1. Introduction

This section discusses the transformation of education towards the needs of the Fourth Industrial Revolution (Industry 4.0). We consider the challenges in shaping the new education (Education 4.0) and its implementation in high schools. Finally, the purpose statement and the paper organization are presented.

1.1. Education in the Era of Industry 4.0

Rapid development and deployment of new disruptive digital technologies have been the cause of the dramatic transformation in the industry and human society, affecting how we live, communicate, work, and learn [

1]. The changes happening in the industry are so drastic that they are widely referred to as the fourth industrial revolution, Industry 4.0 [

2]. The innovative technologies and concepts are being integrated into everyday life and blur the boundaries between physical and virtual, local and remote, natural and artificial [

3].

Consequently, there is an imminent need to prepare the new generation of citizens and engineers and develop an awareness of Industry 4.0 at all levels of education [

4]. To answer this need, educators must elaborate on innovative ways to teach new concepts and use new technologies to enhance educational processes. The coming educational transformation is so substantial that it is growingly regarded as revolutionary and referred to as Education 4.0 [

5].

The current crisis caused by the Covid-19 pandemic has become the catalyst for the broad penetration of innovative technologies in business and social areas. Global connectivity and remote interaction have become imperative for business, social communication, and education. Education systems all over the world are now facing the challenge of adapting themselves to social distancing restrictions. This challenge further enforces the long-term revolutionary transformations, introducing new curriculums, pedagogies, educational frameworks, and technologies.

1.2. Challenges of Education 4.0

Among the long-term challenges of education transformation is to focus student learning on developing knowledge, skills, and attitudes essential in the modern era [

6]. Subsequently, science, technology, engineering, art, and mathematics (STEAM) education needs to be adjusted and upgraded [

7]. It should include the learning of new interdisciplinary subjects such as information and communication technology (ICT), robotics and automated systems (RAS), artificial intelligence (AI), internet of things (IoT), and augmented reality (AR). In parallel, modern education needs to develop students’ awareness of Industry 4.0 and nurture their positive attitudes towards learning new technologies [

8]. Modern education should also develop students’ Industry 4.0 skills required in the modern era. Examples to such skills are problem solving, systems thinking, creativity, self-directed learning, and social skills. The prioritized social skills relate to collaboration with others and include collaborative thinking, communication, and teamwork [

9].

The increased complexity of modern engineering systems requires more advanced knowledge of system design, operation, and maintenance [

10]. The researchers involved in the analysis of workforce development for Industry 4.0 point out that the increasing complexity of the production processes leads to an increase in jobs with higher qualifications and demands for the employees capable of performing strategic, coordinating, and creative tasks with higher responsibilities [

11].

The companies feel the shortage of and demand for human talent with a high technological understanding and advanced practical skills [

12]. Such talented employees increase companies’ productivity, efficiency, and competitive advantage. Consequently, companies compete for the talent, implement talent-development strategies [

13], and establish partnerships with educational institutions to prepare their students for Industry 4.0 [

14].

Academic engineering programs have the central role in preparing professional engineers for the Industry 4.0 economy. The programs vigorously upgrade their curriculums and instructional strategies, and provide student internships in advanced industries, and professional training courses for graduates. The significant challenges these programs face are the shortage of high school graduates interested in engineering, insufficient preparation for the engineering studies, and lack of awareness about the innovations coming with the evolving digital transformation.

1.3. Education 4.0 in High School

The need for the implementation of Education 4.0 approaches in high school is critical. On one hand, the high school age is the suitable time to develop motivation for science and engineering careers. On the other hand, the insufficient level of technical knowledge among school graduates makes it difficult for them to study technological disciplines at tertiary education levels.

As the concepts of Industry 4.0 are beyond the current school curriculum, engineering educators are developing ways to introduce them to school students [

15]. One such way is through STEM enrichment programs for the high achieving students interested in engineering and computer science and, particularly, in robotics and AI. Such programs can apply different models of enrichment.

The Carnegie Mellon Robotics Academy offers an enrichment program called Smart Manufacturing and Advanced Robotics Training (SMART) [

16], including mechanical, electrical, fabrication, software, and robotics integration courses. High school students who successfully pass the courses earn the SMART Robotics Technician Micro-Certifications. Participants of the FIRST and VEX robotics competitions are encouraged to join the program.

The DLR School Lab at the RWTH Aachen University massively conducts various hands-on engineering workshops for high school students. Many of the workshops focus on robotics and artificial intelligence [

17]. In the labs, the students use real and virtual engineering systems to analyze and control processes such as energy supply for smart cities, drone flying, robot locomotion and manipulation.

While most of the enrichment programs are open to all interested students, some are more demanding programs that select capable, highly motivated students, confront them with intellectual and personal challenges, and prepare them for the top-level university programs. An exemplary, rigorous high school program in robotics, automation, and AI is the Beaver Works Summer Institute (BWSI) of the Massachusetts Institute of Technology [

18]. The program selects talented high school students from throughout the United States. The students take a four-month-long preparatory online course and then come to MIT for the four-week summer program. The program offers students the choice of a list of courses, including Autonomous RACECAR, Air Vehicle Racing, Autonomous Cognitive Assistant, and Data Science for Health and Medicine. These university-level courses combine learning the STEM concepts, practice with innovative digital technologies, and performing creative projects. The summer program includes lectures delivered by MIT professors and industrial leaders, and classes for the teamwork and communication skills development. BWSI is working with collaborators to scale up the program nationally and internationally.

The programs discussed above are among the first and still few university initiatives to introduce high school students to the concepts of Industry 4.0 through robotics. The research of such programs is at the very beginning and not yet discussed in recent thematic reviews [

19,

20]. To our knowledge, our paper is the first study considering such an initiative in detail.

The Center for Robotics and Digital Technology Education (CRDTE) at the Technion–Israel Institute of Technology implements school enrichment programs that focus on learning the concepts of Industry 4.0 in robotic environments [

21,

22]. One of these programs, named Intelligent Robotics and Smart Transportation (IRoST), is considered in this paper. The paper extends our preliminary research and conference publication [

23].

1.4. Purpose Statement

Our IRoST program was inspired by the ideas of the BWSI and driven by our purpose to provide high school students in Israel with access to rigorous learning of Industry 4.0 concepts and technologies. The challenges that we faced in the development of IRoST were redesigning the BWSI curriculum and robotic environment, and adapting them to our target audience, budget, and organizational constraints. One more challenge was to involve competent instructors and capable, motivated students in teaching and learning the subject. We met the challenges by conducting a series of case studies [

22,

23,

24,

25], and through collaboration with industry partners (PTC Corporation and Momentum Company), the academy (MIT), and the school system (Israel Ministry of Education and ORT school network).

We delivered the program for the first time in 2017–2018 with 15 students from one high school in Haifa. Given its positive outcomes, the Israel Ministry of Education supported the scaling up of the program with the goal to promote the learning of autonomous vehicles and smart transportation in high schools. In 2018–2019, more than 60 students from five schools participated in the program, and in 2019–2020, there were 83 participants from six schools. All the students studied, at school, one of the advanced-level technology education subjects: computer science, electronics, or mechatronics. Most of them were tenth graders (ages 14–16), with a few ninth graders.

Our ongoing research associated with the IRoST program explores ways to introduce high school students to selected concepts and technologies of Industry 4.0 and promote the development of certain thinking, learning, and technical skills. This research aims to evaluate the contribution of the program to students’ understanding of these Industry 4.0 concepts and technologies, students’ progress in the targeted skills, and their interest in modern robotics. The case study presented below focuses on two selected concepts and technologies, i.e., Internet of Things and collaborative sensing, learned in the program through experimentation with multi-robot systems.

To understand the concepts and processes of connectivity and collaborative sensing in a multi-robot system, the students first learned about robot programming, control, navigation, vision, sensing, and communication. Based on the acquired knowledge, the students implemented the project-based learning assignments focusing on IoT and collaborative sensing. In the educational study, we focused on students’ self-evaluation of the learning experience.

1.5. Paper Organization

The rest of the paper is organized as follows. A literature review on connectivity and collaborative sensing as core concepts of Industry 4.0 is provided in

Section 2. Further, our educational strategy for teaching these concepts to high school students as part of the IRoST program is presented in

Section 3.

Section 4 contains the detailed explanation of the objectives and methods of the study. The study results are presented and discussed in

Section 5 and

Section 6.

3. Implementation of IoT and Collaborative Sensing

This section describes the developed laboratory environment and educational strategy. We present the stages of the IRoST program and elaborate on the IoT and collaborative sensing projects performed by the students.

3.1. CRDTE Laboratory Environment

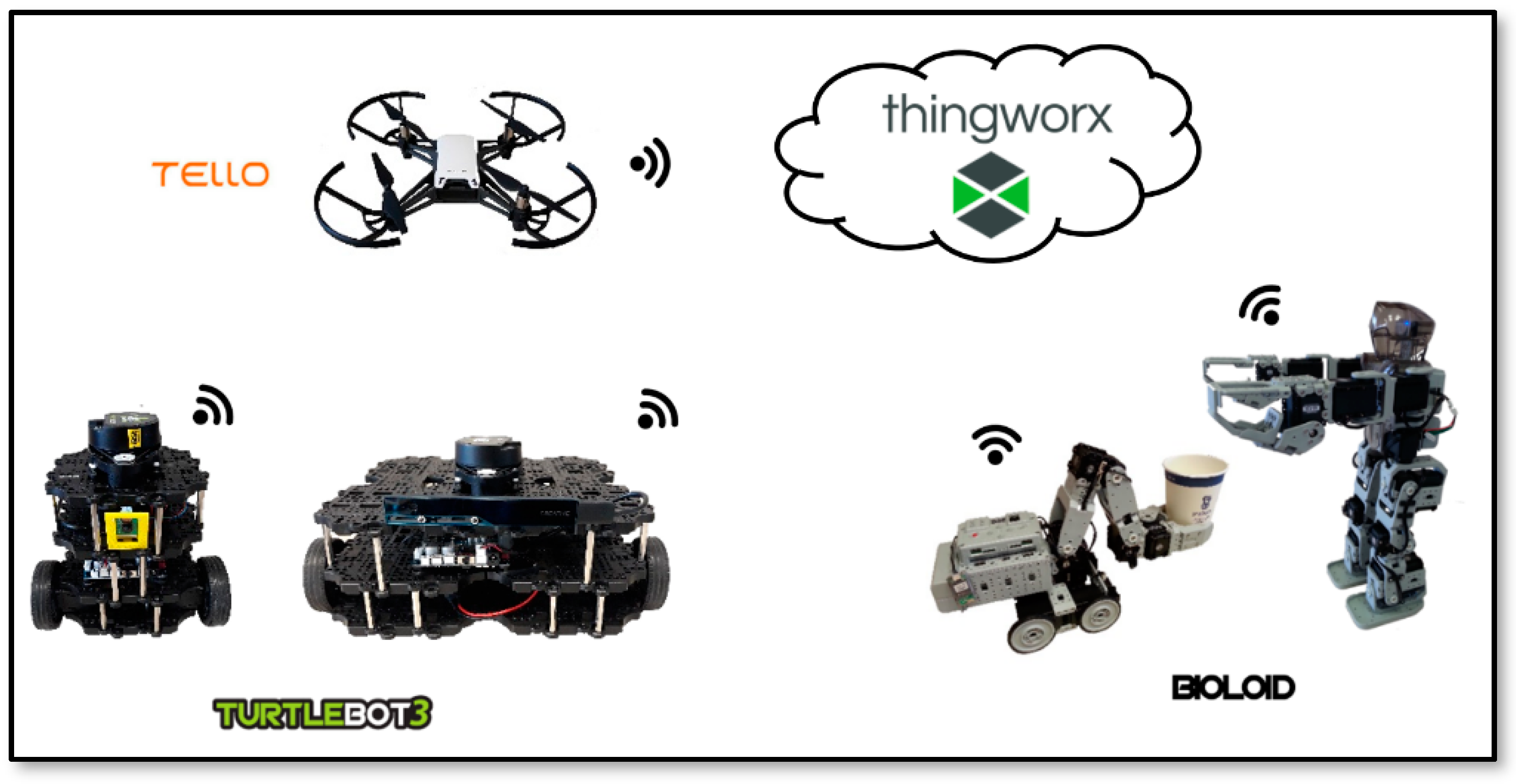

The robotics lab of the center is equipped with various educational robotics kits for practice in construction, programming, and operation of different types of robots, including wheeled robots, humanoids, and drones (see

Figure 1).

The BIOLOID kit is used by students to build and program autonomous robots and utilize them to perform different tasks. The kit is also suitable for students with no background in robotics. Two other kits in our lab are the TurtleBot3 Burger and Waffle, mobile robots that are programmed using the advanced Robot Operating System (ROS). Experimentation with these robots requires preliminary knowledge in robotics and programming. An additional type of robots available in the lab is the Tello drone. To fly this robot, students can use different programming methods. Beginners can use Scratch-based graphical software, while students with programming experience can use ROS for this purpose.

The robots are characterized by different wireless capabilities. While the TurtleBot3 has a built-in Wi-Fi connection, the Bioloids are equipped with Bluetooth devices. Internet communication of Bioloids was provided by coupling each Bioloid with a Raspberry pi, featuring both Bluetooth and Wi-Fi capabilities. The Raspberry pi acted as a “transparent” bidirectional relay between the Bioloid to its IoT application.

The lab environment also includes a set of professional software tools developed by PTC that enable students to apply digital technologies. Among them is ThingWorx—an industrial web-based platform for the development of IoT applications to control and operate smart connected products and systems. The platform enables connectivity within and among the systems and provides tools for monitoring, analyzing, and controlling the system functionality. The students in their projects used this tool to integrate robots into a multi-robot system.

3.2. Educational Strategy

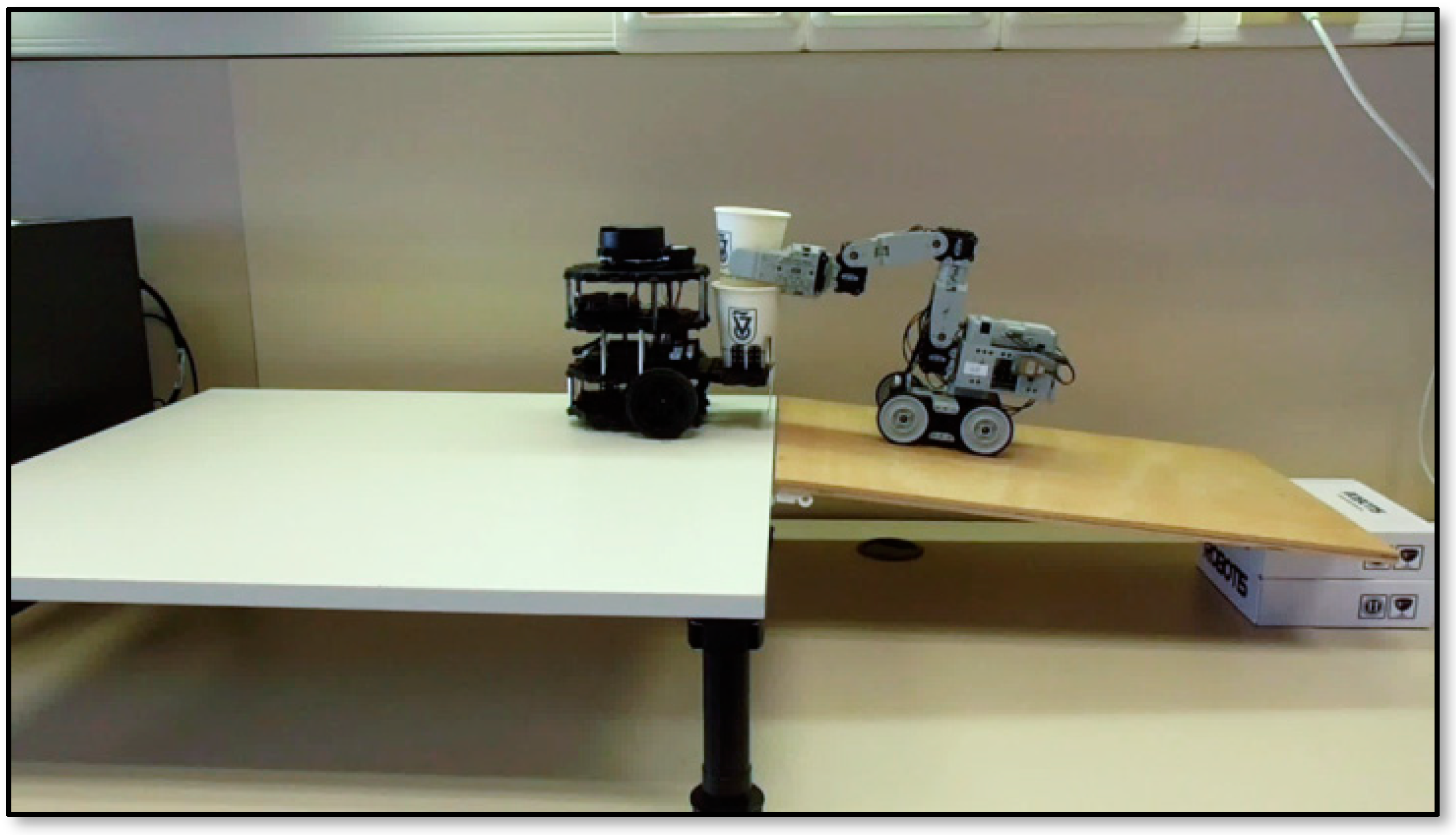

We introduced students to the concepts of connectivity and collaborative sensing by using the learning-by-doing strategy. The students experientially learned the concepts through their tangible implementation in multi-robot tasks. One example was to program two different mobile robots, a Loader, and a Transporter, to implement a cargo handling task. A TurtelBot3 served as the Transporter and a Bioloid as the Loader, as presented in

Figure 2.

The Loader can measure the weight of the cargo it needs to lift, but it cannot sense the slope on which it operates. Thus, the Loader does not have sufficient data to control its stability while lifting weights on different slopes. The Transporter can measure the slope on which it operates but, on the other hand, cannot measure the cargo weight. Without this data, the Transporter cannot determine the optimal trajectory and velocity profile of the transportation, ensuring its stability. Therefore, to succeed in executing the cargo handling task, the robots need to collaborate and share their sensory data in real-time through the IoT connectivity infrastructure. The shared data would allow the coordinated operation of the robots.

The motion parameters for each robot’s execution policy were determined automatically based on reinforcement learning (RL) cycles of trial-and-error experiments. The purpose of the RL procedure for the Transporter was to determine the maximal values of linear and angular acceleration for each load value ensuring the stable movement without risk to roll over or loose the load. For the Loader, the purpose was to find the maximal load that it can manage for each angle of the slope.

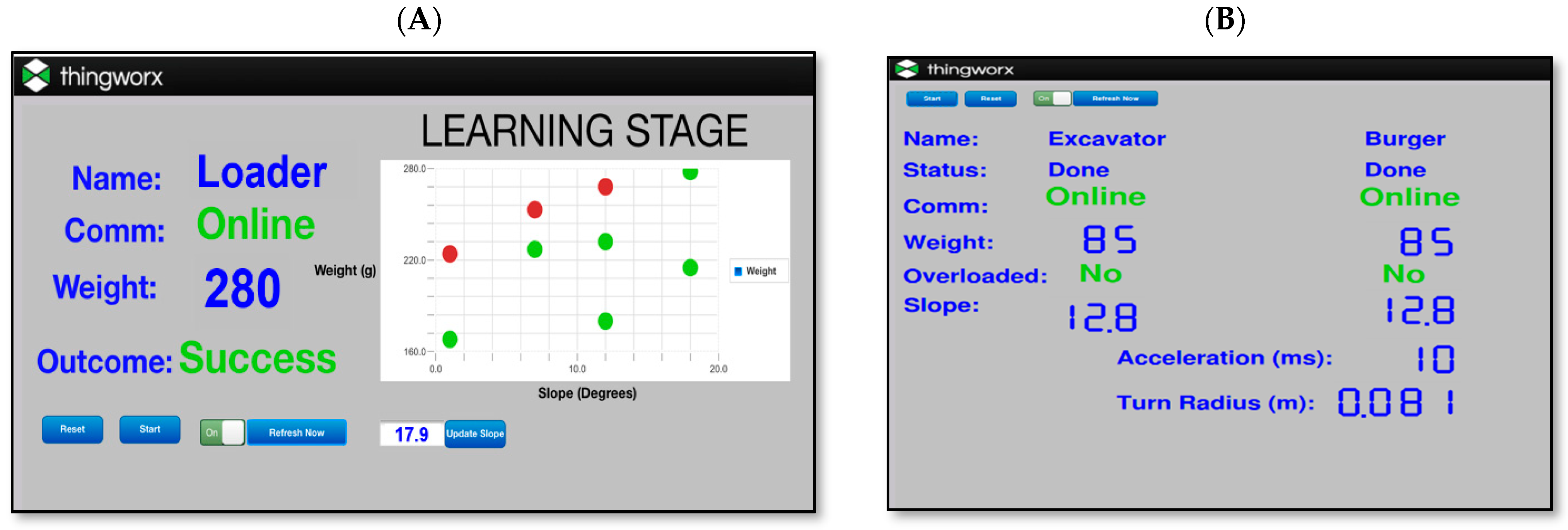

The experimental data from trials of weightlifting experiments for the Loader was accumulated and processed by the IoT platform ThingWorx. The measured values of slopes, weights, and the trials’ results were stored in the cloud and later used by the robots when executing the task.

The students monitored the RL process by using a ThingWorx dashboard (a graphic user interface) that displayed numerically and graphically the measured parameters in real-time.

Figure 3A presents the screenshot of the dashboard at some moment of time during the RL process, showing results of weightlifting trials by the Loader on different slopes. The dashboard indicates that the Loader is online, displays the measured parameters of the last weightlifting experiment (the weight 280 g, the slope 17.9°) received by ThingWorx, and reports on the successful trial. The diagram in the dashboard presents the results of the first experiments made until the screenshot was taken. In the diagram, the green dots indicate successful trials, and the red dots indicate failures. This diagram updates in real time with each additional trial, providing the opportunity for the students to visually observe how the frontier between the areas containing the success and failure trials (Pareto front) is forming. Here, the dashboard serves to monitor the Loader’s learning process, and this visual insight allows the students to better grasp the principles of reinforcement learning from this practical experience. The resulting Pareto front is automatically approximated by a function that is used by the Loader during the collaborative cargo handling task to determine optimal parameters of the weightlifting for each slope.

A similar RL procedure was also implemented for the Transporter to estimate the maximal values of linear and angular accelerations for different load weights. The ThingWorx dashboard for monitoring the learning process for the Transporter was designed in the same manner as for the Loader and is not presented here.

The collaborative sensing during the execution of the cargo handling task is implemented as follows. Upon obtaining the Start signal from the user, ThingWorx activates the Transporter, which starts moving. The robot makes a short circular trip on the sloped surface and then returns to the initial position. During this run, the robot measures the slope value and communicates it to ThingWorx, which automatically transmits it to the Loader along with the signal to start the cargo loading. The Loader measures the cargo weight. Then, using the received value of the slope, the measured weight, and the Pareto front function, the Loader determines the optimal weightlifting parameters. Once the cargo is loaded on the Transporter, the Loader communicates to ThingWorx that the weightlifting is completed and transmits the weight value that it has just measured. ThingWorx relays the “go ahead” signal along with the weight value to the Transporter. Then, the Transporter calculates the optimal acceleration parameters for this weight (using Pareto front function) and starts transporting along the determined optimal trajectory.

The dashboard presented in

Figure 3B is used to monitor and control the multi-robot system during the entire collaborative task execution. This dashboard displays the status of both robots in real-time and also the buttons to control robot operations. By observing the status data, the user can detect overloads and see how the weight and the slope influence the resulting acceleration and turning radius of the Transporter.

The presented implementation of the multi-robot task served for the validation of the proposed strategy for teaching connectivity and collaborative sensing. Later on, this strategy was applied in the final projects performed by high school students in the framework of the Intelligent Robotics and Smart Transportation (IRoST) program described in the following sections.

3.3. Stages of the IRoST Program

Our program consisted of two stages: the preparatory course and the advanced course in robot programming that included the final mini project. The preparatory course’s purpose was to provide students with different technological backgrounds the knowledge and skills needed for the advanced course. The preparatory course was conducted each year from October to December. The students from the Haifa area schools learned the course in the Technology Lab of the Technion Faculty of Education in Science and Technology. It included eleven weekly two-hour sessions taught by the CRDTE staff and a 6 h workshop, at which the students learned the basics of IoT and Robot Operation System (ROS). The students practiced constructing, programming, and operating different robots.

Figure 4 captured the students at work: one of them (

Figure 4A) is constructing the Bioloid Loader; three others (

Figure 4B) are programming the TurtleBot3 Transporter.

Students from outside Haifa took the preparatory course in their schools, taught by their teachers. The course introduced them to robotics, Python programming, and Linux and did not address IoT and collaborative sensing subjects.

The advanced course focused on robot programming in the ROS environment and was based on the knowledge in robot control, Python, Linux, and ROS acquired in the preparatory course. Programming in ROS presented a challenge for many students. Our purpose for teaching ROS in the course was to expose the students to the modern environment providing a rich set of tools for programming a wide variety of robots. We prepared the course together with MIT engineering students participating in the MIT MISTI Global Teaching Labs program, using the learning materials provided by the MIT Beaver Works Summer Institute. The students visited Israel in January during their vacation break and gave the course under our guidance.

The students from each school completed the 30 h advanced course during one week in an accelerated mode, being excused from their regular classes. The students from the Haifa area attended the course given by two MIT students and assisted by the CRDTE staff in the Technion Technology Lab. Two other MIT students (hosted by ORT) taught the course to the other groups in their respective schools, assisted by the school teachers.

During the advanced course, the students learned the fundamentals of robot programming and operation and practiced with robots and simulators. The topics included Simultaneous Localization and Mapping (SLAM) navigation and computer vision (CV).

Figure 5A shows two MIT students (on the left) during the course in January 2020, guiding a high school student from one of the Haifa schools on how to use the computer vision Open CV library. In

Figure 5B, one of the MIT students, who taught the course in 2019, helps students from a high school located in the center of Israel to debug a robot control program.

The preparatory and the advanced courses were supported by the learning materials posted on the dedicated website at the Technion Moodle learning platform and accessible to students and teaching staff. These materials included presentations, laboratory worksheets, exercises, and handouts. We utilized the course forum facilities of the Moodle platform for communication between the students and the instructors.

Each group of students performed a final mini project. For the students from the Haifa area schools, the assignment was to develop a multiple-robot system to execute a collaborative task using IoT and collaborative sensing. Examples of final mini projects are presented in the next section. For the students from the schools outside Haifa, the final mini projects focused on robot navigation and SLAM and did not implement IoT or collaborative sensing.

3.4. IoT and Collaborative Sensing Projects

The projects performed by the students from the Haifa area schools implemented collaborative sensing scenarios in which two or more different robots share sensor data through IoT, in a similar way as in the cargo handling project described in

Section 3.2. Starting from the 2018–2019 program, all the student groups demonstrated their final mini projects at the final event held at the Technion in the presence of teachers, parents, and people from the academy, educational system, and industry. Presented below are three examples of the final mini projects.

The first example is an IoT-based automated cargo handling and transportation system developed by students in 2018–2019 (

Figure 6A). The two Loader robots navigate using IR sensors and can Pick up, load, unload, and weigh the cargo, but cannot track the cargo location. The Transporter robot cannot weigh the cargo but can transport it and track its location using the SLAM algorithm based on its Lidar laser sensor. The whole operation is monitored and controlled through an IoT dashboard.

Figure 6B presents another project carried out in 2019–2020, in which the students modeled an autonomous IoT-based system for intercepting aerial targets. The drone, seen in the upper right corner, identifies the target and sends coordinates of its relative position via the internet. The IoT system receives the raw information, generates firing data, and sends it to the two target intercepting robots, the first with Nerf missiles (bottom right) and the second with a laser beam (bottom left).

In the third example, the autonomous vehicles receive travel data from an IoT-based control system. Each robot uses computer vision to drive on the road and respond to stop signs while implementing a neural network-based algorithm. This final mini project, shown in

Figure 7, was also carried out in 2019–2020.

4. The Educational Study

This section presents the research settings and introduces the participants of this study. Then, we discuss the methods of data collection and analysis.

4.1. Research Setting

Our educational study implements the participatory multi-case study approach. We found this approach appropriate for our empirical studies in which we develop robotic environments and instructional strategies and explore experiential learning in these environments [

22]. We evaluated learning outcomes and investigated how they are affected by the learning environment and strategy. In this report, we briefly describe our case study conducted in the 2019–2020 IRoST program framework. This study aims to evaluate the contribution of the program to students’ understanding of the selected subjects related to connectivity and collaborative sensing technologies, students’ progress in specific targeted Industry 4.0 skills, and their interest in modern robotics.

The research questions in this case study were:

Whether and to what extent can the program develop students’ understanding of the subjects related to connectivity and collaborative sensing of robot systems?

If and how can the program contribute to the development of students’ skills and interest in learning Industry 4.0 technologies?

4.2. Participants

Six groups of high-school students, mainly tenth graders (ages 14–16), majoring in different technological disciplines from six comprehensive high schools throughout the country participated in the program. About 20% of the 83 participants were females. Students from schools 1 and 5 in the south and center of Israel majored in electronics. Students from School 2 in Haifa and School 6 in the north of Israel majored in computer science. Students from Schools 3 and 4 majored in mechatronics and aeronautical engineering, respectively. The three groups from Haifa schools included 35 students, and the three groups from schools outside Haifa included 48 students.

4.3. Data Collection

Regarding the first research question, we evaluated the knowledge acquired in the program using three questionnaires. The knowledge questionnaire was administered at the end of the IoT workshop given at the Technion to 22 students from the Haifa schools. This questionnaire included multiple-choice questions that examined the understanding of the IoT concepts. We also asked the students about their interest in learning the subject and used their responses to answer the second research question.

The mid-course questionnaire was administered at the end of the preparatory course and before the advanced course. This questionnaire asked the students to self-evaluate on the five-point Likert scale the contribution of the preparatory course for enhancing their knowledge in the learned subjects. We administered the questionnaire to the students from schools 2, 3, and 4 from Haifa, and schools 1 and 5 outside Haifa, in total 67 students. We used student responses to answer the first research question.

The program evaluation questionnaire was administered at the end of the program and asked the students to self-evaluate the program’s contribution to their knowledge, skills, and interests. Sixty-one students from the three Haifa schools and schools 5 and 6 outside Haifa answered the questionnaire. The questionnaire included three sections. In the first section, related to the first research question, the students evaluated the contribution of the advanced course for enhancing their knowledge in the learned subjects. Other sections of the questionnaire related to the second research question. The second section asked students to self-evaluate their progress in several skills, due to participation in the program. In the third section, the students evaluated the program’s contribution to their interest in the learned subjects.

4.4. Data Analysis

The discussion of the concepts of connectivity and collaborative sensing in

Section 2.1 and

2.2 indicated that these concepts are interlinked with other core concepts implemented in the multi-robot systems developed by the students. IoT in a multi-robot system is more than just a transparent communication channel among the robots. It also encompasses data collection, analysis, selection, and dispatching to transmit data among the system’s robots. Likewise, collaborative sensing is more than just exchanging sensor readings among robots. It is a process that involves all aspects of the system functioning, related to sharing the sensory data among the robots. Therefore, to understand the concepts and processes of connectivity and collaborative sensing in a multi-robot system, students need to know the subjects related to the system’s structure and function. From this perspective, we asked the students to self-evaluate their progress in IoT and robot construction, programming, control, navigation, vision, and communication. Additionally, we evaluated students’ understanding of IoT using a knowledge questionnaire. The knowledge questions focused on client–server communication architectures and their implementation using the IoT platform ThingWorx.

We evaluated the contribution of the preparatory course and the whole program using students’ responses to the mid-course and program evaluation questionnaires. The data were analyzed using the SPSS software. To evaluate the role of the preparatory and advanced course in the program, we used the Wilcoxon Signed-Ranks test to compare the evaluations of the contribution to the progress in each of the learning subjects after the preparatory and advanced courses.

The Pearson correlation test was used to determine correlations related to the contribution of the program to learning different subjects and to the interest in them. We also compared the evaluations given by the group of students from Haifa schools and the group of students from the other schools. For this purpose, we applied the Kolmogorov–Smirnov test to examine whether the distribution of evaluations in each of the groups was normal. The test revealed that the evaluations in both groups and for all learning subjects were not normally distributed (the p value is p < 0.01). Therefore, we used the Mann–Whitney U test to determine if the observed difference between the students from Haifa schools and from other schools is statistically significant. Additionally, we calculated the percentage of the students who highly positively evaluated the program’s contribution to their knowledge, skills, and interest in learned subjects.

5. Findings

This section presents the findings of the study related to the two research questions formulated in

Section 4.1.

5.1. Understanding the Learned Concepts

The answer to the first research question, about the program’s contribution to students’ understanding of the learned concepts, is based on the results of the questionnaires administered at different stages of the program (

Section 4.3). Students’ answers to the mid-course questionnaire, conducted at the end of the preparatory course are summarized in

Table 1. The first column presents a list of the subjects learned in the preparatory course. Columns 2–6 relate to the schools and show the percentage of students who evaluated the contribution as high or very high. The minus sign (−) in some of the cells means that the corresponding subject was not taught in the given school.

As indicated, for most cases and subjects, the preparatory course considerably contributed to the student’s knowledge. The data in

Table 1 reflect the fact that IoT was learned only by the students from schools 2, 3, and 4 in Haifa, and drone programming was learned only by the students from school 4. As follows from the table, the students from School 5 concentrated on learning Python programming, while the students from the other four schools acquired knowledge in most of the program’s subjects.

The high evaluation of the course’s contribution to learning the IoT subject by most students from the Haifa schools moderately correlates with students’ grades in the IoT knowledge questionnaire, the correlation coefficient r = 0.54 (p < 0.05). It is also in line with the relatively high average grade of 72 that the students scored in the IoT knowledge questionnaire. The questionnaire did not directly address learning collaborative sensing since this concept was addressed through project-based learning in the advanced course.

Table 2 summarizes answers to the first section of the program evaluation questionnaire, in which the students evaluated the contribution of the advanced course to enhancing their knowledge. The first column presents the subjects taught in the course. Columns 2–6 show the percentage of students from each school who evaluated the contribution to their knowledge in the listed subjects as high or very high. Here, the minus sign (−) has the same meaning as in

Table 1, while the zero sign (0) indicates that the subject was taught but none of the students evaluated the contribution of the program to learning the subject as high or very high.

The table shows that the advanced course considerably enhanced student’s knowledge in most of the learned subjects. We also found that for almost all the subjects, the students’ evaluations of the advanced course contribution to students’ learning was significantly higher than of the preparatory course.

For example, the mean score (M) for learning Python in the advanced course M = 4.0 (standard deviation SD = 0.9) was higher than the score M = 2.7 (SD = 1.3) in the preparatory course. The Wilcoxon Signed Ranks Test indicated that the advanced course scores were significantly higher: the test statistic Z = −4.25 with p < 0.001. We obtained similar results for the contribution of the courses to learning computer vision. The mean score was M = 2.9 (SD = 1.5) for the progress in the advanced course and M = 1.7 (SD = 1.2) in the preparatory course. Again, the Wilcoxon Signed Ranks Test results showed that the advanced course scores were significantly higher than the preparatory course scores: Z = −4.25, p < 0.001.

The assignments for the final mini project given to the Haifa schools students differ from that of the other schools. While the former focused on a multi-robot task using IoT and collaborative sensing, the latter focused on robot navigation and SLAM. The Mann–Whitney U test revealed the Haifa groups’ significant advantage in robot construction, IoT, and computer vision. For example, the mean score given by the Haifa students for the contribution of the advanced course to the progress in learning IoT (M = 3.6, SD = 1.3) was higher than that given by the students from other schools (M = 1.7, SD = 1.2). The Mann–Whitney U test indicated that this difference is statistically significant (the test statistic U = 144.5, p < 0.001). As different from the above examples, the mean score given by the Haifa students for the progress in learning the Gazebo simulator (M = 2.6, SD = 1.5) was lower than that of students from other schools (M = 4.1, SD = 1.0). This difference was found statistically significant (U = 204.5, p value less than 0.001). We found moderate positive Pearson correlations between the knowledge enhancement in IoT and other learning subjects, including computer vision r = 0.57, robot construction r = 0.55, and drone programming r = 0.43, all with p < 0.001.

5.2. Development of Skills and Interest in the Subject

To answer the second research question and evaluate if and how the program contributed to the development of the targeted Industry 4.0 skills and raised students’ interest in learning the innovative technologies, we used the second and third sections of the final questionnaire. In the second section, the students evaluated their advance in the skills targeted by the program.

Students’ answers are summarized in

Table 3, in which the first column presents a list of skills. Columns 2–6 present the percentage of students from each school who evaluated the program’s contribution to developing their skills as high or very high. The data indicate that the program had an overwhelming impact on the students from three out of five schools. Most of the students highly evaluated their progress in almost all the listed skills. For students from two other schools (School 3 and School 5), the contribution was lower but still high. We attribute this finding to the fact that the students from these two groups learned robotics at school in parallel with participation in our program and attributed to it only partial credit for their progress.

The Mann–Whitney U test indicated a significant difference (U = 331, p < 0.05) in the evaluation of the contribution to learning robot operation skills between the students from the Haifa schools and the other schools. The mean score given by the Haifa students (M = 3.4, SD = 1.4) was higher than that given by the students from other schools (M = 3.1, SD = 1.5).

In their answers to the third section of the final questionnaire, the students evaluated the program’s contribution to their interest in specific subjects. The answers are summarized in

Table 4. The first column of the table includes a list of subjects. Columns 2–6 show the percentage of students from each school who evaluated the contribution as high or very high.

Table 4 indicates that the program had an overwhelming impact on students from all the groups in raising students’ interest in learning the listed subjects. We note the particularly high impact on the students from School 2 and School 4. The students from School 6 self-evaluated the impact of software practices more highly than hardware practices, possibly since they were computer science majors. A slightly lower self-evaluation of the program’s impact on the students from School 3 and School 5 may be because they attributed the increase in their interest in robotics to learning the subject at school.

For each of the subjects, we found a positive Pearson correlation between the interest in the subject and the contribution of the course to learning the subject, with p < 0.001. The correlations were very strong (0.83 < r < 0.87) for ROS, computer vision, and control. The correlations were strong (0.69 < r < 0.77) for Python programming, Linux, and IoT, and moderate (r = 0.53) for robot navigation.

We also found positive Pearson correlations between interest in doing projects and interest in all other subjects, with p < 0.001. The correlations were high moderate to strong (0.57 < r < 0.68) for interest in robot navigation, Python programming, ROS, and control. The correlations were moderate (0.50 < r < 0.54) for interest in computer vision, Linux, and IoT.

The Mann–Whitney U test indicated that the evaluation of the interest of the students from Haifa schools was significantly higher than that of the other students in the subjects listed in

Table 5.

6. Discussion and Conclusions

In this paper, we stressed the vital need to accommodate Industry 4.0 concepts and technologies into education, particularly in high school. The new era’s skills for life and work have been widely discussed [

6]. The objective is to develop approaches that facilitate the acquisition of such skills; this is what this paper is about. When developing and implementing an approach to the posed goal, we had to address technical, pedagogical, organizational, and research challenges.

The technical challenge was to develop an environment in which high school students can experientially learn digital technologies implemented in robotic systems. Our study indicates that intelligent robotics and smart transportation provide good opportunities for creating such environments. In our program’s preparatory course, the students performed a series of workshops. They learned the basics of robotics, Python programming, Linux, computer vision, IoT with ThingWorx, other digital technologies, and their application in robotic systems. The students learned to develop robot software in ROS in the advanced course and then performed final projects. The practice with real and virtual robots opened the door for students’ remote experimentation through physical and augmented reality experiences. The new technologies served not only as learning subjects but also as teaching tools. These technologies enable us to reduce the number of physical robots required for student practice in class. Such tools could be especially efficient in the current educational situation of social distancing.

The pedagogical challenge was to develop a practical approach to introduce the students with limited and heterogeneous technological background to the concepts and technologies of Industry 4.0 that are beyond the school curriculum. We addressed this challenge by creating an enrichment program for high school students motivated to learn robotics and digital technologies. We found that the abstract academic approach to teaching the subject was unsuitable for school students and instead developed an alternative approach that combined experiential learning and project-based learning practices. In our approach, the experiential activities revolved around examples of tangible technical solutions that students learned to apply in their projects.

The organizational challenge was to develop a coalition of partners for the development and implementation of the enrichment program. Our coalition includes partners in the academy, the industry, and in the high schools, driven by shared goals and complementary expertise in the new technologies and engineering education. As part of this partnership, PTC Corp contributes expertise and professional software tools to promote the learning of the Industry 4.0 concepts and technologies in the academy and schools. The company supports our enrichment program by providing sponsorship and access to the software systems they develop for Industry 4.0. The MIT Beaver Works Summer Institute and MISTI program strive to develop new engineering education approaches and disseminate them internationally. Our Technion Center hosts MIT students who perform internship projects and come to Israel to teach high school students. The Ministry of Education strives to upgrade the technology education curricula and focus them on meaningful learning and practical skills development. The Ministry recognized our program as a test case in this direction.

Our educational research challenge was to evaluate the learning processes and outcomes of a heterogeneous group of students from different schools where they majored in different technological disciplines. While the students learned the same curriculum in middle school and were expected to enter our high school program with a similar background, in practice, some had better knowledge in programming, others in electronics or mechanics, depending on their major subject. We tried to overcome this diversity by providing each group in the preparatory course with the knowledge they lacked, and this was necessary for the advanced course and the final mini project. We succeeded in prompting all the groups to learn Python programming and introduced most groups to robot construction, Linux, and ROS. However, we faced difficulties engaging the students from outside Haifa to learn the concepts of IoT, computer vision, navigation, and communication in the preparatory course, and to perform projects focused on IoT and collaborative sensing in the advanced course. The final projects of the students from outside Haifa focused on robot navigation and differed from the projects of the students from Haifa. This gave us an opportunity to compare evaluations of the learning experience given by the two groups.

To answer the first research question, we collected and analyzed students’ evaluations of their learning progress in the preparatory and advanced courses. The evaluation data acknowledge the educational value of both parts of the program. The value of the preparatory course is especially prominent for the Haifa groups. The knowledge acquired in this stage enabled those groups at the next stages of the program to learn all the advanced subjects and implement in their final mini projects multi-robot systems with capabilities of collaborative sensing and connectivity. To do this, the students applied their knowledge and skills in robot construction, programming, control, navigation, vision, and communication.

Our study showed that all the groups evaluated the contribution of the advanced course to learning almost all the subjects higher than of the preparatory course. We explain this higher evaluation by the special nature of the advanced course. Participation of MIT students in teaching the course strongly motivated students’ learning, so did the accelerated learning and the final mini project.

To answer the second research question, we analyzed the program’s contribution to the development of students’ skills and interest in learning the subjects studied in the program. Following the call to develop Industry 4.0 skills needed by the students in the new era [

9,

14], our program, and especially the advanced course and final mini project, were directed to promoting the development of thinking, learning, and technical skills. We did this by engaging the students in experiential and project-based learning activities.

Students’ evaluations acknowledged the high contribution of the program to their thinking skills (systems thinking and problem-solving), learning skills (self-learning and teamwork), and technical skills (robot programming and operation). The evaluations provided an additional argument for focusing the final mini project on multi-robot tasks that implement IoT and collaborative sensing. As shown in

Section 5.2, the students who performed such projects evaluated their contribution to learning robot operation significantly higher than other students.

We evaluated the students’ interest in the subjects learned in the program, since it implies the essential motivation for the learning, both in acquiring knowledge and in skill development [

36]. The positive correlations, found between students’ evaluations of the program’s contribution to both learning the subjects and to the interest in the subjects, confirm the validity of the above statement in our case. Researchers distinguish between the individual interest, depending on the student’s personality, and situational interest influenced by the learning practice. In our case, all the students joined the program based on their personal interest in the subject. Therefore, in the study, we concentrated on analyzing students’ evaluations of their situational interest in learning the subjects offered by the program. The findings revealed the high interest of most students in all the subjects.

We found that students that focused their final mini project on IoT and collaborative sensing reported a significantly higher interest in learning computer vision and robot control than their peers whose final mini projects focused on robot navigation. We attribute this advantage to the richer learning environment and more challenging project assignments.

In conclusion, as the result of the multi-year effort presented in this paper, the authors proposed, implemented, and evaluated a model of an enrichment program that introduces high school students to the disruptive technologies of Industry 4.0. The combination of experiential and project-based learning in robotic environments and the focus on internet communication and collaborative sensing in multi-robot systems enable the students to acquire knowledge and skills in many subjects relevant to the era of the digital transformation. Given the challenges met in the program, we consider our research as a pilot case study that demonstrates the model’s feasibility. We continue the research towards a more objective evaluation of the leaning outcomes. Based on the experience of our study, we call for further research and development of new pathways towards educating the new generation of users and developers of innovative technologies.