1. Introduction

The term machine olfaction is usually referred to as a technology with which an intelligent machine detects and identifies gases or odors. An electronic nose is a gas/odor identification machine which is comprised of a gas sensor array and an intelligent identification block [

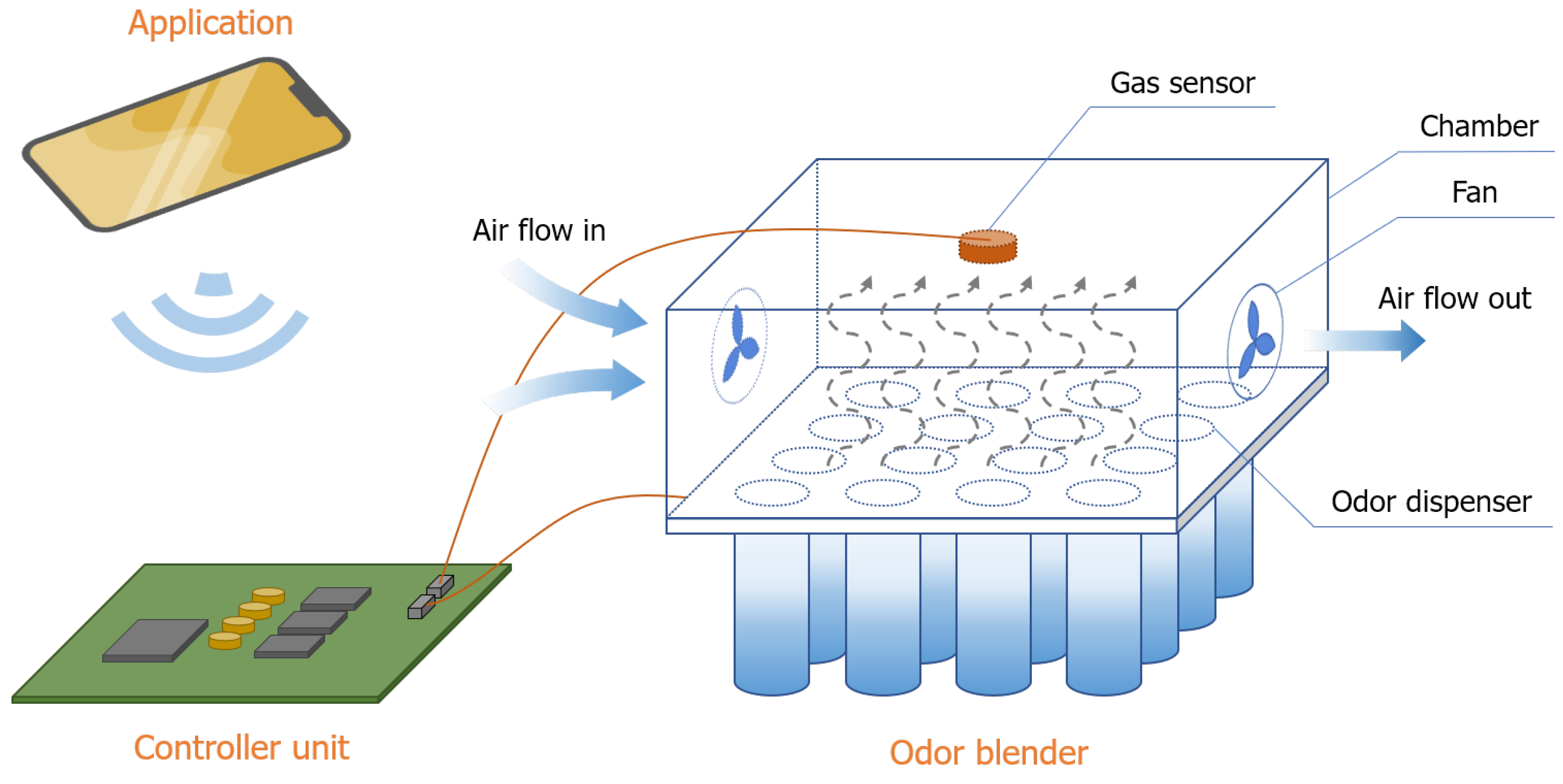

1]. However, machine olfaction should embrace a larger area, in which the subject includes not only gas/odor identifications but also odor representations. In computer vision, colors (images) are captured by cameras and reproduced by displayers or printers. In computer audition, voices are sampled by recorders and played by speakers. It is analogous that machine olfaction includes both intelligent sensation and representation of odors. In other words, an odor identification instrument (electronic nose) ’smells’ and records odors, and an odor representation (odor reproduction or olfactory display) machine reproduces odors. The term odor reproduction and the term olfactory display are different, because they generate odors differently. An odor reproduction instrument blends several odor sources then releases them, in which the blending process utilizes basic components either in a liquid or gas state. An olfactory display releases an odor from one of those well-prepared odor sources. It is reasonable to assume that the number of odors reproduced by an odor reproduction instrument is bigger than an olfactory display if the number of channels are the same.

Many studies concerning olfactory display have been reported in recent decades. Morton L. Heilig et al. invented an olfactory display called the “sensorama simulator”, in which odor-stimulating substances were released from a specially designed chair in the 1960s [

2]. This was probably the first report of an olfactory display. Y. Yanagida et al. developed a nose-tracing air cannon which was capable of tracing human noses and emitting odors [

3]. D. W. Kim et al. designed an aroma-card based olfactory display [

4]. D. Noguchi et al. developed a multi-channel olfactory display which was based on ink-jet technology [

5]. S. H. Abid et al. proposed a multimedia decoder system with an olfactory display that contained six micro-porous piezoelectric transducers [

6]. T. Nakamoto et al. developed an olfactory display based on surface acoustic wave (SAW) technology [

7]. J. A. Covington et al. developed a multi-channel portable olfactory display system which consisted of eight thermalization-based odor generators controlled by a pulse-width modulation (PWM) approach [

8].

Atomization and thermalization are two solutions for building an odor reproduction instrument or an olfactory display. Atomization is an approach to dispense odorants with the advantages that the dispensing process is fast and the dispensing quantity is controllable. Surface acoustic wave (SAW) transducers are a way of atomizing odorants. Liquid on a piezoelectric substrate is vibrated and atomized by a spurred wave generated by an interdigital transducer electrode [

9]. A number of studies on SAW-based olfactory displays have been reported [

7,

10,

11]. The other form of atomization-based olfactory display is based on micro-porous piezoelectric transducers [

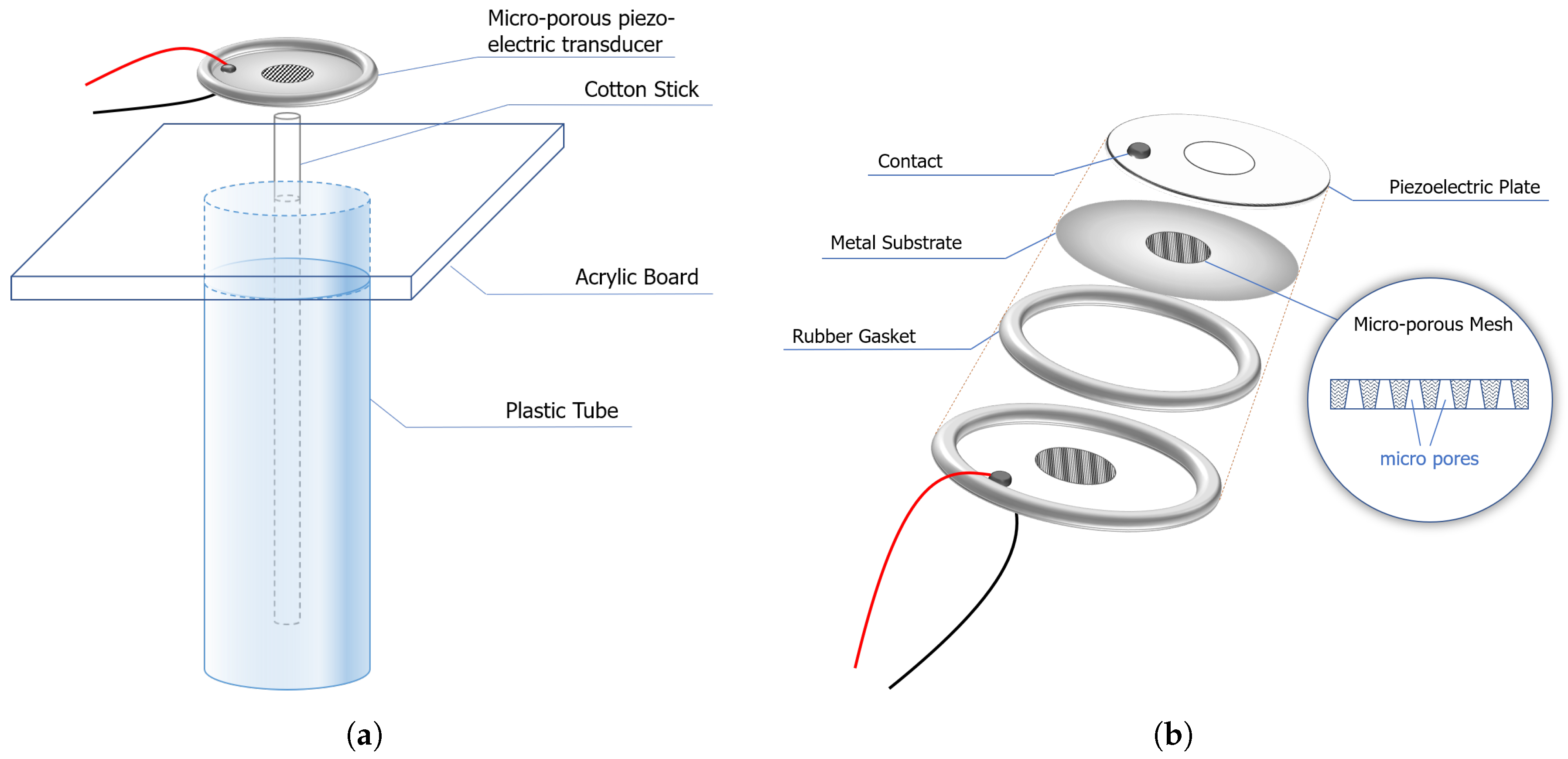

6]. A micro-porous piezoelectric transducer atomizes liquid by means of a metal mesh smashing the liquid. The smash of the metal mesh is driven by the vibration of a piezoelectric substrate. Piezoelectric transducers are suitable for commercial uses, due to their advantage of low cost. Thermalization is the other way of dispensing odors, by vaporizing odor sources in the liquid state or the solid state using PWM heaters [

8,

12]. A temperature controller for odor dispensers should be embedded in a thermalization-based odor reproduction instrument or olfactory display to avoid the possibility of scorching odor sources.

The advance of odor reproduction is slow, and few studies have been reported. A study on the development of an odor reproduction system was reported by T. Nakamoto et al. [

13,

14,

15]. The system consisted of an odor identification instrument (sensor array or portable mass spectrometer) and an odor blender. The blender reproduced odors according to the measurement data recorded by the odor identification instrument. The obstacles to building an odor reproduction system are as follows: Firstly, odor blending should be controlled precisely, because a mixture of various odorants in different proportions may change the odor. Secondly, the scheme of how to reproduce odors according to odor information is ambiguous. In the odor reproduction system proposed by T. Nakamoto et al., as illustrated above, the system was a kind of feedback loop which made reproduction a time-consuming process. D. Harel et al. proposed an odor communication system, in which an odor “sniffer” recorded the odor information and an odor “whiffer” reproduced the odor [

16]. However, the coding of odor information is unpracticable for this kind of system, at present. Perfumery is assumed to be the most similar technique to odor reproduction, although various aspects differ from odor reproduction, such as aroma duration, stability, and so on. The scent of perfume can be divided into three stages: Top note, body note, and basic note, since a bottle of perfume is a combination of fragrance sources which possess different fragrance retention times. However, an odor reproduction system reproduces different odors dynamically. This means that those fragrance sources which have shorter retention times may be selected. Besides, perfumery is an art, to some extent, so flavorists may incorporate their background knowledge into perfume formulas; however, an odor reproduction system needs a more regularized set of rules for blending odor sources. Thirdly, the biological, neurological, and psychological mechanisms of odor perception are unclear as of yet. Stereochemistry and vibrational theory are considered to be the two acceptable theories that described relationships between odorants and odor qualities, although both theories have some exceptions that fail to describe such relationships fully [

17]. Recent research has revealed that strong correlation between odor chemical features and perceptual qualities [

18,

19].

The potential applications of odor reproduction technology are manifold. Odor reproduction can be applied to various applications, such as virtual and augmented reality, smart homes, electronic commerce, and so on. Moreover, odor reproduction can be applied to some medical uses, such as the first-diagnosis of Parkinson’s disease, as the degradation of olfaction is a representative characteristic of the disease [

20]. It is reasonable that an odor reproduction system should have the following features:

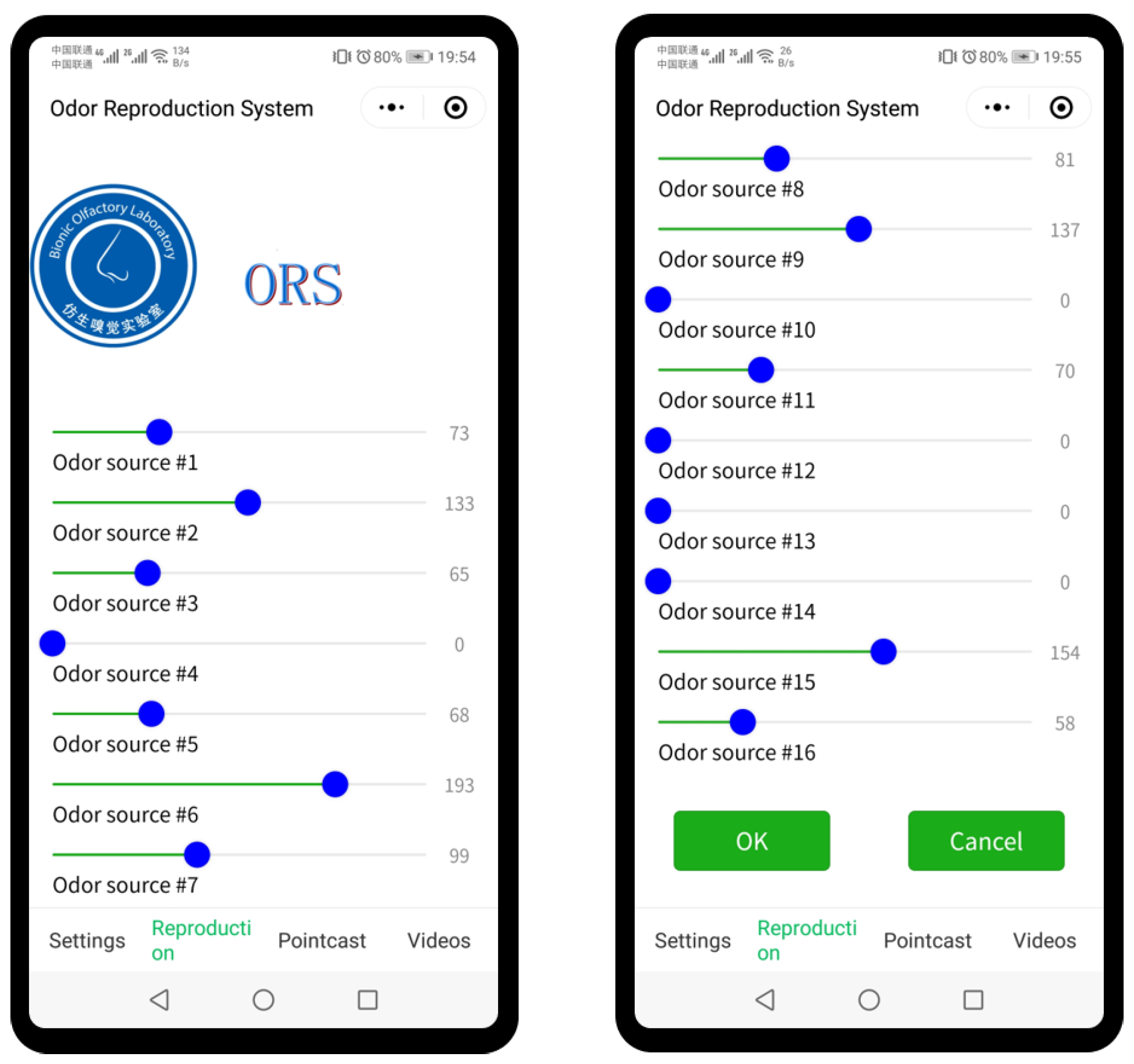

Reproduces odors in real-time;

A limited number of odor sources are used;

Capacity for reproducing a large number of odors; and

Has a user-friendly interface.

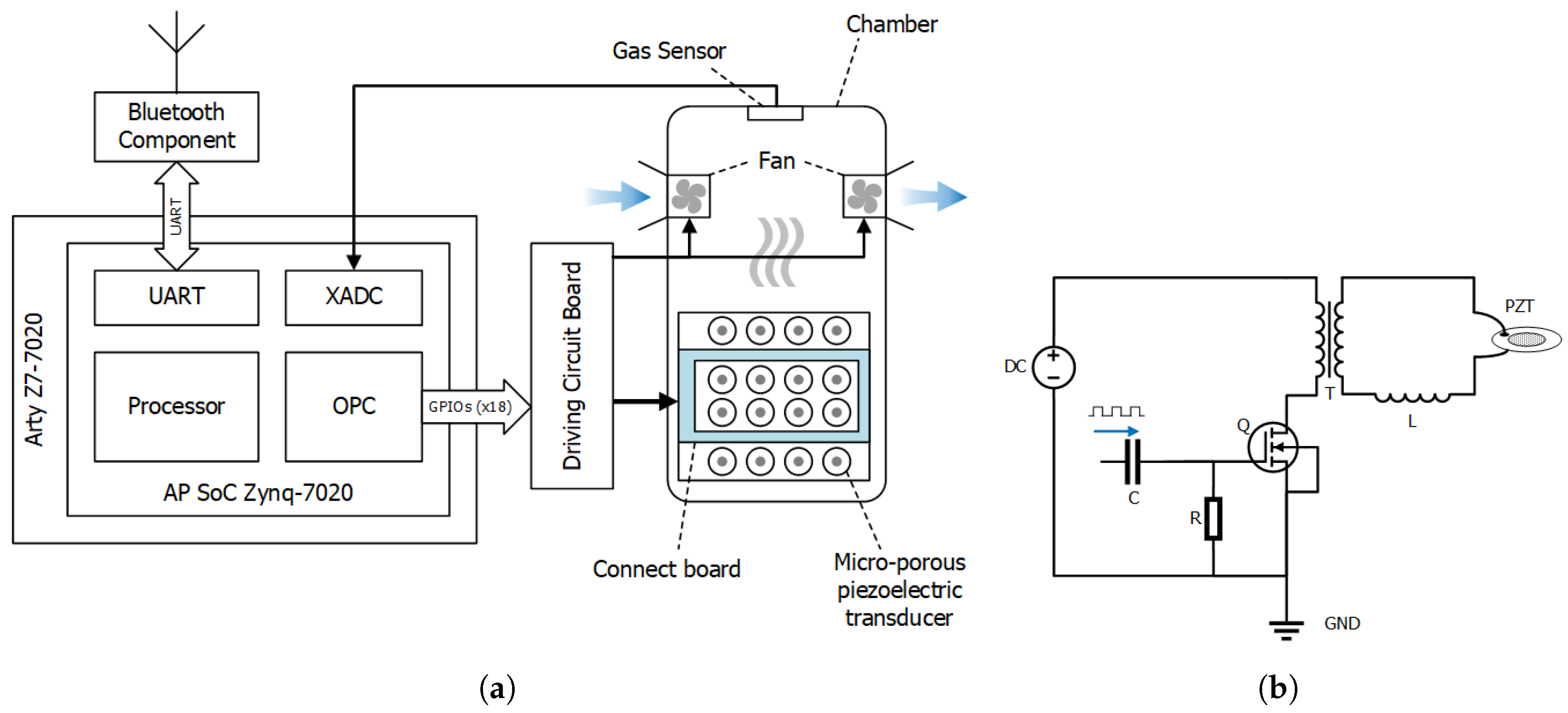

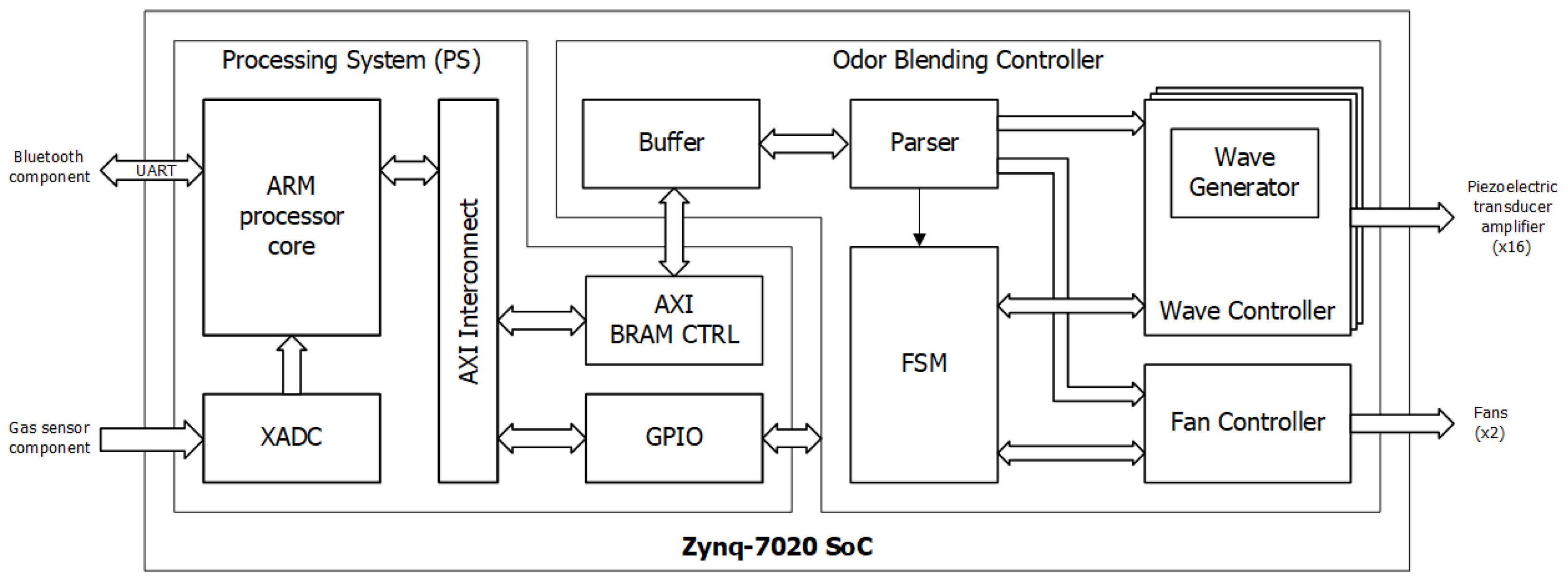

Considering that there is, at present, no appropriate ready-made instrument for the research of odor reproduction, we have developed an odor reproduction system for our future studies of odor reproduction. We have also proposed a method for verifying the performance of the system, using an electronic nose. In the following sections, the development of the odor reproduction system will be illustrated first. After that, the authors propose a method for the evaluation of the system using a commercial electronic nose. Finally, a discussion of the system and odor reproduction is given.

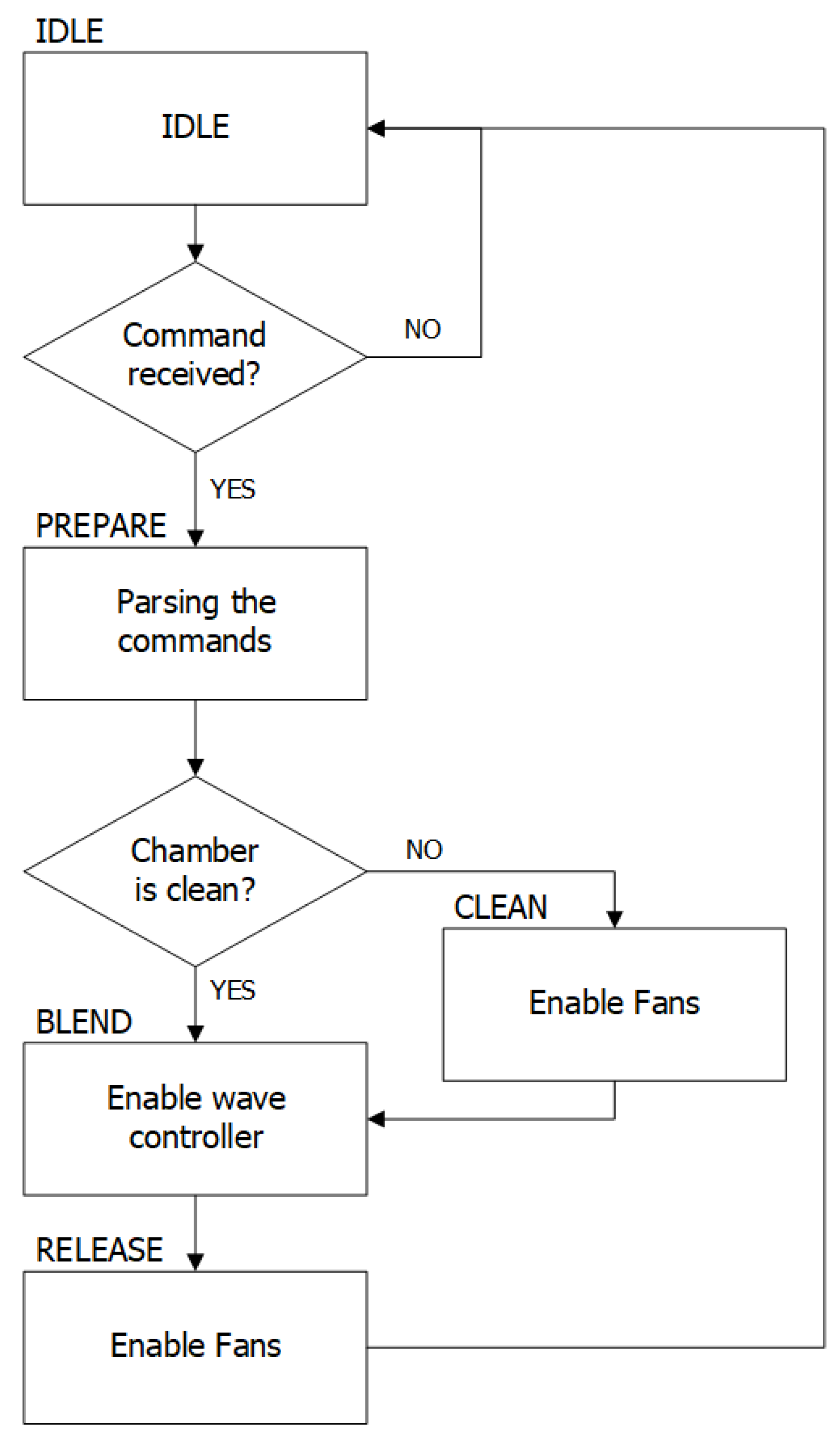

3. Evaluation of the System

This experiment aims to verify the effectiveness of the proposed system reproducing an odor. The evaluation uses a linear classifier (PCA–LDA) with data sampled by a commercial electronic nose, PEN3, manufactured by Airsense Analytics GmbH. The training data were sampled from odors atomized by well-prepared mixed odor sources. The testing data were sampled from odors atomized by proportional blending (blending pure odor sources in various proportions). Four highly pure odor sources were used for the experiment; the sources used are shown in

Table 2. Five circumstances of odor mixture with different proportions were randomly set, as shown in

Table 3.

Four pure odorous chemical liquids were prepared and five liquid mixtures were carefully prepared using the four pure chemicals, in the proportions according to

Table 3. All of these four pure liquids and five liquid mixtures were assembled in the odor dispenser. An odor can be reproduced in two different ways: (1) It can be reproduced by the proportional blending process using the four single pure liquids; or (2) it can be reproduced from a liquid mixture. After that, the electronic nose sampled odors reproduced either by the proportional blending of the four pure liquids or in one of the five mixed liquids. The monitoring procedure of the electronic nose was as follows:

The system atomizes an objective odor into an airtight chamber.

The chamber is kept static for 10 min, so that objective odorants can be fulfilled in the chamber.

The electronic nose monitors the objective odor.

The monitoring procedure was executed 10 times, because each objective odor of the five cases was reproduced from either the proportional blending process or the odor liquid mixture. The electronic nose implemented 6 samples in each monitoring procedure. The working parameter settings of the electronic nose were as follows: Flush time was 120 s; zero-point trim time was 10 s; sampling interval was 5 s; monitoring time was 120 s; and dilution flow was 600 mL/min. As the electronic nose has 10 different types of gas sensors, as shown in

Table 4, the data-set of each sample was a 120 × 10 matrix. It is noted that the fans were closed in the experiment and the chamber was sealed, with two tiny holes opened for the inlet of clean air and the outlet of the objective odor for the electronic nose.

It was assumed that the response patterns sampled by the electronic nose were similar if odors generated in the two different ways were similar.

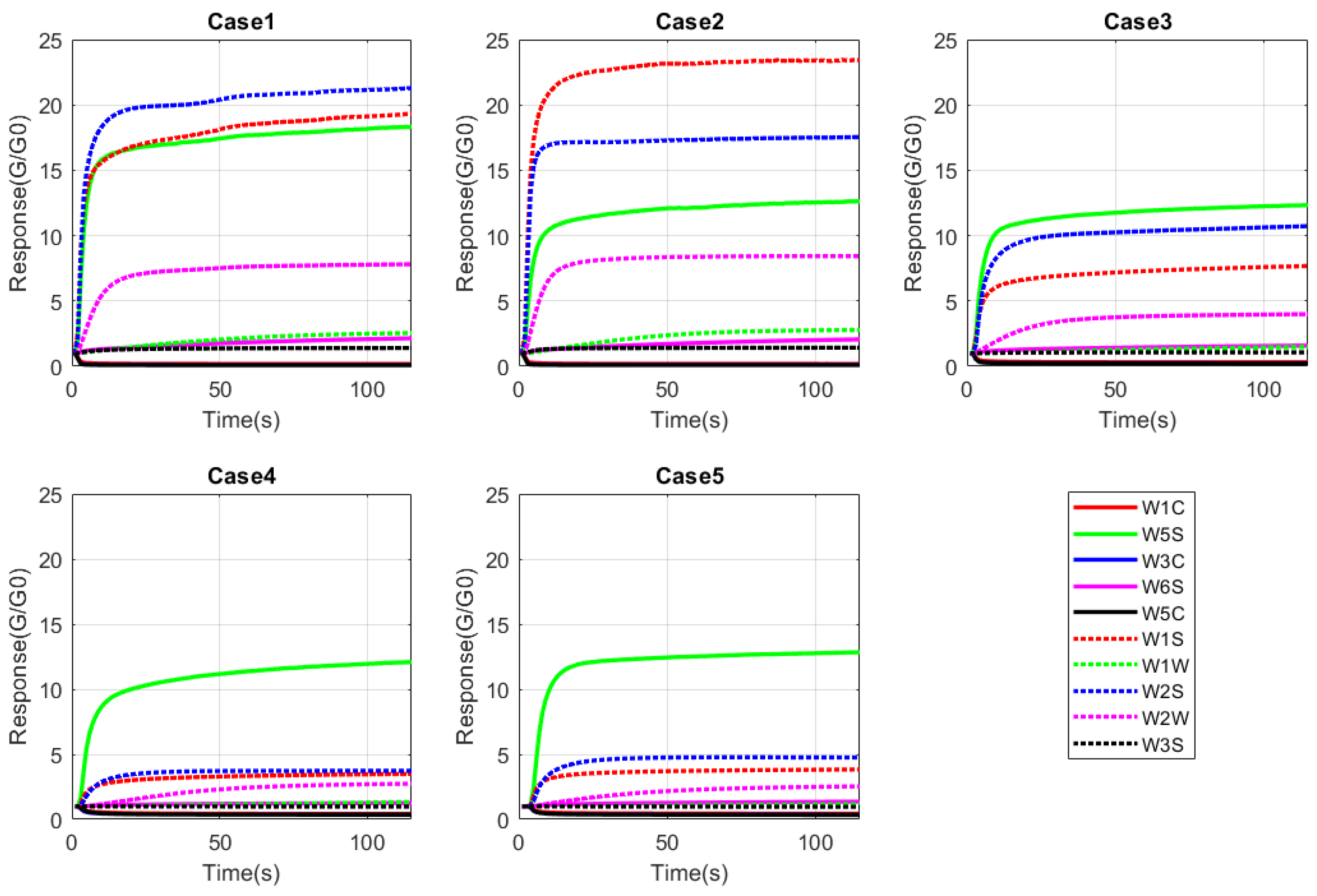

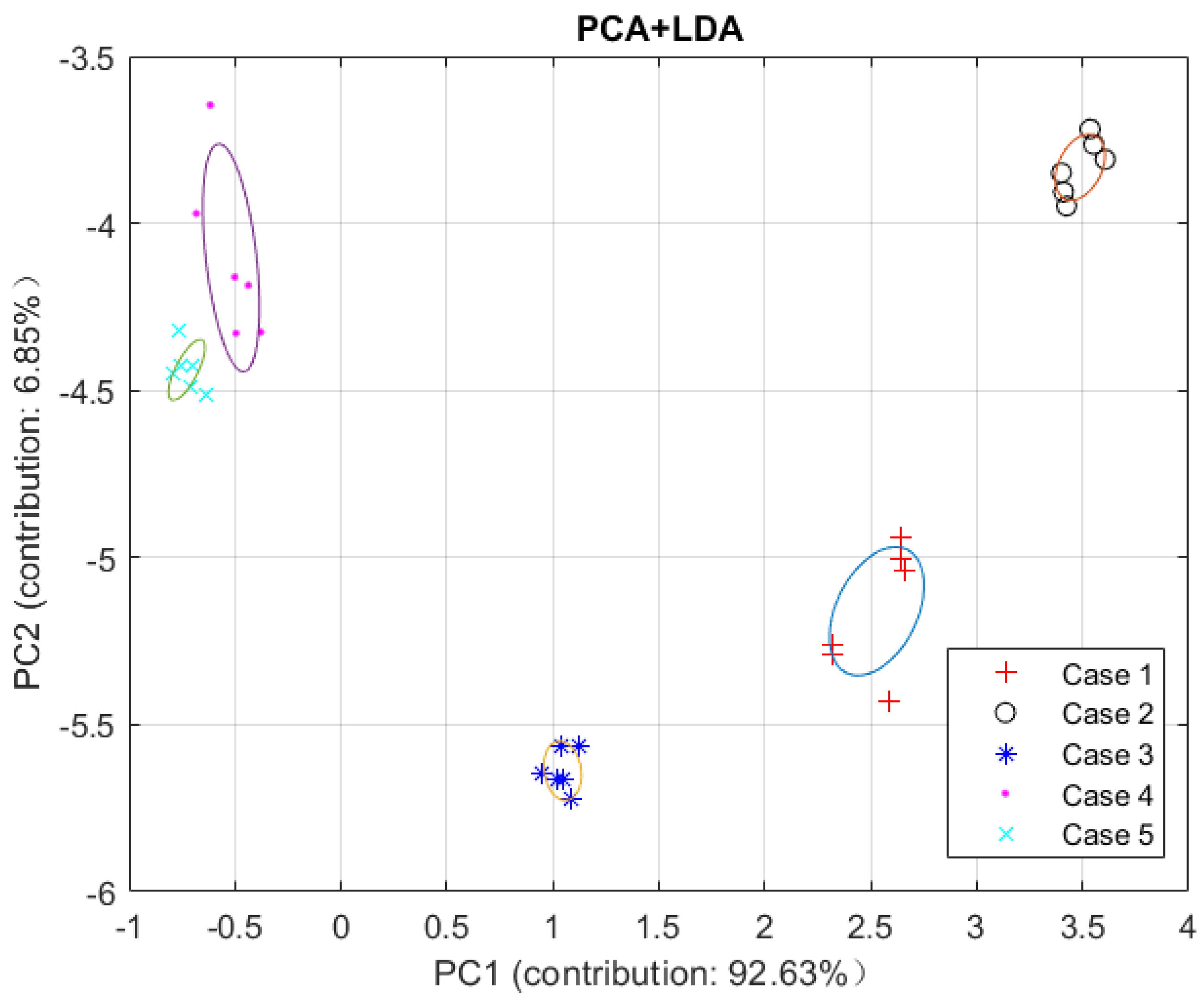

Figure 7 shows the responses of the training dataset. It is clear that the response patterns of the five cases were relatively different. In feature extraction, we simply selected the 15th, 30th, 45th, and 60th response values from the samples, considering that little change occurred after 60 s. The maximum response value and the differential values were extracted, as well. The dimensionality reduction was a combination of principal component analysis (PCA) and linear discriminant analysis (LDA). Pearson correlation was used for classification. Two principal components possessed a total of contribution of 99.48%.

Figure 8 shows that the classification was relatively good.

In the testing stage, responses sampled from the blending of four pure odorous chemicals were imported into the classification model. As shown in

Table 5, the results of the first four cases were satisfactory, in that all identifications were correct. Only one sample was mismatched, in the fifth case. In summary, the total accuracy in all cases was 96.67%, which was satisfactory to evaluate the effectiveness of reproducing odors.

4. Discussion

Unlike an olfactory display, which represents an odor by releasing a prepared odor source, an odor reproduction system reproduces an odor by proportionally blending several odor sources. Accordingly, two components may significantly impact the performance of the system:

Odor sources (fragrance sources) are a fundamental element in an odor reproduction system, since the ultimate purpose of an ORS is to represent different odors. The mechanisms of olfactory perception are yet unclear in biology, neurology, and psychology [

21]. A three-dimensional perceptual space can describe visible light, which has infinite frequencies in a narrow range of the spectrum, but the dimensionality of odor perceptual space is uncertain as of yet. J. B. Castro et al. [

22] applied a non-negative matrix factorization (NMF) technique to derive a 10-dimensional olfactory space from the published data set of Dravnieks [

23]. Meister suggested that the olfactory space may contain at most 20 dimensions [

24]. Bushdid et al. estimated that human beings can discriminate over one trillion odors [

25]. However, this was a controversial estimation [

24,

26]. Evidence has demonstrated that human beings may only discriminate at most 20 diverse odor percepts in an odor mixture [

27]. This suggests that the number of odor sources used in an odor reproduction system may be limited. Moreover, the physical and chemical properties (oil solubility, water-solubility, volatility, viscosity, vapor pressure, or surface tension) of odor sources may lead to failure in blending odorants. Therefore, the odor sources used in an ORS must be carefully selected.

The proportion blending process is characteristic of an odor reproduction system. The quantities of various kinds of odorants should be precisely controlled, as this determines the odor intensity. Heating odor sources (liquid or solid) is one solution for generating odors [

8]. Each odor source has a different evaporation rate, which is influenced by temperature, surface area, pressure, and airflow. The heating temperatures should be controlled below a certain threshold, to prevent scorching of the odor sources. The other way to generate odors is to atomize liquid sources by using piezoelectric transducers [

6,

7]. The atomizing quantity of odorants is determined by the size of transducers, the driving frequency, and the properties (surface tension, viscosity, and so on) of the odor sources. However, the problem that piezoelectric transducers fail to atomize liquids with higher viscosity arises. Moreover, the surface tension of a liquid impacts on the atomizing efficiency of a piezoelectric transducer [

28].

Professional sniffers and odor identification instruments are two ways to evaluate the effectiveness of an odor reproduction system. Professional sniffers are panelists who can discriminate odors correctly. These panelists sniff an odor and give a mark. However, this requires professional training, which is a complicated and time-consuming task. Furthermore, human panelists are easily influenced by their bodily conditions and are sensitive to psychological fluctuations. The other way to evaluate an odor reproduction system is by using an odor identification instrument, such as Gas Chromatography–Mass Spectrometry (GC–MS), Gas Chromatography–Olfactometry (GC–O), or electronic nose instruments. Electronic noses have the advantage of short monitoring time and portability, which makes them suitable instruments for in-field monitoring [

29]. An electronic nose with an array of gas sensors has the capacity for odor identification if the gas sensors are carefully selected and a suitable classification technique is used. In our study, a commercial electronic nose, PEN3, was applied to evaluate the performance of the proposed ORS. It revealed a satisfactory result, although a failure of identification happened. We suspected that the atomizing rates of each micro-porous piezoelectric transducer were slightly different, which influenced the accuracy of the proportion-blending process. Some sensors may have weak selectivity for odorous compounds. Moreover, a more suitable pattern recognition technique may increase the accuracy of identification, especially when an odor mixture contains more odorous chemicals.

The gas sensor component was embedded in the system for two reasons. First, the sensor can be used to monitor the cleanliness of the chamber. Second, it can also be used to measure each atomizing rate of the 16 micro-porous transducers, which is a problem requiring investigation. In the current design, a metal-oxide semiconductor (MOS) gas sensor TGS2600 is used. However, MOS-type sensors have a high selectivity for ethanol, which makes the identification of other chemicals in an odor mixture impossible [

30]. In an odor reproduction system, the gas sensor should satisfy several requirements: Average sensitivity to various types of odorous compounds, corrosion resistance against some odorous compounds, and short response and recovery times.