Techno-Economic Optimization of Small-Scale Hybrid Energy Systems Using Manta Ray Foraging Optimizer

Abstract

1. Introduction

- ■

- A novel MRFO was implemented in this paper for the first time to attain the optimal sizing of a standalone HES based on minimizing the annualized system cost (ASC) and enhancing the system reliability.

- ■

- The off-grid HES consisting of PV/WTGs/battery/diesel was proposed to supply an off-grid northern area in Saudi Arabia—Al Sulaymaniyah village—taking both the technical and economic factors into consideration.

- ■

- The MRFO was compared with five other soft computing algorithms—PSO, GA, GOA, BBBC, and HHO—for verification purposes.

- ■

- The results showed that the MRFO algorithm converges faster than all other five soft computing algorithms followed by PSO, and GOA, respectively. In addition, MRFO, PSO, and GOA can follow the optimal global solution while the HHO, GA and BBBC may fall into the local solution and take longer time to converge.

- ■

- These optimization findings confirmed the supremacy of the MRFO algorithm over the other five soft computing techniques in terms of global solution capture and the convergence time.

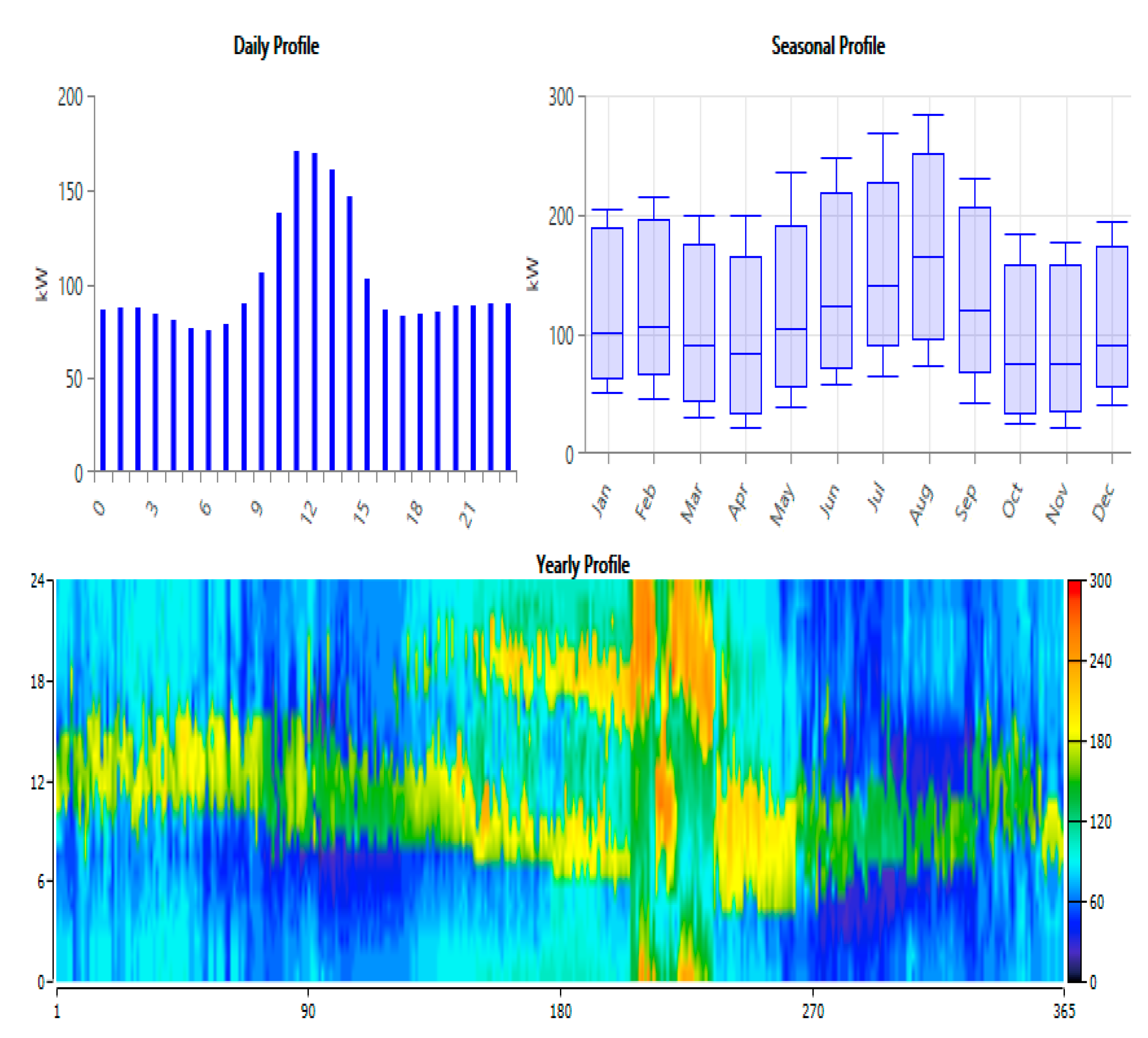

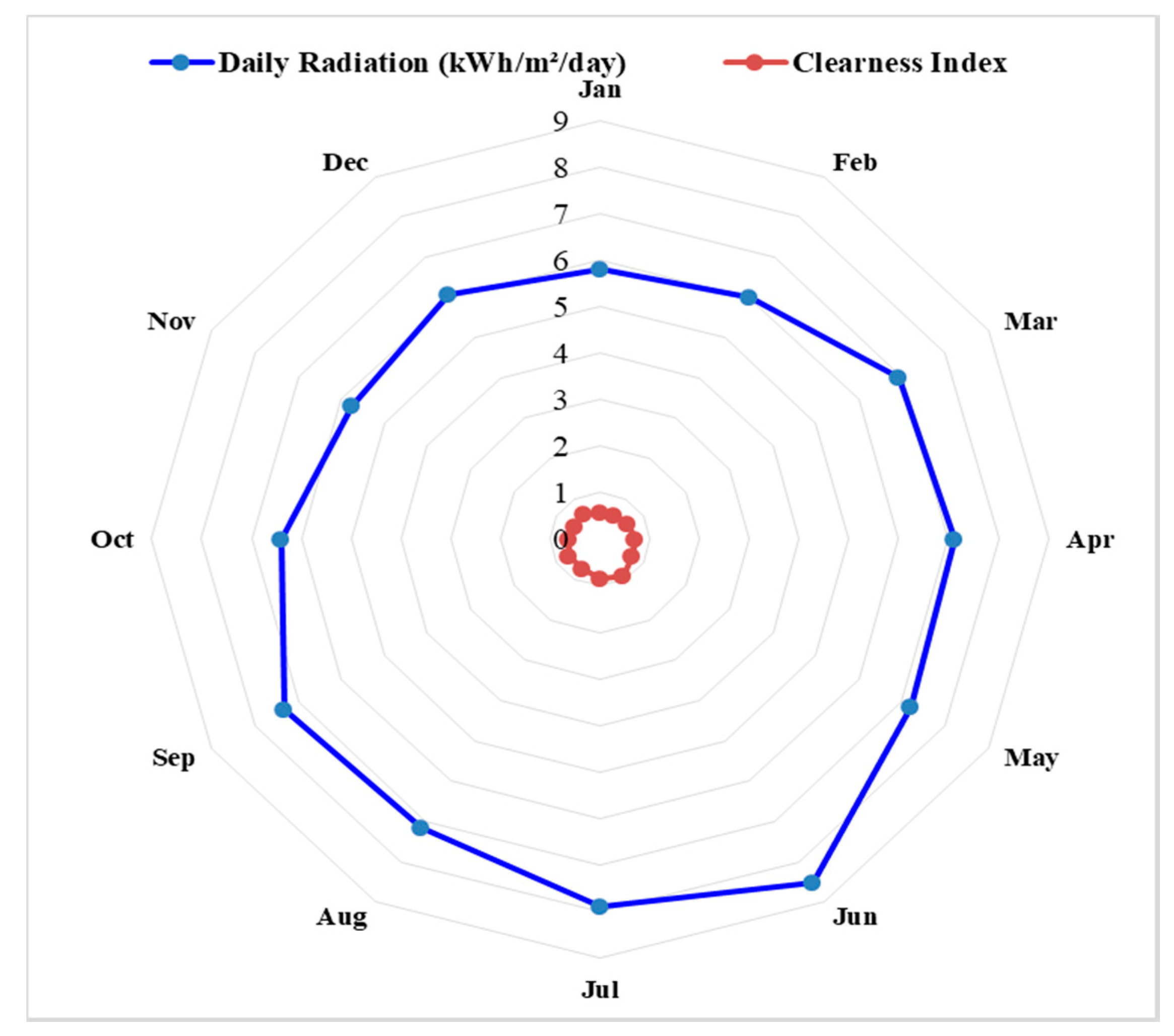

2. Site Description and Meteorological Data

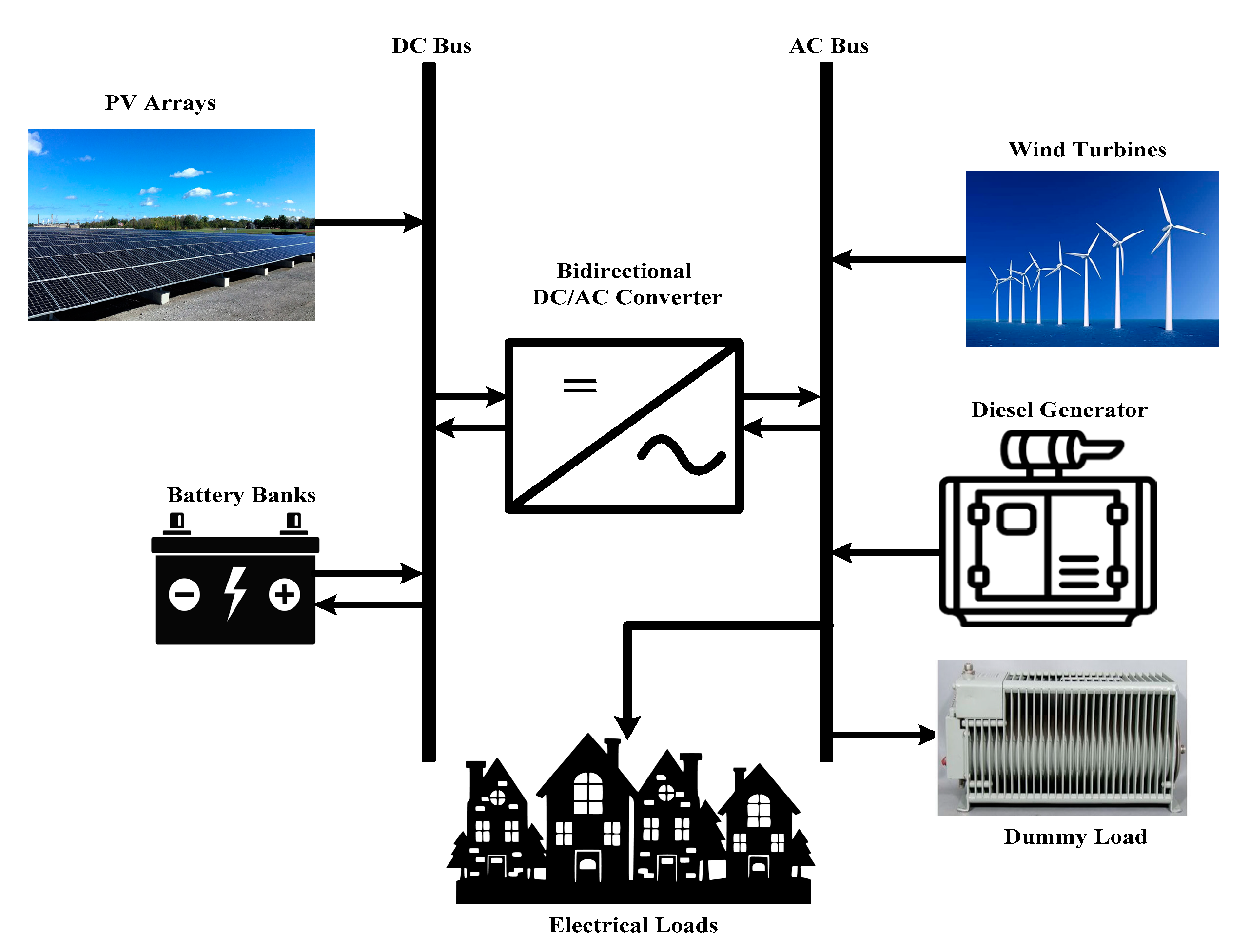

3. Proposed Configuration of the Hybrid Energy System

3.1. PV Array Modeling

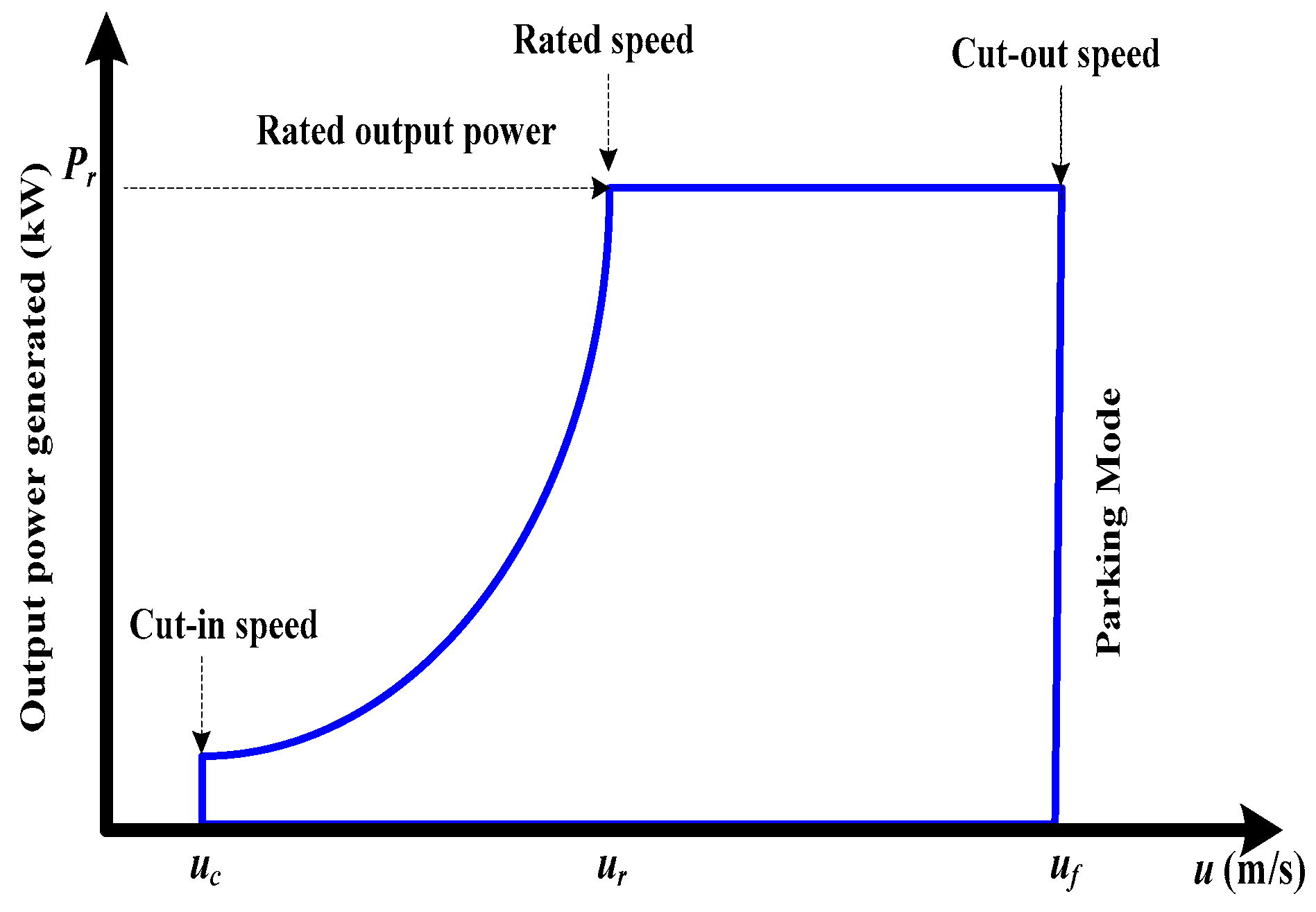

3.2. Wind Turbine Generator Modeling

3.3. Battery Bank Modeling

3.4. Diesel Generator Modeling

3.5. Operation Strategy of the HES

- In the case of load deficiency lower than the minimum allowable power of the diesel generator, the diesel generator will operate at its minimum allowable level, and the surplus power is dumped.

- In the case of the load not supplied higher than the minimum allowable level and less than the diesel generator nominal power, the load not supplied is covered through the diesel generator. Whereas in the case of the load not supplied higher than the diesel generator nominal power, the diesel generator will operate at the nominal power, and the power not supplied is covered through the battery if the stored capacity is appropriate.

4. Problem Statement

4.1. LPSP-Based Reliability Model

4.2. Renewable Energy Fraction

4.3. Application of MRFO in HES Sizing Problem

| Algorithm 1 Pseudo code of the manta ray foraging optimization (MRFO) algorithm for the optimal sizing of an autonomous HES. |

| 1: Initialize the somersault factor dimension , population of manta rays and the maximum iteration |

| 2: Initialize the and |

| 3: Initialize the such that the objective function is as close to as possible. |

| 4: for each individual do |

| 5: for each dimension do |

| 6: Initialize the randomly |

| 7: |

| 8: end for |

| 9: Compute the objective function |

| 10: if then |

| 11: for each dimension do |

| 12: |

| 13: end for |

| 14: end if |

| 15: end for |

| 16: Iteration |

| 17: while . do |

| 18: |

| 19: for each individual do |

| 20: for each dimension do |

| 21: if then |

| 22: Compute and . using (17) |

| 23: if then |

| 24: Update the individual positions using (18) |

| 25: else |

| 26: Update the individual positions using (20) |

| 27: end if |

| 28: else |

| 29: Update the individual positions using (16) |

| 30: end if |

| 31: end for |

| 32: Compute the objective function |

| 33: if then |

| 34: for each dimension do |

| 35: |

| 36: end for |

| 37: end if |

| 38: end for |

| 39: for each individual do |

| 40: for each dimension d do |

| 41: Update the individual positions using (21) |

| 42: Compute the objective function |

| 43: if then |

| 44: |

| 45: end if |

| 46: end if |

| 47: |

| 48: end while |

| 49: Output the best solution found. |

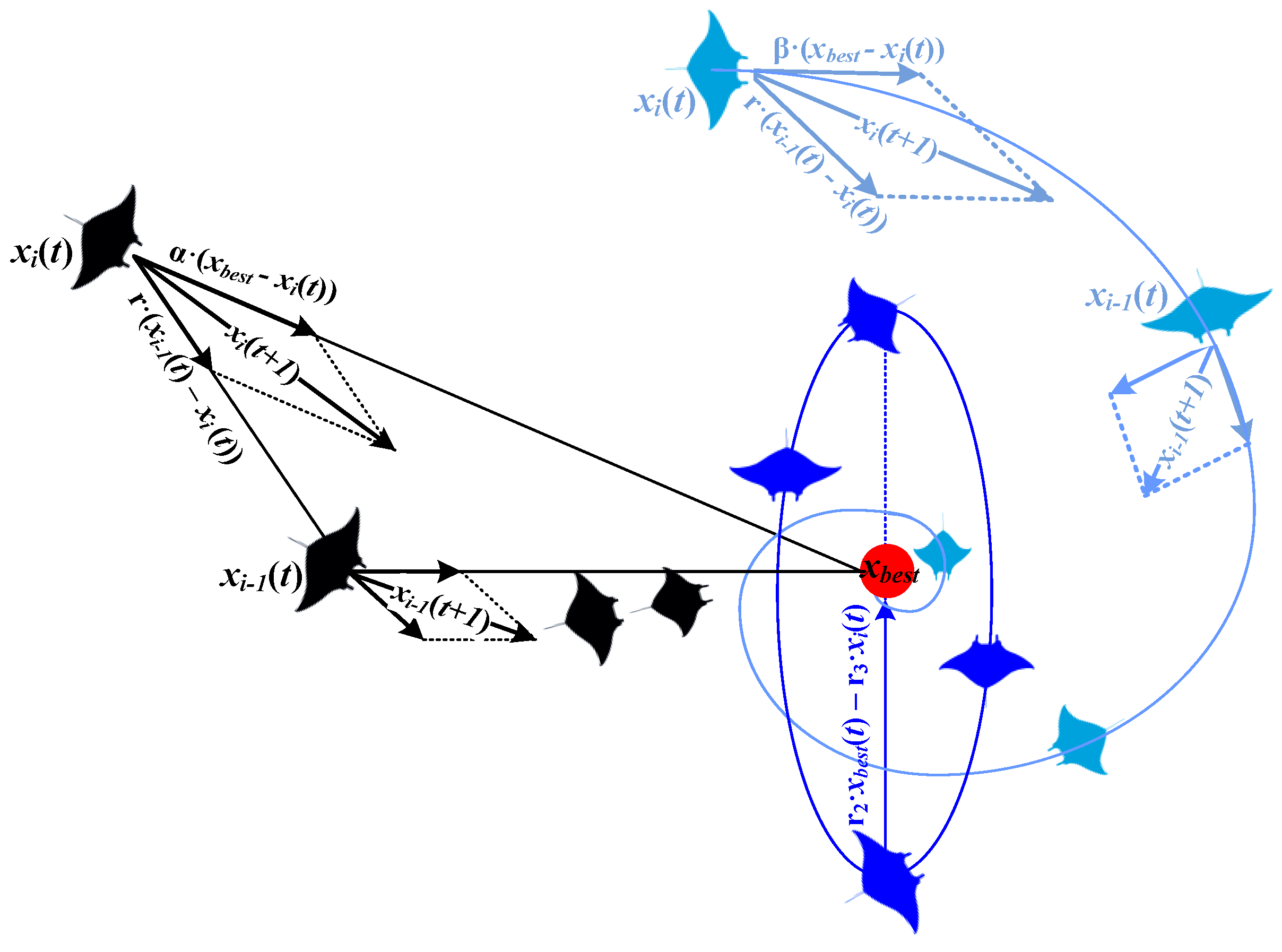

4.3.1. Chain Foraging

4.3.2. Cyclone Foraging

4.3.3. Somersault Foraging

- (i).

- Prepare (a) global solar radiation, wind speed, and load profile; (b) nominal parameters and economic details of the HES components; and (c) the manta ray population, weight coefficient in chain foraging, weight coefficient in cyclone foraging, somersault factor, dimension of the problem, and maximum number of iteration.

- (ii).

- Generate manta ray population through , randomly within the boundaries range using Equation (22):where is the manta ray location produced randomly in the search region, and and represent the lower and upper positions of the dth dimension, respectively.

- (iii).

- Perform the following steps:

- -

- Compute and by using Equations (6) and (8).

- -

- Power management as given in Section 3.5.

- -

- Compute and by using Equations (9) and (11) and obtain the corresponding values of and using Equations (14) and (15), respectively.

- -

- Find the best solution, , based on objective function expressed in Equation (2).

- (iv).

- Update the location of each manta ray using the chain foraging strategy and cyclone foraging strategy as defined in Equations (16), (18), and (20).

- (v).

- Compute the objective function values for each manta ray by following the procedure mentioned in Step (iii) and update the best location found until this point.

- (vi).

- Update the location of each manta ray by using the somersault foraging strategy as defined in Equation (21).

- (vii).

- Repeat Steps (iii) to (vi) until the termination criterion is fulfilled.

5. Simulation Results and Discussion

- ➢

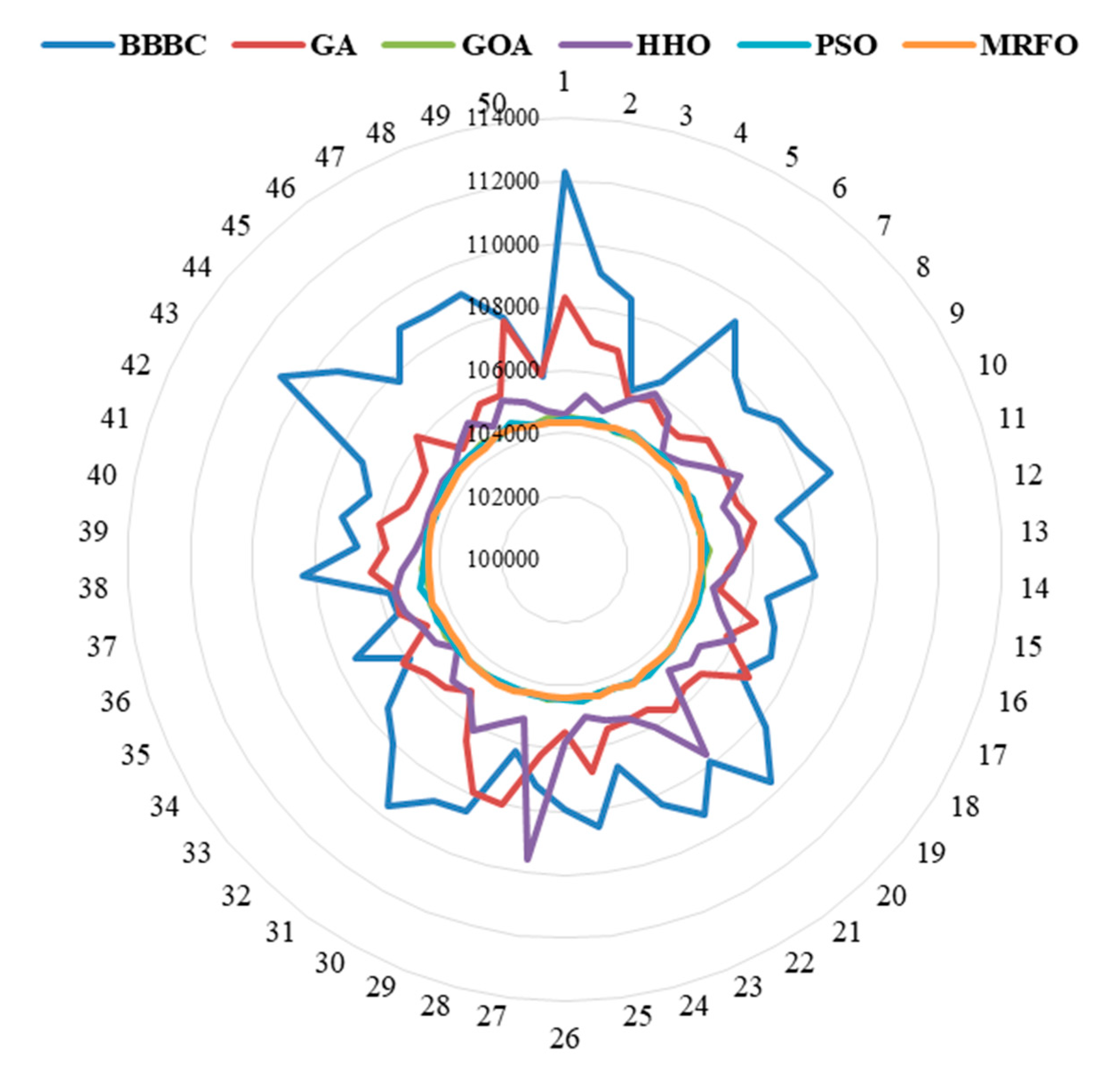

- The soft computing algorithms: MRFO, PSO, and GOA succeeded in following the optimal global solution, whereas HHO, GA, and BBBC failed to reach the optimal solution. As shown in Table 4, the MRFO performed well, where it attained the optimum sizing of the HES with the lowest ASC and highest REF% compared to other five intelligent algorithms.

- ➢

- The soft computing-based algorithms: MRFO, GOA, and PSO attained the smallest STD for the HES including PV, WTG, battery, and diesel generator. This insists on the robustness and promising performance of the MRFO technique.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ma, T.; Yang, H.; Lu, L.; Peng, J. Technical feasibility study on a standalone hybrid solar-wind system with pumped hydro storage for a remote island in Hong Kong. Renew. Energy 2014, 69, 7–15. [Google Scholar] [CrossRef]

- Ciupageanu, D.A.A.; Lazaroiu, G. Dynamic Simulation of a Stand-Alone Photovoltaic/Battery Energy Storage System. In 2018 International Symposium on Fundamentals of Electrical Engineering (ISFEE); IEEE: New York, NY, USA, 2018; pp. 1–5. [Google Scholar]

- Javed, K.K.; Ashfaq, H.H.; Singh, R.R.; Hussain, S.M.M.; Ustun, T.S. Design and performance analysis of a stand-alone PV system with hybrid energy storage for rural India. Electronics 2020, 8, 952. [Google Scholar] [CrossRef]

- Ciupageanu, D.A.A.; Barelli, L.L.; Lazaroiu, G. Design of a Fuzzy Logic Controller for a Remote Power Application. In 2019 IEEE PES Innovative Smart Grid Technologies Europe (ISGT-Europe); IEEE: New York, NY, USA, 2019; pp. 1–5. [Google Scholar]

- Sanajaoba, S.; Fernandez, E. Maiden application of Cuckoo Search algorithm for optimal sizing of a remote hybrid renewable energy System. Renew. Energy 2016, 96, 1–10. [Google Scholar] [CrossRef]

- Oladigbolu, J.O.O.; Ramli, M.A.A.; Al-Turki, Y.A. Optimal design of a hybrid PV solar/micro-hydro/diesel/battery energy system for a remote rural village under tropical climate conditions. Electronics 2020, 9, 1491. [Google Scholar] [CrossRef]

- Nelson, D.B.; Nehrir, M.H.; Wang, C. Unit sizing and cost analysis of stand-alone hybrid wind/PV/fuel cell power generation systems. Renew. Energy 2006, 31, 1641–1656. [Google Scholar] [CrossRef]

- Luna-Rubio, R.; Trejo-Perea, M.; Vargas-Vázquez, D.; Ríos-Moreno, G.J. Optimal sizing of renewable hybrids energy systems: A review of methodologies. Sol. Energy 2012, 86, 1077–1088. [Google Scholar] [CrossRef]

- Hung, D.Q.; Mithulananthan, N.; Bansal, R.C. Analytical strategies for renewable distributed generation integration considering energy loss minimization. Appl. Energy 2013, 105, 75–85. [Google Scholar] [CrossRef]

- Diaf, S.; Belhamel, M.; Haddadi, M.; Louche, A. Technical and economic assessment of hybrid photovoltaic/wind system with battery storage in Corsica island. Energy Policy 2008, 36, 743–754. [Google Scholar] [CrossRef]

- Kaabeche, A.A.; Belhamel, M.M.; Ibtiouen, R. Sizing optimization of grid-independent hybrid photovoltaic/wind power generation system. Energy 2011, 36, 1214–1222. [Google Scholar] [CrossRef]

- Farh, H.M.; Al-Shaalan, A.M.M.; Eltamaly, A.M.; Al-Shamma′A, A.A. A Novel Crow Search Algorithm Auto-Drive PSO for Optimal Allocation and Sizing of Renewable Distributed Generation. IEEE Access 2020, 8, 27807–27820. [Google Scholar] [CrossRef]

- Al-Shamma′A, A.A.; Alturki, F.A.; Farh, H.M. Techno-economic assessment for energy transition from diesel-based to hybrid energy system-based off-grids in Saudi Arabia. Energy Transit. 2020, 4, 1–13. [Google Scholar] [CrossRef]

- Farh, H.M.; Al-Shaalan, A.M.; Eltamaly, A.M.; Al-Shamma′A, A.A. A novel severity performance index for optimal allocation and sizing of photovoltaic distributed generations. Energy Rep. 2020, 6, 2180–2190. [Google Scholar] [CrossRef]

- Askarzadeh, A. Distribution generation by photovoltaic and diesel generator systems: Energy management and size optimization by a new approach for a stand-alone application. Energy 2017, 122, 542–551. [Google Scholar] [CrossRef]

- Hadidian-Moghaddam, M.J.; Arabi-Nowdeh, S.; Bigdeli, M. Optimal sizing of a stand-alone hybrid photovoltaic/wind system using new grey wolf optimizer considering reliability. J. Renew. Sustain. Energy 2016, 8, 035903. [Google Scholar] [CrossRef]

- Kaabeche, A.; Diaf, S.; Ibtiouen, R. Firefly-inspired algorithm for optimal sizing of renewable hybrid system considering reliability criteria. Sol. Energy 2017, 155, 727–738. [Google Scholar] [CrossRef]

- Maleki, A.; Askarzadeh, A. Artificial bee swarm optimization for optimum sizing of a stand-alone PV/WT/FC hybrid system considering LPSP concept. Sol. Energy 2014, 107, 227–235. [Google Scholar] [CrossRef]

- Shezan, S.A.; Julai, S.; Kibria, M.A.; Ullah, K.R.; Saidur, R.; Chong, W.T.; Akikur, R.K. Performance analysis of an off-grid wind-PV (photovoltaic)-diesel-battery hybrid energy system feasible for remote areas. J. Clean. Prod. 2016, 125, 121–132. [Google Scholar] [CrossRef]

- Ferrari, L.; Bianchini, A.; Galli, G.; Ferrara, G.; Carnevale, E.A. Influence of actual component characteristics on the optimal energy mix of a photovoltaic-wind-diesel hybrid system for a remote off-grid application. J. Clean. Prod. 2018, 178, 206–219. [Google Scholar] [CrossRef]

- Kaviani, A.K.; Baghaee, H.R.; Riahy, G.H. Optimal sizing of a stand-alone wind/photovoltaic generation unit using particle swarm optimization. Simulation 2009, 85, 89–99. [Google Scholar] [CrossRef]

- Baghaee, H.R.; Mirsalim, M.; Gharehpetian, G.B.; Talebi, H.A. Reliability/cost-based multi-objective Pareto optimal design of stand-alone wind/PV/FC generation microgrid system. Energy 2016, 115, 1022–1041. [Google Scholar] [CrossRef]

- Koutroulis, E.; Kolokotsa, D.; Potirakis, A.; Kalaitzakis, K. Methodology for optimal sizing of stand-alone photovoltaic/wind-generator systems using genetic algorithms. Sol. Energy 2006, 80, 1072–1088. [Google Scholar] [CrossRef]

- Bilal, B.O.; Nourou, D.; Sambou, V.; Ndiaye, P.A.; Ndongo, M. Multi-objective optimization of hybrid PV/wind/diesel/battery systems for decentralized application by minimizing the levelized cost of energy and the CO2 emissions. Int. J. Phys. Sci. 2015, 10, 192–203. [Google Scholar]

- Al-Shamma′A, A.A.; Addoweesh, K.E. Techno-economic optimization of hybrid power system using genetic algorithm. Int. J. Energy Res. 2014, 38, 1608–1623. [Google Scholar] [CrossRef]

- Sanchez, V.M.; Chavez-Ramirez, A.U.; Duron-Torres, S.M.; Hernandez, J.; Arriaga, L.G.; Ramirez, J.M. Techno-economical optimization based on swarm intelligence algorithm for a stand-alone wind-photovoltaic-hydrogen power system at south-east region of Mexico. Int. J. Hydrog. Energy 2014, 39, 16646–16655. [Google Scholar] [CrossRef]

- Sharafi, M.; ElMekkawy, T.Y. A dynamic MOPSO algorithm for multiobjective optimal design of hybrid renewable energy systems. Int. J. Energy Res. 2014, 38, 1949–1963. [Google Scholar] [CrossRef]

- Maleki, A.; Askarzadeh, A. Comparative study of artificial intelligence techniques for sizing of a hydrogen-based stand-alone photovoltaic/wind hybrid system. Int. J. Hydrogen Energy 2014, 39, 9973–9984. [Google Scholar] [CrossRef]

- Ghorbani, N.; Kasaeian, A.; Toopshekan, A.; Bahrami, L.; Maghami, A. Optimizing a hybrid wind-PV-battery system using GA-PSO and MOPSO for reducing cost and increasing reliability. Energy 2018, 154, 581–591. [Google Scholar] [CrossRef]

- Fathy, A. A reliable methodology based on mine blast optimization algorithm for optimal sizing of hybrid PV-wind-FC system for remote area in Egypt. Renew. Energy 2016, 95, 367–380. [Google Scholar] [CrossRef]

- Askarzadeh, A. Electrical power generation by an optimised autonomous PV/wind/tidal/battery system. Iet Renew. Power Gener. 2016, 11, 152–164. [Google Scholar] [CrossRef]

- Gharibi, M.; Askarzadeh, A. Size and power exchange optimization of a grid-connected diesel generator-photovoltaic-fuel cell hybrid energy system considering reliability, cost and renewability. Int. J. Hydrog. Energy 2019, 44, 25428–25441. [Google Scholar] [CrossRef]

- Zhao, J.; Yuan, X. Multi-objective optimization of stand-alone hybrid PV-wind-diesel-battery system using improved fruit fly optimization algorithm. Soft Comput. 2016, 20, 2841–2853. [Google Scholar] [CrossRef]

- Eteiba, M.B.; Barakat, S.; Samy, M.M.; Wahba, W.I. Optimization of an off-grid PV/Biomass hybrid system with different battery technologies. Sustain. Cities Soc. 2018, 40, 713–727. [Google Scholar] [CrossRef]

- Sedighizadeh, M.; Esmaili, M.; Esmaeili, M. Application of the hybrid Big Bang-Big Crunch algorithm to optimal reconfiguration and distributed generation power allocation in distribution systems. Energy 2014, 76, 920–930. [Google Scholar] [CrossRef]

- Erdinc, O.; Uzunoglu, M. Optimum design of hybrid renewable energy systems: Overview of different approaches. Renew. Sustain. Energy Rev. 2012, 16, 1412–1425. [Google Scholar] [CrossRef]

- Moghaddam, M.J.H.; Kalam, A.; Nowdeh, S.A.; Ahmadi, A.; Babanezhad, M.; Saha, S. Optimal sizing and energy management of stand-alone hybrid photovoltaic/wind system based on hydrogen storage considering LOEE and LOLE reliability indices using flower pollination algorithm. Renew. Energy 2019, 135, 1412–1434. [Google Scholar] [CrossRef]

- Bukar, A.L.; Tan, C.W.; Lau, K.Y. Optimal sizing of an autonomous photovoltaic/wind/battery/diesel generator microgrid using grasshopper optimization algorithm. Sol. Energy 2019, 188, 685–696. [Google Scholar] [CrossRef]

- Holland, J. Genetic algorithms. Sci. Am. 1992, 267, 66–73. [Google Scholar] [CrossRef]

- Eberhart, R.; Kennedy, J. A new optimizer using particle swarm theory. In MHS’95. Proceedings of the Sixth International Symposium on Micro Machine and Human Science; IEEE: New York, NY, USA, 1995; pp. 39–43. [Google Scholar]

- Saremi, S.; Mirjalili, S.; Lewis, A. Grasshopper optimisation algorithm: Theory and application. Adv. Eng. Softw. 2017, 105, 30–47. [Google Scholar] [CrossRef]

- Erol, O.K.; Eksin, I. A new optimization method: Big bang–big crunch. Adv. Eng. Softw. 2006, 37, 106–111. [Google Scholar] [CrossRef]

- Heidari, A.A.; Mirjalili, S.; Faris, H.; Aljarah, I.; Mafarja, M.; Chen, H. Harris hawks optimization: Algorithm and applications. Future Gener. Comput. Syst. 2019, 97, 849–872. [Google Scholar] [CrossRef]

- Rehman, S.; Al-Hadhrami, L.M.; Alam, M.M.; Meyer, J.P. Empirical correlation between hub height and local wind shear exponent for different sizes of wind turbines. Sustain. Energy Technol. Assess. 2013, 4, 45–51. [Google Scholar] [CrossRef]

- Elshurafa, A.M.; Alsubaie, A.M.; Alabduljabbar, A.A.; Al-Hsaien, S.A. Solar PV on mosque rooftops: Results from a pilot study in Saudi Arabia. J. Build. Eng. 2019, 25, 100809. [Google Scholar] [CrossRef]

- Givler, T.; Lilienthal, P. Using HOMER Software, NREL’s Micropower Optimization Model, to Explore the Role of Gen.-Sets in Small Solar Power Systems; Case Study: Sri Lanka; National Renewable Energy Lab: Golden, CO, USA, 2005.

- Pallabazzer, R. Evaluation of wind-generator potentiality. Sol. Energy 1995, 55, 49–59. [Google Scholar] [CrossRef]

- Belfkira, R.; Zhang, L.; Barakat, G. Optimal sizing study of hybrid wind/PV/diesel power generation unit. Sol. Energy 2011, 85, 100–110. [Google Scholar] [CrossRef]

- Skarstein, Ø.; Uhlen, K. Design considerations with respect to long-term diesel saving in wind/diesel plants. Wind Eng. 1989, 13, 72–87. [Google Scholar]

| Item | Load Demand | Solar Irradiance | Wind Speed |

|---|---|---|---|

| Load Demand | 1 | 0.3492 | 0.0292 |

| Solar Irradiance | 0.3492 | 1 | −0.0331 |

| Wind Speed | 0.0292 | −0.0331 | 1 |

| Component | Parameters | Values | Units |

|---|---|---|---|

| Photovoltaic Module | Life span | 20 | years |

| Efficiency | 16 | % | |

| Capital cost | 1000 | USD/kW | |

| O&M cost | 15 | USD/kW/year | |

| WTG | Life span | 20 | years |

| Capital cost | 1300 | USD/kW | |

| O&M cost | 30.33 | USD/kW/year | |

| Cut-In/cut-off/rated speed | 3/25/12 | m/s | |

| Hub-height | 60 | M | |

| Batteries | Life span | 5 | years |

| Capital cost | 200 | USD/kWh | |

| O&M cost | 5 | USD/kWh/year | |

| Round-trip efficiency | 80 | % | |

| Depth of discharge | 60 | % | |

| Diesel Generator | Life span | 15,000 | hours |

| Capital cost | 300 | USD/kW | |

| O&M cost | 0.012 | USD/kWh | |

| DC/AC Converter | Life span | 10 | years |

| Capital cost | 133 | USD/kW | |

| Project Factors | Life span | 20 | years |

| Interest rate | 3 | % | |

| Inflation rate | 2 | % |

| Algorithm | Parameter | Value |

|---|---|---|

| GA | Population | 100 |

| Selection | Roulette wheel | |

| Mutation rate | 0.2 | |

| Crossover rate | 0.8 | |

| PSO | Swarm | 100 |

| Inertia weight | 1 | |

| Cognitive constant | 0.25 | |

| GOA | Social constant | 1.75 |

| Grasshopper swarms | 100 | |

| HHO | Adaptive parameter | [0, 1] |

| Number of hawks | 100 | |

| BBBC | Energy of rabbit | 2 |

| Population size | 100 | |

| MRFO | Constant parameter | α = 1 |

| Somersault factor | 2 | |

| Random numbers | [0, 1] |

| Algorithm | Performance Indicators | PPV (kW) | PWT (kW) | PBatt (kW) | PDsl (kW) | ASC (USD/year) | REF (%) | Surplus (%) |

|---|---|---|---|---|---|---|---|---|

| GA | Optimal | 238.9 | 239.8 | 189.3 | 271.3 | 104,812.6 | 67.0 | 16.64 |

| Worst | 328.1 | 0 | 114.1 | 310.7 | 108,302.1 | 42.7 | 19.21 | |

| Mean | 248.5 | 229.8 | 178.5 | 268.516 | 105,931.5 | 66.22 | 18.45 | |

| STD | 21.854 | 46.487 | 37.925 | 17.772 | 789.541 | 4.175 | 1.736 | |

| PSO | Optimal | 240.3 | 229.9 | 188.5 | 267.8 | 104,342.2 | 66.4 | 16.01 |

| Worst | 220.9 | 239.3 | 202.8 | 266.5 | 104,708.0 | 66.1 | 15.95 | |

| Mean | 240.0 | 230.0 | 188.5 | 268.4 | 104,461.8 | 66.34 | 17.98 | |

| STD | 4.526 | 7.944 | 7.317 | 2.182 | 75.441 | 0.509 | 0.871 | |

| GOA | Optimal | 238.9 | 231.3 | 192.1 | 267.7 | 104,347.7 | 66.5 | 16.00 |

| Worst | 245.3 | 238.9 | 165.6 | 268.6 | 104,651.3 | 66.9 | 17.61 | |

| Mean | 239.8 | 232.6 | 186.8 | 267.9 | 104,449.4 | 66.5 | 16.43 | |

| STD | 3.240 | 6.902 | 7.582 | 1.659 | 73.029 | 0.442 | 0.510 | |

| HHO | Optimal | 240.6 | 229.7 | 186.3 | 268.2 | 104,438.5 | 66.3 | 39.36 |

| Worst | 342.5 | 0 | 389.9 | 280.4 | 109,566.1 | 47.4 | 11.94 | |

| Mean | 252.6 | 221.2 | 226.7 | 260.2 | 105,333.8 | 66.44 | 17.09 | |

| STD | 23.2 | 48.3 | 59.5 | 11.5 | 822.927 | 4.486 | 3.70 | |

| BBBC | Optimal | 251.5 | 215.6 | 193.9 | 283.9 | 105,610.9 | 65.9 | 16.34 |

| Worst | 139.1 | 384.1 | 139.1 | 285.5 | 112,262.1 | 92.4 | 53.12 | |

| Mean | 235.1 | 215.5 | 192.2 | 283.4 | 107,887.2 | 82.8 | 51.77 | |

| STD | 60.1 | 71.3 | 96.7 | 4.0 | 132,8.873 | 10.24 | 11.65 | |

| MRFO | Optimal | 238.7 | 231.6 | 192.5 | 267.6 | 104,324.1 | 67.2 | 16.79 |

| Worst | 241.8 | 244.8 | 180.8 | 266.7 | 104,524.5 | 66.8 | 16.52 | |

| Mean | 239.2 | 232.1 | 189.0 | 268.1 | 104,390.1 | 66.55 | 16.25 | |

| STD | 2.056 | 6.052 | 5.272 | 1.073 | 58.392 | 0.827 | 0.87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

A. Alturki, F.; M. H. Farh, H.; A. Al-Shamma’a, A.; AlSharabi, K. Techno-Economic Optimization of Small-Scale Hybrid Energy Systems Using Manta Ray Foraging Optimizer. Electronics 2020, 9, 2045. https://doi.org/10.3390/electronics9122045

A. Alturki F, M. H. Farh H, A. Al-Shamma’a A, AlSharabi K. Techno-Economic Optimization of Small-Scale Hybrid Energy Systems Using Manta Ray Foraging Optimizer. Electronics. 2020; 9(12):2045. https://doi.org/10.3390/electronics9122045

Chicago/Turabian StyleA. Alturki, Fahd, Hassan M. H. Farh, Abdullrahman A. Al-Shamma’a, and Khalil AlSharabi. 2020. "Techno-Economic Optimization of Small-Scale Hybrid Energy Systems Using Manta Ray Foraging Optimizer" Electronics 9, no. 12: 2045. https://doi.org/10.3390/electronics9122045

APA StyleA. Alturki, F., M. H. Farh, H., A. Al-Shamma’a, A., & AlSharabi, K. (2020). Techno-Economic Optimization of Small-Scale Hybrid Energy Systems Using Manta Ray Foraging Optimizer. Electronics, 9(12), 2045. https://doi.org/10.3390/electronics9122045