Comparative Study on Reliability and Advanced Numerical Analysis of BGA Subjected to Product-Level Drop Impact Test for Portable Electronics

Abstract

:1. Introduction

2. Experiment

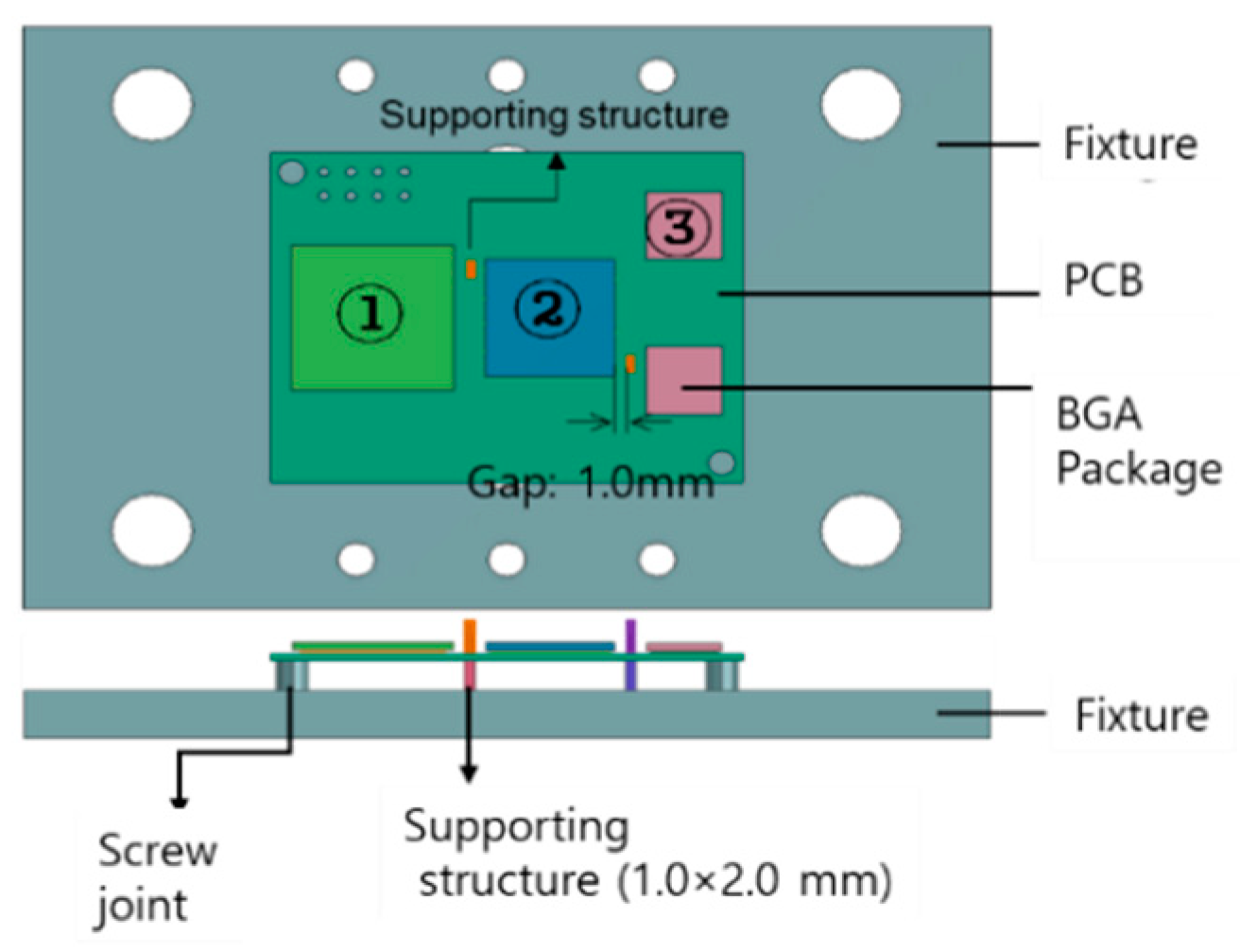

2.1. Test Setup

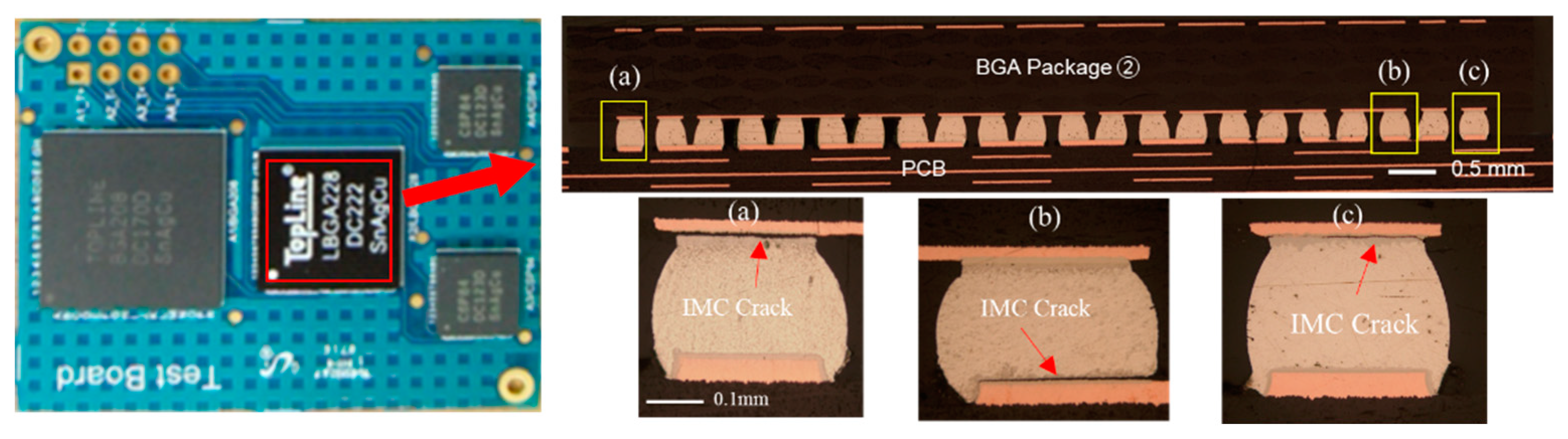

2.2. Test Results

3. FEA Method

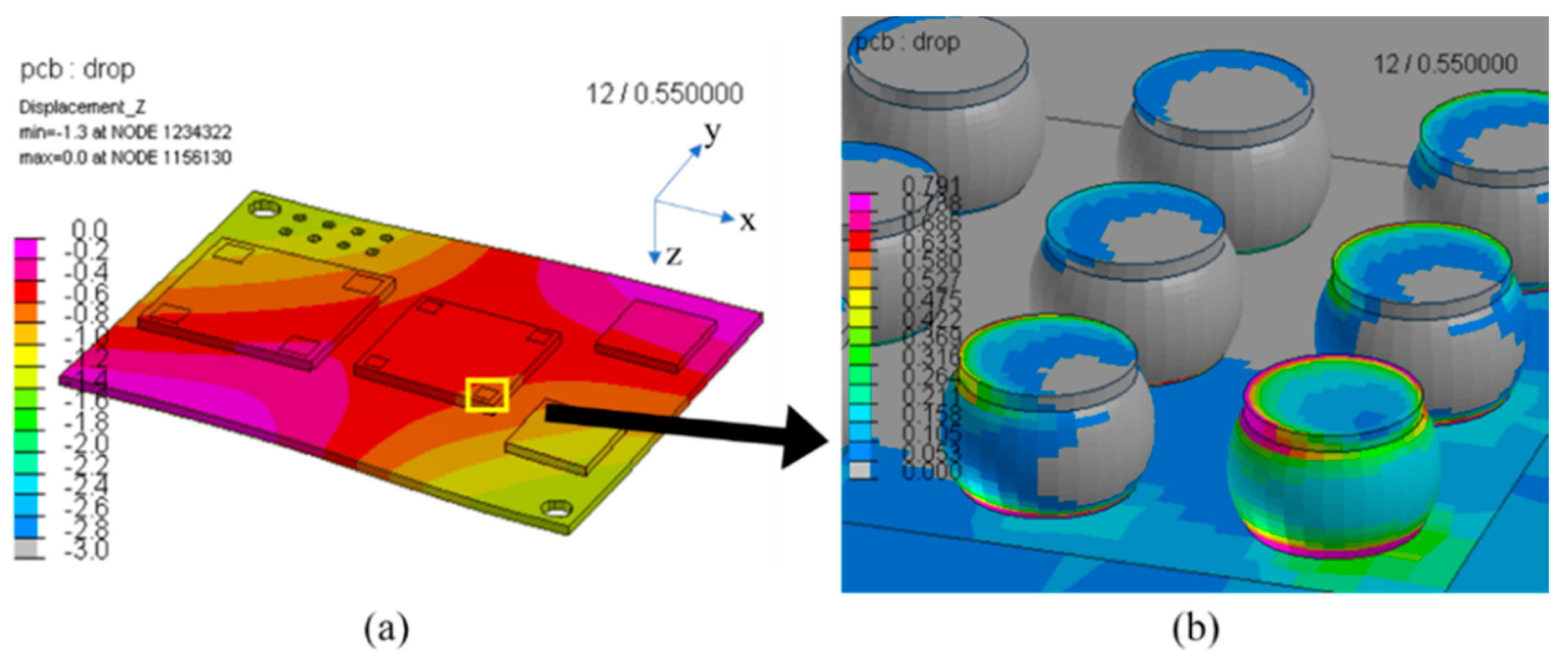

3.1. Validation of the Drop FEA Model

3.2. Beam Model vs. Solid Model

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhou, C.Y.; Yu, T.X.; Lee, R.S. Drop/impact tests and analysis of typical portable electronic devices. Int. J. Mech. Sci. 2008, 50, 905–917. [Google Scholar] [CrossRef]

- Xu, Y.; Li, M.; Li, C. The Research of Test System of Notebook Use Reliability. Adv. Mater. Res. 2013, 684, 630–633. [Google Scholar] [CrossRef]

- Yau, Y.H.; Hua, S.N. A Comprehensive Review of Drop Impact Modeling on Portable Electronic Devices. Appl. Mech. Rev. 2011, 64, 020803. [Google Scholar] [CrossRef] [Green Version]

- Shnawah, D.A.; Sabri, M.F.M.; Badruddin, I.A. A review on thermal cycling and drop impact reliability of SAC solder joint in portable electronic products. Microelectron. Reliab. 2012, 52, 90–99. [Google Scholar] [CrossRef]

- Singh, B.; Menezes, G.; McCann, S.; Jayaram, V.; Ray, U.; Sundaram, V.; Pulugurtha, R.; Smet, V.; Tummala, R. Board-Level Thermal Cycling and Drop-Test Reliability of Large, Ultrathin Glass BGA Packages for Smart Mobile Applications, IEEE Transactions on Components. Packag. Manuf. Technol. 2017, 7, 726–733. [Google Scholar] [CrossRef]

- Gu, J.; Lei, Y.; Lin, J.; Fu, H.; Wu, Z. The Failure Models of Lead Free Sn-3.0Ag-0.5Cu Solder Joint Reliability Under Low-G and High-G Drop Impact. J. Electron. Mater. 2017, 46, 1396–1404. [Google Scholar] [CrossRef]

- Yu, D.; Kwak, J.; Park, S.; Chung, S.; Yoon, J. Effect of Shield-Can on Dynamic Response of Board-Level Assembly. J. Electron. Packag. 2012, 134, 031010. [Google Scholar] [CrossRef] [Green Version]

- Mishiro, K.; Ishikawa, S.; Abe, M.; Kumai, T.; Higashiguchi, Y.; Tsubone, K.I. Effect of the Drop Impact on BGA/CSP Package Reliability. Microelectron. Reliab. 2002, 42, 77–82. [Google Scholar] [CrossRef]

- Farris, A.; Pan, J.; Liddicoat, A.; Toleno, B.J.; Maslyk, D.; Shangguan, D.; Bath, J.; Willie, D.; Geiger, D.A. Drop Test Reliability of Lead-free Chip Scale Packages. In Proceedings of the 58th Electronic Components and Technology Conference, Lake Buena Vista, FL, USA, 27–30 May 2008; pp. 1173–1180. [Google Scholar]

- An, T.; Qin, F. Effects of the intermetallic compound microstructure on the tensile behavior of Sn3.0Ag0.5Cu/Cu solder joint under various strain rates. Microelectron. Reliab. 2014, 54, 932–938. [Google Scholar] [CrossRef]

- Jiang, N.; Zhang, L.; Liu, Z.; Sun, L.; Long, W.; He, P.; Xiong, M.; Zhao, M. Reliability issues of lead-free solder joints in electronic devices. Sci. Technol. Adv. Mater. 2019, 20, 876–901. [Google Scholar] [CrossRef] [Green Version]

- Shao, J.; Zhang, H.; Chen, B. Experimental Study on the Reliability of PBGA Electronic Packaging under Shock Loading. Electronics 2019, 8, 279. [Google Scholar] [CrossRef] [Green Version]

- Wu, M.L.; Lan, J.S. Reliability and failure analysis of SAC 105 and SAC 1205N lead-free solder alloys during drop test events. Microelectron. Reliab. 2018, 80, 213–222. [Google Scholar] [CrossRef]

- Xu, Z.J.; Jiang, T.; Song, F.B.; Lo, J.C.C.; Lee, S.W.R. Modeling of Board Level Solder Joint Reliability under Mechanical Drop Test with the Consideration of Plastic Strain Hardening of Lead-free Solder. In Components, Packaging, and Manufacturing Technology Symposium, Japan; IEEE: Piscataway, NJ, USA, 2010; pp. 1–4. [Google Scholar]

- Zhu, L.; Marcinkiewicz, W. Drop Impact Reliability Analysis of CSP Packages at Board and Product Levels through Modeling Approaches. IEEE Trans. Compon. Packag. Technol. 2005, 28, 449–456. [Google Scholar]

- Tee, T.Y.; Ng, H.S.; Lim, C.T.; Pek, E.; Zhong, Z. Drop test and Impact life prediction model for QFN packages. J. SMT 2003, 16, 31–39. [Google Scholar]

- Tee, T.Y.; Ng, H.S.; Lim, C.T.; Pek, E.; Zhong, Z. Impact Life prediction modeling of TFBGA packages under board level drop test. Microelectron. Reliab. 2004, 44, 1131–1142. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Park, S. Elasto-plastic behavior of actual SAC solder joints for drop test modeling. Microelectron. Reliab. 2011, 51, 2126–2129. [Google Scholar] [CrossRef]

- JEDEC. Board Level Drop Test Methods of Components for Handheld Electronic Products, JESD22-B111a; JEDEC: Arlington, VA, USA, 2016. [Google Scholar]

- Park, S.; Shah, C.; Kwak, J.B.; Jang, C.S.; Chung, S.W.; Pitarresi, J.M. Measurement of Transient Dynamic Response of Circuit Boards of a Handheld Device During Drop Using 3D Digital Image Correlation. J. Electron. Packag. 2008, 130, 044502. [Google Scholar] [CrossRef]

- Wang, G.Z.; Cheng, Z.N.; Becker, K.; Wilde, J. Applying Anand Model to Represent the Viscoplastic Deformation Behavior of Solder Alloys. J. Electron. Packag. 2001, 123, 247–253. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z. Thermo-fatigue life evaluation of SnAgCu solder joints in flip chip assemblies. J. Mater. Process. Technol. 2007, 183, 6–12. [Google Scholar] [CrossRef]

- Amalu, E.H.; Ekere, N.N. High temperature reliability of lead-free solder joints in a flip chip assembly. J. Mater. Process. Technol. 2012, 212, 471–483. [Google Scholar] [CrossRef]

- Amalu, E.H.; Ekere, N.N. Modelling evaluation of Garofalo-Arrhenius creep relation for lead-free solder joints in surface mount electronic component assemblies. J. Manuf. Syst. 2016, 39, 9–23. [Google Scholar] [CrossRef]

- Kang, J.S. Parametric study of warpage in PBGA packages. Int. J. Adv. Manuf. Technol. 2020, 107, 4213–4219. [Google Scholar] [CrossRef]

- Iqbal, N.; Xue, P.; Wang, B.; Li, Y. On the high strain rate behavior of 63-37 Sn-Pb eutectic solders with temperature effects. Int. J. Impact Eng. 2014, 74, 126–131. [Google Scholar] [CrossRef] [Green Version]

| BGA Package | Outer Size (mm) | Ball Diameter (mm) | Ball Pitch (mm) | Number of Balls (ea) | Array Type |

|---|---|---|---|---|---|

| ① | 15.0 × 15.0 × 1.21 | 0.4 | 0.8 | 170 | Peripheral |

| ② | 12.0 × 12.0 × 1.15 | 0.3 | 0.5 | 222 | Peripheral |

| ③ | 7.0 × 7.0 × 1.1 | 0.3 | 0.5 | 123 | Full |

| Fixtures | N (Number of Samples) | Scale Parameter (η) Characteristic Life | Shape Parameter (β) | AD (Anderson-Darling) |

|---|---|---|---|---|

| fixture I | 12 | 22.8 | 0.98 | 0.486 |

| fixture II | 10 | 34.2 | 1.28 | 0.339 |

| fixture III | 10 | 159 | 1.29 | 0.509 |

| BGA Package | Fixture I (0.8 mm Thick PCB) | Fixture I (0.6 mm Thick PCB) | Fixture II (0.6 mm Thick PCB) | Fixture III (0.6 mm Thick PCB) |

|---|---|---|---|---|

| ① | 63.9 | 25.2 | 123.7 | 91.5 |

| ② | 32.7 | 22.9 | 34.2 | 159 |

| Components | Density (Kg/mm3) | Elastic Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|

| BGA Package (EMC) | 1.89 × 10−6 | 28 | 0.35 |

| Cu pad | 8.94 × 10−6 | 117 | 0.34 |

| Solder joints | 7.44 × 10−6 | 90 | 0.42 |

| PCB | 1.91 × 10−6 | 16.8 | 0.36 |

| FEA Model | Solid Element | Beam Element |

|---|---|---|

| Minimum Mesh Size (mm) | 0.003816 | 0.16 |

| Number of Element (ea) | 755,288 | 90,507 |

| Time Step (ms) | 3.14 × 10−7 | 1.86 × 10−5 |

| Elapsed time (s) (12 core CPU) | 403,600 (113 h) | 2415 (40 min) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chung, S.; Kwak, J.B. Comparative Study on Reliability and Advanced Numerical Analysis of BGA Subjected to Product-Level Drop Impact Test for Portable Electronics. Electronics 2020, 9, 1515. https://doi.org/10.3390/electronics9091515

Chung S, Kwak JB. Comparative Study on Reliability and Advanced Numerical Analysis of BGA Subjected to Product-Level Drop Impact Test for Portable Electronics. Electronics. 2020; 9(9):1515. https://doi.org/10.3390/electronics9091515

Chicago/Turabian StyleChung, Soonwan, and Jae B. Kwak. 2020. "Comparative Study on Reliability and Advanced Numerical Analysis of BGA Subjected to Product-Level Drop Impact Test for Portable Electronics" Electronics 9, no. 9: 1515. https://doi.org/10.3390/electronics9091515

APA StyleChung, S., & Kwak, J. B. (2020). Comparative Study on Reliability and Advanced Numerical Analysis of BGA Subjected to Product-Level Drop Impact Test for Portable Electronics. Electronics, 9(9), 1515. https://doi.org/10.3390/electronics9091515