists are observed to produce an order of magnitude less power than able-bodied (AB) cyclists [

16], limiting FES cycling to stationary bikes or horizontal surfaces. Biomechanical studies of cycling include Hull et al. [

1] and Yamazaki et al. [

17] demonstrating accurate dynamic simulations for AB cyclists, Fregly et al. examining steady state pedaling [

18], and Gfohler et al. developing models in SCI cyclists that relate joint torques and angles [

19,

20].

The pedaling power model used in this paper is derived from the results of Szecsi et al. [

21] developed on stationary tricycles wherein data was collected in two phases for 16 persons with SCI. The ankle was placed in a boot to constrain the foot to a 90

angle with the cnemis and restricting motion to the sagittal plane, typical of FES cycling. Their experiments involved a passive pedaling phase followed by an active phase in which stimulation of the subject’s legs rotated the crank at a cadence of 60 rpms against a machine-controlled resistance of 30 W (15 W per leg). An inverse dynamic approach was used to determine the knee and hip moments from the pedal contact forces [

22]. Their data is measured from top dead center (TDC), an absolute crank angle of 22

as used in this work. Based on their prior work showing that AB cyclists have four distinct power peaks (P1, P2, P3, and P4) during one rotation of the crank, FES cyclists were found to fall into two groups [

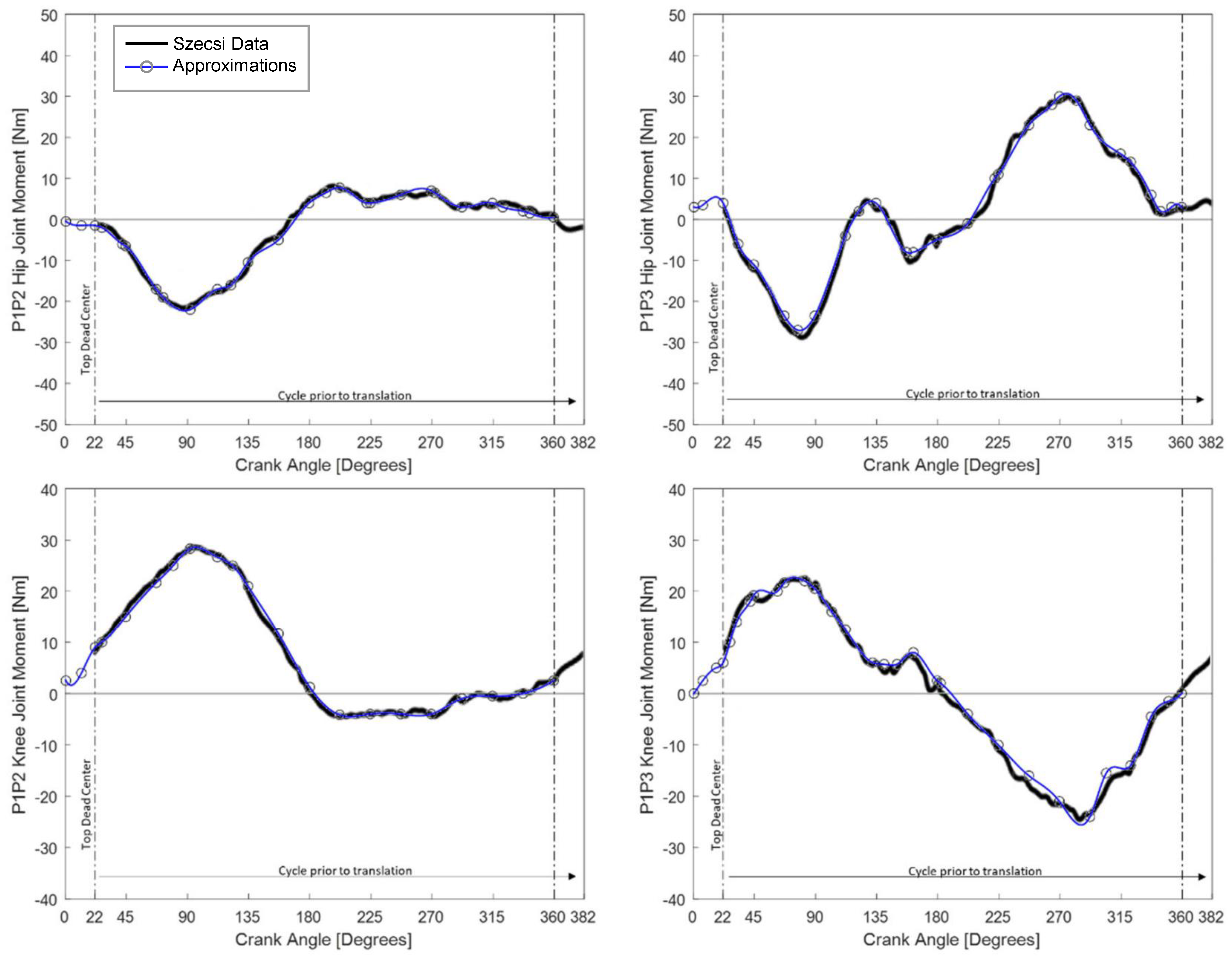

23]. Of the 16 SCI subjects, 75% produced the power alignment with the P1 and P2 phases (the P1P2 group). The remaining 25% produced power in alignment with the P1 and P3 phases (the P1P3 group). The knee and hip joint moments, calculated from the inverse dynamics, as a function of crank angle are shown for each group in

Figure 1.

The literature on riders using FES typically involves a tricycle featuring a traditional drivetrain, designed for the power stroke of an AB cyclist using voluntary movement of the lower limbs. Some innovative approaches have been attempted to address the challenges of FES cycling. An energy storage device proposed by Ibrahim et al. sought to store power in an elastic band to evenly redistribute positive power at the crank through the full duration of the pedaling sequence [

24]. Shan [

25] and Gfohler et al. [

20] proposed ovate pedaling motion in an effort to increase power production in both AB and SCI cyclists. In line with these efforts, this work proposes that an alternative drivetrain could achieve greater power throughput than the traditional recumbent tricycle (TRT).

The contribution of this paper is to present a design methodology and recumbent tricycle architectures with the capacity to increase the power throughput for FES cycling. Previous research [

8] proposed a six-bar pedalling linkage, with a coupler-rocker configuration, where analysis shows over a 50% power increase when compared to a traditional tricycle design. This paper introduces another six-bar linkage, with a coupler-driver configuration, that promises to increase power throughput by over 100%. The paper is organized as follows. The design approach is outlined in detail in

Section 2, following closely the work of Bazler et al. [

8]. Kinematic and quasi-static models are described in

Section 3 as derived from the traditional recumbent tricycle.

Section 4 discusses transferring the torque into a form that can be used in alternate tricycle deigns.

Section 5 presents the considerations in the six-bar linkage-based designs, and

Section 6 details its optimization.

Section 7 compares the results of the three tricycle architectures.

Section 8 concludes the paper.

3. Traditional Recumbent Tricycle Model

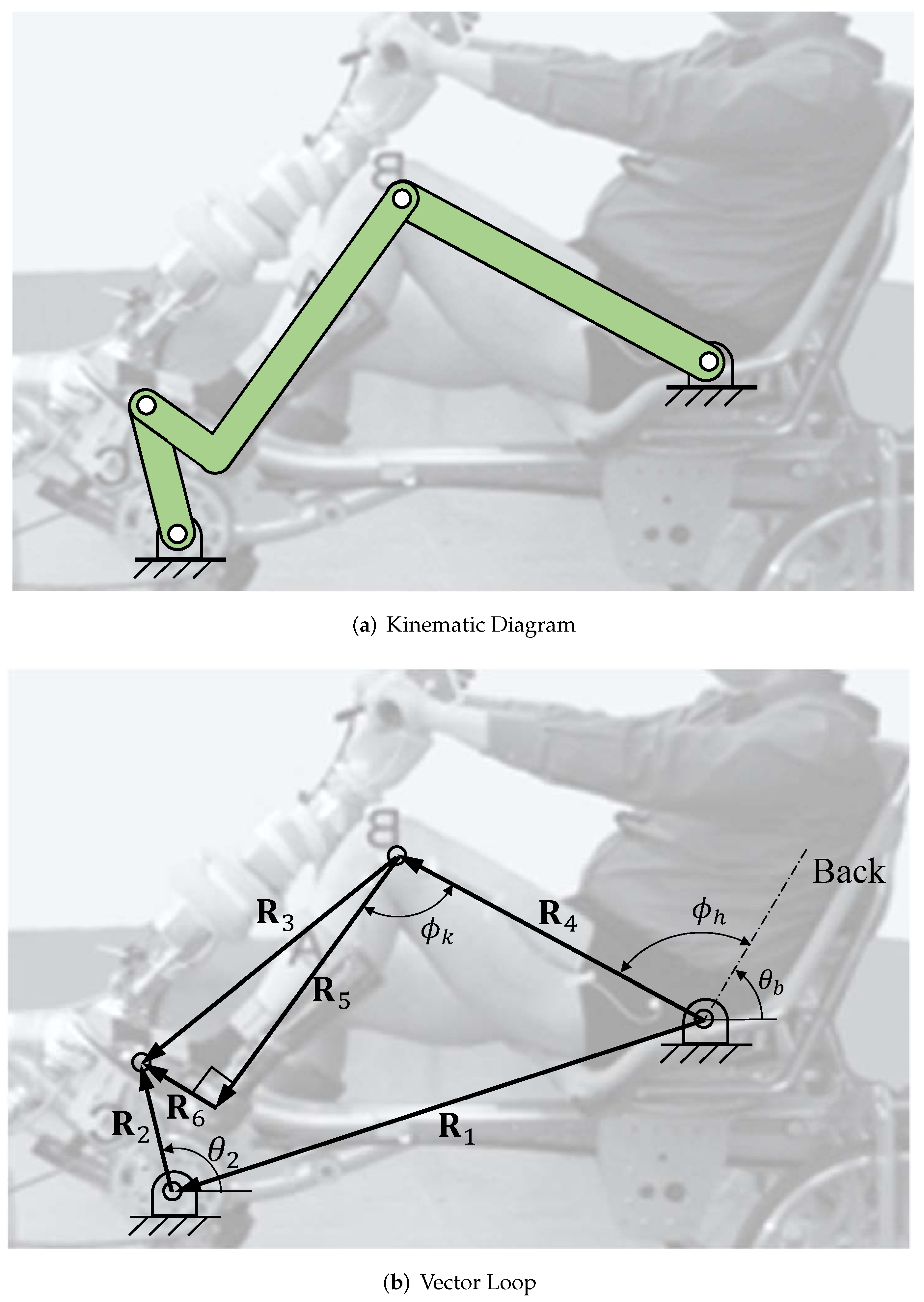

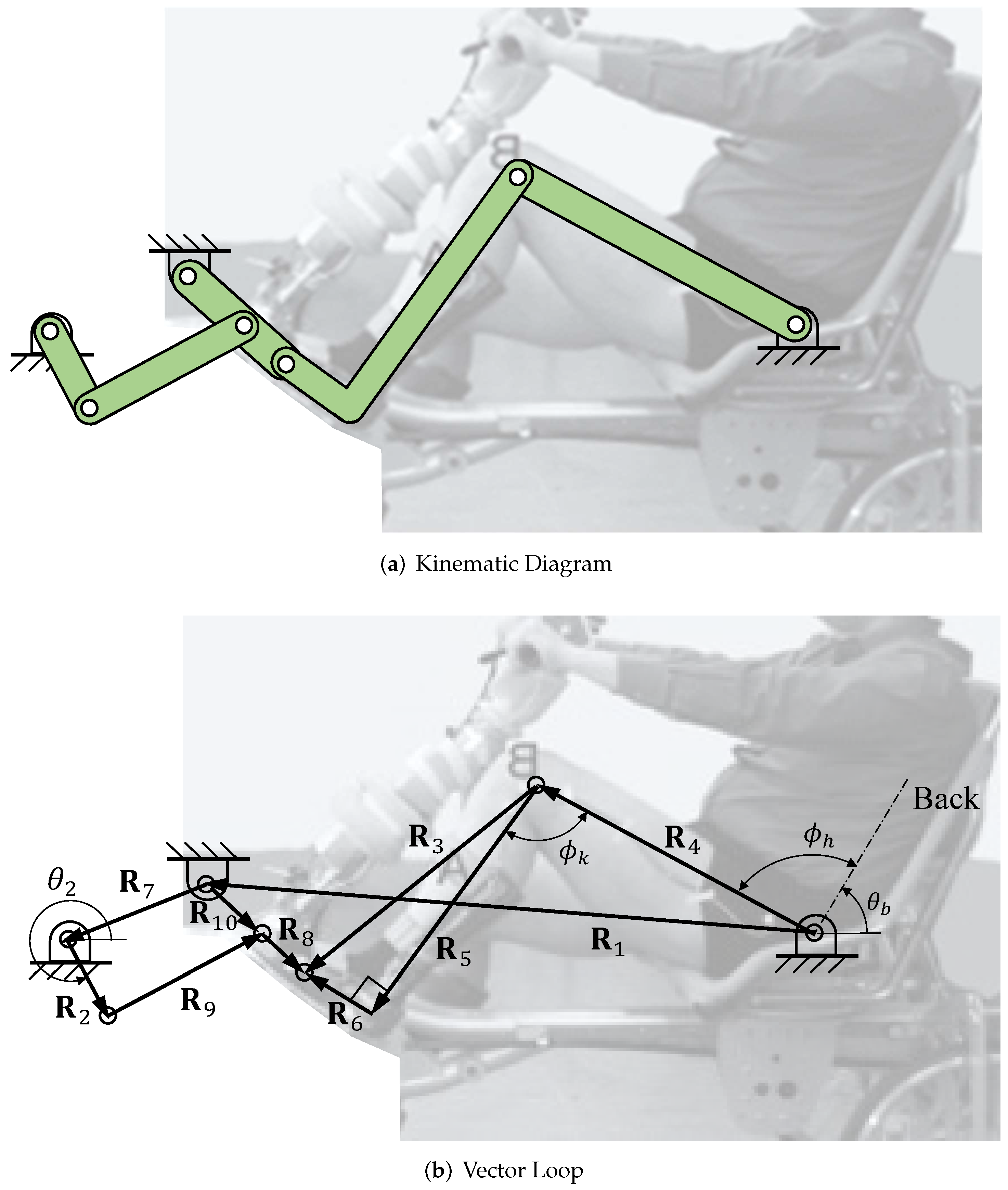

The kinematics of the interaction between the cyclist and the TRT is modeled as a four-bar linkage.

Figure 2b displays the vector diagram. The recumbent tricycle frame is designated as

.

The thigh serves as an oscillating link. The cnemis and foot are held at a constant relative angle by a rigid boot and are combined to form the coupler . The cycle pedal arm is a fully-rotating crank. The frame dimensions are = cm and the crank length is = 15.0 cm.

The loop closure equation for the TRT model is

where

is the length of vector

i,

and

is the angle of vector

i measured counterclockwise from the positive horizontal axis. With a specified crank angle

, Equation (

2) can be readily solved for

and

. Note that the hip angle is

, where

is the seat recline angle. In addition, the knee angle is

.

The time derivative of Equation (

2) generates the velocity equation,

As with the position analysis, the angular velocities of the lower leg

and upper leg

are determined from Equation (

3).

Szecsi’s experimental work [

21] imposed a constant angular velocity (cadence) of

= 60 rpm on the cyclist pedaling. Using a gear reduction of

= 1.31 between the crank sprocket and the driving wheel, the linear velocity of the tricycle was determined by using a wheel diameter of

= 66 cm, to be

= 5.71 km/h, which is consistent with the average speed of cyclists at the Cybathlon in 2016 [

14]. Given

and the TRT dimensions, a position, velocity, and acceleration analysis are performed. Determining the relationship of the knee angle

and hip angle

to the crank angle

is required to utilize the experimental data on the alternate six-bar linkage designs.

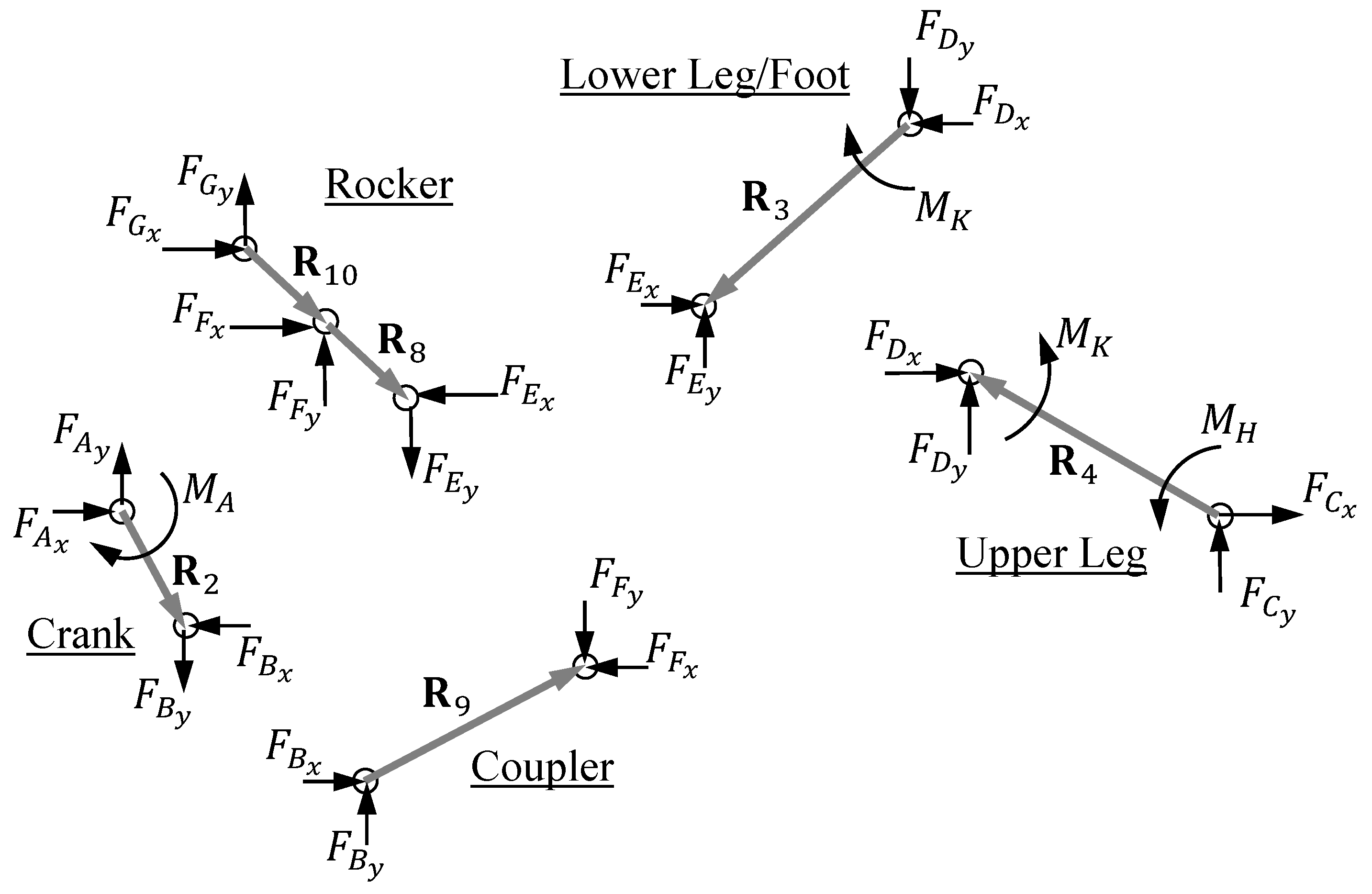

Free-body diagrams of the thigh, cnemis/foot, and crank are shown in

Figure 3. A quasi-static model was deemed appropriate as the angular velocities and accelerations of

and

are low. As a consequence, inertial forces are ignored when generating the free-body diagrams. Further, the cycle-averaged power will be used as a comparison parameter between the TRT and the alternative six-bar designs. Over one cycle of the crank, the potential and kinetic energies related to the leg segment masses, would sum to zero and would have no effect on the cycle-averaged power. From

Figure 3, the force and moment equilibrium equations become

The hip-joint moment

and knee-joint moment

as a function of crank angle

serves as input for the force analysis. Given the link kinematics

, from Equations (

2) and (

4) become a square system of

,

, and

. As such, a statically equivalent torque at the crank center,

, is generated a function of

.

The experimental data of

Figure 1 represents the average of several FES cyclists, each with different leg lengths. To generate a model that represents an average rider,

,

, and

, were altered until a simulated cycle-averaged power was consistent with Szecsi’s experiments. The average leg lengths for the P1P2 group are

= 51.5 cm,

= 51.5 cm, and

= 6.9 cm. The average leg lengths that represent the P1P3 group are

= 54.2 cm,

= 54.2 cm, and

= 6.9 cm.

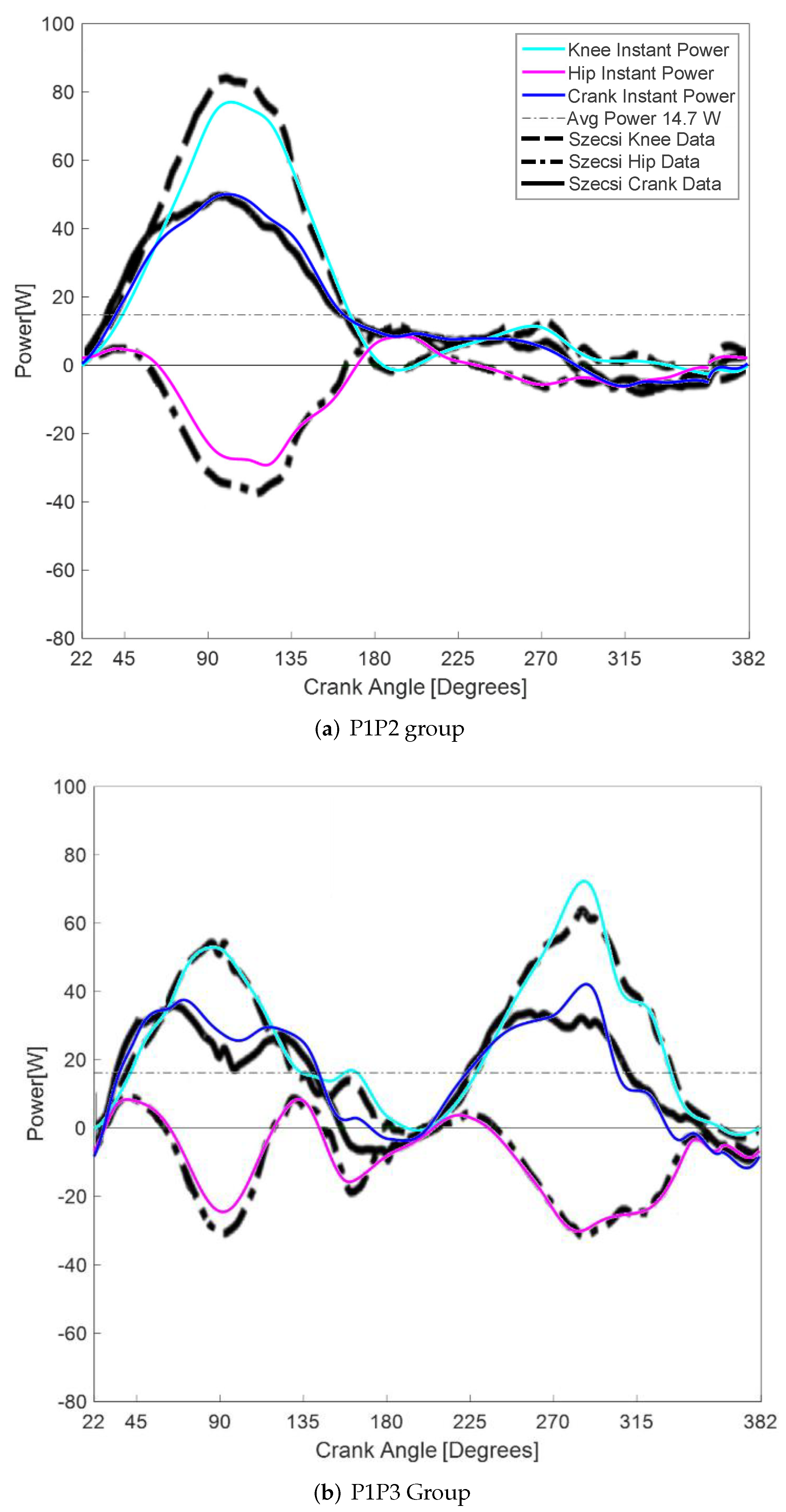

The crank torque

is calculated with the P1P2 and P1P3 knee and hip moments from

Figure 1 for 0

360

using a constant angular velocity of the crank. The instantaneous power is calculated through Equation (

1) and overlayed on Szecsi’s data in

Figure 4.

Each SCI FES cyclist in Szecsi’s experiments produced an average of 30 Watts per cycle of the crank. Presuming that each leg equally contributes to the power generation, the single-leg TRT model is expected to produce a cycle-average of 15 W. With representative rider dimensions selected as = 52.0 cm, = 52.0 cm, and = 6.9 cm, the P1P2 group produced =14.7 W per leg whereas the P1P3 produced = 16.2 W.

4. Joint Moment Transformation

The measured joint torques (i.e., joint moments) shown in

Figure 1 are provided by Szesci as a function of crank angle. Those torques are used as inputs to the TRT power model of

Section 3. Alternative tricycle linkage designs will exhibit significantly different leg kinematics. In order to utilize Szesci’s measurements when exploring alternative designs, the joint torque dependency must be transformed.

Yoon et al. [

26] show that joint torque is a function of three inputs: joint angle, joint motion, and muscular contraction speed. The preferred FES cyclist torque data would be available as a function of these dependencies. Without that experimental data, the approach taken in this work combines the three inputs. Joint torque is mapped from crank angle to joint angle and joint motion (i.e., joint extension and flexion). Additionally, the motion of the hip and knee joints are prevented from exceeding those experienced in the TRT cyclist model. This constraint is present not because the leg is incapable of moving beyond these ranges, but because of the lack of data for modeling purposes.

The TRT model provides the joint angle as a function of crank angle, which is combined with Szesci’s torque as a function of crank angle. In that way, a continuous curve of joint torque as a function of joint angle is produced and shown in

Figure 5. The angular velocity of each joint is used to distinguish joint extension or flexion, which affects joint torque as the motion is derived from stimulating different muscle groups. A positive (or zero) joint angular velocity is identified as extension. Conversely, a negative angular joint velocity is identified as flexion. Extension and flexion are denoted in

Figure 5 as alternate line styles.

6. Optimization

Both six-bar models have ten design parameters, and not the 14 stated in the Introduction because the parameters associated with the human leg cannot be varied. The ten parameters are collected as

=

,

,

,

,

,

,

,

]. An objective function is posed to maximize the average power throughout the cycle

. The optimization is formally posed as

where

is the number of angles within the kinematic model and

ℑ refers to the imaginary part of

.

In order to determine

from Equation (

1), the kinematic vector loop closure equations are solved throughout a cycle of

. The kinematic loop closure for the CDT are given in Equations (

5) and () and for the CRT in Equations (

10) and (). Subsequently, the force and moment equilibrium equations, given in Equations (

9) for the CDT and Equations (

14) for the CRT, are used to determine the reaction moment at the crank

that is used in Equation (

1). The motivation for the optimization constraints posed in Equation (

15) are provided below.

The loop closure equations must produce a linkage that can be assembled for every position of the crank. That is,

. Additionally, the crank rotation must produce a linear velocity consistent with the TRT (

= 5.71 km/h),

Grashof’s criteria is enforced to ensure full crank rotatability,

where

is required to be the shortest of the four links.

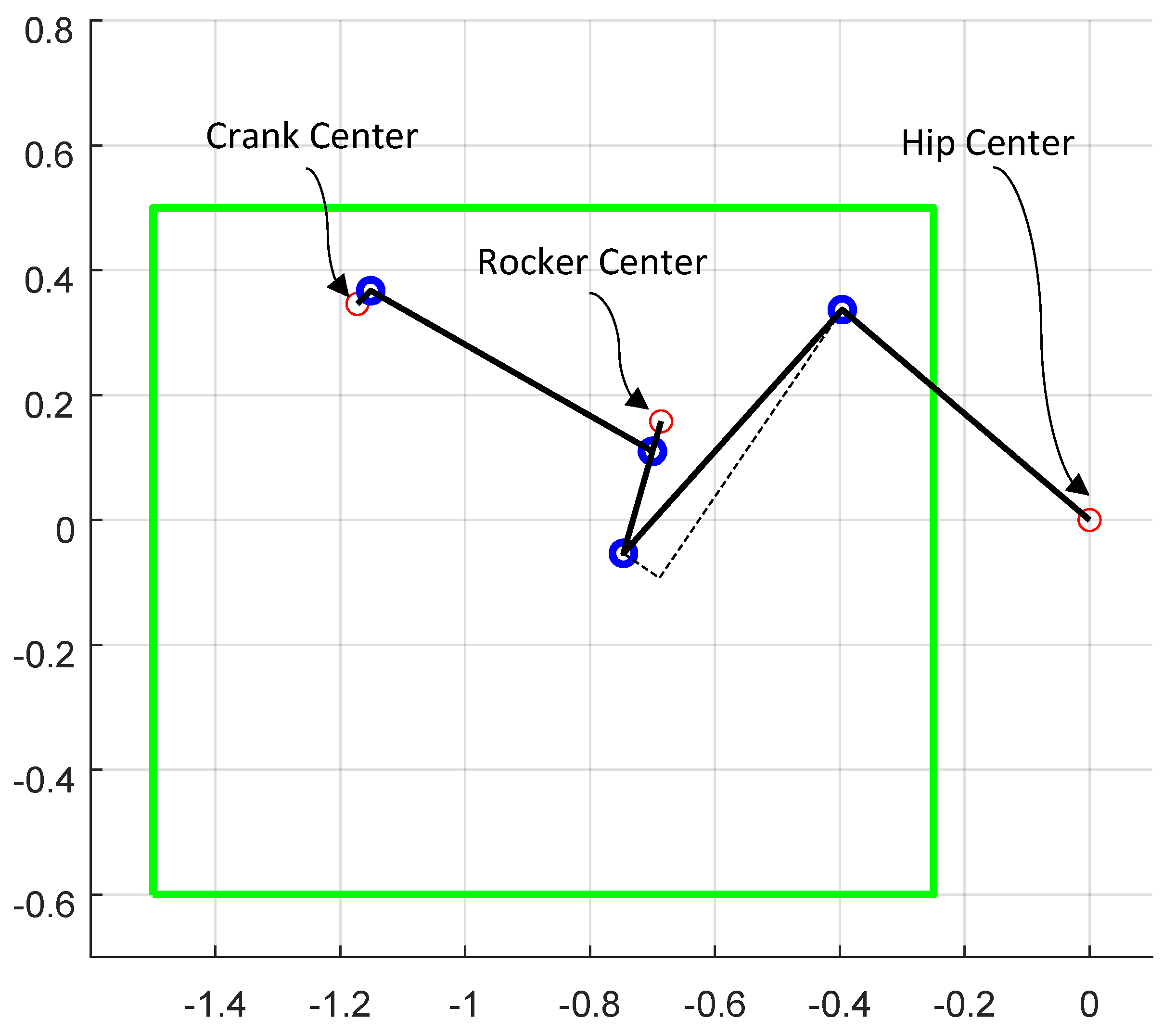

To align with the results generated during the TRT analysis, the hip joint was restricted to the range

. Likewise, the knee joint was restricted to the range

. As expected, test optimizations produced unusable mechanisms due to positioning of components and undesirable link lengths. As such, a final set of constraints on dimensions was introduced for the sake of practicality and manufacturability: the crank

2.5 cm, the rocker

2.5 cm, the angle-to-pedal length

35.5 cm, and crank center and rocker center locations constrained to lie within the envelope shown in

Figure 10.

This nonlinear problem includes a significant number of inequality constraints. As such, a standard gradient-based optimization proved problematic. A Random Pursuit Optimization was used instead to identify optimal design values

. The optimization initiates with a guess,

, for the ten design parameters that satisfies all constraints. The corresponding average power over one full cycle,

, is calculated for

. A new guess,

, is generated from

through the introduction of small, random changes. That is, for the potential first optimization step,

i = 1,

where

. The values of

are evaluated against the entire set of constraints. If satisfied,

is passed to the objective function and

is determined. If

, the new optimal is

. A new guess,

, is generated by making small, random changes to

according to Equation (

18). If

, the optimal design values remain unchanged and

. A new guess for

is generated by making a different set of random changes to

.

Convergence was determined by limiting the number of iterations since the last improvement. Due to the randomness associated with altering the ten parameters, and to be confident that a design approaching the optimum has been obtained, the convergence criteria was established to be 10,000 consecutive iterations of parameters that satisfy the constraints without improving . Code to perform the aforementioned procedure was generated by the authors using MATLAB.

7. Results and Discussion

An optimization as described in the prior section was performed for both six-bar designs using the torque input for the P1P2 group and the P1P3 group. The resulting power and extreme joint angles encountered during motion for the TRT, CRT and CDT architectures are presented in

Table 1. The

solution for the CRT design that generated the highest power output for the P1P2 group is designated R1, while

for the CRT design with the P1P3 group is designated R2. Similarly, D1 is

corresponding with the CDT design for the P1P2 group and D2 is

corresponding with the CDT design for the P1P3 group. Once the design was achieved, the cycle-averaged power output for both groups

and

was determined and are given in

Table 1. The average power for both groups

is also shown.

Note from

Table 1 that all six-bar designs provide substantial increases in power output when compared to the TRT. Further, the R1 and D1 designs were optimized for the P1P2 group, yet the P1P3 group would generate comparable power with those tricycle designs. Conversely, the R2 and D2 designs were optimized for the P1P3 group, but the P1P2 group generates notably less power.

Designs R1, R2, D1, D2 are further evaluated to identify the best six-bar tricycle design based upon the following set of metrics: manufacturability, joint torque curve continuity, equal power distribution over the entire crank cycle, and percent increase in average power for each group.

7.1. Manufacturability

The dimensions of the TRT, R1, R2, D1 and D2 designs are provided in

Table 2. The length

represents the distance from the ankle to the center of the pedal. Since the cyclist’s foot is placed in a boot, zero and negative values are permissible.

Manufacturability considerations include several design criteria such as the distance from the hip center to crank center, length of the the rocker arm, height of the rocker arm pivot relative to rider’s line of sight, estimated weight of the design, etc. All four design six-bar designs are deemed suitable and will yield an acceptable mechanical design.

7.2. Joint Torque Curve Continuity

The joint torque curves of

Figure 5 are truncated when the kinematics of a six-bar linkage design requires the cyclist’s knee or hip to move less than the TRT during a full pedaling motion. The discontinuity at the ends of the plots on

Figure 11 are not biomechanically correct. Yet, these truncated curves are used in the CRT and CDT power modeling because the experimental data needed to generate continuous curves does not exist.

For example, notice that design R2 requires knee movement from

to

, whereas the TRT requires

to

. At the lower extreme of

, the knee joint torque is assumed to shift instantaneously from the extension curve with 20 Nm of torque to flexion curves with −1 Nm. A continuous joint torque curve would likely reduce the power generated as the sharp corners in

Figure 11 would become rounded and decrease the torque produced at the joint limit extremes. As such, the power from the six-bar linkage models will be more accurate when the design requires joint movements that closely align with the TRT joint movements. The CDT designs D1 and D2 have more similar joint angle extremes when compared to the TRT. Accordingly, the CDT modeled power is more representative of the biomechanical output.

7.3. Power Distribution

An ideal tricycle design enables a cyclist to generate a constant level of power throughout the crank rotation, thereby creating smooth forward motion. However, Szesci [

21] observed that FES cyclists generate uneven levels of power, exhibiting propulsive and recovery phases. Understanding that power fluctuations will occur, a favorable design will limit the instantaneous power variations and prevent negative values. When the power output becomes negative, power is extracted from the tricycle’s kinetic energy and used to move the cyclist’s legs. This transfer of power from tricycle to the cyclist’s legs is referred to as an inactive zone, where the leg is not in a configuration that can be stimulated to produce positive work. The inactive zones create a choppy pedaling motion and may lead to the cyclist becoming locked at the TDC or BDC of the TRT crank. Video from the Cybathlon demonstrates this phenomena [

15].

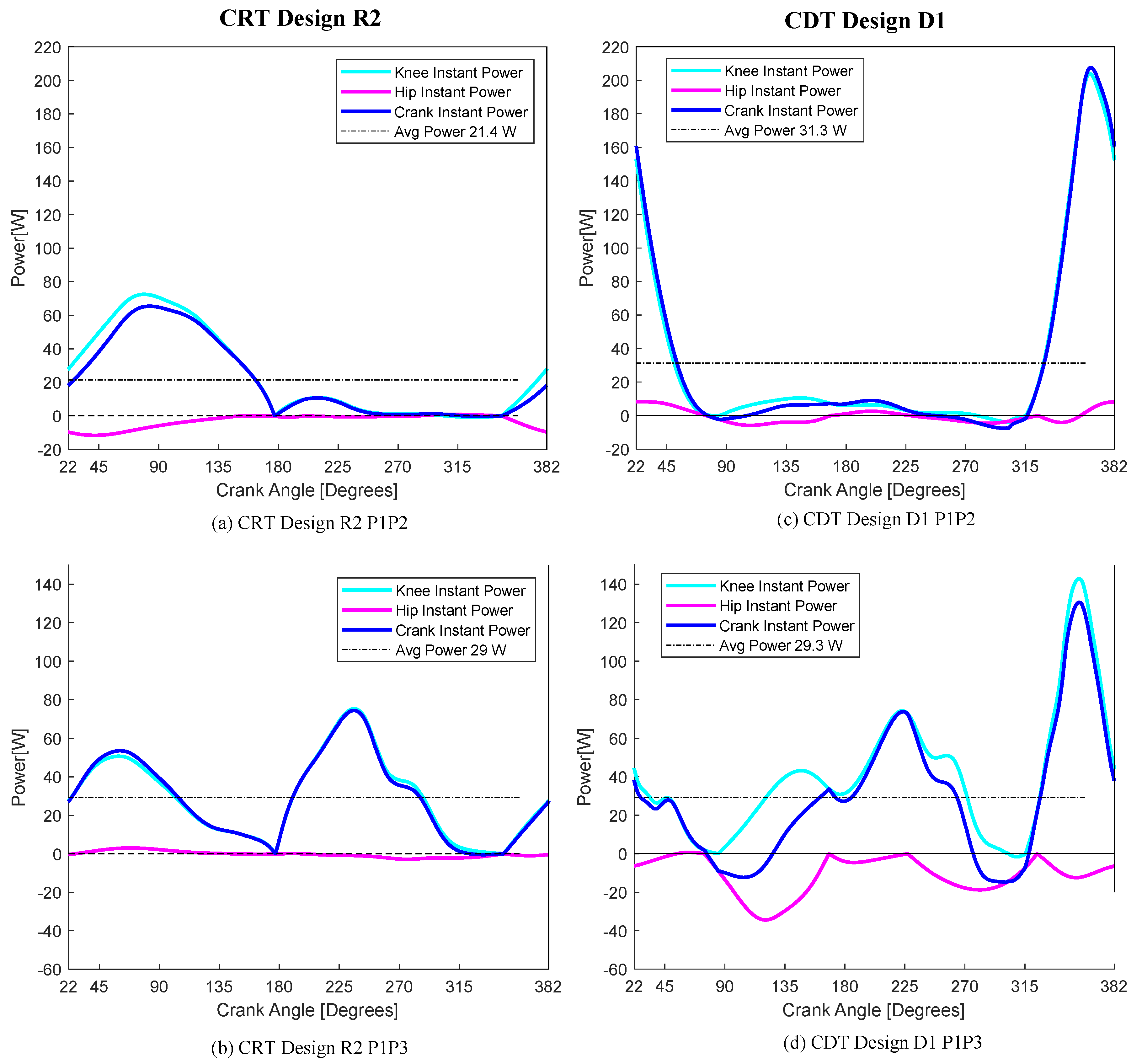

The instantaneous power curves for the R2 and D1 designs are given in

Figure 12 for both the P1P2 and P1P3 groups. The curves in

Figure 12a,c exhibit a high power peak in one phase of the crank because the P1P2 group riders generate almost all of their joint torques in this region. This single peak is consistent with the TRT instantaneous power with the P1P2 group shown in

Figure 4a. Note that in the TRT inactive zones, the remainder of the power decreases in the second half of the cycle while becoming negative. In the CRT and CDT designs of

Figure 12a,c, the power remains above or at zero throughout the remainder of the cycle.

The P1P3 group exhibits two power peaks as discussed in

Section 3 and shown in

Figure 4b. Accordingly, the R2 and D2 designs with the P1P3 group yield the highest power output. Additionally, the power curves in

Figure 12b,d are not dominated by a single peak and are expected to produce smoother tricycle motion.

7.4. Design Recommendation

The tricycle design selected for further consideration should allow any FES rider of an unknown power group to effectively produce a significant power improvement above the TRT. The tricycle design should have high average power for both groups (

and

), satisfy the manufacturability criteria, and biomechanically satisfy the additional constraints required for FES cycling. Design D1 produces comparable power in each group with a group average power of 30.32 W, which is nearly double the TRT. Design D1 achieves the increased power by altering the motion of the leg and maintaining the joint angle in regions of high toque to ensure that positive power is produced for the duration of the crank cycle. The optimization recognized that a significant portion of the hip range did not produce positive power at the crank, therefore the kinematics of the design D1 limits the hip from entering this region. Further, design D1 limits any antagonistic joint moments created at the hip through limiting its joint range. Lastly, the D1 design also nearly matches the knee joint angle ranges of the TRT. Therefore, the recommendation is that the biomechanical interaction of the cyclist and the Coupler Driver Tricycle, design D1 be investigated to confirm that an an FES cyclist is capable of producing the anticipated joint torque curves. A scaled kinematic sketch of the recommended Design D1 is shown in

Figure 13.