1. Introduction

Compared to the traditional three-phase motors, multi-phase motors have the advantages of reduced torque ripples and fault tolerant ability [

1,

2,

3,

4]. Those with multiple three-phase stator windings enjoy popularity among the multi-phase machines (such as six-phase and 15-phase), due to the fact that not only do they have the advantages of multi-phase motors, but also the modular three-phase structures can inherent the use of the well established three-phase topology [

1,

2]. An asymmetric six-phase permanent magnet synchronous motor (ASP_PMSM) has two sets of three-phase stator windings which are spatially shifted 30 electrical degrees with neutral points being isolated [

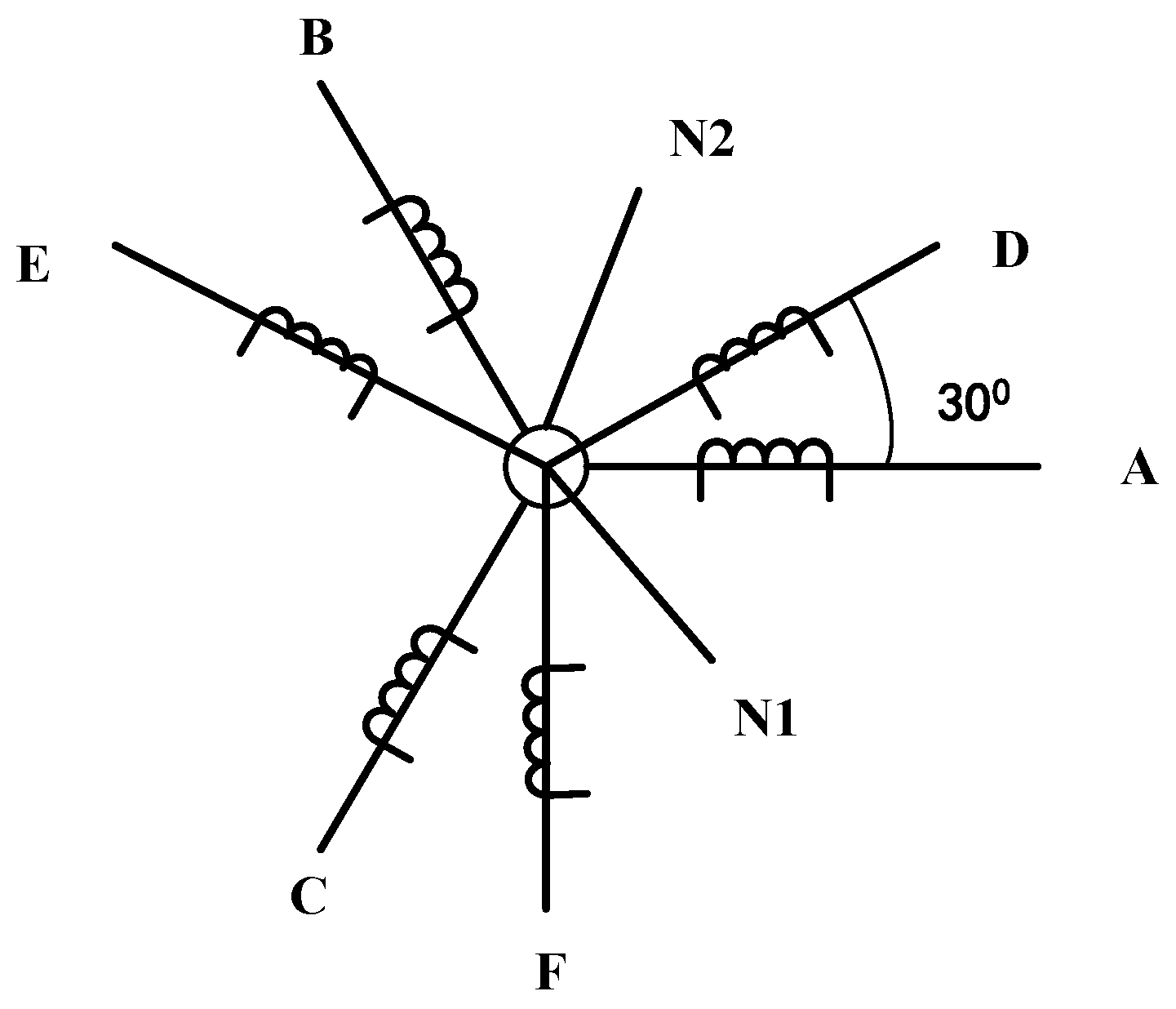

1], as shown in

Figure 1.

In recent years, various research studies related to ASP_PMSM drive system have been studied thoroughly. Two modeling and control methods have been adopted for the ASP_PMSM. They are the double

d-q approach [

5,

6,

7] and the vector space decomposition (VSD) approach [

8,

9,

10]. The former scheme has the advantages of modeling and control schemes of traditional three-phase motors and each set of three-phase winding is regarded as a basic unit. It should be remarked that coupling effects exist between two pairs of

d-

q stator voltage equations, while for the VSD method, two sets of three-phase windings are treated as a whole. All the phase variables can be mapped into three orthogonal subspaces, i.e.,

α–β subspace,

x-y subspace and

O1-O2 subspace. Only in

α–β subspace does the electromechanical energy take place, while the

x-y and

O1-O2 subspaces are only pertinent to the loss. Because the VSD scheme reveals the characteristics of multi-degree freedom for the ASP_PMSM [

8,

9,

10], the current control becomes more flexible compared to the double

d-q transformation. Therefore, most of the recent research studies pertinent to ASP_PMSM are based on the VSD method.

Two dimensional current control which only controls the torque producing

α–β currents is insufficient [

8]. Four-dimensional current control based on the VSD approach can be used not only for torque control but also for the inverter dead time effect [

8,

9,

10,

11]. In

α–β subspace, the currents are controlled in the rotor coordinates to achieve vector control [

8,

9,

10,

11,

12,

13,

14]. This coordinate system is a natural selection because not only are the controllable currents direct currents in steady state but also, the inductance matrix can be decoupled.

Rotor field oriented control (RFOC) is adopted for the motor control in

α–β subspace [

12,

13,

14,

15,

16] because the stator currents can be decomposed into an excitation current component and a torque producing current component which can be controlled separately. Although it offers a lot of advantages, the coupling effects due to the rotating coordinate system exist between the two pairs of voltage equations. In [

16,

17], a synchronous-frame proportional-integrator (PI) controller which is augmented with the cross-coupling voltage calculated based on the feedback current is adopted. However, when the motor parameters are not well known or vary during operation, the actual currents cannot track the reference currents. The design of a current regulator in a discrete time domain has been discussed by some scholars [

17,

18], e.g., the Euler or Tustin method. However, the control delay and the characteristics of the inverter are not considered and the proposed design method increases the computation burden and is very complex to design.

In

x-y subspace, by applying the duty cycle control strategy, the components which cause loss are eliminated through a suitable selection of virtual voltage vectors [

19]. However, the harmonic losses caused by the dead time of converters and the structure of motor itself are not considered. Proportional-Integral (PI) regulators implemented in one positive-sequence synchronous rotating frame (SRF) and one negative-sequence SRF at the same time can be adopted to suppress the current harmonics [

20,

21,

22]. But the multiple coordinate transformations lead to a heavy computational burden and complexity. Accordingly, a resonant controller can be an advantageous alternative [

23,

24,

25,

26] to PI regulator in SRF due to the benefits, such as less sensitivity to noise, reduced computational burden and complexity owing to the lack of multiple Park transformations, a lower number of regulators due to the ability to track both positive and negative sequences at the same time. However, phase delay due to the inductive load and the discrepancy between the actual resonant frequency and the desired resonant frequency owing to the discretization are not considered, which will affect the control performance.

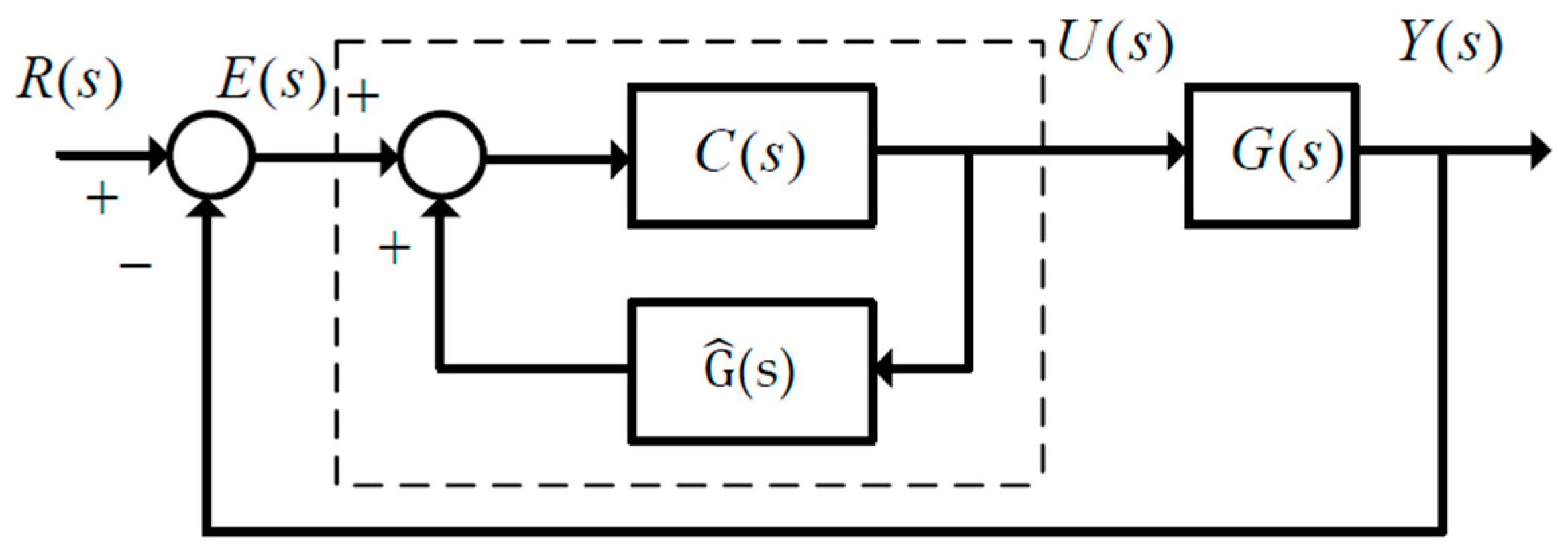

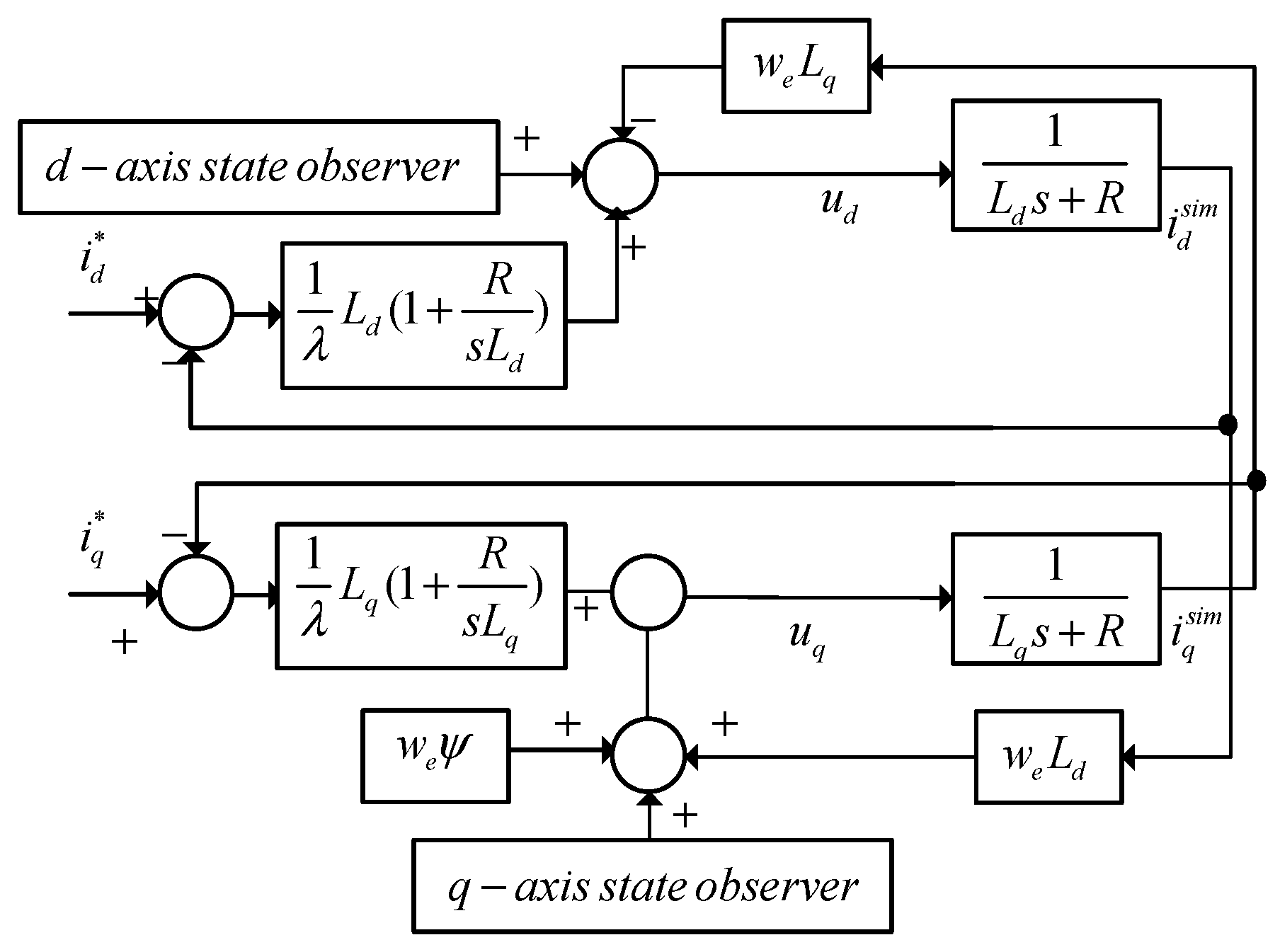

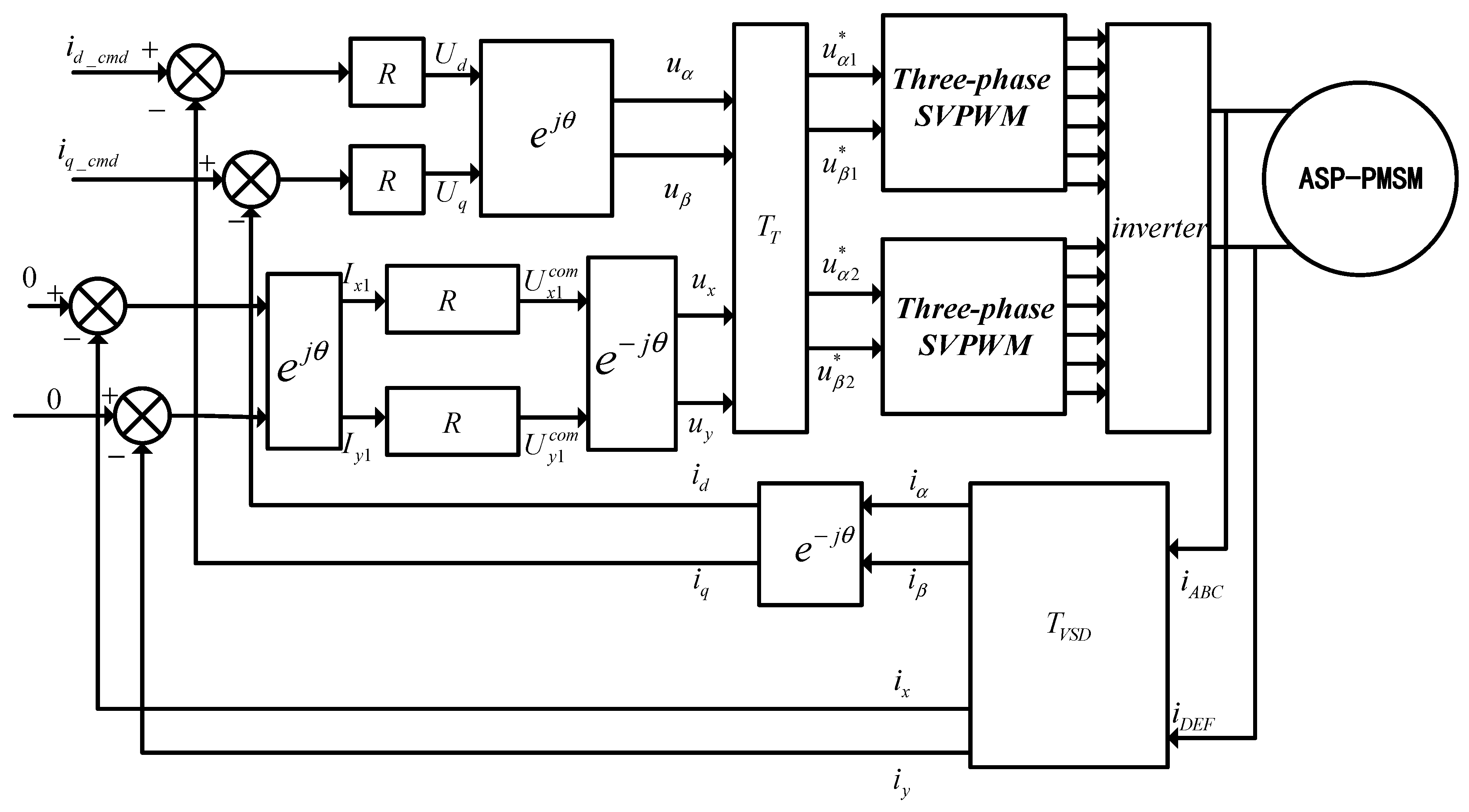

This paper proposes current control methods based on VSD transformation for ASP_PMSM. In α–β subspace, internal model control (IMC) with a state observer is adopted to reduce the current fluctuations of d and q axes currents. In x-y subspace, an adaptive-linear-neuron (ADALINE)-based control algorithm is employed to suppress the current harmonics due to the dead time and the non-linearity of the inverter, which is independent of the current polarity and avoids the multiple coordinate transformations compared to the traditional PI controller implemented in one positive-sequence SRF and one negative-sequence SRF at the same time. Moreover, the discretization errors around the resonant frequency can be avoided. The experimental results show that the internal model control (IMC) with the state observer in α–β subspace can reduce the current fluctuations of d and q axes currents compared to the traditional IMC method and the proposed ADALINE algorithm can suppress the current harmonics effectively without the drawbacks compared to the other methods.

This paper is structured as follows.

Section 2 gives the relationship between the double

dq and VSD model in order to give a detailed explanation of VSD transformation. In

Section 3, the current regulator design for

α–β subspace is analyzed. A state observer is introduced to improve the robustness against the parametric variations and un-modelled dynamics. In

Section 4, an ADALINE-based control algorithm is introduced to suppress the current harmonics.

Section 5 gives the PWM techniques for the implementation for the four dimensional current control of ASP-PMSM. The experimental verification is given in

Section 6 and the main conclusions are summarized in

Section 7.

2. Relationship Between the Double dq and VSD Model

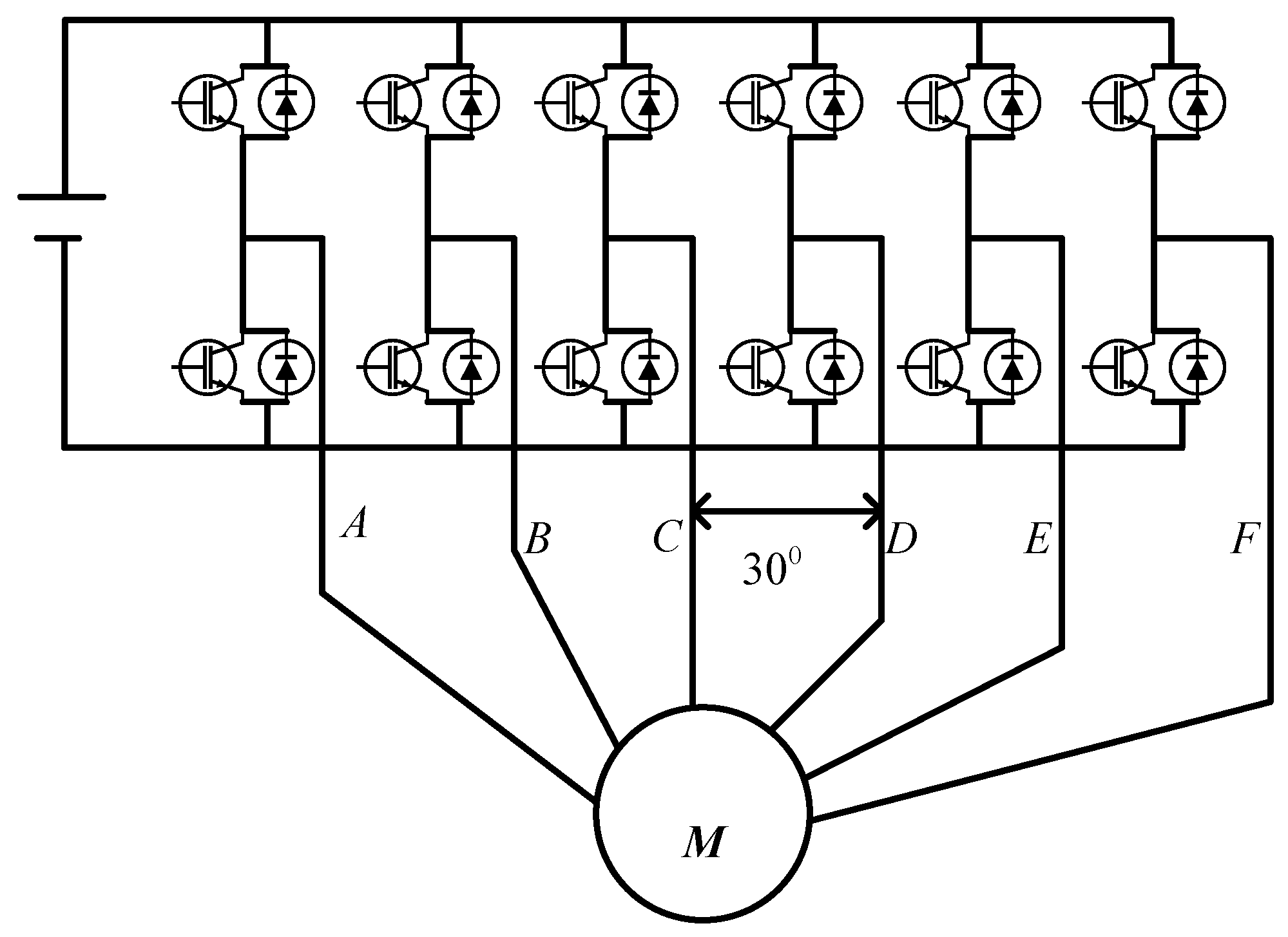

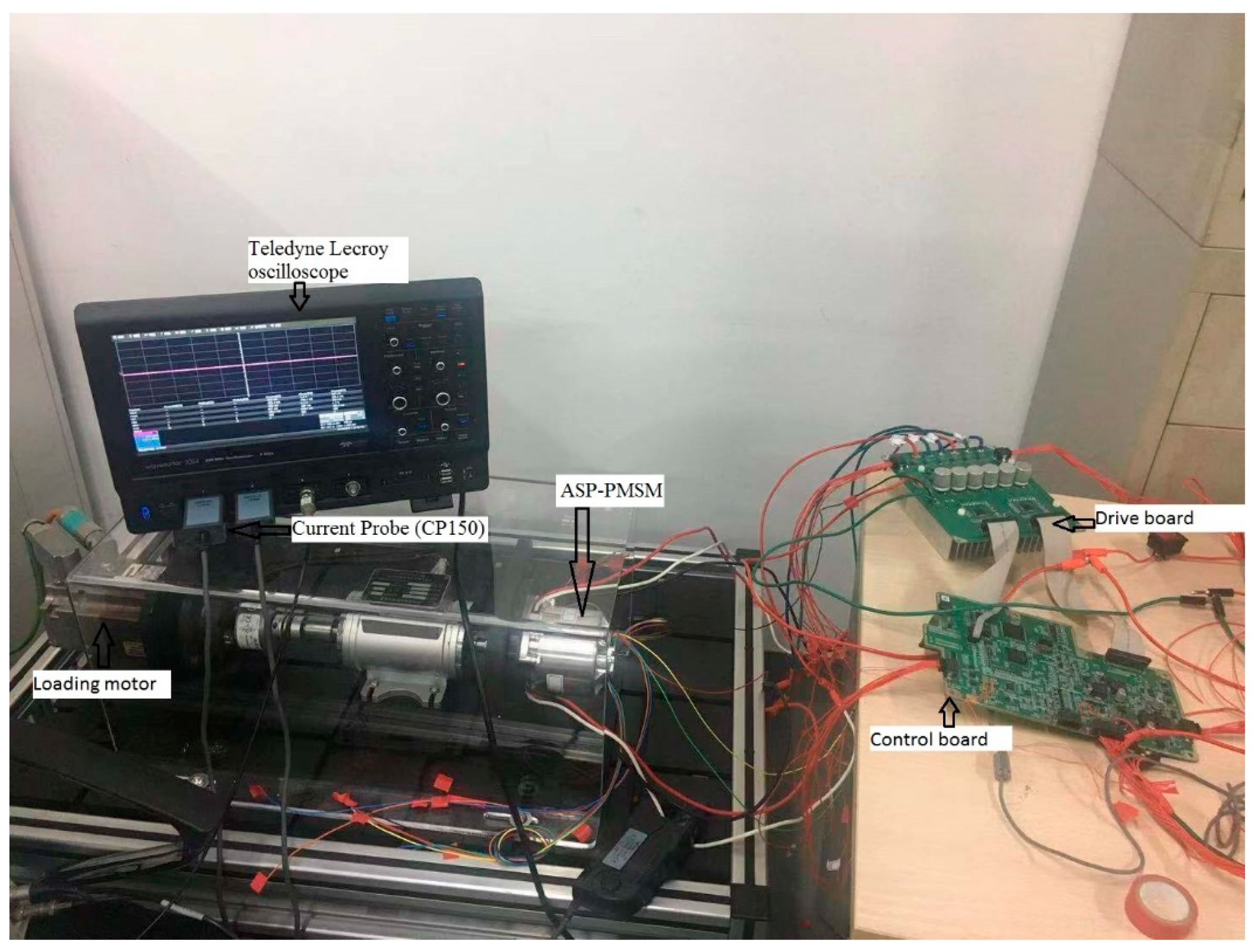

As shown in

Figure 2, the drive system of ASP_PMSM, in this paper, has two sets of three-phase VSIs sharing the same dc-link voltage which can supply two sets of three-phase windings.

In the early studies of asymmetrical dual three-phase machines, a double

dq or a double stator modelling approach has been utilized to control the motor [

5,

6,

7]. Using this method, two three-phase decoupling (Clarke) transformations are applied separately on the phase variables for each three-phase winding. This transforms the six phase variables into two sets of stationary reference frame variables, which can be denoted as

α1–β1 and

α2–β2 components for windings ABC and DEF, respectively.

Symbol

f represents arbitrary machine variables (voltage, current or flux). The spatial 30-degree displacement between the two windings is accounted for in the decoupling transformation. For an asymmetrical six-phase machine, the amplitude invariant transformations for windings 1 and 2 are given with Equations (3) and (4), respectively,

while VSD provides an alternative approach for describing the operation of a six-phase machine. Using the VSD model, a six-phase machine can be represented via three orthogonal subspaces [

8,

9,

10], i.e., the

α–β,

x–y, and zero-sequence subspaces. This approach gives an alternative description of the machine, which is useful for machine control and the development of pulse width modulation (PWM) techniques. After the VSD transformation, harmonics of different orders are mapped into different subspaces. The fundamental component and harmonics with the order 12n ± 1(n = 1, 2, 3 …) are mapped into the

α–β subspace. The harmonics with the order 6n ± 1(n = 1, 3, 5 …) are mapped into the

x–y subspace. The harmonics with the order 6n ± 3(n = 1, 3, 5 …) are mapped into the

O1–O2 subspace, i.e., the zero sequence subspace. With the neutral points being isolated, no current components in the

O1–O2 subspace would exist. Therefore, the ASP_PMSM with the isolated neutrals is a four-order system. The mathematical model and the VSD modelling process of the dual three-phase motor are described in more detail in [

8,

9,

10]. The static decoupling transformation matrix is

Despite the various advantages of the VSD model, the variables are more difficult to interpret physically, unlike in the double

dq model where

α1–β1 variables are clearly related to the winding 1 and

α2–β2 variables to the winding 2 of the machine. It is therefore desirable to provide a better physical interpretation of the VSD model variables by relating them with variables in the double

dq model. This can be done by simply comparing the decoupling transformation matrices for the two methods. By comparing Equations (3)–(5), it can be seen that the

α component in the VSD model is proportional to the sum of the

α1 and

α2 components. The

β component in the VSD model is proportional to the sum of the

β1 and

β2 components of the double

dq model. On the other hand, the

x component is proportional to the difference between the

α1 and

α2 components, while the

y component is proportional to the difference between the

β1 and

β2 components with the signs for the

x and

y components being inverted. As will be shown later, this opposite sign influences the rotational direction of the

x–y current phasor caused by the converter asymmetry. The relationship is given with

The fifth and seventh current harmonics in windings 1 and 2 can be represented as

where

k1 and

k2 are the weights of the fifth and seventh current harmonics in winding 1, while

k3 and

k4 are the weights of the fifth and seventh current harmonics in winding 2.

we is the electrical angular speed.

According to Equations (6) and (7), the expression of

x-

y currents can de deduced as

It is worth noting that the rotational direction of the current harmonics has changed due to the opposite polarity in the x-y currents. Therefore, the positive sequence component in α–β subspace will become the negative sequence component in x-y subspace, and vice versa.

Since only the components in the

α–

β subspace are related to electromechanical energy conversion, it is only necessary to transform

α–

β components into the general synchronous reference frame

d–

q components. The

x–

y subspace can remain in the stator-fixed coordinate system. The rotating transformation matrix is

where

θ is the electrical rotor position,

I2 is a two-dimensional unit matrix, and the transformation matrix

T between the original phase-variable (ABC, DEF) and the variables after rotating coordinates (

d–

q,

x–

y) is defined as

The voltage, flux, and torque equations are shown in Equations (11)–(13) respectively.

where

Ld,

Lq are

d-q axes inductances, and

Lz is stator self-leakage inductance.

P is the number of pole pairs.

ψf is the permanent magnet flux linkage.

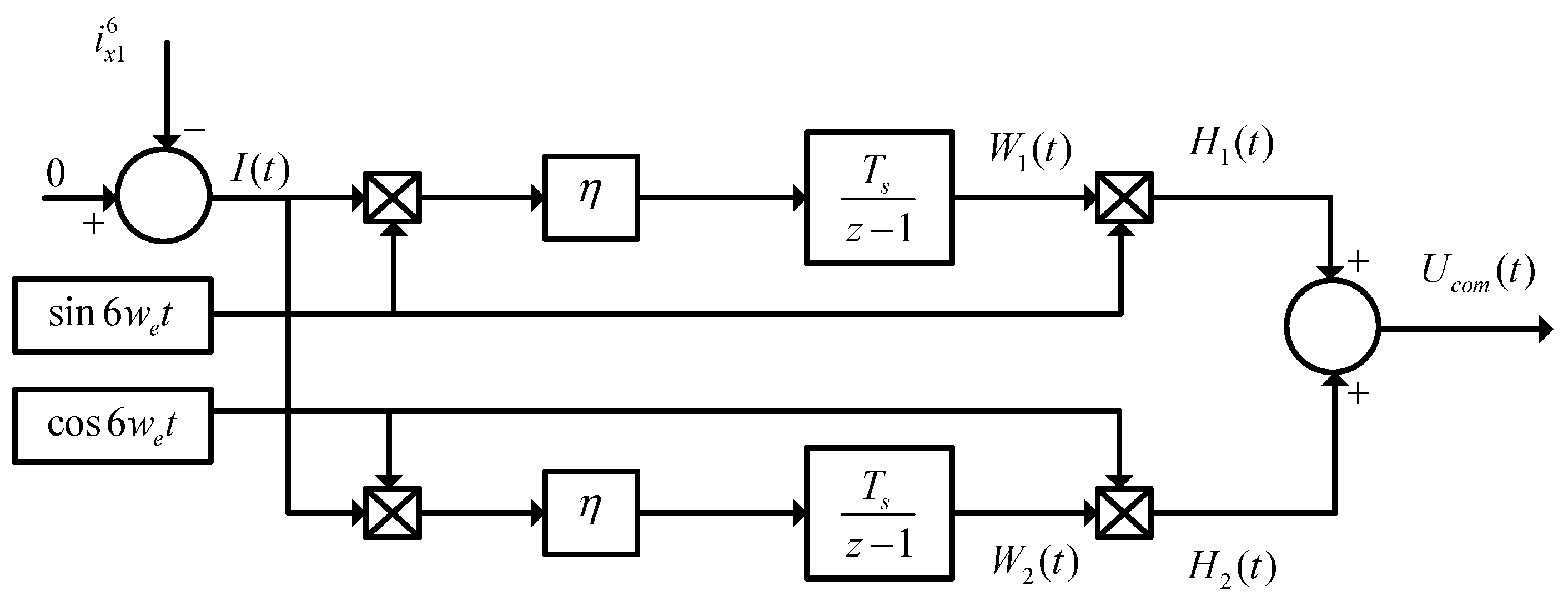

4. Current Control Method in x-y Subspace

A feedback current control loop is adopted in x-y subspace to suppress the sixth order current harmonics. An ADALINE-based voltage compensator based on the least mean square (LMS) algorithm is used to generate the compensating voltage.

As discussed in

Section 2, the signs of the fifth and seventh current harmonics are inverted, which will appear as +fifth and −seventh in the

x-y subspace. The +fifth and -seventh harmonic currents will become +sixth and −sixth, respectively, after the inverse Park transformation. Thus, an ADALINE-based voltage compensator should be implemented in the synchronous frame rotating at −

we (clockwise rotation) which can be defined as the

x1-

y1 coordinate axis in order to eliminate the sixth current harmonics. Thus, the sixth current harmonics in the

x1-

y1 coordinate axis can be defined as follows:

In order to reduce the current harmonics in

x-

y subspace, the desired current harmonics in

x-

y subspace should be 0. Let the compensation voltage vector on the

x1-

y1 coordinate axis be defined as

The ADALINE network is an efficient scheme in detecting harmonics, which can also track the harmonic components with satisfactory performance due to the characteristics of the supervised learning mechanism. The block diagram is shown in

Figure 5. It should be remarked that the ADALINE-based algorithm is a single-layer linear neural element which is trained online according to the input signals, the target response and the weight updating rule.

ucom can be calculated as

where

X denotes the reference input vector, which is calculated by taking the cosine and sine terms of the six times of the electric rotor position

θ.

W is the adjustable weight vector.

For illustration purposes, the

x1-axis is analyzed in detail. The

ux1com in Equation (37) can be rewritten in vector form described as

The least mean square (LMS) algorithm is very popular for the ADALINE, which has the advantages of a simple structure and easy implementation. For illustration purposes, the

x1-axis is analyzed in detail. The block diagram of the ADALINE algorithm based on the LMS algorithm is shown in

Figure 6.

In terms of classical control,

W1(

Z) in the Z-domain can be expressed as

where

η is the learning rate and

Z () is the

Z-transform.

H1(

t) can be expressed as

Transforming

H1(

t) into

Z-domain,

H1(

Z) can be obtained as

Similarly,

H2(

Z) can be obtained as follows

Ucom(

Z) can be calculated as

The closed loop transfer function of ADALINE based on the LMS algorithm is

From the aforementioned analysis, the ADALINE based on the LMS algorithm is equivalent to the resonant controller with resonant frequency adaption. It can achieve infinite gain at a specific frequency. Moreover, it can avoid the multiple coordinate transformations of the PI controller implemented in one positive-sequence SRF and one negative-sequence SRF at the same time. Compared to the resonant controller, the discretization errors around the resonant frequency can be avoided.

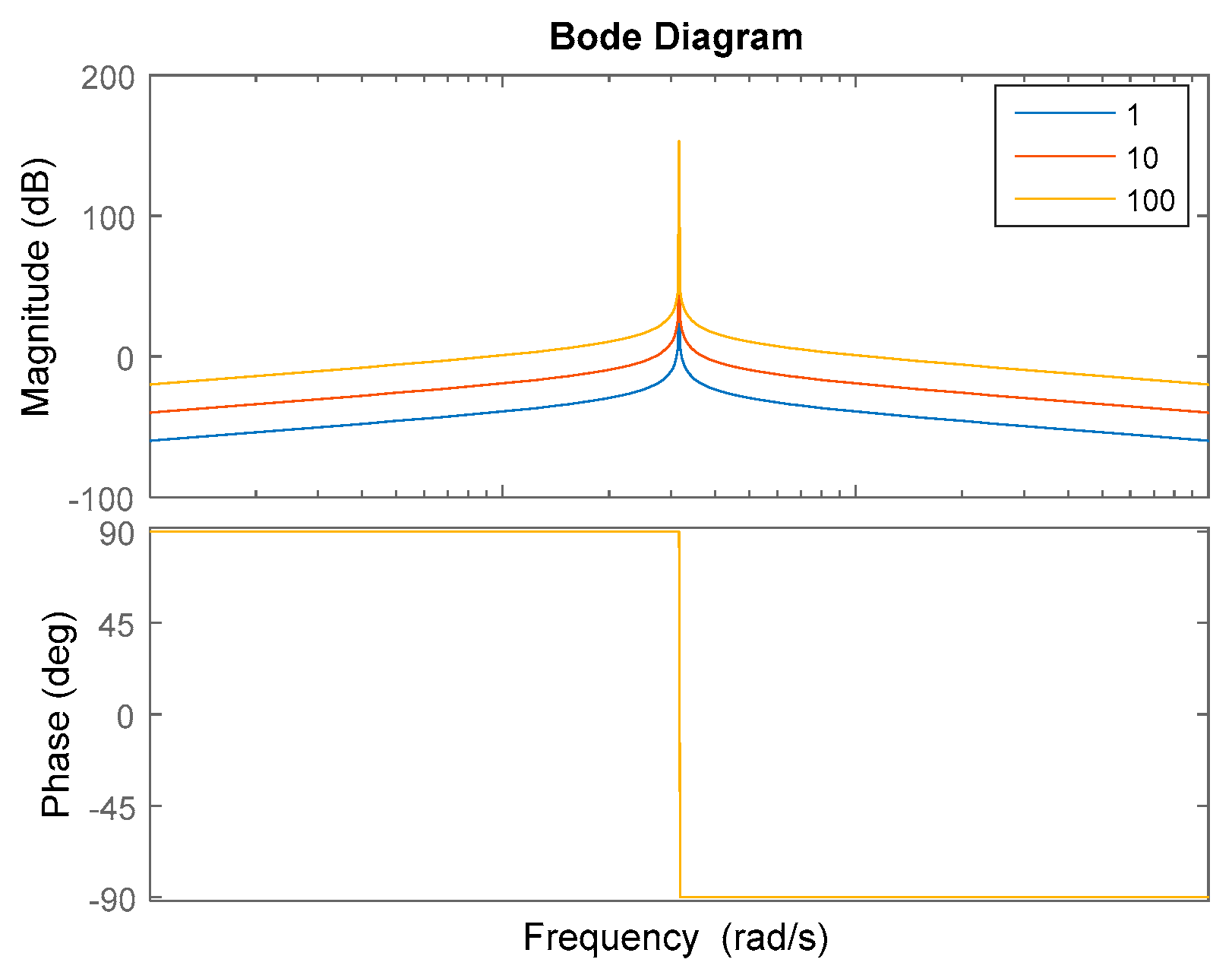

Figure 7 depicts the bode diagram with different

η values (1, 10,100) of ADALINE based on the LMS algorithm. The convergence speed of the controller increases as

η increases, but this will influence frequency selection characteristics and amplify the noises. In addition, it can be seen from the Bode diagram that the phase lag around the frequency to be suppressed is 90 degrees, which is far from 180 degrees and ensures the stability of the ADALINE-based control algorithm.

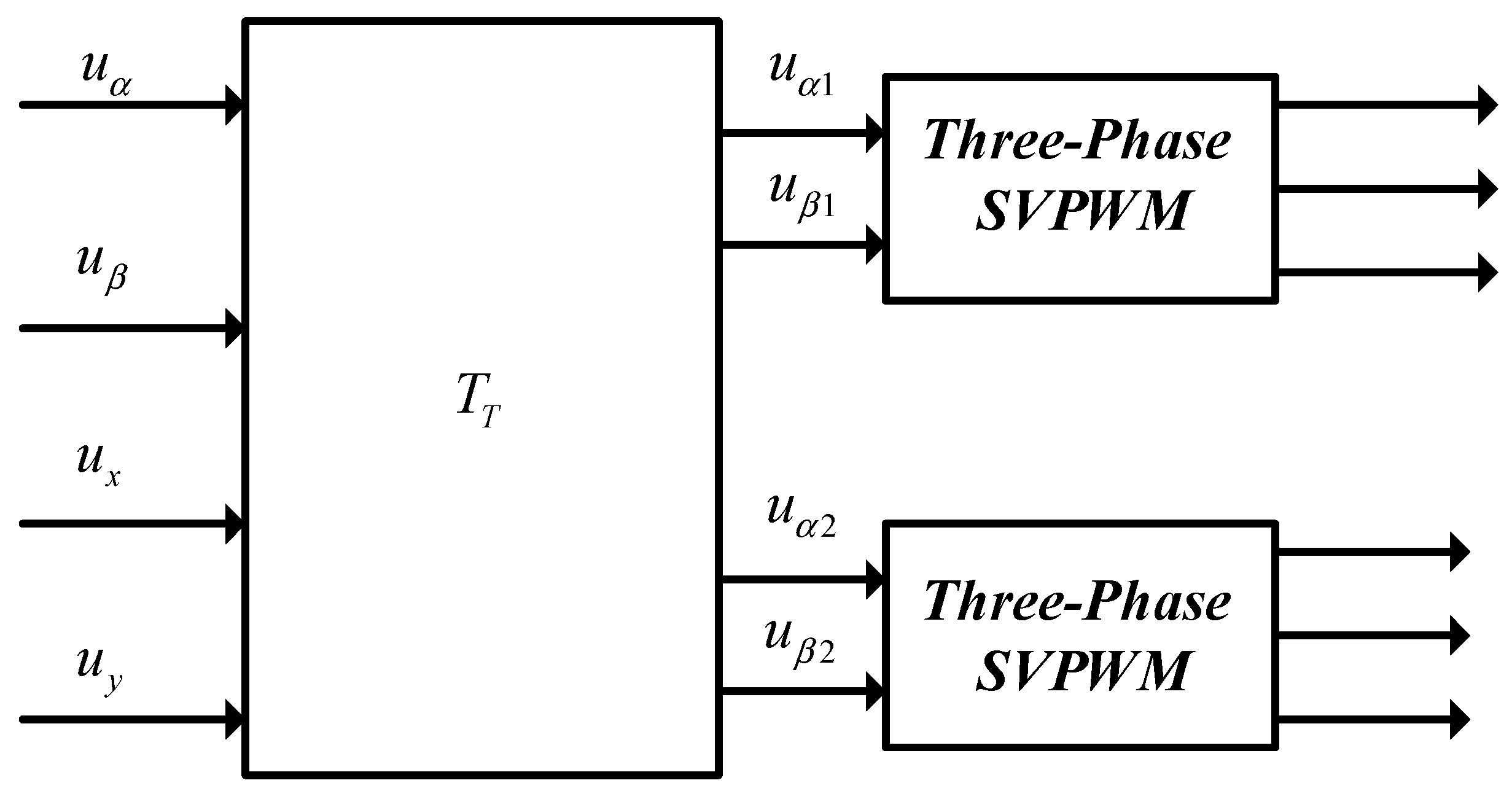

5. PWM Techniques for Four Dimensional Current Control of ASP_PMSM

The reference voltages in the

α–β and

x-y subspaces need to be synthesized simultaneously in order to realize the four-dimensional current control. The three-phase decoupling PWM strategy can decompose the voltage vector of six-phase voltage source inverter into two vectors of two three-phase voltage source inverters with a 30 degrees phase shift. Therefore, the three-phase SVPWM algorithm can be adopted to implement four-dimensional current control [

26].

The six-phase inverter can be viewed as two independent three-phase inverters with a 30-degree phase shift. In terms of Equations (1) and (2) the reference voltage vectors of the two independent three-phase inverters can be defined as

where

and

denote the voltage vector of ABC and DEF windings, respectively.

and

are the

α–β voltage components in the ABC windings, while

and

are the

α–

β voltage components in the DEF windings.

The reference voltage vectors in

α–

β and

x-

y subspaces can be represented as

where

and

denote the voltage vectors in the

α–

β and

x-

y subspaces, respectively. It should be remarked that the signs for the

x-

y components are inverted.

In terms of Equations (46) and (47), the relationship between the voltage vectors of the six-phase inverter and the three-phase inverter is shown as follows

where

is the conjugate function of

.

Equation (48) can be rewritten in the matrix form shown below

where

TT is

From Equations (49) and (50), it is obvious that the traditional three-phase SVPWM can be adopted. The implementation of PWM for ASP_PMSM is shown in

Figure 8.

From the above analysis, the proposed current control scheme is divided into two parts, including four independent current components and PWM implementation, as depicted in

Figure 9.