1. Introduction

The Insulated Gate Bipolar Transistor (IGBT) module is a power electronic integrated module composed of multiple IGBT chips, diode chips, solder layers, bond wires, ceramic copper-clad substrates, heat dissipation base plates, and power terminals. IGBT modules are mainly used in inverters, frequency converters, uninterruptible power supplies, wind power, and solar power generation. They are the core components of power converters and have one of highest failure rates out of all the power converters [

1]. To reduce the failure rate and improve the reliability of the power converter, it is of great significance to monitor the failure status of the IGBT module [

2].

At present, many scholars at home and abroad are committed to the reliability research of IGBT modules, most of which focus on the online measurement of IGBT health-sensitive parameters (HSPs) or thermosensitive electrical parameters (TSEPs). Researchers measure the collector, gate, emitter, and appropriate Kelvin terminals of the IGBT module to obtain the external electrical parameters of the IGBT module, and realize the health monitoring of the IGBT module through the fault characteristic parameters [

3,

4,

5]. Reference [

6,

7] proposed measuring IGBT saturation voltage drop

VCE(sat) during the operation of the power converter. This method must ensure that the measured current is constant during operation, but it is difficult to achieve in practice. Reference [

8,

9,

10] proposes using the on-state voltage drop

VCE(ON)a under load current to monitor the shedding of IGBT bond wires in real time. Still, this parameter has a weak anti-interference ability. In reference [

11], the on-state voltage drop

VCE(on)B at the inflection point is used to monitor the aging and shedding of bond wires, which has strong resistance to junction temperature interference. However, the measurement of the on-state voltage drop

VCE(ON) needs to consider the high-voltage isolation problem, and the measurement is from thousands of volts in the off phase to a few volts in the on phase. The measurement range is broad, and the measurement circuit must consider a large

VCE voltage swing. There are certain difficulties in practical applications. Reference [

12] uses on-state resistance

RCE(ON) to monitor the aging degree of the IGBT module package online. Although it has high sensitivity, its resistance to junction temperature interference is low, and the first bond wire lift-off in the IGBT module cannot be detected. Reference [

13,

14,

15] uses the peak gate current

IGPeak to monitor the shedding of the bond wire in the parallel IGBT module. Although this parameter has a strong resistance to changes in junction temperature, detecting the peak gate current value is difficult in practical applications. In addition, the gate current is relatively small, and the measurement is performed on the side close to the IGBT module. The detection circuit also needs to deal with the challenge of electromagnetic interference. In reference [

16], the grid emitter voltage variation

dVCE/

dt was used to detect the drop of the bond wire during the process of turning the circuit on and off. This method could not identify the first bond wire lift-off. Reference [

17] proposes using the gate-emitter pre-threshold voltage

VGE(pre-th) to monitor IGBT chip failures in multi-chip IGBT modules. This method can only monitor chip failures and cannot monitor a small number of bond wire fall-off failures. Most of the above research methods can only monitor one of the failures of the IGBT bond wire lift-off or the IGBT chip failure, and it cannot be monitored at the same time. Temperature-sensitive electrical parameters need to be considered when used as fault characteristic parameters. However, in the above studies, temperature-sensitive electrical parameters have not been normalized to eliminate the impact of temperature on failure monitoring.

Aiming at the shortcomings of the existing research methods, this paper proposes using the IGBT module transconductance as the characteristic quantity to identify both the chip failure and the bond wire failure in the multi-chip IGBT module and realize the failure monitoring of the IGBT module. The paper first analyzes the failure mechanism and module structure of the multi-chip IGBT module; then, it proposes a reliability model based on the module transconductance and analyzes the relationship between chip failure, bond wire failure, and the IGBT module transmission characteristic curve (iC-uGE) Finally, the quantitative relationship between chip failure and bond wire failure and module transconductance is measured and calculated through simulation. Furthermore, the temperature is normalized, which can eliminate the influence of temperature on failure monitoring. The results show that the method has good sensitivity to chip failures and bond wire failures, can realize the failure monitoring of multi-chip IGBT modules, and is of great significance for improving the reliability of power converters.

The sections of this article are arranged as follows. In

Section 2, the failure mechanism and module structure of the multi-chip IGBT module are introduced in detail. In

Section 3, a reliability model based on the module transconductance is constructed.

Section 4 is based on the reliability model to monitor the chip failure and bond wire failure status of the DIM800NSM33-F IGBT module. The results are discussed and analyzed in

Section 5.

2. Multi-Chip IGBT Module Failure Mechanism and Structure

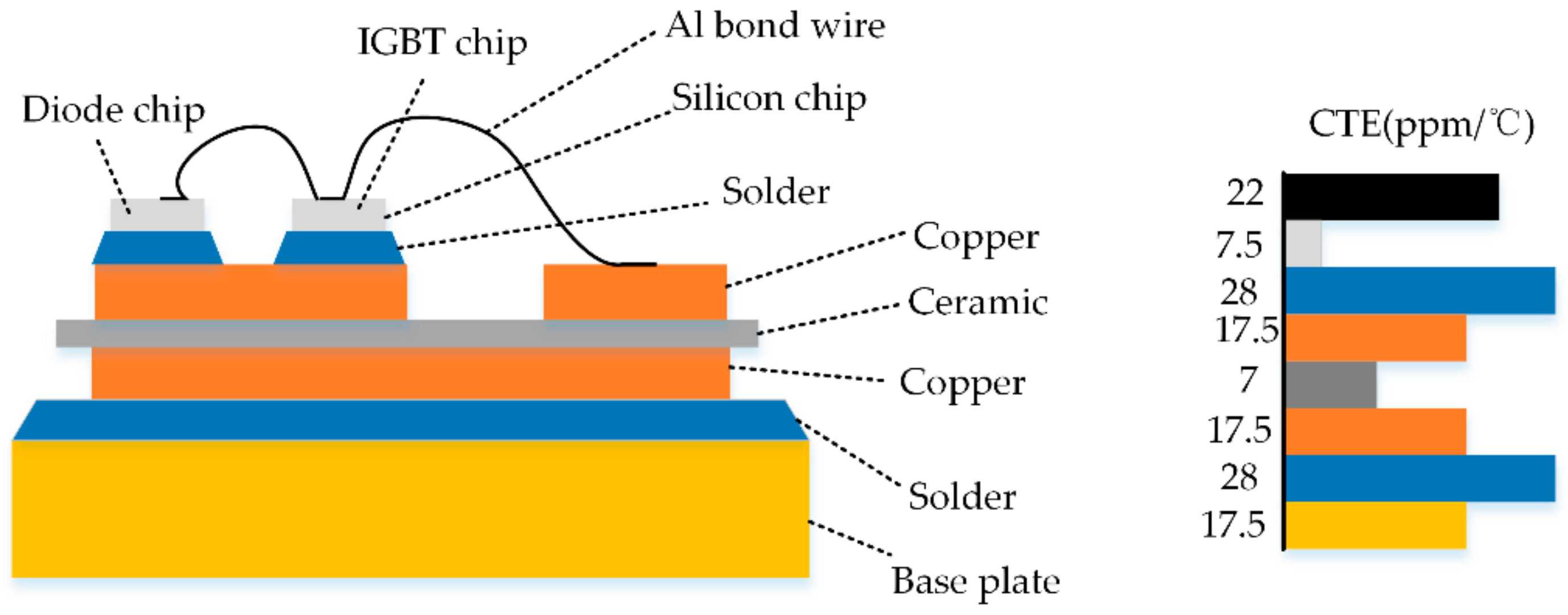

The failure of the solder layer and the falling off of the bond wires are the main aging failure mechanisms of IGBT modules. The bond wire is mainly used to connect the chip (IGBT chip or diode chip) and the terminal (gate or emitter). The main reason for the bond wire to fall off is the inconsistent coefficient of thermal expansion (CTE) of each layer of the semiconductor device.

Figure 1 shows the IGBT module packaging structure and the coefficient of thermal expansion of each layer of material. The IGBT chip and the diode chip are electrically connected by bond wires, as are the chip and the copper substrate. During the normal operation of the IGBT, the heat generated by the power loss of the semiconductor chip will pass through the multi-layer structure to the heat sink to produce a junction temperature fluctuation Δ

T, which causes the bond wire to generate shear stress at its welding point, and the changing stress produces cracks, which leads to the bond wires fall-off [

18,

19]. Initially, cracks are generated at both ends of the bond wire; then, they are gradually extended to the middle until the bond wire completely falls off. Once a bond wire in the module falls off, the current passing through the remaining bond wires will increase immediately, thereby accelerating the fall-off process of the remaining bond wires [

20]. The deformation

εt of the IGBT due to the fluctuation of the junction temperature can be expressed by Equation (1):

where α

Al and α

Si are the CTEs of aluminum and silicon,

L is the length of the aluminum bond wire; Δ

T is the junction temperature fluctuation.

For multi-chip IGBT modules, in addition to the parasitic parameters of the cell chip, stray parameters such as the substrate, board lining, solder layer, and bond wire in the module packaging process need to be considered [

21]. Among the stray parameter changes caused by IGBT failure, the bond wire fall-off is the most typical. Therefore, the chip fault and bond wire fault studied in this paper are caused by the bond wire fall-off. If the bond wires of a certain unit IGBT chip are all falling off, the number of effective IGBT chips connected in parallel in the IGBT module will be reduced, and the fault type is chip failure at this time. If the bond wire of a certain unit IGBT chip falls off, the number of effective bond wires on the chip will be reduced, and the fault type is bond wire failure at this time. The reliability of multi-chip IGBT modules depends on the health of all parallel IGBT chips and bond wires. Therefore, it is very important to evaluate the overall health of the multi-chip IGBT module by monitoring IGBT chip failure and bond wire failure [

22].

Figure 2 shows the equivalent diagram of the internal structure of the multi-chip IGBT module. There are n IGBT chips in parallel. This article takes the DIM800NSM33-F IGBT module as the research object. This module is a commercial module. The physical map and the internal equivalent circuit of a single chip in the module are shown in

Figure 3. The module is a 16-unit IGBT module. Each chip has eight emitter bond wires, and there are 128 emitter bond wires in total. Refer to the data sheet for the basic parameters of the module, as shown in

Table 1. The acceptable number of chip losses for IGBT modules depends on the working environment and working requirements. Generally, 10% chip losses in IGBT modules and 70% bond wire lift-off on the chip are considered acceptable [

23]. Therefore, for the DIM800NSM33-F IGBT module, the detection of two chip failures in 16 chips is set as the safety margin. The failure simulation is the situation of the first two chips that failed; the first chip that failed is called “Chip 1”, the second chip that failed is called “Chip 2”.

3. Reliability Model Based on Module Transconductance

The transmission characteristic curve of the IGBT module usually adopts Auto Curve Tracer to test, the horizontal axis is the gate-emitter voltage uGE, and the vertical axis is the collector current iC, which is affected by temperature. The general definition of transconductance refers to the slope of the transmission characteristic curve of the IGBT chip, which is the characteristic parameter of the IGBT chip itself. For the entire IGBT module, its module transconductance is affected by IGBT chip fatigue and bond wire failure. The transmission characteristic of IGBT refers to the response function of iC to uGE changes at different temperatures. The gradient of the transmission characteristic at a given temperature is called the transconductance of the device at that temperature. IGBT is a device that uses input voltage to control output current. The ratio of output current to input voltage is represented by transconductance, which also reflects the gain of IGBT. The chip transconductance gmc reflects the sensitivity of ic to uGE, and the module transconductance gm reflects the sensitivity of ic to ui. This article mainly focuses on the failure research of the IGBT module chip and bond wire, which belongs to module package level failure: a slow and gradual process.

The relationship between IGBT chip fatigue, bond wire lift-off, and module transconductance is analyzed in detail below. According to the working principle of the IGBT chip, when the IGBT chip operates in the active area, the governing equation of the collector current

ic is shown in Equation (2) [

24]:

where

μni is the electron migration speed,

COX is the oxide layer capacitance,

Z and

L are the length and width between the gate-emitter of the MOSFET, α

pnp is the current gain of the PNP transistor,

UGE(th) is the threshold voltage of the IGBT chip; the above parameters are all determined by the chip structure and material, but they are all affected by the junction temperature

Tj of the chip.

For simplification, the parameter

A is used to characterize the parameters related to the physical size and structure of the chip in Equation (2), and the chip transconductance

gmc is the sensitivity of

ic to

uGE as shown in Equation (3):

From

Figure 3b, we can see that for a single IGBT branch, the circuit equation during the switching transient device is Equation (4):

where

Rw is the equivalent parasitic resistance of bond wires;

Rcu and

Lcu are the equivalent parasitic resistance and inductance of the copper layer;

ui is the gate drive voltage of the IGBT module; and

iG is the gate current of the IGBT module.

Let is the equivalent stray inductance of the IGBT emitter lead, and

Ret is the equivalent stray resistance of the IGBT emitter lead.

The parasitic resistance of the IGBT is about 40 μΩ, the parasitic inductance is about 30 nH, and the bonding wire resistance is about 50 mΩ. The parasitic resistance and all parasitic inductances are relatively small compared to the bonding wire resistance. In practical applications,

dic/

dt is about 3000 A/μs, and

dig/

dt is about 0.2 A/μs. When the IGBT works in the safe active region, the collector current

ic and the gate current

ig remain almost constant. Considering that the measurement of the transconductance

gm of the detection parameter module in this paper is when the IGBT is working in the safe active area, Equation (4) can be simplified to Equation (5):

When

ui is equal to

UGE(th), the current flowing through the IGBT is zero. In order to study the influence of IGBT module transconductance and bond wire resistance

RW on the module transconductance, we substitute Equation (5) into Equation (1) and perform appropriate transformations to obtain the relationship between

ic and

ui as Equation (6):

The module transconductance

gm of the IGBT module reflects the sensitivity of

ic to

ui, which can be derived as Equation (7):

Comparing Equations (2) and (6), we can see that the relationship between chip transconductance

gmc and module transconductance

gm is as shown in Equation (8):

The transconductance of the IGBT module is not only related to the transconductance of the IGBT chip itself but also to the health of the parallel chip and the bond wires. The module transconductance will decrease as

Rw increases during the aging failure process. From Equation (2), we can get Equation (9):

Then, we put Equation (9) into Equation (7) to get the module transconductance, as shown in Equation (10). The transconductance expression of this module has nothing to do with the threshold voltage affected by the gate oxide layer.

Among the failure modes of power devices, package-related failures are the most common and are generally considered to be the main factors affecting the life of IGBTs. It can be seen from Equation (10) that the module transconductance is a function of parameter Rw, parameter A, and collector current ic. Parameter A characterizes the physical size and structural parameters of the chip, and it is generally believed that these parameters will not change with aging. In this case, the bond wire lift-off is the only aging factor that affects the module transconductance change. For multi-chip IGBT modules, the chip characteristics and bond wire resistance on each branch may not be consistent, and the gate oxide degradation of each chip may also be different. For simplicity, it is assumed that the chip branches are consistent, and the aging process is also consistent, so as to eliminate the influence of the threshold voltage UGE(th).

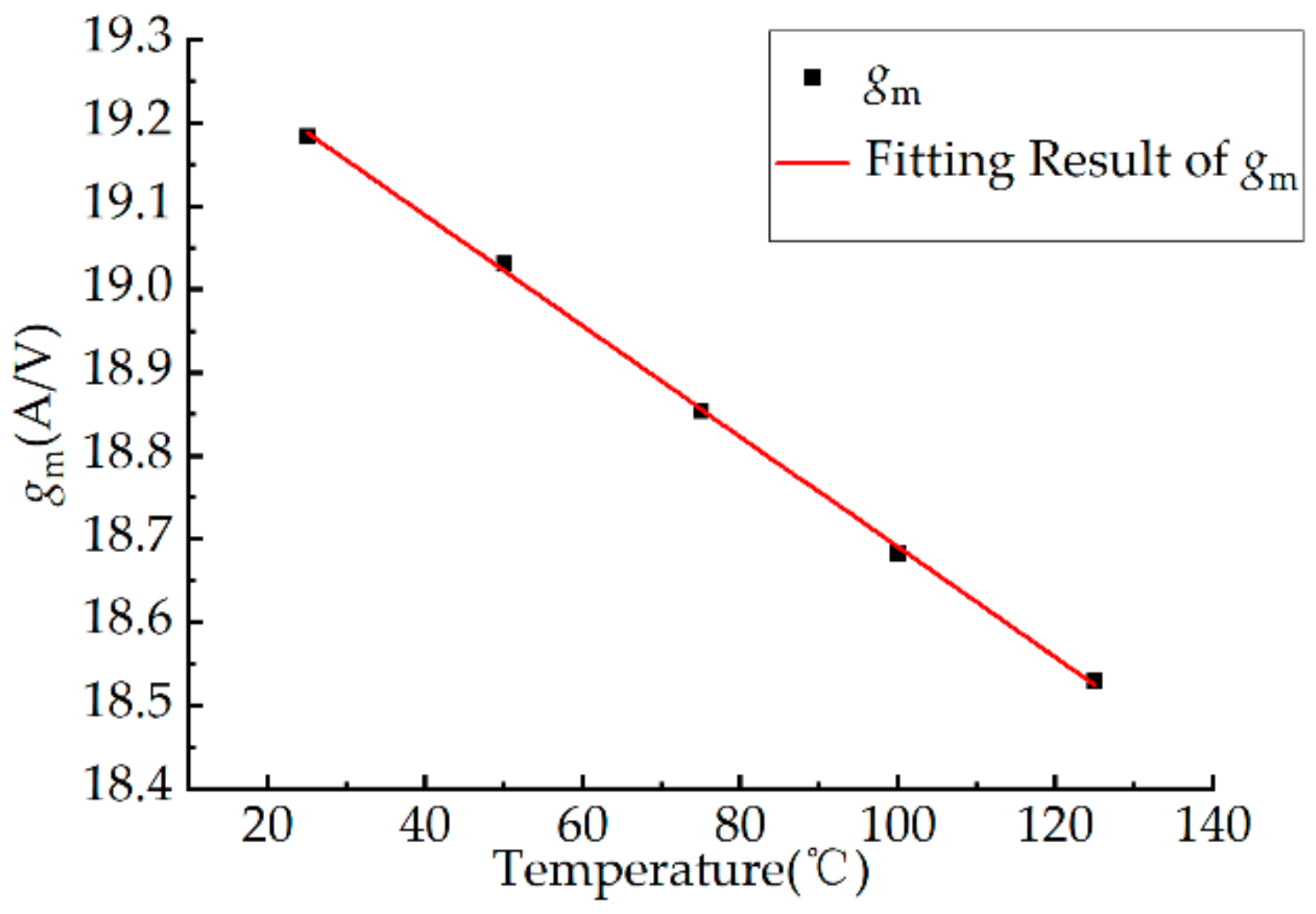

The junction temperature will affect the electrical characteristics of the IGBT. The dependence of the physical material parameters of the silicon-based semiconductor on temperature determines the temperature dependence of its operating characteristics. The lifetime of carriers increases with the decrease of temperature and mobility, and the charge storage in the drift region decreases with the increase of temperature, so the IGBT switching process is affected by temperature. In the IGBT module, both the parameter

Rw and the parameter

A are affected by the junction temperature, and the transconductance of the module under the same collector current can be expressed as Equation (11):

In actual engineering, with the aging of the IGBT module, the equivalent resistance of the module will change accordingly. At the same time, the junction temperature

Tj will also fluctuate during the normal operation of the power converter [

25,

26]. The influence of fluctuation on the transconductance of the module can be expressed by Equation (12):

where

T0 is the selected reference temperature;

Rw0 is the equivalent resistance of bonding wire in the healthy state of the IGBT module;

Ti is the temperature after change; and

Rwi is the bond wire equivalent resistance after module aging failure.

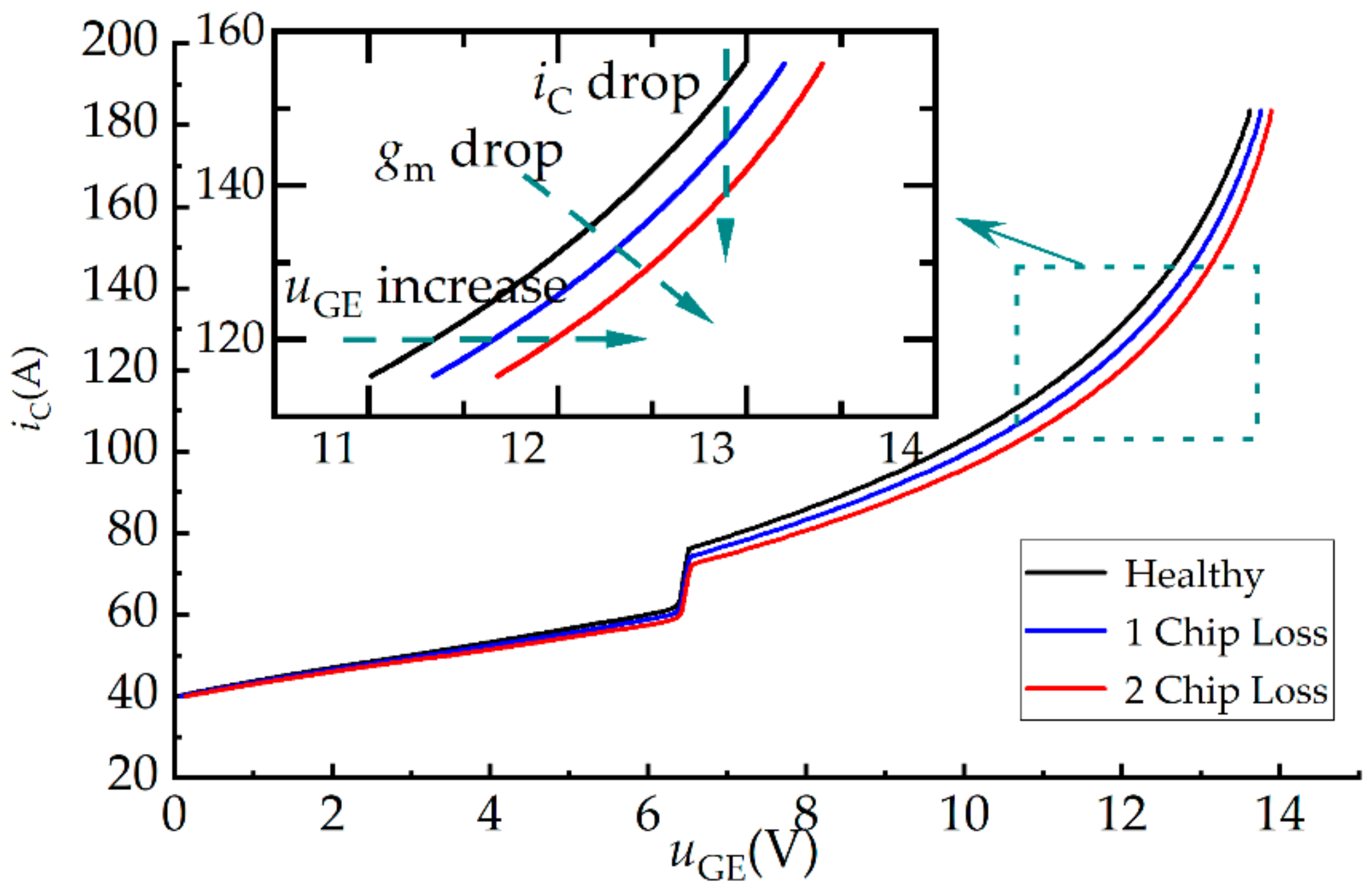

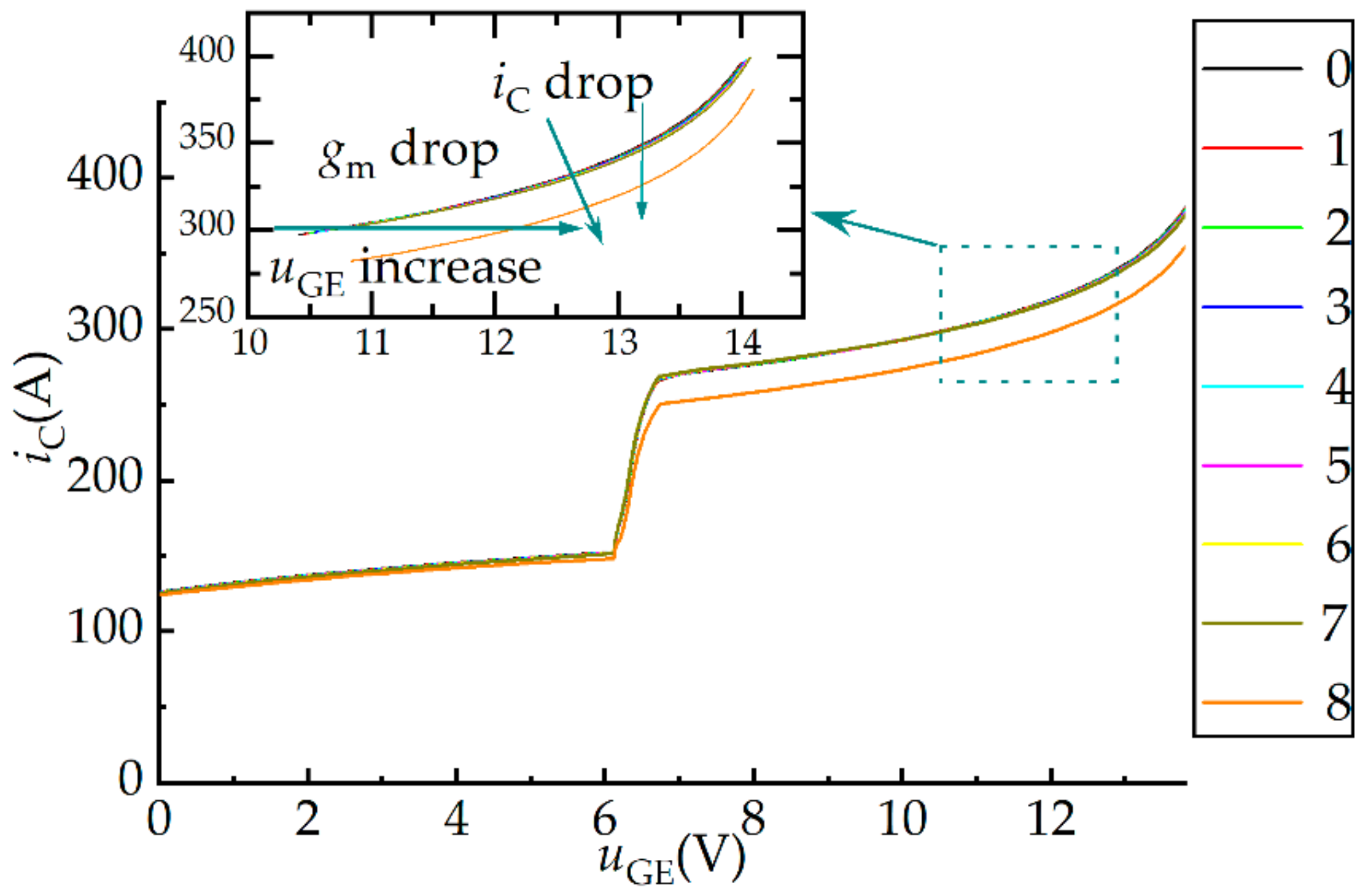

Figure 4 shows the transmission characteristic curve before and after the IGBT module bonding wire lift-off. As the bond wires fall off, the collector current gradually decreases in the active area. At the same collector current

iC measurement point, the gate-emitter voltage after the bond wire falling off increases from

uGE1 to

uGE2, and the power loss of the IGBT module will also increase, which will lead to an increase in junction temperature and failure of the bond wire. The resulting junction temperature difference is

T2 −

T1. Therefore, when the module transconductance is used to monitor the health of a multi-chip parallel IGBT module, it is necessary to eliminate the effect of junction temperature. The extraction of module transconductance requires the chip to work in the active area, and it is also necessary to consider that the IGBT module is located in the safe operating area (SOA).

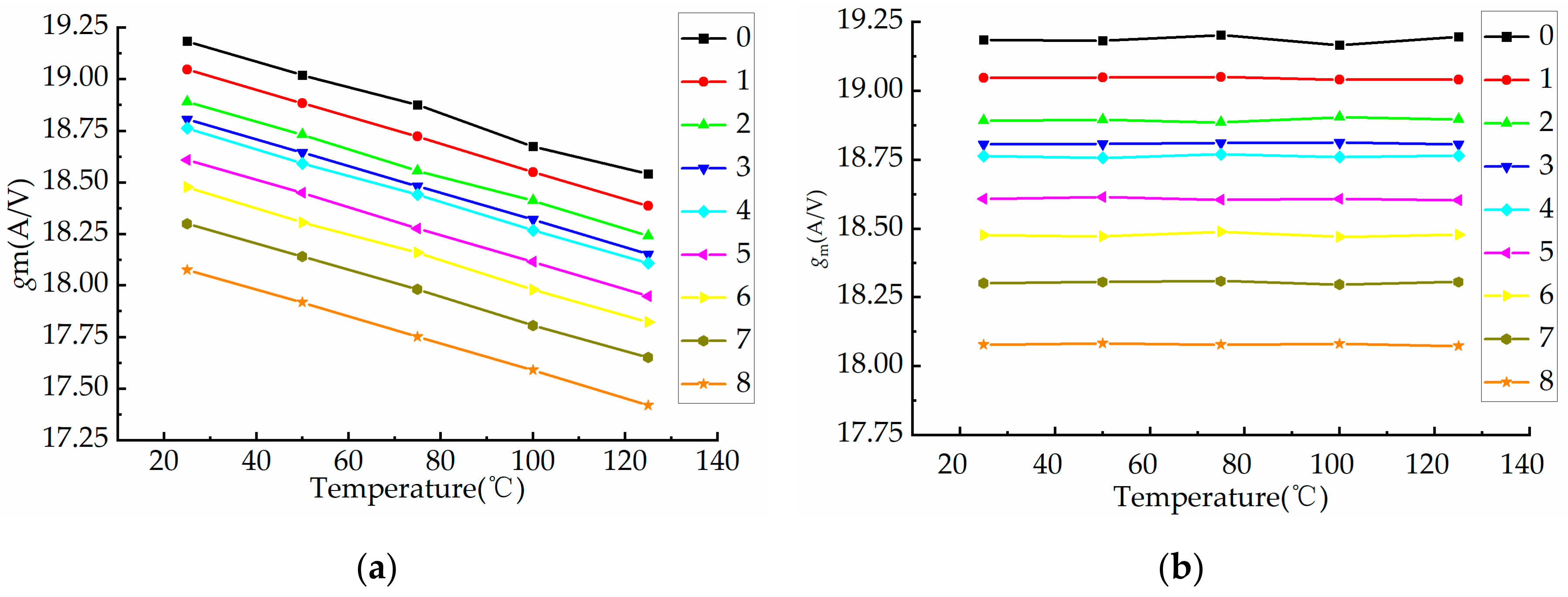

5. Result Analysis

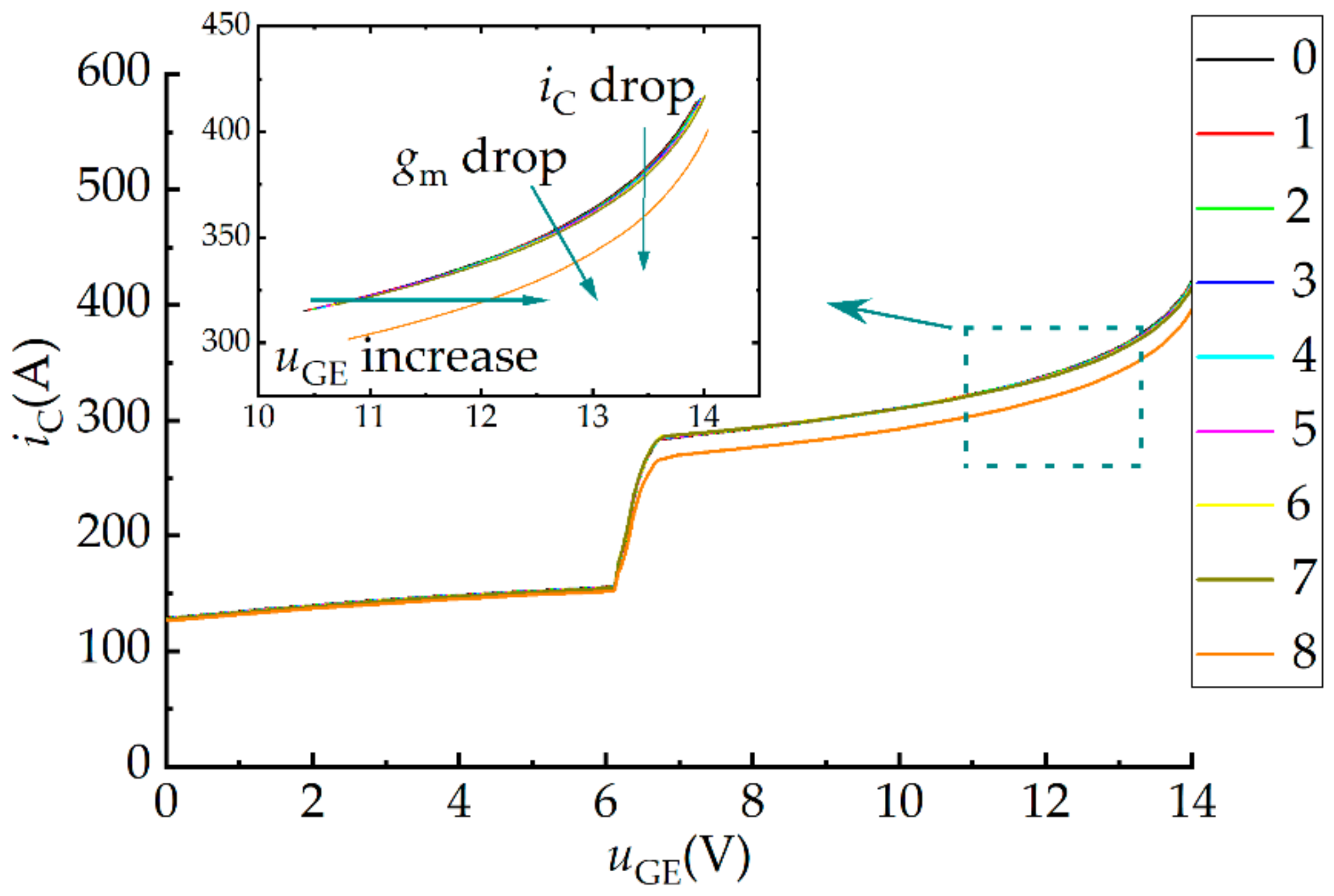

According to the above theoretical analysis and test results, it can be known that the chip failure and bond wire failure in the multi-chip IGBT module will cause the module transmission characteristic curve uGE-iC to change, and the module transconductance value calculated from the transmission characteristic curve can be used as characteristic parameters for health monitoring of the IGBT module. Since the temperature dependence of the module transconductance can conceal its fault characteristics or reduce its ability to monitor bond wire or chip faults, temperature calibration processing is required to eliminate temperature effects. The temperature-corrected module transconductance can effectively monitor chip failures and bond wire failures in IGBT modules.

For the IGBT module selected in this article, when one IGBT chip fails, the value of the module transconductance decreases by 6.243%. When two IGBT chips fail, the value of the module transconductance decreases by 12.472%. At this time, it can be basically determined that the IGBT module is in an aging failure state. It means that system failure will occur at any time, and the IGBT module should be repaired or replaced in time. If 70% of the bond wires on one IGBT chip fall off, it can be determined that the chip is close to aging failure [

28]. When six bond wires in Chip 1 lift off, the value of the module transconductance is reduced by 3.721%, which means that Chip 1 is about to fail; when six bond wires lift off in Chip 2, the value of the module transconductance decreases by 10.286%, which means that the system is at risk of failure, Chip 2 is about to age and fail, and the module should be degraded or repaired.

Table 12 compares different state monitoring methods. Under the same test object and condition, the pre-threshold voltage

VGE(pre-th) during the gate-emitter turn-on transient, collector-emitter voltage change rate

dVCE/

dt, and gate peak current

IG(peak) have high sensitivity, but the three fault characteristic parameters are affected by temperature, and

VGE(pre-th) and

dVCE/

dt cannot be used to monitor bond wire faults.

dVCE/

dt has a weak anti-interference ability. The

IG(peak) measurement circuit needs to consider electromagnetic interference. The advantages of the method proposed in this article are as follows. (1) It can monitor chip faults and bonding wire faults at the same time, and it has good sensitivity. (2) This method has low sampling signal frequency and short measurement time, and it can ignore external heat sources and other electrical signals. It has a strong anti-interference ability such as the influence of external noise. (3) The parameter module mentioned in this article has a good linear relationship between the transconductance and temperature. This method is added to the temperature calibration process, which can be more accurately achieved under different junction temperatures IGBT module fault status monitoring. The method proposed in this paper can be used for in situ monitoring of the fault status of multi-chip parallel IGBT modules. It can be used to perform in situ monitoring when the converter is shut down (such as when the fan cuts off the wind speed, when the electric vehicle is stopped, etc.). Limitations and challenges include the stability of in situ monitoring devices, the lack of a standardized analysis of fault diagnosis, and condition assessment technology. However, this method cannot locate the specific location of chip faults and bond wire faults in the IGBT module and will continue to study the real-time online location and monitoring of IGBT module faults in the future.