Separation and Purification of Biogenic 1,3-Propanediol from Fermented Glycerol through Flocculation and Strong Acidic Ion-Exchange Resin

Abstract

1. Introduction

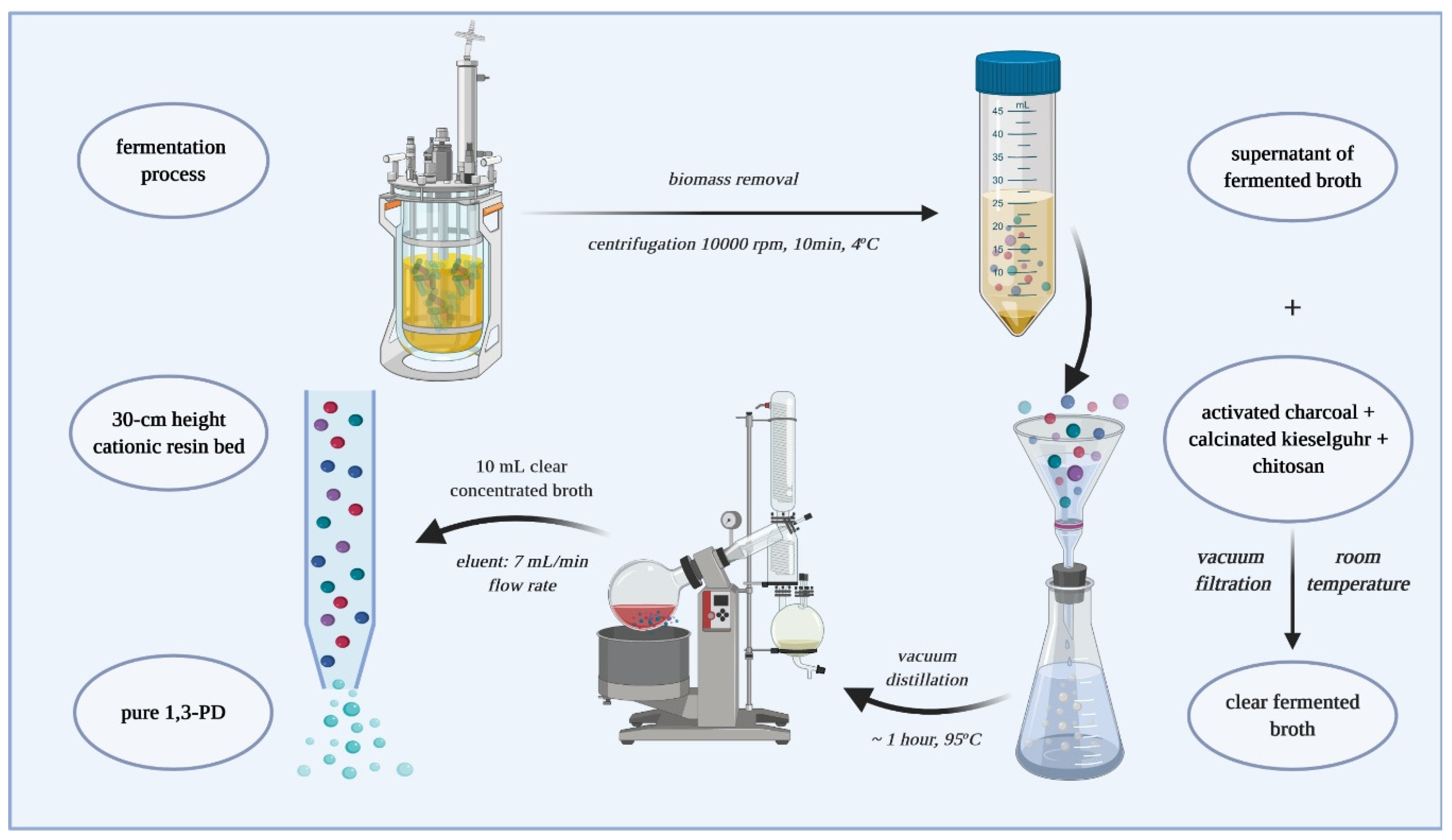

2. Materials and Methods

2.1. Reagents

2.2. Fermentation Process

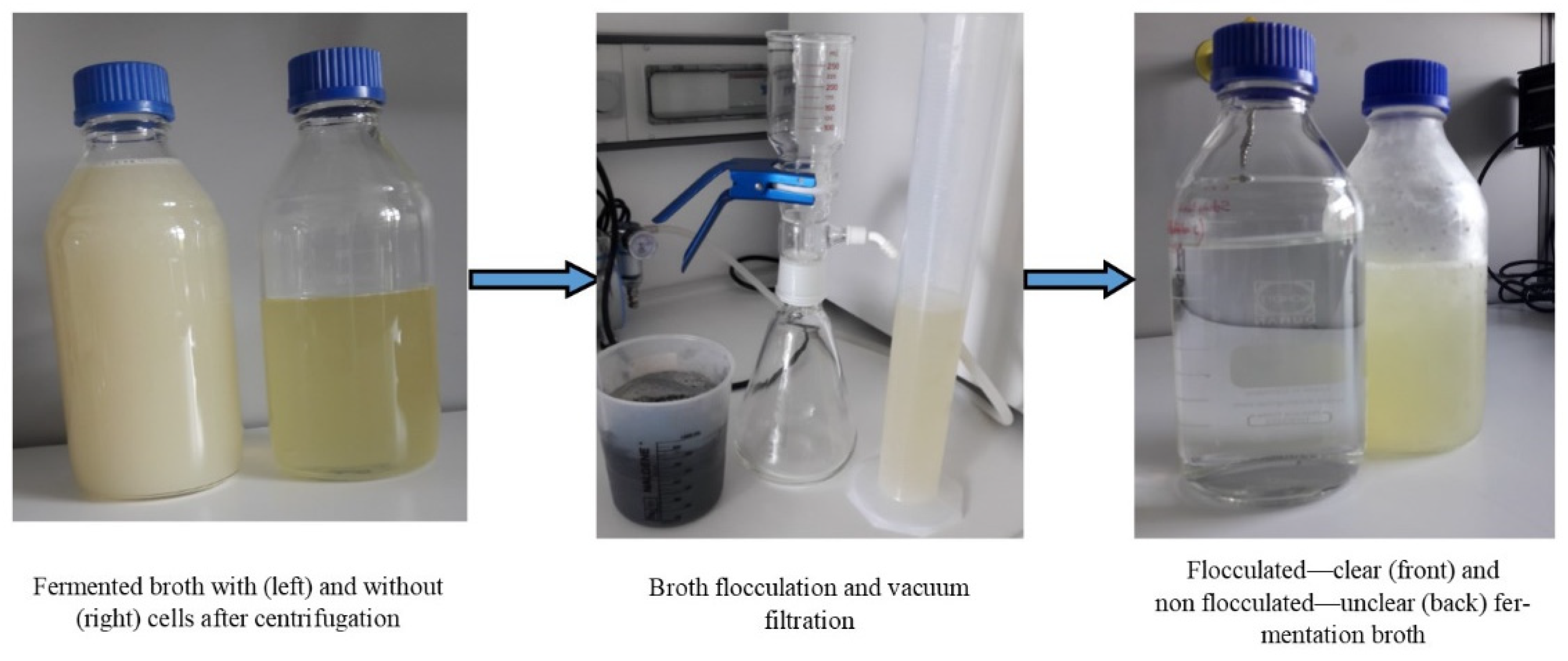

2.3. Broth Flocculation

2.4. Purification through an Ion Exchange Resin

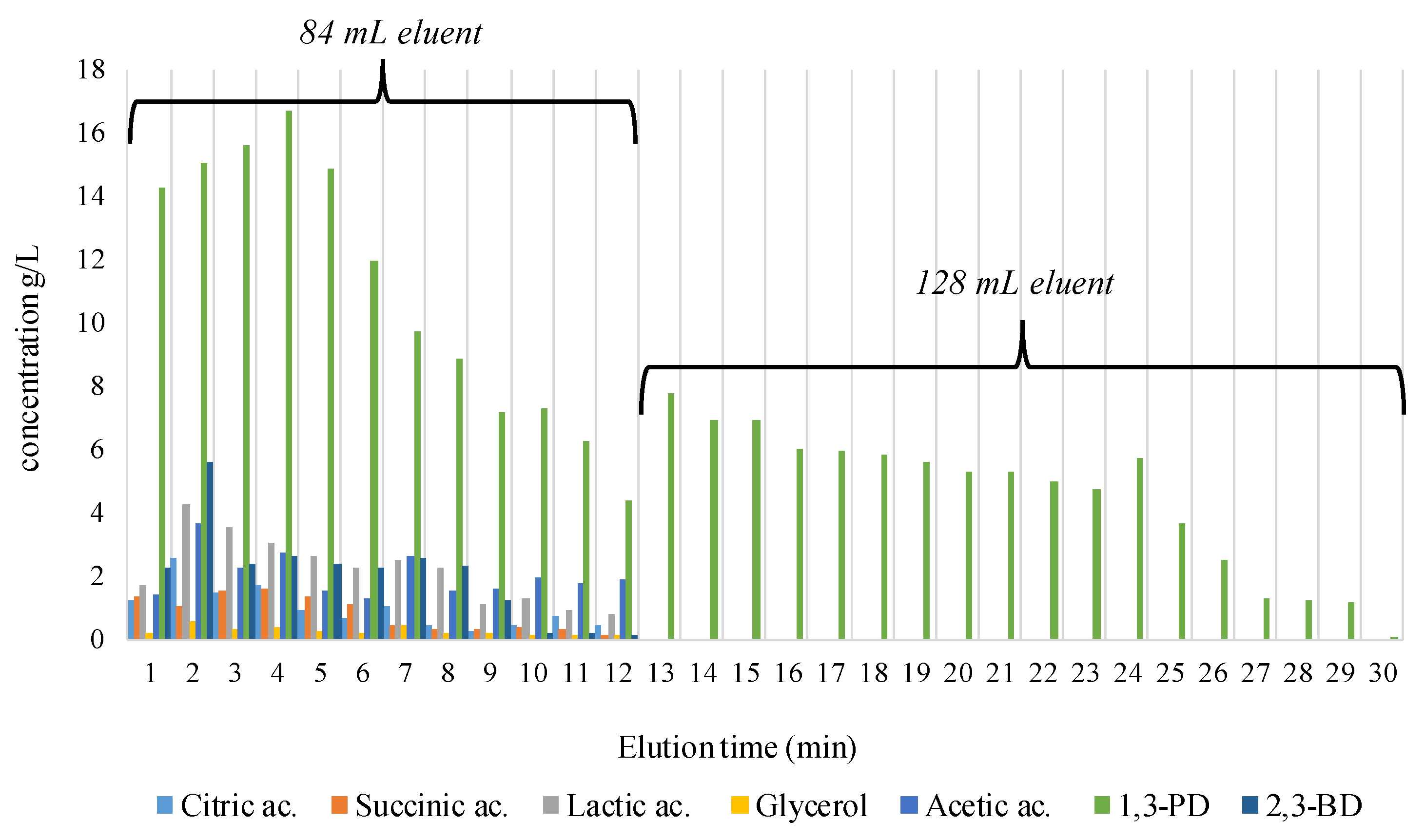

Purification Process Using a 30-cm Resin Bed

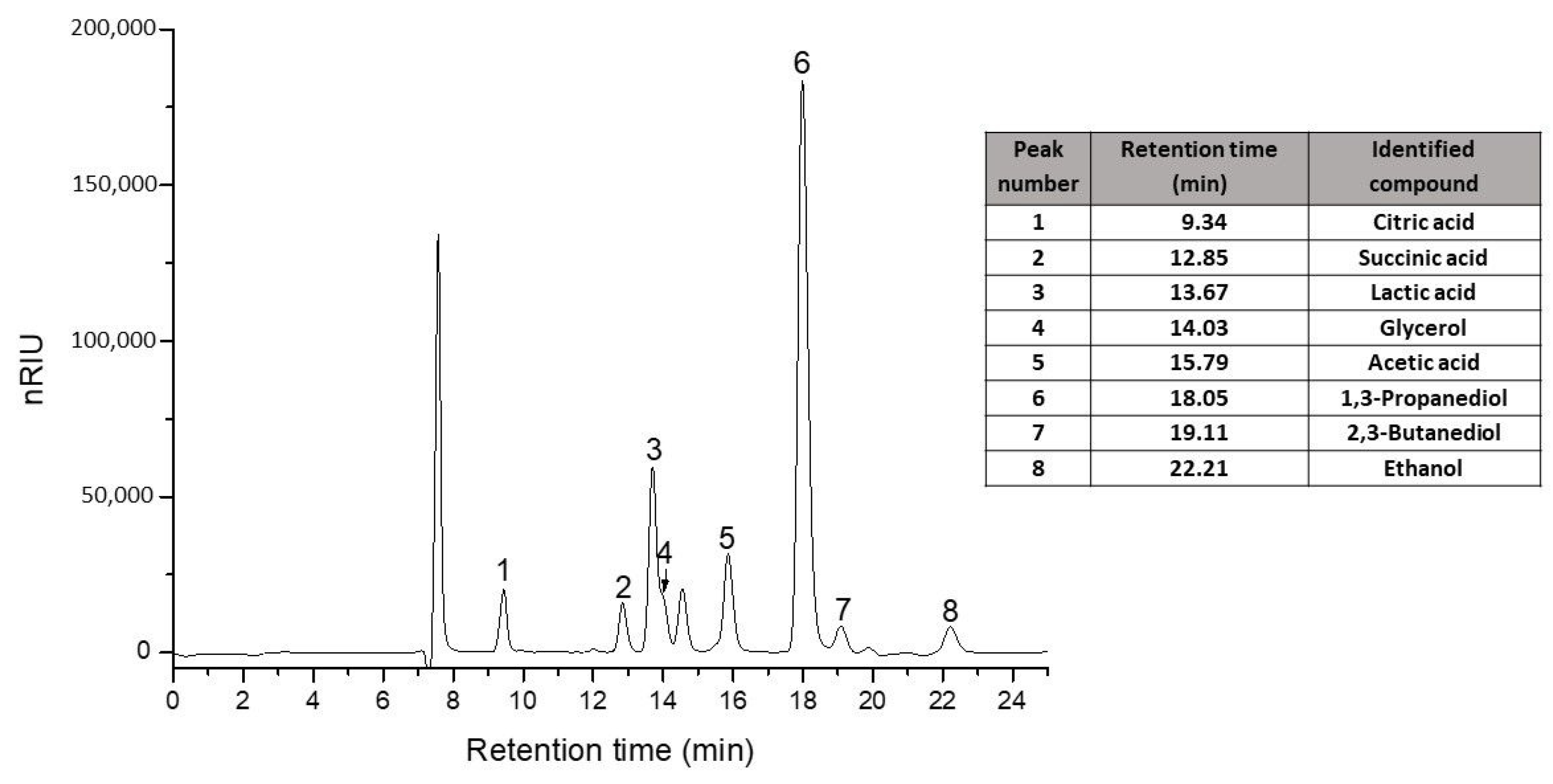

2.5. HPLC Analysis

3. Results and Discussions

3.1. Broth Flocculation and Concentration

3.2. Purification of Biogenic 1,3-PD through a Cationic Exchange Resin

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mitrea, L.; Trif, M.; Cătoi, A.-F.; Vodnar, D.C. Utilization of biodiesel derived-glycerol for 1,3-PD and citric acid production. Microb. Cell Factor. 2017, 16, 190. [Google Scholar] [CrossRef] [PubMed]

- Laura, M.; Călinoiu, L.-F.; Precup, G.; Bindea, M.; Rusu, B.; Trif, M.; Ferenczi, L.J.; Ştefănescu, B.E.; Vodnar, D.C. Inhibitory potential of lactobacillus plantarum on Escherichia Coli. Bull. Univ. Agric. Sci. Veter- Med. Cluj-Napoca. Food Sci. Technol. 2017, 74, 99. [Google Scholar] [CrossRef][Green Version]

- Laura, M.; Ranga, F.; Fetea, F.; Dulf, F.; Rusu, A.; Trif, M.; Vodnar, D.C. Biodiesel-derived glycerol obtained from renewable biomass-A suitable substrate for the growth of Candida zeylanoides yeast strain ATCC 20367. Microorganisms 2019, 7, 265. [Google Scholar] [CrossRef]

- Teleky, B.-E.; Martău, G.-A.; Ranga, F.; Chețan, F.; Vodnar, D.C. Exploitation of lactic acid bacteria and baker’s yeast as single or multiple starter cultures of wheat flour dough enriched with soy flour. Biomolecules 2020, 10, 778. [Google Scholar] [CrossRef] [PubMed]

- Vodnar, D.C.; Dulf, F.; Pop, O.L.; Socaciu, C. L (+)-lactic acid production by pellet-form Rhizopus oryzae NRRL 395 on biodiesel crude glycerol. Microb. Cell Factor. 2013, 12, 92. [Google Scholar] [CrossRef] [PubMed]

- Teleky, B.-E.; Vodnar, D.-C. Biomass-derived production of itaconic acid as a building block in specialty polymers. Polymers 2019, 11, 1035. [Google Scholar] [CrossRef]

- Hao, J.; Liu, H.; Liu, D. Novel route of reactive extraction to recover 1,3-propanediol from a dilute aqueous solution. Ind. Eng. Chem. Res. 2005, 44, 4380–4385. [Google Scholar] [CrossRef]

- Wang, S.; Qiu, L.; Dai, H.; Zeng, X.; Fang, B. Highly pure 1,3-propanediol: Separation and purification from crude glycerol-based fermentation. Eng. Life Sci. 2015, 15, 788–796. [Google Scholar] [CrossRef]

- Xiu, Z.-L.; Zeng, A.-P. Present state and perspective of downstream processing of biologically produced 1,3-propanediol and 2,3-butanediol. Appl. Microbiol. Biotechnol. 2008, 78, 917–926. [Google Scholar] [CrossRef]

- Kumar, V.; Durgapal, M.; Sankaranarayanan, M.; Somasundar, A.; Rathnasingh, C.; Song, H.; Seung, D.; Park, S. Effects of mutation of 2,3-butanediol formation pathway on glycerol metabolism and 1,3-propanediol production by Klebsiella pneumoniae J2B. Bioresour. Technol. 2016, 214, 432–440. [Google Scholar] [CrossRef]

- Anand, P.; Saxena, R.K.; Marwah, R.G. A novel downstream process for 1,3-propanediol from glycerol-based fermentation. Appl. Microbiol. Biotechnol. 2011, 90, 1267–1276. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.; Xie, S.; Wang, S.; Xue, Y.; Jiang, L.; Liu, L. Optimization of protein removal from soybean whey wastewater using chitosan ultrafiltration. J. Food Process. Eng. 2016, 40. [Google Scholar] [CrossRef]

- Agerkvist, I.; Eriksson, L.; Enfors, S.-O. Selective flocculation with Chitosan in Escherichia coli disintegrates: Effects of pH and nuclease treatment. Enzym. Microb. Technol. 1990, 12, 584–590. [Google Scholar] [CrossRef]

- Hao, J.; Xu, F.; Liu, H.; Liu, D. Downstream processing of 1,3-propanediol fermentation broth. J. Chem. Technol. Biotechnol. 2005, 81, 102–108. [Google Scholar] [CrossRef]

- Krahnstöver, T.; Wintgens, T. Optimizing the flocculation of powdered activated carbon in wastewater treatment by dosing iron salt in single- and two-stage processes. J. Water Process. Eng. 2017, 20, 130–137. [Google Scholar] [CrossRef]

- Baraniak, B.M.; Waleriańczyk, E. Flocculation. In Encyclopedia of Food Sciences and Nutrition, 2nd ed.; Caballero, B., Ed.; Academic Press: Oxford, UK, 2003; pp. 2531–2535. Available online: https://doi.org/10.1016/B0-12-227055-X/00485-5 (accessed on 10 August 2020).

- Gao, Q.; Duan, Q.; Wang, D.; Zhang, Y.; Zheng, C. Separation and purification of γ-aminobutyric acid from fermentation broth by flocculation and chromatographic methodologies. J. Agric. Food Chem. 2013, 61, 1914–1919. [Google Scholar] [CrossRef]

- O’Mahony, K.; Freitag, R.; Dhote, B.; Hilbrig, F.; Müller, P.; Schumacher, I. Capture of bacteria from fermentation broth by body feed filtration: A solved problem? Biotechnol. Prog. 2006, 22, 471–483. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, Z.; Tan, T. Studies on purification of 1,3-propanediol by molecular distillation. Biotechnol. Bioprocess. Eng. 2013, 18, 697–702. [Google Scholar] [CrossRef]

- Rukowicz, B.; Alejski, K. A biologically-derived 1,3-propanediol recovery from fermentation broth using preparative liquid chromatography. Sep. Purif. Technol. 2018, 205, 196–202. [Google Scholar] [CrossRef]

- Boonsongsawat, T.; Shotipruk, A.; Tantayakom, V.; Prasitchoke, P.; Chandavasu, C.; Boonnoun, P.; Muangnapoh, C. Solvent extraction of biologically derived 1,3-propanediol with ethyl acetate and ethanol cosolvent. Sep. Sci. Technol. 2010, 45, 541–547. [Google Scholar] [CrossRef]

- Cui, C.; Zhang, Z.; Chen, B. Environmentally-friendly strategy for separation of 1,3-propanediol using biocatalytic conversion. Bioresour. Technol. 2017, 245, 477–482. [Google Scholar] [CrossRef] [PubMed]

- Hilaly, A.K.; Binder, T.P. Method of Recovering 1,3-Propanediol from Fermentation Broth. U.S. Patent No. US6479716B2, 11 December 2002. [Google Scholar]

- Zhang, J.; Amini, A.; O’Neal, J.A.; Boyer, T.H.; Zhang, Q. Development and validation of a novel modeling framework integrating ion exchange and resin regeneration for water treatment. Water Res. 2015, 84, 255–265. [Google Scholar] [CrossRef] [PubMed]

- Luerruk, W.; Shotipruk, A.; Tantayakom, V.; Prasitchoke, P.; Muangnapoh, C. Adsorption of 1,3-propanediol from synthetic mixture using polymeric resin as adsorbents. Front. Chem. Eng. China 2009, 3, 52–57. [Google Scholar] [CrossRef]

- Cho, M.-H.; Joen, S.I.; Pyo, S.-H.; Mun, S.; Kim, J.-H. A novel separation and purification process for 1,3-propanediol. Process. Biochem. 2006, 41, 739–744. [Google Scholar] [CrossRef]

- Rukowicz, B.; Miesiac, I.; Alejski, K. Separation of 1,3-propanediol from aqueous solutions by ion exchange chromatography. Pol. J. Chem. Technol. 2014, 16, 82–86. [Google Scholar] [CrossRef]

- Wu, R.C.; Xu, Y.Z.; Song, Y.Q.; Luo, J.A.; Liu, D. A novel strategy for salts recovery from 1,3-propanediol fermentation broth by bipolar membrane electrodialysis. Sep. Purif. Technol. 2011, 83, 9–14. [Google Scholar] [CrossRef]

- Malinowski, J.J. Reactive extraction for downstream separation of 1,3-propanediol. Biotechnol. Prog. 2000, 16, 76–79. [Google Scholar] [CrossRef]

- Saxena, R.K.; Anand, P.; Saran, S.; Isar, J. Microbial production of 1,3-propanediol: Recent developments and emerging opportunities. Biotechnol. Adv. 2009, 27, 895–913. [Google Scholar] [CrossRef]

- Waszak, M.; Markowska-Szczupak, A.; Gryta, M. Application of nanofiltration for production of 1,3-propanediol in membrane bioreactor. Catal. Today 2016, 268, 164–170. [Google Scholar] [CrossRef]

- Müller, A.; Górak, A. Extraction of 1,3-propanediol from aqueous solutions using different ionic liquid-based aqueous two-phase systems. Sep. Purif. Technol. 2012, 97, 130–136. [Google Scholar] [CrossRef]

- Laura, M.; Trif, M.; Vodnar, D.C. The effect of crude glycerol impurities on 1,3-propanediol biosynthesis by Klebsiella pneumoniae DSMZ 2026. Renew. Energy 2020, 153, 1418–1427. [Google Scholar] [CrossRef]

- Mitrea, L.; Vodnar, D.C. Klebsiella pneumoniae-A useful pathogenic strain for biotechnological purposes: Diols biosynthesis under controlled and uncontrolled pH levels. Pathogens 2019, 8, 293. [Google Scholar] [CrossRef] [PubMed]

- Kraus, G.A. Synthetic methods for the preparation of 1,3-propanediol. CLEAN-Soil Air Water 2008, 36, 648–651. [Google Scholar] [CrossRef]

- Zeng, A.-P.; Sabra, W. Microbial production of diols as platform chemicals: Recent progresses. Curr. Opin. Biotechnol. 2011, 22, 749–757. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Xu, Y.; Zheng, Z.; Liu, D. 1,3-Propanediol and its copolymers: Research, development and industrialization. Biotechnol. J. 2010, 5, 1137–1148. [Google Scholar] [CrossRef]

- Wilkens, E.; Ringel, A.K.; Hortig, D.; Willke, T.; Vorlop, K.-D. High-level production of 1,3-propanediol from crude glycerol by Clostridium butyricum AKR102a. Appl. Microbiol. Biotechnol. 2012, 93, 1057–1063. [Google Scholar] [CrossRef]

- Lee, C.S.; Aroua, M.K.; Daud, W.M.A.W.; Cognet, P.; Pérès-Lucchese, Y.; Fabre, P.-L.; Reynes, O.; Latapie, L. A review: Conversion of bioglycerol into 1,3-propanediol via biological and chemical method. Renew. Sustain. Energy Rev. 2015, 42, 963–972. [Google Scholar] [CrossRef]

- Laura, M.; Călinoiu, L.-F.; Martău, G.-A.; Szabo, K.; Teleky, B.-E.; Mureșan, V.; Rusu, A.; Socol, C.T.; Vodnar, D.C. Poly(vinyl alcohol)-based biofilms plasticized with polyols and colored with pigments extracted from tomato by-products. Polymers 2020, 12, 532. [Google Scholar] [CrossRef]

- Szabo, K.; Teleky, B.-E.; Laura, M.; Călinoiu, L.-F.; Martău, G.-A.; Simon, E.; Varvara, R.-A.; Vodnar, D.C. Active packaging-Poly (vinyl alcohol) films enriched with tomato by-products extract. Coatings 2020, 10, 141. [Google Scholar] [CrossRef]

| Medium/Compounds Header | Citric Ac. | Succinic Ac. | Lactic Ac. | Glycerol | Acetic Ac. | 1,3-PD | 2,3-BD | Ethanol |

|---|---|---|---|---|---|---|---|---|

| Nonflocculated Fermentation Broth | 1.62 | 1.17 | 3.42 | 0.30 | 4.06 | 28.86 | 4.89 | 1.43 |

| Flocculated (Clear) Fermentation Broth | 1.31 | 0.97 | 2.83 | 0.28 | 3.28 | 26.88 | 2.93 | 1.23 |

| Concentrated Fermentation Broth | 12.52 | 9.22 | 30.01 | 3.52 | 27.56 | 265.06 | 33.31 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitrea, L.; Leopold, L.F.; Bouari, C.; Vodnar, D.C. Separation and Purification of Biogenic 1,3-Propanediol from Fermented Glycerol through Flocculation and Strong Acidic Ion-Exchange Resin. Biomolecules 2020, 10, 1601. https://doi.org/10.3390/biom10121601

Mitrea L, Leopold LF, Bouari C, Vodnar DC. Separation and Purification of Biogenic 1,3-Propanediol from Fermented Glycerol through Flocculation and Strong Acidic Ion-Exchange Resin. Biomolecules. 2020; 10(12):1601. https://doi.org/10.3390/biom10121601

Chicago/Turabian StyleMitrea, Laura, Loredana Florina Leopold, Cosmina Bouari, and Dan Cristian Vodnar. 2020. "Separation and Purification of Biogenic 1,3-Propanediol from Fermented Glycerol through Flocculation and Strong Acidic Ion-Exchange Resin" Biomolecules 10, no. 12: 1601. https://doi.org/10.3390/biom10121601

APA StyleMitrea, L., Leopold, L. F., Bouari, C., & Vodnar, D. C. (2020). Separation and Purification of Biogenic 1,3-Propanediol from Fermented Glycerol through Flocculation and Strong Acidic Ion-Exchange Resin. Biomolecules, 10(12), 1601. https://doi.org/10.3390/biom10121601