A Path Planning Strategy with Ant Colony Algorithm for Series Connected Batteries

Abstract

1. Introduction

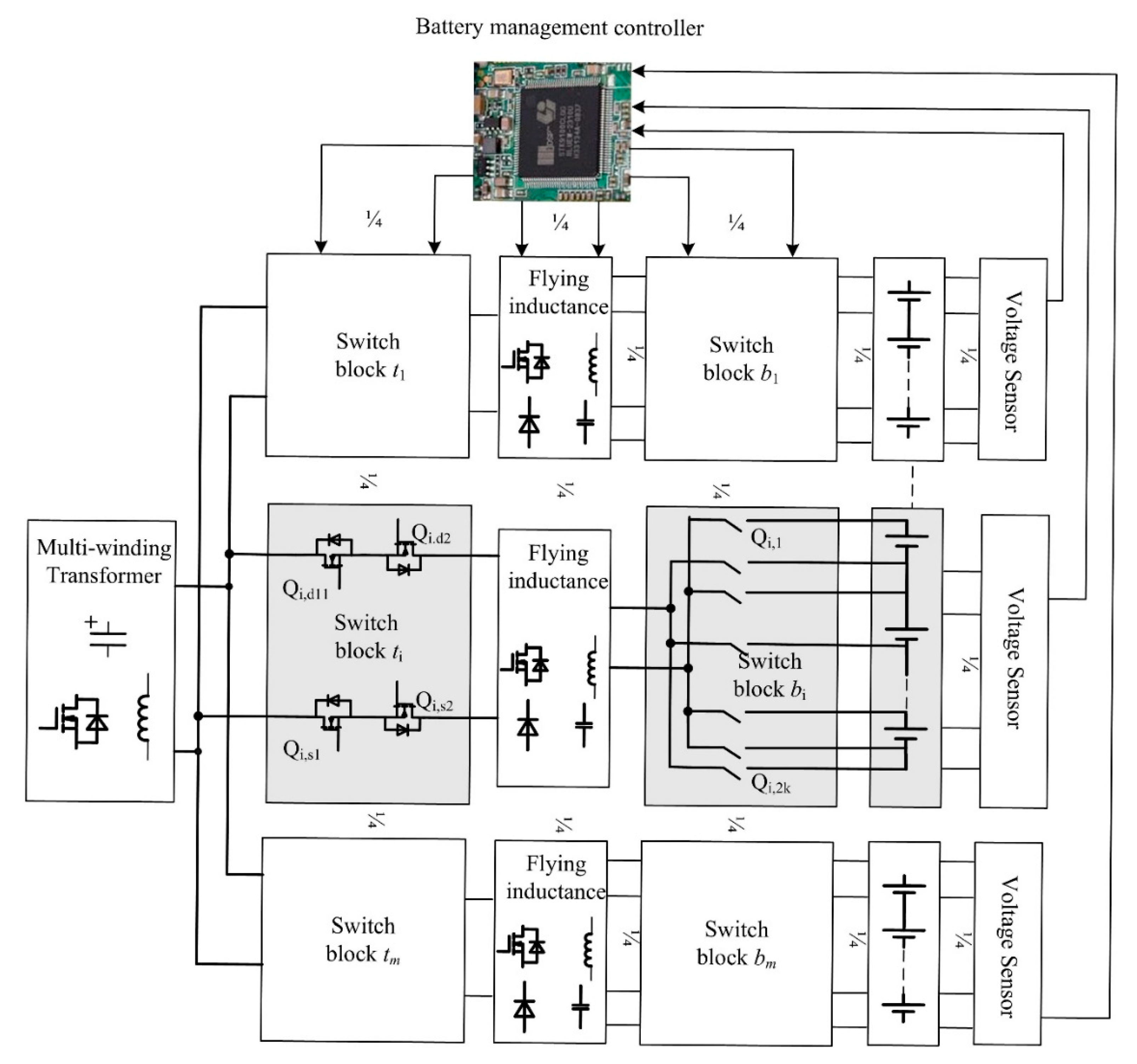

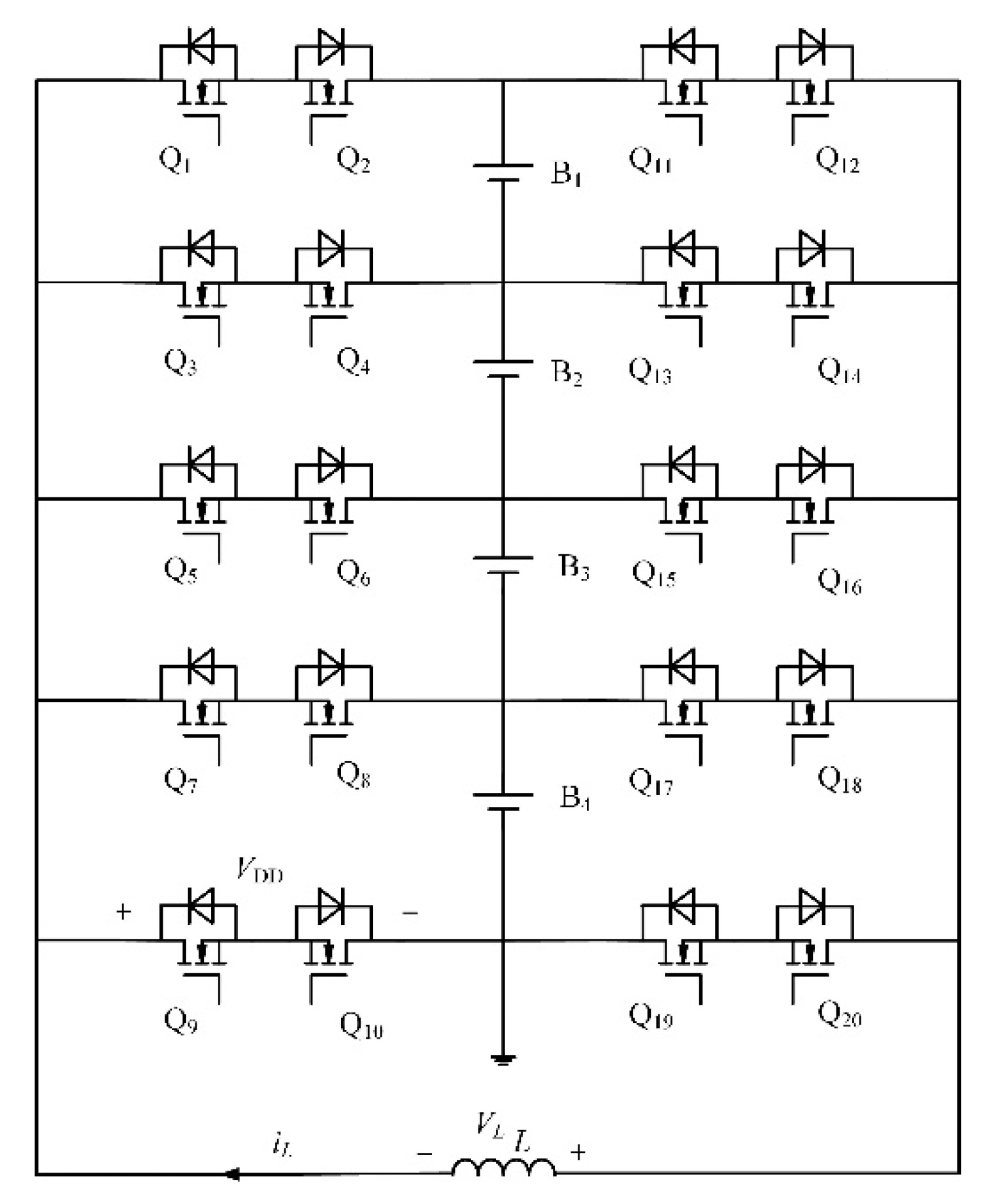

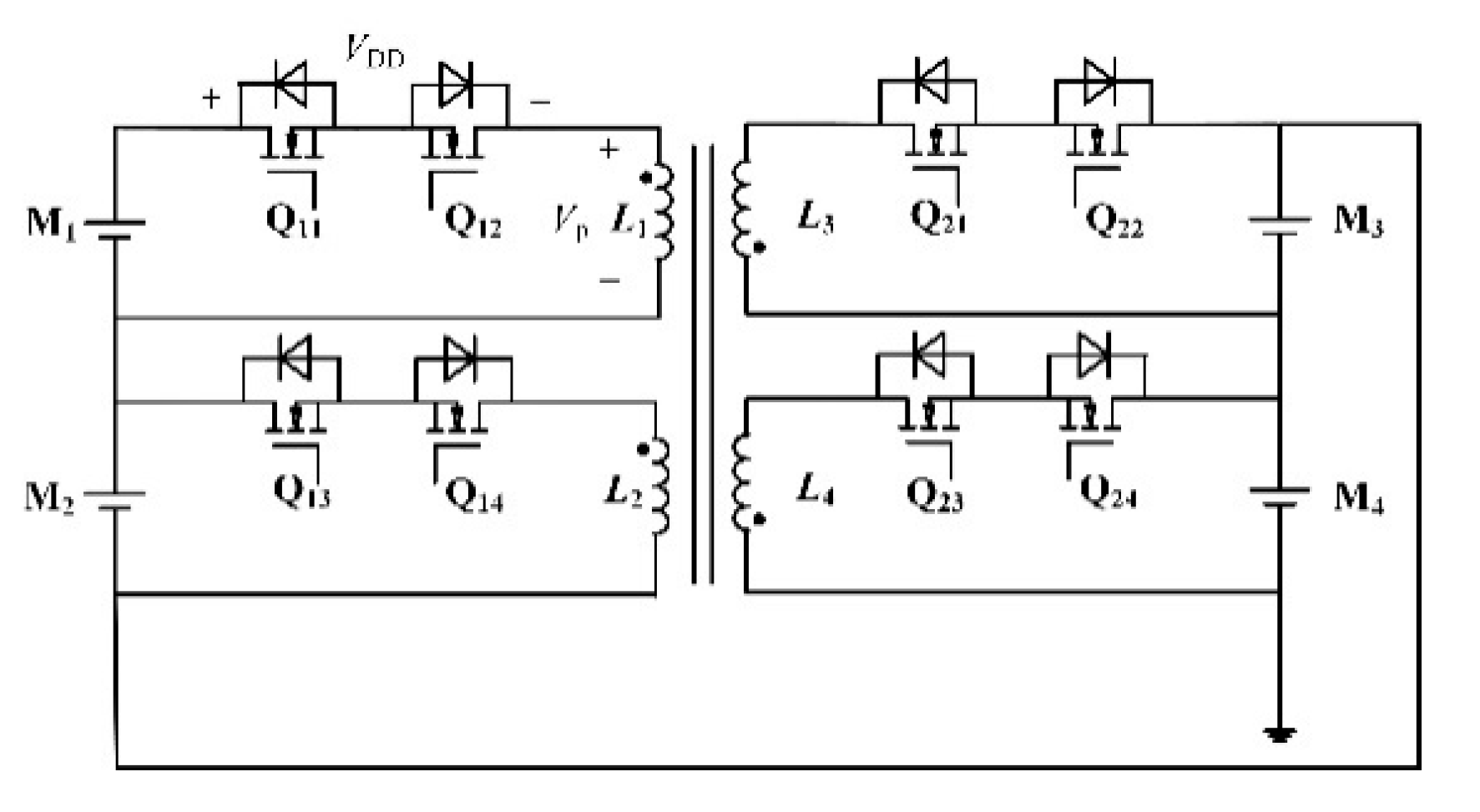

2. Two-Layer Balancing System

2.1. System Structure

- (1)

- All the switches are considered identical including the parasitic parameters and energy loss coefficient.

- (2)

- Equalizers of the same type have identical energy loss coefficient while they differ of different types.

2.2. Graph Model for Two-Layer Balancing System

- (1)

- Digraph is a graph with a set of N nodes, E directed edges and ordered pairs of different nodes.

- (2)

- Target node is the terminal node of the energy flow path. It can be either the start point or the end point of the energy flow path. In the balancing system, the energy storage units are defined as the target nodes such as the batteries or the supercapacitors.

- (3)

- Intermediate node is the node that stores energy temporarily which corresponds to the energy storage element in the equalizer like a capacitor, inductor or transformer. There is a coefficient η stored in conversion matrix, which represents the energy conversion efficiency for each intermediate node. It is considered identical of the same type.

- (4)

- The graph can be represented as an n × m matrix through the adjacency matrix where the nodes in the digraph constitute the row and the edges compose the line. There are only two non-zero elements in the row corresponding to arc (i, j) where it is −1 corresponding to the row of node i and it is 1 corresponding to the line of node j.

- (5)

- The real-valued function f (i, j) represents the net flow in the arc (i, j). It can be considered as the number of a commodity, which can be positive or negative. It is worth noting that the net flow in arcs needs to obey the conservation law at each node. As for the intermediate node, the total net flow into the node should be equal to that out of the node without considering the loss during the conversion process. When it comes to the target node, the source battery has more outflow and the target one has more inflow.

3. Balancing Problem Formulation

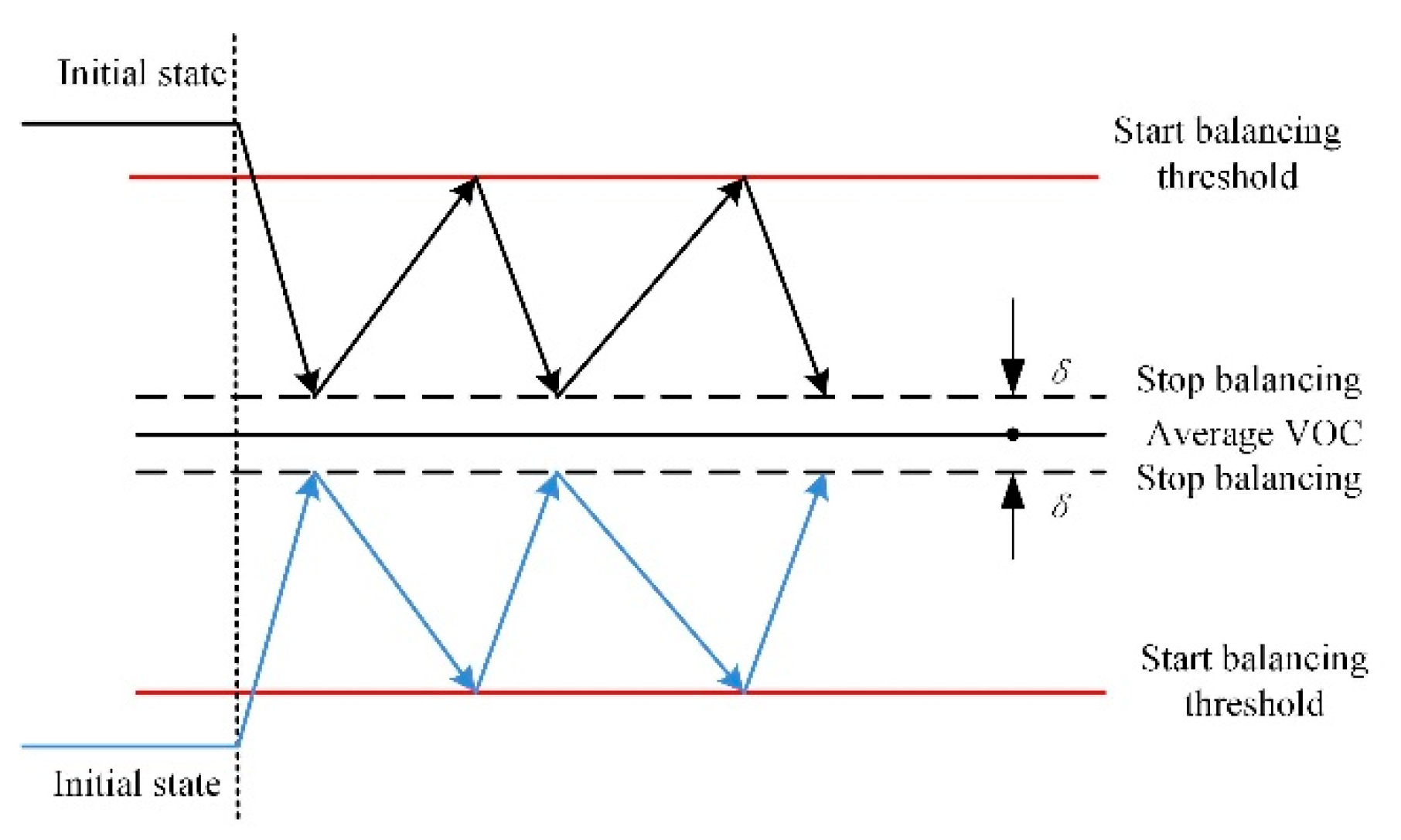

3.1. Balancing Rules

3.2. Best Balancing Efficiency Model

3.3. Best Balancing Speed Model

4. Path Planning Strategy

4.1. Definitions of Some Matrices

- (1)

- Demand matrix (D): It is a row vector that contains the VOC difference.

- (2)

- Unit priority matrix (Lp): Its first column contains the unit index and the second column shows the unit priority.

- (3)

- Edge flow matrix (F): It is a row vector that contains the energy flow of each edge.

- (4)

- Edge state matrix (Ys): It is a row vector where it is 1 if the edge is chosen, otherwise, it is 0.

4.2. Principal Sequences

- (1)

- Definitions of digraph matrices: the node-edge adjacency matrix and demand matrix are defined and initialized according to the status of the equalizer.

- (2)

- Imbalanced status detection: it is of great significance to estimate the batteries’ state according to their VOCs. Once one or more imbalanced nodes are detected, update the demand matrix D according to the calculated power of each node. The demand matrix D is assigned a negative value if the battery cell is overcharging, that is, its VOC is higher than others’. Otherwise, D is assigned a positive value.

- (3)

- Label edges weights: test the edges around the imbalanced nodes and label each edge on the basis of energy transmission efficiency.

- (4)

- Route selection: it is a path that meets the objective of the algorithm and minimizes the energy loss during transmission simultaneously. It should also guarantee each battery cell’s VOC within acceptable range. It is necessary to sum up the values of each row gained by multiplying the flux of each edge by the incidence matrix.

- (5)

- Feasibility testing: Update the distribution of new power flow in the digraph once a scheme is chosen. The distribution is decided according to the overlap of weights which influences the balancing speed.

4.3. Solving Steps with ant Colony Algorithm

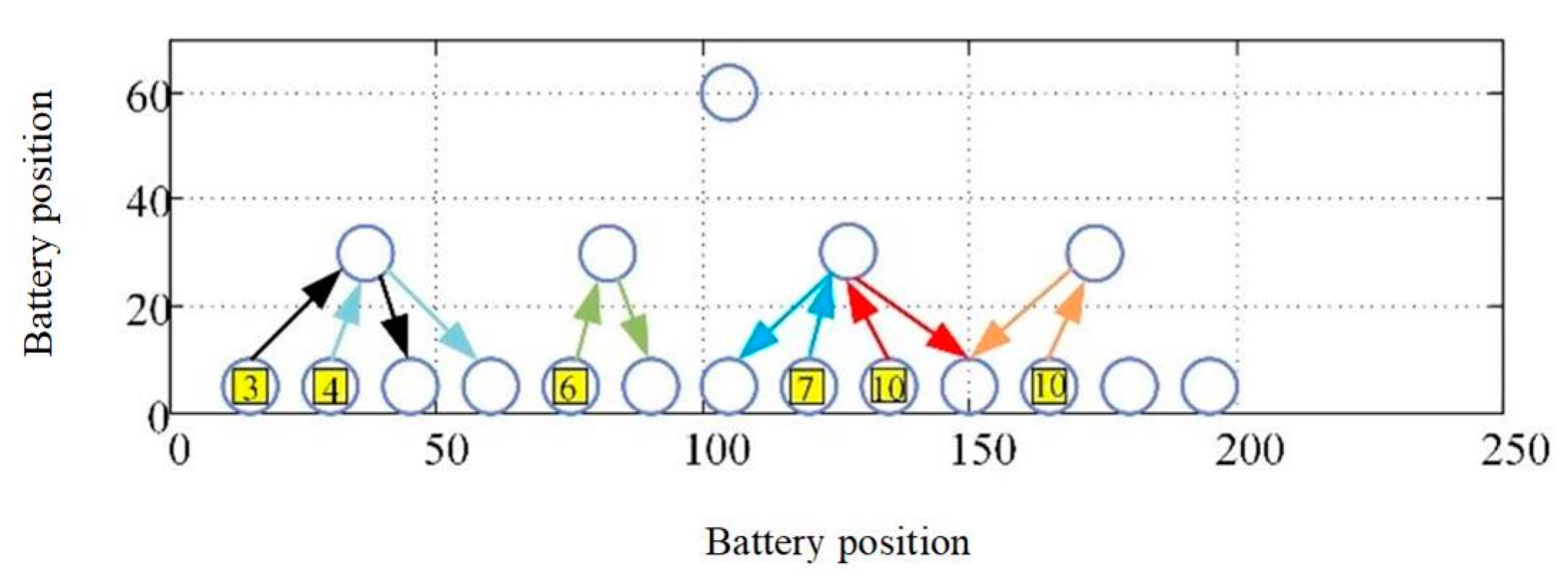

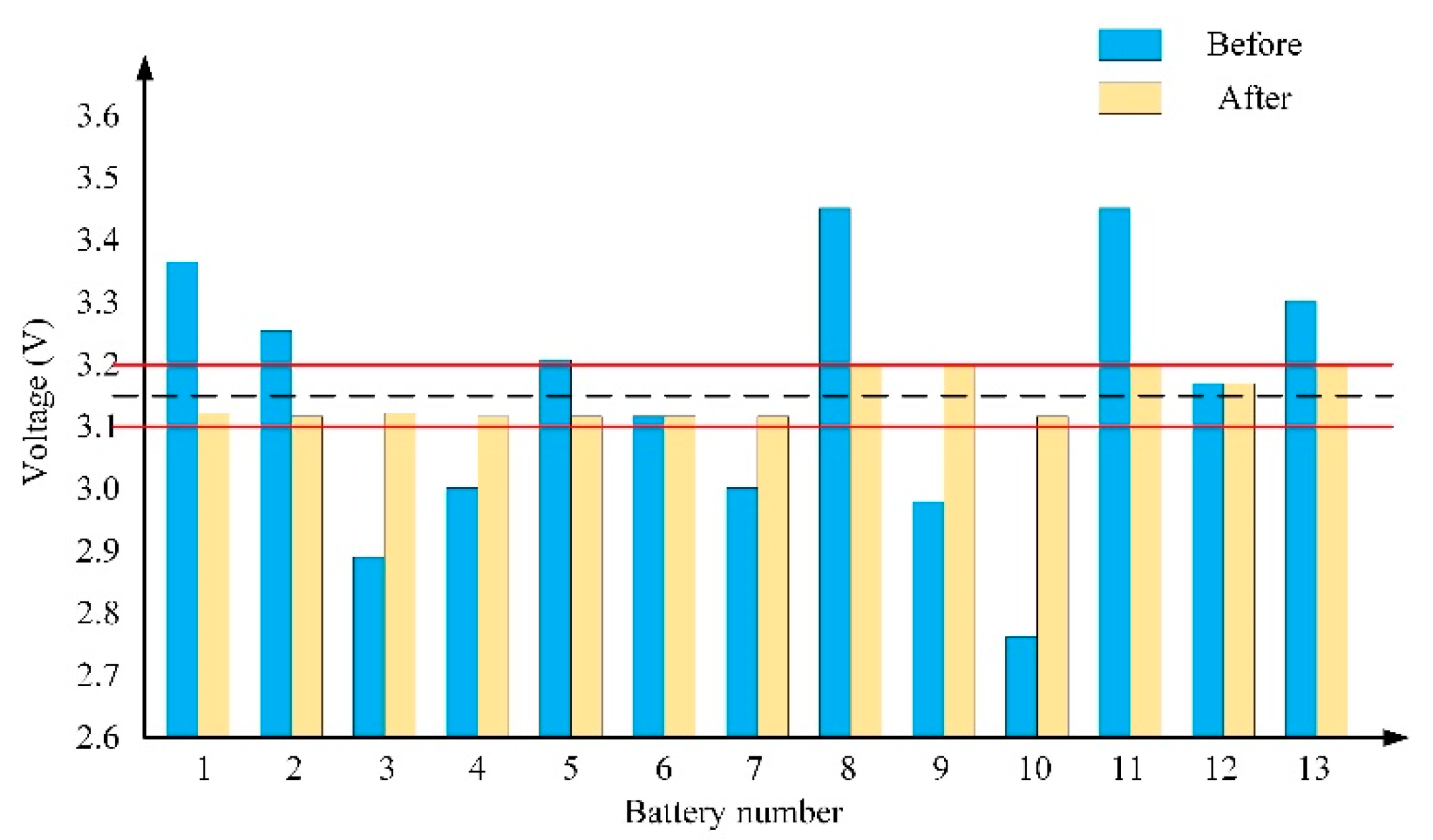

5. Analysis of Balancing Path Planning for 13 Series Connected Batteries

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kim, H.-S.; Park, K.-B.; Park, S.-H.; Moon, G.-W.; Youn, M.-J. A new two-switch flyback battery equalizer with low voltage stress on the switches. In Proceedings of the 2009 IEEE Energy Conversion Congress and Exposition, Jose, CA, USA, 20–24 September 2009; pp. 511–516. [Google Scholar]

- Shang, Y.; Cui, N.; Zhang, C. An Optimized Any-Cell-to-Any-Cell Equalizer Based on Coupled Half-Bridge Converters for Series-Connected Battery Strings. IEEE Trans. Power Electron. 2019, 34, 8831–8841. [Google Scholar] [CrossRef]

- Shang, Y.; Cui, N.; Duan, B.; Zhang, C. Analysis and Optimization of Star-Structured Switched-Capacitor Equalizers for Series-Connected Battery Strings. IEEE Trans. Power Electron. 2017, 33, 9631–9646. [Google Scholar] [CrossRef]

- Li, S.; Mi, C.C.; Zhang, M. A high efficiency low cost direct battery balancing circuit using a multi-winding transformer with reduced switch count. In Proceedings of the 2012 Twenty-Seventh Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Orlando, FL, USA, 5–9 February 2012; pp. 2128–2133. [Google Scholar]

- Baronti, F.; Roncella, R.; Saletti, R. Performance comparison of active balancing techniques for lithium-ion batteries. J. Power Sources 2014, 267, 603–609. [Google Scholar] [CrossRef]

- Du, W.; Huang, X.; Yang, S.; Zhang, F.; Wu, X.; Qian, Z. A novel equalization method with defective-battery- Modularization. IEEE Trans. Veh. Technol. 2009, 58, 3216–3223. [Google Scholar]

- Shang, Y.; Zhang, C.; Cui, N.; Mi, C.C. A Delta-Structured Switched-Capacitor Equalizer for Series-Connected Battery Strings. IEEE Trans. Power Electron. 2019, 34, 452–461. [Google Scholar]

- Park, H.-S.; Kim, C.H.; Park, K.-B.; Moon, G.-W.; Lee, J.-H. Design of a Charge Equalizer Based on Battery replacing for series-connected lithium battery strings. In Proceedings of the First IEEE Energy Conversion Congress and Exposition (ECCE2009), San Jose, CA, USA, 20–24 September 2009; pp. 1806–1811. [Google Scholar]

- Moody, M. A high reliability battery management system. J. Power Sources 1986, 18, 223–231. [Google Scholar] [CrossRef][Green Version]

- Daowd, M.; Omar, N.; Bossche, P.V.D.; Van Mierlo, J. Passive and active battery balancing comparison based on MATLAB simulation. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011; pp. 1–7. [Google Scholar]

- Gallardo-Lozano, J.; Romero-Cadaval, E.; Milanes-Montero, M.I.; Guerrero-Martinez, M.A. Battery equalization active methods. J. Power Sources 2014, 246, 934–949. [Google Scholar] [CrossRef]

- Hsieh, Y.; Moo, C.; Tsai, I.; Cheng, J. Dynamic charge equalization for series-connected batteries. In Proceedings of the 2002 IEEE International Conference on Industrial Technology, Bankok, Thailan, 11–14 December 2003; Volume 150, pp. 501–505. [Google Scholar]

- Zhang, W.; Gong, X.; Han, G.; Zhao, Y. An Improved Ant Colony Algorithm for Path Planning in One Scenic Area with Many Spots. IEEE Access 2017, 5, 13260–13269. [Google Scholar] [CrossRef]

- Shang, Y.; Xia, B.; Yang, J.; Zhang, C.; Cui, N.; Mi, C.C. A delta-structured switched-capacitor equalizer for series-connected battery strings. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017; pp. 4493–4496. [Google Scholar]

- Dorigo, M.; Maniezzo, V.; Colorni, A. Ant system: Optimization by a colony of cooperating agents. IEEE Trans. Syst. Mancybern. Part B 1996, 26, 29–41. [Google Scholar] [CrossRef]

- Wang, X.; Choi, T.M.; Liu, H.; Yue, X. A novel hybrid ant colony optimization algorithm for emergency transportation problemsduring post disaster scenarios. IEEE Trans. Syst. Man Cybern. Syst. 2018, 48, 545–556. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, J.; Wang, Y. Performance Analysis of the (1+1) Evolutionary Algorithm for the Multiprocessor Scheduling Problem. Algorithmica 2014, 73, 21–41. [Google Scholar] [CrossRef]

- Yu, Y.; Yao, X.; Zhou, Z.-H. On the approximation ability of evolutionary optimization with application to minimum set cover. Artif. Intell. 2012, 180–181, 20–33. [Google Scholar] [CrossRef]

- Farhanchi, M.; Hassanzadeh, R.; Mahdavi, I.; Mahdavi-Amiri, N. A modified ant colony system for finding the expected shortest path in networks with variable arc lengths and probabilistic nodes. Appl. Soft Comput. 2014, 21, 491–500. [Google Scholar] [CrossRef]

- Sudholt, D.; Thyssen, C. Running time analysis of Ant Colony Optimization for shortest path problems. J. Discret. Algorithms 2012, 10, 165–180. [Google Scholar] [CrossRef]

- Calle, J.; Rivero, J.; Cuadra, D.; Isasi, P. Extending ACO for fast path search in huge graphs and social networks. Expert Syst. Appl. 2017, 86, 292–306. [Google Scholar] [CrossRef]

- Cheng, L.; Liu, G.; Huang, H.; Wang, X.; Chen, Y.; Zhang, J.; Meng, A.; Yang, R.; Yu, T. Equilibrium analysis of general N-population multi-strategy games for generation-side long-term bidding: An evolutionary game perspective. J. Clean. Prod. 2020, 276, 124123. [Google Scholar] [CrossRef]

- Niu, Y.; Wang, S.; He, J.; Xiao, J. A novel membrane algorithm for capacitated vehicle routing problem. Soft Comput. 2014, 19, 471–482. [Google Scholar] [CrossRef]

- De Grancy, G.S.; Reimann, M. Vehicle routing problems with time windows and multiple service workers: A systematic comparison between ACO and GRASP. J. Oper. Res. 2014, 24, 29–48. [Google Scholar]

- Chen, Y.; Liu, X.; Cui, Y.; Zou, J.; Yang, S. A Multi-winding Transformer Cell-to-Cell Active Equalization Method for Lithium-Ion Batteries with Reduced Number of Driving Circuits. IEEE Trans. Power Electron. 2016, 37, 4916–4929. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, X.; Fathy, H.K.; Zou, J.; Yang, S. A graph-theoretic framework for analyzing the speeds and efficiencies of battery pack equalization circuits. Int. J. Electr. Power Energy Syst. 2018, 98, 85–99. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Y.; Fathy, H.K. Nonlinear Model-Predictive Optimal Control of an Active Cell-to-Cell Lithium-Ion Battery Pack Balancing Circuit. IFAC-PapersOnLine 2017, 50, 14483–14488. [Google Scholar] [CrossRef]

- Zhuo, X.; Gao, Y. Network coding resources optimization of coding-link cost based on the modified ant colony algorithm. In Proceedings of the 2017 3rd IEEE International Conference on Computer and Communications, Chengdu, China, 13–16 December 2017; pp. 536–540. [Google Scholar]

- Li, Y.; Zhang, C.; Yang, Q.; Li, J.; Zhang, Y.; Zhang, X.; Xue, M. Improved ant colony algorithm for adaptive frequency-tracking control in WPT system. IET Microw. Antennas Propag. 2017, 12, 23–28. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, X.; Han, J.; Yang, W. An optimization algorithm for equalization scheme of series-connected energy storage cells. In Proceedings of the IEEE Transportation Electrification Conference and Expo, Asia-Pacific, Harbin, China, 7–10 August 2017; pp. 1–6. [Google Scholar]

- Jiao, Z.; Ma, K.; Rong, Y.; Wang, P.; Zhang, H.; Wang, S. A path planning method using adaptive polymorphic ant colony algorithm for smart wheelchairs. J. Comput. Sci. 2018, 25, 50–57. [Google Scholar] [CrossRef]

- Rathee, M.; Kumar, S.; Gandomi, A.H.; Dilip, K.; Balusamy, B.; Patan, R. Ant Colony Optimization Based Quality of Service Aware Energy Balancing Secure Routing Algorithm for Wireless Sensor Networks. IEEE Trans. Eng. Manag. 2019, 1–13. [Google Scholar] [CrossRef]

- Dai, S.; Wang, J.; Shan, Z.; Wei, Y. Analysis, Design and Implementation of Flexible Interlaced Converter for Lithium Battery Active Balancing in Electric Vehicles. J. Power Electron. 2019, 19, 858–868. [Google Scholar]

- Dong, W.; Li, Y.; Xiang, J. Optimal Sizing of a Stand-Alone Hybrid Power System Based on Battery/Hydrogen with an Improved Ant Colony Optimization. Energies 2016, 9, 785. [Google Scholar] [CrossRef]

| Elements in the Balancing System | Graph Elements |

|---|---|

| Capacitor or inductance | Intermediate Node |

| Battery cell | Target Node |

| Energy transferred path | Directed edge |

| Steps | Items |

|---|---|

| 1 | Define of digraph matrices |

| 2 | Define of nodes and edges |

| 3 | Detect the imbalanced statusIf yes, obtain the Demand matrix D, Edge state matrix Ys and Unit priority matrix Lp, and then calculate the optimal solution according to Equations (6) and (7) Else, go back to step 3 |

| 4 | Output matrices related to edges |

| 5 | Update the Edge status matrix Ys |

| Items | Simple Strategy | Best Balancing Efficiency | Best Balancing Speed |

|---|---|---|---|

| Maximum voltage difference | 0.1 V | <0.1 V | <0.1 V |

| Equivalent loss | 0.3941 | 0.2305 | 0.2975 |

| Energy transferred path | 42,400 s | 20,100 s | 16,400 s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Shen, T.; Yang, S.; Liu, X.; Yang, R.; Cheng, L. A Path Planning Strategy with Ant Colony Algorithm for Series Connected Batteries. Electronics 2020, 9, 1816. https://doi.org/10.3390/electronics9111816

Chen Y, Shen T, Yang S, Liu X, Yang R, Cheng L. A Path Planning Strategy with Ant Colony Algorithm for Series Connected Batteries. Electronics. 2020; 9(11):1816. https://doi.org/10.3390/electronics9111816

Chicago/Turabian StyleChen, Yang, Teng Shen, Shiyan Yang, Xiaofang Liu, Ru Yang, and Lefeng Cheng. 2020. "A Path Planning Strategy with Ant Colony Algorithm for Series Connected Batteries" Electronics 9, no. 11: 1816. https://doi.org/10.3390/electronics9111816

APA StyleChen, Y., Shen, T., Yang, S., Liu, X., Yang, R., & Cheng, L. (2020). A Path Planning Strategy with Ant Colony Algorithm for Series Connected Batteries. Electronics, 9(11), 1816. https://doi.org/10.3390/electronics9111816