In Vitro Antioxidant Activity Optimization of Nut Shell (Carya illinoinensis) by Extrusion Using Response Surface Methods

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Pecan Nut Shell Samples

2.3. Extrusion Processing

2.4. Experimental Design and Extrusion Conditions

2.5. Techno-Functional Characterization

2.6. Phenolic Determination

2.6.1. Extraction for Total Phenolic Compounds

2.6.2. Condensed Tannin Content

2.6.3. Determination of 1,1-Diphenyl-2-Picrylhydrazyl Radical Scavenging Activity

2.7. Optimized Treatment Characterization

2.7.1. Free Phenolic Compounds Extraction and Identification and Quantification

2.7.2. Protein and Dietary Fiber Determination

2.8. Statistical Analysis

3. Results and Discussion

3.1. Physical Characterization

3.2. Chemical Characterization

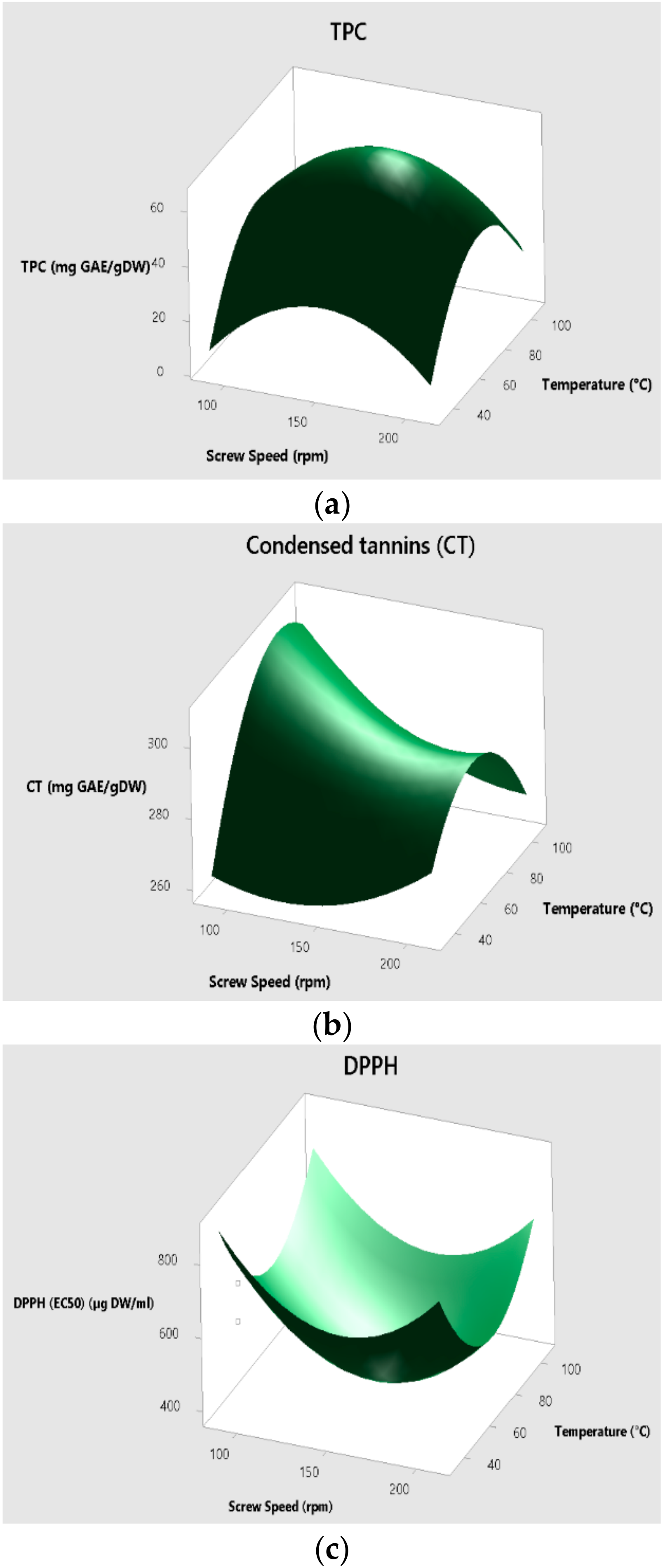

3.2.1. Total Phenolic Content

3.2.2. Condensed Tannin Contents

3.2.3. Radical Scavenging Activity

3.3. Polyphenolic Compounds, Dietary Fiber, and Protein Composition

3.3.1. Identification and Quantification of Polyphenolic Compounds by LC-MSD-TOF

3.3.2. Protein and Fiber Content

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Haddad, E.H. Health Effects of a Pecan [Carya Illinoinensis (Wangenh.) K: Koch] Nut-Rich Diet; Elsevier Inc.: Amsterdam, The Netherlands, 2011; ISBN 9-78012-375-6886. [Google Scholar]

- Wagener, E.A.; William, L. Kerr Effects of Oil Content on The Sensory, Textural and Physical Properties of Pecan Butter (Carya illinoinensis) Emily. J. Texture Stud. 2018, 1, 2018. [Google Scholar]

- Reyes-Vázquez, N.; Urrea-López, R. Retos y Oportunidades Para el Aprovechamiento de la Nuez Pecanera en México; CIATEJ: Guadalajara, México, 2016; ISBN 9-78607-974-2188. [Google Scholar]

- Ozcariz-Fermoselle, M.V.; Fraile-Fabero, R.; Girbés-Juan, T.; Arce-Cervantes, O.; Oria de Rueda-Salgueiro, J.A.; Azul, A.M. Use of lignocellulosic wastes of pecan (Carya illinoinensis) in the cultivation of Ganoderma lucidum. Rev. Iberoam. Micol. 2018, 35, 103–109. [Google Scholar] [CrossRef] [PubMed]

- Do Prado, A.C.P.; da Silva, H.S.; da Silveira, S.M.; Barreto, P.L.M.; Vieira, C.R.W.; Maraschin, M.; Ferreira, S.R.S.; Block, J.M. Effect of the extraction process on the phenolic compounds profile and the antioxidant and antimicrobial activity of extracts of pecan nut [Carya illinoinensis (Wangenh) C. Koch] shell. Ind. Crops Prod. 2014, 52, 552–561. [Google Scholar] [CrossRef]

- Müller, L.G.; Pase, C.S.; Reckziegel, P.; Barcelos, R.C.S.; Boufleur, N.; Prado, A.C.P.; Fett, R.; Block, J.M.; Pavanato, M.A.; Bauermann, L.F.; et al. Hepatoprotective effects of pecan nut shells on ethanol-induced liver damage. Exp. Toxicol. Pathol. 2013, 65, 165–171. [Google Scholar] [CrossRef]

- Reckziegel, P.; Boufleur, N.; Barcelos, R.C.S.; Benvegnú, D.M.; Pase, C.S.; Muller, L.G.; Teixeira, A.M.; Zanella, R.; Prado, A.C.P.; Fett, R.; et al. Oxidative stress and anxiety-like symptoms related to withdrawal of passive cigarette smoke in mice: Beneficial effects of pecan nut shells extract, a by-product of the nut industry. Ecotoxicol. Environ. Saf. 2011, 74, 1770–1778. [Google Scholar] [CrossRef]

- Hernández-Montoya, V.; Mendoza-Castillo, D.I.; Bonilla-Petriciolet, A.; Montes-Morán, M.A.; Pérez-Cruz, M.A. Role of the pericarp of Carya illinoinensis as biosorbent and as precursor of activated carbon for the removal of lead and acid blue 25 in aqueous solutions. J. Anal. Appl. Pyrolysis 2011, 92, 143–151. [Google Scholar] [CrossRef]

- Garcia-Amezquita, L.E.; Tejada-Ortigoza, V.; Heredia-Olea, E.; Serna-Saldívar, S.O.; Welti-Chanes, J. Differences in the dietary fiber content of fruits and their by-products quantified by conventional and integrated AOAC official methodologies. J. Food Compos. Anal. 2018, 67, 77–85. [Google Scholar] [CrossRef]

- De La Rosa, L.A.; Alvarez-Parrilla, E.; Shahidi, F. Phenolic compounds and antioxidant activity of kernels and shells of Mexican pecan (Carya illinoinensis). J. Agric. Food Chem. 2011, 59, 152–162. [Google Scholar] [CrossRef]

- Akbari, V.; Jamei, R.; Heidari, R.; Esfahlan, A.J. Antiradical activity of different parts of Walnut (Juglans regia L.) fruit as a function of genotype. Food Chem. 2012, 135, 2404–2410. [Google Scholar] [CrossRef]

- Robbins, K.S.; Gong, Y.; Wells, M.L.; Greenspan, P.; Pegg, R.B. Reprint of “Investigation of the antioxidant capacity and phenolic constituents of US. pecans.”. J. Funct. Foods 2015, 18, 1002–1013. [Google Scholar] [CrossRef]

- De la Rosa, L.A.; Vazquez-Flores, A.A.; Alvarez-Parrilla, E.; Rodrigo-García, J.; Medina-Campos, O.N.; Ávila-Nava, A.; González-Reyes, S.; Pedraza-Chaverri, J. Content of major classes of polyphenolic compounds, antioxidant, antiproliferative, and cell protective activity of pecan crude extracts and their fractions. J. Funct. Foods 2014, 7, 219–228. [Google Scholar] [CrossRef]

- Brennan, C.; Brennan, M.; Derbyshire, E.; Tiwari, B.K. Effects of extrusion on the polyphenols, vitamins and antioxidant activity of foods. Trends Food Sci. Technol. 2011, 22, 570–575. [Google Scholar] [CrossRef]

- White, B.L.; Howard, L.R.; Prior, R.L. Polyphenolic composition and antioxidant capacity of extruded cranberry pomace. J. Agric. Food Chem. 2010, 58, 4037–4042. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Tang, X.; Zhang, M.; Hu, X.; Yu, C.; Zhu, Z.; Shao, Y. Effects of different extrusion temperatures on extrusion behavior, phenolic acids, antioxidant activity, anthocyanins and phytosterols of black rice. RSC Adv. 2018, 8, 7123–7132. [Google Scholar] [CrossRef]

- Jan, R.; Saxena, D.C.; Singh, S. Effect of extrusion variables on antioxidant activity, total phenolic content and dietary fibre content of gluten-free extrudate from germinated Chenopodium (Chenopodium album) flour. Int. J. Food Sci. Technol. 2017, 52, 2623–2630. [Google Scholar] [CrossRef]

- Jing, Y.; Chi, Y. Effects of twin-screw extrusion on soluble dietary fibre and physicochemical properties of soybean residue. Food Chem. 2013, 138, 884–889. [Google Scholar] [CrossRef]

- Yuan, G.; Pan, Y.; Li, W.; Wang, C.; Chen, H.; Chang, S.K.; Alasalvar, C.; Shahidi, F.; Wang, Q.; Cao, J.; et al. Effect of extrusion on physicochemical properties, functional properties and antioxidant activities of shrimp shell wastes protein. J. Funct. Foods 2019, 21, 1096–1105. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Amezquita, L.E.; Tejada-Ortigoza, V.; Pérez-Carrillo, E.; Serna-Saldívar, S.O.; Campanella, O.H.; Welti-Chanes, J. Functional and compositional changes of orange peel fiber thermally-treated in a twin extruder. LWT 2019, 111, 673–681. [Google Scholar] [CrossRef]

- Höglund, E.; Eliasson, L.; Oliveira, G.; Almli, V.L.; Sozer, N.; Alminger, M. Effect of drying and extrusion processing on physical and nutritional characteristics of bilberry press cake extrudates. LWT 2018, 92, 422–428. [Google Scholar] [CrossRef]

- Cortés-Ceballos, E.; Pérez-Carrillo, E.; Serna-Saldívar, S.O. Addition of Sodium Stearoyl Lactylate to Corn and Sorghum Starch Extrudates Enhances the Performance of Pregelatinized Beer Adjuncts. Cereal Chem. 2015, 92, 88–92. [Google Scholar] [CrossRef]

- Association Official Analytical Chemists. Official Methods of Analysis, 15th ed.; AOAC: Washington, DC, USA, 1990. [Google Scholar]

- Ruiz-Gutiérrez, M.G.; Amaya-Guerra, C.A.; Quintero-Ramos, A.; Pérez-Carrillo, E.; Meléndez-Pizarro, C.O. Use of Red Cactus Pear (Opuntia ficus-indica) Encapsulated Powder to Pigment Extruded Cereal. J. Food Qual. 2017, 2017, 12. [Google Scholar] [CrossRef]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol. 1998, 299, 152–178. [Google Scholar]

- Flores-Córdova, M.A.; Sánchez, E.; Muñoz-Márquez, E.; Ojeda-Barrios, D.L.; Soto-Parra, J.M.; Preciado-Rangel, P. Phytochemical composition and antioxidant capacity in Mexican pecan nut. Emir. J. Food Agric. 2017, 29, 346–350. [Google Scholar]

- Villasante, J.; Girbal, M.; Metón, I.; Almajano, M.P. Effects of pecan nut (Carya illinoiensis) and roselle flower (Hibiscus sabdariffa) as antioxidant and antimicrobial agents for sardines (Sardina pilchardus). Molecules 2019, 24, 85. [Google Scholar] [CrossRef] [PubMed]

- Adom, K.K.; Liu, R.H. Antioxidant activity of grains. J. Agric. Food Chem. 2002, 50, 6182–6187. [Google Scholar] [CrossRef] [PubMed]

- Acosta-Estrada, B.A.; Lazo-Vélez, M.A.; Nava-Valdez, Y.; Gutiérrez-Uribe, J.A.; Serna-Saldívar, S.O. Improvement of dietary fiber, ferulic acid and calcium contents in pan bread enriched with nejayote food additive from white maize (Zea mays). J. Cereal Sci. 2014, 60, 264–269. [Google Scholar] [CrossRef]

- Hsu, H.W.; Vavak, D.L.; Satterlee, L.D.; Miller, G.A. A multienzyme technique for estimating protein digestibility. J. Food Sci. 1977, 42, 1269–1273. [Google Scholar] [CrossRef]

- Borchani, C.; Besbes, S.; Masmoudi, M.; Bouaziz, M.A.; Blecker, C.; Attia, H. Influence of Oven-Drying Temperature on Physicochemical and Functional Properties of Date Fibre Concentrates. Food Bioprocess Technol. 2012, 5, 1541–1551. [Google Scholar] [CrossRef]

- Figuerola, F.; Hurtado, M.L.; Estévez, A.M.; Chiffelle, I.; Asenjo, F. Fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment. Food Chem. 2005, 91, 395–401. [Google Scholar] [CrossRef]

- Garau, M.C.; Simal, S.; Rosselló, C.; Femenia, A. Effect of air-drying temperature on physico-chemical properties of dietary fibre and antioxidant capacity of orange (Citrus aurantium v. Canoneta) by-products. Food Chem. 2007, 104, 1014–1024. [Google Scholar] [CrossRef]

- Jan, K.; Riar, C.S.; Saxena, D.C. Value addition to agro industrial by-products: Effect of temperature and plasticizer on various properties of pellets developed using extrusion technology. J. Food Process. Preserv. 2017, 41, e13257. [Google Scholar] [CrossRef]

- Zheng, J.; Rehmann, L. Extrusion pretreatment of lignocellulosic biomass: A review. Int. J. Mol. Sci. 2014, 15, 18967–18984. [Google Scholar] [CrossRef] [PubMed]

- Dar, A.H.; Sharma, H.K.; Kumar, N. Effect of extrusion temperature on the microstructure, textural and functional attributes of carrot pomace-based extrudates. J. Food Process. Preserv. 2014, 38, 212–222. [Google Scholar] [CrossRef]

- Jan, K.; Riar, C.S.; Saxena, D.C. Engineering and functional properties of biodegradable pellets developed from various agro-industrial wastes using extrusion technology. J. Food Sci. Technol. 2015, 52, 7625–7639. [Google Scholar] [CrossRef] [PubMed]

- Altan, A.; McCarthy, K.L.; Maskan, M. Twin-screw extrusion of barley–grape pomace blends: Extrudate characteristics and determination of optimum processing conditions. J. Food Eng. 2008, 89, 24–32. [Google Scholar] [CrossRef]

- Nascimento, J.A.; Arau, K.L.G. V Ethanolic extracts of Moringa oleifera Lam. Evaluation of its potential as an antioxidant additive for fish oil. J. Therm. Anal. Calorim. 2013, 114, 833–838. [Google Scholar] [CrossRef]

- Ačkar, Đ.; Jozinović, A.; Babić, J.; Miličević, B.; Balentić, J.P.; Šubarić, D. Resolving the problem of poor expansion in corn extrudates enriched with food industry by-products. Innov. Food Sci. Emerg. Technol. 2018, 47, 517–524. [Google Scholar] [CrossRef]

- Mahungu, S.M.; Diaz-Mercado, S.; Li, J.; Schwenk, M.; Singletary, K.; Faller, J. Stability of isoflavones during extrusion processing of corn/soy mixture. J. Agric. Food Chem. 1999, 47, 279–284. [Google Scholar] [CrossRef]

- Žilić, S.; Mogol, B.A.; Akillioǧlu, G.; Serpen, A.; Delić, N.; Gökmen, V. Effects of extrusion, infrared and microwave processing on Maillard reaction products and phenolic compounds in soybean. J. Sci. Food Agric. 2014, 94, 45–51. [Google Scholar] [CrossRef]

- Esposito, F.; Arlotti, G.; Bonifati, A.M.; Napolitano, A.; Vitale, D.; Fogliano, V. Antioxidant activity and dietary fibre in durum wheat bran by-products. Food Res. Int. 2005, 38, 1167–1173. [Google Scholar] [CrossRef]

- Kristiawan, M.; Micard, V.; Maladira, P.; Alchamieh, C.; Maigret, J.E.; Réguerre, A.L.; Emin, M.A.; Della Valle, G. Multi-scale structural changes of starch and proteins during pea flour extrusion. Food Res. Int. 2018, 108, 203–215. [Google Scholar] [CrossRef] [PubMed]

- Adarkwah-Yiadom, M.; Duodu, K.G. Effect of extrusion cooking and simulated in vitro gastrointestinal digestion on condensed tannins and radical scavenging activity of type II and type III whole grain sorghum. Int. J. Food Sci. Technol. 2017, 52, 2282–2294. [Google Scholar] [CrossRef]

- Singh, J.P.; Kaur, A.; Shevkani, K.; Singh, N.; Singh, B. Physicochemical characterisation of corn extrudates prepared with varying levels of beetroot (Beta vulgaris) at different extrusion temperatures. Int. J. Food Sci. Technol. 2016, 51, 911–919. [Google Scholar] [CrossRef]

- Olszowy, M.; Dawidowicz, A.L. Is it possible to use the DPPH and ABTS methods for reliable estimation of antioxidant power of colored compounds? Chem. Pap. 2018, 72, 393–400. [Google Scholar] [CrossRef]

- Ramos-Enríquez, J.R.; Ramírez-Wong, B.; Robles-Sánchez, R.M. Effect of Extrusion Conditions and the Optimization of Phenolic Compound Content and Antioxidant Activity of Wheat Bran Using Response Surface Methodology. Plant Foods Hum. Nutr. 2018, 73, 228–234. [Google Scholar] [CrossRef]

- Rathod, R.P.; Annapure, U.S. Antioxidant activity and polyphenolic compound stability of lentil-orange peel powder blend in an extrusion process. J. Food Sci. Technol. 2017, 54, 954–963. [Google Scholar] [CrossRef]

- Hilbig, J.; Alves, V.R.; Müller, C.M.O.; Micke, G.A.; Vitali, L.; Pedrosa, R.C.; Block, J.M. Ultrasonic-assisted extraction combined with sample preparation and analysis using LC-ESI-MS/MS allowed the identification of 24 new phenolic compounds in pecan nut shell [Carya illinoinensis (Wangenh) C. Koch] extracts. Food Res. Int. 2018, 106, 549–557. [Google Scholar] [CrossRef]

- Gulati, P.; Weier, S.A.; Santra, D.; Subbiah, J.; Rose, D.J. Effects of feed moisture and extruder screw speed and temperature on physical characteristics and antioxidant activity of extruded proso millet (Panicum miliaceum) flour. Int. J. Food Sci. Technol. 2016, 51, 114–122. [Google Scholar] [CrossRef]

- Colonna, P.; Mercier, C. Macromolecular modifications of manioc starch components by extrusion-cooking with and without lipids. Carbohydr. Polym. 1983, 3, 87–108. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, C.; Li, J.; Hussain, S.; Yan, S.; Wang, Q. Effects of extrusion on structural and physicochemical properties of soluble dietary fiber from nodes of lotus root. LWT 2018, 93, 204–211. [Google Scholar] [CrossRef]

- Ge, Q.; Mao, J.W.; Cai, C.; Huang, J.; Zhou, Y.; Fang, J.; Sun, Y.; Sha, R. Effects of twin-screw extrusion on physicochemical properties and functional properties of bamboo shoots dietary fiber. J. Biobased Mater. Bioenergy 2017, 11, 385–390. [Google Scholar] [CrossRef]

- Du, B.; Jiao, Y.; Li, Y.; Yin, G.; Yang, G. Study on Modification of the Banana Peel in the Extrusion. Adv. Mater. Res. 2011, 238, 2172–2178. [Google Scholar] [CrossRef]

- Wang, J.; Xia, S.; Wang, B.; Ali, F.; Li, X. Effect of twin-screw extrusion on gelatinization characteristics of oat powder. J. Food Process Eng. 2019, 42, e13014. [Google Scholar] [CrossRef]

| Treatment | Order Run | Replicates | Factors | |

|---|---|---|---|---|

| Temperature (°C) | Screw Speed (rpm) | |||

| 1 | 2 | 2 | 33.25 | 150 |

| 2 | 11 | 2 | 40 | 100 |

| 3 | 4 | 2 | 40 | 200 |

| 4 | 8 | 2 | 70 | 150 |

| 5 | 10 | 2 | 70 | 88.75 |

| 6 | 9 | 2 | 70 | 150 |

| 7 | 7 | 2 | 70 | 211.25 |

| 8 | 1 | 2 | 70 | 150 |

| 9 | 3 | 2 | 100 | 100 |

| 10 | 6 | 2 | 100 | 200 |

| 11 | 5 | 2 | 106.75 | 150 |

| Treatment | Moisture (%) | WAI (g) | OAI (g) | WSI (%) | L* | a* | b* | C* (Chroma) | ℎ∘ (Hue Angle) |

|---|---|---|---|---|---|---|---|---|---|

| Control | 5.97 ± 0.06 a | 1.96 ± 0.03 c | 2.40 ± 0.02 cde | 3.00 ± 0.14 f | 10.92 ± 0.68 g | 6.51 ± 0.42 f | 7.88 ± 0.75 g | 10.23 ± 0.47 f | 50.39 ± 0.00 b |

| T1 (33.25 °C, 150 rpm) | 4.74 ± 0.09 bc | 2.88 ± 0.10 abc | 2.29 ± 0.01 e | 3.70 ± 0.03 de | 14.83 ± 0.05 f | 8.81 ± 0.22 de | 11.93 ± 0.07 f | 14.83 ± 0.06 de | 53.60 ± 0.68 a |

| T2 (40 °C, 100 rpm) | 4.21 ± 0.04 d | 3.33 ± 0.10 ab | 3.02 ± 0.01 a | 3.44 ± 0.01 e | 14.40 ± 0.09 f | 9.95 ± 0.01 b | 13.73 ± 0.15 b | 16.96 ± 0.00 b | 54.10 ± 0.05 a |

| T3 (40 °C, 200 rpm) | 4.88 ± 0.05 b | 2.26 ± 0.08 c | 2.54 ± 0.01 bc | 4.360 ± 0.09 b | 22.42 ± 0.08 b | 10.74 ± 0.06 a | 14.49 ± 0.02 a | 18.04 ± 0.09 a | 54.15 ± 0.41 a |

| T4 (70 °C, 150 rpm) | 4.40 ± 0.06 cd | 2.55 ± 0.31 abc | 2.42 ± 0.01 cde | 3.50 ± 0.01 e | 16.66 ± 0.03 e | 9.23 ± 0.14 c | 12.24 ± 0.14 ef | 15.33 ± 0.02 cd | 53.01 ± 0.05 ab |

| T5 (70 °C, 88.75 rpm) | 4.68 ± 0.06 bc | 2.43 ± 0.22 bc | 2.37 ± 0.02 cde | 4.36 ± 0.06 b | 19.64 ± 0.03 c | 10.13 ± 0.01 b | 13.26 ± 0.01 bc | 16.68 ± 0.02 b | 52.64 ± 0.03 ab |

| T6 (70 °C, 150 rpm) | 4.39 ± 0.02 cd | 2.55 ± 0.32 abc | 2.39 ± 0.01 cde | 3.59 ± 0.14 e | 16.22 ± 0.10 e | 9.19 ± 0.09 cd | 12.38 ± 0.15 ef | 15.41 ± 0.15 c | 53.41 ± 0.05 ab |

| T7 (70 °C, 211.25 rpm) | 4.60 ± 0.01 bc | 3.55 ± 0.67 a | 2.74 ± 0.00 b | 4.14 ± 0.06 bc | 19.55 ± 0.00 c | 10.02 ± 0.01 b | 13.06 ± 0.06 cd | 16.46 ± 0.00 b | 52.52 ± 0.03 ab |

| T8 (70 °C, 150 rpm) | 4.42 ± 0.09 cd | 2.50 ± 0.24 bc | 2.27 ± 0.18 e | 3.58 ± 0.15 e | 16.38 ± 0.12 e | 9.19 ± 0.04 cd | 12.46 ± 0.21 def | 15.48 ± 0.05 c | 53.59 ± 0.03 a |

| T9 (100 °C, 100 rpm) | 4.15 ± 0.14 d | 2.56 ± 0.41 abc | 2.33 ± 0.01 cde | 3.53 ± 0.01 cd | 16.66 ± 0.14 e | 8.66 ± 0.15 e | 11.90 ± 0.01 f | 15.33 ± 0.02 e | 54.17 ± 0.05 a |

| T10 (100 °C, 200 rpm) | 4.95 ± 0.01 b | 2.43 ± 0.22 bc | 2.31 ± 0.01 de | 2.87 ± 0.14 f | 17.78 ± 0.14 d | 9.27 ± 0.14 c | 12.69 ± 0.01 cde | 15.72 ± 0.01 c | 53.86 ± 0.07 a |

| T11 (106.75 °C, 150 rpm) | 4.59 ± 0.02 bc | 2.42 ± 0.22 bc | 2.52 ± 0.01 cd | 4.47 ± 0.10 a | 23.37 ± 0.01 a | 10.58 ± 0.02 a | 14.63 ± 0.03 a | 18.06 ± 0.01 a | 53.48 ± 0.02 ab |

| Peak | UV/MAX | Phenolic Compounds | [M − H]− m/z | Molecular Weight Da | tR (min) | Content in Control (Non-Extruded Shell) (μg/g DS) | Content in 70 °C and 150 rpm (μg/g DS) | |

|---|---|---|---|---|---|---|---|---|

| Experimental Mass (m/z) | Theoretical Mass (m/z) | |||||||

| 1 | 215, 270 | p-hydroxybenzoic acid | 137.01 | 137.02 | 138.12 | 2.49 | 1.46 ± 0.17 a | 0.88 ± 0.10 b |

| 2 | 213, 271 | Gallic acid | 169. 02 | 169.08 | 170.12 | 3.35 | 0.90 ± 0.08 a | 1.55 ± 0.09 b |

| 3 | 231, 259 | Protocatechuic acid | 153.02 | 153.02 | 154.12 | 5.11 | NQ | NQ |

| 4 | 252, 360 | Ellagic acid pentose | 433.05 | 433.05 | 434.31 | 7.87 | 0.32 ± 0.06 a | 0.41 ± 0.09 b |

| 5 | 255, 368 | Ellagic acid | 301.01 | 301.00 | 302.19 | 8.56 | 1.56 ± 0.23 a | 1.74 ± 0.17 b |

| 6 | 254, 286 | Methyl ellagic acid pentoside | 477.08 | 477.08 | 448.33 | 9.06 | NQ | NQ |

| 7 | 223, 289 | Epigallocatechin gallate | 457.18 | 457.18 | 458.37 | 9.74 | NQ | NQ |

| 8 | 221, 251, 365 | Di-methyl ellagic acid rhamnoside | 475.10 | 475.10 | 476.39 | 10.13 | NQ | 0.32 ± 0.02 a |

| 9 | Di methyl ellagic acid | 329.04 | 329.04 | 330.25 | 10.68 | 0.32 ± 0.05 a | 0.33 ± 0.04 a | |

| Treatment | Protein % | IVDP % | TDF % | SDF % | IDF % |

|---|---|---|---|---|---|

| Control (non-extruded) | 2.56 ± 0.25 a | 85.07 ± 0.11b | 75.41 b | 0 ± 0 b | 75.41 ± 1.7 a |

| Optimized extruded (70 °C and 150 rpm) | 2.41 ± 0.21 b | 87.70 ± 0.20a | 79.1 a | 3.07 ± 0.21 a | 76.03 ± 1.59 b |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villasante, J.; Pérez-Carrillo, E.; Heredia-Olea, E.; Metón, I.; Almajano, M.P. In Vitro Antioxidant Activity Optimization of Nut Shell (Carya illinoinensis) by Extrusion Using Response Surface Methods. Biomolecules 2019, 9, 883. https://doi.org/10.3390/biom9120883

Villasante J, Pérez-Carrillo E, Heredia-Olea E, Metón I, Almajano MP. In Vitro Antioxidant Activity Optimization of Nut Shell (Carya illinoinensis) by Extrusion Using Response Surface Methods. Biomolecules. 2019; 9(12):883. https://doi.org/10.3390/biom9120883

Chicago/Turabian StyleVillasante, Juliana, Esther Pérez-Carrillo, Erick Heredia-Olea, Isidoro Metón, and María Pilar Almajano. 2019. "In Vitro Antioxidant Activity Optimization of Nut Shell (Carya illinoinensis) by Extrusion Using Response Surface Methods" Biomolecules 9, no. 12: 883. https://doi.org/10.3390/biom9120883

APA StyleVillasante, J., Pérez-Carrillo, E., Heredia-Olea, E., Metón, I., & Almajano, M. P. (2019). In Vitro Antioxidant Activity Optimization of Nut Shell (Carya illinoinensis) by Extrusion Using Response Surface Methods. Biomolecules, 9(12), 883. https://doi.org/10.3390/biom9120883