An AMOLED Pixel Circuit Based on LTPS Thin-film Transistors with Mono-Type Scanning Driving

Abstract

:1. Introduction

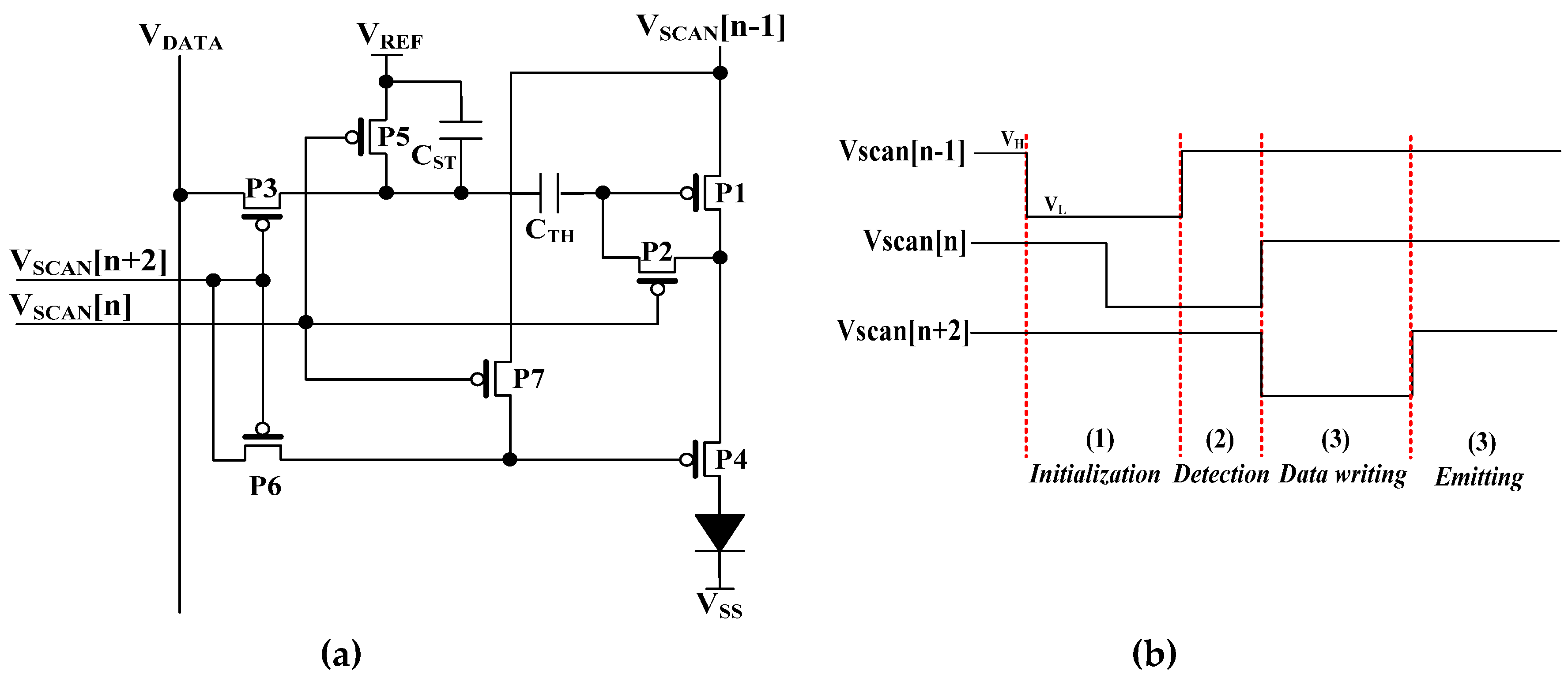

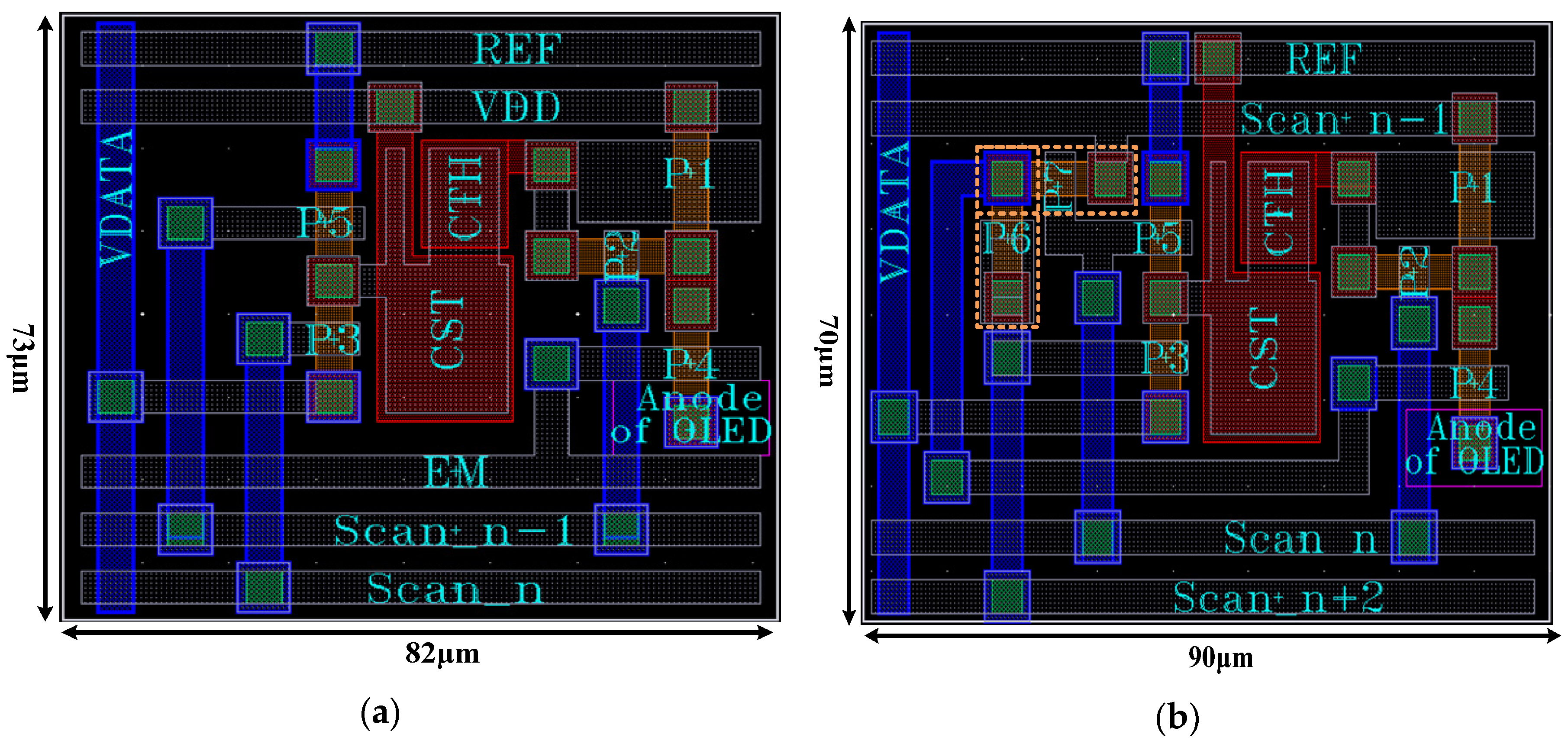

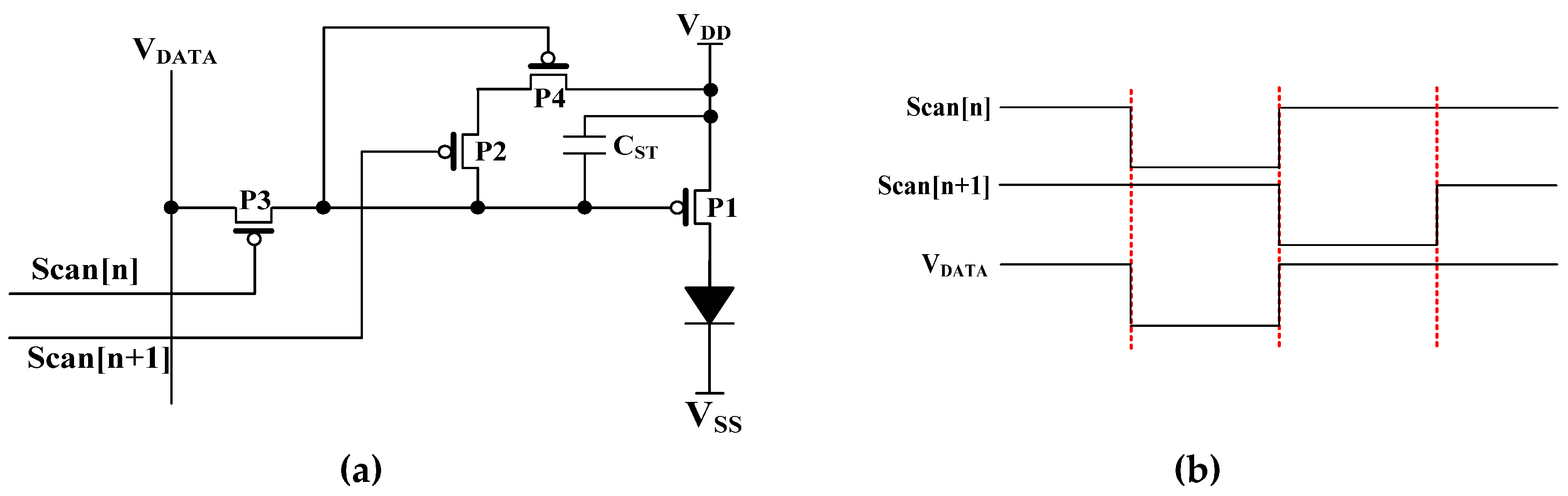

2. Pixel Circuit Description

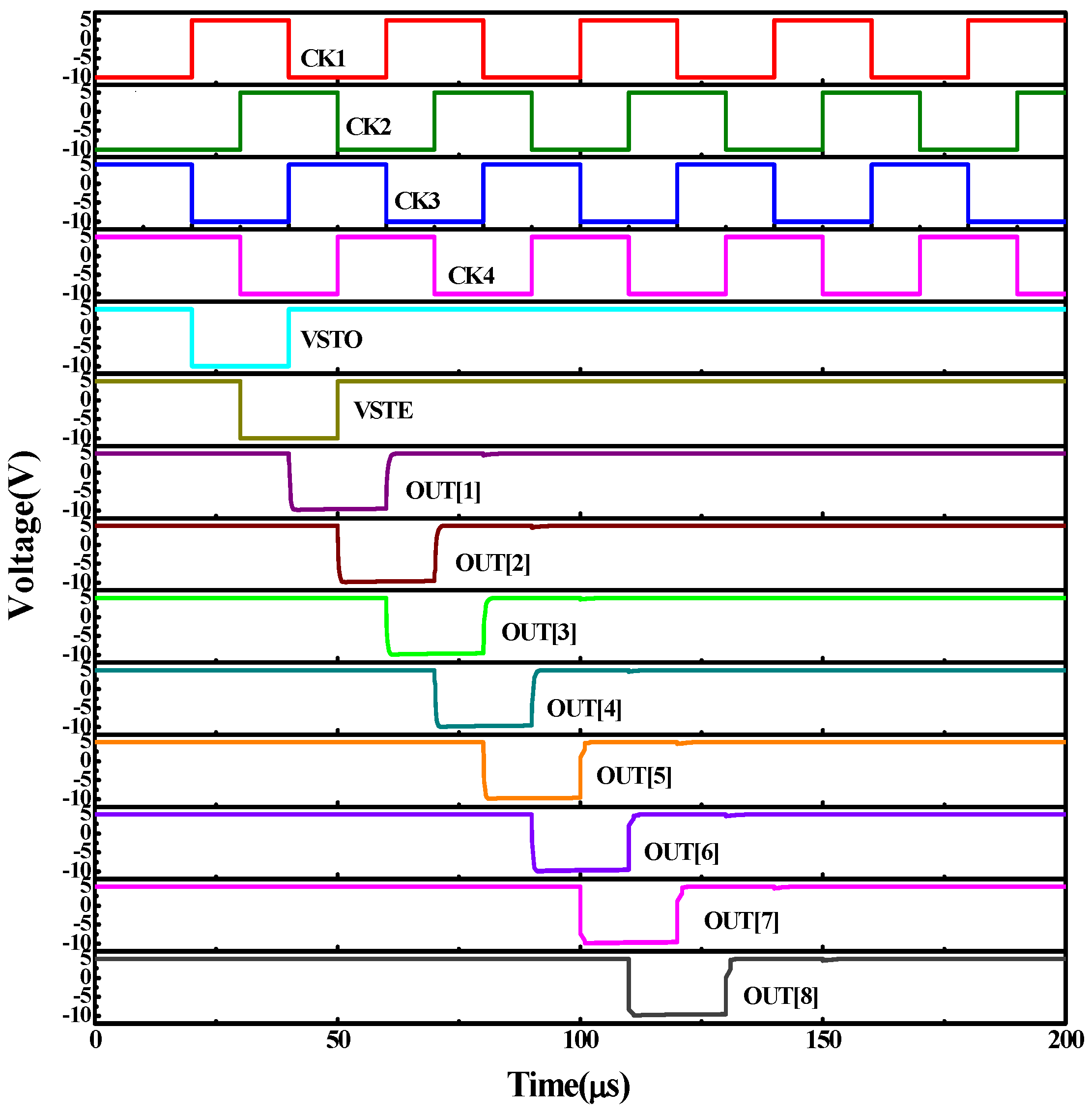

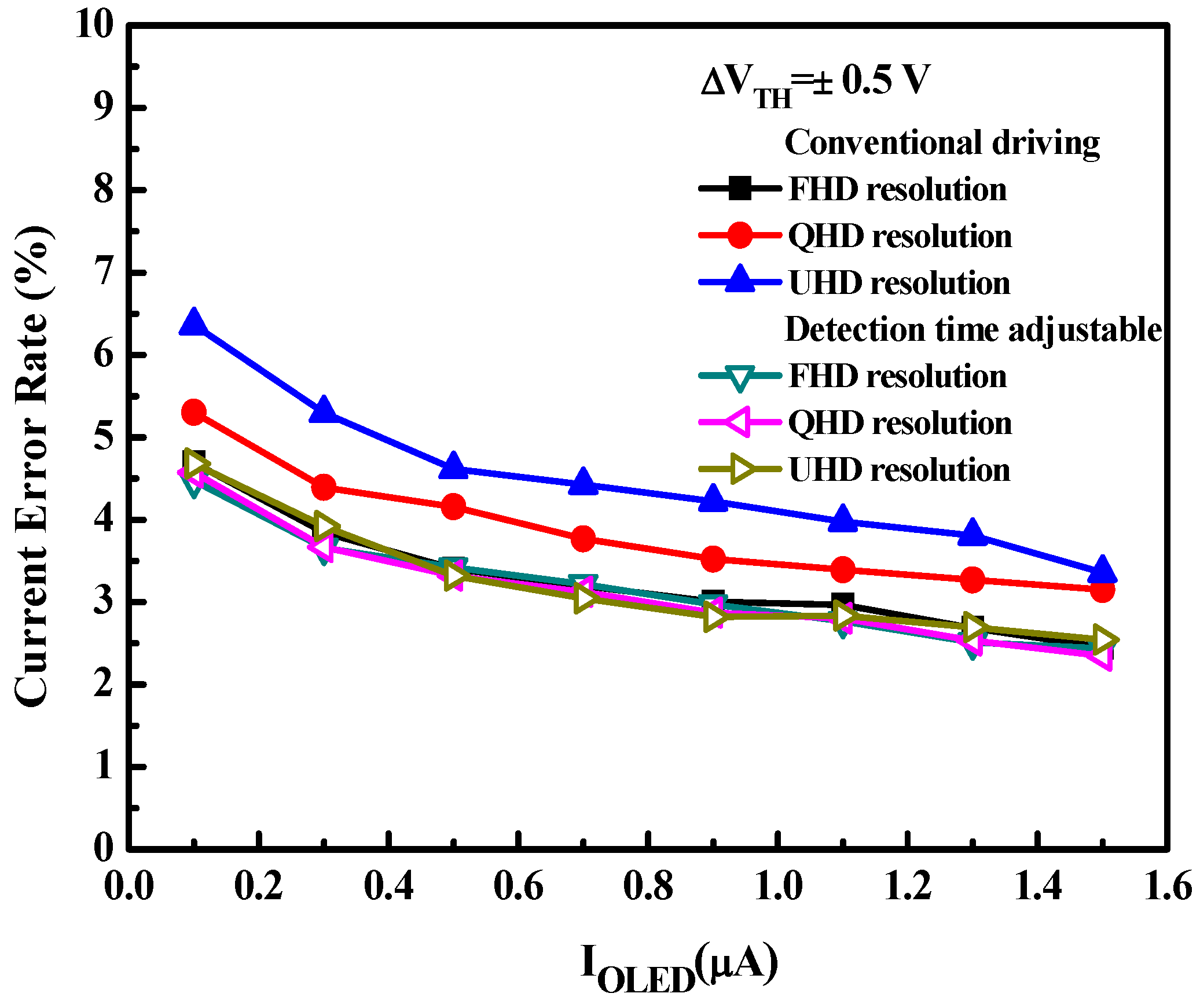

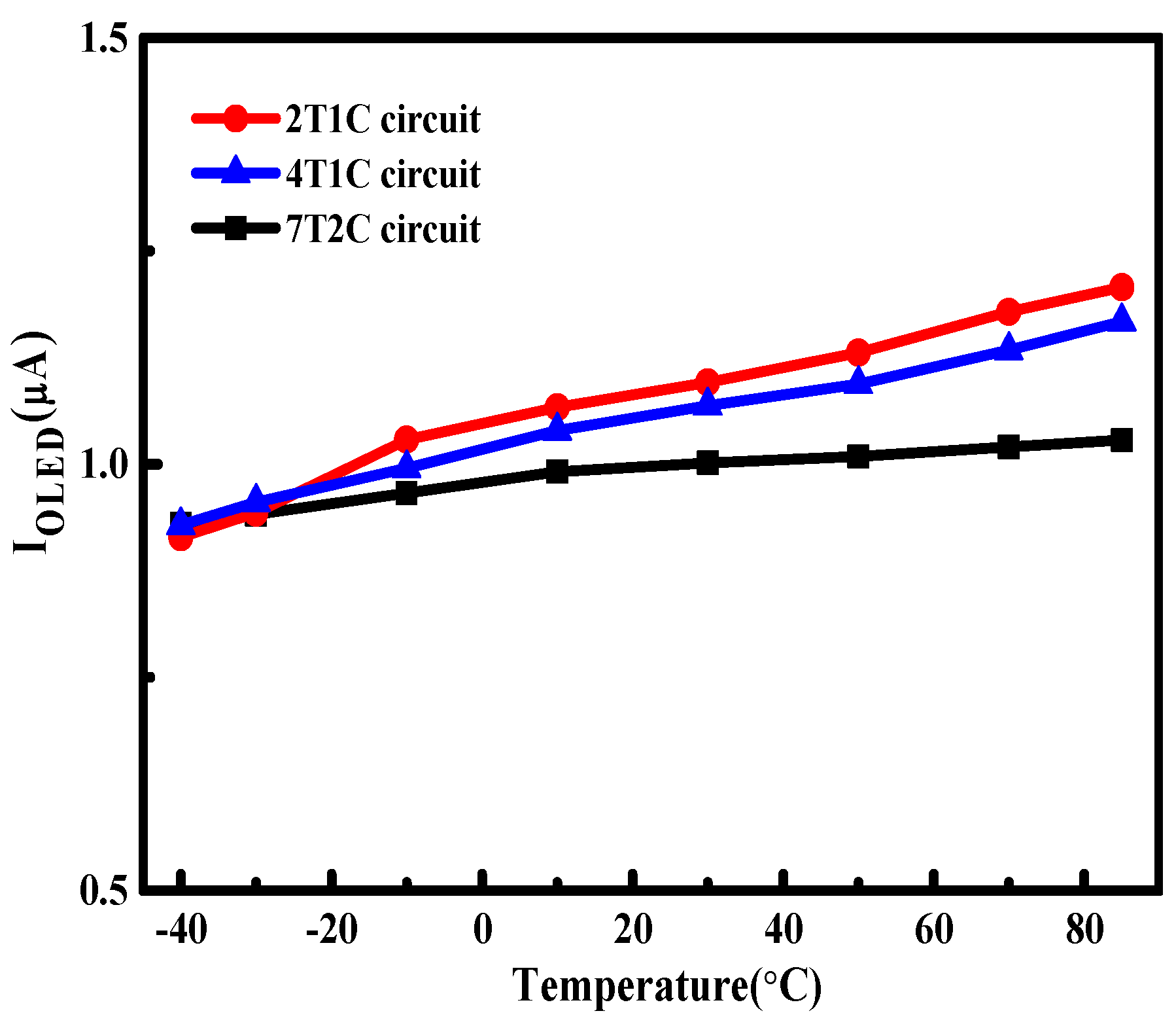

2.1. Initialization Phase

2.2. Detection Phase

2.3. Data Writing Phase

2.4. Emitting Phase

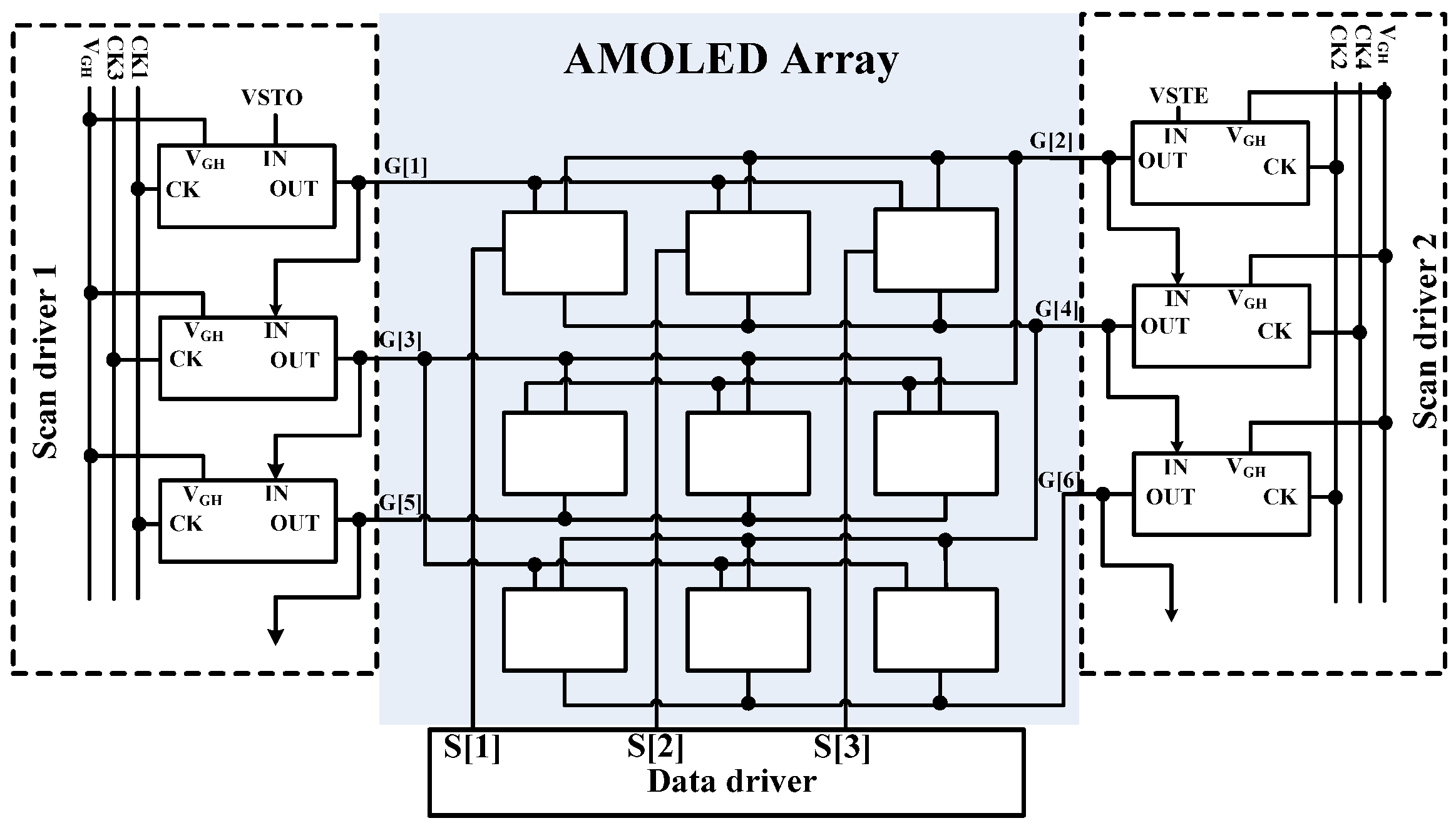

3. Gate Driver Description

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Park, C.I.; Seong, M.; Kim, M.A.; Kim, D.; Jung, H.; Cho, M.; Lee, S.H.; Lee, H.; Min, S.; Kim, J.; et al. 54-1: Distinguished Paper: World 1st Large Size 77-inch Transparent Flexible OLED Display. SID Symp. Dig. Tech. Pap. 2018, 49, 710–713. [Google Scholar] [CrossRef]

- Seol, H.-C.; Ra, J.-H.; Hong, S.-K.; Kwon, O.-K. An AMOLED Panel Test System Using Universal Data Driver ICs for Various Pixel Structures. IEEE Trans. Electron. Devices 2016, 64, 189–194. [Google Scholar] [CrossRef]

- Qin, T.; Liao, C.; Huang, S.; Yu, T.; Deng, L. Analytical drain current model for symmetric dual-gate amorphous indium gallium zinc oxide thin-film transistors. Jpn. J. Appl. Phys. 2017, 57, 14301. [Google Scholar] [CrossRef]

- Li, C.; Liao, C.-W.; Yu, T.-B.; Ke, J.-Y.; Huang, S.; Deng, L. Concise Modeling of Amorphous Dual-Gate In-Ga-Zn-O Thin-Film Transistors for Integrated Circuit Designs. Chin. Phys. Lett. 2018, 35, 027302. [Google Scholar] [CrossRef]

- Lin, C.L.; Chen, P.S.; Chen, H.M.; Chen, F.H. A novel p-Type LTPS TFT pixel circuit compensating for threshold voltage and mobility variations. J. Disp. Tech. 2014, 10, 995–1000. [Google Scholar]

- Wadhwa, N.; Bahubalindruni, P.G.; Chapagai, K.; Goes, J.; Deb, S.; Barquinha, P. Sixth-order differential Sallen-and-Key switched capacitor LPF using a-IGZO TFTs. Int. J. Circuit Theory Appl. 2018, 47, 32–42. [Google Scholar] [CrossRef] [Green Version]

- Keum, N.-H.; Oh, K.; Hong, S.-K.; Kwon, O.-K. A Pixel Structure Using Block Emission Driving Method for High Image Quality in Active Matrix Organic Light-Emitting Diode Displays. J. Disp. Technol. 2016, 12, 1250–1256. [Google Scholar] [CrossRef]

- Fan, C.-L.; Chen, Y.-C.; Yang, C.-C.; Tsai, Y.-K.; Huang, B.-R. Novel LTPS-TFT Pixel Circuit with OLED Luminance Compensation for 3D AMOLED Displays. J. Disp. Technol. 2016, 12, 425–428. [Google Scholar] [CrossRef]

- Wu, W.; Zhou, L.; Yao, R.-H.; Peng, J.-B. A New Voltage-Programmed Pixel Circuit for Enhancing the Uniformity of AMOLED Displays. IEEE Electron. Device Lett. 2011, 32, 931–933. [Google Scholar] [CrossRef]

- Park, J.; Fujii, M.; Moon, J.; Wang, I. The method to compensate IR-drop of AMOLED display. SID Symp. Dig. Tech. Pap. 2018, 40, 983–985. [Google Scholar] [CrossRef]

- In, H.-J.; Kwon, O.-K. A Simple Pixel Structure Using Polycrystalline-Silicon Thin-Film Transistors for High-Resolution Active-Matrix Organic Light-Emitting Diode Displays. IEEE Electron. Device Lett. 2012, 33, 1018–1020. [Google Scholar] [CrossRef]

- Liao, C.; Deng, W.; Song, D.; Huang, S.; Deng, L. Mirrored OLED pixel circuit for threshold voltage and mobility compensation with IGZO TFTs. Microelectron. J. 2015, 46, 923–927. [Google Scholar] [CrossRef]

- Ashtiani, S.J.; Servati, P.; Striakhilev, D.; Nathan, A. A 3-TFT Current-Programmed Pixel Circuit for AMOLEDs. IEEE Trans. Electron. Devices 2005, 52, 1514–1518. [Google Scholar] [CrossRef]

- Chaji, G.; Nathan, A. A Fast Settling Current Driver Based on the CCII for AMOLED Displays. J. Disp. Technol. 2005, 1, 283–288. [Google Scholar] [CrossRef]

- In, H.-J.; Oh, K.-H.; Lee, I.; Ryu, D.-H.; Choi, S.-M.; Kim, K.-N.; Kim, H.-D.; Kwon, O.-K. An Advanced External Compensation System for Active Matrix Organic Light-Emitting Diode Displays With Poly-Si Thin-Film Transistor Backplane. IEEE Trans. Electron. Devices 2010, 57, 3012–3019. [Google Scholar] [CrossRef]

- Bang, J.-S.; Kim, H.-S.; Kim, K.-D.; Kwon, O.-J.; Shin, C.-S.; Lee, J.; Cho, G.-H. A Hybrid AMOLED Driver IC for Real-Time TFT Nonuniformity Compensation. IEEE J. Solid-state Circuits 2016, 51, 966–978. [Google Scholar]

- Lin, C.-C.; Yen, S.; Hsu, S.-Y.; Kuo, T.-W.; Lee, T.-S.; Liu, C.-H.; Lin, S.-L.; Hsiao, H.-Y.; Kung, C.-H.; Yeh, Y.-F.; et al. 7–3: AMOLED Pixel Structure Using the Close Loop Negative Feedback Method for High Resolution Displays. SID Symp. Dig. Tech. Pap. 2016, 47, 61–64. [Google Scholar] [CrossRef]

- Lee, J.-P.; Jeon, H.-S.; Moon, D.-S.; Bae, B.S. Threshold Voltage and IR Drop Compensation of an AMOLED Pixel Circuit Without a VDD Line. IEEE Electron. Device Lett. 2013, 35, 72–74. [Google Scholar] [CrossRef]

- Lin, C.-L.; Lai, P.-C.; Shih, L.-W.; Hung, C.-C.; Lai, P.-C.; Lin, T.-Y.; Liu, K.-H.; Wang, T.-H. Compensation Pixel Circuit to Improve Image Quality for Mobile AMOLED Displays. IEEE J. Solid-state Circuits 2018, 54, 489–500. [Google Scholar] [CrossRef]

- Kim, Y.W.; Kwak, W.K.; Lee, J.Y.; Choi, W.S.; Lee, K.Y.; Kim, S.C.; Yoo, E.J. 9.1: 40 Inch FHD AM-OLED Display with IR Drop Compensation Pixel Circuit. SID Symp. Dig. Tech. Pap. 2009, 40, 85. [Google Scholar] [CrossRef]

- Lee, J.; Choi, B. Effects of Channel Type and Doping on Hysteresis in Low-Temperature Poly-Si Thin-Film Transistors. IEEE Trans. Electron. Devices 2018, 65, 986–994. [Google Scholar] [CrossRef]

- Hwang, H.W.; Hong, S.; Hwang, S.S.; Kim, K.W.; Ha, Y.M.; Kim, H.J. Analysis of Recoverable Residual Image Characteristics of Flexible Organic Light-Emitting Diode Displays Using Polyimide Substrates. IEEE Electron. Device Lett. 2019, 40, 1108–1111. [Google Scholar] [CrossRef]

- Chen, M.; Lei, J.; Huang, S.; Liao, C.; Deng, L. Poly-Si TFTs integrated gate driver circuit with charge-sharing structure. J. Semicond. 2017, 38, 55001. [Google Scholar] [CrossRef]

- Radfar, M.; Shah, K.; Singh, J. A highly sensitive and ultra low-power forward body biasing circuit to overcome severe process, voltage and temperature variations and extreme voltage scaling. Int. J. Circuit Theory Appl. 2013, 43, 233–252. [Google Scholar] [CrossRef]

- Anthony, B.; Xavier, A.; Frederic, C.; Dominique, D.; Jean, B.B. A robust inverter-based amplifier versus PVT for discrete-time integrators. Int. J. Circuit Theory Appl. 2018, 46, 2160–2169. [Google Scholar]

| Reference | TFT Number | TFT Type | Number of Scan Lines | Scanning Signal Types | Flicker Prevention | Detection Time Extension |

|---|---|---|---|---|---|---|

| [5] | 6T1C | p-type, poly-Si | 3 | 3 | No | Yes |

| [7] | 5T2C | p-type, poly-Si | 3 | 3 | Yes | Yes |

| [8] | 5T2C | p-type, poly-Si | 4 | 4 | Yes | Yes |

| [9] | 5T2C | n-type, a-Si:H | 3 | 3 | Yes | Yes |

| [11] | 3T2C | p-type, poly-Si | 2 | 2 | No | No |

| [17] | 5T2C | p-type, poly-Si | 3 | 3 | Yes | Yes |

| This work | 7T2C | p-type, poly-Si | 2 | 1 | Yes | Yes |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| W/L (P1) | 4 μm/10 μm | W/L (P7) | 4 μm/4 μm |

| W/L (P2) | 4 μm/4 μm | VSCA | −10–5 V |

| W/L (P3) | 4 μm/4 μm | VSS | −4 V |

| W/L (P4) | 4 μm/4 μm | VREF | −1 V |

| W/L (P5) | 4 μm/4 μm | CTH | 0.1 pF |

| W/L (P6) | 4 μm/4 μm | CST | 0.3 pF |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| W/L (G1) | 500 μm/4 μm | W/L (G6) | 10 μm/4 μm |

| W/L (G2) | 30 μm/4 μm | C1 | 0.8 pF |

| W/L (G3) | 20 μm/4 μm | CK | −10–5 V |

| W/L (G4) | 10 μm/4 μm | IN | −10–5 V |

| W/L (G5) | 10 μm/4 μm | VGH | 5 V |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ke, J.; Deng, L.; Zhen, L.; Wu, Q.; Liao, C.; Luo, H.; Huang, S. An AMOLED Pixel Circuit Based on LTPS Thin-film Transistors with Mono-Type Scanning Driving. Electronics 2020, 9, 574. https://doi.org/10.3390/electronics9040574

Ke J, Deng L, Zhen L, Wu Q, Liao C, Luo H, Huang S. An AMOLED Pixel Circuit Based on LTPS Thin-film Transistors with Mono-Type Scanning Driving. Electronics. 2020; 9(4):574. https://doi.org/10.3390/electronics9040574

Chicago/Turabian StyleKe, Jianyuan, Lianwen Deng, Liying Zhen, Qing Wu, Congwei Liao, Heng Luo, and Shengxiang Huang. 2020. "An AMOLED Pixel Circuit Based on LTPS Thin-film Transistors with Mono-Type Scanning Driving" Electronics 9, no. 4: 574. https://doi.org/10.3390/electronics9040574

APA StyleKe, J., Deng, L., Zhen, L., Wu, Q., Liao, C., Luo, H., & Huang, S. (2020). An AMOLED Pixel Circuit Based on LTPS Thin-film Transistors with Mono-Type Scanning Driving. Electronics, 9(4), 574. https://doi.org/10.3390/electronics9040574