Evaluating the Potential of Renewable Energy Sources in a Full-Scale Upflow Anaerobic Sludge Blanket Reactor Treating Municipal Wastewater in Ghana

Abstract

:1. Introduction

2. Materials and Methods

2.1. Description of the Wastewater Treatment Plant Used in the Study

2.2. Biogas Quantification and Characterisation

2.3. Excess Sludge Quantification and Characterisation

2.3.1. Sludge Quantification

2.3.2. Sludge Characterisation Technique

- Proximate Analysis

- Ultimate Analysis

- Calorific Value (CV) Analysis

2.4. Evaluation of Energy Balance at the Mudor WWTP

2.4.1. Energy Demand at the Mudor WWTP

2.4.2. Energy Recovery Potential of the Mudor WWTP Biogas and Sludge By-Products

3. Results and Discussion

3.1. Wastewater Characteristics and Biogas Energy Recovery Potential

Unitary Relationships between CH4, Biogas and Energy Generation for the UASB Reactors

3.2. Characteristics of Sewage Sludge for Energy Recovery Potential Evaluation

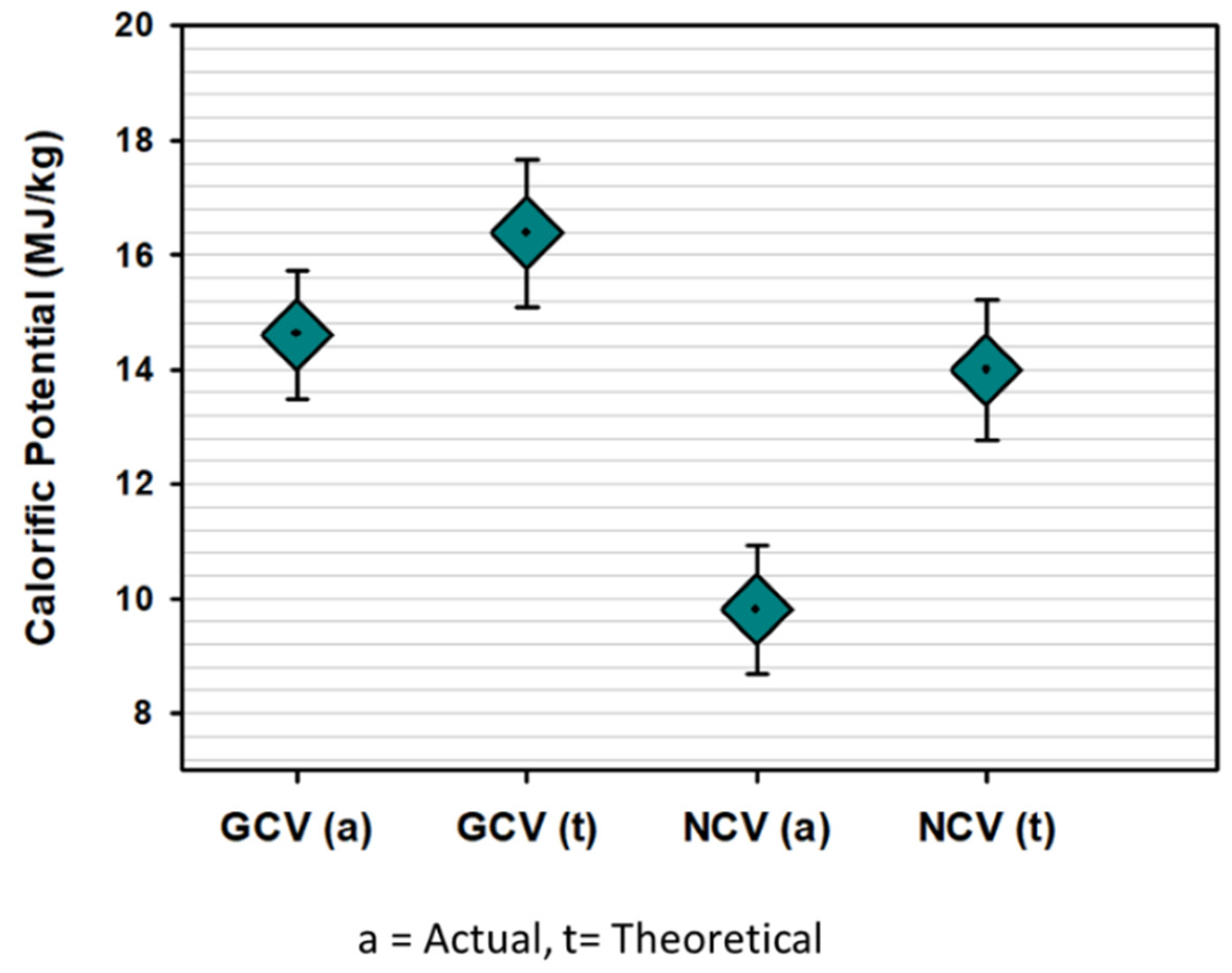

3.3. Sewage Sludge Energy Generation Potential

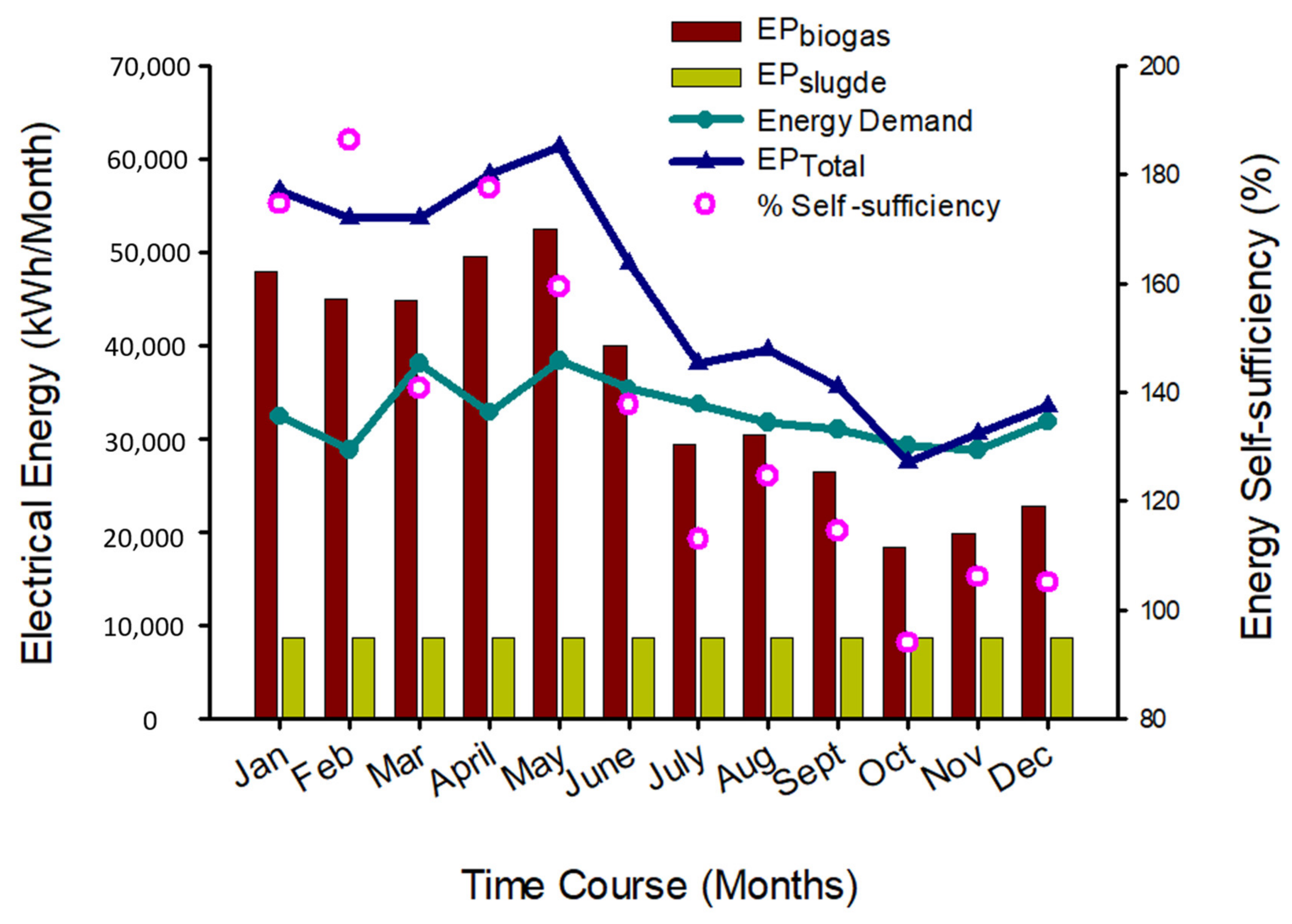

3.4. Actual Energy Demand of the Mudor WWTP

3.5. Energy Self-Sufficiency of the Mudor WWTP through Biogas and Sludge Energy Recovery

3.6. Perspectives on Energy Recovery from Full-Scale WWTPs in Ghana

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- MLGRDE. Environmental Sanitation Policy—Ministry of Local Government and Rural Development; Ministry of Local Government and Rural Development: Accra, Ghana, 2010. [Google Scholar]

- Lettinga, G.; van Velsen, A.F.M.; Hobma, S.W.; de Zeeuw, W.; Klapwijk, A. Use of the upflow sludge blanket (USB) reactor concept for biological wastewater treatment, especially for anaerobic treatment. Biotechnol. Bioeng. 1980, 22, 699–734. [Google Scholar] [CrossRef]

- Halalsheh, M.; Sawajneh, Z.; Zu’bi, M.; Zeeman, G.; Lier, J.; Fayyad, M.; Lettinga, G. Treatment of strong domestic sewage in a 96 m3 UASB reactor operated at ambient temperatures: Two-stage versus single-stage reactor. Bioresour. Technol. 2005, 96, 577–585. [Google Scholar] [CrossRef] [PubMed]

- Chernicharo, C.A.L.; van Lier, J.B.; Noyola, A.; Bressani Ribeiro, T. Anaerobic sewage treatment: State of the art, constraints and challenges. Rev. Environ. Sci. Biotechnol. 2015, 14, 649–679. [Google Scholar] [CrossRef]

- Passos, F.; Bressani-Ribeiro, T.; Rezende, S.; Chernicharo, C.A.L. Potential applications of biogas produced in small-scale UASB-based sewage treatment plants in Brazil. Energies 2020, 13, 12. [Google Scholar] [CrossRef]

- Lopes, L.S.; Rosa, A.P.; Marco, J.S.; Possetti, G.R.; Mesquita, T.C.R. Energy potential of biogas and sludge from UASB reactors in the State of Paraná, Brazil. Rev. Ambient. Agua 2019, 15, 8. [Google Scholar] [CrossRef] [Green Version]

- UN Wastewater Report, Wastewater—The Untapped Resource (The United Nations World Water Development Report). 2017. Available online: https://www.unep.org/resources/publication/2017-un-world-water-development-report-wastewater-untapped-resource (accessed on 15 September 2022).

- Gu, Y.; Li, Y.; Li, X.; Luo, P.; Wang, H.; Robinson, Z.P.; Wang, X.; Wu, J.; Li, F. The feasibility and challenges of energy self-sufficient wastewater treatment plants. Appl. Energy 2017, 204, 1463–1475. [Google Scholar] [CrossRef] [Green Version]

- Rosa, A.P.; Conesa, J.A.; Fullana, A.; Melo, G.C.B.; Borges, J.M.; Chernicharo, C.A.L. Energy potential and alternative usages of biogas and sludge from UASB reactors: Case study of the Laboreaux wastewater treatment plant. Water Sci. Technol. 2016, 73, 1680–1690. [Google Scholar] [CrossRef]

- Noyola, A.; Morgan-Sagastume, J.M.; López-Hernández, J.E. Treatment of biogas produced in anaerobic reactors for domestic wastewater: Odor control and energy/resource recovery. Rev. Environ. Sci. Biotechnol. 2006, 5, 93–114. [Google Scholar] [CrossRef]

- Rodriguez, D.J.; Serrano, H.A.; Delgado, A.; Nolasco, D.; Saltiel, G. From Waste to Resource Recovery: Shifting Paradigms for Smarter Wastewater Interventions in Latin America and the Caribbean; World Bank: Washington, DC, USA, 2020. [Google Scholar]

- UNEP. The Heat is on—A World of Climate Promises not Yet Delivered. Emissions Gap Report. 2021. Available online: https://www.unep.org/resources/emissions-gap-report-2021 (accessed on 10 October 2022).

- Griggs, D.; Nilsson, M.; Stevance, A.; McCollum, D. A Guide to SDG Interactions: From Science to Implementation; International Council for Science: Paris, France, 2017; Available online: https://pure.iiasa.ac.at/id/eprint/14591/ (accessed on 6 September 2022).

- Quaschning, V.V. Renewable Energy and Climate Change; John Wiley and Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Rosa, A.P.; Chernicharo, C.A.L.; Lobato, L.C.S.; Silva, R.V.; Padilha, R.F.; Borges, J.M. Assessing the potential of renewable energy sources (biogas and sludge) in a full-scale UASB-based treatment plant. Renew. Energy 2018, 124, 21–26. [Google Scholar] [CrossRef]

- Patinvoh, R.J.; Taherzadeh, M.J. Challenges of biogas implementation in developing countries. Curr. Opin. Environ. Sci. Health 2019, 12, 30–37. [Google Scholar] [CrossRef]

- Lisowyj, M.; Wright, M.M. A review of biogas and an assessment of its economic impact and future role as a renewable energy source. Rev. Chem. Eng. 2020, 36, 401–421. [Google Scholar] [CrossRef]

- Sagoe, G.; Danquah, F.S.; Amofa-Sarkodie, E.S.; Appiah-Effah, E.; Ekumah, E.; Mensah, E.K.; Karikari, K.S. GIS-aided optimisation of faecal sludge management in developing countries: The case of the Greater Accra Metropolitan Area, Ghana. Heliyon 2019, 5, 13. [Google Scholar] [CrossRef] [Green Version]

- Climate and Average Weather Year Round in Accra. Available online: https://weatherspark.com/y/42322/Average-Weather-in-Accra-Ghana-Year-Round (accessed on 29 March 2022).

- ASIP Accra Sewerage Improvement Project (ASIP)—Appraisal Report; Office of the Accra Sewerage Improvement Project: Accra, Ghana, 2005.

- GSS. Population and Housing Census: Provisional Results. 2021. Available online: https://census2021.statsghana.gov.gh/ (accessed on 13 April 2022).

- Ahmed, I.; Ofori-Amanfo, D.; Awuah, E.; Cobbold, F. Performance Assessment of the Rehabilitated Mudor Sewage Treatment Plant at James Town Accra-Ghana. J. Water Resour. Prot. 2018, 10, 725–739. [Google Scholar] [CrossRef] [Green Version]

- Arthur, P.M.A.; Konaté, Y.; Sawadogo, B.; Sagoe, G.; Dwumfour-Asare, B.; Ahmed, I.; Williams, M.N. V Performance evaluation of a full-scale up flow anaerobic sludge blanket reactor coupled with trickling fi lters for municipal wastewater treatment in a developing country. Heliyon 2022, 8, 13. [Google Scholar] [CrossRef]

- Rosa, A.P.; Lobato, L.C.S.; Chernicharo, C.A.L.; Martins, D.C.R.B.; Maciel, F.M.; Borges, J.M. Improving performance and operational control of UASB reactors via proper sludge and scum discharge routines. Water Pract. Technol. 2012, 7, wpt2012046. [Google Scholar] [CrossRef]

- APHA, American Public Health Association. Standard Methods for the Examination of Water and Wastewater, 23rd ed.; Baird, R.B., Eaton, A.D., Rice, E.W., Eds.; American Public Health Association: Washington, DC, USA, 2017. [Google Scholar] [CrossRef]

- Singh, D.; Chhonkar, P.K.; Pande, R.N. Soil Testing in Soil, Plant, Water Analysis, Methods Manual AIRA; ICAR: New Delhi, India, 1999. [Google Scholar]

- Mclean, E.O. Aluminium in Methods of Soil Analysis; Black, C.A., Ed.; Agronomy No. 9, Part 2; America Science Agronomy: Madison, WI, USA, 1965; pp. 978–998. [Google Scholar]

- Bremner, J.M.; Mulvaney, C.S. Nitrogen-total. In Methods of Soil Analysis, Part 2, Chemical and Microbiological Properties, 2nd ed.; Page, A.L., Miller, R.H., Keeney, D.R., Eds.; American Society of Agronomy: Madison, WI, USA, 1982; pp. 595–624. [Google Scholar]

- Nelson, D.W.; Sommers, L.W. Total carbon and organic matter. In Methods of Soil Analysis Part 2, 2nd ed.; No.9; Page, A.L., Miller, R.H., Keeney, D.R., Eds.; American Society of Agronomy; Soil Science of America: Madison, WI, USA, 1982. [Google Scholar]

- Petrovič, A.; Vohl, S.; Cenčič Predikaka, T.; Bedoić, R.; Simonič, M.; Ban, I.; Čuček, L. Pyrolysis of solid digestate from sewage sludge and lignocellulosic biomass: Kinetic and thermodynamic analysis, characterization of biochar. Sustainability 2021, 13, 9642. [Google Scholar] [CrossRef]

- ASTM E711-87; Standard Test Method for Gross Calorific Value of Refuse-derived Fuel by the Bomb Calorimeter 1987 (Withdrawn 2004). ASTM International: West Conshohocken, PA, USA, 2004. Available online: www.astm.org (accessed on 5 November 2022).

- Galhano dos Santos, R.; Bordado, J.M. Design of simplified models for the estimation of higher heating value of refused derived fuels. Fuel 2018, 212, 212. [Google Scholar] [CrossRef]

- Souza, C.L.; Chernicharo, C.A.L.; Aquino, S.F. Quantification of dissolved methane in UASB reactors treating domestic wastewater under different operating conditions. Water Sci. Technol. 2011, 64, 2259–2264. [Google Scholar] [CrossRef] [Green Version]

- Lobato, L.C.S.; Chernicharo, C.A.L.; Souza, C.L. Estimates of methane loss and energy recovery potential in anaerobic reactors treating domestic wastewater. Water Sci. Technol. 2012, 66, 2745–2753. [Google Scholar] [CrossRef]

- Syed-Hassan, S.S.A.; Wang, Y.; Hu, S.; Su, S.; Xiang, J. Thermochemical processing of sewage sludge to energy and fuel: Fundamentals, challenges and considerations. Renew. Sustain. Energy Rev. 2017, 80, 888–913. [Google Scholar] [CrossRef]

- Chiang, K.Y.; Chien, K.L.; Lu, C.H. Characterization and comparison of biomass produced from various sources: Suggestions for selection of pretreatment technologies in biomass-to-energy. Appl. Energy 2012, 100, 164–171. [Google Scholar] [CrossRef]

- Tic, W.J.; Guziałowska-Tic, J.; Pawlak-Kruczek, H.; Wóznikowski, E.; Zadorozny, A.; Niedźwiecki, Ł.; Wnukowski, M.; Krochmalny, K.; Czerep, M.; Ostrycharczyk, M.; et al. Novel concept of an installation for sustainable thermal utilization of sewage sludge. Energies 2018, 11, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Chan, W.P.; Wang, J.Y. Comprehensive characterisation of sewage sludge for thermochemical conversion processes—Based on Singapore survey. Waste Manag. 2016, 54, 131–142. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.; Phuleria, H.C.; Chandel, M.K. Estimation of energy recovery potential of sewage sludge in India: Waste to watt approach. J. Clean. Prod. 2020, 276, 122538. [Google Scholar] [CrossRef]

- Vamvuka, D.; Sfakiotakis, S.; Saxioni, S. Evaluation of urban wastes as promising co-fuels for energy production—A TG/MS study. Fuel 2015, 147, 170–183. [Google Scholar] [CrossRef]

- García, G.; Arauzo, J.; Gonzalo, A.; Sánchez, J.L.; Ábrego, J. Influence of feedstock composition in fluidised bed co-gasification of mixtures of lignite, bituminous coal and sewage sludge. Chem. Eng. J. 2013, 222, 345–352. [Google Scholar] [CrossRef]

- Gezer Gorgec, A.; Insel, G.; Yağci, N.; Doğru, M.; Erdinçler, A.; Sanin, D.; Filibeli, A.; Keskinler, B.; Çokgör, E.U. Comparison of energy efficiencies for advanced anaerobic digestion, incineration, and gasification processes in municipal sludge management. J. Residuals Sci. Technol. 2016, 13, 57–64. [Google Scholar] [CrossRef] [Green Version]

- Qi, Y. A National Survey of Biogas Use at Wastewater Treatment Plants in the United States: The Results; Water Environment Federation: Alexandria, VA, USA, 2013. [Google Scholar]

- Bachmann, N. Sustainable Biogas Production in Municipal Wastewater Treatment Plants; IEA Bioenergy: Massongex, Switzerland, 2015; Volume 20. [Google Scholar]

- Mehariya, S.; Patel, A.K.; Obulisamy, P.K.; Punniyakotti, E.; Wong, J.W.C. Co-digestion of food waste and sewage sludge for methane production: Current status and perspective. Bioresour. Technol. 2018, 265, 519–531. [Google Scholar] [CrossRef]

- Vinardell, S.; Astals, S.; Koch, K.; Mata-Alvarez, J.; Dosta, J. Co-digestion of sewage sludge and food waste in a wastewater treatment plant based on mainstream anaerobic membrane bioreactor technology: A techno-economic evaluation. Bioresour. Technol. 2021, 330, 124978. [Google Scholar] [CrossRef]

- Präger, F.; Paczkowski, S.; Sailer, G.; Derkyi, N.S.A.; Pelz, S. Biomass sources for a sustainable energy supply in Ghana—A case study for Sunyani. Renew. Sustain. Energy Rev. 2019, 107, 413–424. [Google Scholar] [CrossRef]

- Arthur, R.; Baidoo, M.F.; Osei, G.; Boamah, L.; Kwofie, S. Evaluation of potential feedstocks for sustainable biogas production in Ghana: Quantification, energy generation, and CO2 abatement. Cogent Environ. Sci. 2020, 6, 1868162. [Google Scholar] [CrossRef]

- Metcalf & Eddy. Wastewater Engineering, Treatment and Resource Recovery, 5th ed.; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Vaccari, M.; Foladori, P.; Nembrini, S.; Vitali, F. Benchmarking of energy consumption in municipal wastewater treatment plants—A survey of over 200 plants in Italy. Water Sci. Technol. 2018, 77, 2242–2252. [Google Scholar] [CrossRef]

- Maktabifard, M.; Zaborowska, E.; Makinia, J. Achieving Energy Neutrality in Wastewater Treatment Plants through Energy Savings and Enhancing Renewable Energy Production; Springer: Heidelberg, The Netherlands, 2018; Volume 17, ISBN 1115701894. [Google Scholar]

- Gu, Y.; Li, Y.; Li, X.; Luo, P.; Wang, H.; Wang, X.; Wu, J.; Li, F. Energy Self-sufficient Wastewater Treatment Plants: Feasibilities and Challenges. Energy Procedia 2017, 105, 3741–3751. [Google Scholar] [CrossRef]

- Chae, K.J.; Kang, J. Estimating the energy independence of a municipal wastewater treatment plant incorporating green energy resources. Energy Convers. Manag. 2013, 75, 664–672. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Y.; Keller, A.A.; Li, X.; Feng, S.; Dong, Y.n.; Li, F. Comparative analysis of energy intensity and carbon emissions in wastewater treatment in USA, Germany, China and South Africa. Appl. Energy 2016, 184, 873–881. [Google Scholar] [CrossRef] [Green Version]

- Mamais, D.; Noutsopoulos, C.; Dimopoulou, A.; Stasinakis, A.; Lekkas, T.D. Wastewater treatment process impact on energy savings and greenhouse gas emissions. Water Sci. Technol. 2015, 71, 303–308. [Google Scholar] [CrossRef]

- Ghana Water Company to Cut Water Supply to Parts of Accra from September 13. Pulse Ghana. 2021. Available online: https://www.pulse.com.gh/news/local/ghana-water-company-to-cut-water-supply-to-parts-of-accra-from-september-13/zmf7hb7 (accessed on 5 December 2022).

- Guo, Z.; Sun, Y.; Pan, S.-Y.; Chiang, P.-C. Integration of Green Energy and Advanced Energy-Efficient Technologies for Municipal Wastewater Treatment Plants. Int. J. Environ. Res. Public Health 2019, 16, 1282. [Google Scholar] [CrossRef] [Green Version]

- Lettinga, G. The anaerobic treatment approach towards a more sustainable and robust environmental protection. Water Sci. Technol. 2005, 52, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Centeno-Mora, E.; Fonseca, P.R.; Andreão, W.L.; Brandt, E.M.F.; de Souza, C.L.; de Lemos Chernicharo, C. Mitigation of diffuse CH4 and H2S emissions from the liquid phase of UASB-based sewage treatment plants: Challenges, techniques, and perspectives. Environ. Sci. Pollut. Res. 2020, 27, 35979–35992. [Google Scholar] [CrossRef]

| Characteristics | UASB Reactors | Trickling Filters | Secondary Clarifiers |

|---|---|---|---|

| Population equivalent (Inhab) | 100,000 | ||

| Flow (m3/h) | 180.5 | 90.2 | - |

| Hydraulic retention time (h) | 47.6 | - | 18.1 |

| Organic loading rate (kgBOD5/m3/d) | 0.81 | 0.19 | - |

| Hydraulic loading rate (m3/m2//h) | - | 0.19 | - |

| Number of Units | 6 | 3 * | 2 |

| Shape | Modular | Circular | Circular |

| Dimension of each unit (m) | 20 × 10 | D = 24.5 | D = 24.5 |

| Depth of each unit (m) | 6.5 | 3.0 | 4.2 |

| Volume of each unit (m3) | 1300.0 | 1414.0 | 1540.0 |

| Descriptive Statistics | Raw Sewage (m3/d) | CODinf (mg/L) | CODrem (kg/d) | Biogas Flow (Nm3/d) | CH4 (%) | N2 (%) | CO2 (%) | O2 (%) |

|---|---|---|---|---|---|---|---|---|

| Maximum | 6054 | 8150 | 34,194 | 1809 | 76.5 | 28.2 | 9.1 | 14.6 |

| Minimum | 1572 | 450 | 889 | 100 | 54.0 | 19.9 | 3.2 | 1.4 |

| Average | 4096 | 2007 | 6303 | 611 | 65.0 | 24.6 | 4.7 | 5.7 |

| SD * | 837 | 1061 | 4826 | 275 | 9.0 | 3.1 | 2.2 | 4.6 |

| Unit Relationships | Units | Current Study | Simulated Values * |

|---|---|---|---|

| CH4 volume per volume of sewage | m3CH4/m3 sewage | 0.09 | 0.07–0.14 |

| Specific CH4 yield | m3CH4/kgCODremoved | 0.10 | 0.11–0.19 |

| Biogas volume per volume of sewage | m3biogas/m3 sewage | 0.17 | 0.06–0.10 |

| Specific biogas yield | m3biogas/kgCODremoved | 0.14 | 0.16–0.24 |

| Energy production potential per kg of COD removed | MJ/kgCODremoved | 2.19 | 4.10–7.00 |

| Energy production potential per volume of sewage | MJ/m3 sewage | 3.37 | 1.50–2.90 |

| Energy production potential per volume of biogas produced | MJ/m3 biogas | 20.17 | 25.1–28.7 |

| Parameter | Current Study | Reported Ranges in the Literature | References | |

|---|---|---|---|---|

| Range | Average | |||

| Proximate Analysis | ||||

| Moisture content (wt %) | 63.00–82.00 | 75.00 ± 2.60 | 73.40–86.40 | [38] |

| Volatile matter (wt %) a | 50.50–80.90 | 62.90 ± 5.50 | 21.70–82.30 | [35,37] |

| Ash content (wt %) a | 19.00–49.50 | 36.60 ± 5.10 | 10.80–76.80 | [35] |

| Fixed carbon (wt %) a | 2.40–5.20 | 3.10 ± 1.20 | 1.81–21.80 | [35] |

| Ultimate Analysis | ||||

| Carbon (wt %) | 22.30–32.80 | 28.5 ± 5.27 | 32.1–69.3 | [35,37] |

| Hydrogen (wt %) | 11.02–12.69 | 11.8 ± 0.64 | 3.85–8.60 | [35,37] |

| Nitrogen (wt %) | 2.68–3.82 | 3.33 ± 0.33 | 2.25–9.08 | [35] |

| Sulphur (wt %) | 0.31–1.56 | 1.14 ± 0.32 | 0.60–2.05 | [35] |

| Oxygen (wt %) | 15.9–36.20 | 27.50 ± 6.50 | 18.20–56.30 | [35,37] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arthur, P.M.A.; Konaté, Y.; Sawadogo, B.; Sagoe, G.; Dwumfour-Asare, B.; Ahmed, I.; Bayitse, R.; Ampomah-Benefo, K. Evaluating the Potential of Renewable Energy Sources in a Full-Scale Upflow Anaerobic Sludge Blanket Reactor Treating Municipal Wastewater in Ghana. Sustainability 2023, 15, 3743. https://doi.org/10.3390/su15043743

Arthur PMA, Konaté Y, Sawadogo B, Sagoe G, Dwumfour-Asare B, Ahmed I, Bayitse R, Ampomah-Benefo K. Evaluating the Potential of Renewable Energy Sources in a Full-Scale Upflow Anaerobic Sludge Blanket Reactor Treating Municipal Wastewater in Ghana. Sustainability. 2023; 15(4):3743. https://doi.org/10.3390/su15043743

Chicago/Turabian StyleArthur, Philomina Mamley Adantey, Yacouba Konaté, Boukary Sawadogo, Gideon Sagoe, Bismark Dwumfour-Asare, Issahaku Ahmed, Richard Bayitse, and Kofi Ampomah-Benefo. 2023. "Evaluating the Potential of Renewable Energy Sources in a Full-Scale Upflow Anaerobic Sludge Blanket Reactor Treating Municipal Wastewater in Ghana" Sustainability 15, no. 4: 3743. https://doi.org/10.3390/su15043743

APA StyleArthur, P. M. A., Konaté, Y., Sawadogo, B., Sagoe, G., Dwumfour-Asare, B., Ahmed, I., Bayitse, R., & Ampomah-Benefo, K. (2023). Evaluating the Potential of Renewable Energy Sources in a Full-Scale Upflow Anaerobic Sludge Blanket Reactor Treating Municipal Wastewater in Ghana. Sustainability, 15(4), 3743. https://doi.org/10.3390/su15043743