Power Supply Platform and Functional Safety Concept Proposals for a Powertrain Transmission Electronic Control Unit

Abstract

1. Introduction

2. Design Challenges

- What is needed (simplest solution) to supply the TC3xx with power from the FS65xx SBC to fulfill ASIL-D? How are the 3.3 V and 1.3 V internally generated by the TC3xx?

- What happens (over a lifetime) with the TC3xx if the power supply from the SBC is made as described in the datasheet?

- How will the overall safety concept look?

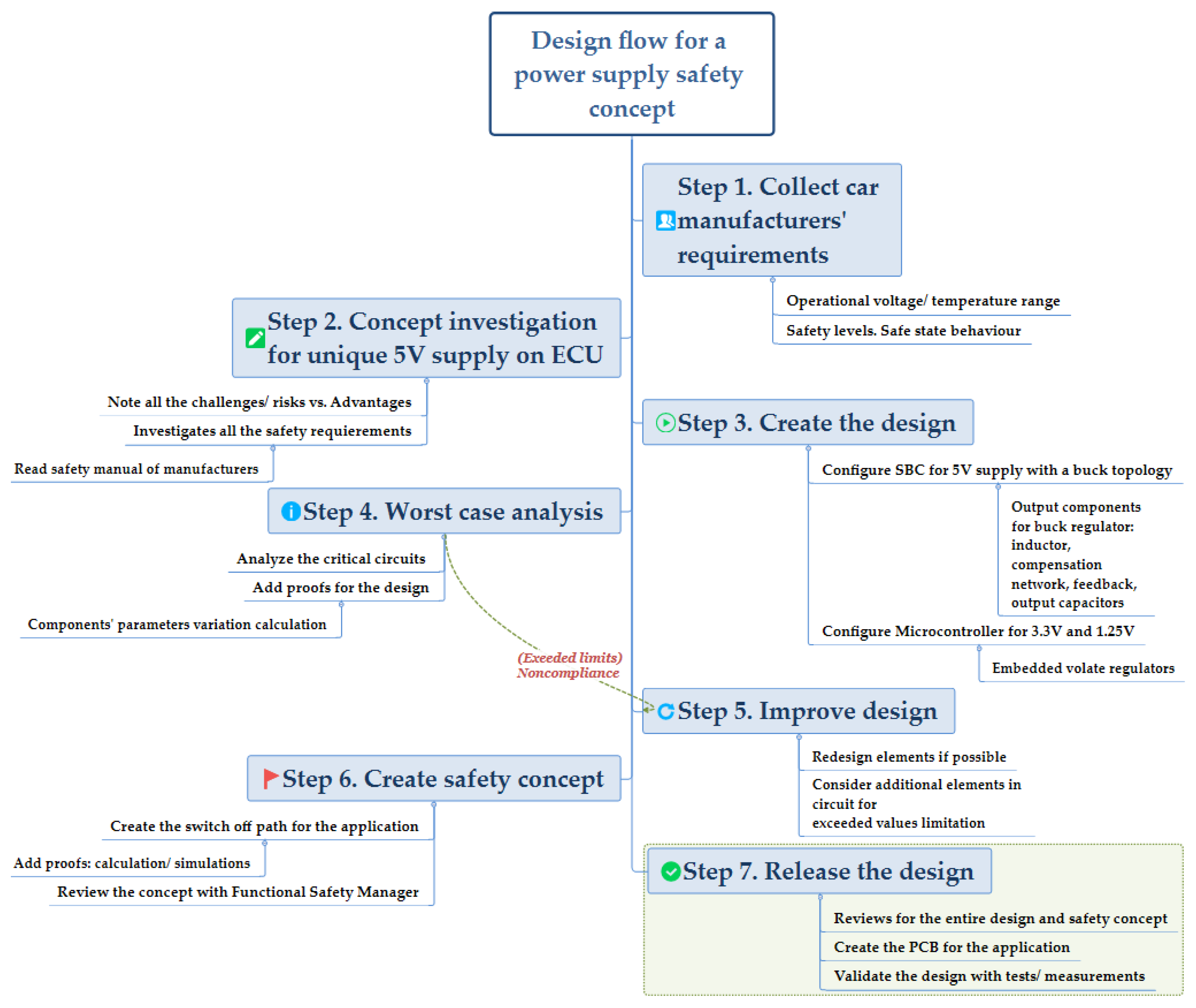

3. Design Flow Proposal

4. Power Supply Design and Safety Requirements Evaluation

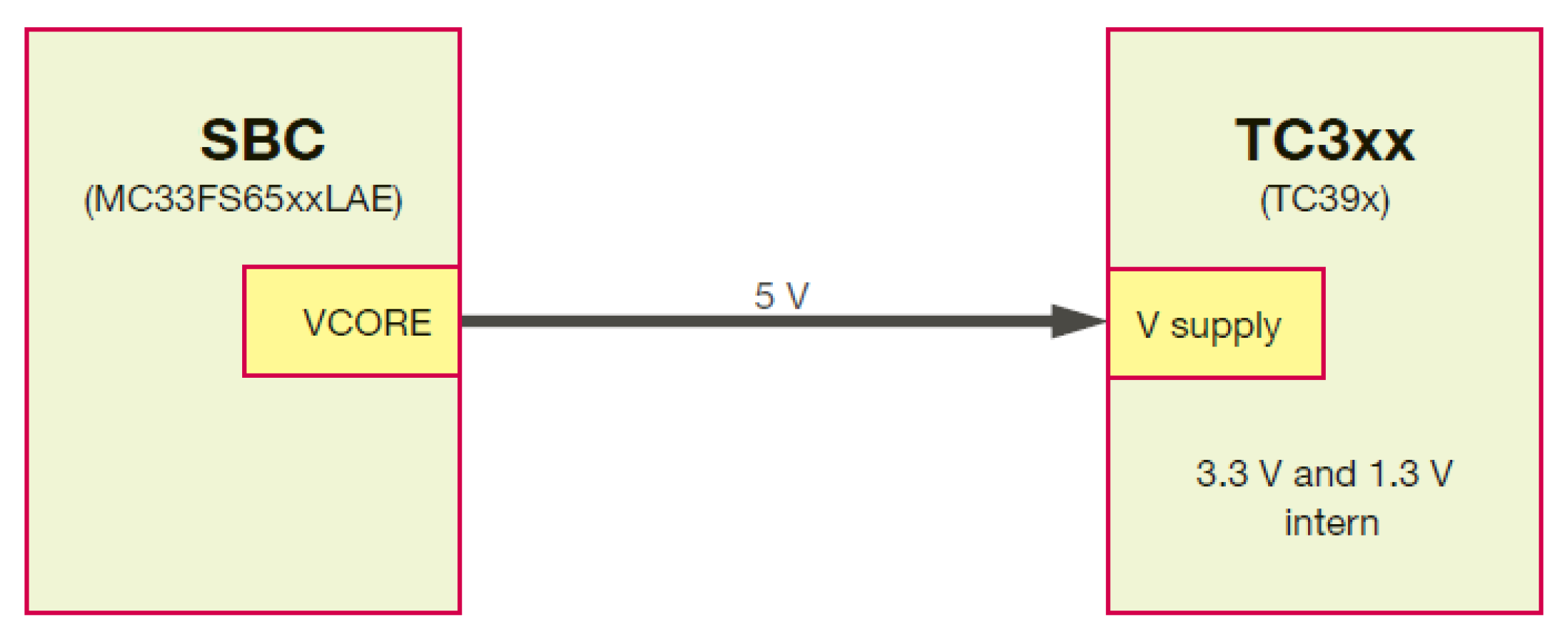

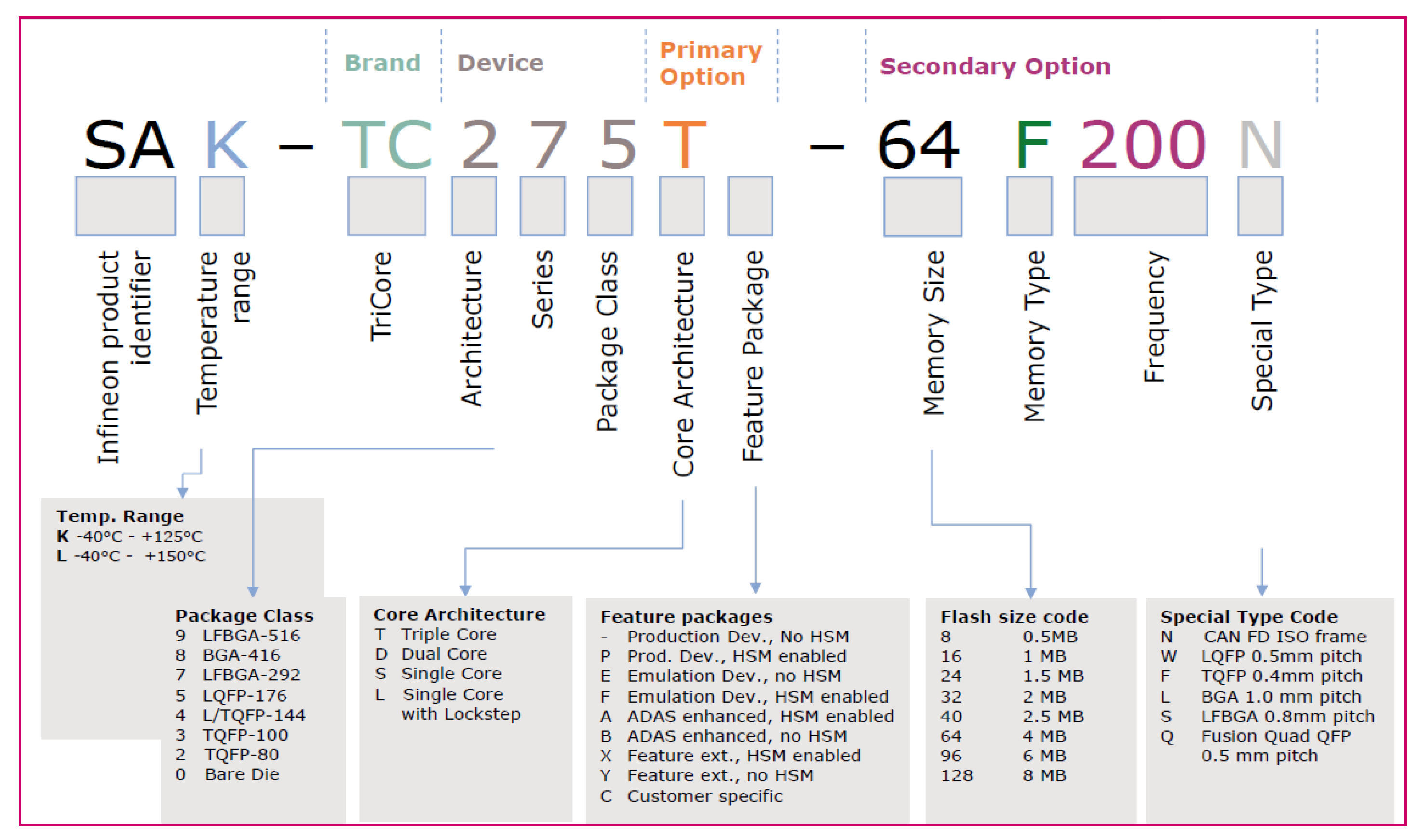

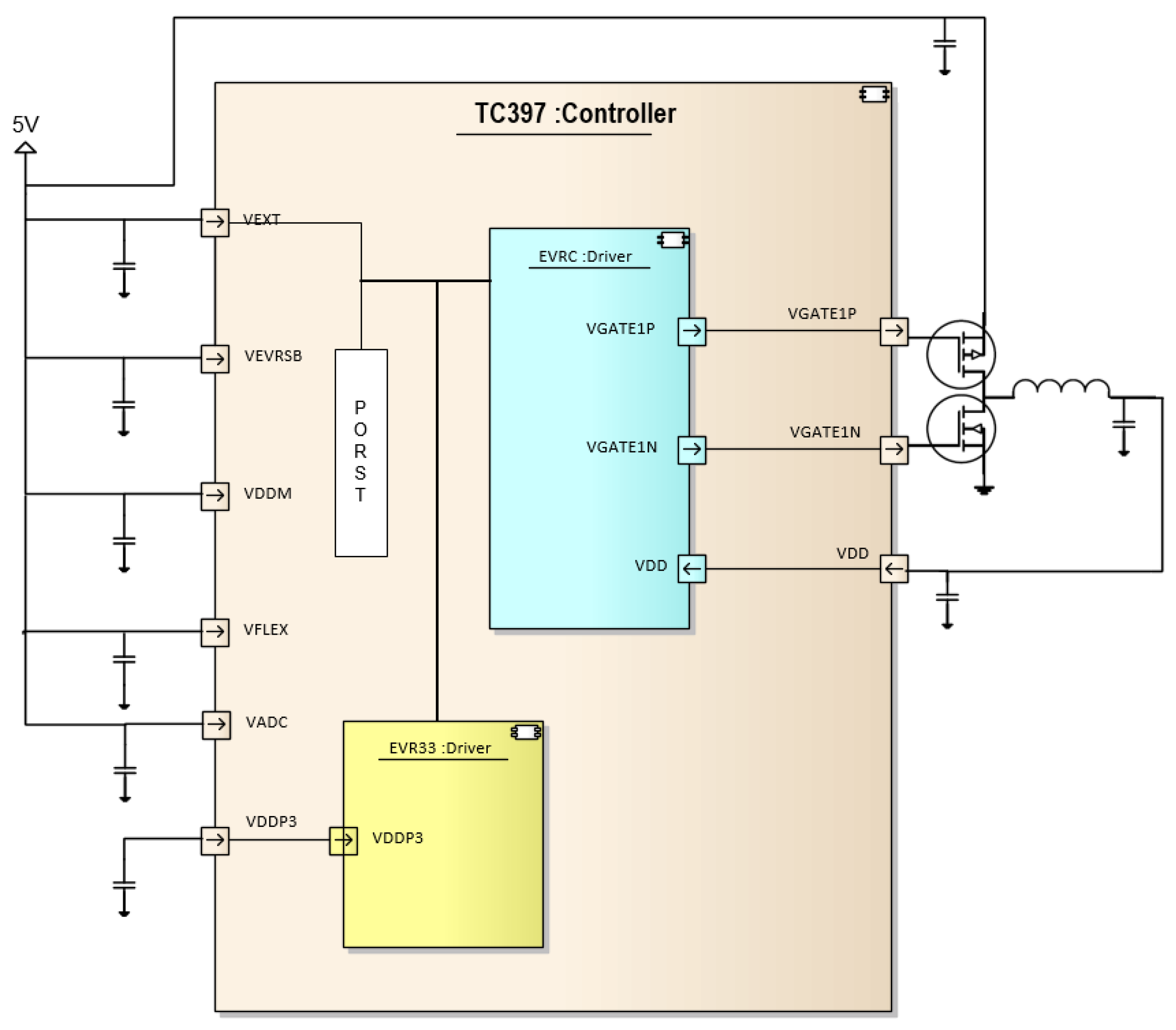

4.1. What Is Needed (Simplest Solution) to Supply the TC397 with Power from FS6512 SBC to Fulfill ASIL-D?

4.1.1. V Configuration of FS6512: For VCORE—BUCK Regulator

4.1.2. V Configuration Supply Concept for TC397

4.2. What Happens (over Lifetime) with the TC3xx If the Power Supply from PSBC Is Done Like in the Data Sheet?

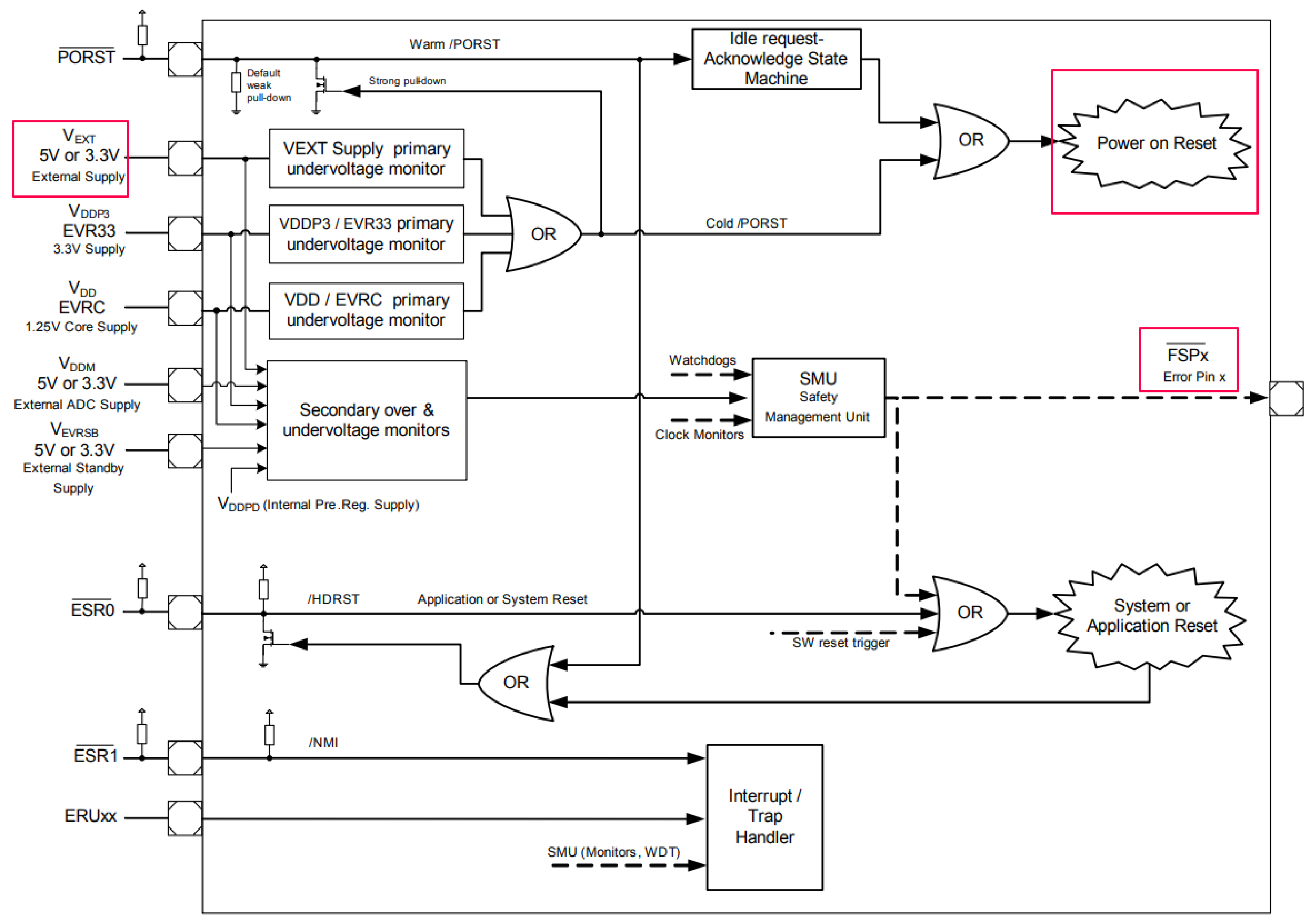

4.2.1. TC397 Microcontroller Requirements in Terms of Supply

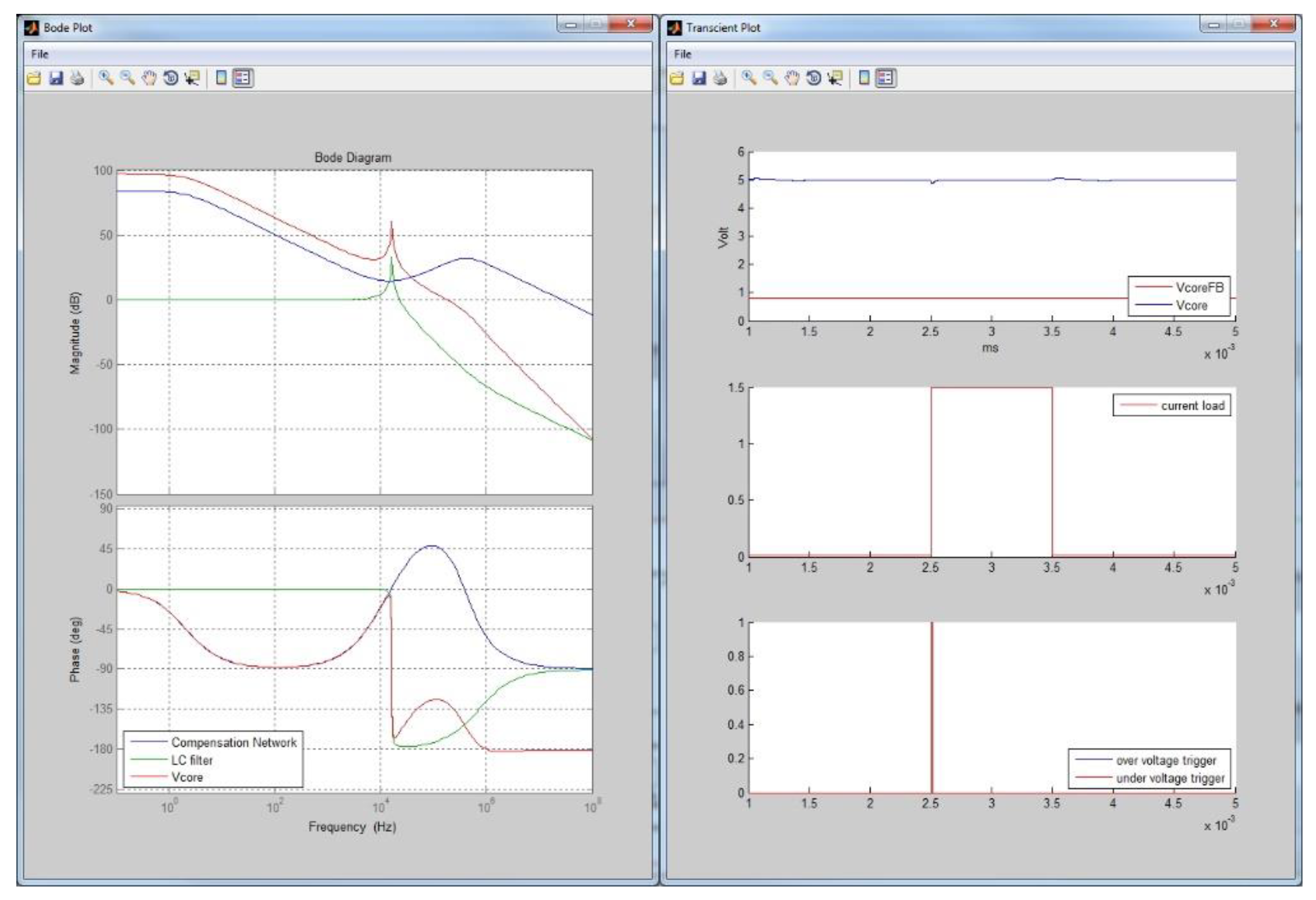

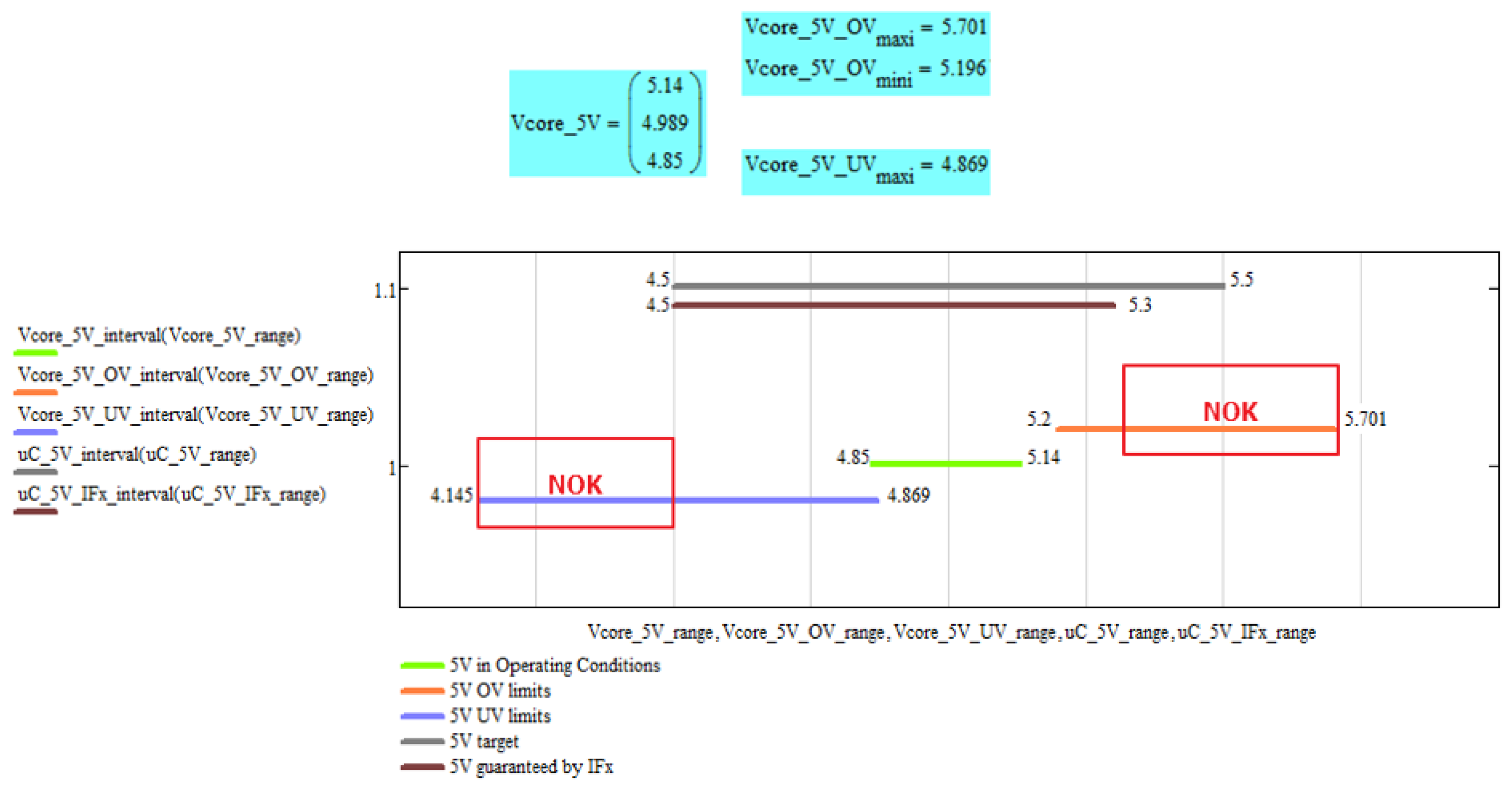

4.2.2. VCORE 5 V Worst-Case Mathcad Calculation

5. Power Supply Safety Concept Design Proposal

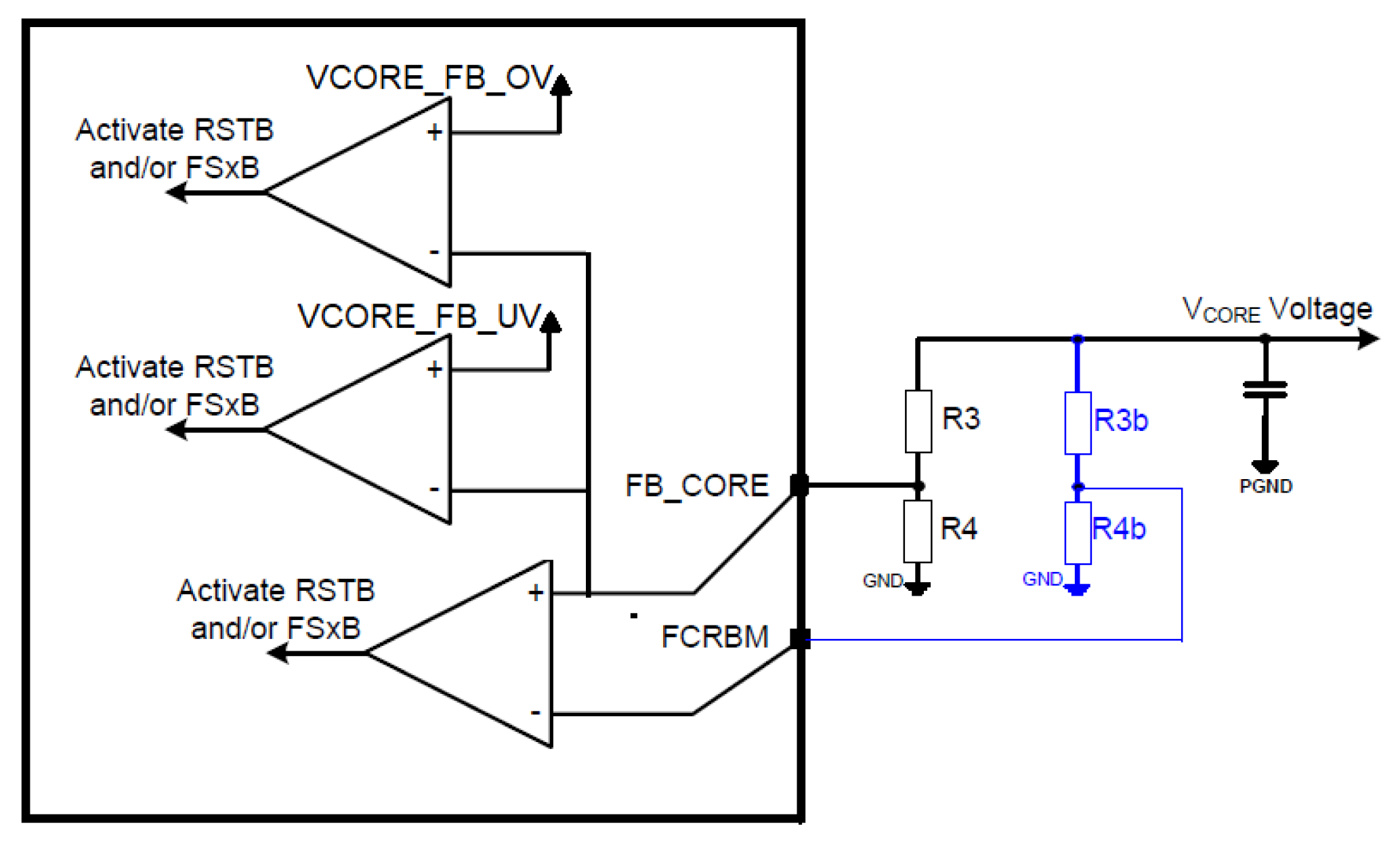

5.1. Safety Connections

5.1.1. Check the SBC Safety Activation

5.1.2. Check the µC Safety Activation

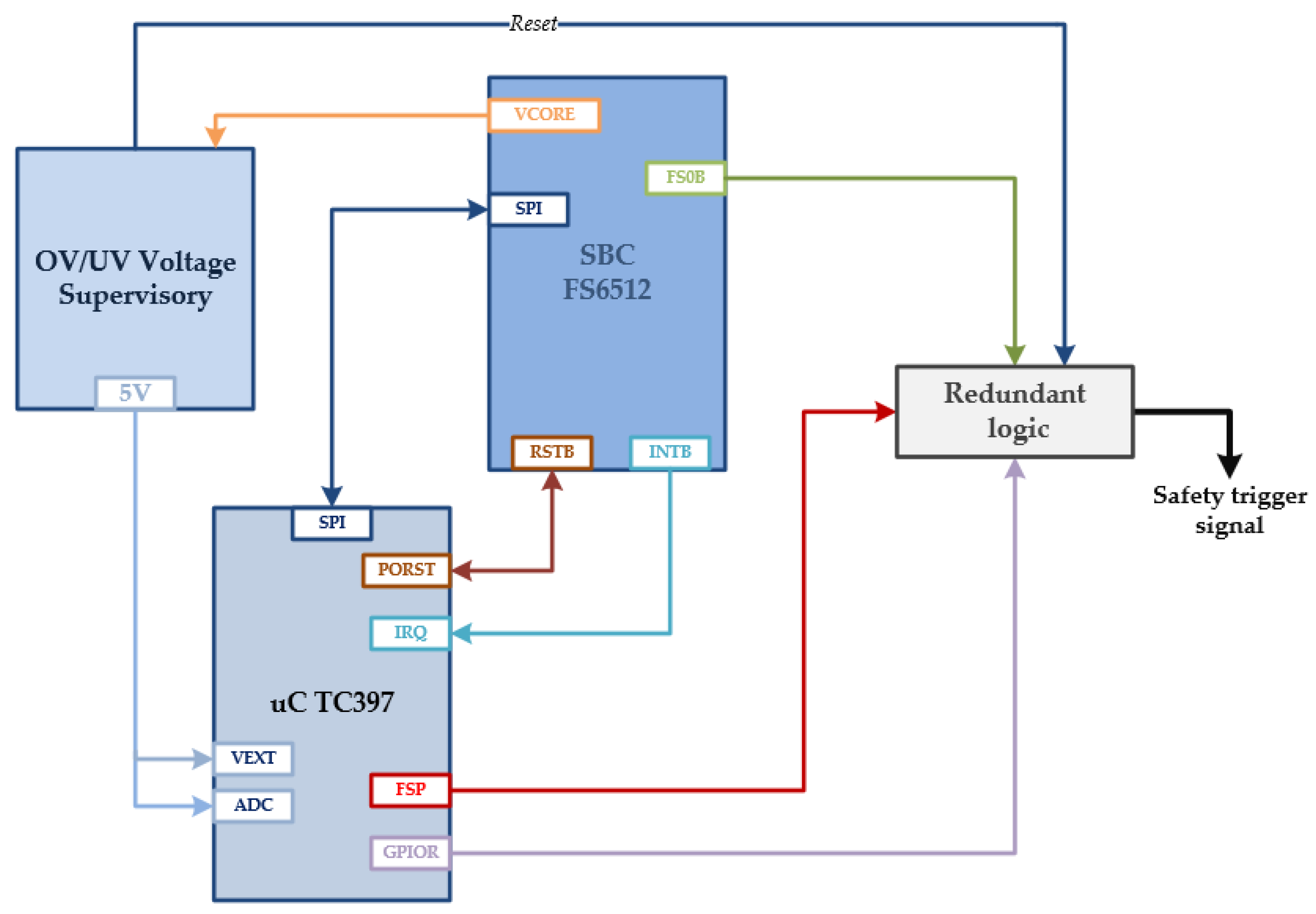

5.2. Safety Architecture for the Switch-Off Concept

- FS0B from the SBC;

- FSP from the microcontroller;

- Redundant digital output pin from the microcontroller (GPIOR pin);

- Under or overvoltage reset pin from the voltage supervisor block (OV/UV).

6. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- FS6500-FS4500—Safety Power System Basis Chip with CAN FD and LIN Transceivers—Datasheet (REV 6.0), 4 October 2017. Available online: https://www.nxp.com/docs/en/product-numbering-scheme/FS6500-FS4500SDS.pdf (accessed on 23 February 2019).

- ISO 26262—Road Vehicles—Function Safety; International Organization for Standardization. Available online: https://www.iso.org/standard/68383.html (accessed on 5 March 2019).

- IEC 61508 Standard—Electrical, Electronic and Programmable Electronic Safety Related Systems. Available online: https://www.iecee.org/dyn/www/f?p=106:49:0::::FSP_STD_ID:5516 (accessed on 26 February 2019).

- AURIXTM TC3xx. Available online: https://www.infineon.com/dgdl/Infineon-AURIX_TC3xx_Part1-UserManual-v01_00-EN.pdf?fileId=5546d462712ef9b701717d3605221d96 (accessed on 14 March 2019).

- Ismail, A.; Jung, W. Research trends in automotive functional safety. In Proceedings of the 2013 International Conference on Quality, Reliability, Risk, Maintenance, and Safety Engineering (QR2MSE), Chengu, China, 15–18 July 2013; pp. 1–4. [Google Scholar]

- Mariani, R. The impact of functional safety standards in the design and test of reliable and available integrated circuits. In Proceedings of the 2012 17th IEEE European Test Symposium (ETS), Annecy, France, 28–31 May 2012; p. 1. [Google Scholar]

- Park, J.S.; Suh, I.; Choe, C.Y.; Ro, M.; Brewerton, S.P. Intelligent ECU End of Line Testing to Support ISO26262 Functional Safety Requirements. SAE Int. J. Passeng. Cars Electron. Electr. Syst. 2013, 6, 162–168. [Google Scholar] [CrossRef]

- Leu, K.L.; Huang, H.; Chen, Y.Y.; Huang, L.R.; Ji, K.M. An intelligent brake-by-wire system design and analysis in accordance with ISO-26262 functional safety standard. In Proceedings of the International Conference on Connected Vehicles and Expo (ICCVE), Shenzhen, China, 19–23 October 2015; pp. 150–156. [Google Scholar]

- Hillenbrand, M.; Heinz, M.; Adler, N.; Matheis, J.; Müller-Glaser, K.D. Failure mode and effect analysis based on electric and electronic architectures of vehicles to support the safety lifecycle ISO/DIS 26262. In Proceedings of the 21st IEEE International Symposium on Rapid System Protyping, Fairfax, VA, USA, 8–11 June 2010; pp. 1–7. [Google Scholar]

- Chang, Y.C.; Huang, L.R.; Liu, H.C.; Yang, C.J.; Chiu, C.T. Assessing automotive functional safety microprocessor with ISO 26262 hardware requirements. In Proceedings of the 2014 International Symposium on VLSI Design, Automation and Test (VLSIDAT), Hsinchu, Taiwan, 28–30 April 2014; pp. 1–4. [Google Scholar]

- Azevedo, L.S.; Parker, D.; Walker, M.; Papadopoulos, Y.; Araújo, R.E. Assisted Assignment of Automotive Safety Requirements. IEEE Softw. 2014, 31, 62–68. [Google Scholar] [CrossRef]

- Takeichi, M.; Sato, Y.; Suyama, K.; Kawahara, T. Failure rate calculation with priority FTA method for functional safety of complex automotive subsystems. In Proceedings of the 2011 International Conference on Quality, Reliability, Risk, Maintenance, and Safety Engineering (ICQR2MSE), Xi’an, China, 17–19 June 2011; pp. 55–58. [Google Scholar]

- Sinha, P. Architectural design and reliability analysis of a fail operational brake-by-wire system from ISO 26262 perspectives. Reliab. Eng. Syst. Saf. 2011, 96, 1349–1359. [Google Scholar] [CrossRef]

- Siegl, S.; Hielscher, S.; German, K.R.; Berger, C. Formal specification and systematic model-driven testing of embedded automotive systems. In Proceedings of the Design, Automation & Test in Europe Conference & Exhibition (DATE), Grenoble, France, 14–18 March 2011; pp. 1–6. [Google Scholar]

- Grimm, T.; Djones Lettnin, I.D.; Hübner, M. A Survey on Formal Verification Techniques for Safety-Critical Systems-on-Chip. Electronics 2018, 7, 81. [Google Scholar] [CrossRef]

- Ferlini, F.; Seman, L.O.; Bezerra, E.A. Enabling ISO 26262 Compliance with Accelerated Diagnostic Coverage Assessment. Electronics 2020, 9, 732. [Google Scholar] [CrossRef]

| TC3xx, C40 nm Technology | |

|---|---|

| Range | Behavior |

| 5.6–6.5 V | 60 h (Safety case, reset asserted, rated max. voltage +30%) |

| 5.6–6.5 V | 10 h (Safety case, reset unasserted, rated max. voltage +30%) |

| 5.3–5.6 V | 100 h (Safety case, reset unasserted) |

| 4.5–5.3 V | 100% of lifetime (Normal functioning, rated max. voltage of 6%) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biba, D.R.; Ancuti, M.C.; Ianovici, A.; Sorandaru, C.; Musuroi, S. Power Supply Platform and Functional Safety Concept Proposals for a Powertrain Transmission Electronic Control Unit. Electronics 2020, 9, 1580. https://doi.org/10.3390/electronics9101580

Biba DR, Ancuti MC, Ianovici A, Sorandaru C, Musuroi S. Power Supply Platform and Functional Safety Concept Proposals for a Powertrain Transmission Electronic Control Unit. Electronics. 2020; 9(10):1580. https://doi.org/10.3390/electronics9101580

Chicago/Turabian StyleBiba, Diana Raluca, Mihaela Codruta Ancuti, Alexandru Ianovici, Ciprian Sorandaru, and Sorin Musuroi. 2020. "Power Supply Platform and Functional Safety Concept Proposals for a Powertrain Transmission Electronic Control Unit" Electronics 9, no. 10: 1580. https://doi.org/10.3390/electronics9101580

APA StyleBiba, D. R., Ancuti, M. C., Ianovici, A., Sorandaru, C., & Musuroi, S. (2020). Power Supply Platform and Functional Safety Concept Proposals for a Powertrain Transmission Electronic Control Unit. Electronics, 9(10), 1580. https://doi.org/10.3390/electronics9101580