A Voltage-Based Hierarchical Diagnosis Approach for Open-Circuit Fault of Two-Level Traction Converters

Abstract

:1. Introduction

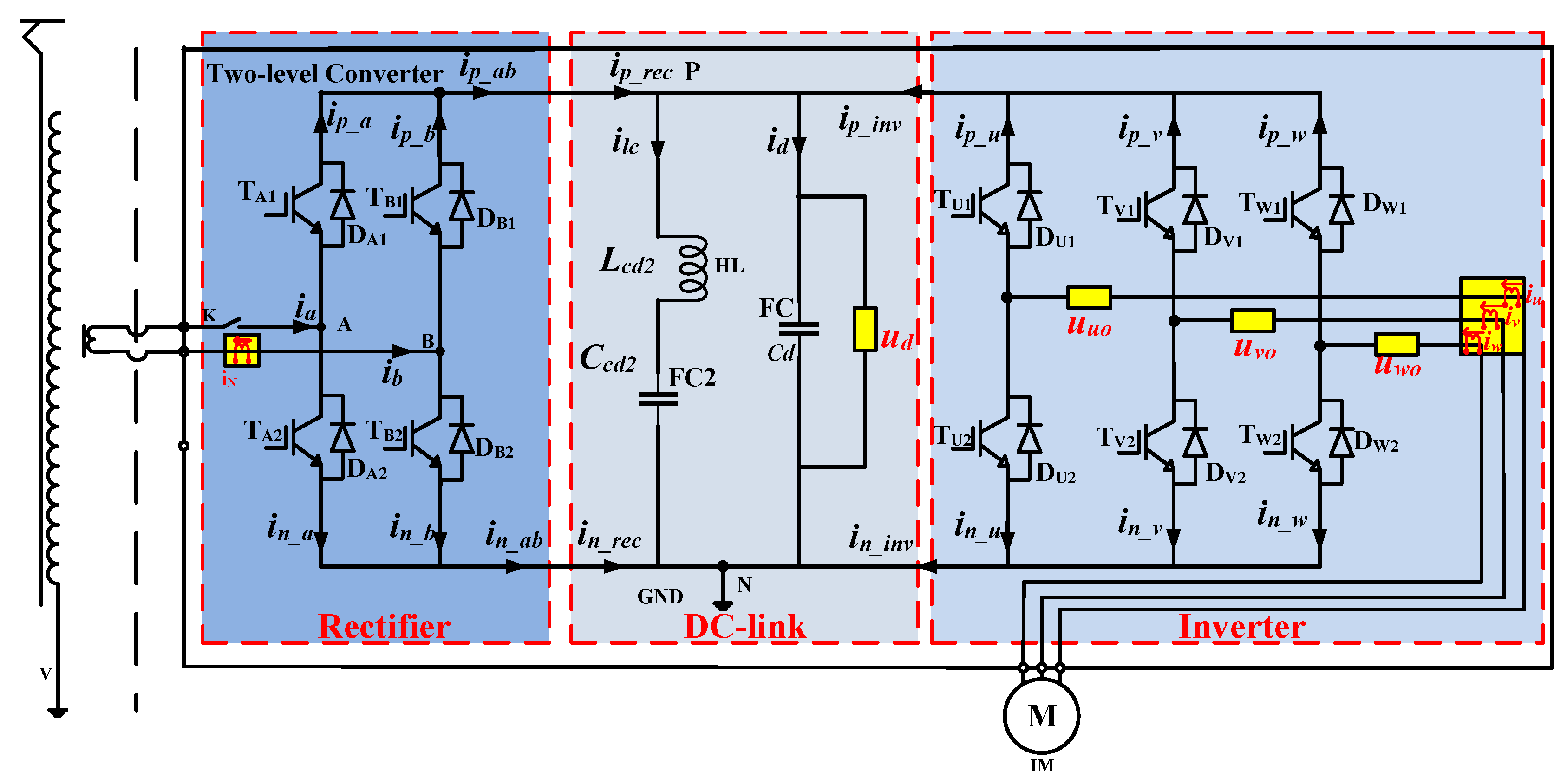

2. Estimation of DC-Link Voltage and Residual Generation

3. Faulty Features Analysis

3.1. Residual Change in Fault Cases

3.2. Switching Matching Feature

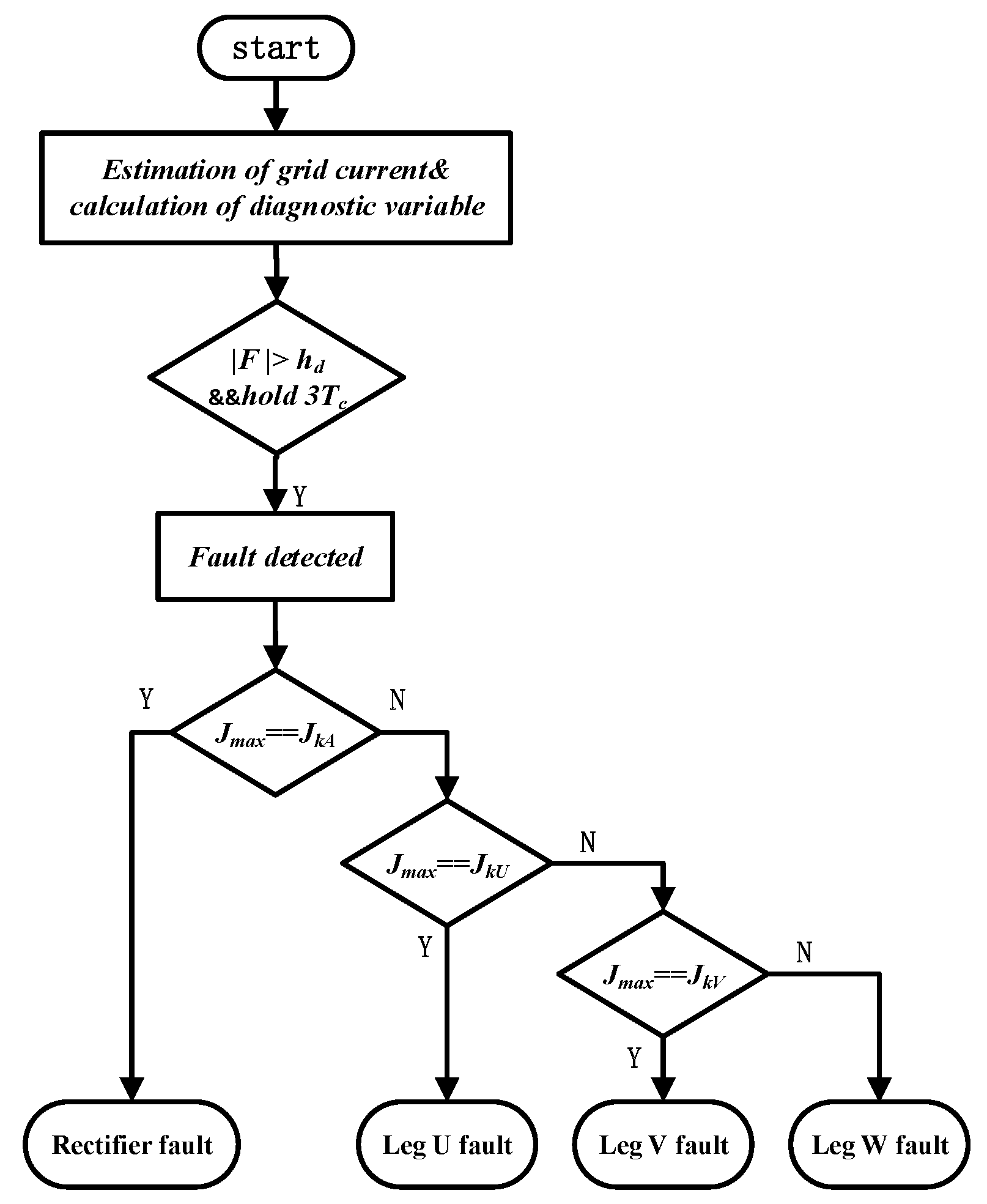

4. Diagnosis Algorithm

4.1. Fault Detection

4.2. Vectors Similarity-Based Leg-Level Diagnosis

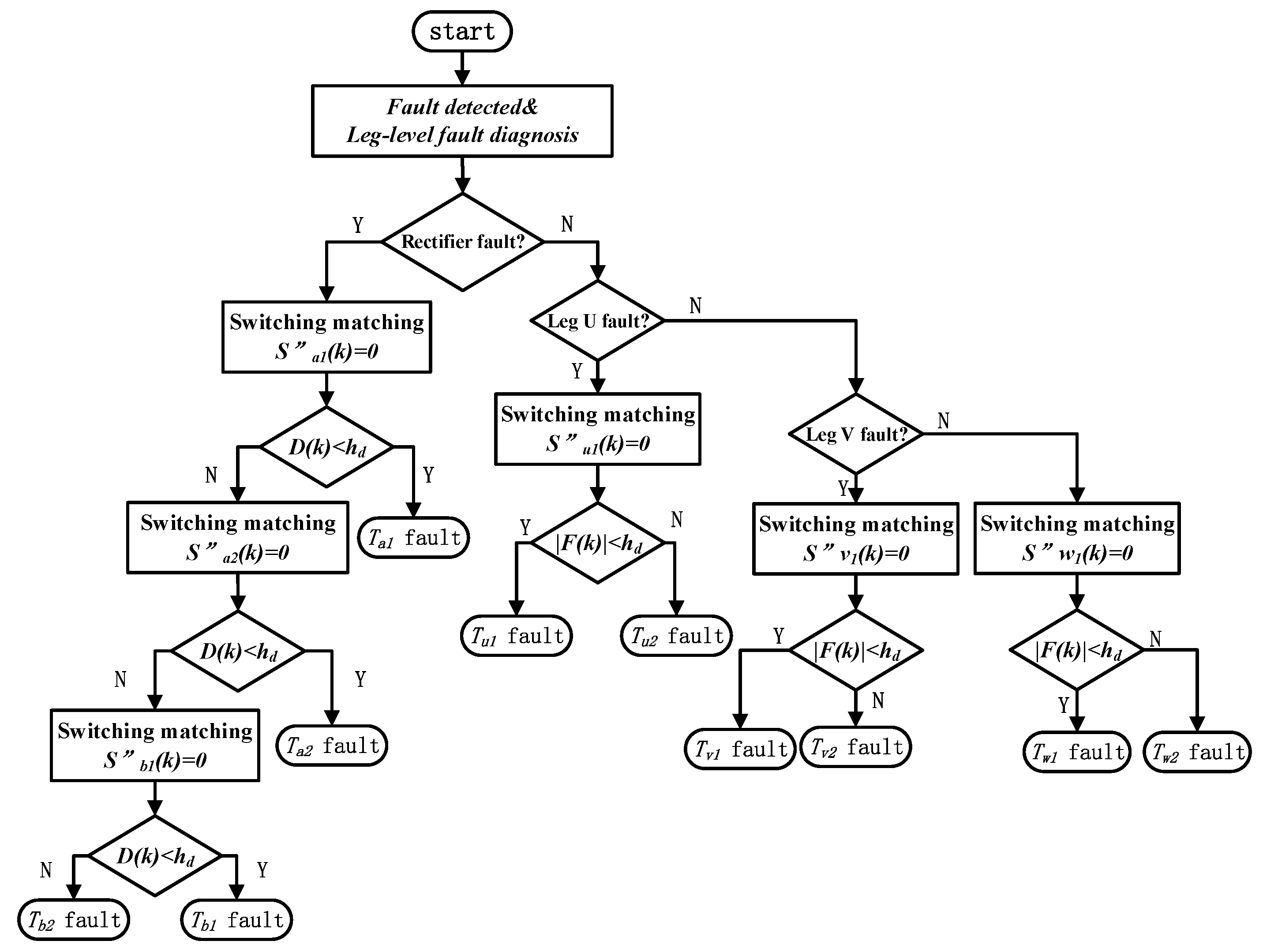

4.3. Switching Matching-Based Device-Level Diagnosis

- (a)

- Inverter side: If the fault occurred in U phase of inverter, firstly, the data of sliding window are set to 0 by the switching matching mechanism. Then, after model formula calculate, the values of diagnostic factor sliding window also changed, according to the first, second row and the seventh, eighth row in Table 3, if the fault location is , the data in sliding window will be less than detection threshold , if not, the fault location for . Similarly, the other two phases of the inverter can be judged. The diagnostic process is shown in Figure 5.

- (b)

- Rectifier side: Different from the inverter, the current direction of the network side through the two-phase legs of the rectifier is opposite, and the amplitude is the same. Therefore, according to the analysis of the results in Table 3, it can be seen that there are some special conditions that may lead to misdiagnosis. According to this situation, RDCF was established above to locate the rectifier fault. The steps are similar to the inverter but at most two switching matches are required to successfully locate the fault. The specific steps are shown in Figure 5.

5. Experimental Results

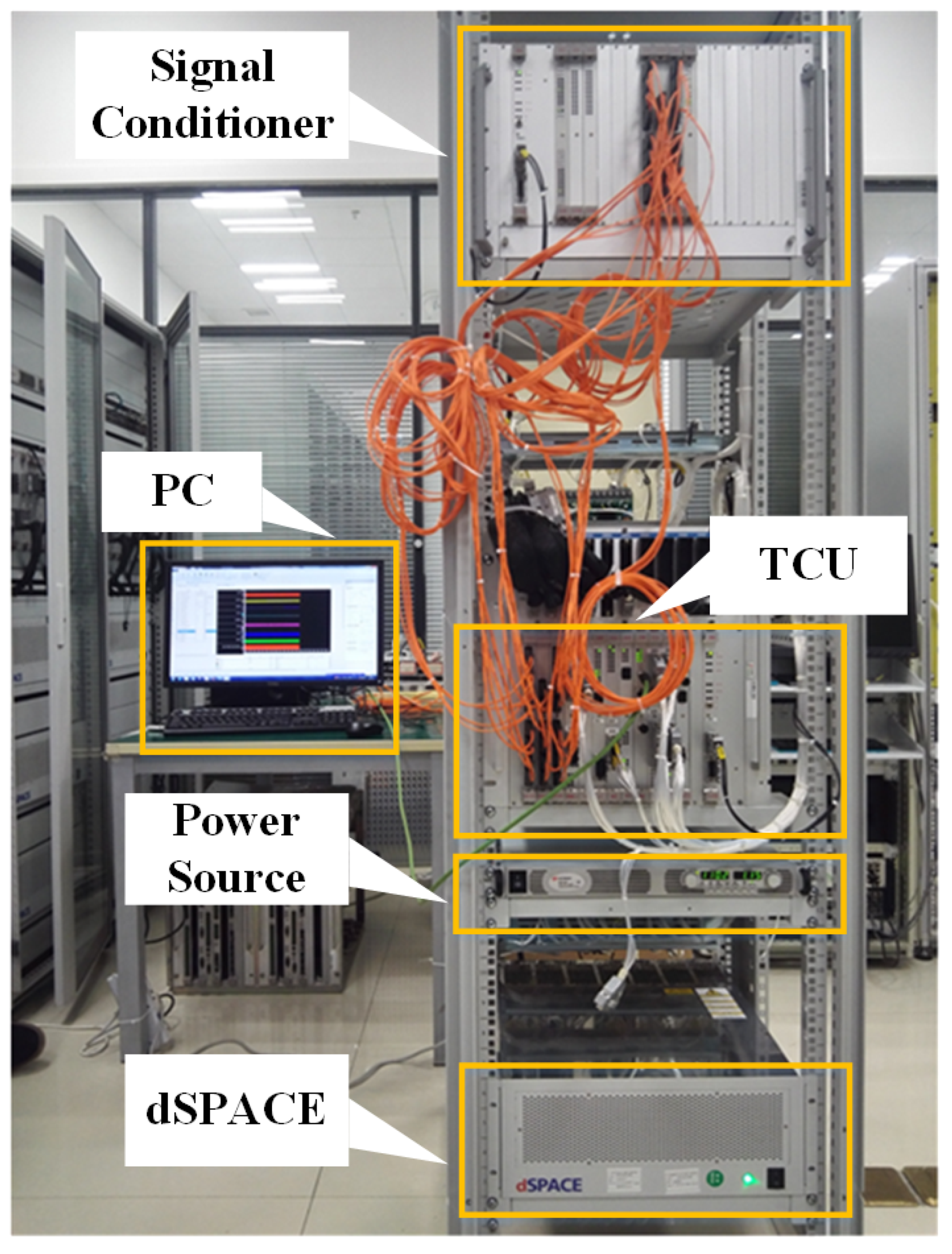

5.1. Experiment Setup

5.2. Fault Detection

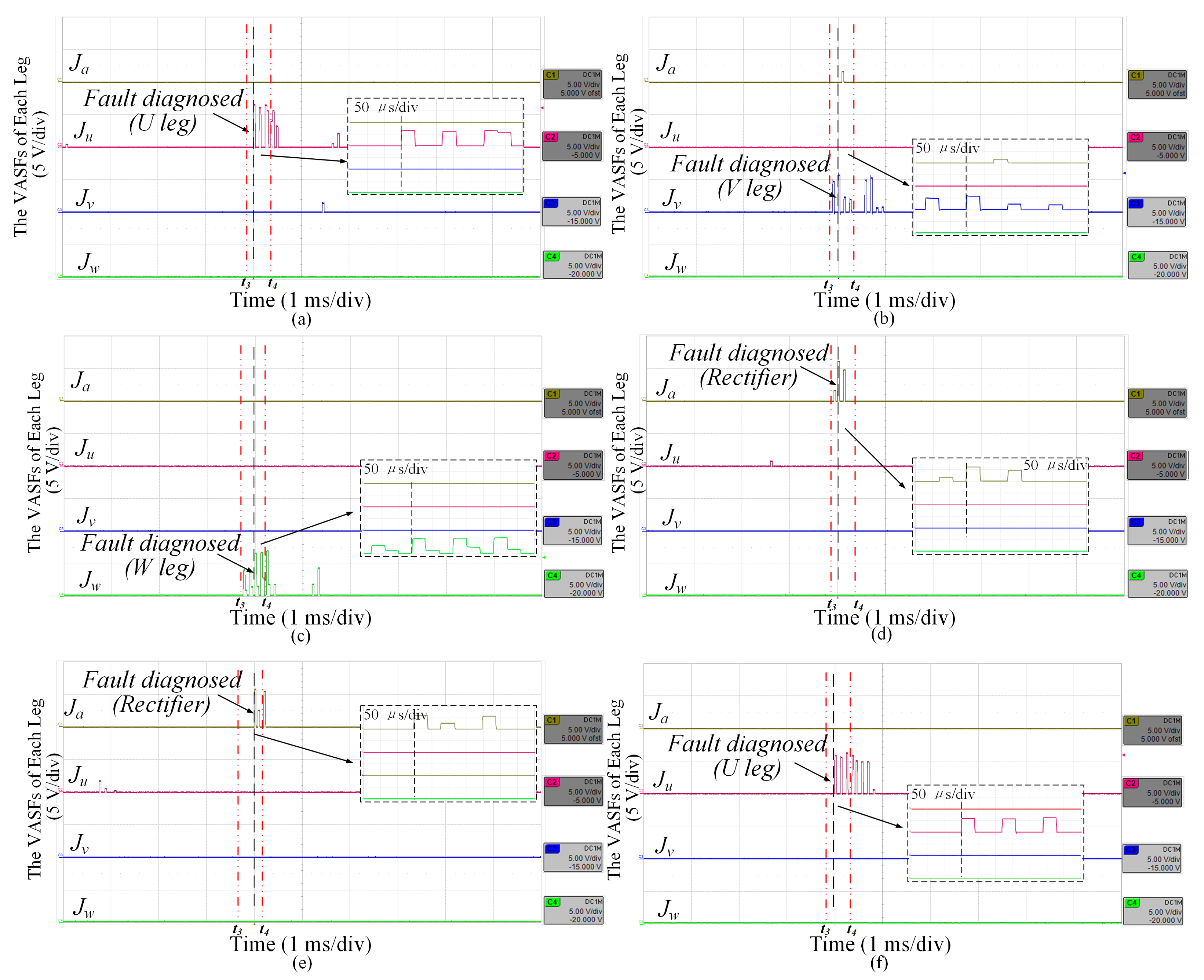

5.3. Leg-Level Diagnosis

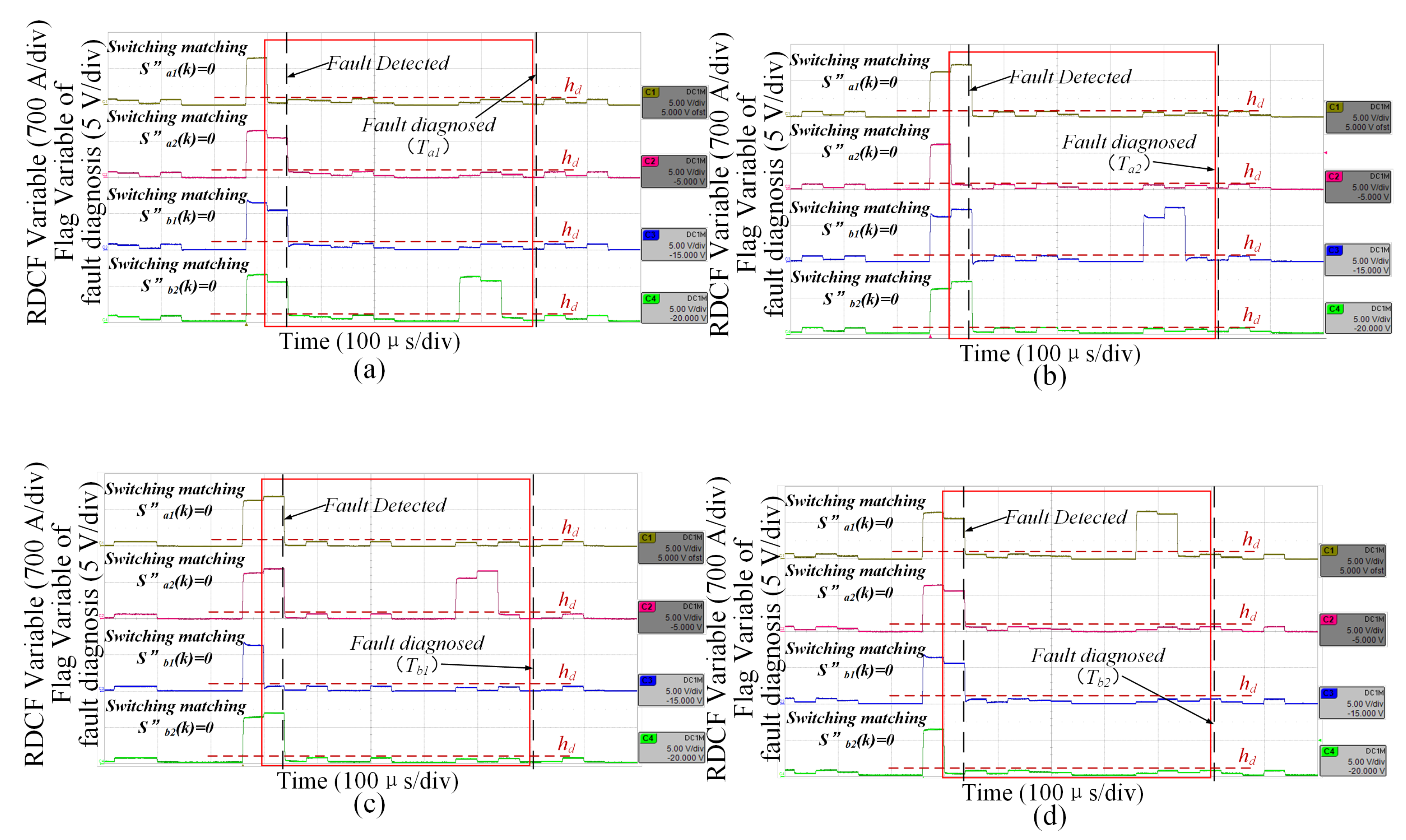

5.4. Device-Level Diagnosis

5.5. Comparison with Other Relevant Methods

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Blaabjerg, F.; Ma, K. Future on power electronics for wind turbine systems. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 139–152. [Google Scholar] [CrossRef]

- Geng, Z.; Liu, Z.; Hu, X.; Liu, J. Low-frequency oscillation suppression of the vehicle grid system in high-speed railways based on H control. Energies 2018, 11, 1594. [Google Scholar] [CrossRef]

- Chen, Z.; Li, X.; Yang, C.; Peng, T.; Yang, C.; Karimi, H.; Gui, H. A data-driven ground fault detection and isolation method for main circuit in railway electrical traction system. ISA Trans. 2019, 87, 264–271. [Google Scholar] [CrossRef]

- Wang, H.; Liserre, M.; Blaabjerg, F. Toward reliable power electronics: Challenges, design tools, and opportunities. IEEE Ind. Electron. Mag. 2013, 7, 17–26. [Google Scholar] [CrossRef]

- Li, P.; Zhang, C.; Padmanaban, S.; Zbigniew, L. Multiple modulation strategy of flying capacitor DC/DC converter. Electronics 2019, 8, 774. [Google Scholar] [CrossRef]

- Chen, Z.; Ding, X.; Peng, T.; Yang, C.; Gui, W. Fault detection for non-gaussian processes using generalized canonical correlation analysis and randomized algorithms. IEEE Trans. Ind. Electron. 2018, 65, 1559–1567. [Google Scholar] [CrossRef]

- Tao, H.; Peng, T.; Yang, C.; Chen, Z.; Yang, C.; Gui, W. Open-circuit fault analysis and modeling for power converter based on single arm model. Electronics 2019, 8, 633. [Google Scholar] [CrossRef]

- Gou, B.; Ge, X.; Wang, S.; Feng, X.; Kuo, J.; Habetler, T. An open-switch fault diagnosis method for single-phase PWM rectifier using a model-based approach in high-speed railway electrical traction drive system. IEEE Trans. Power Electron. 2016, 31, 3816–3826. [Google Scholar] [CrossRef]

- Ge, X.; Pu, J.; Gou, B.; Liu, Y. An open-circuit fault diagnosis approach for single-phase three-level neutral-point-clamped converters. IEEE Trans. Power Electron. 2017, 33, 2559–2570. [Google Scholar] [CrossRef]

- Xie, D.; Ge, P. Current residual-based method for open circuit fault diagnosis in single-phase PWM converter. IET Power Electron. 2018, 11, 2279–2285. [Google Scholar] [CrossRef]

- Lee, J.; Lee, K.; Blaabjerg, F. Open-switch fault detection method of a back-to-back converter using NPC topology for wind turbine systems. IEEE Trans. Ind. Appl. 2015, 51, 325–335. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, C.; Li, Z.; Li, Z.; Liu, J.; Cao, H.; Zhang, X. Voltage vector error fault diagnosis for open-circuit faults of three-phase four-wire active power filters. IEEE Trans. Power Electron 2017, 32, 2215–2226. [Google Scholar] [CrossRef]

- Shu, C.; Ya-Ting, C.; Tian, Y.; Xun, W. A novel diagnostic technique for open-circuited faults of inverters based on output line-to-line voltage model. IEEE Trans. Ind. Electron. 2016, 63, 4412–4421. [Google Scholar] [CrossRef]

- Yang, C.; Gui, W.; Chen, Z.; Zhang, J.; Peng, T.; Yang, C.; Karimi, H.; Ding, X. Voltage difference residual-based open-circuit fault diagnosis approach for three-level converters in electric traction systems. IEEE Trans. Power Electron. 2019, 1–16. [Google Scholar] [CrossRef]

- Wu, F.; Zhao, J. Current similarity analysis-based open-circuit fault diagnosis for two-level three-phase PWM rectifier. IEEE Trans. Power Electron. 2017, 32, 3935–3945. [Google Scholar] [CrossRef]

- Hong, C.; Chen, W.; Wang, C.; Deng, J. Open circuit fault diagnosis and fault tolerance of three-phase bridgeless rectifier. Electronics 2018, 7, 291. [Google Scholar]

- Chen, H.; Jiang, B. A review of fault detection and diagnosis for the traction system in high-speed trains. IEEE Trans. Intell. Transp. Syst. 2019, 1–16. [Google Scholar] [CrossRef]

- Li, H.; Zhou, W.; Wang, X.; Munk-Nielsen, S.; Li, D.; Wang, Y.; Dai, X. Influence of paralleling dies and paralleling half-bridges on transient current distribution in multichip power modules. IEEE Trans. Power Electron. 2018, 33, 6483–6487. [Google Scholar] [CrossRef]

- Li, H.; Liao, X.; Zeng, Z.; Hu, Y.; Li, Y.; Liu, S.; Li, R. Thermal coupling analysis in a multichip paralleled IGBT module for a DFIG wind turbine power converter. IEEE Trans. Energy Convers. 2017, 32, 80–90. [Google Scholar] [CrossRef]

- Bemporad, A.; Morari, M. Control of systems integrating logic, dynamics, and constraints. Automatica 1999, 35, 402–427. [Google Scholar] [CrossRef]

- Zhang, J.; Peng, T.; Yang, C.; Chen, Z.; Yang, C.; Wen, H. A voltage-based open-circuit Fault Diagnosis Approach for Single Phase Two-Level Converters. In Proceedings of the 2019 International Symposium on Industrial Electronics (ISIE), Vancouver, BC, Canada, 12–14 June 2019; pp. 1737–1742. [Google Scholar]

- Lu, B.; Sharma, S. A literature review of IGBT fault diagnostic and protection methods for power inverters. IEEE Trans. Ind. Appl. 2009, 45, 1770–1777. [Google Scholar]

- Chen, Z.; Yang, C.; Peng, T.; Dan, H.; Li, C.; Gui, W. A Cumulative Canonical Correlation Analysis-based Sensor Precision Degradation Detection Method. IEEE Trans. Ind. Appl. 2019, 66, 6321–6330. [Google Scholar] [CrossRef]

- Yang, C.; Yang, C.; Peng, T.; Yang, X.; Gui, H. A Fault-Injection Strategy for Traction Drive Control System. IEEE Trans. Ind. Electron. 2017, 64, 5719–5727. [Google Scholar] [CrossRef]

- Yang, X.; Yang, C.; Peng, T.; Chen, Z.; Liu, B.; Gui, W. Hardware-in-the-Loop Fault Injection for Traction Control System. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 696–706. [Google Scholar] [CrossRef]

- Peng, T.; Tao, H.; Yang, C.; Chen, Z.; Yang, C.; Gui, W.; Karimi, H. A uniform modeling method based on open-circuit faults analysis for NPC-three-level converter. IEEE Trans. Circuits Syst. II Express Briefs 2019, 66, 457–461. [Google Scholar] [CrossRef]

| 0 | 0 | 1 | 0 | 0 | 0 | ||

| 0 | 1 | 0 | 0 | 1 | 0 | ||

| 1 | 0 | 1 | 1 | 0 | 1 |

| Faulty IGBT | ||

|---|---|---|

| − | ||

| − |

| Faulty IGBT | Switching IGBT | DCF Change | Current Direction | Control Signal |

|---|---|---|---|---|

| Method | [9] | [11] | [10] | [12] | [14] | Proposed Method |

|---|---|---|---|---|---|---|

| Observation | Currents | Currents | Currents | Pole voltages | DC-link voltages | DC-link voltages |

| Dignosis time | 80 ms | 600 s | 2.15 ms | 10 ms | 360 s | 620 s |

| System type of diagnosis | Three-level | Three-level | Two-level | Two-level | Three-level | Two-level |

| Diagnosis range | Both | Rectifier | Rectifier | Both | Both | Both |

| Diagnosis independence | Device level | Device level | Device level | Part of Device level | Both | Both |

| Forced signal injection | No | Yes | No | Yes | Yes | No |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Peng, T.; Yang, C.; Chen, Z.; Tao, H.; Yang, C. A Voltage-Based Hierarchical Diagnosis Approach for Open-Circuit Fault of Two-Level Traction Converters. Electronics 2019, 8, 992. https://doi.org/10.3390/electronics8090992

Zhang J, Peng T, Yang C, Chen Z, Tao H, Yang C. A Voltage-Based Hierarchical Diagnosis Approach for Open-Circuit Fault of Two-Level Traction Converters. Electronics. 2019; 8(9):992. https://doi.org/10.3390/electronics8090992

Chicago/Turabian StyleZhang, Jingrong, Tao Peng, Chao Yang, Zhiwen Chen, Hongwei Tao, and Chunhua Yang. 2019. "A Voltage-Based Hierarchical Diagnosis Approach for Open-Circuit Fault of Two-Level Traction Converters" Electronics 8, no. 9: 992. https://doi.org/10.3390/electronics8090992

APA StyleZhang, J., Peng, T., Yang, C., Chen, Z., Tao, H., & Yang, C. (2019). A Voltage-Based Hierarchical Diagnosis Approach for Open-Circuit Fault of Two-Level Traction Converters. Electronics, 8(9), 992. https://doi.org/10.3390/electronics8090992