Abstract

This paper is focused in the development of a parallel control loop of the angular velocity and torque for Brushless Direct Current (BLDC) motors. This parallel loop is proposed as an improvement for the performance of those cascaded solutions commonly reported in the body of literature of the field. Performance is improved by reducing the steady state error of the speed considerably when compared with the typical cascaded loop solution under a commanded change of torque. In addition, the steady state response of the parallel loop is reached in a shorter time. Simulations were designed to carry out a comparison between both methodologies. The results of these simulations consider only changes in the set point for speed or torque and are reported here. The control signal was applied to a simulated driver using a switching method known as Direct Torque Control of 2 and 3 phases (DTC-2+3P). These preliminary results show that the parallel control loop outperforms the cascaded control of BLDC motors.

1. Introduction

Brushless Direct Current (BLDC) motors are currently one of the most used motors in the industry, covering several applications. The torque control of BLDC motors is particularly useful in systems, like manipulator robots, elevators, and electric vehicles, among others. BLDC motors stand out for two fundamental characteristics: the first one is that the magnetic field of the rotor is generated through permanent magnets, allowing a considerable reduction in heating due to losses of Joule effect, as well as allowing the reduction of its size without the risk of failure; the second one is that the commutation of the stator windings is done electronically, using power transistors, which allows elimination of the disadvantages of the mechanical commutation, reducing the maintenance cycles, as well as the elimination of the losses and of the electromagnetic interference generated by the commutation. In order to improve BLDC performance, four areas of research are currently being pursued: improvement on manufacturing materials, power electronic drivers, feedback sensors, and control techniques. The main purpose of this work was centered on the study of control techniques for simultaneous control of speed and torque.

Simultaneous control of motor speed and torque are required in a variety of applications. For instance, robotic joints need to move to a controlled pace, while at the same time keeping torque regulated when carrying a load [1]. Another example of a simultaneous speed and torque control are CNC machines. The cutting speed at which the tool spins is set accordingly to the material being processed, while the feeding rate, the speed at which the tool is pressed against the material, requires control of the torque exerted by the cutting tool on the material. Propellers on a drone need to rotate at a high rate to produce a stream of air powerful enough to force the drone to hover or to fly. However, faster rotation of the propellers implies a higher torque load on the motor. Therefore, simultaneous control of speed and torque may be required for sustained thrust in hover mode. In general, for simultaneous speed and torque control, an important requirement is to keep the speed error close to zero, i.e., without offset, even when change of torque load occurs, which actually happens in many practical applications.

A common method for simultaneous control of speed and torque consists of a double loop control, one of which involves a PI controller with a speed feedback loop; the other one is made up of a controller for torque. Both of these controllers are set up in a cascaded configuration [2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22]. Belov [1] presents a triple control loop in cascade, considering position, speed, and torque, with an ANN compensator for torque.

In this work, two algorithms for simultaneous speed and torque control that were studied are presented. The first of these controllers consists of a double loop, similar to the controllers just described in the paragraph above [2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22]. The second controller consists of two independent control loops, in which both outputs are added up and constitute the control signal. The proposed configuration consisting of two parallel loops seems to have not been considered in previous works, and the authors assume this to be one of the contributions of the present work.

Lad [5] realized an experimental scheme with a cascaded loop, in which can be seen that the actual speed do not match the set point speed. In each change of set up speed, the steady state speed shows an steady state error. Gao [10] experimented with a cascaded control. For a sudden increase in the torque load, speed decreases, increasing the steady state error for speed. On the one hand, when the load is decreased, the steady state error is smaller. On the other hand, when the load is increased, the steady state error for speed increases. Additional examples of speed error, due to a change in the torque load, are found in Reference [21,23]. Our simulations show that the cascaded controller possess such disadvantage. However, the parallel configuration presented here significantly reduces the steady state error on speed when the load changes.

The main contribution of this work consists on the design and application of a parallel loop for simultaneous torque-speed control. The simulation results of the parallel loop controller are compared with the results from a conventional cascaded loop controller. The results presented here show that the parallel loop controller presents an improvement over the cascaded loop controller when the torque load is changed.

One of the objectives pursued is the reduction of the mechanical torque ripple that is generated on the shaft as a result of the switching phenomena, including the constructional nature of the motor and the commutation of transistors. For that purpose, Direct Torque Control (DTC) was chosen as the commutation technique applied for the motor driver. In conventional DTC, the electromagnetic torque and stator flow are controlled in a direct fashion, where each transistor is commuted optimally [4,24,25]. The commutation sequence of the transistors can be read in order from a look-up table [24]. Other works report DTC control using only electromagnetic torque feedback, neglecting the stator flow [11,26]. This last approach was used in this work. We determined that the DTC-2+3P is the most appropriate method because it combines the benefits of DTC-2P and DTC-3P.

The rest of the paper is organized as follows: In Section 2, the non-linear model of a BLDC motor is described in detail. Section 3 presents the description of the two control loops, namely, cascaded loop and parallel loop. Section 4 illustrates the DTC commutation technique used. In Section 5, the simulation setup is described, the comparison conditions are defined, and simulation results are presented. Finally, Section 6 summarizes the conclusions of the work.

2. Mathematical Model of a BLDC Motor and Driver

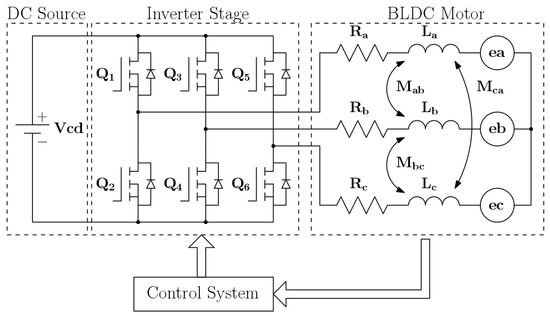

Consider a BLDC motor wired in a star configuration, as shown in Figure 1.

Figure 1.

General block diagram depicting the main components of a Brushless Direct Current (BLDC) motor and its driver.

The angular position of the rotor is related to the electrical phase by

where p is the number of pole pairs of the rotor. In a similar way, the angular velocity of the rotor is related to the rate of change of the electrical phase by

Assuming that the switching MOSFETs and the flyback diodes can be modeled as ideal switching devices [27,28], then, a general network equation for the motor is found to be

where subindex x denotes either phase a, b, or c. Here, is the voltage applied to each phase of the stator, is the intrinsic resistance of the wiring per phase, and is the current per phase. Finally, is the back-EMF per phase. The total coupling flux results from the vector addition of the magnetic flux produced by the currents in the stator and the magnetic flux generated by the permanent magnets in the rotor. For example, observing phase of the motor from Figure 1, the magnetic flux can be described by

The terms, , , and represent self-inductance of the wiring in phase , the two mutual inductances between the wiring of phases and , and phases and , respectively. The term represents the magnetic flux produced by the permanent magnets, which is coupled to the phase . For the purpose of the present analysis, it is assumed that the motor is perfectly balanced; thus, , , , and .

Here, the term is known as the back-EMF of the phase (either a, b, or c), and it is denoted as in the rest of this work. In vector form, Equation (5) becomes

The back-EMF in phase a can be computed from

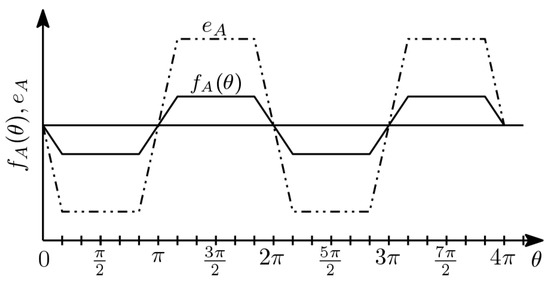

where is a constant value, and represents the back-EMF waveform function of phase a (see Figure 2). Taking advantage of the symmetry of the waveforms, we have and .

Figure 2.

Waveform of and .

Separating the time derivative of the current in Equation (6) and replacing the terms as in Equation (7), we get

The electrical portion of the motor is related to the mechanical part as described by the well known equation

and inserting the back-EMF terms defined in Equation (7) into Equation (9) results in

Finally, the mechanical torque of the motor is modeled by

where is the electromagnetic torque; is the torque produced by the load attached to the shaft of the rotor; is the angular velocity of rotation; J is the overall inertia moment of the rotor and load; and is the viscous friction coefficient of the rotor and load. Rearranging Equation (11) and replacing with the right side of Equation (10) leads to

In general, the electromechanical operation of the motor can be represented in state equation form as

which is constructed by rearranging Equations (8) and (12).

In this case, the state vector is defined as

and the input vector is

Function is defined as

and the matrix is

The resulting state Equation is

3. Control Loop

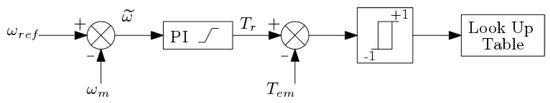

In a typical cascaded control configuration, the output of the PI velocity controller operates as reference for torque of the second loop. In the torque control loop, the torque error, , results from subtracting the electromagnetic torque from the previously computed torque references. This can be seen in Figure 3.

Figure 3.

Block diagram of a cascaded PI controller.

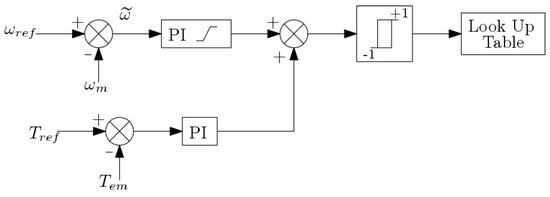

The proposed parallel loop control consists of two independent control loops. One of these loops is a PI velocity control, and the other one is a PI torque control. The output of both PI controllers is added up to produce the control action, as shown in Figure 4.

Figure 4.

Block diagram of a parallel PI controller.

In both controllers, an anti-windup compensator was implemented. The anti-windup compensator avoids controller saturation resulting from an excessive growth of the integral action error [27,29].

4. Direct Torque Control (DTC)

In the DTC method, the electrical parameters of the motor must be transformed into a stationary reference frame known as the plane. The horizontal axis is fixed alongside the a axis and the vertical axis , which leads axis by . The transformation is carried out analytically, by means of the Clarke’s transformation matrix [7], as follows:

For a single switching device, it is needed to:

- Define voltage vectors and work sectors in the plane.

- Study the effect of the voltage vectors on the magnetic flux of the stator on each sector of the plane, and define a look-up table for the angular position of the rotor.

- Using a measurement of the actual angular position of the rotor and the control error as entry readings of the look-up table, we find the voltage vector, which is to be applied to the phases of the motor.

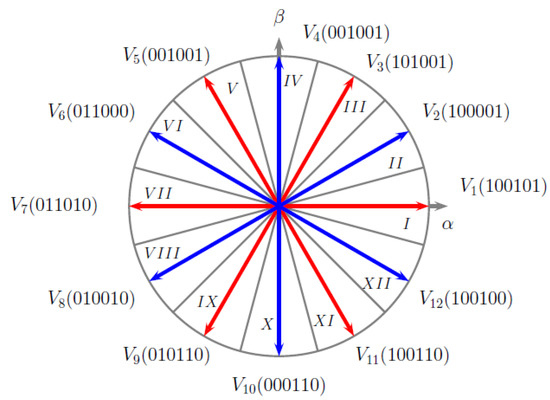

Keeping in mind that each phase is electrically excited from a half-bridge arrangement, there are a total of six switching transistors, therefore, six logical states, which define the corresponding switching state of each transistor. Each switching state is associated to a voltage vector in either the or the plane. For the DTC-2+3P, twelve voltage vectors and twelve operation sectors are defined for the plane. Both voltage vectors and sectors for DTC-2+3P are illustrated in Figure 5.

Figure 5.

Voltage vectors and sectors for a Direct Torque Control of 2 and 3 phases (DTC-2+3P).

Rotor torque is a function of angular velocity of the flux vector of the stator [30]; thus, directly affecting this parameter, torque can be made to increase or decrease accordingly. This is achieved by applying the appropriate voltage vector to the stator when the vector flux is pointing at a previously determined sector.

A DTC-2+3P was implemented based on the effect just described. The flux control was not implemented, and the control signal was processed in a two-level hysteresis block to produce the control action. Table 1 illustrates the operation modes, required by each sector, for a DTC-2+3P control. The operation vectors are shown in Figure 5.

Table 1.

Look-up table for a DTC-2+3P, without flux control.

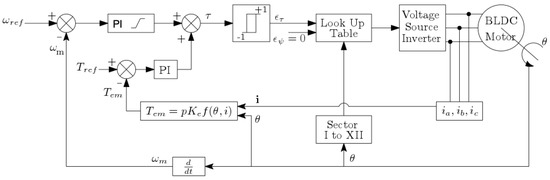

Figure 6 illustrates in a block diagram, the combination of the mathematical model of the motor, the control loops shown in Figure 3 and Figure 4, and the look-up table to implement DTC-2+3P control.

Figure 6.

Block diagram of the DTC-2+3P closed loop control proposed in this work.

5. Simulation

5.1. Simulation Block Parameters

Simulink from MATHWORKS was used to conduct all simulations. All power components used in the simulations are part of the Simscape Power Systems toolbox. The solver is set to operate in discrete mode, with a sampling time of 3 s. Power MOSFETs were simulated by setting up the Mosfet block with the parameters shown in Table 2.

Table 2.

Operational parameters of the MOSFET transistors.

The BLDC motor was simulated using the Permanent Magnet Synchronous Machine block, which possesses an input for load torque. This block implements the mathematical model described in Section 2. The motor parameters were set up in agreement with those illustrated in Table 3.

Table 3.

Nominal operational parameters of the BLDC motor model used for simulation.

5.2. Simulated Comparison Test

A simulation test was designed to carry out a comparison between the conventional cascaded DTC control and the method proposed in this work. For this purpose, the following operational parameters were analyzed

- Rise time/Fall time ()

- Settling time ()

- Mean value ()

- Ripple value ()

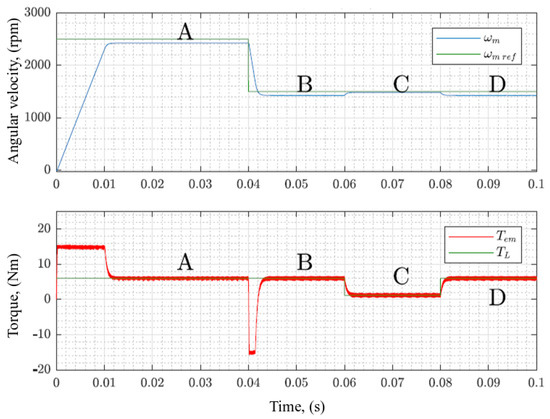

Performance for both speed and torque control was tested for both methods, based on four operational set-points. Point A drives the motor from initial conditions or 0 rpm and 0 N·m, up to a speed of 2500 rpm and a torque of 6 N·m. This first set point is followed by a second or B set-point, where speed is reduced to 1500 rpm and torque is kept constant at 6 N·m. The set-point B is then followed by the C set-point, where speed is now kept constant at 1500 rpm, while torque is reduced to 1.2 N·m. Finally, on set-point D, speed is kept constant while torque is increased back to 6 N·m.

5.3. Simulation Results

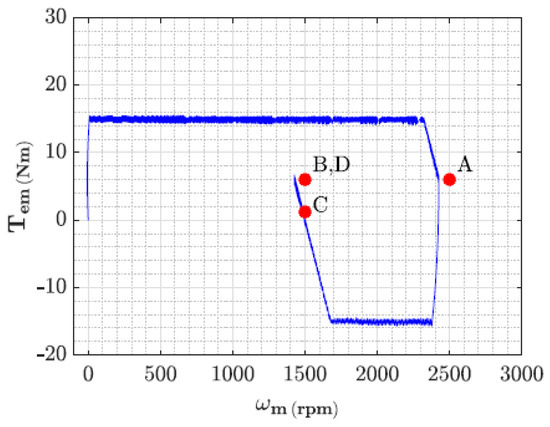

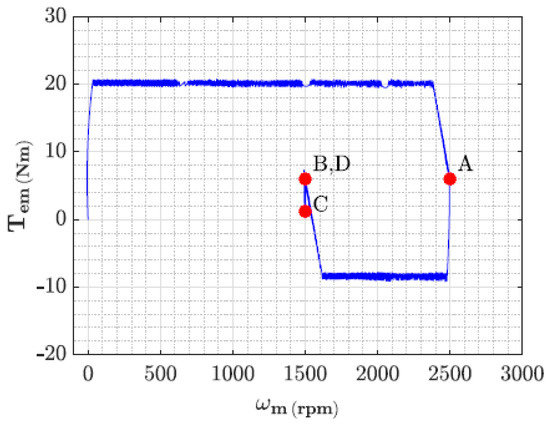

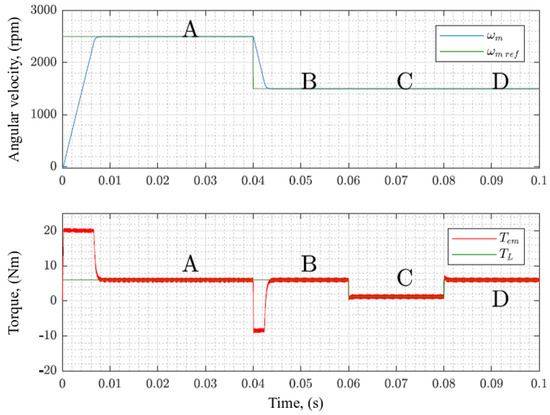

The cascaded PI controller shown in Figure 3 was simulated by applying the sequence illustrated in Table 4. Figure 7 shows the response of the mechanical characteristics, in a torque versus velocity plot, for the whole length of the simulation, highlighting the desired operating points. Figure 8 illustrates the speed and torque curves, respectively, in time domain. Table 5 shows the values of the operating parameters analyzed.

Table 4.

Operational range for simulations.

Figure 7.

PI control loop, series configuration. Mechanical characteristics.

Figure 8.

PI control loop, series configuration. Speed and torque plots.

Table 5.

PI control loop, cascaded configuration. Transient and steady state responses.

The parallel loop PI controller, illustrated in Figure 4, was simulated under the same conditions as the cascaded PI. Figure 9 depicts the mechanical response of the controller. Figure 10 shows the speed and torque curves, respectively. Table 6 presents the values of the selected operational parameters used to evaluate the performance of the controller.

Figure 9.

PI control loop, parallel configuration. Mechanical characteristics.

Figure 10.

PI control loop, parallel configuration. Transient and steady state responses.

Table 6.

PI control loop, parallel configuration. Transient and steady state responses.

5.4. Discussion

- At the beginning, when the rotor is gathering up speed, from 0–2500 rpm, an overshoot is observed on the torque response for both controllers. For the cascaded PI controller, this overshoot goes up to a maximum of 15 N·m. In the case of the parallel PI controller, the overshoot goes over 20 N·m. Although this may be seen as a disadvantage, it can be observed that the duration of the overshoot in the parallel PI controller is shorter than in the cascaded PI controller.

- Moving to operation point B, when speed is now reduced to 1500 rpm, an overshoot on the torque is now observed in the opposite direction. In this case, the magnitude of the overshoot is smaller for the parallel PI controller, reaching N·m. For the cascaded PI controller, the overshoot reaches close to N·m but shows a shorter duration than that of the parallel PI controller.

- The time span of the rise time in the speed plot corresponds to the duration of the torque overshoot. Therefore, on the one hand, it can be concluded that under simultaneous speed-torque control, torque must be increased transiently in order to increase the speed. On the other hand, torque must be reduced in order to reduce speed. This interrelation between torque and speed can be explained by studying Equation (11). Here, the input to control speed is precisely . Whence, reducing the angular speed requires a negative torque.

- From visual inspection, it becomes evident that the controller is insensitive to changes in the load torque. This is different from the cascaded controller when speed must remain constant, while a change on the torque set-point must be performed. This is illustrated in points C and D. In clear contrast, the parallel loop allows that both speed and torque be regulated with a small or no error at all.

- It can be observed that, in the case of the cascaded PI controller, there is a steady state error, which is proportional to the magnitude of the reference torque . This is not the case for the parallel PI controller.

- Taking into account the response time, insensitivity to torque changes, steady state error, and the level of torque ripple, it can be concluded that the proposed parallel controller offers an improved performance over the cascaded controller.

6. Conclusions

In this work, a parallel loop control for simultaneous control of torque and speed is presented and comparisons with cascaded controllers were analyzed. The simulated power driver was based on the DTC-2+3P commutation configuration, which is an improved commutation technique over the DTC-2P and DTC-3P configurations. Simulations were carried out for both cascaded control and parallel control, for comparison purposes. In particular, transitions among different operating points were considered, especially those where the torque set-point is changed either to increase or decrease. It was observed from cascaded controllers that a steady state error on speed develops after a transition among different set-point changes for torque, [5,10,21,23]. Therefore, the cascaded controller configuration keeps close regulation for torque but may fail to keep close regulation for speed. Moreover, the parallel controller proposed in this work reduces the steady state error on speed during the transition among any set-point changes for torque, thus keeping close regulation for speed and torque simultaneously. The parallel controller is, therefore, insensitive to variations on the reference torque. Taking into account the rise and fall times, settling time, steady state error, ripple, and the insensitivity to changes in the torque reference, it is concluded that the parallel loop controller provides an improvement over the conventional cascaded loop controller for simultaneous control of speed and torque.

Implementation of the parallel controller and research about sensorless techniques are considered for future work.

Author Contributions

Conceptualization was carried out by R.G.-F. Formal analysis was performed by J.R.N. and L.A.G.-D. Investigation was in charge of J.C.-P. and R.G.-F. while Methodology was done by J.R.N. and L.A.G.-D. The project administrators are L.A.G.-D. and R.G.-F. The Software development and validation was the work of J.C.-P. The supervisors of the work were R.G.-F. and J.R.N. The original writing was the work of L.A.G.-D., while reviewing and editing was done by J.R.N. and visualization was performed by R.G.-F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Belov, M.P.; Dang Khoa, T.; Truong, D.D. BLDC of Robotic Manipulators with Neural Torque Compensator based Optimal Robust Control. In Proceedings of the 2019 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (EIConRus), Saint Petersburg and Moscow, Russia, 28–31 January 2019; pp. 437–441. [Google Scholar]

- Nagaraju, A. Modeling of Direct Torque Control ( DTC ) of BLDC Motor Drive. Int. J. Sci. Technol. Eng. 2017, 3, 413–419. [Google Scholar]

- Liu, Y.; Zhu, Z.Q.; Howe, D. Commutation-torque-ripple minimization in direct-torque-controlled PM brushless DC drives. IEEE Trans. Ind. Appl. 2007, 43, 1012–1021. [Google Scholar] [CrossRef]

- Liu, Y.L.Y.; Zhu, Z.Q.; Howe, D. Direct torque control of brushless DC drives with reduced torque ripple. IEEE Trans. Ind. Appl. 2005, 41, 599–608. [Google Scholar] [CrossRef]

- Lad, C.K.; Chudamani, R. A simple overlap angle control strategy for reducing commutation torque ripple in a brushless DC motor drive. Eng. Sci. Technol. Int. J. 2017, 20, 1406–1419. [Google Scholar] [CrossRef]

- Korkmaz, F.; Topaloğlu, I.; Mamur, H. Modified Direct Torque Control for Bldc Motor Drives. Int. J. Control Theory Comput. Model. (IJCTCM) 2016, 6, 1–9. [Google Scholar] [CrossRef]

- Korkmaz, F. A New Approach to DTC Method For BLDC Motor Adjustable Speed Drives. Comput. Sci. Inf. Technol. 2016, 6, 37–44. [Google Scholar]

- Hadeed, H.; Gottscheber, A. Six Step Control vs Direct Torque Control comparative evaluation for BLDC drive. Int. J. Recent Innov. Trends Comput. Commun. 2017, 5, 422–427. [Google Scholar]

- Garcia, X.d.T.; Zigmund, B.; Terlizzi, A.A.; Pavlanin, R.; Salvatore, L. Comparison between FOC and DTC Strategies for Permanent Magnet Synchronous Motors. Adv. Electr. Electron. Eng. 2006, 5, 76–81. [Google Scholar]

- Gao, J.; Hu, Y. Direct self-control for BLDC motor drives based on three-dimensional coordinate system. IEEE Trans. Ind. Electron. 2010, 57, 2836–2844. [Google Scholar]

- Li, W.; Wu, A.; Wang, Y.; Dong, N. Direct torque control for BLDCM based on optimized sliding mode observer. In Proceedings of the 2016 12th World Congress on Intelligent Control and Automation (WCICA), Guilin, China, 12–15 June 2016; pp. 2907–2912. [Google Scholar]

- Yang, J.; Hu, Y.; Huang, W.; Chu, J.; Gao, J. Direct torque control of Brushless DC motor without flux linkage observation. In Proceedings of the 2009 IEEE 6th International Power Electronics and Motion Control Conference, Wuhan, China, 17–20 May 2009; pp. 1934–1937. [Google Scholar]

- Haipeng, P.; Minming, G.; Junjie, G. A Kind of Simplified Structure Direct Torque Control Method for Brushless DC Motor. In Proceedings of the 2013 Third International Conference on Instrumentation, Measurement, Computer, Communication and Control, Shenyang, China, 21–23 September 2013; pp. 1480–1483. [Google Scholar]

- Geraee, S.; Shafiei, M.; Sahami, A.R.; Alavi, S. Position sensorless and adaptive speed design for controlling brushless DC motor drives. In Proceedings of the 2017 North American Power Symposium (NAPS), Morgantown, WV, USA, 17–19 September 2017; pp. 1–6. [Google Scholar]

- Mars, R.; Bouzidi, B.; Badsi, B.E.; Yangui, A. DTC of three-level inverter fed brushless DC motor drives with torque ripple reduction. In Proceedings of the 2018 Thirteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 10–12 April 2018; pp. 1–10. [Google Scholar]

- Sandeep, J.; Nair, D.S.; George, S.; Ashok, S.; Jagadan, G.; Ramchand, R. Performance Comparison of Direct Torque Controlled Permanent Magnet Machines. In Proceedings of the IECON 2018—44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 631–636. [Google Scholar]

- Uyar, O.; Cunkas, M. Torque and Speed Control of BLDC Motor for Pedelec. In Proceedings of the 5th International Conference on Innovation in Science and Technology, Barcelona, Spain, 7–9 December 2018; pp. 64–73. [Google Scholar]

- Sharma, T.R.; Pal, Y. Direct Torque Control of BLDC Drives With Reduced Torque Pulsations. In Proceedings of the 2019 3rd International conference on Electronics, Communication and Aerospace Technology (ICECA), Coimbatore, India, 12–14 June 2019; pp. 1242–1247. [Google Scholar]

- Kommula, B.N.; Kota, V.R. Direct instantaneous torque control of Brushless DC motor using firefly Algorithm based fractional order PID controller. J. King Saud Univ. - Eng. Sci. 2018, 32, 133–140. [Google Scholar] [CrossRef]

- Yuan, T.; Wang, D. Performance Improvement for PMSM DTC System through Composite Active Vectors Modulation. Electronics 2018, 7, 263. [Google Scholar] [CrossRef]

- Park, J.B.; Wang, X. Sensorless Direct Torque Control of Surface-Mounted Permanent Magnet Synchronous Motors with Nonlinear Kalman Filtering. Energies 2018, 11, 969. [Google Scholar] [CrossRef]

- Wang, D.; Yuan, T.; Wang, X.; Wang, X.; Li, W. A Composite Vectors Modulation Strategy for PMSM DTC Systems. Energies 2018, 11, 2729. [Google Scholar] [CrossRef]

- Agrawal, L.K.; Chauhan, B.K.; Banerjee, G.K. A Composite Vectors Modulation Strategy for PMSM DTC Systems. Int. J. Pure Appl. Math. 2018, 116, 3955–3959. [Google Scholar]

- Vas, P. Sensorless Vector and Direct Torque Control; Monographs in Electrical and Electronic Engineering; Oxford University Press: New York, NY, USA, 1998; Volume 1, p. 768. [Google Scholar]

- Toufouti, R.; Meziane, S.; Benalla, H. Direct Torque Control for Induction Motor Using Fuzzy Logic. ACSE J. 2006, 6, 19–26. [Google Scholar]

- Ozturk, S.B.; Toliyat, H.A. Direct torque control of brushless dc motor with non-sinusoidal back-EMF. In Proceedings of the 2007 IEEE International Electric Machines Drives Conference, Antalya, Turkey, 3–5 May 2007; pp. 165–171. [Google Scholar]

- Xia, C.L. Permanent Magnet Brushless DC Motor Drives and Controls; John Wiley & Sons Singapore Pte. Ltd.: Singapore, 2012. [Google Scholar]

- Krause, P.C.; Wasynczuk, O.; Sudhoff, S.D.; Pekarek, S. Analysis of Electric Machinery and Drives Systems, 2nd ed.; Wiley-IEEE Press: Piscataway, NJ, USA, 2002. [Google Scholar]

- Astrom, K.J.; Rundqwist, L. Integrator Windup and How to Avoid It. In Proceedings of the 1989 American Control Conference, Pittsburgh, PA, USA, 21–23 June 1989; pp. 1693–1698. [Google Scholar]

- Akshay, R.S.R.; Chaudhari, M.A. Direct torque control of PM BLDC motor using fuzzy controllers. In Proceedings of the 2017 International Conference on Innovations in Information, Embedded and Communication Systems (ICIIECS), Coimbatore, India, 17–18 March 2017; pp. 1–6. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).