1. Introduction

Improved waste management is a key element in efforts towards achieving a resource-efficient Europe. Waste management principles are nowadays substantiated in the European Commission’s “Roadmap on a resource efficient Europe” [

1] as well as in the EU Waste Framework Directive [

2]. In the directive, municipal waste (MSW) defined as “waste from households, as well as other waste which, because of its nature or composition, is similar to waste from households” [

3] enjoys a prominent position in all waste management schemes, since it comprises the main bulk of waste that should be managed daily. Its contemporary management hierarchy, as laid out in Article 4 of the revised Waste Framework Directive [

2], dictates a legally binding prioritization of waste management alternatives with prevention of MSW generation being prioritized and promoted, and disposal (mainly as landfilling) being least prioritized. As such, prevention (of waste generation) is considered the top priority, followed in descending order by (processes of) re-use, recycling, energy and raw materials recovery and finally disposal (in the form of landfilling) [

4]. Out of these processes, waste disposal is recognized as the most harmful one from an environmental viewpoint, and as such it should be carefully designed and applied. When all reuse and recycling potential of the waste is depleted, recuperation of the materials found in waste and exploitation of its energy reserves becomes the next priority. This in turn completely changes the notion of the undesired end-of-life product or by-product, which is transformed into a valuable product (e.g., as proven in the case of municipal sludge by [

5]). Furthermore, transformation of waste into a product (e.g., as a building material, as described here) substantiates social responsibility initiatives for construction companies as a way of characterizing the company’s commitment to sustainability.

MSW in Greece is a diverse mixture of refuse comprising organic waste, plastics, metal, paper, hazardous and biohazardous components and inert materials among others [

6]. Recycling of plastic, paper, aluminum, other metals and glass, usually without pre-separation, has systematically taken place in Greece since 2001 (the “blue bin” scheme) [

7]. This scheme in 2018 served 10.3 million inhabitants and engaged 35 Recycling Sorting Centers [

8]. Furthermore, a separate system for glass only has been put into practice since 2013 [

8]. Additional recycling schemes for specialized waste (spent batteries, waste of electric and electronic equipment, used cooking oil, car parts, fluorescent lamps, etc.) also exist but they are not relevant for the present research. Much more can be done for recycling in Greece, especially in the aspects of education and sensitization of the public [

9]. In addition, environmental performance of household waste management based on the Life Cycle Approach for Greece shows that there is room for improvement for recycling management in comparison to six other EU countries [

10]. In general, municipal waste may be managed via land filling, recycling, composting, incineration, pyrolysis and thermal treatment for energy recovery, however, all of these processes pose a number of environmental concerns [

11,

12]. MSW contains combustible matter to a significant degree, thus energy recovery by its thermal processing is feasible. Its incineration at high temperature (1450 °C) produces ash that contains mineral matter. This ash can be mixed with the appropriate ingredients for clinker formulation for mortar production. Ash from MSW incineration for cement production has been the core topic for numerous publications and relevant patents; as such, [

13] manufactured durable bricks from the municipal solid waste incinerator’s fine ash and cement, and [

14,

15] produced cement-based mixtures from MSW fly ash and Portland cement at an optimum ratio of ash/cement. As such, residues of municipal waste are commonly incorporated in cement production through co-incineration [

16]. Nevertheless, health and environmental risks arising from the incorporation of various wastes (formation of noxious by-products; see also [

17] or pollutant leaching; see also [

18,

19]) should always be addressed. In the present work, the application of the Greek patent No. 1003333 [

20], for a Zero Waste with Mortar Production (ZWMP) method, with demonstrated feasibility [

21], is examined from an economic point of view for the management of MSW in Northern Greece and hence to other similar prefectures in the European Union. This application, which is characterized by minimal noxious emissions [

21], may aid the reduction of GHG emissions in relation to the current landfilling Greek practice [

22] and may improve the performance of the country in the LCA Characterization factors “Global Warming”, “Marine Eutrophication”, “Terrestrial Eutrophication”, “(non-carcinogenic) Human Toxicity” and “Eco-toxicity”, which is currently low, directly attributed to extensive landfilling [

10]. At the same time, it can produce valuable goods at very competitive prices from waste material.

4. Results and Discussion

The raw materials (including MSW-derived ash) that are needed for daily mortar production are given in

Table 4.

For the production of 500 t/day of mortar, 100 t/day ash is required. Based on that, the ash produced from ZWMP and the quantities of mortar that can be achieved in each region are provided in

Table 5.

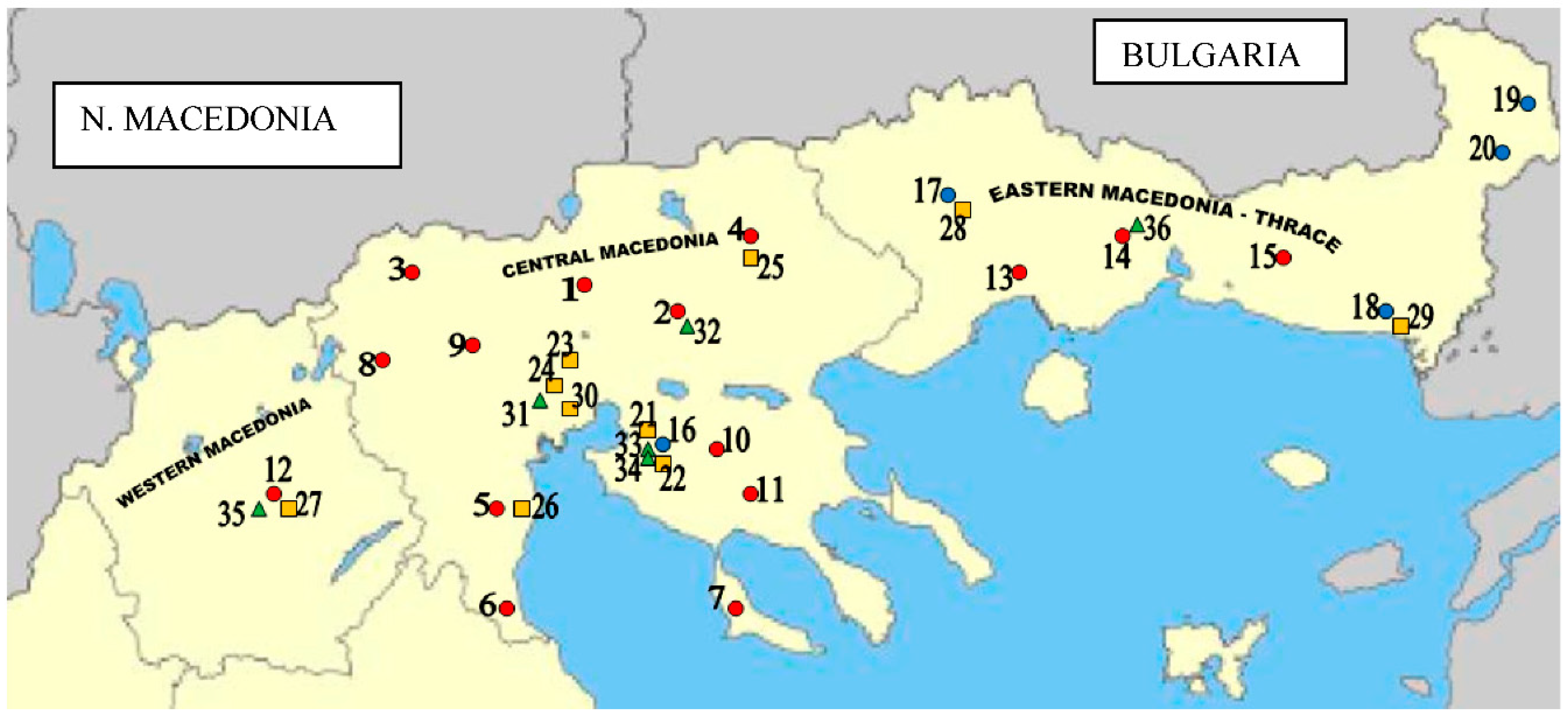

The selected areas for ZWMP plants establishment are depicted in

Figure 1. In Central Macedonia, four plants are envisaged based on the following criteria: One in the proximity of the SL of Mavrorachi, the largest SL in Central Macedonia with a total capacity of 14,900,000 m

3 [

29]. In the aforementioned MSW management plan [

29], it is mentioned that a facility of “mechanical-biological treatment & thermal treatment” (Integrated Facility of Processing and Disposal of Waste, IFPDW), 30 km from the Mavrorachi SL had been granted a positive Preliminary Environmental Impact Assessment under the Greek Law, and a Public Private Partnership (PPP) was sought. However, until 2011, no contractor was awarded. Therefore, this siting was chosen for the first Central Macedonia plant. A second IFPDW is suggested in the municipality of Ag. Antonios that is found 6.5 km southeastern of the rehabilitated WDS of Tagarades. This facility is envisaged to contain a mechanical/biological sorting facility, a biogas and secondary gas power plant, a novel SL for residual waste and a hazardous waste SL. A positive Preliminary Environmental Impact Assessment (PEIA) under the Greek Law for the siting was granted in 2008 and an Environmental Assessment Approval was also granted for the technologies of anaerobic digestion/aerobic biological drying applied in the facility. This site was also chosen for the siting of the second and the third Central Macedonia plant, since a positive PEIA for solid waste management facilities exists. Furthermore, the siting is ideal for the majority of the solid waste produced; all other SL (with the exception of Palaiokastro) have a 100-fold lower capacity than the Mavrorachi facility in Thessaloniki that is going to be partially alleviated by the Agios Antonios IFPDW. The last plant siting has been chosen to be within the industrial estate of Sindos, an area zoned and planned for the purpose of the industrial development of Thessaloniki, which is provided with good transportation access. Regarding the region of Western Macedonia, a siting in the proximity of the SL of Kozani is proposed, since this area is considered seminal in the latest waste management plan and is also able to host additional waste management facilities [

30]. In Eastern Macedonia and Thrace, one plant close to SL of Xanthi is proposed, which is the largest SL of the prefecture (total capacity of 500,000 m

3) [

32]. The sitings have considered the NIMBY syndrome (it is expected to be lessened in sites already enrolled in industrial activities and in MSW management activities and in sites found legislatively fit for MSW management activities). It should be highlighted that public acceptability is quite important in implementing waste management schemes, as shown in similar projects in EU [

38], and the intensity of the opposition to the scheme is usually dependent on the concern level of the pre-existing general environment [

39]. As such, public concern in these sitings is expected to be low.

The calculated mortar production capacities of the five plants of Northern Greece are given in

Table 6.

The investment cost of the ZWMP plants of Sindos, Mavrorachi, Kozani and Xanthi are given in

Table 7, and the corresponding operating cost per year in

Table 8.

As such, the total capital investment cost per plant in € is 16,582,586, 15,531,077, 30,589,676, 8,042,265 and 17,174,633 for the six plants of Sindos, Mavrorachi, Ag. Antonios I and II, Kozani and Xanthi, respectively.

The cost investment for all the six ZWMP plants of the three regions of North Greece (Central Macedonia, Western Macedonia, Eastern Macedonia and Thrace) is 87,920,237€. Usually, EU funding supports the construction of such plants covering a part of the investment cost.

The annual total operating cost per plant (

Table 8) was calculated to be 6,698,414, 6,569,957, 13,081,751, 3,274,835 and 7,731,530€ for the six plants of Sindos, Mavrorachi, Ag. Antonios I and II, Kozani and Xanthi, respectively. This estimation takes into account the cost of the ingredients, as well as maintenance, fuel, packaging, working personnel and administration personnel cost.

The overall annual operating cost for all the six ZWMP plants of the three regions of North Greece (Central Macedonia, Western Macedonia, Eastern Macedonia and Thrace is 37,356,487€. Based on the above data, the total cost of production for the MSW-containing mortar was estimated to be roughly 29–30 €/t. Considering an ex-works mortar wholesale price of 55 €/t, an annual gross income before taxes of 30,480,457€ and net profit/y of approximately 21,641,132€ for all the six ZWMP plants of the three regions of North Greece (Central Macedonia, Western Macedonia, Eastern Macedonia and Thrace) was estimated.

The results derived from this study suggest that the management of MSW of North Greece through the ZWMP method is profitable while, in general, this method is considered environmentally friendly [

21].

Due to the economic crisis in Greece, reconstruction and construction works in general have been negatively impacted; however, there is still room for construction opportunities and especially renovations. Nevertheless, a critical shift in the prioritization of construction works is slowly taking place; as depicted by relevant research, the main forces of shift towards sustainable construction in Greece were energy saving and resources utilization, stricter land use regulations and efficient urban planning policies [

40]. As such, a circular economy scheme that utilizes waste from one industry as initial material for another falls well within the concept of sustainable construction works.

The overall production of the six ZWMP plants in North Greece was calculated to be 3524 t/d. This is above the estimated today’s demand of Northern Greece. Nevertheless, since today’s price of such products in Greece ranges between 90 to above 120 €/t, [

41] the ex-works wholesale price of 55 €/t is highly conservative and extremely attractive not only for Greece but also for many other countries. The price of 55 €/t is highly competitive for the East Mediterranean area and Middle East markets. Various ports (Thessaloniki, Kavala and Alexandroupoli) are relatively close to the plants and this may aid access to international markets. Furthermore, the estimated production cost of the product in the proposed plant units is competitive in relation to other mortar-producing plants in Greece.

It should be also taken into account that the full operational cost of a sanitary landfill in Greece is approximately 45 €/t [

42]. High deviation was noted, but the average value was much higher than the EU estimates for Greek SL. Furthermore, no depreciation of the investment costs happens for existing landfills operating beyond their design lives. This value is above the product cost per ton of a ZWMP plant. Furthermore, since each individual plant is profitable separately, priority can be given to the construction of the most promising ZWMP plants, which will be relatively close to big cities, harbors and railway networks and close to limestone deposits, which exist in abundance in various sites in Greece and the Mediterranean area.

Finally, although the results were based on data focusing on Greece, the ZWMP approach should be considered in similar cases for other countries, especially in the Mediterranean Basin, Africa and Asia and elsewhere, where financially appropriate (mortar cost, availability and cost or raw materials, personnel cost etc.).

SL

SL SL

SL WDS

WDS  RSC

RSC ZWMP Plants

ZWMP Plants