Potential of Pressure Sensor Based Mass Estimation Methods for Electric Buses

Abstract

1. Introduction

1.1. Worldwide Spread of Electric Buses

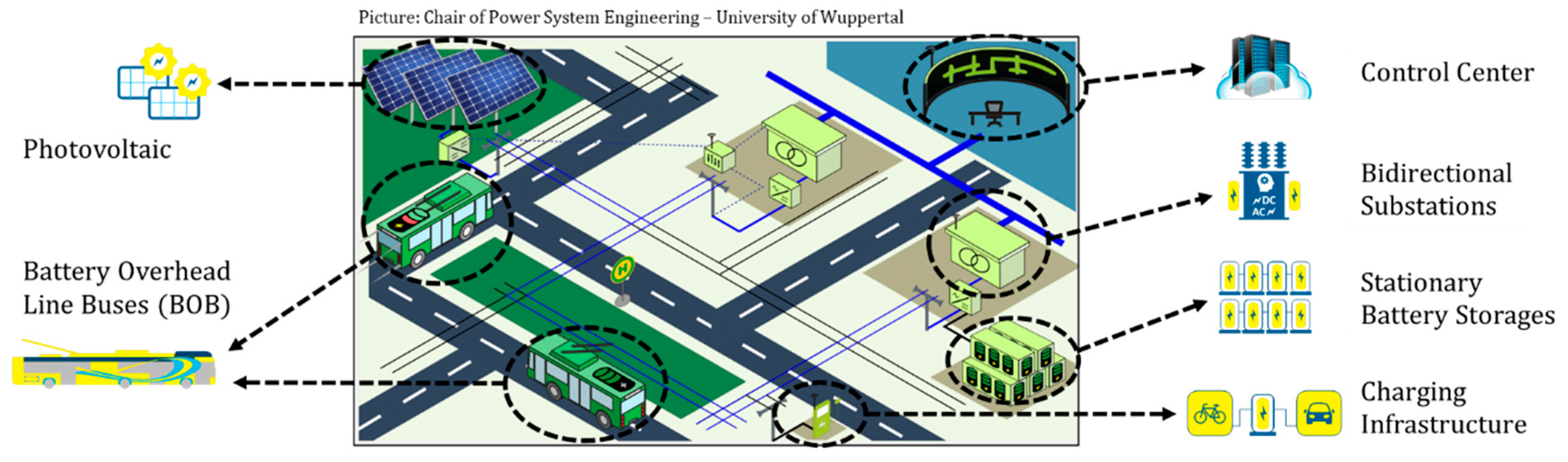

1.2. Project Introduction

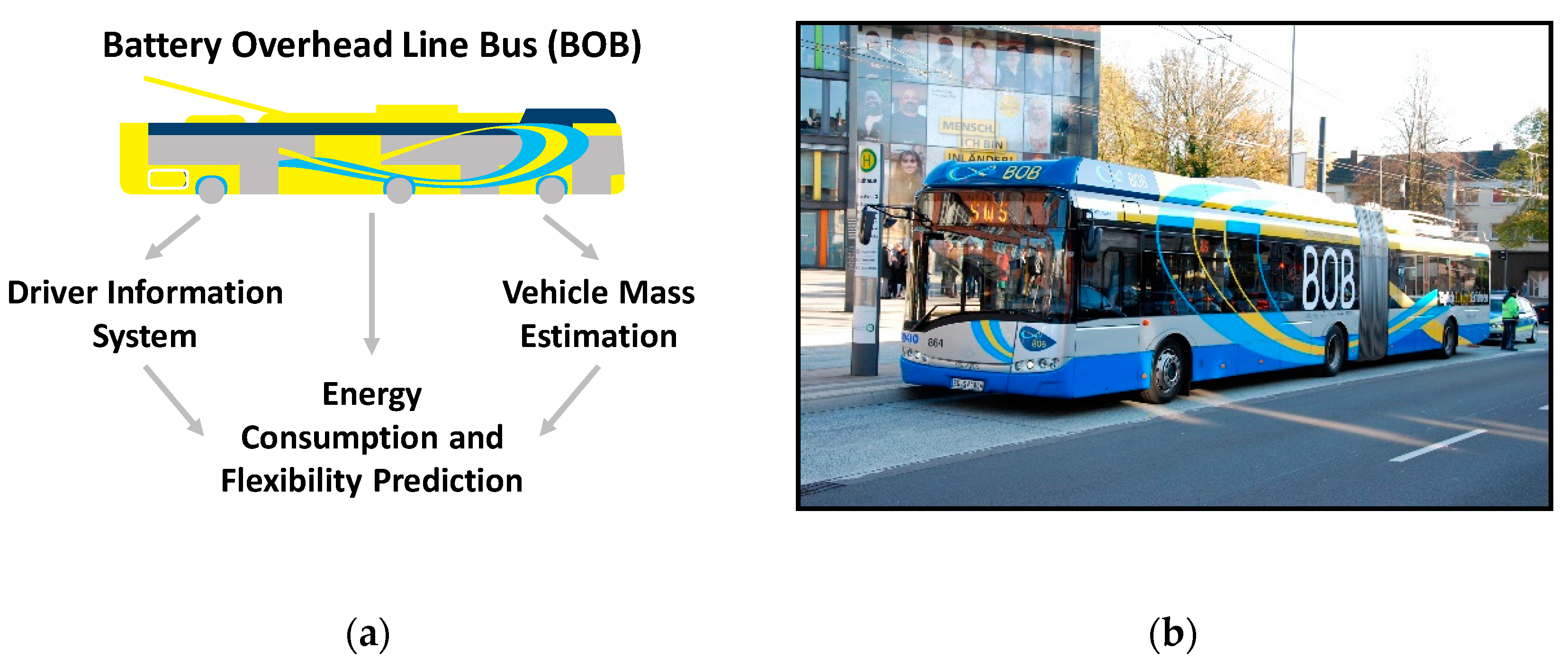

1.3. Topic Introduction

1.4. Related Work

1.5. Scope of Application

2. Materials and Methods

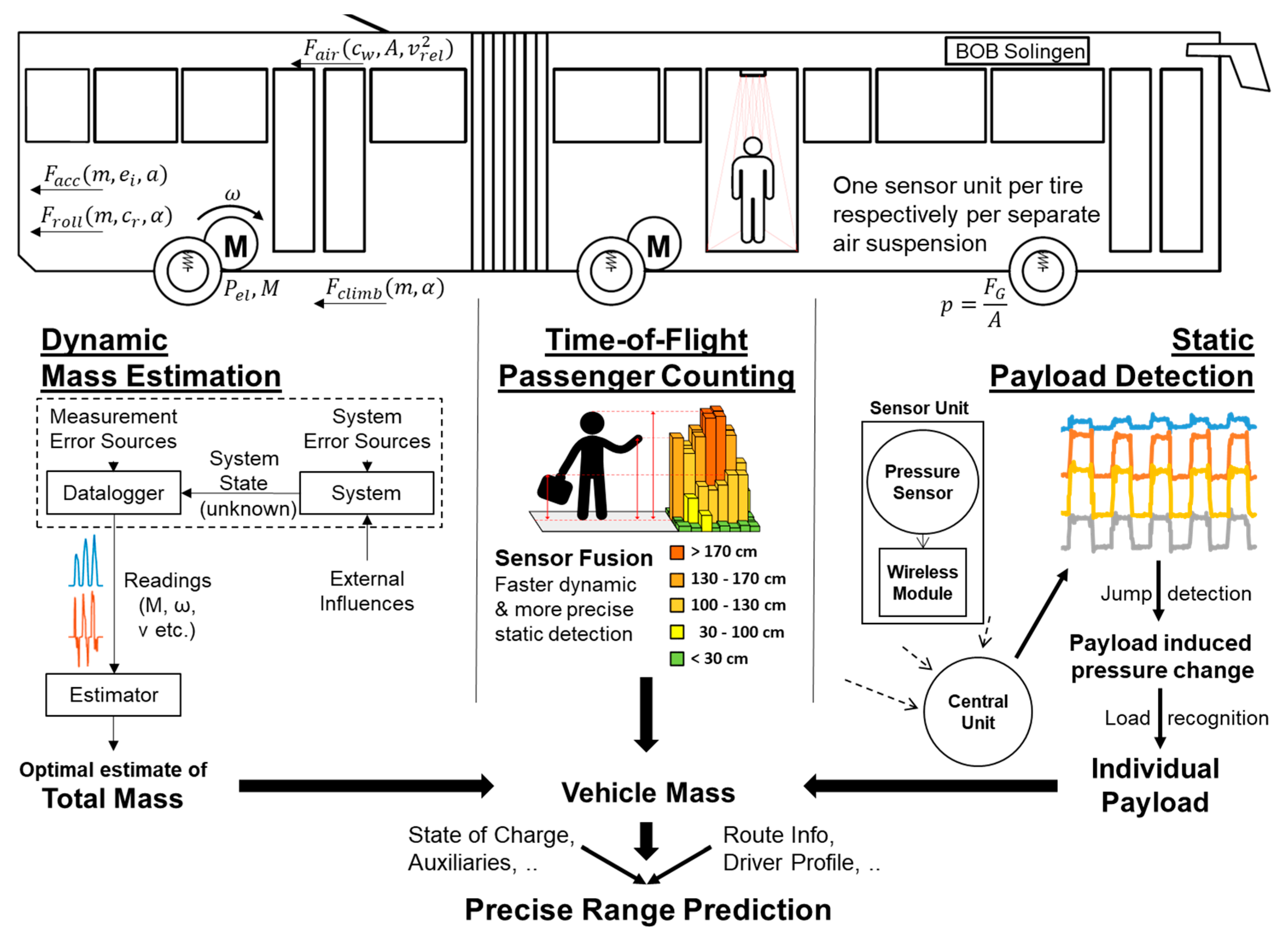

2.1. Overall Concept

2.1.1. Dynamic Mass Estimation

2.1.2. Time-of-Flight (ToF) Passenger Counting

2.1.3. Static Payload Detection

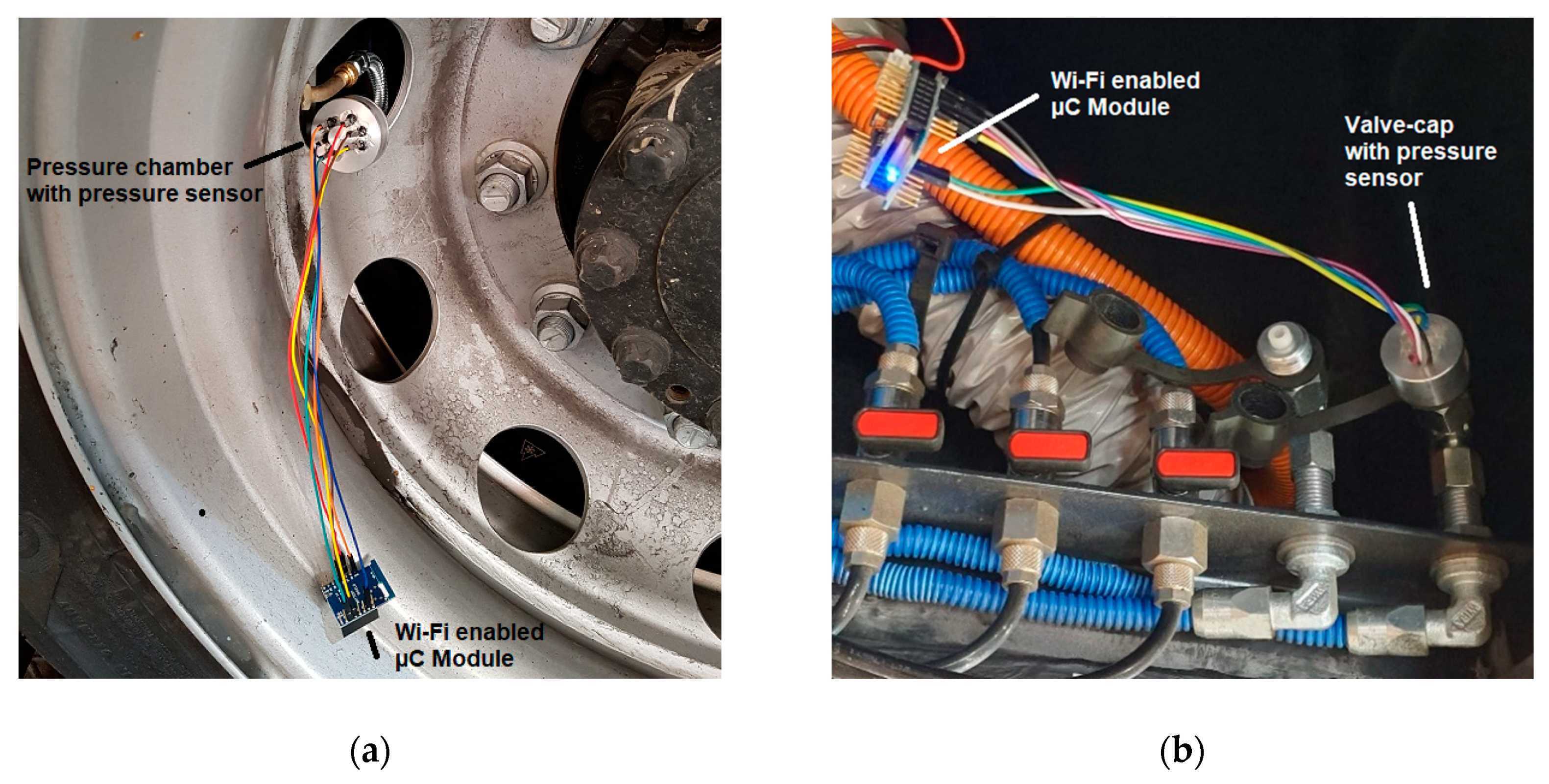

2.2. Used Hardware

2.3. Filter Algorithm

3. Results

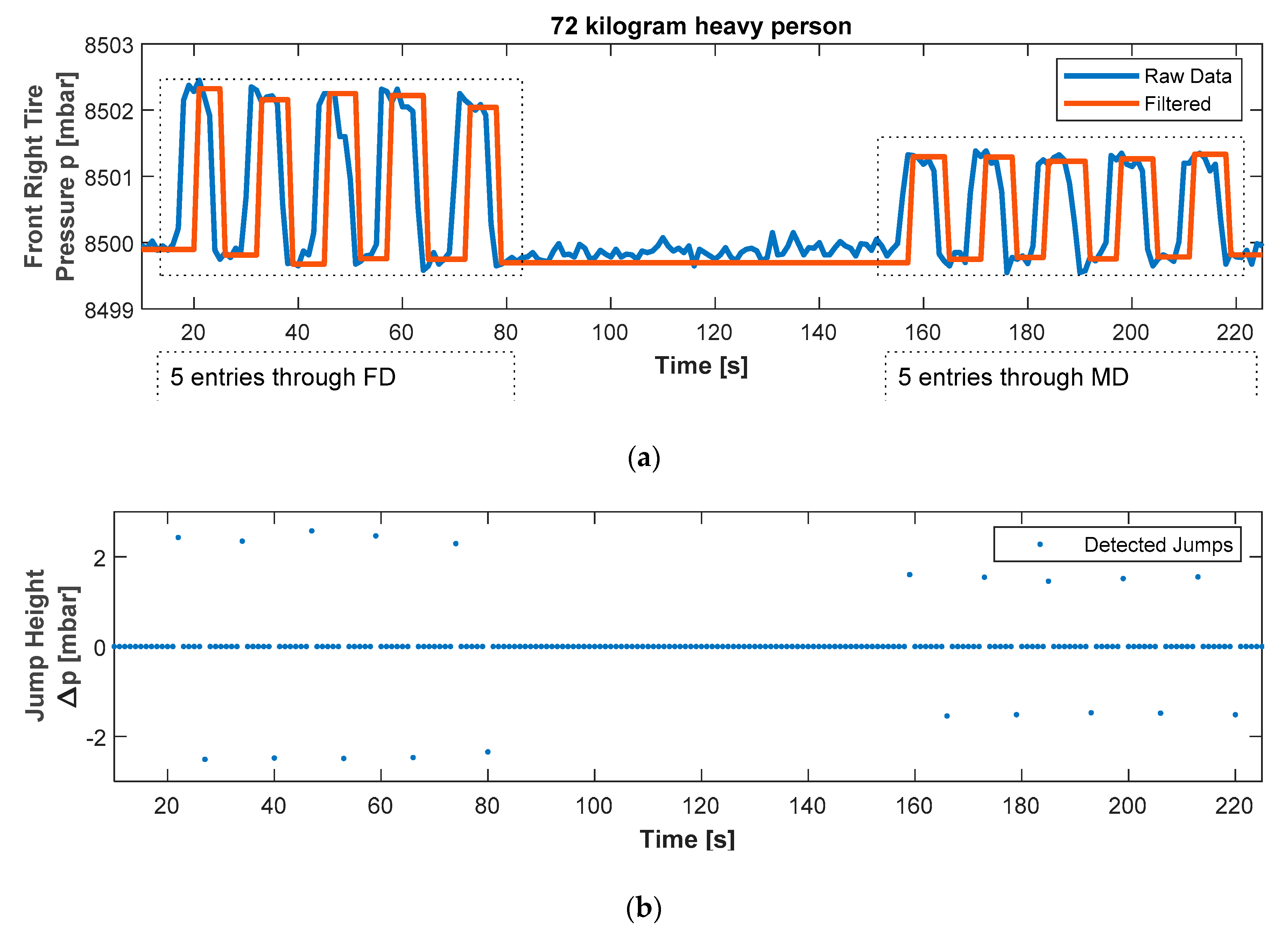

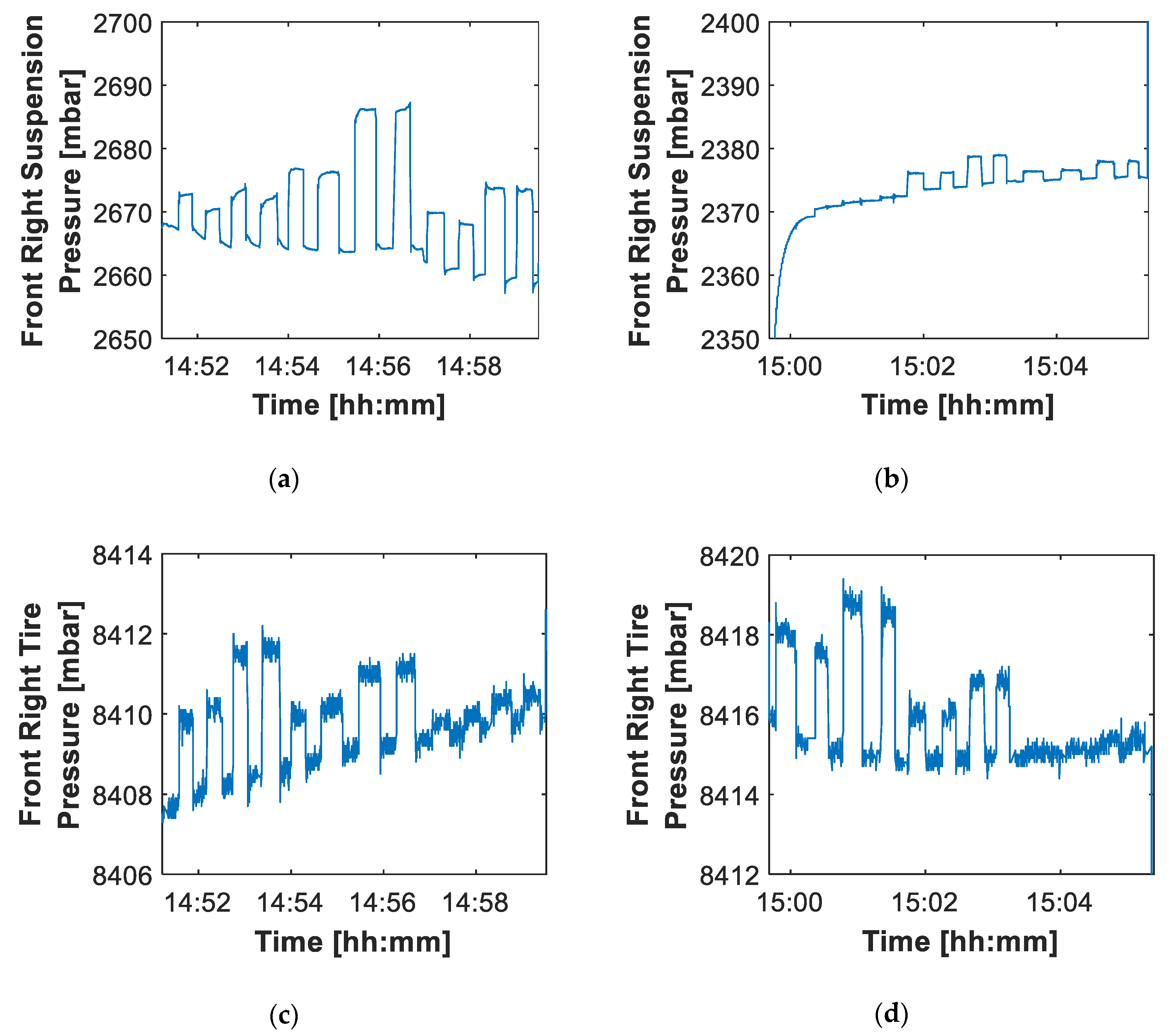

3.1. Measurements on the Tire

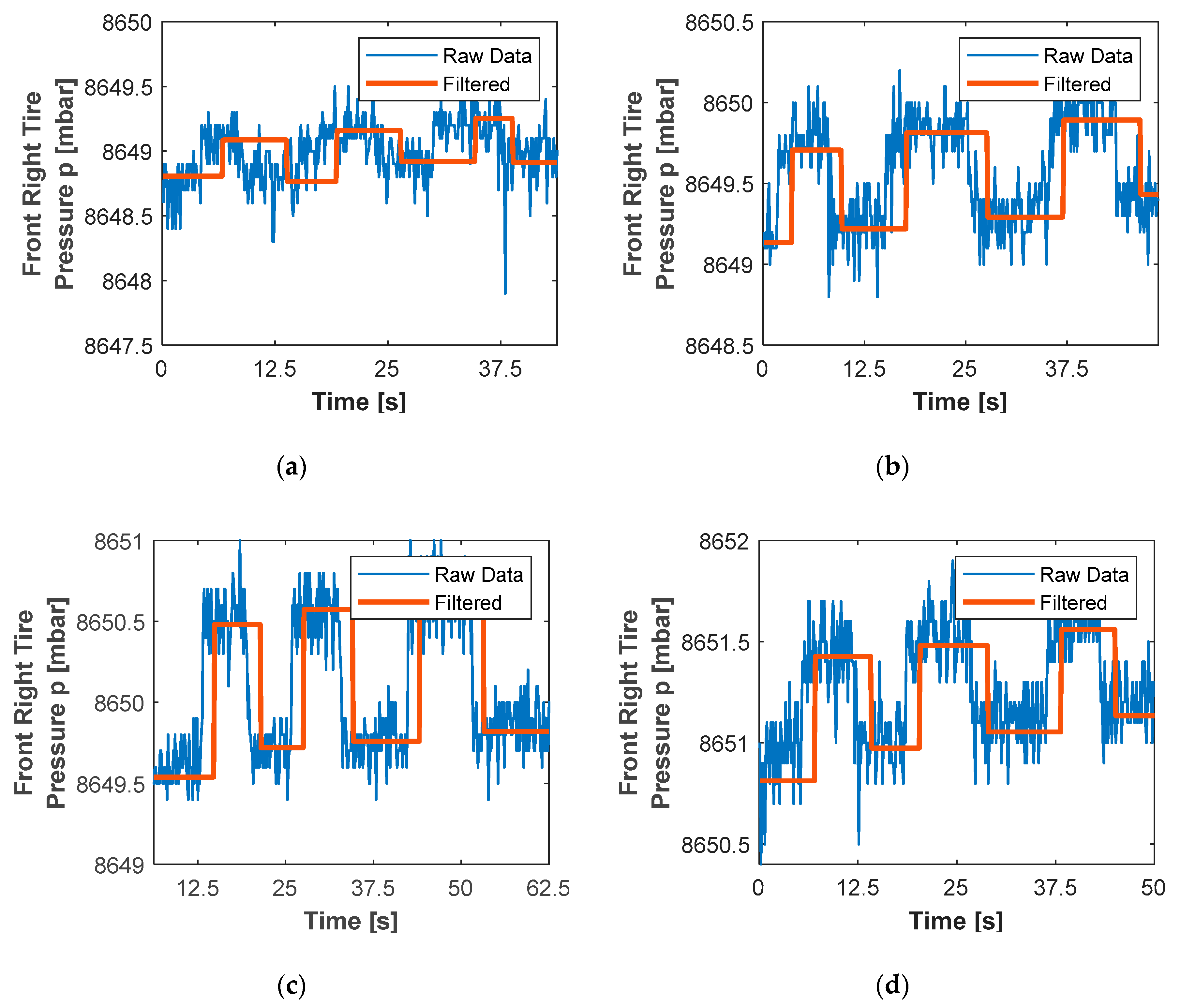

3.1.1. Influence of Initial Pressure

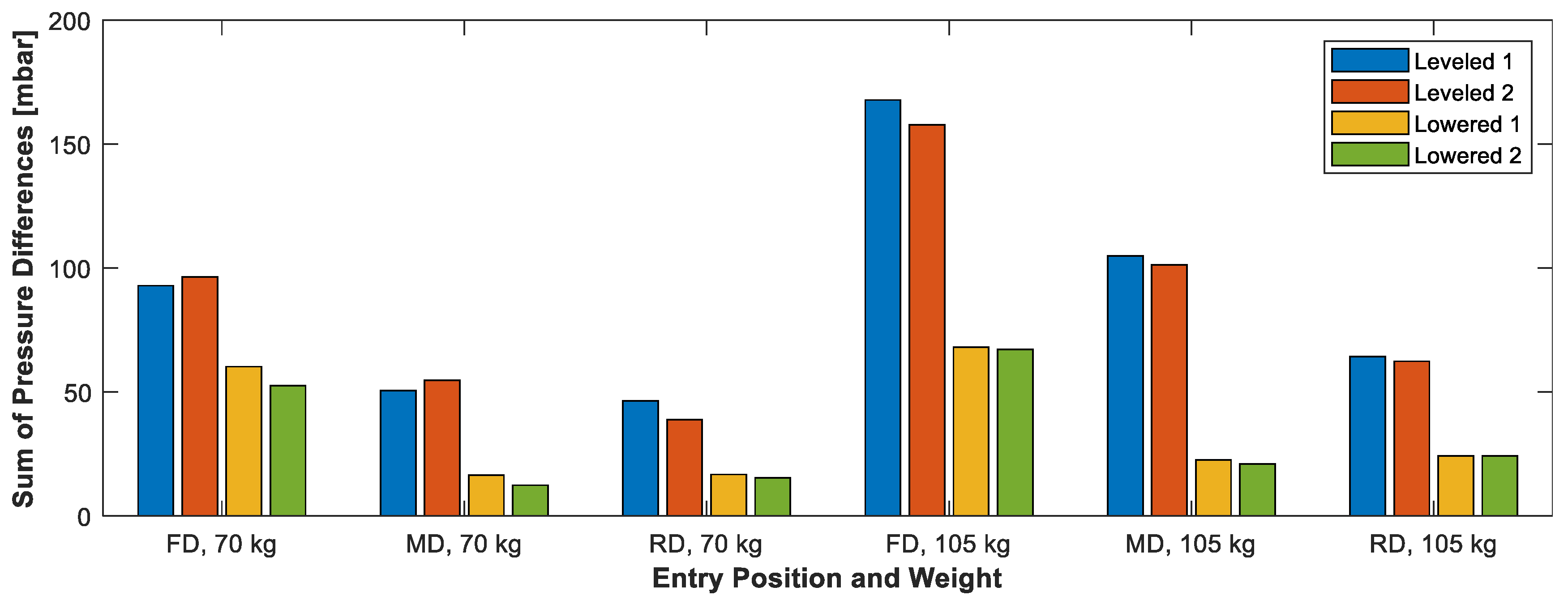

3.1.2. Influence of Entry Position

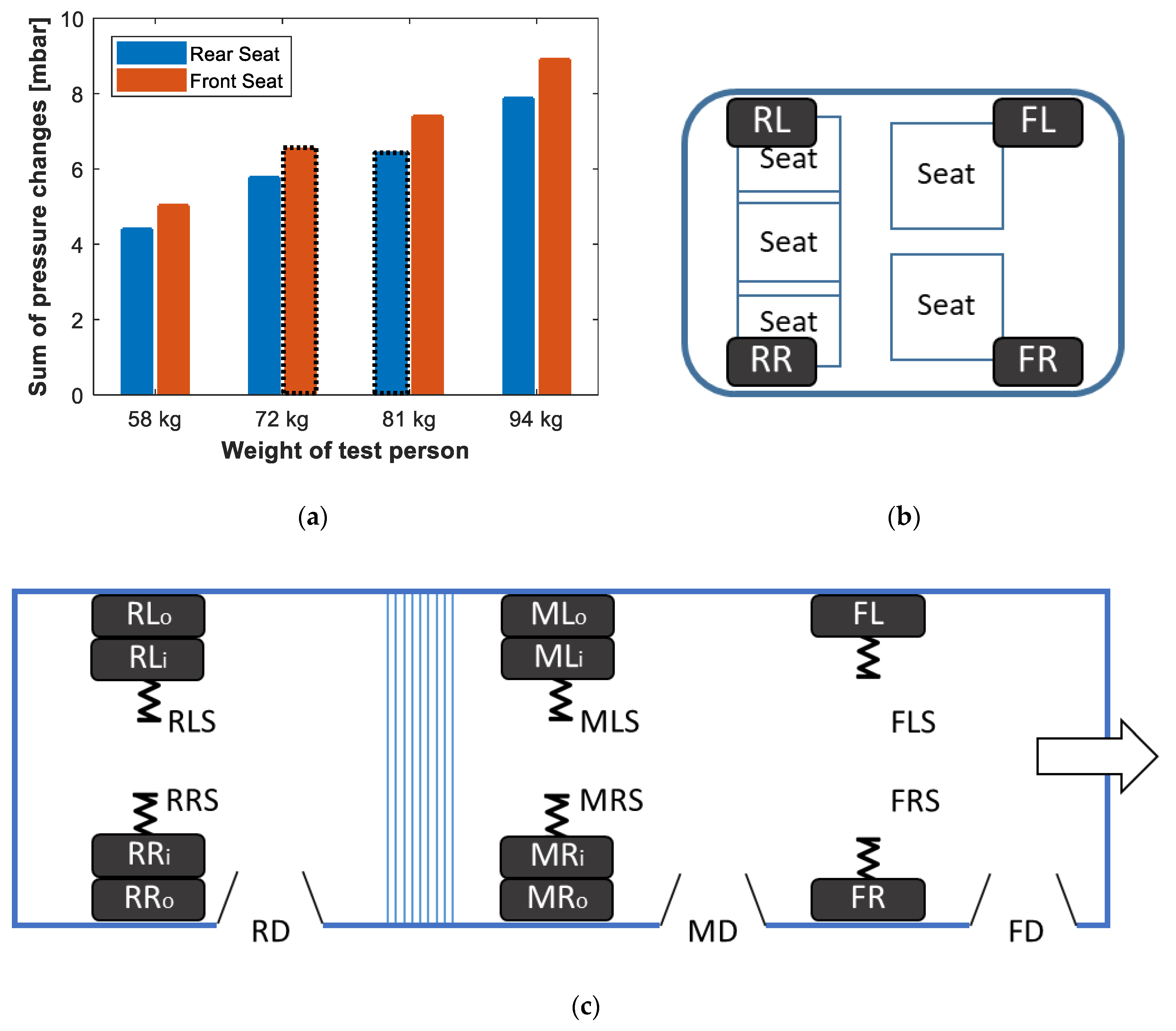

3.1.3. Proportionality of Pressure Steps and Weight

3.1.4. Estimation of the Lowest Detectable Payload

3.2. Measurements on the Air Suspension

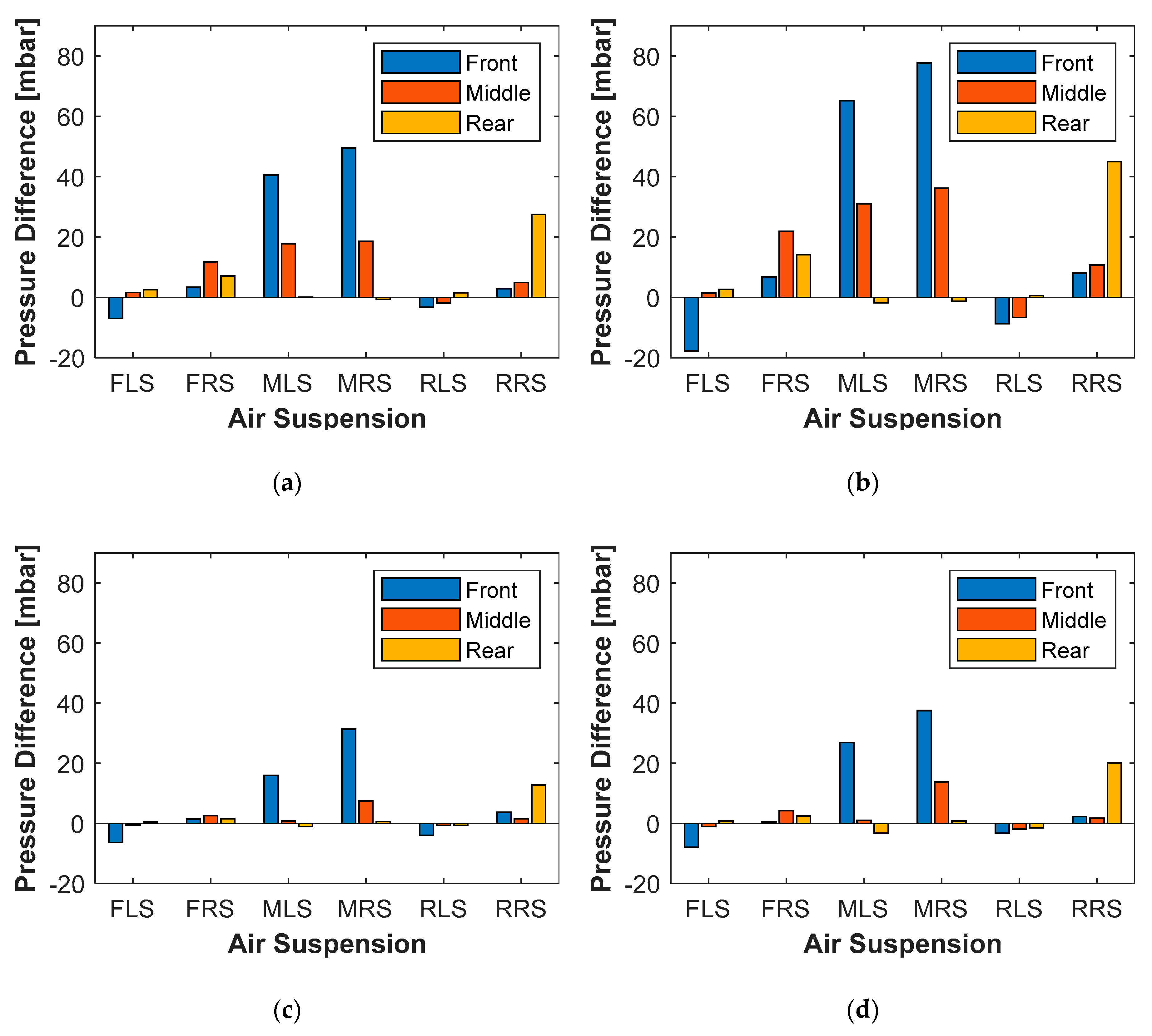

3.2.1. Distribution among the Individual Air Springs

3.2.2. Influence of Lowering

3.2.3. Influence of Entry Position

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kellerman, A. Automated and Autonomous Spatial Mobilities; Edward Elgar Publishing: Cheltenham, UK, 2018. [Google Scholar]

- France 24. Paris Orders 800 New Electric Buses to Fight Smog. 9 April 2019. Available online: https://www.france24.com/en/20190409-paris-orders-800-new-electric-buses-fight-smog (accessed on 14 June 2019).

- PricewaterhouseCoopers GmbH. E-Bus-Radar; PwC: Berlin, Germany, 2019. [Google Scholar]

- Frontier Group & U.S. PIRG Education Fund. Electric Buses—Clean Transportation for Healthier Neighborhoods and Clean Air; Frontier Group: North Shields, UK, 2018. [Google Scholar]

- International Energy Agency. Global Energy & CO2 Status Report—The Latest Trends in Energy and Emission in 2018; International Energy Agency: Paris, France, 2019. [Google Scholar]

- International Energy Agency. CO2 Emissions from Fuel Combustion, 2019 Edition; International Energy Agency: Paris, France, 2019. [Google Scholar]

- United Nations Environment Programme. Air Pollution in Asia and the Pacific: Science-Based Solutions; UNEP: Bangkok, Thailand, 2019. [Google Scholar]

- The International Council on Clean Transportation. Policy Update: China Announced 2019 Subsidies for New Energy Vehicles; The International Council on Clean Transportation: Washington, DC, USA, 2019. [Google Scholar]

- The World Bank. Electric Mobility & Development. The World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Keegan, M. Shenzhen’s Silent Revolution: World’s First Fully Electric Bus Fleet Quietens Chinese Megacity. The Guardian. 12 December 2018. Available online: https://www.theguardian.com/cities/2018/dec/12/silence-shenzhen-world-first-electric-bus-fleet (accessed on 14 June 2019).

- Lin, Y.; Zhang, K.; Shen, Z.-J.M.; Miao, L. Charging Network Planning for Electric Bus Cities: A Case Study of Shenzhen, China. Sustainability 2019, 11, 4713. [Google Scholar] [CrossRef]

- Transport & Environment. Electric Buses Arrive on Time: Marketplace, Economic, Technology, Environmental and Policy Perspectives for Fully Electric Buses in the EU; Transport & Environment: Brussels, Belgium, 2018. [Google Scholar]

- Melliger, M.; van Vliet, O.; Liimatainen, H. Anxiety vs reality—Sufficiency of battery electric vehicle range in Switzerland and Finland. Transp. Res. Part D Transp. Environ. 2018, 65, 101–115. [Google Scholar] [CrossRef]

- Federal Ministry of Transport and Digital Infrastructure. Pressemitteilung BMVI übergibt 15-Mio-Euro-Förderung für Hybrid-Oberleitungsbusse; Federal Ministry of Transport and Digital Infrastructure: Berlin, Germany, 2017.

- Ritter, A.; Elbert, P.; Onder, C. Energy Saving Potential of a Battery Assisted Fleetof Trolley Buses. IFAC-PapersOnLine 2016, 11, 377–384. [Google Scholar] [CrossRef]

- Santis, A.; Lauber, L.; Luder, D.; Broennimann, S.; Filliger, R.; Vezzini, A. SwissTrolley plus: R&D on battery lifespan. In Proceedings of the SCCER Mobility 4th Annual Conference, Zurich, Switzerland, 15 September 2017. [Google Scholar]

- HAN Automotive Research. Project Description of “E-Bus 2020”; HAN Automotive Research: Arnhem, The Netherlands, 2020. [Google Scholar]

- Stadtwerke Solingen GmbH. Elektromobilität bei den Stadtwerken; Stadtwerke Solingen GmbH: Solingen, Germany, 2018. [Google Scholar]

- Zhang, X.; Xu, L.; Li, J.; Ouyang, M. Real-Time Estimation of Vehicle Mass and Road Grade Based on Multi-Sensor Data Fusion. In Proceedings of the 2013 IEEE Vehicle Power and Propulsion Conference (VPPC), Beijing, China, 15–18 October 2013. [Google Scholar]

- Kim, C.; Ro, P.I. Reduced-order modelling and parameter estimation for a quarter-car suspension system. Part D J. Automob. Eng. 2000, 214, 851–864. [Google Scholar] [CrossRef]

- Fechtner, H.; Teschner, T.; Schmuelling, B. Range prediction for electric vehicles: Real-time payload detection by tire pressure monitoring. In Proceedings of the IEEE Intelligent Vehicles Symposium, Seoul, Korea, 28 June–1 July 2015. [Google Scholar]

- Ogawa, A. Tire State Quantity Detecting Apparatus and Method. USA Patent US7243534B2, 17 March 2005. [Google Scholar]

- Hao, S.; Luo, P.; Xi, J. Estimation of vehicle mass and road slope based on steady-state Kalman filter. In Proceedings of the IEEE International Conference on Unmanned Systems (ICUS) 2017, Beijing, China, 27–29 October 2017. [Google Scholar]

- Boada, B.L.; Boada, M.J.L.; Zhang, H. Sensor Fusion Based on a Dual Kalman Filter for Estimation of Road Irregularities and Vehicle Mass Under Static and Dynamic Conditions. IEEE/ASME Trans. Mechatronics 2019, 24, 1075–1086. [Google Scholar] [CrossRef]

- Torabi, S.; Wahde, M.; Hartono, P. Road Grade and Vehicle Mass Estimation for Heavy-duty Vehicles Using Feedforward Neural Networks. In Proceedings of the 2019 4th International Conference on Intelligent Transportation Engineering (ICITE), Singapore, 5–7 September 2019. [Google Scholar]

- Kim, I.; Kim, H.; Bang, J.; Huh, K. Development of estimation algorithms for vehicle’s mass and road grade. Int. J. Automot. Technol. 2013, 14, 889–895. [Google Scholar] [CrossRef]

- Hac, A.B. Dynamic Estimation of Vehicle Inertial Parameters and Tire Forces from Tire Sensors. USA Patent US20090177346A1, 9 July 2009. [Google Scholar]

- Grewal, K.S.; Darnell, P.M. Model-based EV range prediction for Electric Hybrid Vehicles. In Proceedings of the Hybrid and Electric Vehicles Conference 2013 (HEVC 2013), London, UK, 6–7 November 2013. [Google Scholar]

- Carlson, R.B.; Lohse-Busch, H.; Diez, J.; Gibbs, J. The Measured Impact of Vehicle Mass on Road Load Forces and Energy Consumption for a BEV, HEV, and ICE Vehicle. SAE Int. J. Altern. Powertrains 2013, 2, 105–114. [Google Scholar] [CrossRef]

- Kidambi, N.; Harne, R.L.; Fujii, Y.; Pietron, G.M.; Wang, K.W. Methods in Vehicle Mass and Road Grade Estimation. SAE Int. J. Passeng. Cars-Mech. Syst. 2014, 7, 981–991. [Google Scholar] [CrossRef]

- Ehsani, M.; Gao, Y.; Emadi, A. Modern Electric, Hybrid Electric, and Fuell Cell Vehicles; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Maalej, K.; Kelouwani, S.; Agbossou, K.; Dube, Y.; Henao, N. Long-Trip Optimal Energy Planning with Online Mass Estimation for Battery Electric Vehicles. IEEE Trans. Veh. Technol. 2014, 64, 4929–4941. [Google Scholar] [CrossRef]

- Feng, Y.; Xiong, L.; Han, W. Vehicle Identification Method and System for Quality. Chinese Patent CN103946679, 25 May 2016. [Google Scholar]

- Pence, B. Recursive Parameter Estimation using Polynomial Chaos Theory Applied to Vehicle Mass Estimation for Rough Terrain. Ph.D. Thesis, The University of Michigan, Ann Arbor, MI, USA, 2011. [Google Scholar]

- Li, B.; Li, W.; Du, H. Trajectory control for autonomous electric vehicles with in-wheel motors based on a dynamics model approach. IET Intell. Transp. Syst. 2016, 10, 318–330. [Google Scholar] [CrossRef]

- Subosits, J.; Gerdes, J.C.; J., S.; J.C., G. Autonomous vehicle control for emergency maneuvers: The effect of topography. In Proceedings of the 2015 American Control Conference (ACC), Chicago, IL, USA, 1–3 July 2015. [Google Scholar]

- Weiskircher, T.; Wang, Q.; Ayalew, B. Predictive Guidance and Control Framework for (Semi-) Autonomous Vehicles in Public Traffic. IEEE Trans. Control Syst. Technol. 2017, 25, 2034–2046. [Google Scholar] [CrossRef]

- Pohl, J.; Ekmark, J. A Lane Keeping Assist System for Passenger Cars-Design Aspects for the Driver Interface. In Proceedings of the 18th International Technical Conference on the Enhanced Safety of Vehicles, Nagayo, Japan, 19–22 May 2003. [Google Scholar]

- Economic Commission for Europe of the United Nations. Regulation No 64 of the Economic Commission for Europe of the United Nations (UN/ECE); Economic Commission for Europe of the United Nations: Geneva, Switzerland, 2010. [Google Scholar]

- U.S. Department of Transportation. National Highway Traffic Safety Administration, Federal Motor Vehicle Safety Standards: Tire Pressure Monitoring Systems; U.S. Department of Transportation: Washington DC, USA, 2005.

- Fechtner, H.; Spaeth, U.; Patelkos, E.; Schmuelling, B. Optimisation of driver and driving assistance systems of electric vehicles by a static vehicle mass estimation. In Proceedings of the IET Hybrid and Electric Vehicle Conference, IET HEVC 2016, London, UK, 2–3 November 2016. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spaeth, U.; Fechtner, H.; Weisbach, M.; Schmuelling, B. Potential of Pressure Sensor Based Mass Estimation Methods for Electric Buses. Electronics 2020, 9, 711. https://doi.org/10.3390/electronics9050711

Spaeth U, Fechtner H, Weisbach M, Schmuelling B. Potential of Pressure Sensor Based Mass Estimation Methods for Electric Buses. Electronics. 2020; 9(5):711. https://doi.org/10.3390/electronics9050711

Chicago/Turabian StyleSpaeth, Utz, Heiko Fechtner, Michele Weisbach, and Benedikt Schmuelling. 2020. "Potential of Pressure Sensor Based Mass Estimation Methods for Electric Buses" Electronics 9, no. 5: 711. https://doi.org/10.3390/electronics9050711

APA StyleSpaeth, U., Fechtner, H., Weisbach, M., & Schmuelling, B. (2020). Potential of Pressure Sensor Based Mass Estimation Methods for Electric Buses. Electronics, 9(5), 711. https://doi.org/10.3390/electronics9050711