Photovoltaic Module Array Global Maximum Power Tracking Combined with Artificial Bee Colony and Particle Swarm Optimization Algorithm

Abstract

:1. Introduction

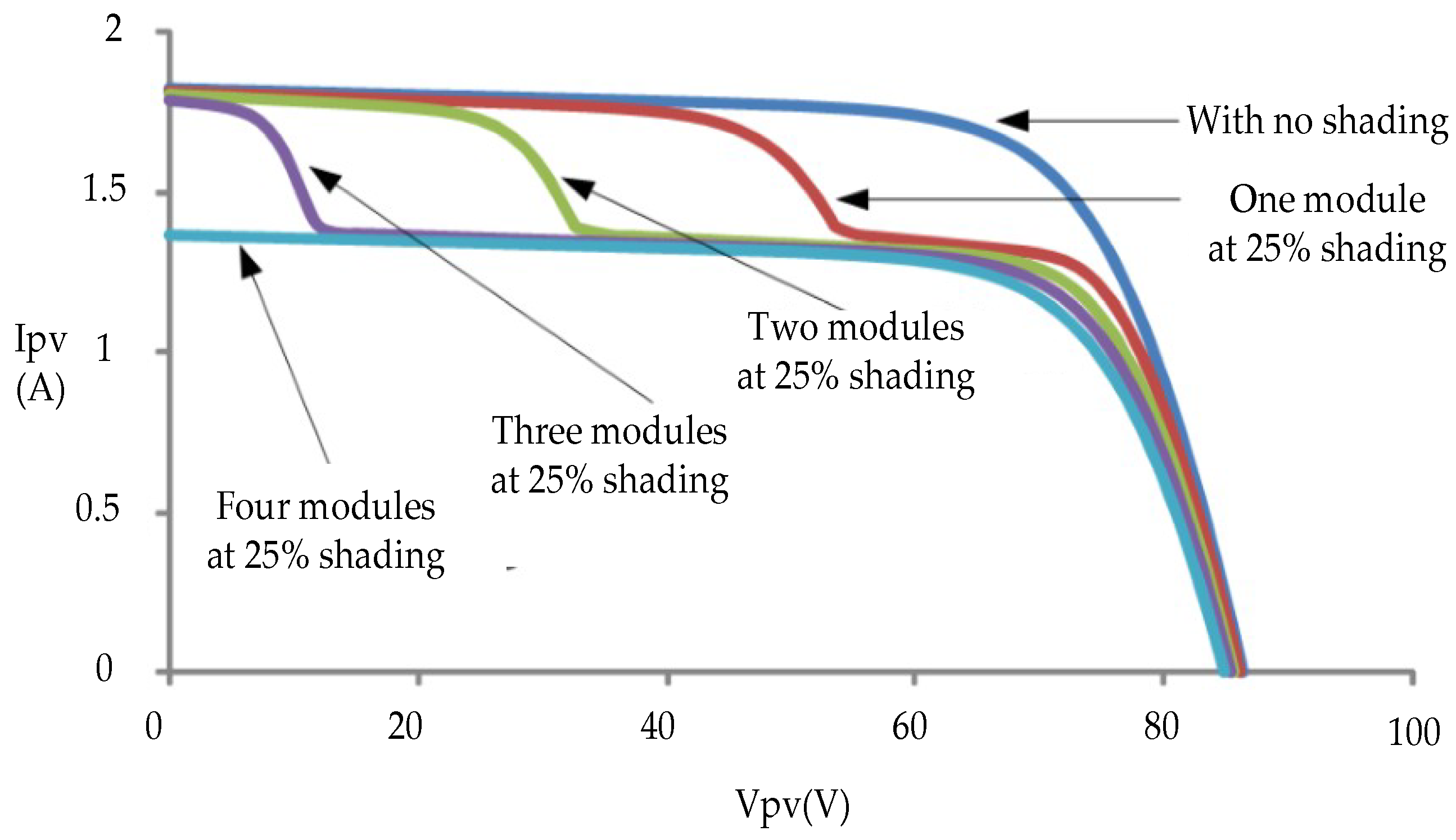

2. The Characteristics of a Photovoltaic Module Array

3. Particle Swarm Optimization Algorithm

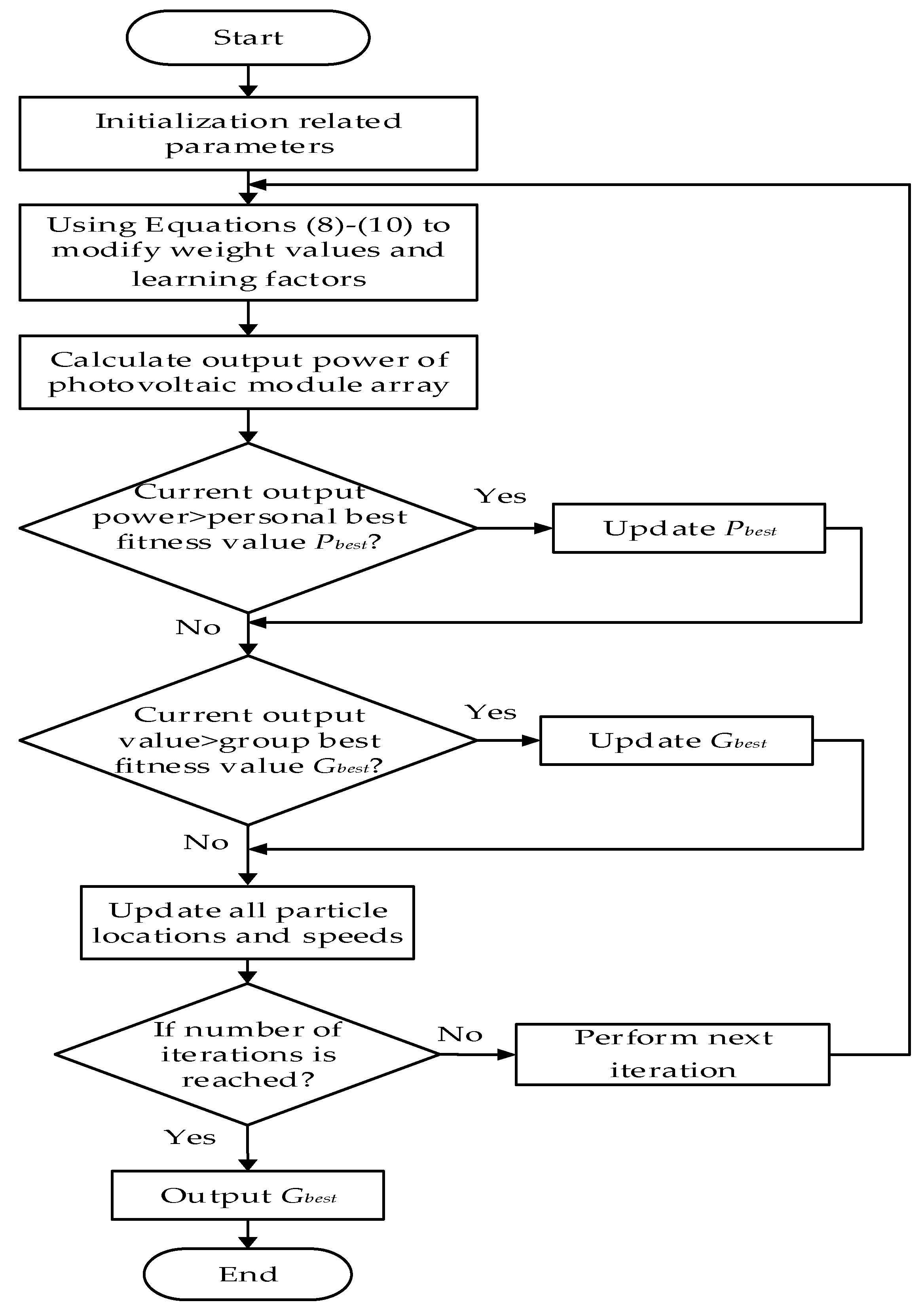

3.1. Traditional Particle Swarm Optimization Algorithm

- Set the number of particles, the maximum number of iterations, weight values, and learning factors.

- Initialize the particle swarm, and randomly set the location and speed of each particle.

- Substitute the initialization location into the objective function to evaluate the fitness function value of the particles.

- The fitness function values of each particle are compared to each other to select a best value . If this best value is larger than the one we got in the previous iteration, it will be used to replace the optimal value obtained the last time.

- and the swarm’s best memory value are compared. If is superior to , it is updated.

- The core formula of the PSO is used to update the particle speed and location. The formula is as shown in Equations (1) and (2).

- If the termination conditions are met, tracking stops; otherwise, repeat Step 4 through Step 6, and the termination condition is to reach the highest number of iterations.

- Weight value (W): Represents the correlation with the last moving distance of its own particles.

- Cognition learning factor (C1): Represents the learning parameters related to its own particles.

- Social learning factor (C2): Represents the learning parameters related to other particles.

- : Represents the moving speed of i number of particles at j number of iterations.

- : Represents the location of i number of particles at j number of iterations.

- rand1(): Represents the first set of random number generator, which produces values between 0 and 1.

- rand2(): Represents the second set of random number generator, which produces values between 0 and 1.

- : Represents the personal best solution of i number of particles.

- : Represents the best solution of the group.

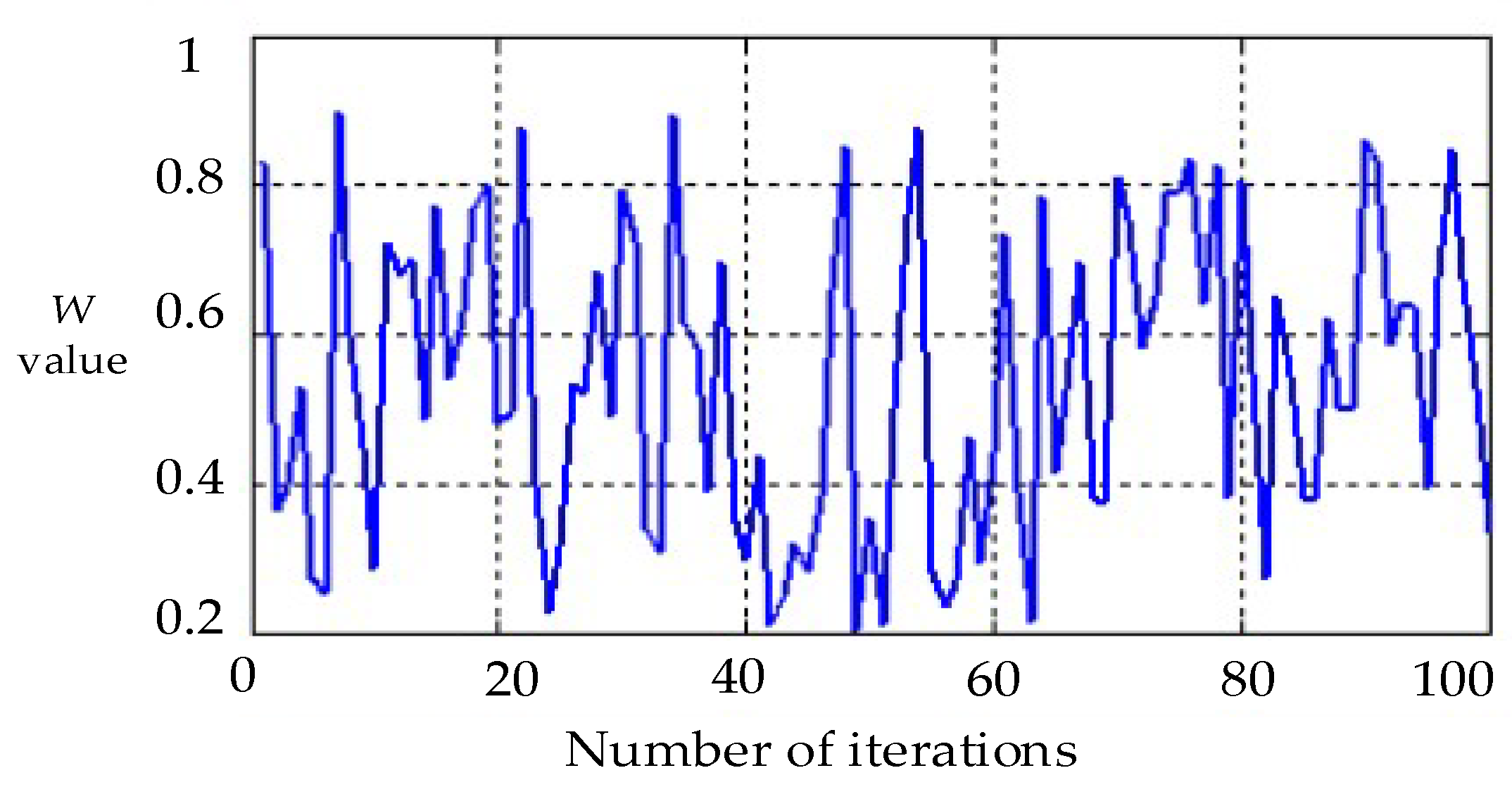

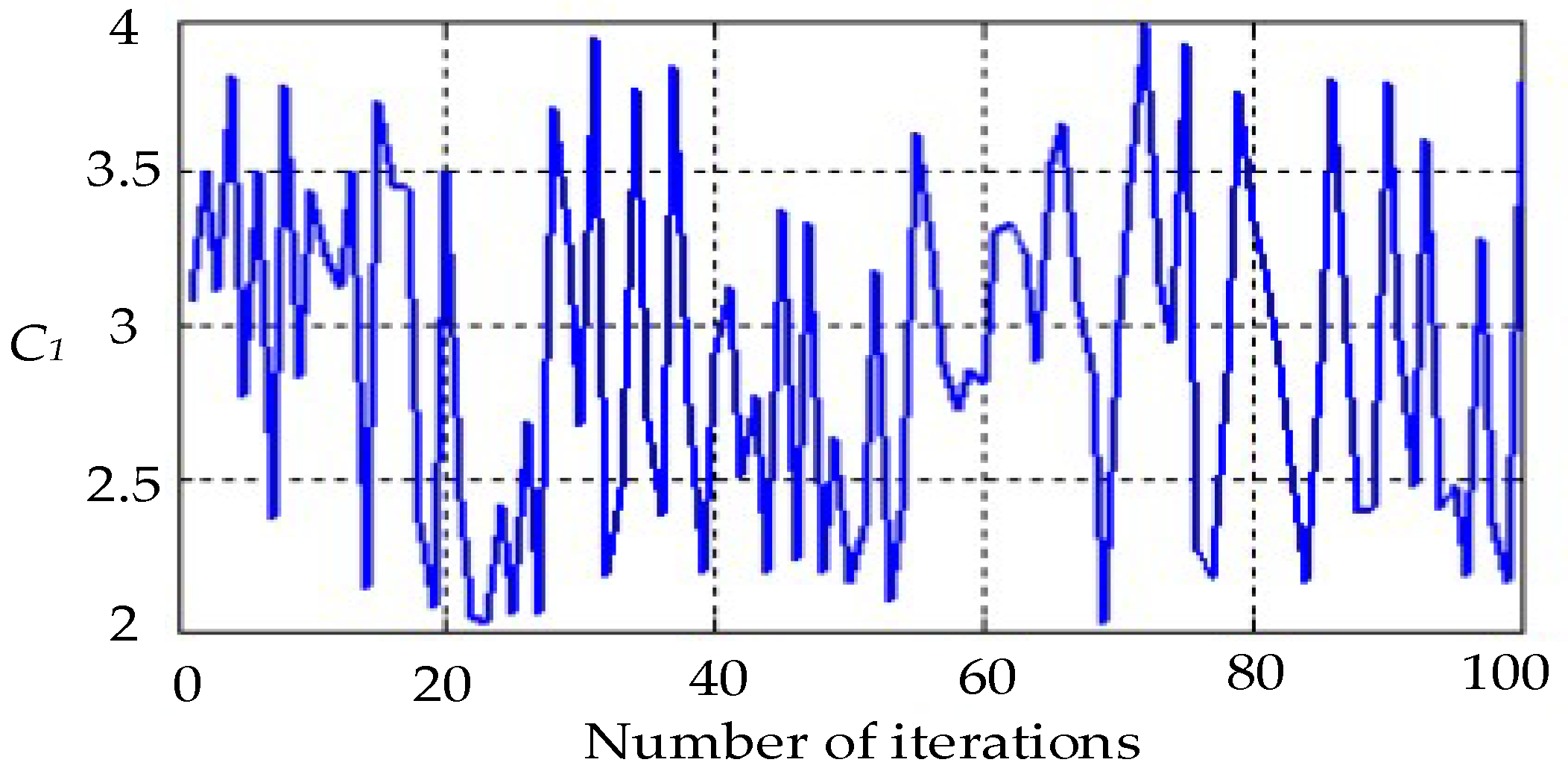

3.2. Improved Article Swarm Optimization Algorithm

- Upper limit of weight value (Wmax): Represents the upper limit of the correlation with the moving distance of its own particles.

- Lower limit of weight value (Wmin): Represents the lower limit of the correlation with the moving distance of its own particles.

- : Represents the current number of iterations.

- n: Represents the highest number of iterations.

- Upper limit of cognition learning factor (C1,max): Represents the upper limit of the learning parameters related to its own particles.

- Lower limit of cognition learning factor (C1,min): Represents the lower limit of the learning parameters related to its own particles.

- Upper limit of social learning factor (C2,max): Represents the upper limit of the learning parameters related to other particles.

- Lower limit of social learning factor (C2,min): Represents the lower limit of the learning parameters related to other particles.

3.3. Combining Artificial Bee Colony Algorithm

4. Simulation Results

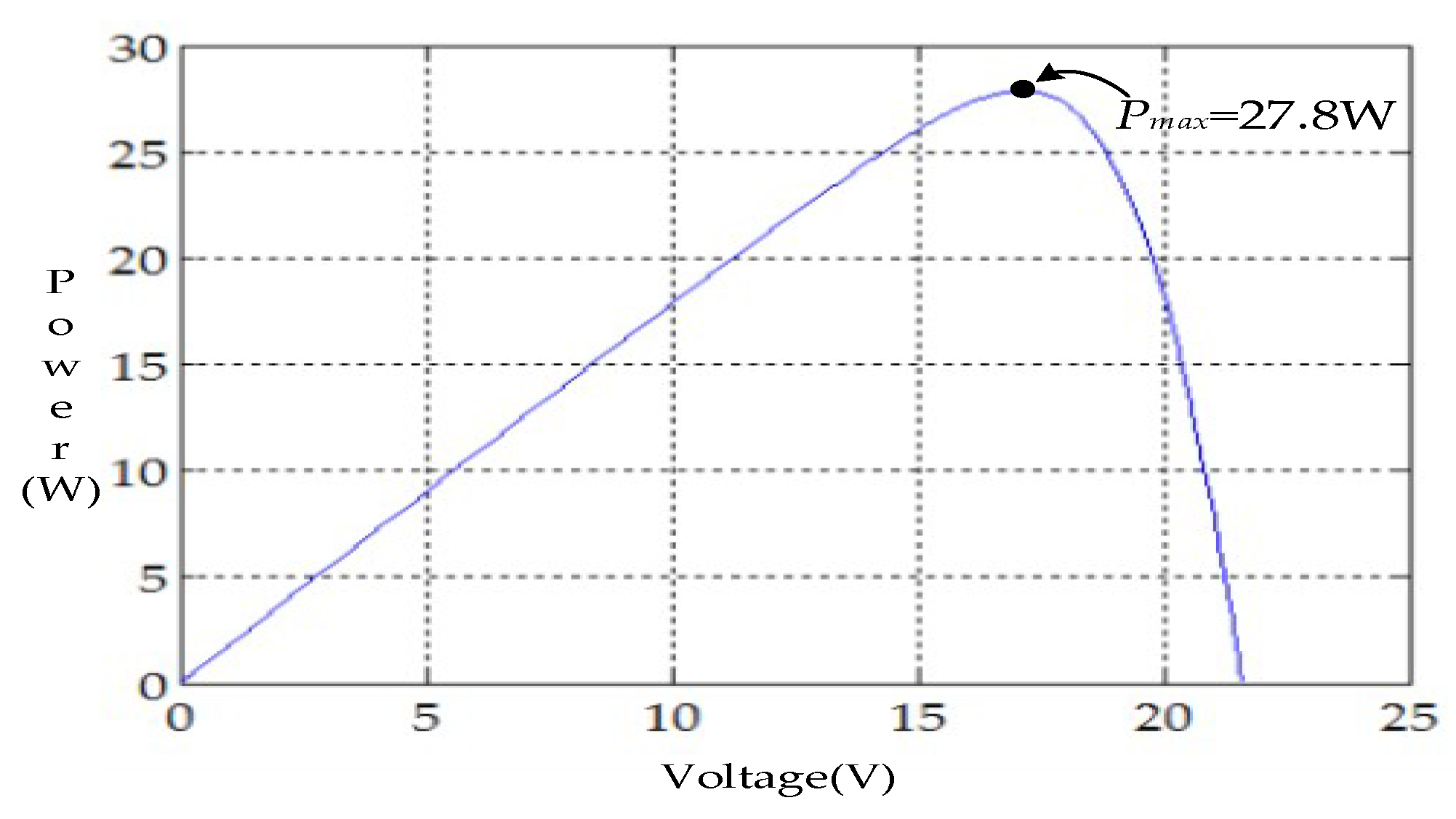

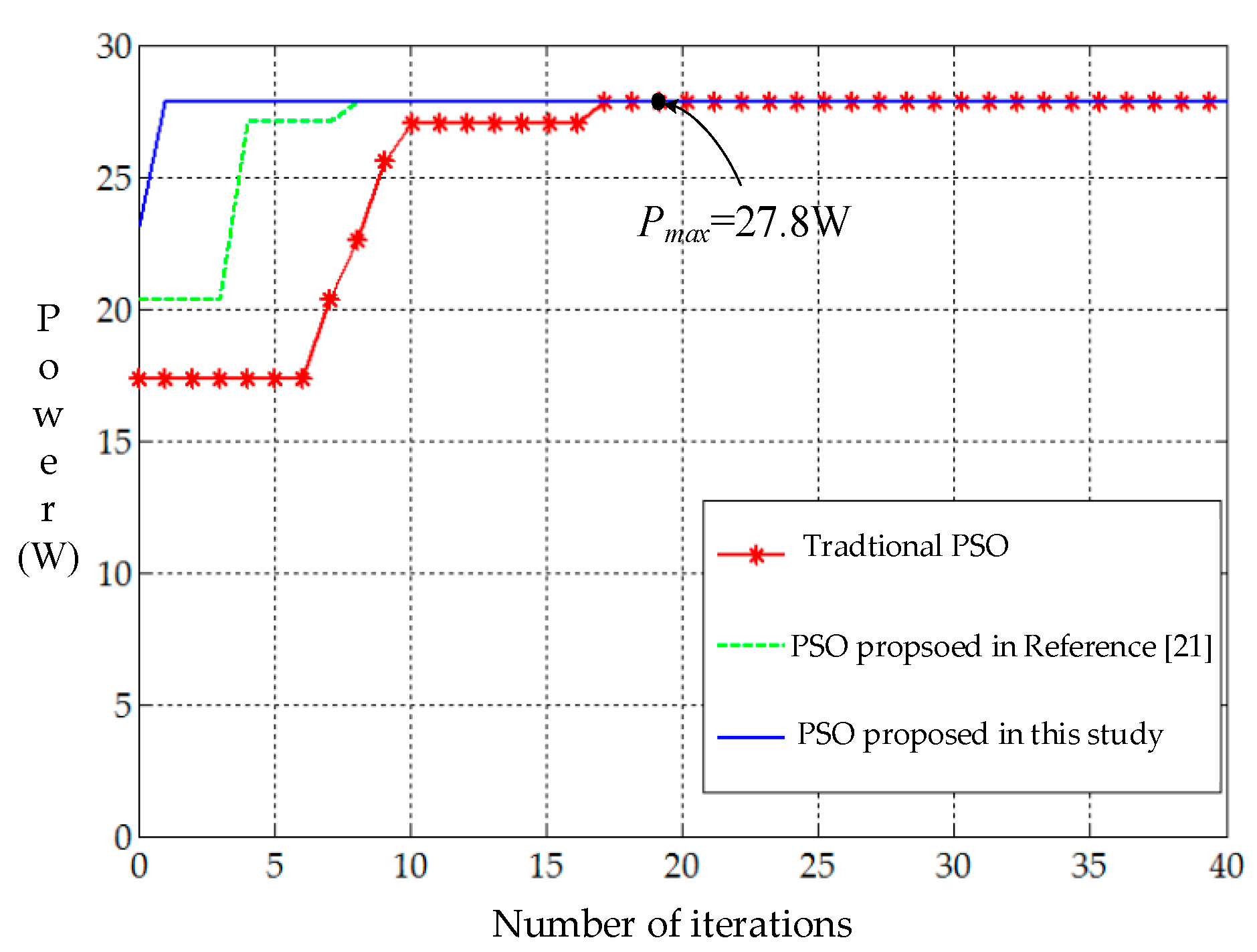

4.1. Case 1 (One-Series, One-Parallel: Shading 0%)

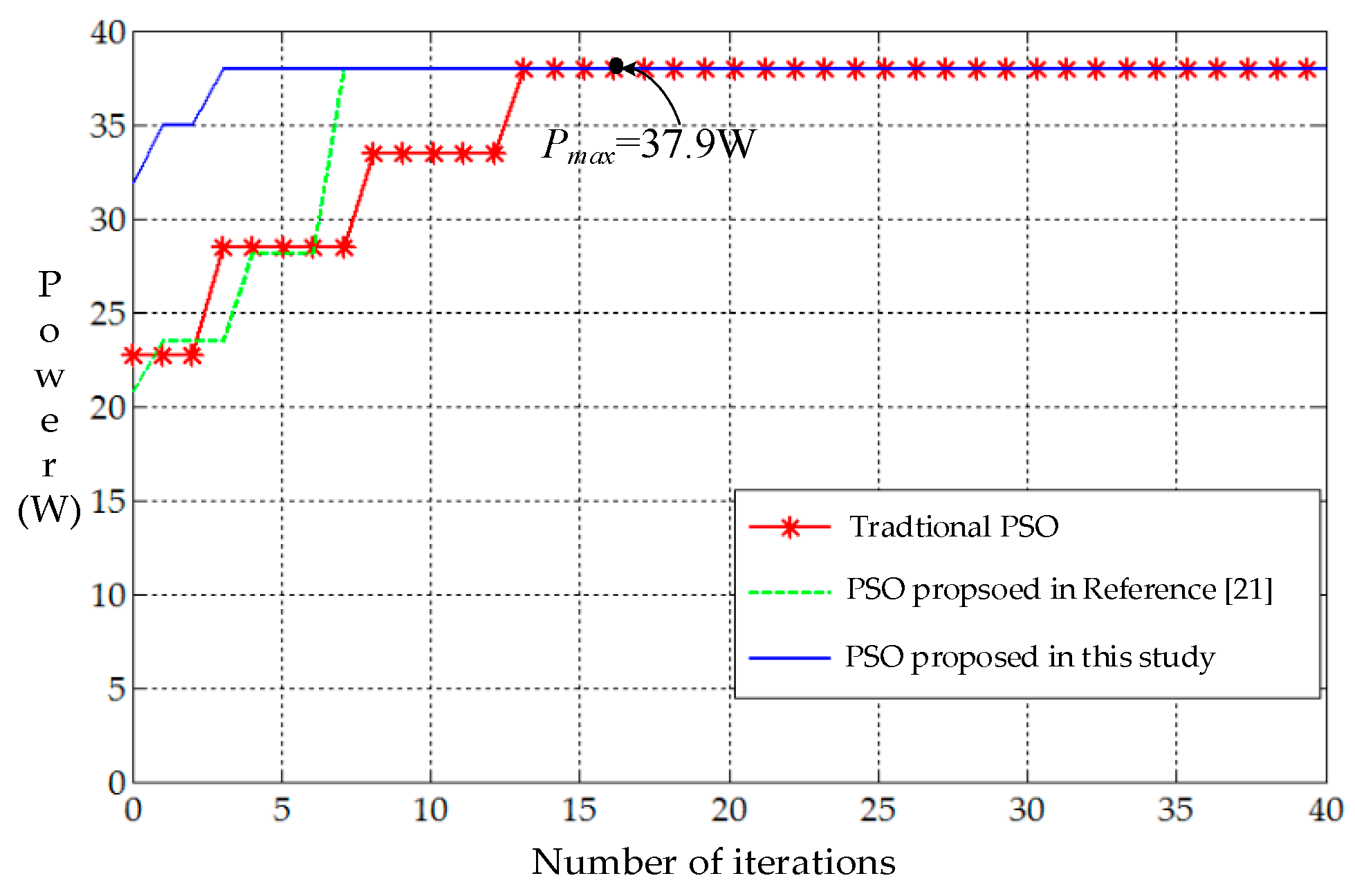

4.2. Case 2 (Two-Series One-Parallel: Shading 0% + Shading 40%)

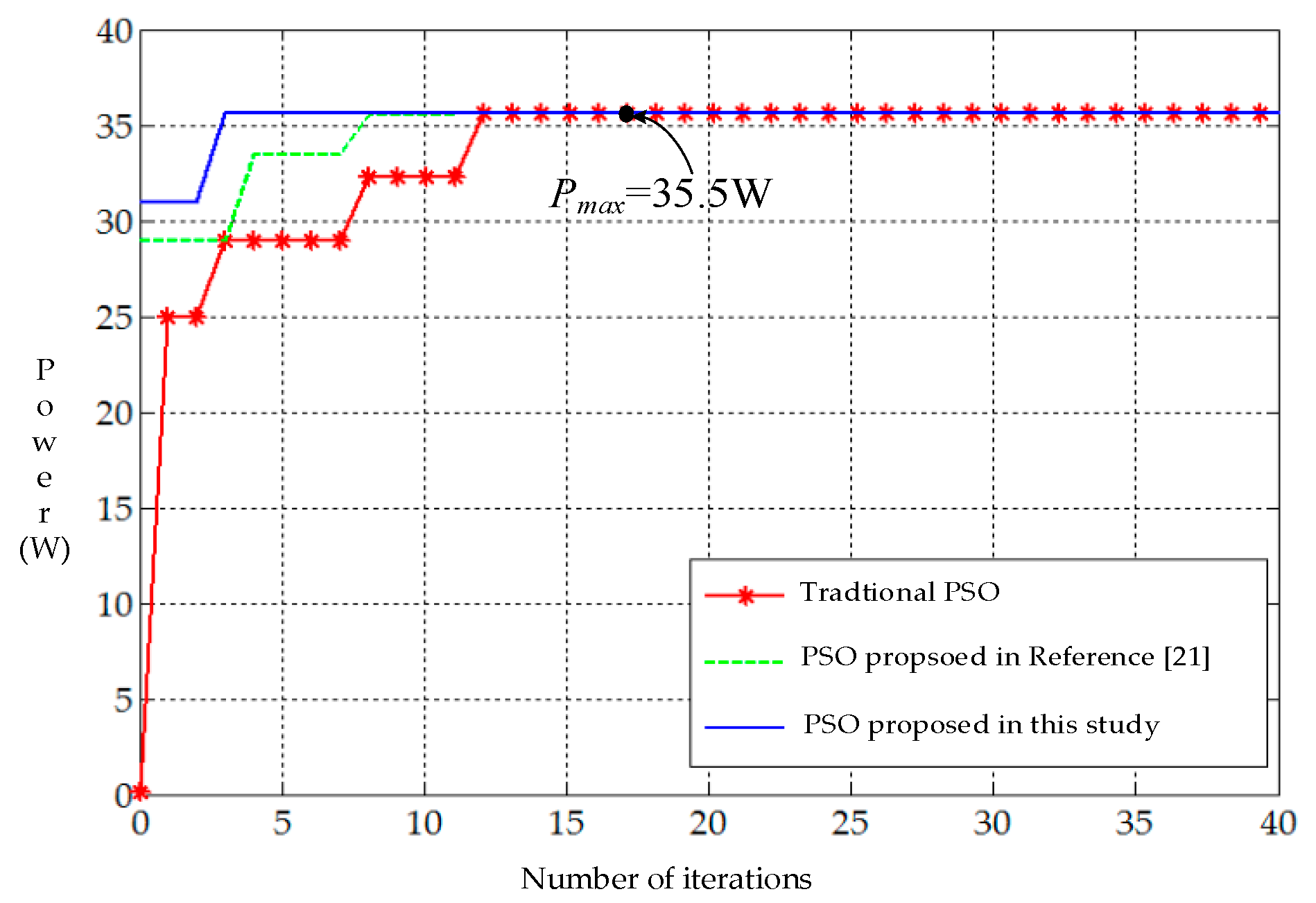

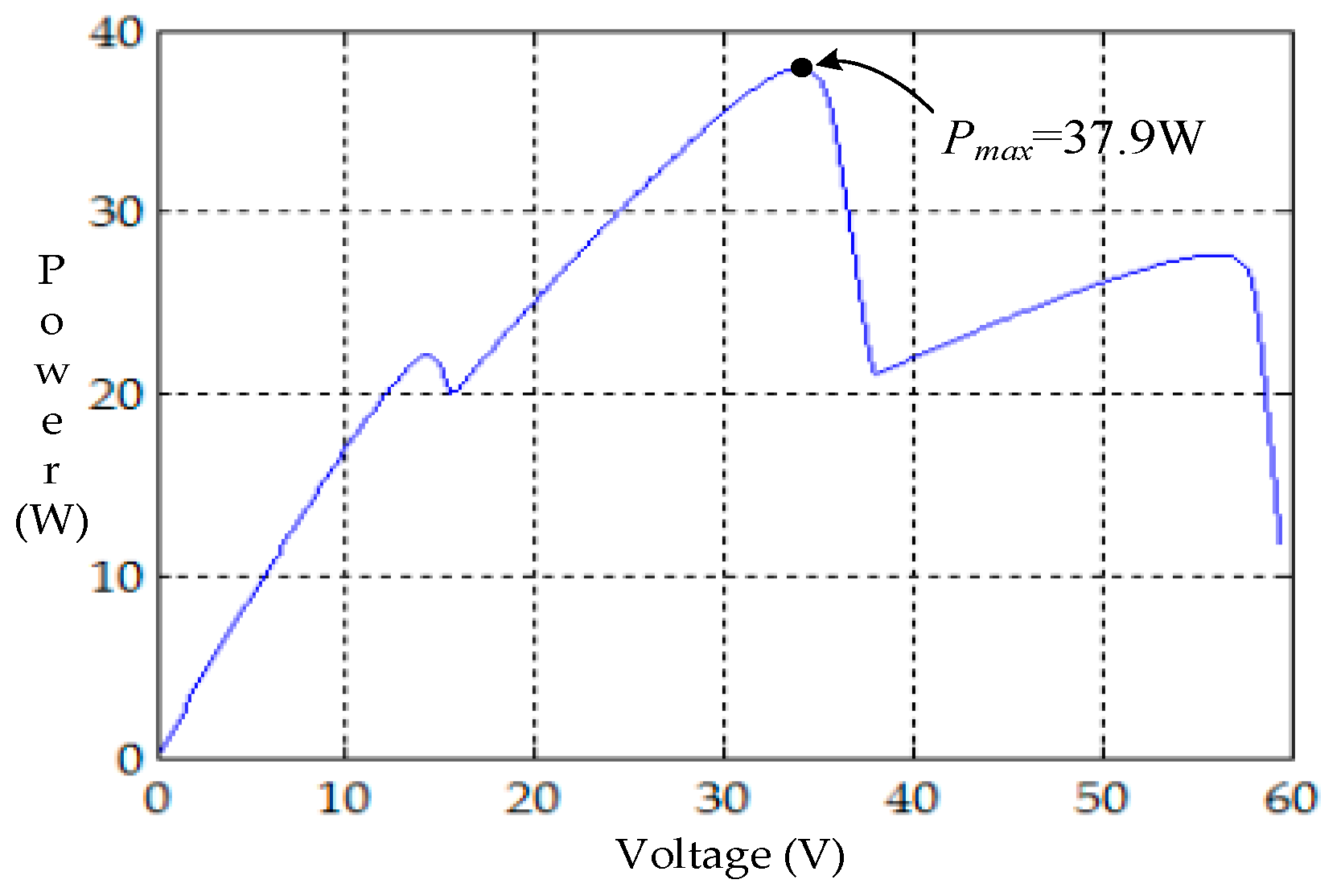

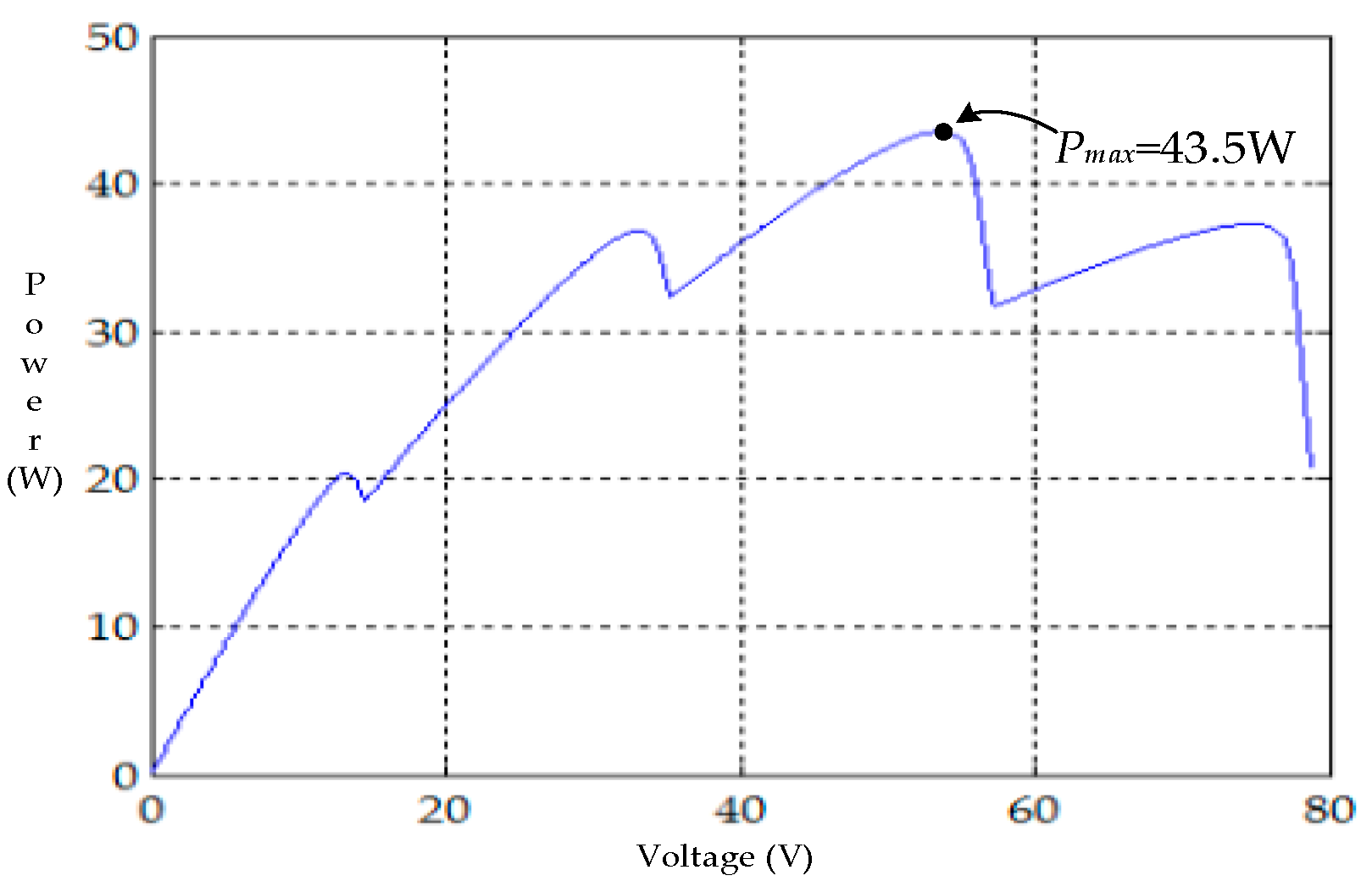

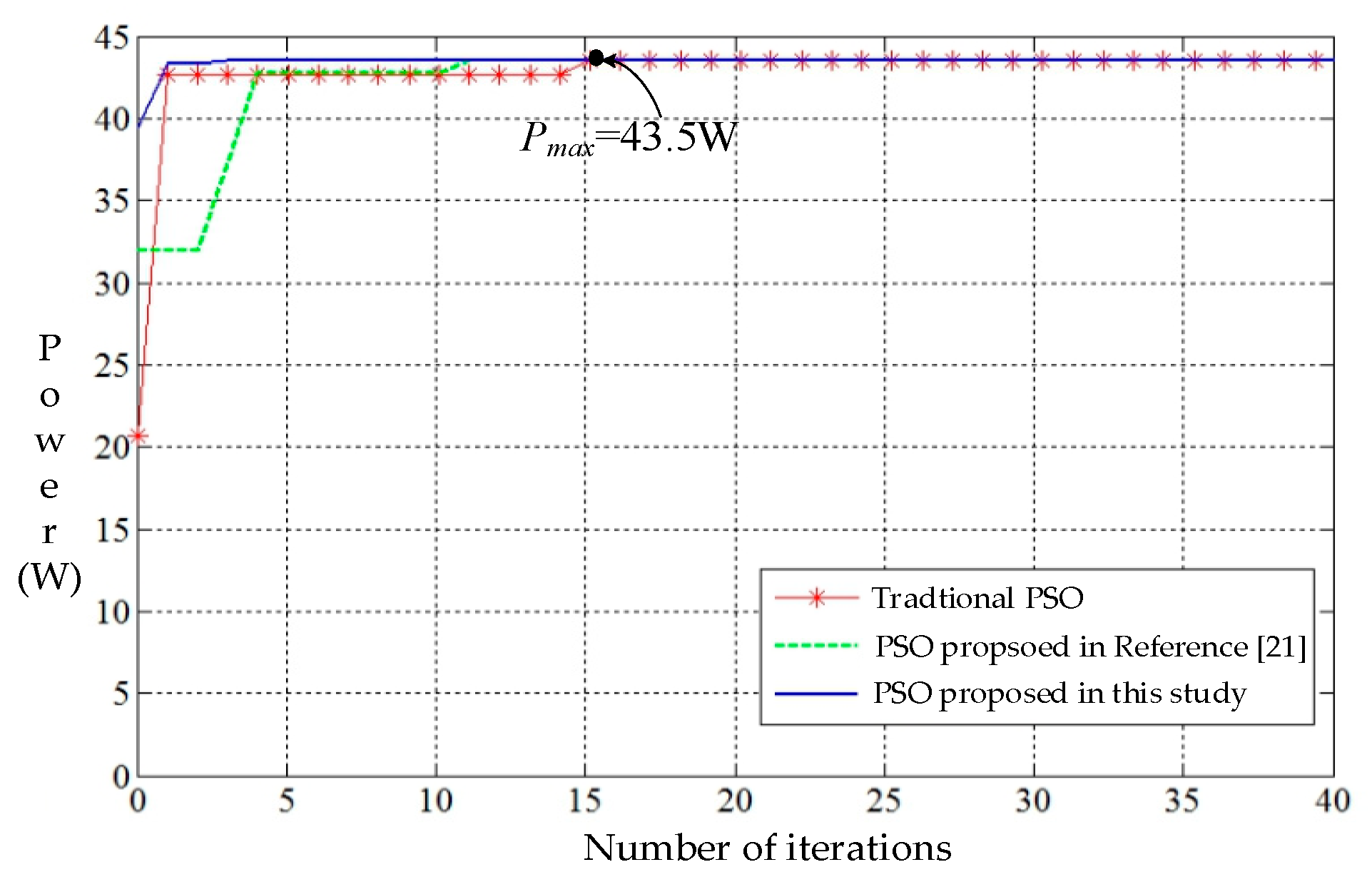

4.3. Case 3 (Three-Series One-Parallel: Shading 0% + Shading 30% + Shading 70%)

4.4. Case 4 (Four-Series One-Parallel: Shading 0% + Shading 30% + Shading 50% + Shading 70%)

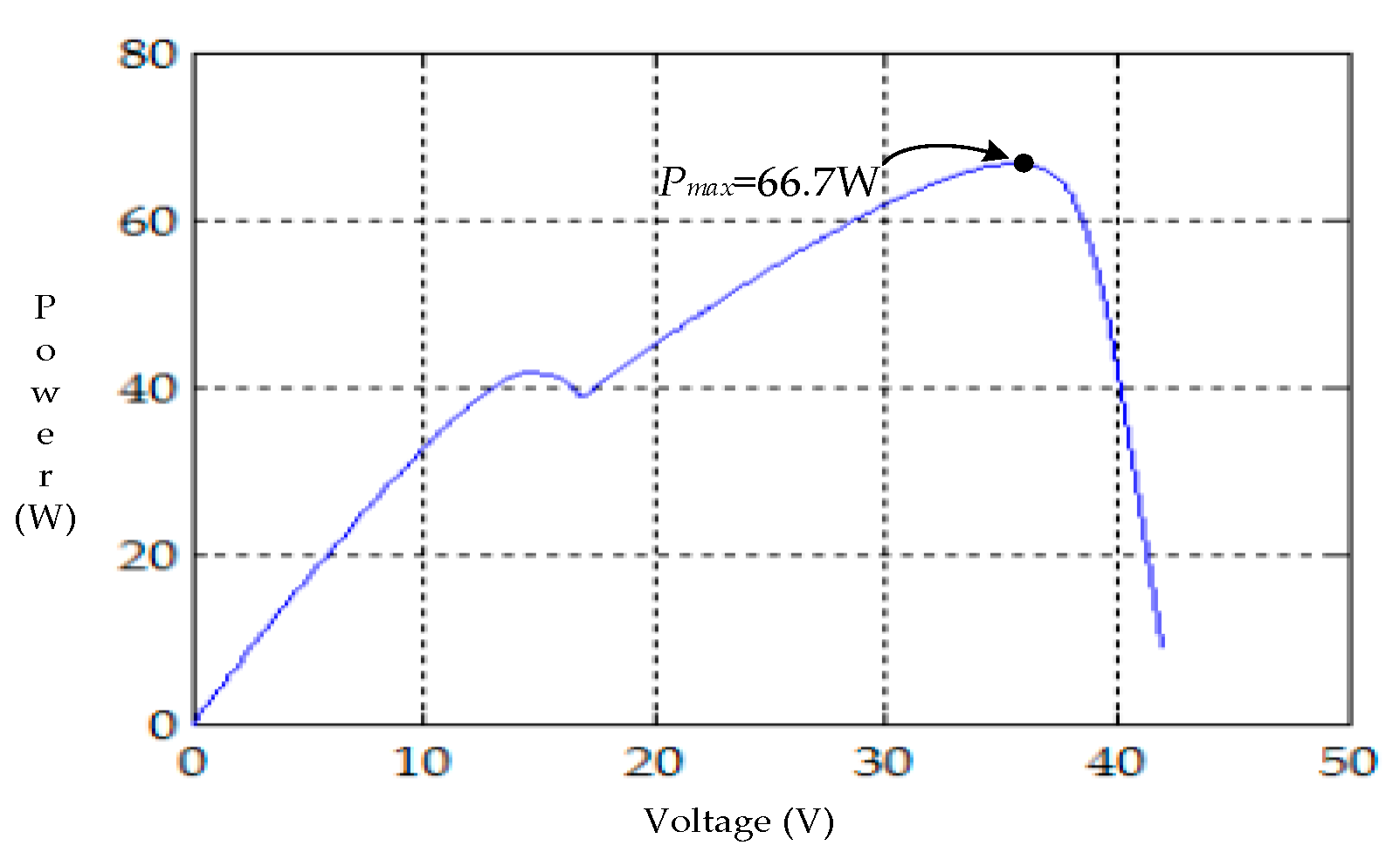

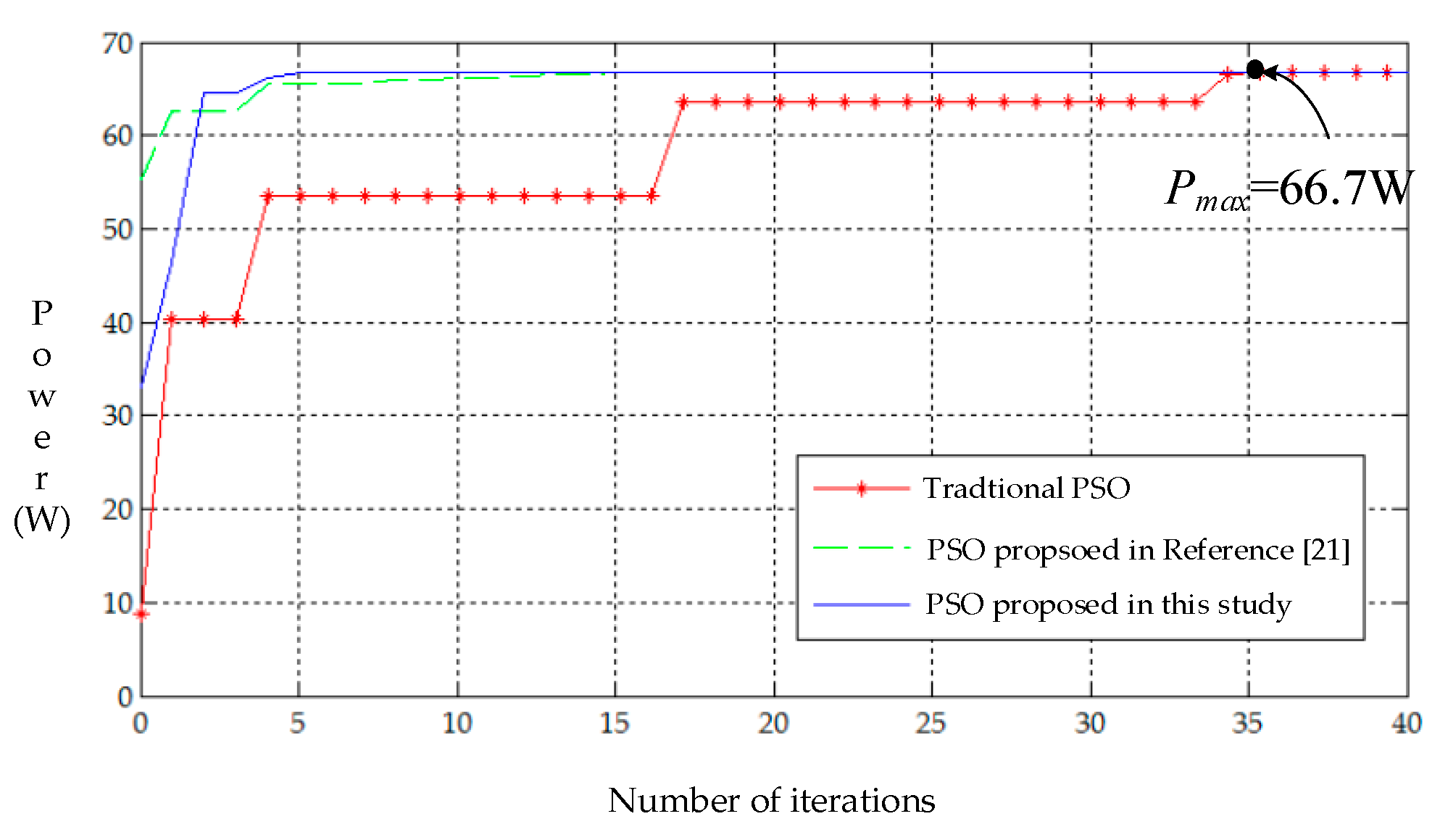

4.5. Case 5 (Two-Series Two-Parallel: (Shading 30% + Shading 0%)//(Shading 0% + Shading 50%))

4.6. Case Simulation Result Comparison and Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Masoum, M.A.S.; Sarvi, M. Voltage and current based MPPT of solar arrays under variable insolation and temperature conditions. In Proceedings of the 43th International Universities Power Engineering Conference (UPEC), Padova, Italy, 1–4 September 2008; pp. 39–43. [Google Scholar]

- Masoum, M.A.S.; Dehbonei, H.; Fuchs, E.F. Theoretical and experimental analyses of photovoltaic systems with voltage and current-based maximum power-point tracking. IEEE Trans. Energy Conver. 2002, 17, 514–522. [Google Scholar] [CrossRef]

- Esram, T.T.; Chapman, P.L. Comparison of photovoltaic array MPP tracking techniques. IEEE Trans. Energy. Conver. 2007, 22, 439–449. [Google Scholar] [CrossRef]

- Femia, N.; Granozio, D.; Petrone, G.; Vitelli, M. Predictive and adaptive MPPT perturb and observe method. IEEE Trans. Aero. Elec. Sys. 2007, 43, 934–950. [Google Scholar] [CrossRef]

- Liu, F.; Duan, B.; Kang, Y. A variable step size INC MPPT method for PV systems. IEEE Trans. Ind. Electron. 2008, 55, 2622–2628. [Google Scholar]

- Wang, Y.J.; Hsu, P.C. Analytical modeling of partial shading and different orientation of photovoltaic modules. IET. Renew. Power. Gen. 2010, 4, 272–282. [Google Scholar] [CrossRef]

- Kottas, T.L.; Boutalis, Y.B.; Karis, A.D. New MPP tracker for PV arrays using fuzzy controller in close cooperation with fuzzy cognitive networks. IEEE Trans. Energy. Conver. 2006, 21, 793–803. [Google Scholar] [CrossRef]

- Ramaprabba, R.; Gothandaraman, V.; Kanimozhi, K.; Divya, R.; Mathur, B.L. Maximum power point tracking using GA-optimized artificial neural network for solar PV system. In Proceedings of the 1st International Conference on Electrical Energy Systems (ICEES), Newport Beach, CA, USA, 3–5 January 2011; pp. 264–268. [Google Scholar]

- Veerachary, T.; Senjyu, T.; Uezato, K. Neural-network-based maximum-power-point tracking of coupled-inductor interleaved-boost-converter-supplied PV system using fuzzy controller. IEEE Trans. Ind. Electron. 2003, 50, 749–758. [Google Scholar] [CrossRef]

- Sundareswaran, K.; Senjyu, T.; Nayak, P.S.R.; Simon, S.P.; Palani, S. Enhanced energy output from a PV system under partial shaded conditions through artificial bee colony. IEEE Trans. Energy. Conver. 2015, 6, 198–209. [Google Scholar] [CrossRef]

- Chao, K.H.; Chiu, C.L. Design and implementation of an intelligent maximum power point tracking controller for photovoltaic systems. Int. Rev. Electr. Eng. 2012, 7, 3759–3768. [Google Scholar]

- Kvasov, D.E.; Menniti, D.; Pinnarelli, A.; Sergeyev, Y.D.; Sorrentino, N. Tuning fuzzy power-system stabilizers in multi-machine systems by global optimization algorithms based on efficient domain partitions. Electr. Power Syst. Res. 2008, 78, 1217–1229. [Google Scholar] [CrossRef]

- Kvasov, D.E.; Sergeyev, Y.D. Lipschitz global optimization methods in control problems. Automat. Rem. Contr. 2013, 78, 1435–1448. [Google Scholar] [CrossRef]

- Kvasov, D.E.; Mukhametzhanov, M.S. Metaheuristic vs. deterministic global optimization algorithms: The univariate case. Appl. Math. Comput. 2018, 318, 245–259. [Google Scholar] [CrossRef]

- Sergeyev, Y.D.; Kvasov, D.E.; Mukhametzhanov, M.S. On the efficiency of nature-inspired metaheuristics in expensive global optimization with limited budget. Sci. Rep. 2018, 8, 453. [Google Scholar] [CrossRef] [PubMed]

- Solar Pro official website. Available online: https://www.lapsys.co.jp/english/products/download.html (accessed on 12 April 2019).

- Kennedy, J.; Eberhart, R.C. Particle swarm optimization. In Proceedings of the IEEE International Conference on Neural Networks (ICNN), Perth, Australia, 27 November–1 December 1995; pp. 1942–1948. [Google Scholar]

- Eberhart, R.C.; Kennedy, J. A new optimizer using particle swarm theory. In Proceedings of the sixth International Symposium on Micro Machine and Human Science (MHS), Nagoya, Japan, 4–6 October 1995; pp. 39–43. [Google Scholar]

- Srinivasan, D.; Loo, W.H.; Cheu, R.L. Traffic incident detection using particle swarm optimization. In Proceedings of the IEEE International Conference on Swarm Intelligence Symposium (SIS), Indianapolis, IN, USA, 26 April 2003; pp. 144–151. [Google Scholar]

- Han, W.H.; Yang, P.; Ren, H.; Sun, J. Comparison study of several kinds of inertia weights for PSO. In Proceedings of the IEEE International Conference on Progress in Informatics and Computing (PIC), Shanghai, China, 10–12 December 2010; pp. 280–284. [Google Scholar]

- Chang, L.Y.; Chung, Y.N.; Chao, J.J. Smart global MPP tracking controller of photovoltaic module arrays. Energies 2018, 11, 567. [Google Scholar] [CrossRef]

- Liu, Y.; Ling, X.; Liang, Y. Improved artificial bee colony algorithm with mutual learning. J. Syst. Eng. Electron. 2012, 2, 265–275. [Google Scholar] [CrossRef]

| Parameter Name | Parameter Setting Value |

|---|---|

| Number of particles | 4 |

| Number of iterations | 100 |

| Weight value W | 0.4 |

| Cognition learning factor C1 | 2 |

| Social learning factor C2 | 2 |

| Parameter Name | Parameter Setting Value |

|---|---|

| Number of particles | 4 |

| Number of iterations | 100 |

| Upper limit of weight value Wmax | 0.9 |

| Lower limit of weight value Wmin | 0.2 |

| Upper limit of cognition learning factor C1,max | 4 |

| Lower limit of cognition learning factor C1,min | 2 |

| Upper limit of social learning factor C2,max | 4 |

| Lower limit of social learning factor C2,min | 2 |

| Parameter | Value |

|---|---|

| Rated maximum output power () | 27.8 W |

| Current at maximum output power point () | 1.63 A |

| Voltage at maximum output power point () | 17.1 V |

| Short-circuit current () | 1.82 A |

| Open-circuit voltage () | 21.6 V |

| Case | Shading Condition | P–V Curve Peaks |

|---|---|---|

| 1 | One-series, one-parallel connected: shading 0% | One peak |

| 2 | Two-series, one-parallel connected: shading 0% + shading 40% | Two peaks |

| 3 | Three-series, one-parallel connected: shading 0% + shading 30% + shading 70% | Three peaks |

| 4 | Four-series, one-parallel connected: shading 0% + shading 30% + shading 50% + shading 70% | Four peaks |

| 5 | Two-series, two-parallel connected: (shading 30% + shading 0%)//(shading 0% + shading 50%) | Two peaks |

| Case | Number of Iterations | ||

|---|---|---|---|

| Traditional PSO | PSO Proposed in Reference [21] | PSO Proposed in this Study | |

| 1 | 17 | 5 | 2 |

| 2 | 12 | 6 | 3 |

| 3 | 11 | 7 | 2 |

| 4 | 15 | 11 | 3 |

| 5 | 34 | 15 | 5 |

| Case | Number of P–V Curve Peaks | Average Number of Iterations/Standard Deviation | ||

|---|---|---|---|---|

| Traditional PSO | PSO Proposed in Reference [21] | PSO Proposed in this Study | ||

| 1 | One peak | 8.58/3.95 | 7.2/3.16 | 6.45/2.80 |

| 2 | Two peaks | 18.63/9.21 | 11.5/6.54 | 8.4/3.42 |

| 3 | Three peaks | 31.14/12.21 | 24.94/6.60 | 14.05/4.2 |

| 4 | Four peaks | 31.27/12.99 | 18.3/8.69 | 14.38/4.99 |

| 5 | Two peaks | 22.7/5.66 | 17.48/4.42 | 10.8/3.13 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chao, K.-H.; Hsieh, C.-C. Photovoltaic Module Array Global Maximum Power Tracking Combined with Artificial Bee Colony and Particle Swarm Optimization Algorithm. Electronics 2019, 8, 603. https://doi.org/10.3390/electronics8060603

Chao K-H, Hsieh C-C. Photovoltaic Module Array Global Maximum Power Tracking Combined with Artificial Bee Colony and Particle Swarm Optimization Algorithm. Electronics. 2019; 8(6):603. https://doi.org/10.3390/electronics8060603

Chicago/Turabian StyleChao, Kuei-Hsiang, and Cheng-Chieh Hsieh. 2019. "Photovoltaic Module Array Global Maximum Power Tracking Combined with Artificial Bee Colony and Particle Swarm Optimization Algorithm" Electronics 8, no. 6: 603. https://doi.org/10.3390/electronics8060603

APA StyleChao, K.-H., & Hsieh, C.-C. (2019). Photovoltaic Module Array Global Maximum Power Tracking Combined with Artificial Bee Colony and Particle Swarm Optimization Algorithm. Electronics, 8(6), 603. https://doi.org/10.3390/electronics8060603