Feedforward Interpolation Error Compensation Method for Field Weakening Operation Region of PMSM Drive

Abstract

:1. Introduction

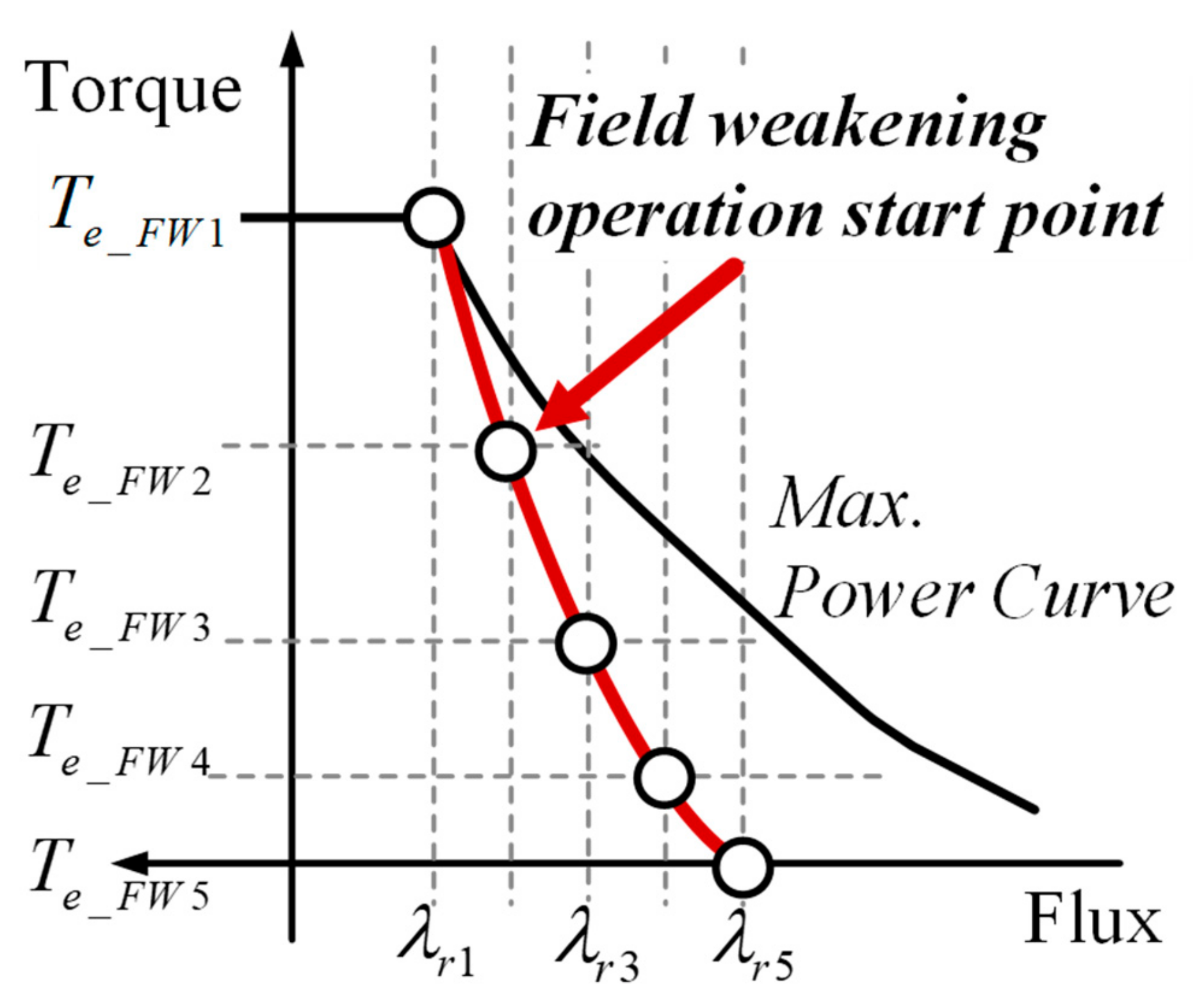

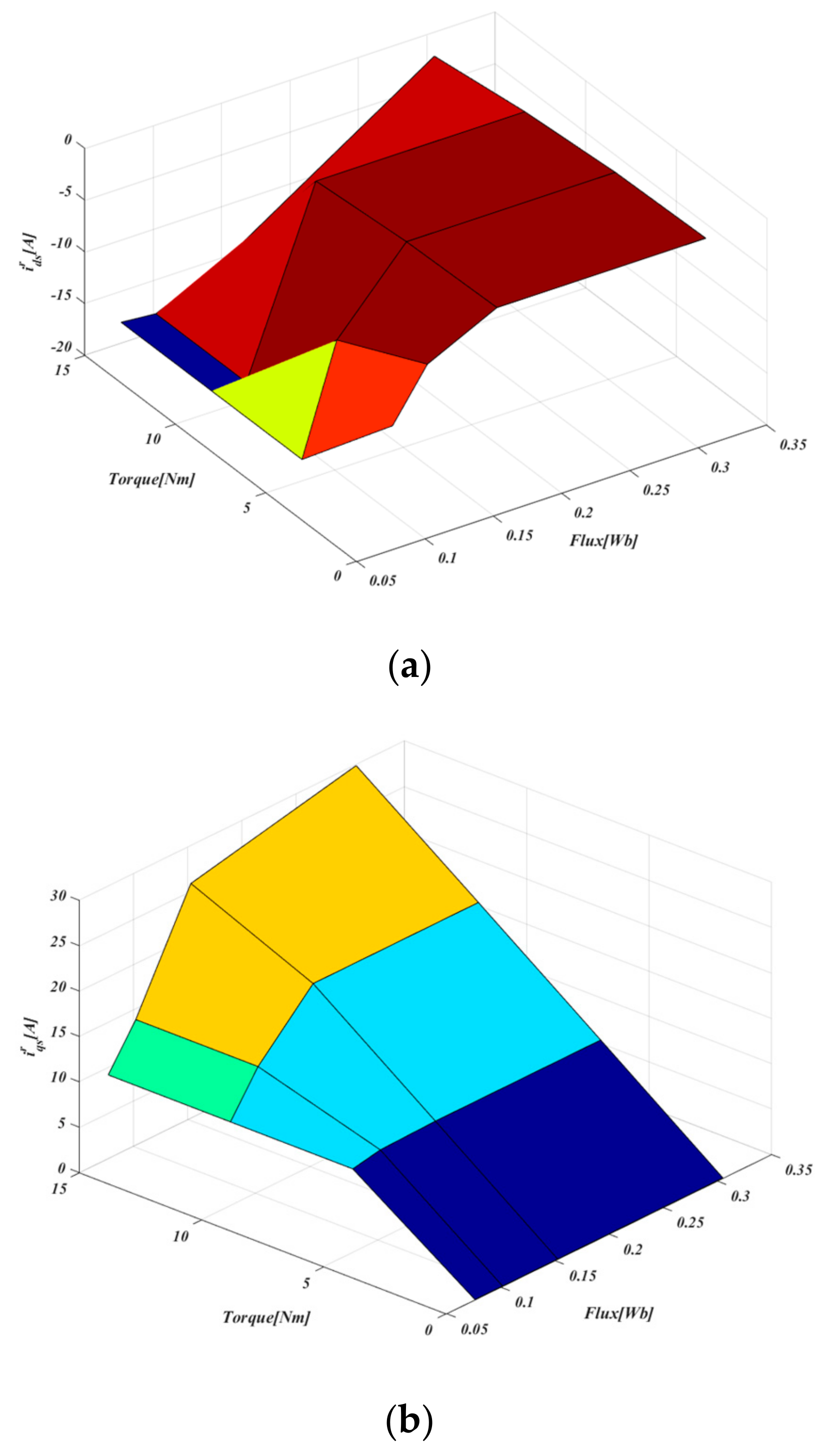

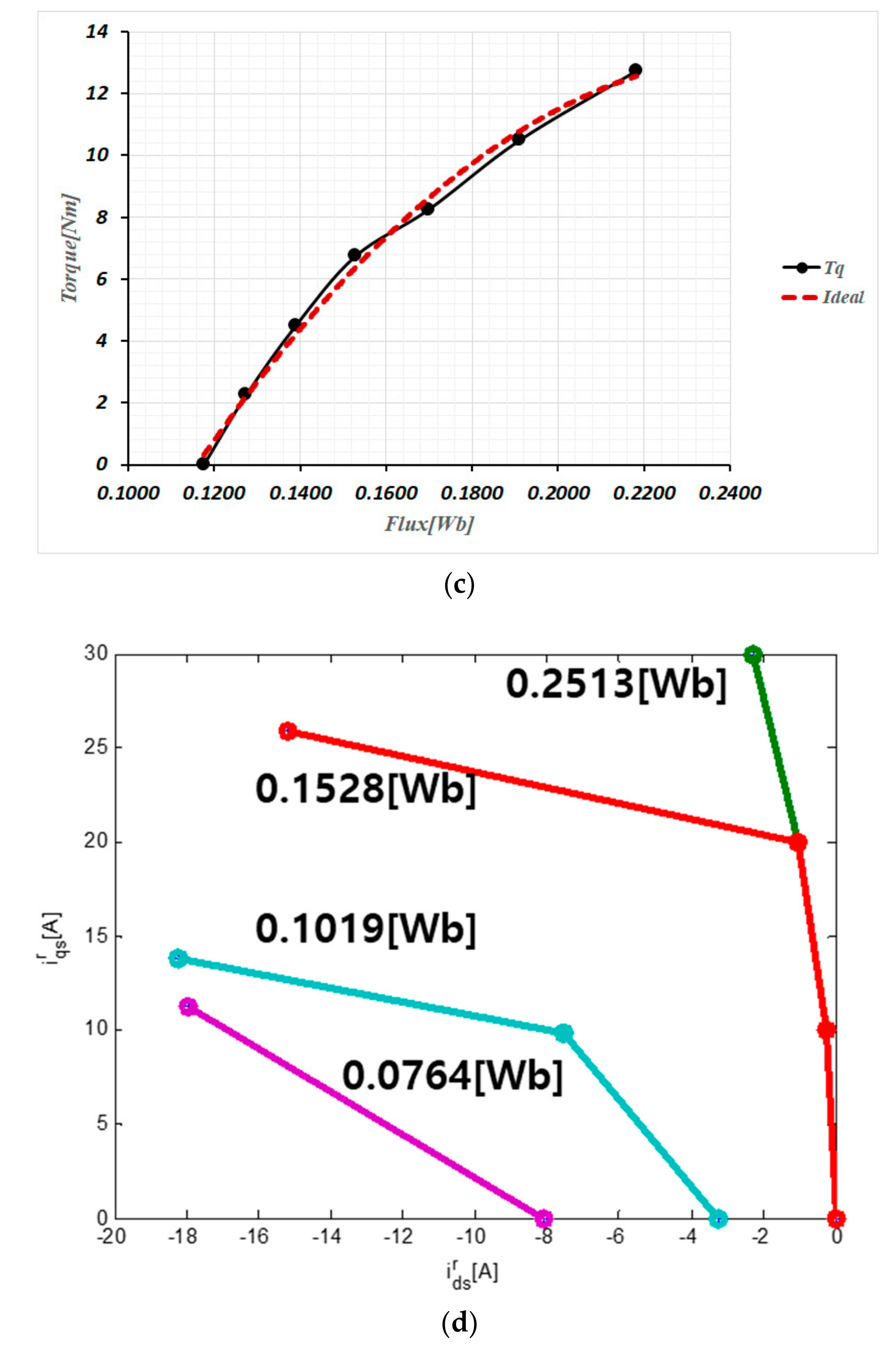

2. Interpolation Error of the 2D Interpolation Technique for PMSM Drives

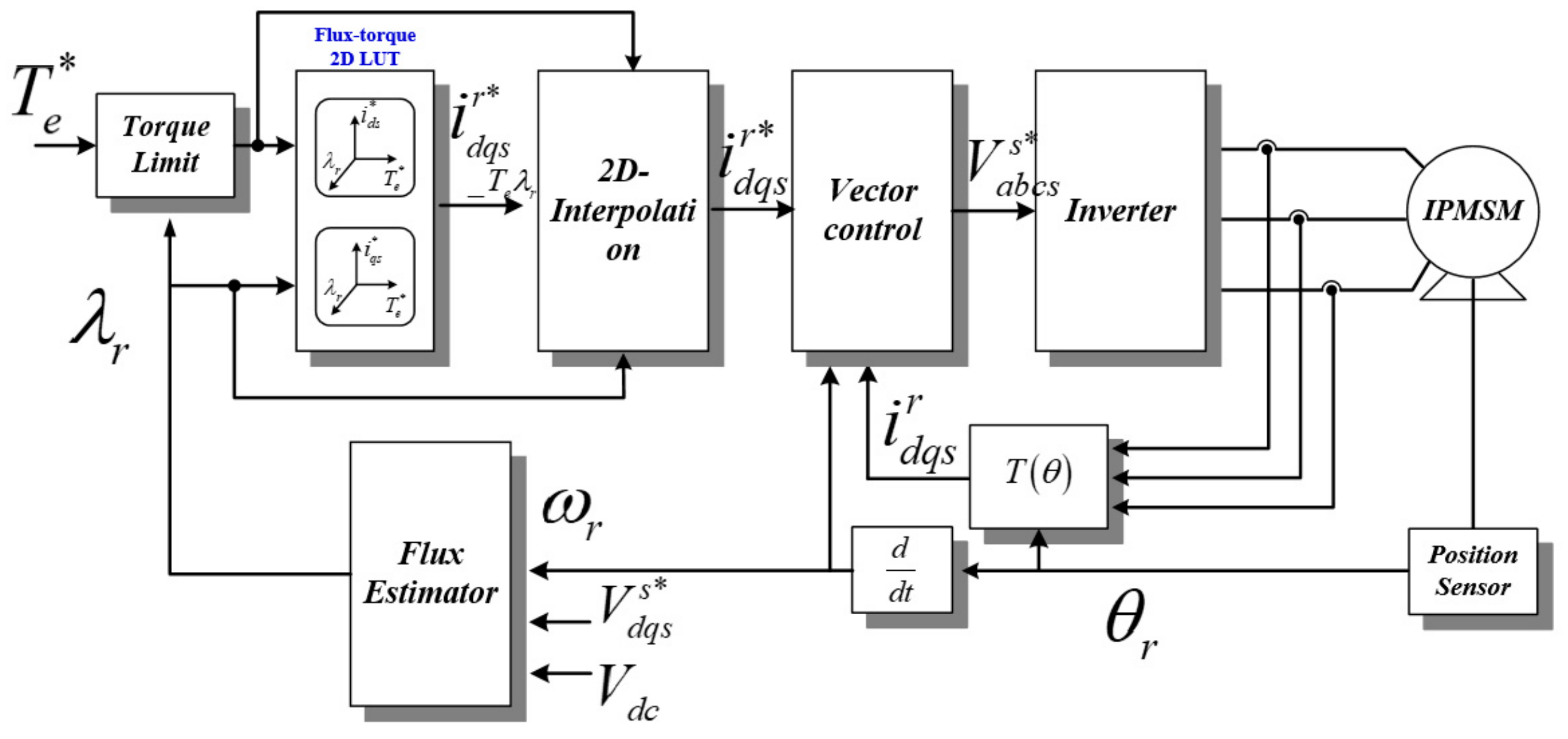

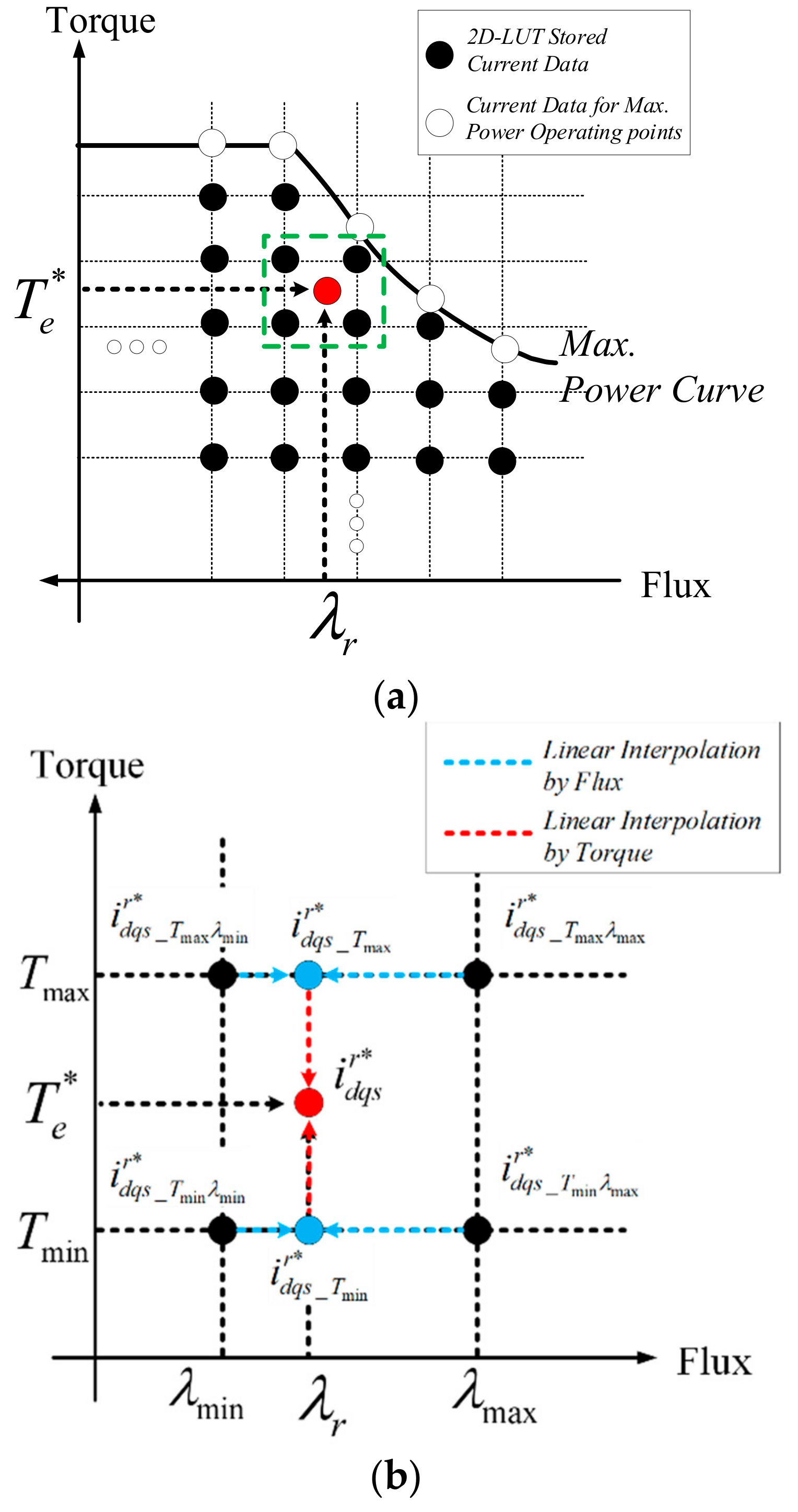

2.1. Two-Dimensional Interpolation Technique

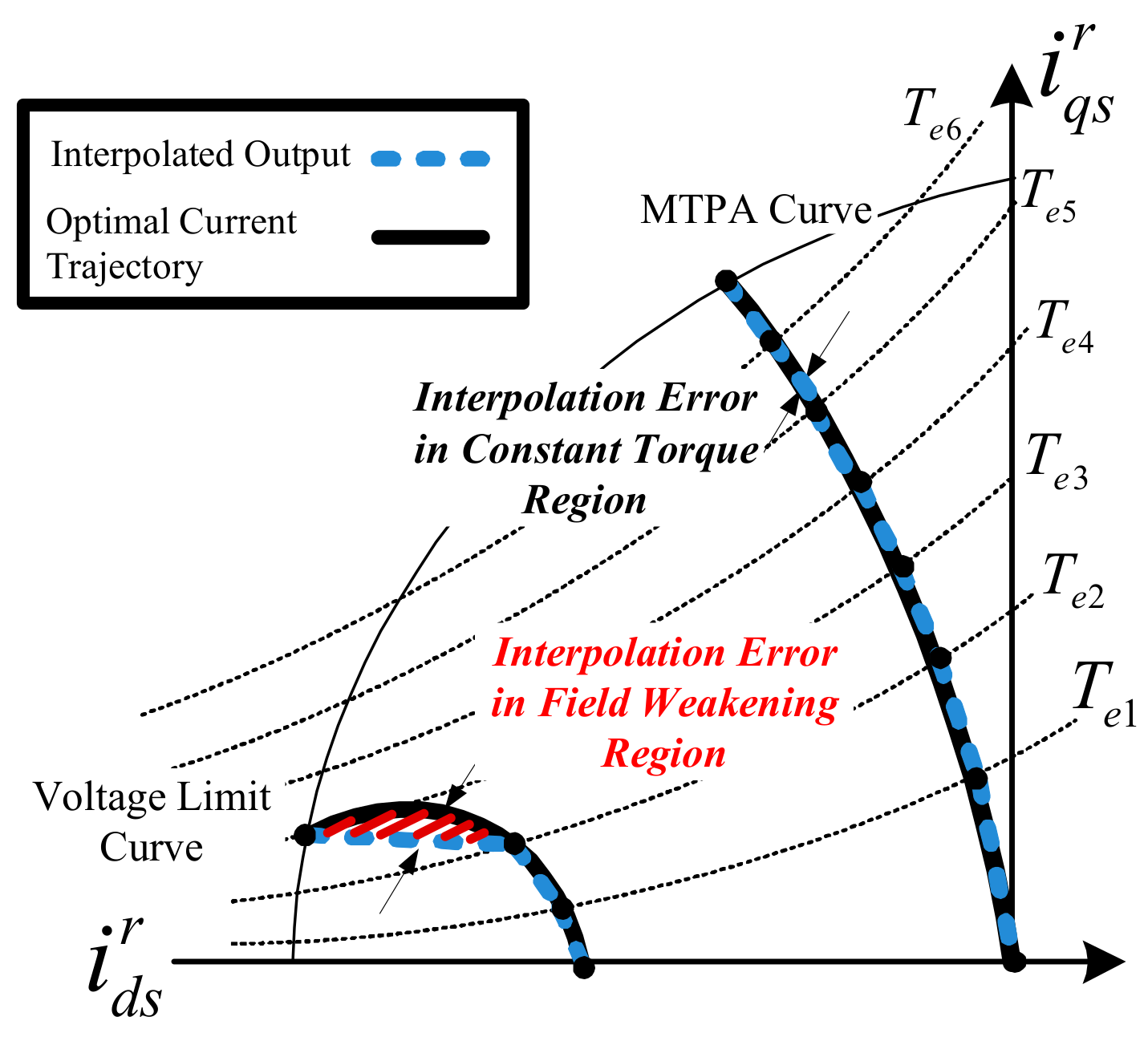

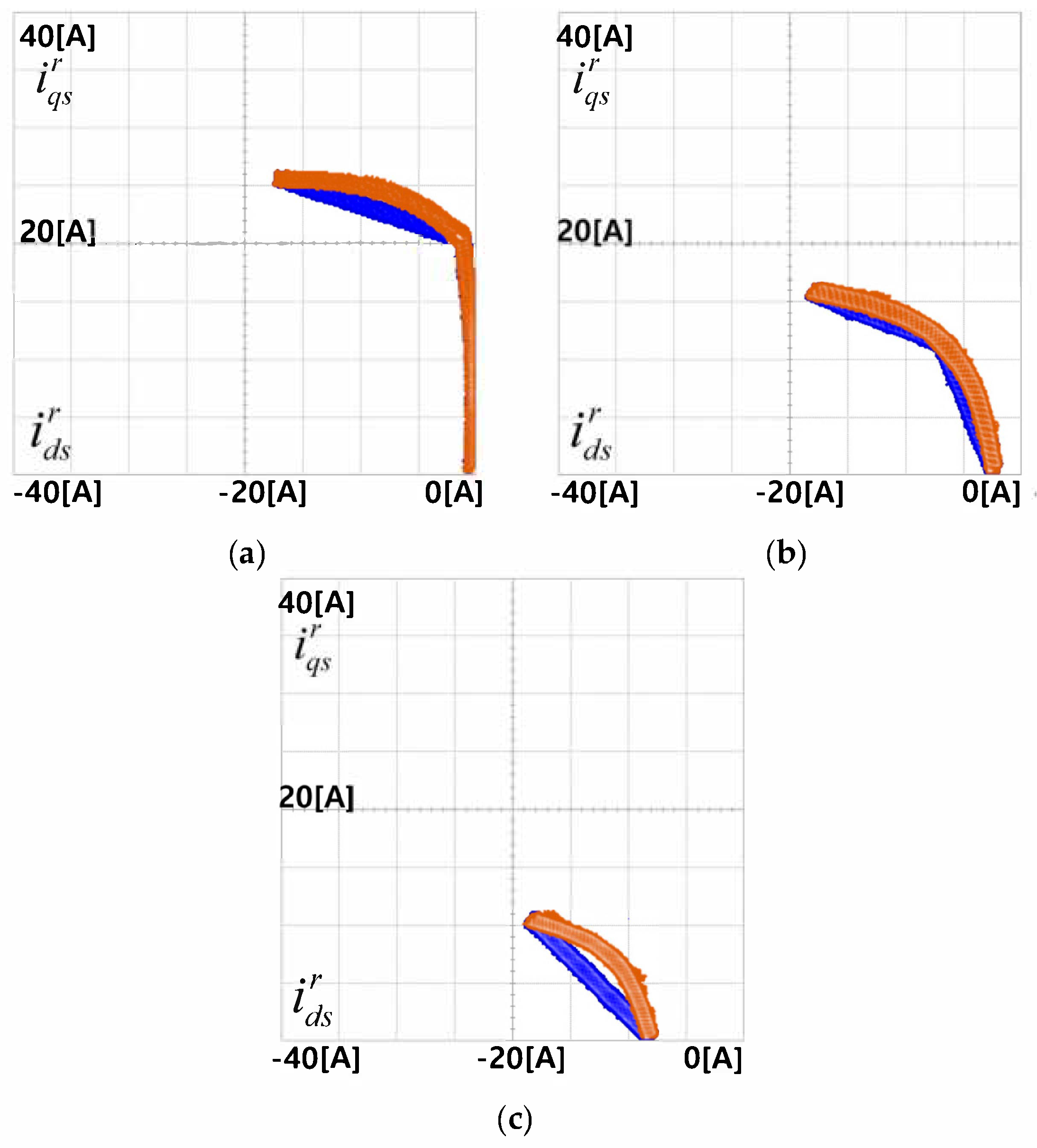

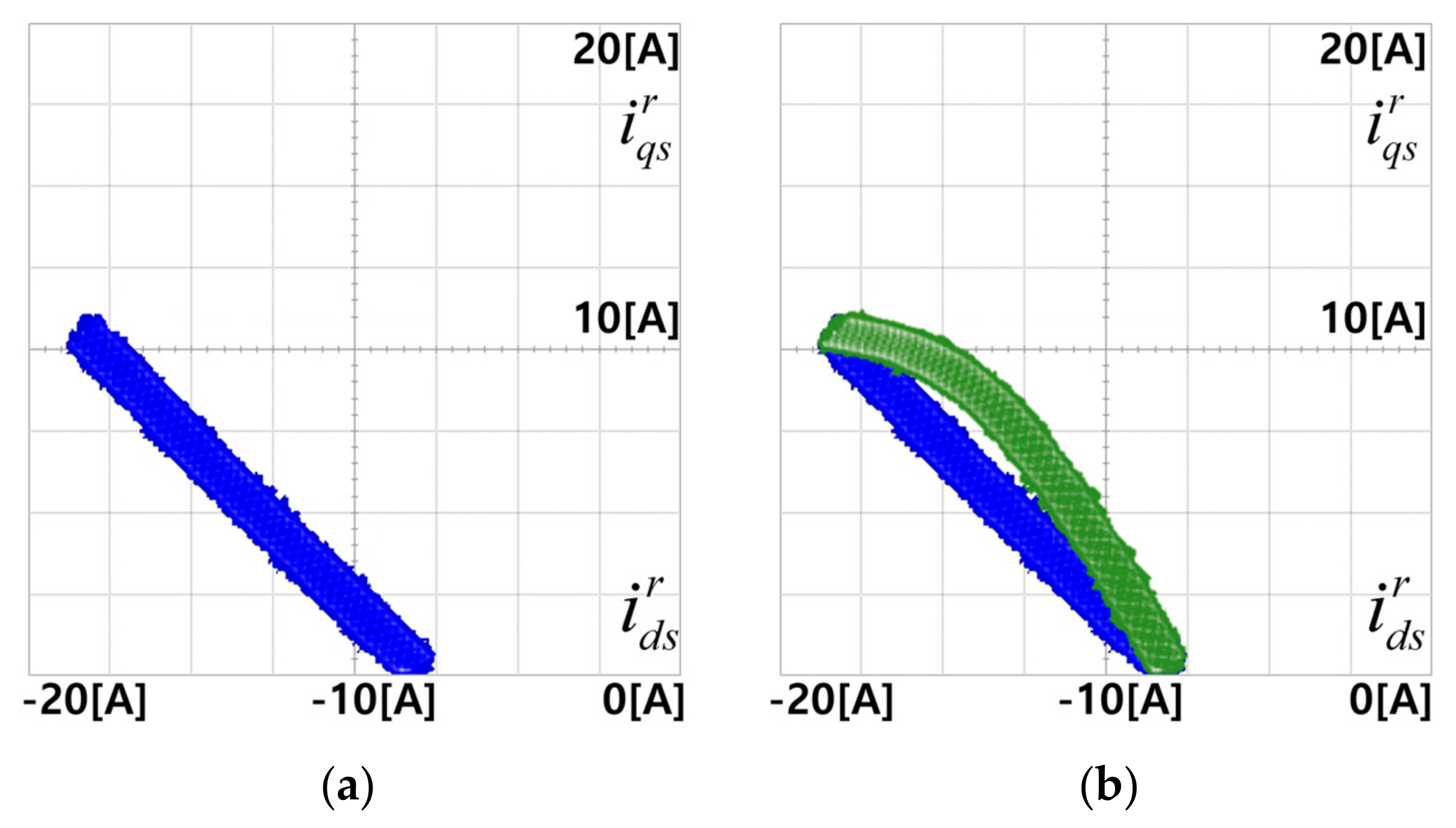

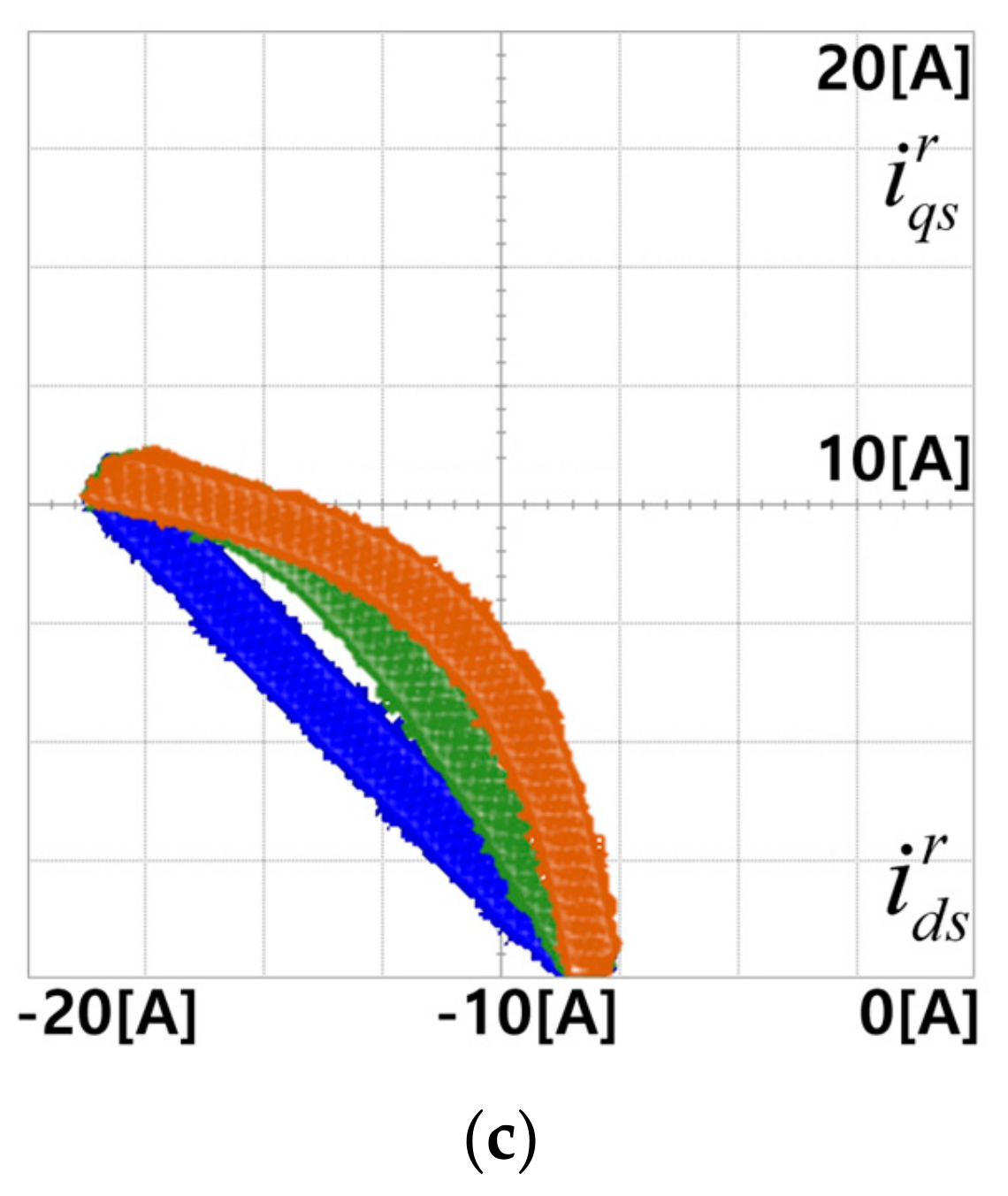

2.2. Two-Dimensional Interpolation Error In Look-Up Table Based PMSM Control

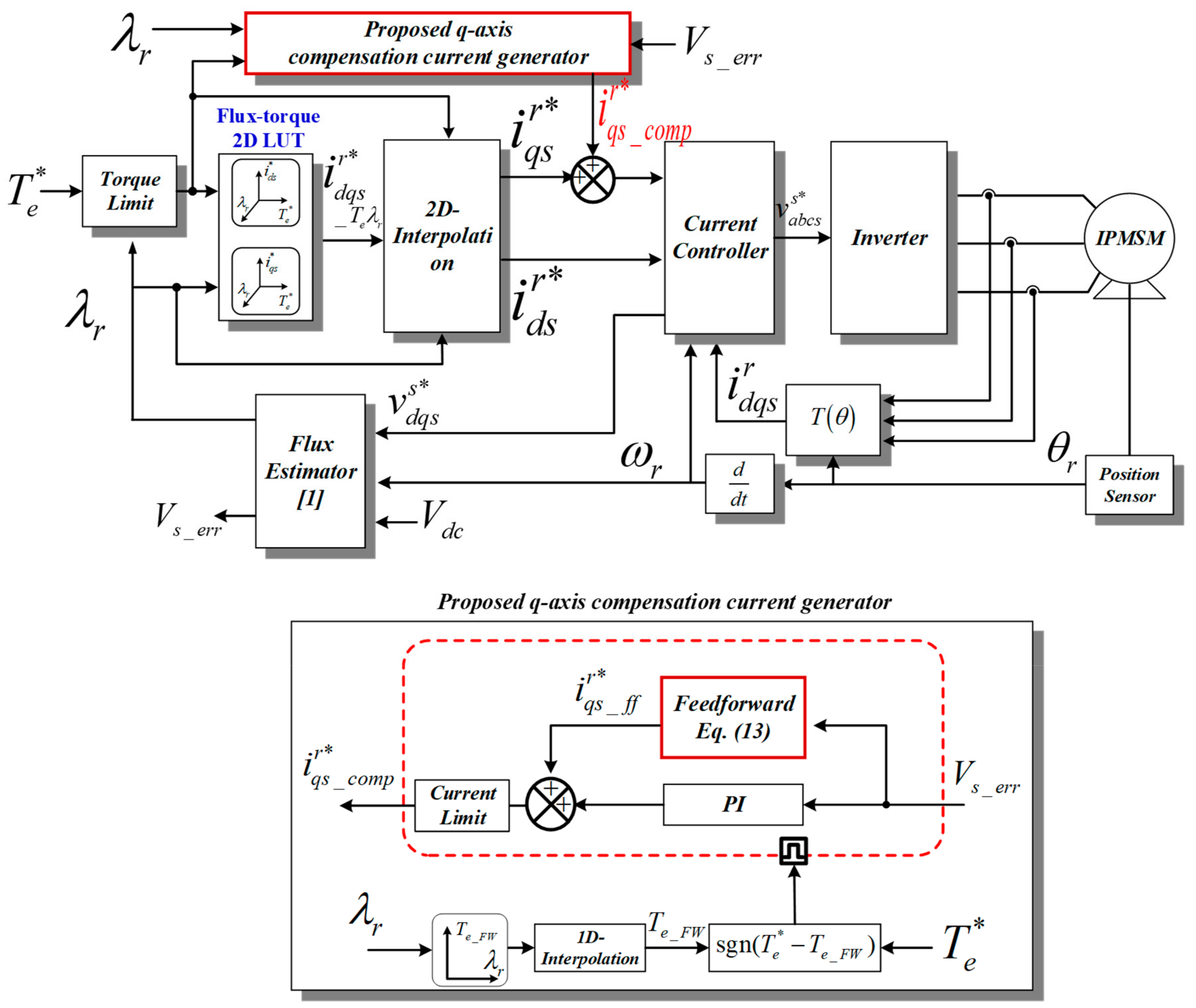

3. An Interpolation Error Compensation Method with DC-Link Voltage Feedforward Controller

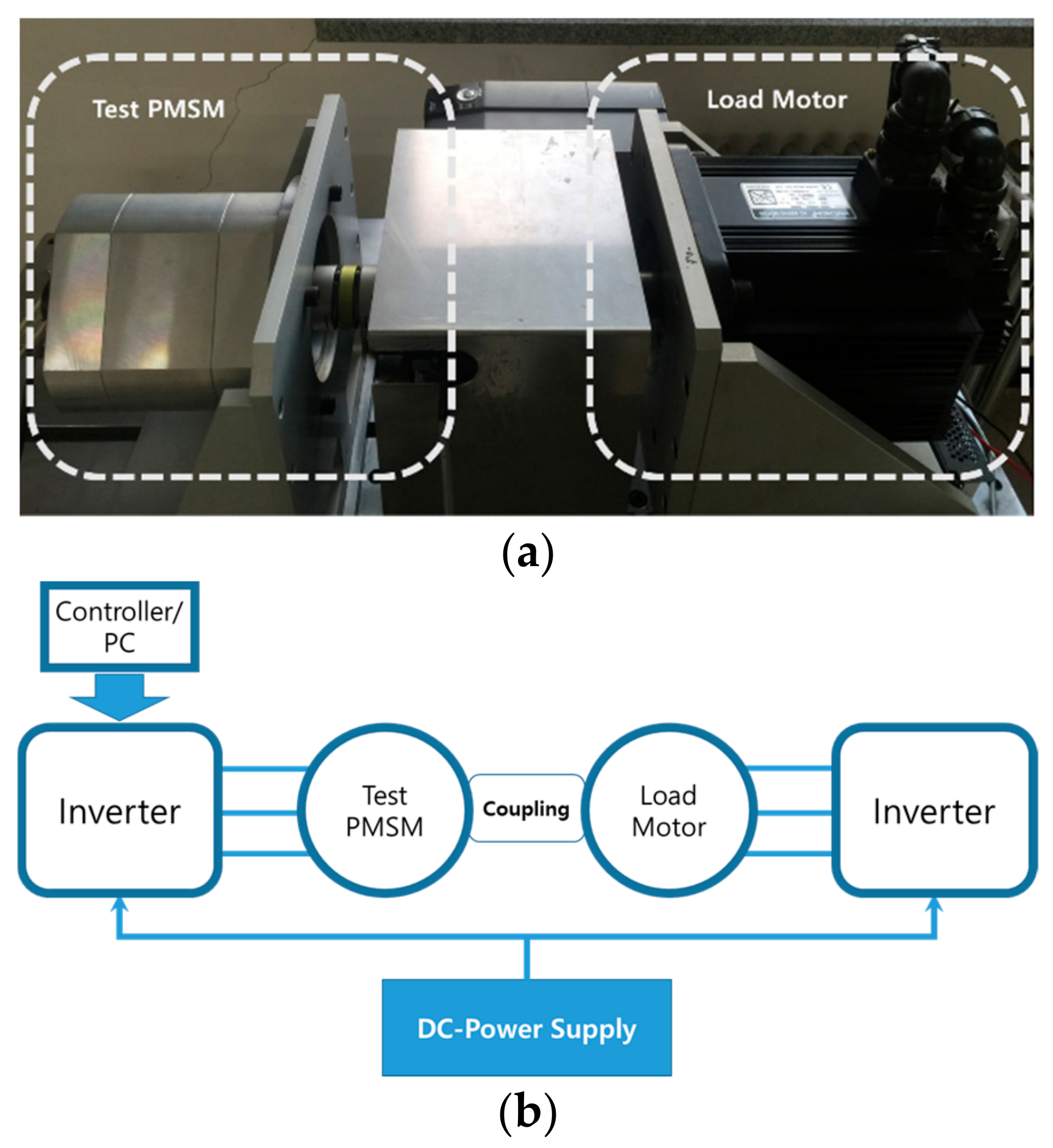

4. Experiment

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jung, S.-Y.; Hong, J.; Nam, K. Current minimizing torque control of the IPMSM using Ferrari’s method. IEEE Trans. Power Electron. 2013, 28, 5603–5617. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, J.H.; Park, J.H.; Won, C.Y. Field-weakening strategy in condition of DC-link voltage variation using on electric vehicle of IPMSM. In Proceedings of the 2011 International Conference on Electrical Machines and Systems, Beijing, China, 20–23 August 2011; pp. 1–6. [Google Scholar]

- Yang, N.; Luo, G.; Liu, W.; Wang, K. Interior permanent magnet synchronous motor control for electric vehicle using look-up table. In Proceedings of the 7th International Power Electronics and Motion Control Conference, Harbin, China, 2–5 June 2012; pp. 1015–1019. [Google Scholar]

- Kwon, T.-S.; Choi, G.-Y.; Kwak, M.-S.; Sul, S.-K. Novel Flux-Weakening Control of an IPMSM for Quasi-Six-Step Operation. IEEE Trans. Ind. Appl. 2008, 44, 1722–1731. [Google Scholar] [CrossRef]

- Cheng, B.; Tesch, T.R. Torque Feedforward Control Technique for Permanent-Magnet Synchronous Motors. IEEE Trans. Ind. Electron. 2010, 57, 969–974. [Google Scholar] [CrossRef]

- Lee, J.-H.; Won, C.-Y.; Lee, B.-K.; Kim, H.-B.; Baek, J.-H.; Han, K.-B.; Chung, U.-I. IPMSM Torque Control Method Considering DC-link Voltage Variation and Friction Torque for EV/HEV applications. In Proceedings of the 2012 IEEE Vehicle Power and Propulsion Conference, Seoul, Korea, 9–12 October 2012; pp. 1063–1069. [Google Scholar]

- Tursini, M.; Chiricozzi, E.; Petrella, R. Feedforward Flux-Weakening Control of Surface-Mounted Permanent-Magnet Synchronous Motors Accounting for Resistive Voltage Drop. IEEE Trans. Ind. Electron. 2010, 57, 440–448. [Google Scholar] [CrossRef]

- Park, J.-H.; Lee, J.-H.; Lee, J.-H.; Won, C.-Y. Current Control Method of IPMSM in Constant Power Region for HEV. In Proceedings of the 2011 International Conference on Electrical Machines and Systems, Beijing, China, 20–23 August 2011; pp. 1015–1019. [Google Scholar]

- Lenke, R.U.; de Doncker, R.W.; Kwak, M.-S.; Kwon, T.-S.; Sul, S.-K. Field Weakening Control of Interior Permanent Magnet Machine using Improved Current Interpolation Technique. In Proceedings of the 2006 37th IEEE Power Electronics Specialists Conference, Jeju, Korea, 18–22 June 2006; pp. 1–5. [Google Scholar]

- Cintron-Rivera, J.G.; Foster, S.N.; Nino-Baron, C.A.; Strangas, E.G. High performance controllers for Interior Permanent Magnet Synchronous Machines using look-up tables and curve-fitting methods. In Proceedings of the 2013 International Electric Machines & Drives Conference, Chicago, IL, USA, 12–15 May 2013; pp. 268–275. [Google Scholar]

- Yoon, Y.-D.; Lee, W.-J.; Sul, S.-K. New flux weakening control for high saliency interior permanent magnet synchronous machine without any tables. In Proceedings of the 2017 European Conference on Power Electronics and Applications (ECPEA), Aalborg, Denmark, 2–5 September 2007; pp. 1–7. [Google Scholar]

- Huang, S.; Chen, Z.; Huang, K.; Gao, J. Maximum Torque Per Ampere and Flux-weakening Control for PMSM Based on Curve Fitting. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference (VPPC), Lille, France, 1–3 September 2010; pp. 1–5. [Google Scholar]

- Lee, J.-H. DC-link voltage feedforwarded interpolation error compensation method for field weakening operation region of look-up table based PMSM drive. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Tokyo, Japan, 22–25 May 2019; Volume 600. [Google Scholar]

- Lee, J.-H. Interpolation Error Compensation Method for PMSM Torque Control. Trans. Korean Inst. Electron. Eng. 2018, 67, 391–397. [Google Scholar] [CrossRef]

| Pole | 8 |

| Phase Resistance [mΩ] | 20 |

| d-axis Inductance [mH] | 2.03 |

| q-axis Inductance [mH] | 2.13 |

| Permanent Magnet Flux [Wb] | 0.1439 |

| Rated DC-Link Voltage [V] | 48 |

| Rated Torque [Nm] | 15 |

| Rated Speed [rpm] | 200 |

| Max. Speed [rpm] | 1500 |

| Max. Phase Current [A] | 30 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, Y.-B.; Lee, J.-H. Feedforward Interpolation Error Compensation Method for Field Weakening Operation Region of PMSM Drive. Electronics 2019, 8, 1052. https://doi.org/10.3390/electronics8091052

Ji Y-B, Lee J-H. Feedforward Interpolation Error Compensation Method for Field Weakening Operation Region of PMSM Drive. Electronics. 2019; 8(9):1052. https://doi.org/10.3390/electronics8091052

Chicago/Turabian StyleJi, Young-Bae, and Jung-Hyo Lee. 2019. "Feedforward Interpolation Error Compensation Method for Field Weakening Operation Region of PMSM Drive" Electronics 8, no. 9: 1052. https://doi.org/10.3390/electronics8091052

APA StyleJi, Y.-B., & Lee, J.-H. (2019). Feedforward Interpolation Error Compensation Method for Field Weakening Operation Region of PMSM Drive. Electronics, 8(9), 1052. https://doi.org/10.3390/electronics8091052