A Multiplicatively Weighted Voronoi-Based Workspace Partition for Heterogeneous Seeding Robots

Abstract

1. Introduction

- Single-task (ST) robots versus multi-task (MT) robots.

- Single-robot (SR) tasks versus multi-robot (MR) tasks.

- Instantaneous assignment (IA) versus time-extended assignment (TA).

- An MW Voronoi-based approach for workspace partitioning for a heterogeneous MRS was applied to conduct seeding tasks.

- The heterogeneous MRTA applied in this study was optimized by considering various weighting factors associated with the heterogeneous robots.

- An experiment and evaluation were used to demonstrate the applicability of our approach.

2. Seeding Robot Control

2.1. Kinematic and Dynamic Modeling

2.2. Distributed Control

2.2.1. Obstacle Avoidance

2.2.2. Path Following

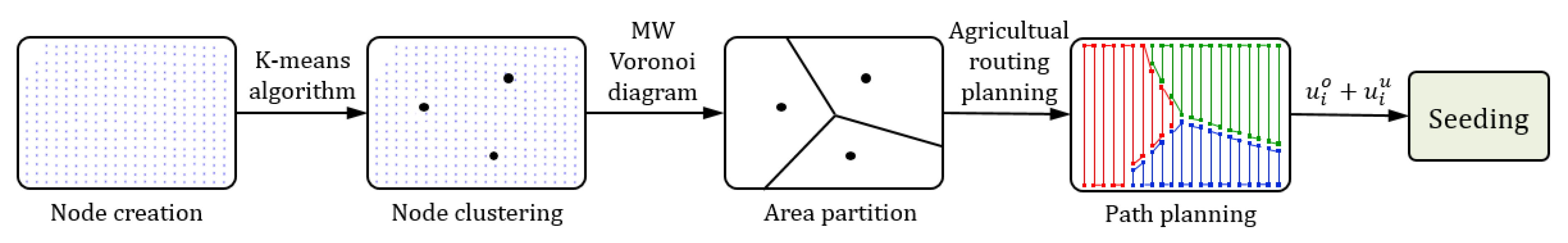

3. Task Allocation

- Creating a node for the seeding task from the agricultural field;

- Node clustering using a k-means algorithm;

- MW Voronoi-based area partitioning;

- Path planning;

- Seeding.

3.1. Node Creation

3.2. Node Clustering

3.3. Area Partitioning

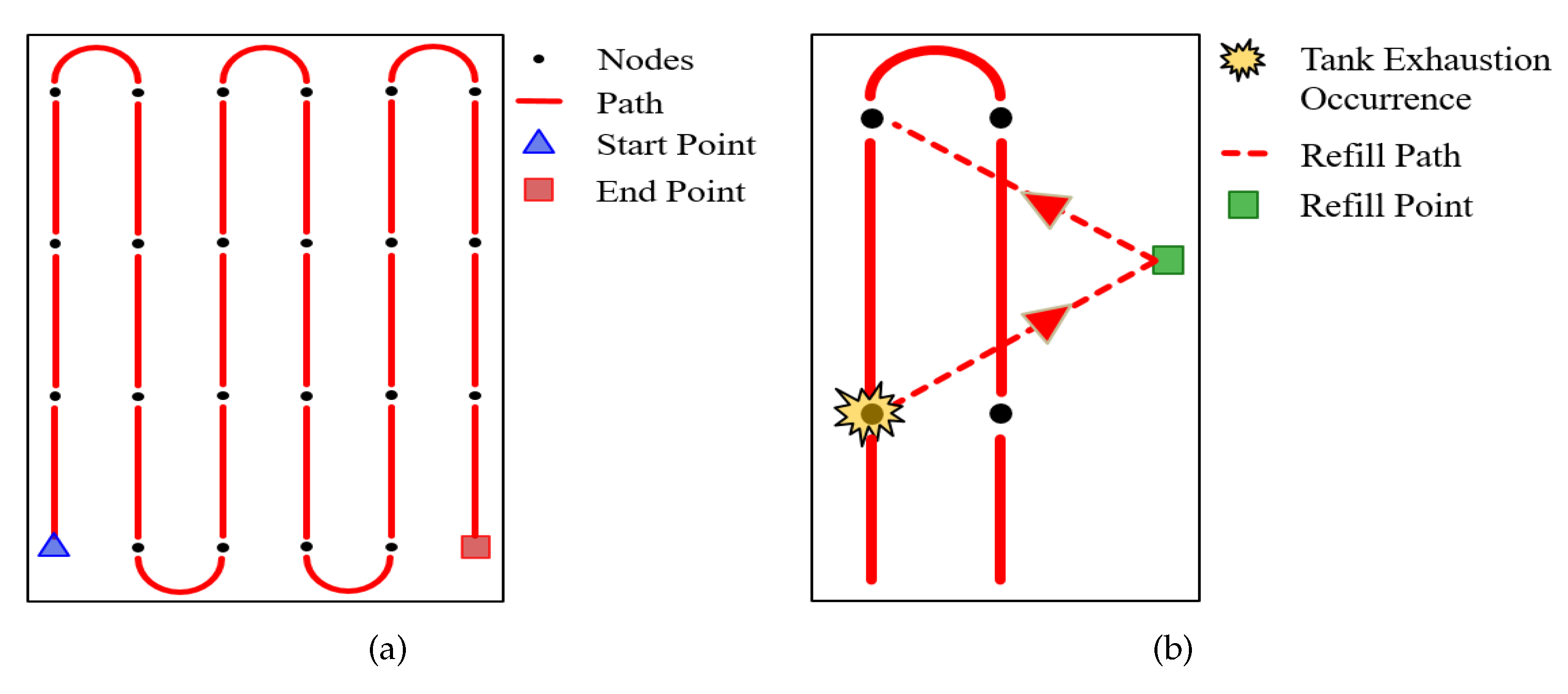

3.4. Path Planning

3.4.1. Agricultural Routing Planning

3.4.2. Refill Planning

4. Simulations

4.1. Experimental Setup

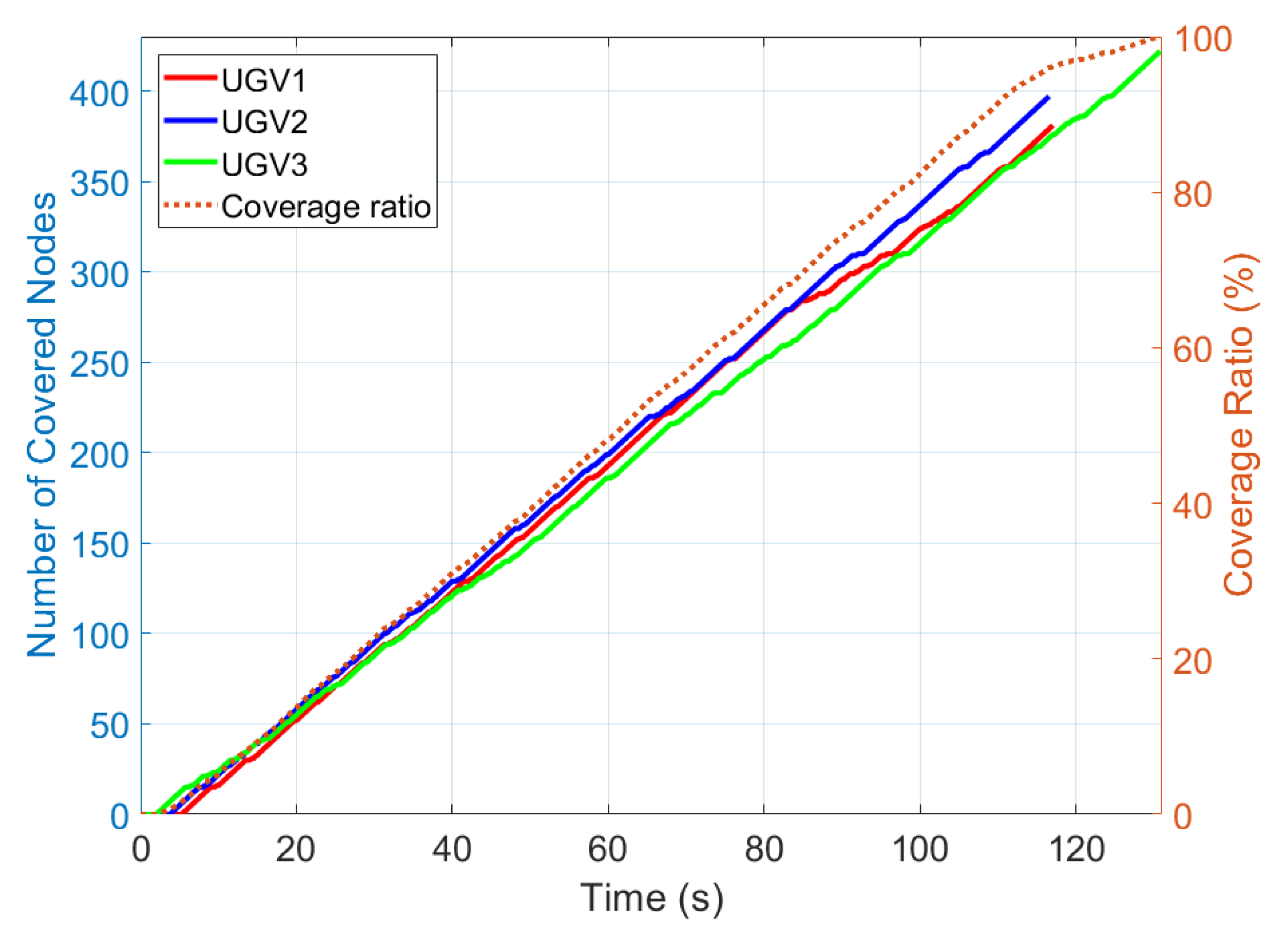

4.2. Results and Discussion

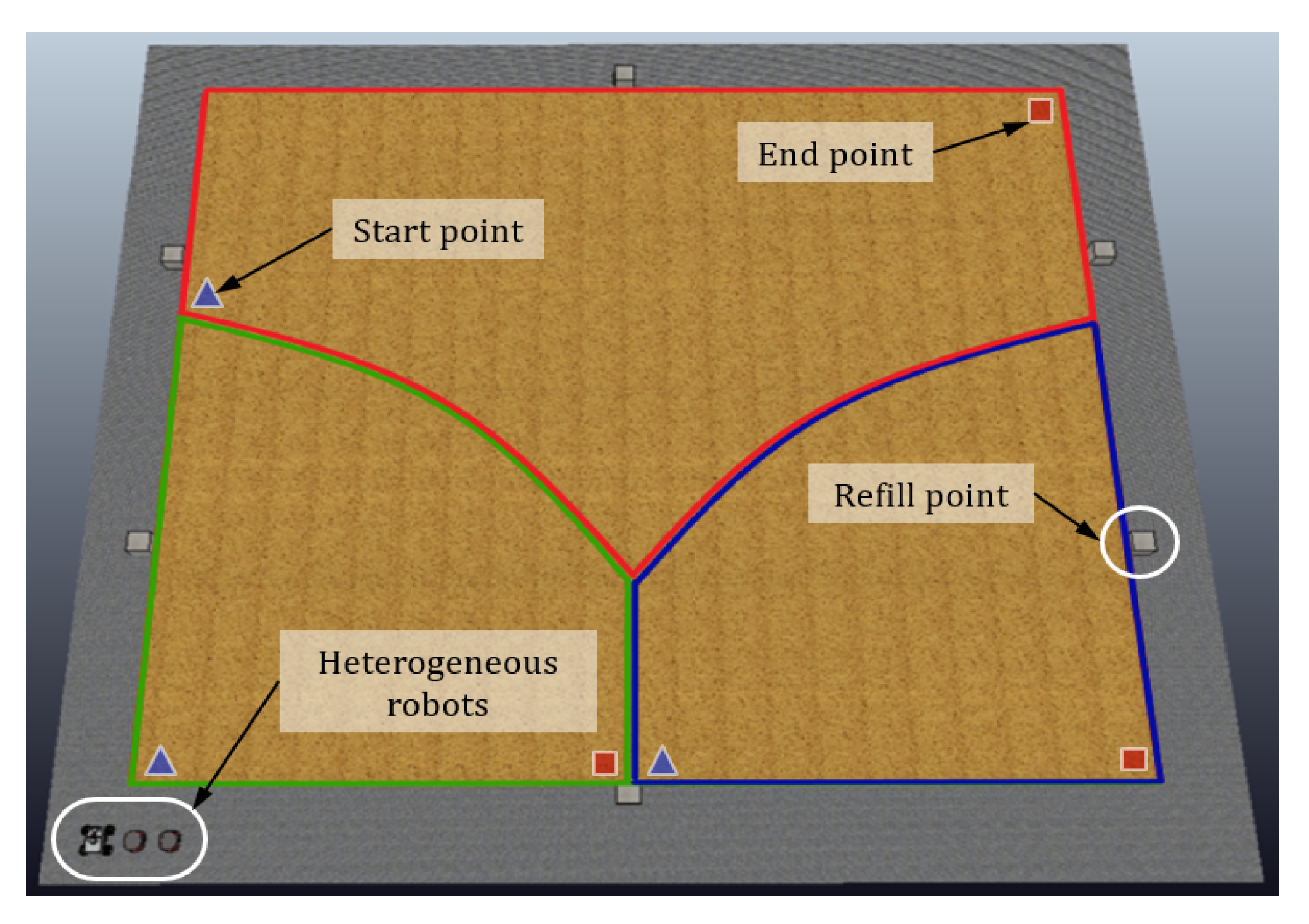

5. Real-World Implementation

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sakaue, O. Development of Seeding Production Robot and Automated Transplanter System. Jpn. Agric. Res. Q. 1996, 30, 221–226. [Google Scholar]

- Naik, N.S.; Shete, V.V.; Danve, S.R. Precision agriculture robot for seeding function. In Proceedings of the 2016 IEEE International Conference on Inventive Computation Technologies (ICICT), Coimbatore, India, 26–27 August 2016; Volume 2, pp. 1–3. [Google Scholar]

- Blackmore, S.; Stout, B.; Wang, M.; Runov, B. Robotic agriculture–the future of agricultural mechanisation. In Proceedings of the 5th European Conference on Precision Agriculture, Uppsala, Sweden, 9–12 June 2005; pp. 621–628. [Google Scholar]

- Ju, C.; Son, H.I. Performance evaluation of multiple UAV systems for remote sensing in agriculture. In Proceedings of the Workshop on Robotic Vision and Action in Agriculture at the IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018; pp. 21–26. [Google Scholar]

- Roldán, J.J.; del Cerro, J.; Garzón-Ramos, D.; Garcia-Aunon, P.; Garzón, M.; de León, J.; Barrientos, A. Robots in agriculture: State of art and practical experiences. In Service Robots; IntechOpen: Rijeka, Croatia, 2017. [Google Scholar]

- Kim, J.; Kim, S.; Ju, C.; Son, H.I. Unmanned Aerial Vehicles in Agriculture: A Review of Perspective of Platform, Control, and Applications. IEEE Access 2019, 7, 105100–105115. [Google Scholar] [CrossRef]

- Vu, Q.; Raković, M.; Delic, V.; Ronzhin, A. Trends in Development of UAV-UGV Cooperation Approaches in Precision Agriculture. In Proceedings of the International Conference on Interactive Collaborative Robotics, Leipzig, Germany, 18–22 September 2018; Springer: Berlin/Heidelberg, Germany, 2018; pp. 213–221. [Google Scholar]

- Potena, C.; Khanna, R.; Nieto, J.; Siegwart, R.; Nardi, D.; Pretto, A. AgriColMap: Aerial-Ground Collaborative 3D Mapping for Precision Farming. IEEE Robot. Autom. Lett. 2019, 4, 1085–1092. [Google Scholar] [CrossRef]

- Gonzalez-de Santos, P.; Ribeiro, A.; Fernandez-Quintanilla, C.; Lopez-Granados, F.; Brandstoetter, M.; Tomic, S.; Pedrazzi, S.; Peruzzi, A.; Pajares, G.; Kaplanis, G.; et al. Fleets of robots for environmentally-safe pest control in agriculture. Precis. Agric. 2017, 18, 574–614. [Google Scholar] [CrossRef]

- Conesa-Muñoz, J.; Bengochea-Guevara, J.M.; Andujar, D.; Ribeiro, A. Efficient distribution of a fleet of heterogeneous vehicles in agriculture: A practical approach to multi-path planning. In Proceedings of the 2015 IEEE International Conference on Autonomous Robot Systems and Competitions, Vila Real, Portugal, 8–10 April 2015; pp. 56–61. [Google Scholar]

- Roldán, J.; Garcia-Aunon, P.; Garzón, M.; de León, J.; del Cerro, J.; Barrientos, A. Heterogeneous multi-robot system for mapping environmental variables of greenhouses. Sensors 2016, 16, 1018. [Google Scholar] [CrossRef] [PubMed]

- Tourrette, T.; Deremetz, M.; Naud, O.; Lenain, R.; Laneurit, J.; De Rudnicki, V. Close coordination of mobile robots using radio beacons: A new concept aimed at smart spraying in agriculture. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 7727–7734. [Google Scholar]

- Khamis, A.; Hussein, A.; Elmogy, A. Multi-robot task allocation: A review of the state-of-the-art. In Cooperative Robots and Sensor Networks 2015; Springer: Berlin/Heidelberg, Germany, 2015; pp. 31–51. [Google Scholar]

- Gerkey, B.P.; Mataric, M.J. A framework for studying multi-robot task allocation. In Multi-Robot Systems: From Swarms to Intelligent Automata; Kluwer: Dordrecht, The Netherlands, 2003; Volume 2, pp. 15–26. [Google Scholar]

- Ju, C.; Son, H.I. Modeling and Control of Heterogeneous Agricultural Field Robots based on Ramadge-Wonham Theory. IEEE Robot. Autom. Lett. 2019, 1–8. [Google Scholar] [CrossRef]

- Gerkey, B.P.; Matarić, M.J. A formal analysis and taxonomy of task allocation in multi-robot systems. Int. J. Robot. Res. 2004, 23, 939–954. [Google Scholar] [CrossRef]

- Korsah, G.A.; Stentz, A.; Dias, M.B. A comprehensive taxonomy for multi-robot task allocation. Int. J. Robot. Res. 2013, 32, 1495–1512. [Google Scholar] [CrossRef]

- Ma, X.; Meng, F.; Li, Y.; Chen, W.; Xi, Y. Multi-agent-based auctions for multi-robot exploration. In Proceedings of the 2006 IEEE 6th World Congress on Intelligent Control and Automation, Dalian, China, 21–23 June 2006; Volume 2, pp. 9262–9266. [Google Scholar]

- Kalra, N.; Ferguson, D.; Stentz, A. Hoplites: A market-based framework for planned tight coordination in multirobot teams. In Proceedings of the 2005 IEEE International Conference on Robotics and Automation, Barcelona, Spain, 18–22 April 2005; pp. 1170–1177. [Google Scholar]

- Ju, C.; Son, H.I. Multiple UAV systems for agricultural applications: Control, implementation, and evaluation. Electronics 2018, 7, 162. [Google Scholar] [CrossRef]

- Ju, C.; Son, H.I. Hybrid Systems based Modeling and Control of Heterogeneous Agricultural Robots for Field Operations. In Proceedings of the 2019 ASABE Annual International Meeting. American Society of Agricultural and Biological Engineers, Boston, MA, USA, 7–10 July 2019; pp. 1–5. [Google Scholar]

- Aurenhammer, F. Voronoi diagrams—A survey of a fundamental geometric data structure. ACM Comput. Surv. (CSUR) 1991, 23, 345–405. [Google Scholar] [CrossRef]

- Brandt, J.W.; Algazi, V.R. Continuous skeleton computation by Voronoi diagram. CVGIP Image Underst. 1992, 55, 329–338. [Google Scholar] [CrossRef]

- Renzaglia, A.; Dibangoye, J.; Doze, V.L.; Simon, O. Multi-UAV Visual Coverage of Partially Known 3D Surfaces: Voronoi-based Initialization to Improve Local Optimizers. arXiv 2019, arXiv:1901.10272. [Google Scholar]

- Cortes, J.; Martinez, S.; Karatas, T.; Bullo, F. Coverage control for mobile sensing networks. IEEE Trans. Robot. Autom. 2004, 20, 243–255. [Google Scholar] [CrossRef]

- Breitenmoser, A.; Metzger, J.C.; Siegwart, R.; Rus, D. Distributed coverage control on surfaces in 3d space. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; pp. 5569–5576. [Google Scholar]

- Kim, J.; Son, H.I. A Voronoi Diagram-Based Workspace Partition for Weak Cooperation of Multi-Robot System in Orchard. IEEE Access 2020, 8, 20676–20686. [Google Scholar] [CrossRef]

- Arslan, O.; Koditschek, D.E. Voronoi-based coverage control of heterogeneous disk-shaped robots. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 4259–4266. [Google Scholar]

- Sun, Y.L.; Er, M.J. Hybrid fuzzy control of robotics systems. IEEE Trans. Fuzzy Syst. 2004, 12, 755–765. [Google Scholar] [CrossRef]

- Braune, S.; Liu, S.; Mercorelli, P. Design and control of an electromagnetic valve actuator. In Proceedings of the 2006 IEEE Conference on Computer Aided Control System Design, 2006 IEEE International Conference on Control Applications, 2006 IEEE International Symposium on Intelligent Control, Munich, Germany, 4–6 October 2006; pp. 1657–1662. [Google Scholar]

- Knezevic, S.Z.; Evans, S.P.; Mainz, M. Row spacing influences the critical timing for weed removal in soybean (Glycine max). Weed Technol. 2003, 17, 666–673. [Google Scholar] [CrossRef]

- Hossain, A.; Ishimine, Y.; Motomura, K.; Akamine, H. Effects of planting pattern and planting distance on growth and yield of turmeric (Curcuma longa L.). Plant Prod. Sci. 2005, 8, 95–105. [Google Scholar] [CrossRef]

- Wagstaff, K.; Cardie, C.; Rogers, S.; Schrödl, S. Constrained k-means clustering with background knowledge. In Proceedings of the ICML, Williamstown, MA, USA, 28 June–1 July 2001; pp. 577–584. [Google Scholar]

| n | Robot | l (m) | (m/s) | c (kg) | |||

|---|---|---|---|---|---|---|---|

| 3 | UGV 1 (Pioneer 3-AT) | 0.2 | 0.7 | 10 | 1 | 2 | 3 |

| UGV 2 (Pioneer 3-AT) | 0.25 | 0.7 | 10 | ||||

| UGV 3 (Summit_XL) | 1.5 | 3 | 20 | ||||

| 4 | UGV 1 (Pioneer 3-AT) | 0.2 | 0.7 | 10 | |||

| UGV 2 (Pioneer 3-AT) | 0.25 | 0.7 | 10 | ||||

| UGV 3 (Pioneer 3-AT) | 1.25 | 0.7 | 10 | ||||

| UGV 4 (Summit_XL) | 2.5 | 3 | 20 | ||||

| 5 | UGV 1 (Pioneer 3-AT) | 0.2 | 0.7 | 10 | |||

| UGV 2 (Pioneer 3-AT) | 0.25 | 0.7 | 10 | ||||

| UGV 3 (Pioneer 3-AT) | 1.25 | 0.7 | 10 | ||||

| UGV 4 (Pioneer 3-AT) | 2.25 | 0.7 | 10 | ||||

| UGV 5 (Summit_XL) | 3.5 | 3 | 20 |

| Metric | n | |||

|---|---|---|---|---|

| 3 | 4 | 5 | ||

| The number of nodes assigned | Individual values | 673 | 594 | 502 |

| 634 | 520 | 424 | ||

| 909 | 541 | 417 | ||

| 665 | 388 | |||

| 589 | ||||

| Mean (±SD) | 738.67 (±148.8) | 580 (±64.66) | 464 (±81.63) | |

| Tasking time (s) | Individual values | 346.11 | 259.8 | 219.11 |

| 346.12 | 258.16 | 211.19 | ||

| 344.7 | 252.15 | 210.86 | ||

| 264.4 | 214.2 | |||

| 199.14 | ||||

| Mean (±SD) | 345.64 (±0.82) | 258.63 (±5.06) | 210.9 (±7.36) | |

| l (m) | (m/s) | c (kg) | ||||

|---|---|---|---|---|---|---|

| UGV 1 (Husky) | 0.3 | 1 | 75 | 1 | 2 | 0 |

| UGV 2 (Jackal) | 2.2 | 2 | 20 | |||

| UGV 3 (Jackal) | 1.4 | 2 | 20 |

| Metric | n | |

|---|---|---|

| 3 | ||

| The number of nodes assigned | Individual values | 381 |

| 397 | ||

| 422 | ||

| Mean (±SD) | 400 (±20.66) | |

| Tasking time (s) | Individual values | 117.24 |

| 116.52 | ||

| 130.75 | ||

| Mean (±SD) | 121.5 (±8.02) | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Ju, C.; Son, H.I. A Multiplicatively Weighted Voronoi-Based Workspace Partition for Heterogeneous Seeding Robots. Electronics 2020, 9, 1813. https://doi.org/10.3390/electronics9111813

Kim J, Ju C, Son HI. A Multiplicatively Weighted Voronoi-Based Workspace Partition for Heterogeneous Seeding Robots. Electronics. 2020; 9(11):1813. https://doi.org/10.3390/electronics9111813

Chicago/Turabian StyleKim, Jeongeun, Chanyoung Ju, and Hyoung Il Son. 2020. "A Multiplicatively Weighted Voronoi-Based Workspace Partition for Heterogeneous Seeding Robots" Electronics 9, no. 11: 1813. https://doi.org/10.3390/electronics9111813

APA StyleKim, J., Ju, C., & Son, H. I. (2020). A Multiplicatively Weighted Voronoi-Based Workspace Partition for Heterogeneous Seeding Robots. Electronics, 9(11), 1813. https://doi.org/10.3390/electronics9111813