Study of the Preparation and Properties of Chemically Modified Materials Based on Rapeseed Meal

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Rapeseed Meal-Based (RM) Material Preparation

2.3. Mechanical Properties

2.4. Fourier-Transform Infrared Spectroscopy

2.5. Thermogravimetric Analysis

2.6. Scanning Electron Microscopy

3. Results and Discussion

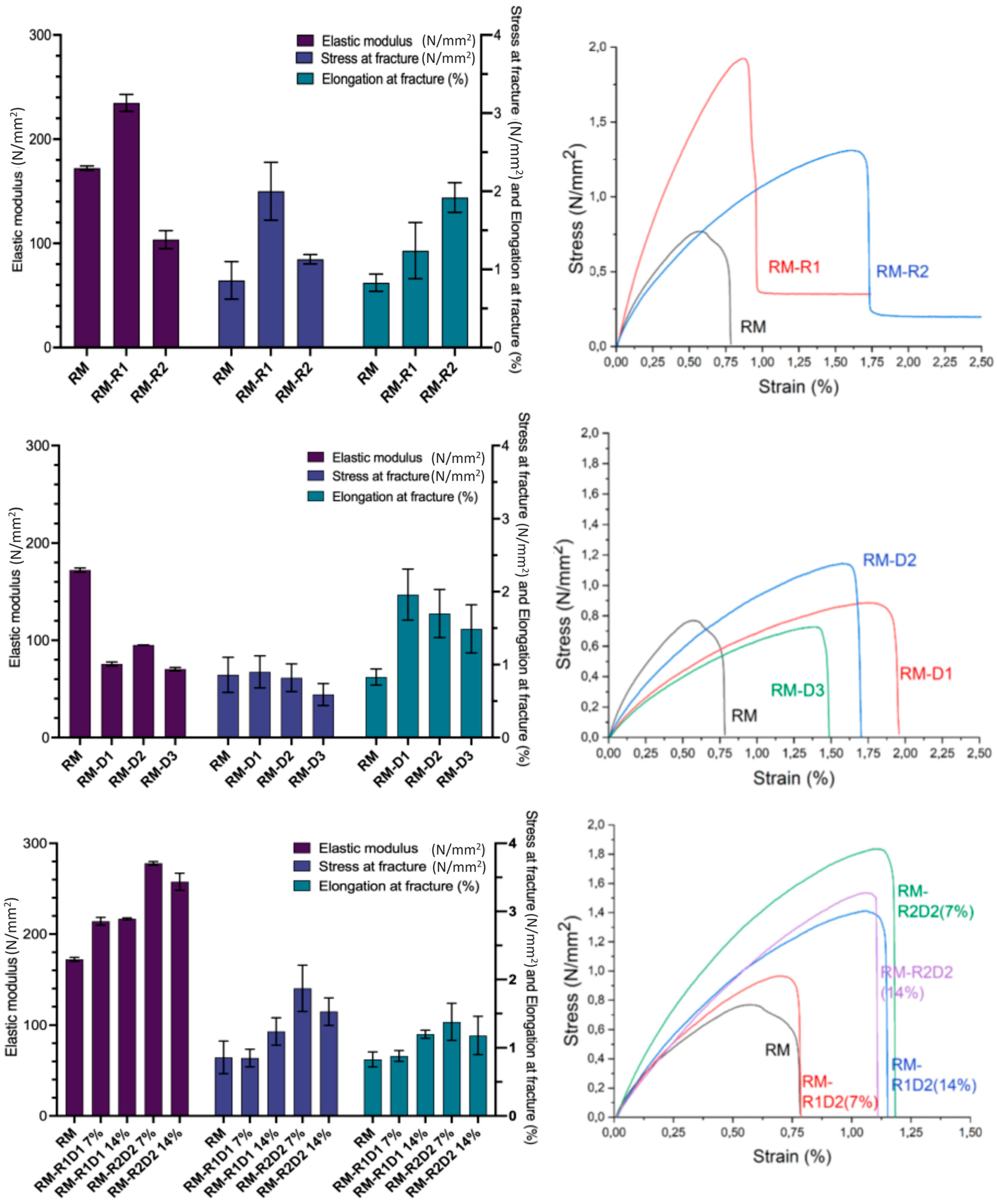

3.1. Influence of Different Crosslinkers on the Tensile Properties of the Specimens

3.2. Effects of Disulfide Bond Reducing Agents and Denaturant

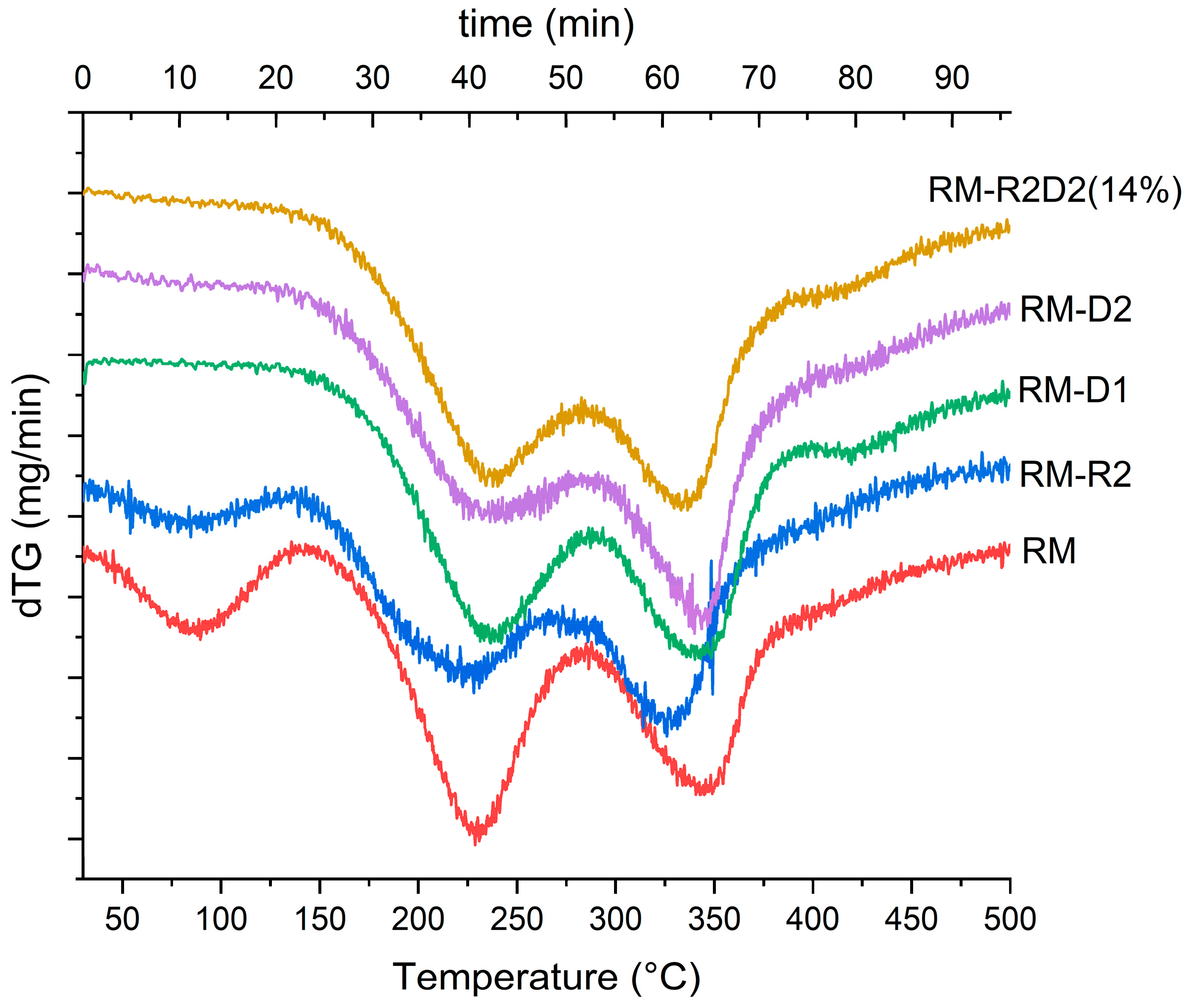

3.3. Thermal Properties

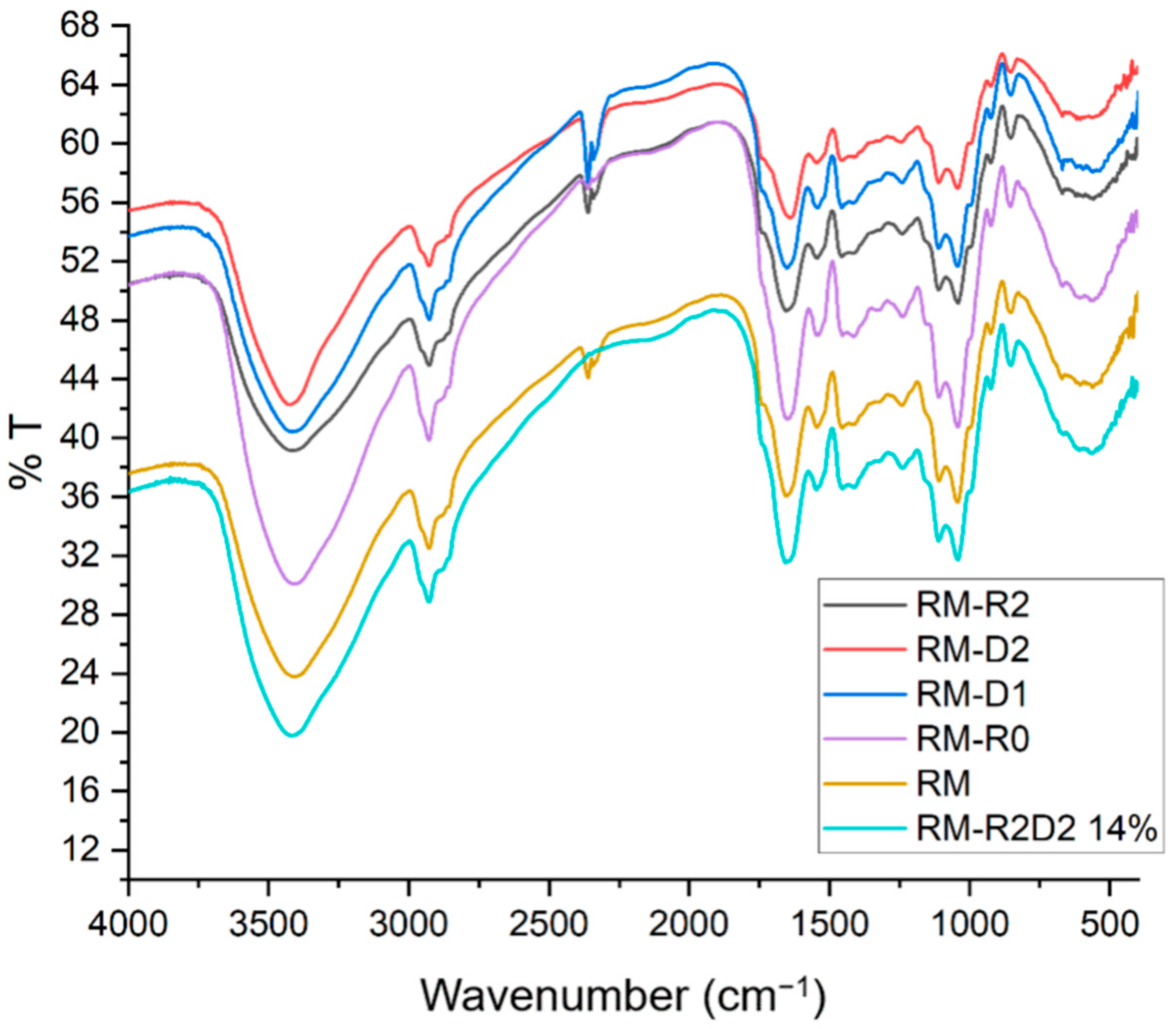

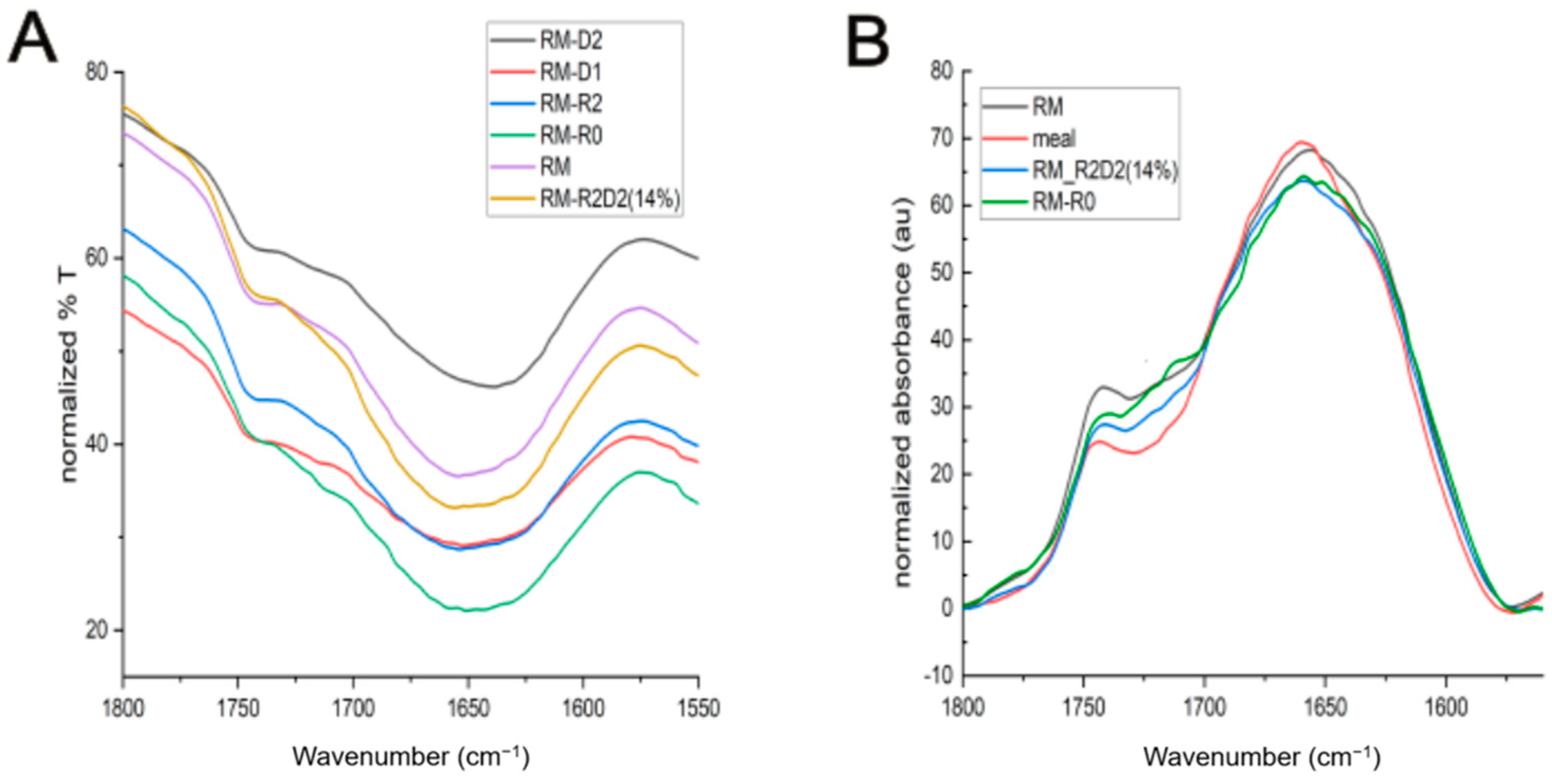

3.4. Protein Conformation Analysis

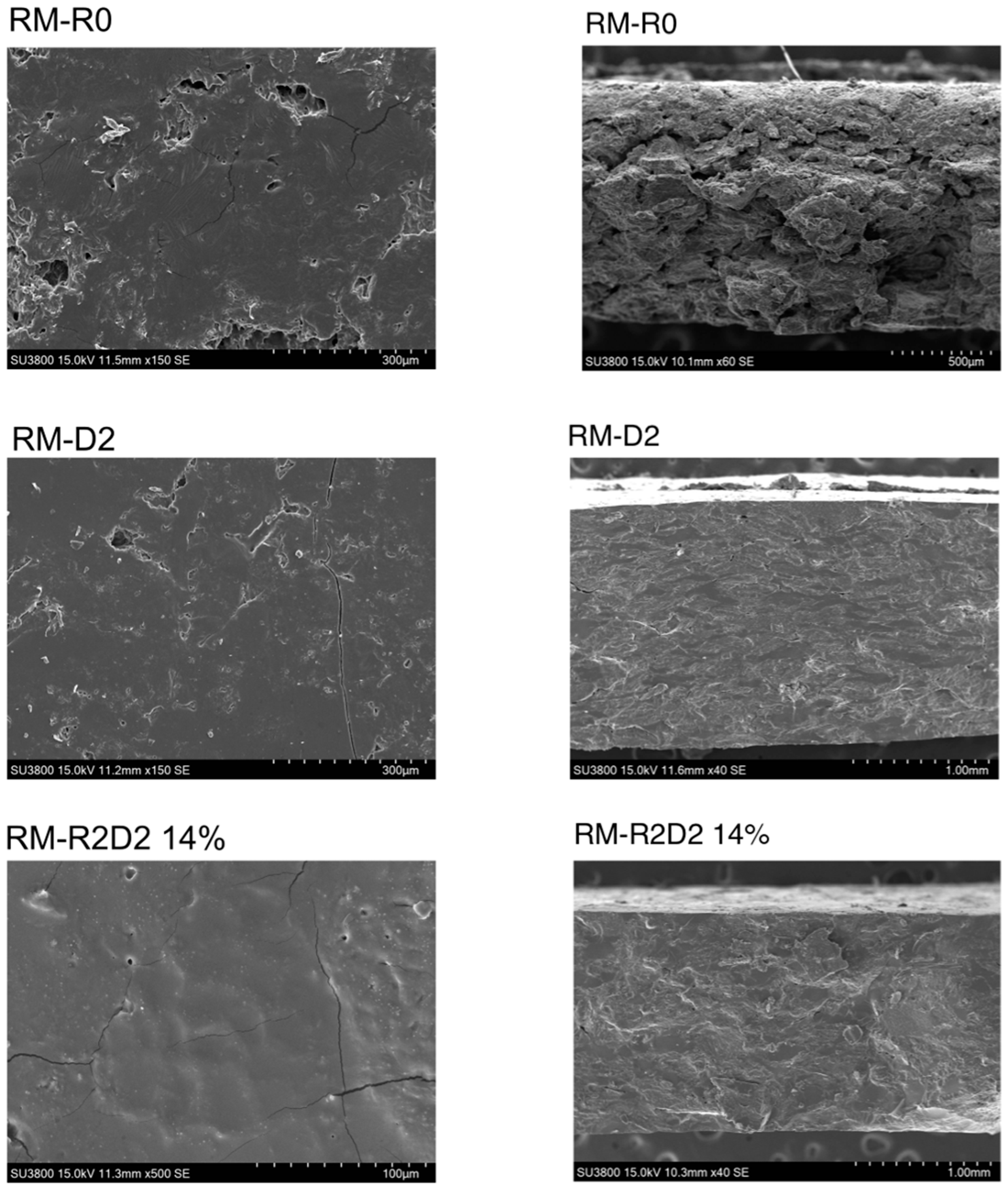

3.5. Material Appearance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hatti-Kaul, R.; Nilsson, L.J.; Zhang, B.; Rehnberg, N.; Lundmark, S. Designing Biobased Recyclable Polymers for Plastics. Trends Biotechnol. 2020, 38, 50–67. [Google Scholar] [CrossRef] [PubMed]

- North, E.J.; Halden, R.U. Plastics and Environmental Health: The Road Ahead. Rev. Environ. Health 2013, 28, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Hahladakis, J.N.; Velis, C.A.; Weber, R.; Iacovidou, E.; Purnell, P. An Overview of Chemical Additives Present in Plastics: Migration, Release, Fate and Environmental Impact during Their Use, Disposal and Recycling. J. Hazard. Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Zhang, L. Structure and Properties of Soy Protein Plastics Plasticized with Acetamide. Macromol. Mater. Eng. 2006, 291, 820–828. [Google Scholar] [CrossRef]

- Bioplastics Facts & Figures. Available online: https://www.european-bioplastics.org/bioplastics-facts-figures/ (accessed on 9 August 2024).

- Ancuța, P.; Sonia, A. Oil Press-Cakes and Meals Valorization through Circular Economy Approaches: A Review. Appl. Sci. 2020, 10, 7432. [Google Scholar] [CrossRef]

- Álvarez-Castillo, E.; Felix, M.; Bengoechea, C.; Guerrero, A. Proteins from Agri-Food Industrial Biowastes or Co-Products and Their Applications as Green Materials. Foods 2021, 10, 981. [Google Scholar] [CrossRef] [PubMed]

- Dziuba, R.; Kucharska, M.; Madej-Kiełbik, L.; Sulak, K.; Wiśniewska-Wrona, M. Biopolymers and Biomaterials for Special Applications within the Context of the Circular Economy. Materials 2021, 14, 7704. [Google Scholar] [CrossRef] [PubMed]

- Aguilar, A.; Twardowski, T.; Wohlgemuth, R. Bioeconomy for Sustainable Development. Biotechnol. J. 2019, 14, 1800638–1800652. [Google Scholar] [CrossRef] [PubMed]

- Ryder, K.; Ali, M.A.; Billakanti, J.; Carne, A. Evaluation of Dairy Co-Product Containing Composite Solutions for the Formation of Bioplastic Films. J. Polym. Environ. 2020, 28, 725–736. [Google Scholar] [CrossRef]

- Production of Rapeseed by Main Producing Countries 2023/24. Available online: https://www.statista.com/statistics/263930/worldwide-production-of-rapeseed-by-country/ (accessed on 29 May 2024).

- Di Lena, G.; Sanchez del Pulgar, J.; Lucarini, M.; Durazzo, A.; Ondrejíčková, P.; Oancea, F.; Frincu, R.-M.; Aguzzi, A.; Ferrari Nicoli, S.; Casini, I.; et al. Valorization Potentials of Rapeseed Meal in a Biorefinery Perspective: Focus on Nutritional and Bioactive Components. Molecules 2021, 26, 6787. [Google Scholar] [CrossRef]

- Raboanatahiry, N.; Li, H.; Yu, L.; Li, M. Rapeseed (Brassica napus): Processing, Utilization, and Genetic Improvement. Agronomy 2021, 11, 1776. [Google Scholar] [CrossRef]

- Bhatty, R.S.; McKenzie, S.L.; Finlayson, A.J. The Proteins of Rapeseed (Brassica napus L.) Soluble in Salt Solutions. Can. J. Biochem. 1968, 46, 1191–1197. [Google Scholar] [CrossRef]

- Yang, C.; Wang, Y.; Vasanthan, T.; Chen, L. Impacts of pH and Heating Temperature on Formation Mechanisms and Properties of Thermally Induced Canola Protein Gels. Food Hydrocoll. 2014, 40, 225–236. [Google Scholar] [CrossRef]

- Gallorini, R.; Aquilia, S.; Bello, C.; Ciardelli, F.; Pinna, M.; Papini, A.M.; Rosi, L. Pyrolysis of Spent Rapeseed Meal: A Circular Economy Example for Waste Valorization. J. Anal. Appl. Pyrolysis 2023, 174, 106138–106147. [Google Scholar] [CrossRef]

- Wanasundara, J.P.D.; Kapel, R.; Albe-Slabi, S. Proteins from Canola/Rapeseed—Current Status. In Sustainable Protein Sources, 2nd ed.; Nadathur, S., Wanasundara, J.P.D., Scanlin, L., Eds.; Academic Press: Cambridge, MA, USA, 2024; pp. 285–309. [Google Scholar]

- Fetzer, A.; Müller, K.; Schmid, M.; Eisner, P. Rapeseed Proteins for Technical Applications: Processing, Isolation, Modification and Functional Properties—A Review. Ind. Crops Prod. 2020, 158, 112986–113004. [Google Scholar] [CrossRef]

- Li, S.; Ciardullo, K.; Donner, E.; Thompson, M.R.; Rempel, C.; Liu, Q. Reactive Processing Preparation of Sustainable Composites from Canola Meal Reinforced by Chemical Modification. Eur. Polym. J. 2018, 102, 187–194. [Google Scholar] [CrossRef]

- Álvarez-Castillo, E.; Bengoechea, C.; Felix, M.; Guerrero, A. Protein-Based Bioplastics from Biowastes: Sources, Processing, Properties and Applications. In Bioplastics for Sustainable Development; Kuddus, M., Roohi, Eds.; Springer: Singapore, 2021; pp. 137–176. [Google Scholar]

- Mensitieri, G.; Di Maio, E.; Buonocore, G.G.; Nedi, I.; Oliviero, M.; Sansone, L.; Iannace, S. Processing and Shelf Life Issues of Selected Food Packaging Materials and Structures from Renewable Resources. New Chall. Food Preserv. 2011, 22, 72–80. [Google Scholar] [CrossRef]

- Newson, W.R.; Kuktaite, R.; Hedenqvist, M.S.; Gällstedt, M.; Johansson, E. Oilseed Meal Based Plastics from Plasticized, Hot Pressed Crambe Abyssinica and Brassica Carinata Residuals. J. Am. Oil Chem. Soc. 2013, 90, 1229–1237. [Google Scholar] [CrossRef]

- Felix, M.; Perez-Puyana, V.; Romero, A.; Guerrero, A. Development of Protein-Based Bioplastics Modified with Different Additives. J. Appl. Polym. Sci. 2017, 134, 45430–45438. [Google Scholar] [CrossRef]

- Mekonnen, T.; Mussone, P.; Khalil, H.; Bressler, D. Progress in Bio-Based Plastics and Plasticizing Modifications. J. Mater. Chem. A 2013, 1, 13379–13398. [Google Scholar] [CrossRef]

- Krochta, J.M. Proteins as Raw Materials for Films and Coatings: Definitions, Current Status, and Opportunities. Protein-Based Film. Coat. 2002, 1, 1–40. [Google Scholar]

- Martinez, A.W.; Caves, J.M.; Ravi, S.; Li, W.; Chaikof, E.L. Effects of Crosslinking on the Mechanical Properties, Drug Release and Cytocompatibility of Protein Polymers. Acta Biomater. 2014, 10, 26–33. [Google Scholar] [CrossRef] [PubMed]

- Reddy, N.; Reddy, R.; Jiang, Q. Crosslinking Biopolymers for Biomedical Applications. Trends Biotechnol. 2015, 33, 362–369. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Min, S.C. Development of Antimicrobial Defatted Soybean Meal-Based Edible Films Incorporating the Lactoperoxidase System by Heat Pressing. J. Food Eng. 2014, 120, 183–190. [Google Scholar] [CrossRef]

- Wu, Q.; Sakabe, H.; Isobe, S. Processing and Properties of Low Cost Corn Gluten Meal/Wood Fiber Composite. Ind. Eng. Chem. Res. 2003, 42, 6765–6773. [Google Scholar] [CrossRef]

- Petraru, A.; Amariei, S. A Novel Approach about Edible Packaging Materials Based on Oilcakes—A Review. Polymers 2023, 15, 3431. [Google Scholar] [CrossRef] [PubMed]

- Popović, S.; Hromiš, N.; Šuput, D.; Bulut, S.; Romanić, R.; Lazić, V. Chapter 3—Valorization of by-Products from the Production of Pressed Edible Oils to Produce Biopolymer Films. In Cold Pressed Oils; Ramadan, M.F., Ed.; Academic Press: Cambridge, MA, USA, 2020; pp. 15–30. [Google Scholar]

- Mirpoor, S.F.; Giosafatto, C.V.L.; Porta, R. Biorefining of Seed Oil Cakes as Industrial Co-Streams for Production of Innovative Bioplastics. A Review. Trends Food Sci. Technol. 2021, 109, 259–270. [Google Scholar] [CrossRef]

- Żelaziński, T. Properties of Biocomposites from Rapeseed Meal, Fruit Pomace and Microcrystalline Cellulose Made by Press Pressing: Mechanical and Physicochemical Characteristics. Materials 2021, 14, 890. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Q.; Rempel, C. Processing and Characteristics of Canola Protein-Based Biodegradable Packaging: A Review. Crit. Rev. Food Sci. Nutr. 2018, 58, 475–485. [Google Scholar] [CrossRef]

- Jang, S.-A.; Lim, G.-O.; Song, K.B. Preparation and Mechanical Properties of Edible Rapeseed Protein Films. J. Food Sci. 2011, 76, C218–C223. [Google Scholar] [CrossRef]

- Li, S.; Donner, E.; Thompson, M.; Zhang, Y.; Rempel, C.; Liu, Q. Preparation and Characterization of Cross-Linked Canola Protein Isolate Films. Eur. Polym. J. 2017, 89, 419–430. [Google Scholar] [CrossRef]

- Jiang, Y.; Simonsen, J.; Zhao, Y. Compression-Molded Biocomposite Boards from Red and White Wine Grape Pomaces. J. Appl. Polym. Sci. 2011, 119, 2834–2846. [Google Scholar] [CrossRef]

- Ben, Z.Y.; Samsudin, H.; Yhaya, M.F. Glycerol: Its Properties, Polymer Synthesis, and Applications in Starch Based Films. Eur. Polym. J. 2022, 175, 111377–111393. [Google Scholar] [CrossRef]

- Ullsten, N.H.; Gällstedt, M.; Hedenqvist, M.S. Chapter 5 Plasticizers for Protein-Based Materials. In Viscoelastic and Viscoplastic Materials; El-Amin, M.F., Ed.; IntechOpen: Rijeka, Croatia, 2016. [Google Scholar]

- Bonnaillie, L.M.; Zhang, H.; Akkurt, S.; Yam, K.L.; Tomasula, P.M. Casein Films: The Effects of Formulation, Environmental Conditions and the Addition of Citric Pectin on the Structure and Mechanical Properties. Polymers 2014, 6, 2018–2036. [Google Scholar] [CrossRef]

- Johansson, E.; Spencer, G.M.; Bettini, E.; Cho, S.-W.; Marttila, S.; Kuktaite, R.; Gällstedt, M.; Hedenqvist, M.S. Biobased Materials Production from Biodiesel Residuals of Rapeseed. ISRN Mater. Sci. 2012, 2012, 193541. [Google Scholar] [CrossRef]

- Lu, S.; Wang, X.; Lu, Q.; Zhang, X.; Kluge, J.A.; Uppal, N.; Omenetto, F.; Kaplan, D.L. Insoluble and Flexible Silk Films Containing Glycerol. Biomacromolecules 2010, 11, 143–150. [Google Scholar] [CrossRef] [PubMed]

- Zahari, I.; Ferawati, F.; Purhagen, J.K.; Rayner, M.; Ahlström, C.; Helstad, A.; Östbring, K. Development and Characterization of Extrudates Based on Rapeseed and Pea Protein Blends Using High-Moisture Extrusion Cooking. Foods 2021, 10, 2397. [Google Scholar] [CrossRef] [PubMed]

- Audic, J.-L.; Chaufer, B.; Daufin, G. Non-Food Applications of Milk Components and Dairy Co-Products: A Review. Lait 2003, 83, 417–438. [Google Scholar] [CrossRef]

- Wusigale; Liang, L.; Luo, Y. Casein and Pectin: Structures, Interactions, and Applications. Trends Food Sci. Technol. 2020, 97, 391–403. [Google Scholar] [CrossRef]

- He, W.; Zhu, G.; Gao, Y.; Wu, H.; Fang, Z.; Guo, K. Combining Renewable Eleostearic Acid and Eugenol to Fabricate Sustainable Plasticizer and Its Effect of Plasticizing on PVC. Chem. Eng. J. 2020, 380, 122532–122551. [Google Scholar] [CrossRef]

- Xu, X.; Yu, J.; Yang, F.; Li, Y.; Ou, R.; Liu, Z.; Liu, T.; Wang, Q. Preparation of degradable chemically cross-linked polylactic acid films and its application on disposable straws. Int. J. Biol. Macromol. 2023, 251, 126394–126405. [Google Scholar] [CrossRef]

- Song, L.; Chi, W.; Zhang, Q.; Ren, J.; Yang, B.; Cong, F.; Li, Y.; Wang, W.; Li, X.; Wang, Y. Improvement of Properties of Polylactic Acid/Polypropylene Carbonate Blends Using Epoxy Soybean Oil as an Efficient Compatibilizer. Int. J. Biol. Macromol. 2023, 253, 127407–127412. [Google Scholar] [CrossRef] [PubMed]

- Singha, S.; Mahmutovic, M.; Zamalloa, C.; Stragier, L.; Verstraete, W.; Svagan, A.J.; Das, O.; Hedenqvist, M.S. Novel Bioplastic from Single Cell Protein as a Potential Packaging Material. ACS Sustain. Chem. Eng. 2021, 9, 6337–6346. [Google Scholar] [CrossRef]

- Rombouts, I.; Lagrain, B.; Brunnbauer, M.; Koehler, P.; Brijs, K.; Delcour, J.A. Identification of Isopeptide Bonds in Heat-Treated Wheat Gluten Peptides. J. Agric. Food Chem. 2011, 59, 1236–1243. [Google Scholar] [CrossRef] [PubMed]

- Kong, J.; Yu, S. Fourier Transform Infrared Spectroscopic Analysis of Protein Secondary Structures. Acta Biochim. Et Biophys. Sin. 2007, 39, 549–559. [Google Scholar] [CrossRef]

- Ye, X.; Junel, K.; Gällstedt, M.; Langton, M.; Wei, X.-F.; Lendel, C.; Hedenqvist, M.S. Protein/Protein Nanocomposite Based on Whey Protein Nanofibrils in a Whey Protein Matrix. ACS Sustain. Chem. Eng. 2018, 6, 5462–5469. [Google Scholar] [CrossRef]

| Feedstock | Processing | Reference |

|---|---|---|

| Albumen protein isolated and crayfish flour | Injection moulding | [23] |

| Defatted Soybean meal | Casting | [28] |

| Gluten meal and Wood fiber | Extrusion | [31] |

| Crambe and Carinata Oilseed Meal | Compression moulding | [23] |

| Rapeseed meal | Compression moulding | [19] |

| Rapeseed Meal, Fruit Pomace and Microcrystalline Cellulose | Compression moulding | [33] |

| Red and White Wine Grape Pomaces | Compression moulding | [30] |

| Rapeseed Protein Isolates | Casting | [34] |

| Rapeseed Protein Isolates | Casting | [35] |

| Rapeseed Protein Isolates | Casting | [36] |

| Sample | Formulation | |||

|---|---|---|---|---|

| Rapeseed Meal/Compatibilizer | Glycerol | Water Solution | Epoxy-PEG | |

| RM-R0 | 100:0 | 27% | Distilled water 7% | - |

| RM | 04:01 | 27% | Distilled water 7% | 2× mol |

| RM-R1 | 04:01 | 27% | (Na2SO3 10%) 7% | 2× mol |

| RM-R2 | 04:01 | 27% | (Na2SO3 20%) 7% | 2× mol |

| RM-D1 | 04:01 | 27% | (UREA 2 M) 7% | 2× mol |

| RM-D2 | 04:01 | 27% | (Guanidine 1 M) 7% | 2× mol |

| RM-D3 | 04:01 | 27% | (SDS 3%) 7% | 2× mol |

| RM-R1D2 (7%) | 04:01 | 27% | (Na2SO3 10% + Guanidine 1 M) 7% | 2× mol |

| RM-R1D2 (14%) | 04:01 | 27% | (Na2SO3 10% + Guanidine 1 M) 14% | 2× mol |

| RM-R2D2 (7%) | 04:01 | 27% | (Na2SO3 20% + Guanidine 1 M) 7% | 2× mol |

| RM-R2D2 (14%) | 04:01 | 27% | (Na2SO3 20% + Guanidine 1 M) 14% | 2× mol |

| Sample | Mechanical Properties | ||

|---|---|---|---|

| Stress at Fracture (N/mm2) | Elastic Modulus (N/mm2) | Elongation at Fracture (%) | |

| RM | 0.86 ± 0.24 | 172.23 ± 2.17 | 0.83 ± 0.11 |

| RM-ES | 0.38 ± 0.06 | 55.91 ± 9.93 | 2.18 ± 0.25 |

| RM-NE | 0.81 ± 0.02 | 60.94 ± 0.85 | 4.70 ± 0.56 |

| Sample | Mechanical Properties | ||

|---|---|---|---|

| Stress at Fracture (N/mm2) | Elastic Modulus (N/mm2) | Elongation at Fracture (%) | |

| RM | 0.86 0.24 | 172.23 2.17 | 0.83 0.11 |

| RM-R1 | 2.00 0.37 | 234.82 8.15 | 1.24 0.37 |

| RM-R2 | 1.13 0.06 | 103.60 8.66 | 1.92 0.06 |

| Sample | Mechanical Properties | ||

|---|---|---|---|

| Stress at Fracture (N/mm2) | Elastic Modulus (N/mm2) | Elongation at Fracture (%) | |

| RM | 0.86 0.24 | 172.23 2.17 | 0.83 0.11 |

| RM-D1 | 0.90 0.22 | 75.67 2.00 | 1.96 0.35 |

| RM-D2 | 0.82 0.19 | 95.17 0.10 | 1.70 0.33 |

| RM-D3 | 0.59 0.15 | 70.35 1.77 | 1.49 0.33 |

| Sample | Mechanical Properties | ||

|---|---|---|---|

| Stress at Fracture (N/mm2) | Elastic Modulus (N/mm2) | Elongation at Fracture (%) | |

| RM-R1D2 7% | 0.85 ± 0.13 | 214.18 ± 4.27 | 0.88 ± 0.08 |

| RM-R1D2 14% | 1.24 ± 0.20 | 216.89 ± 0.98 | 1.20 ± 0.06 |

| RM-R2D2 7% | 1.87 ± 0.34 | 277.99 ± 1.95 | 1.38 ± 0.27 |

| RM-R2D2 14% | 1.53 ± 0.20 | 257.71 ± 9.40 | 0.18 ± 0.28 |

| Peak (ῦ, cm−1) | A% Rapeseed Meal | A% RM | A% RM-R0 | A% RM-R2D2 14% |

|---|---|---|---|---|

| 1622–1624 | 10.4 | 28.3 | 22.21 | 17.4 |

| 1662–1665 | 77.0 | 30.5 | 60.39 | 58.1 |

| 1711–1729 | 12.3 | 39.6 | 15.54 | 22.2 |

| 1745 | 0.3 | 1.6 | 1.86 | 2.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aquilia, S.; Rosi, L.; Pinna, M.; Bianchi, S.; Giurlani, W.; Bonechi, M.; Ciardelli, F.; Papini, A.M.; Bello, C. Study of the Preparation and Properties of Chemically Modified Materials Based on Rapeseed Meal. Biomolecules 2024, 14, 982. https://doi.org/10.3390/biom14080982

Aquilia S, Rosi L, Pinna M, Bianchi S, Giurlani W, Bonechi M, Ciardelli F, Papini AM, Bello C. Study of the Preparation and Properties of Chemically Modified Materials Based on Rapeseed Meal. Biomolecules. 2024; 14(8):982. https://doi.org/10.3390/biom14080982

Chicago/Turabian StyleAquilia, Sara, Luca Rosi, Michele Pinna, Sabrina Bianchi, Walter Giurlani, Marco Bonechi, Francesco Ciardelli, Anna Maria Papini, and Claudia Bello. 2024. "Study of the Preparation and Properties of Chemically Modified Materials Based on Rapeseed Meal" Biomolecules 14, no. 8: 982. https://doi.org/10.3390/biom14080982

APA StyleAquilia, S., Rosi, L., Pinna, M., Bianchi, S., Giurlani, W., Bonechi, M., Ciardelli, F., Papini, A. M., & Bello, C. (2024). Study of the Preparation and Properties of Chemically Modified Materials Based on Rapeseed Meal. Biomolecules, 14(8), 982. https://doi.org/10.3390/biom14080982