1. Introduction

Light Emitting Diode (LED) technology is increasingly popular these days and much research is focused on different aspects of this technology, such as LED topology, LED drivers, power or voltage analysis and LED radiation patterns [

1,

2,

3]. Recently, the new application possibilities offered by LEDs, together with the evolution of solid state technology, are bringing innovation in both general and accent lighting. In the literature, as well as in industries, we have a growing interest in LED light sources applications thanks to their stability, reliability and easy application of digital control [

4]. Typically, LED sources have a fixed Correlated Color Temperature (CCT) and color rendering while the light intensity can be adjusted through LED drivers allowing digital control of the light emission [

5,

6]. In particular, the Tunable White technology is highly developed and widespread and light quality can now be perfectly adapted to match with different scenarios requirements. In fact, the Tunable White LED light sources allow the easy mixing of two lights with different Correlated Color Temperatures, cool and warm [

7]. The Tunable White LEDs offer benefits not available in normal LED light sources, including the minimization of the potential blue hazard, improved color perception without drastically scarifying lumen efficiency, and reliability. However, to achieve a high quality level of light the digital control of the LED drivers used in the Tunable White technology can be very complex. In fact, they are generally controlled in power without knowing the exact values of illuminance and Correlated Color Temperature emitted by LEDs. The method univocally used today to reach the expected values of illuminance and Correlated Color Temperature using Tunable White LEDs consists in carrying out continuous manual settings of the LEDs driver power and measurements of the relative emitted light. This iterative procedure represents an inefficient method for LED light source characterization, especially where it is desired in complex scenarios in comfortable environments at any time and in every circumstance of the day [

8].

Studies show that an adjustable Correlated Color Temperature is beneficial for human health, well-being and productivity [

9]. A person may prefer warm or cool light depending on the time of day, the activity performed or the contribution of natural light. Therefore, it is important to adapt artificial light to the natural light, in order to keep synchronized the human circadian rhythm [

10]. Lighting quality is not only important for practical needs, such as work and visual comfort, but it also has a fundamental role in the emotional sphere, transmitting and emphasizing emotions through simple plays of light [

11]. For this reason, there is a growing demand for dynamic and real-time adjustment of light to meet users needs and generate high comfort light in special scenarios, such as in cultural heritage applications where visual appearance represents a crucial aspect as it allows a subject to immerse himself in the artwork, blending into the art [

12]. These characteristics can be satisfied using appropriate models providing suitable driver settings for Tunable White LEDs to reach a certain light quality. However, in the literature, experimental methods to characterize a LED source and thus derive such models have never been proposed.

In this paper we provide a method to obtain an efficient method for LED light source characterization typically used in cultural heritage applications. In particular, we study the Tunable White LED’s response used in the new lighting system installed in the Scrovegni Chapel, Padua, Italy [

13]. The description refers to the cultural heritage standards, but the proposed method for the model development can be considered valid for any other type of application or LED light sources. Based on the least squares method, an accurate mathematical model for illuminance and Correlated Color Temperature control has been developed with the aim of obtaining an efficient dimming in LED light sources. Moreover, the developed tool allow us to check the LED light source’s output by adjusting the input of the LED drivers, providing the minimum power values necessary to obtain the desired lighting parameters. The described work represents the first example of LED light source characterization based on illuminance and Correlated Color Temperature measurements.

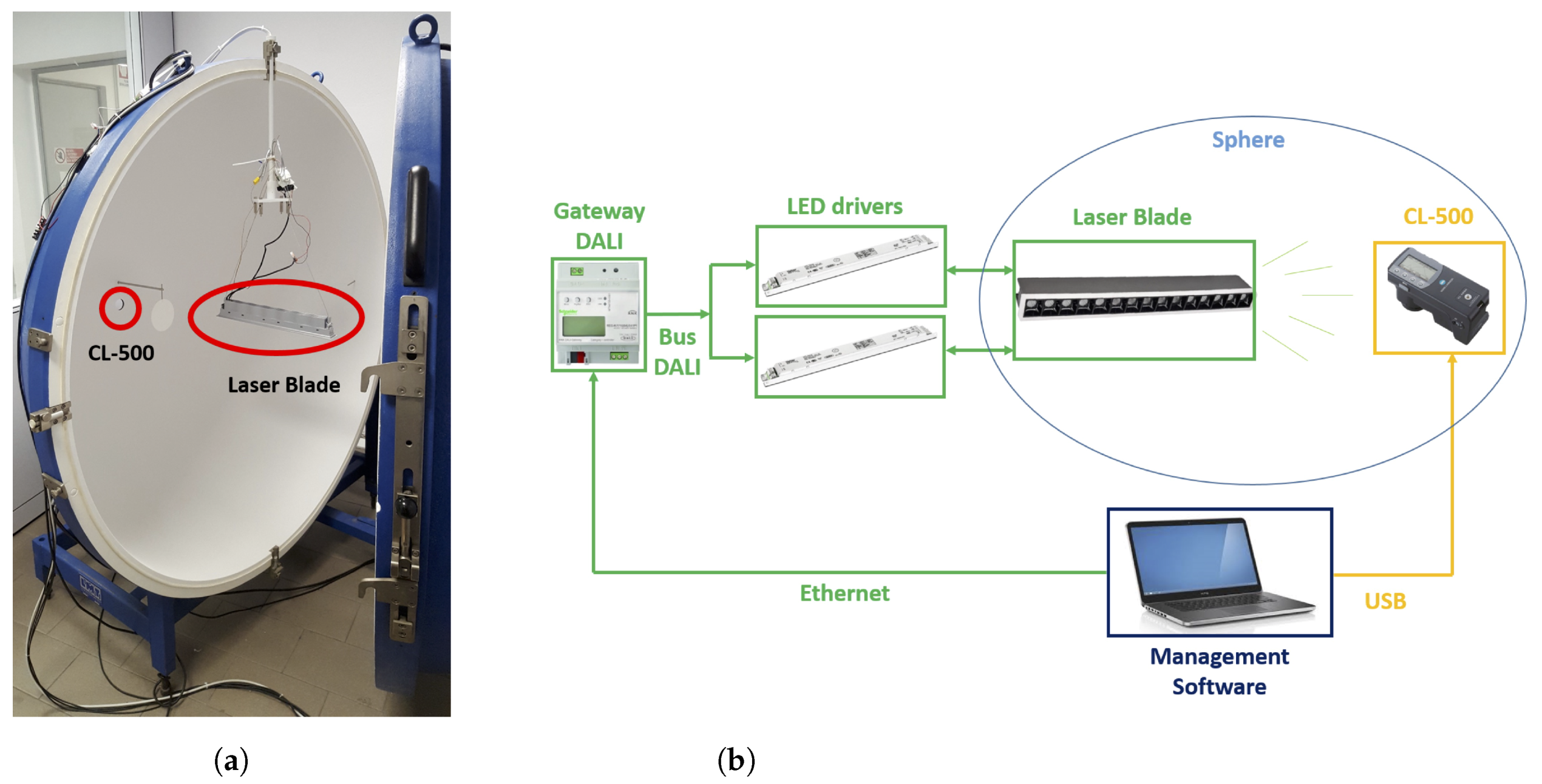

2. Materials and Methods

In order to study and control LED light in high quality lighting, the spectral stability of a LED light source represents a critical aspect [

14], especially when the field of application concerns cultural heritage. The European technical specification UNI CEN/TS 16163 provides the specifications to be used in lighting systems designed for cultural assets such as historic buildings, museums or galleries. In cultural heritage applications, as well as in many other sectors, the quality of LED light sources represents a wide and crucial aspect to investigate. the LED spectrum does not only influence the emitted light chromatic aspect, but also the color’s perception of illuminated objects by the source. For this reason it is necessary to study in detail the LED light source’s response, varying the LED’s input power to analyze how the lighting parameters change and are correlated to each other. In detail, we study the LED light source response in relation to the LED driver’s power in order to obtain an accurate digital control of the lighting system and an excellent colorimetric performance in compliance with the standards of the application field.

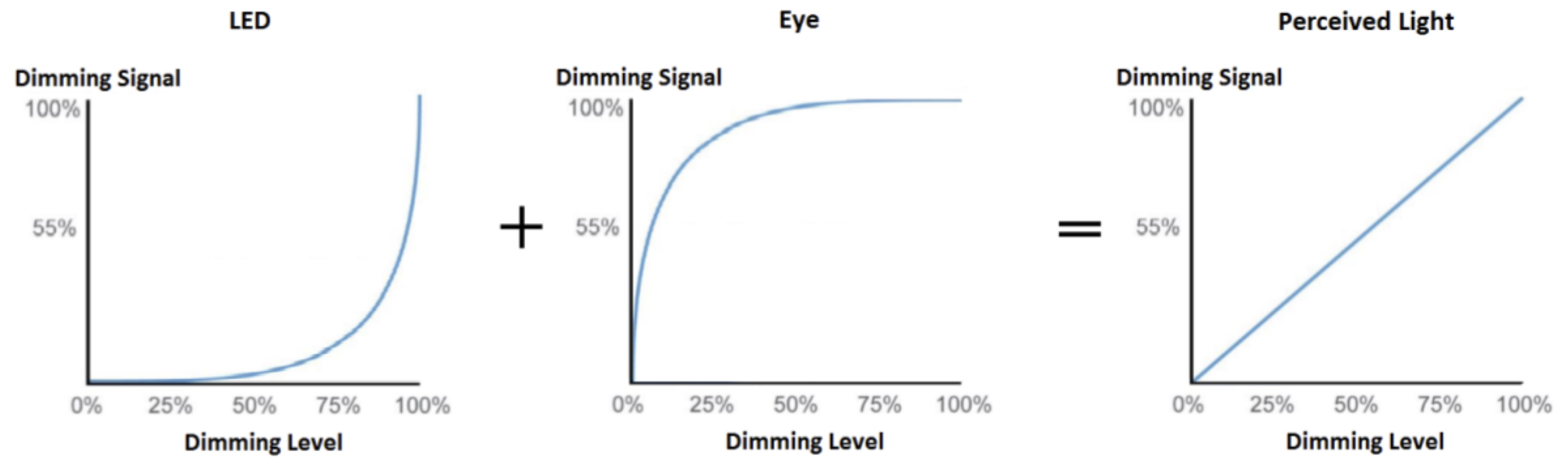

The perception of the human eye is defined by a curve with a logarithmic trend, with greater sensitivity to variations at low percentages of illuminance [

15]. It is fundamental to take into account this aspect in the LED driver settings to obtain an accurate digital control of the lighting system. In fact, given the sensitivity of the human eye, greater attention must be paid to low dimming levels. In order to not lose information in this analysis, it is necessary to choose an adequate number of input values for LED light source power supply. Therefore, variable power steps should be considered to power LEDs with more dense ranges at low values and larger ranges when increasing the power values. Moreover, to obtain a linear perception of the increase in illuminance, the LED light source must be have an illuminance curve with the exponential trend (

Figure 1).

In order to obtain a LED light source in which output values of the illuminance are linked exponentially to the input value, the controller and the LED driver must be properly configured. Therefore, it is very important to choose the right dimming curve (

Figure 2). Typically, digital controllers of lighting systems available are linear, so it has been necessary to select LED drivers with a settable exponential dimming curve. The LED drivers used in this study were DC Maxi Jolly US DALI (TCI, Saronno, Italy) with an exponential dimming curve set.

The aim of this work is to find the appropriate settings to give to LED drivers to generate the desired rendering corresponding to specific lighting parameters. Among the lighting parameters, the most important are illuminance, measured in lux (lx), and color quality, which is generally evaluated in terms of Correlated Color Temperature and measured in kelvin (K) [

12,

16].

Although the CCT is an important aspect of the color appearance, this single parameter is not enough to describe the complex spectral power distribution. For example, two sources with the same CCT can look different. To address this issue, the Duv is defined by the American National Standards Institute (ANSI), as a parameter that quantifies the distance between the chromaticity of a black body radiator and a given light source of equal CCT [

17].

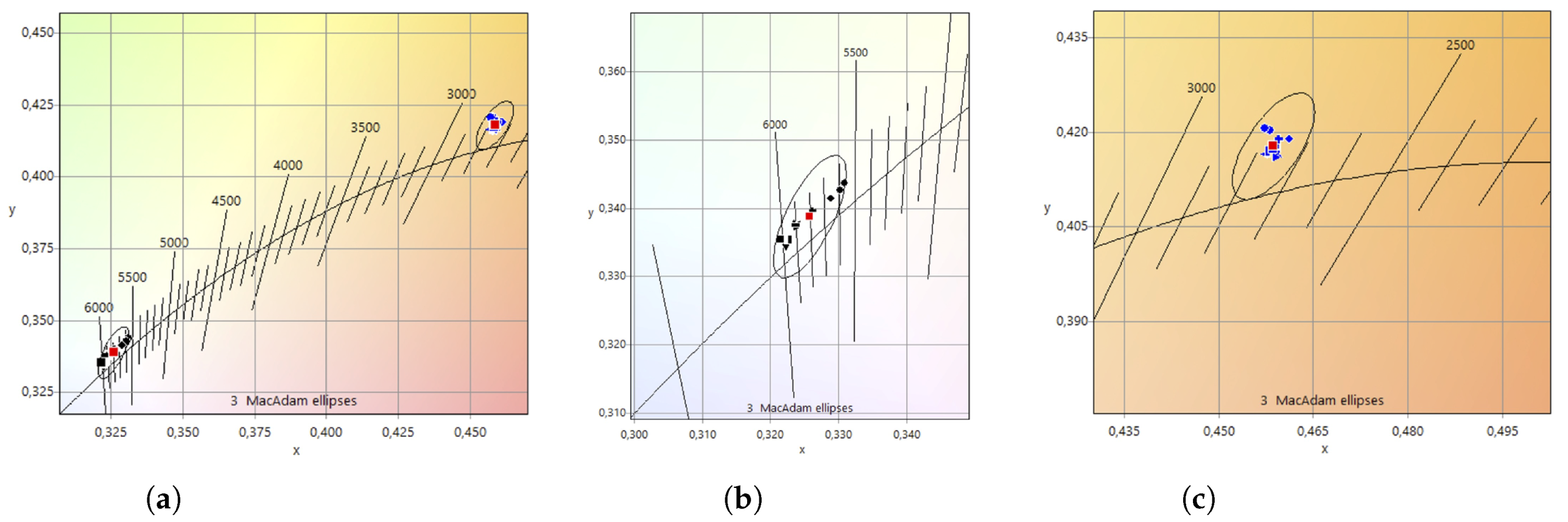

While in some applications, large color tolerances may be acceptable, in other fields, such as museums, the color quality keeping of LED light sources must be carefully considered. The light source’s color is often described using chromaticity coordinates (x,y) which represent a basic principle of the CIE system of colorimetry. In this work we have referred to CIE 1931 [

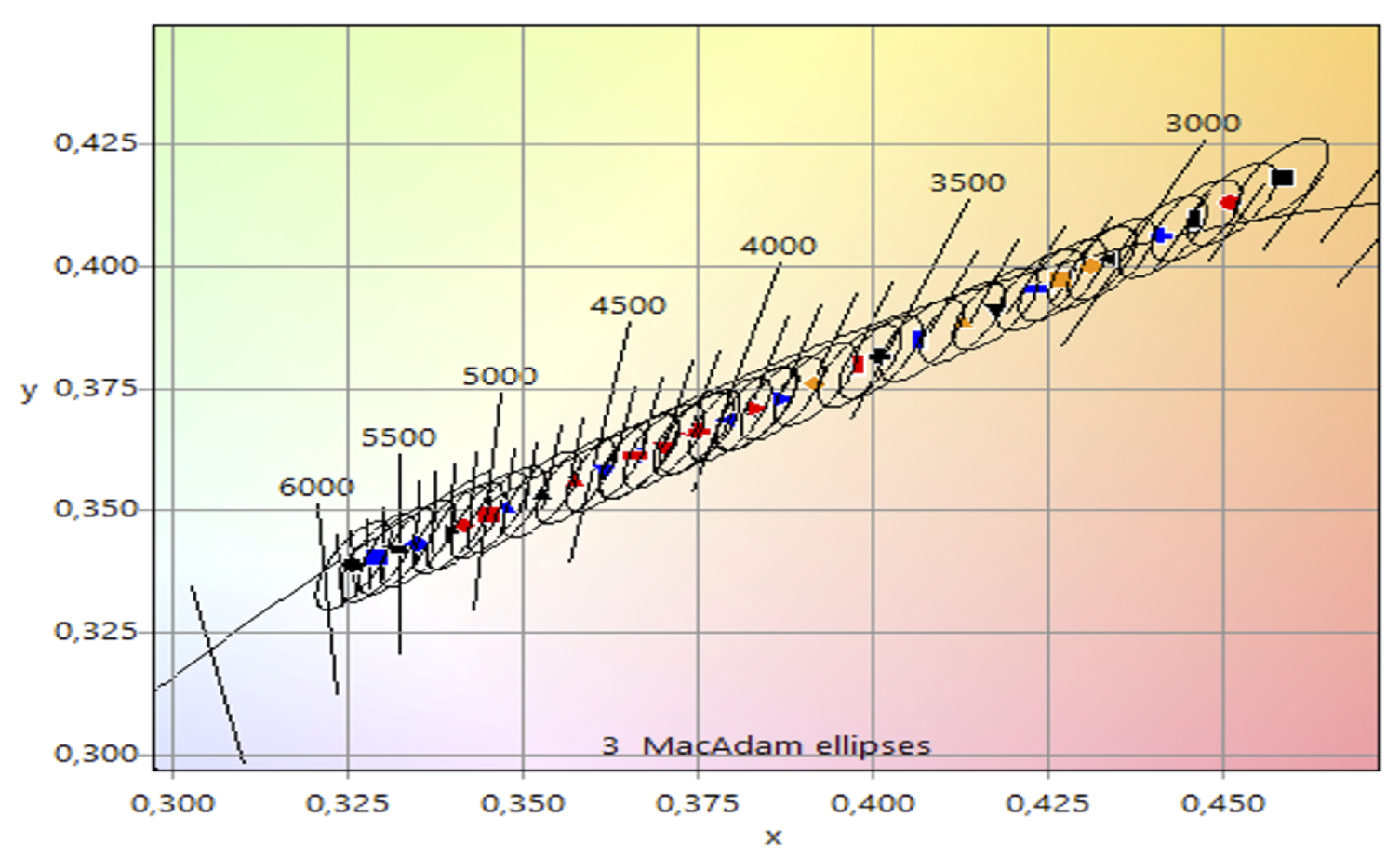

12]. In the lighting literature, a metric commonly used for quantifying perceivable color difference is the MacAdam ellipse, which is a region in the chromaticity diagram. If the chromaticity coordinates of two white LED light sources are located beyond this area, a color difference between these two sources can be detected by human eyes. [

18]. Depending on the reference application field, there are acceptable tolerances defined by ANSI to establish color matching between two sources. For example, for an achromatic (white) wall there must be a 2-step MacAdam ellipse, while to illuminate multicolored scenes or paintings it does not have to exceed a 4-step MacAdam ellipse to make color differences imperceptible [

19]. In this study, we have used LEDs that guarantee variations that fall within a 3-step MacAdam ellipse, as indicated in the manufacturer’s datasheet. In this way, we put ourselves through more stringent case studies with respect to the requirements requested by this application, where color variations are visible from 4-step MacAdam ellipse.

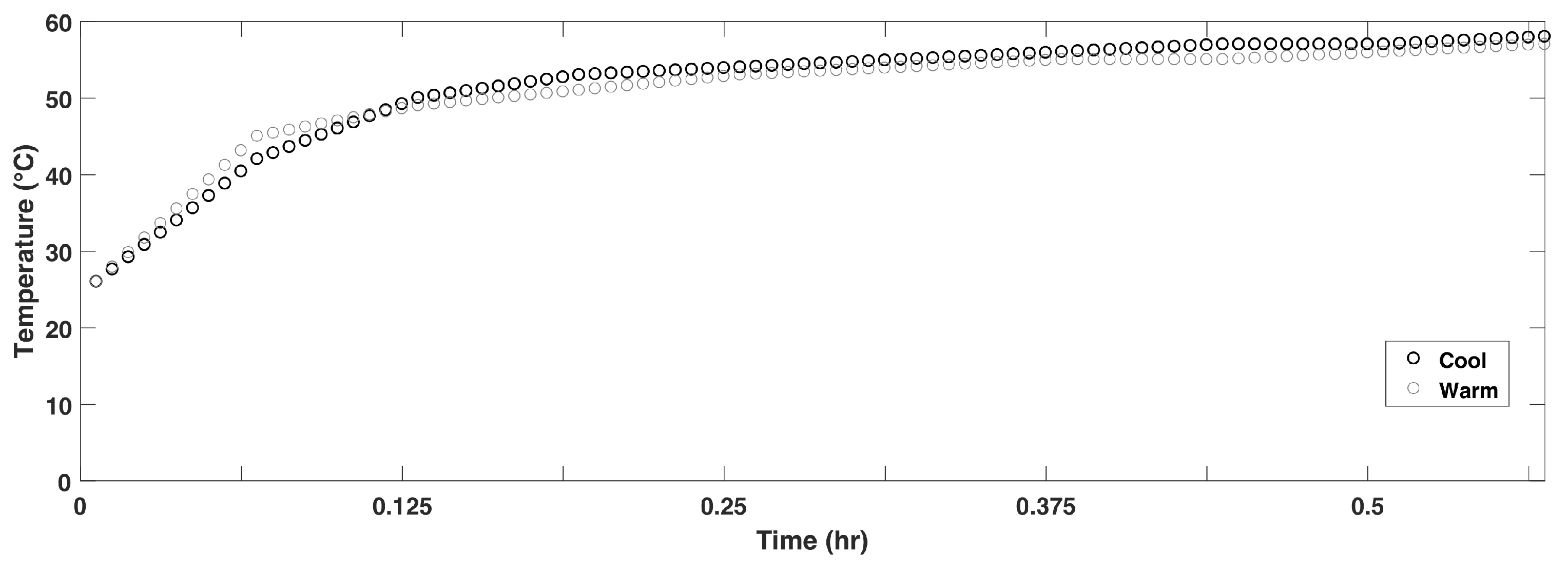

The junction temperature of the LEDs is another aspect that should not be underestimated. It influences the perceivable color difference [

20]. Based on the IES LM-79-08 standard and other studies present in the literature, the junction temperature changes the amplitude and position of the peak wavelength of the spectrum linearly with the heat [

21]. In order to evaluate the thermal stabilization of the LEDs used in this study, a detailed analysis of the spectrum’s trend as a function of the junction temperature over time has been carried out. In this analysis, thermocouples have been placed on warm and cool LEDs powered at maximum power and their junction temperature has been measured using the instrument Agilent 34970A. These measures have been performed on each LED light source considered in this study. The ambient temperature in which measurements are being taken is maintained at 25

C.

Figure 3 shows the mean values of the junction temperature of warm and cool LEDs. Results of the performed analysis have shown that after 25 min the thermal stabilization is almost reached, swinging a few degrees, and consequently also the shape of the spectrum has stabilized. In fact, after 33 min of operation the temperature rose up to about 60

C on both warm and cool LEDs.

4. Results

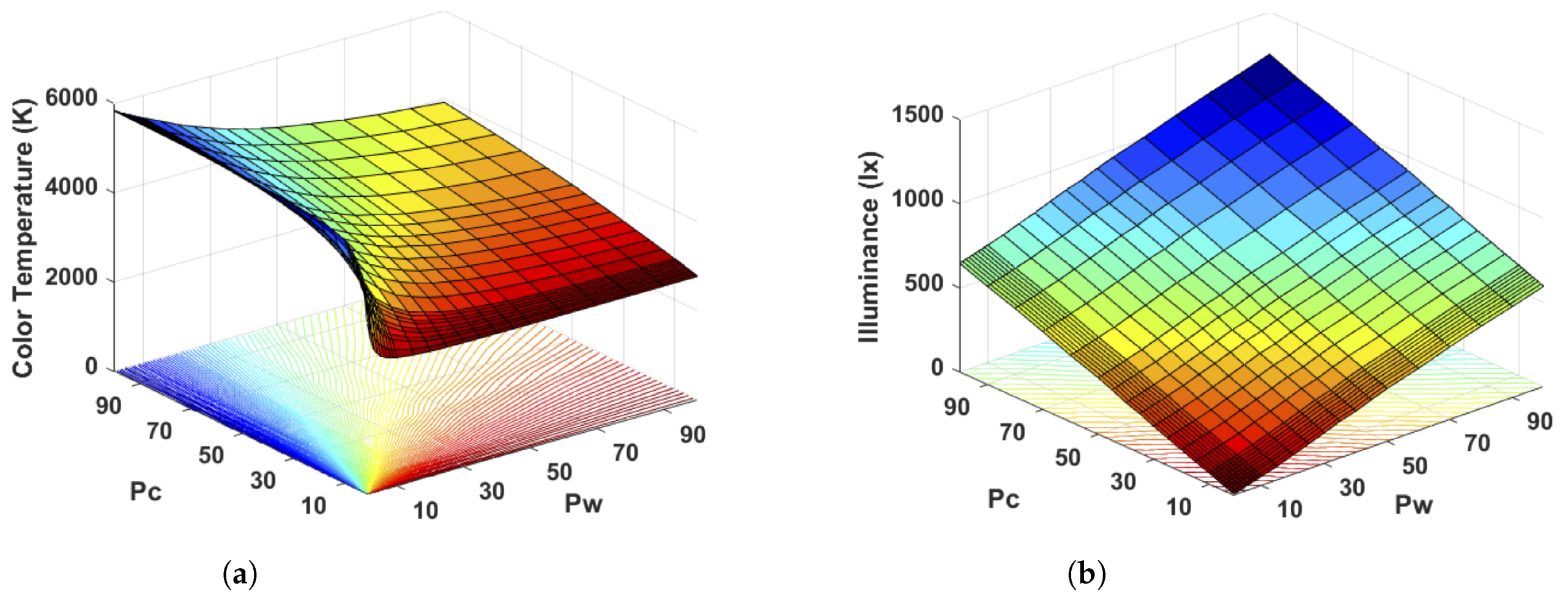

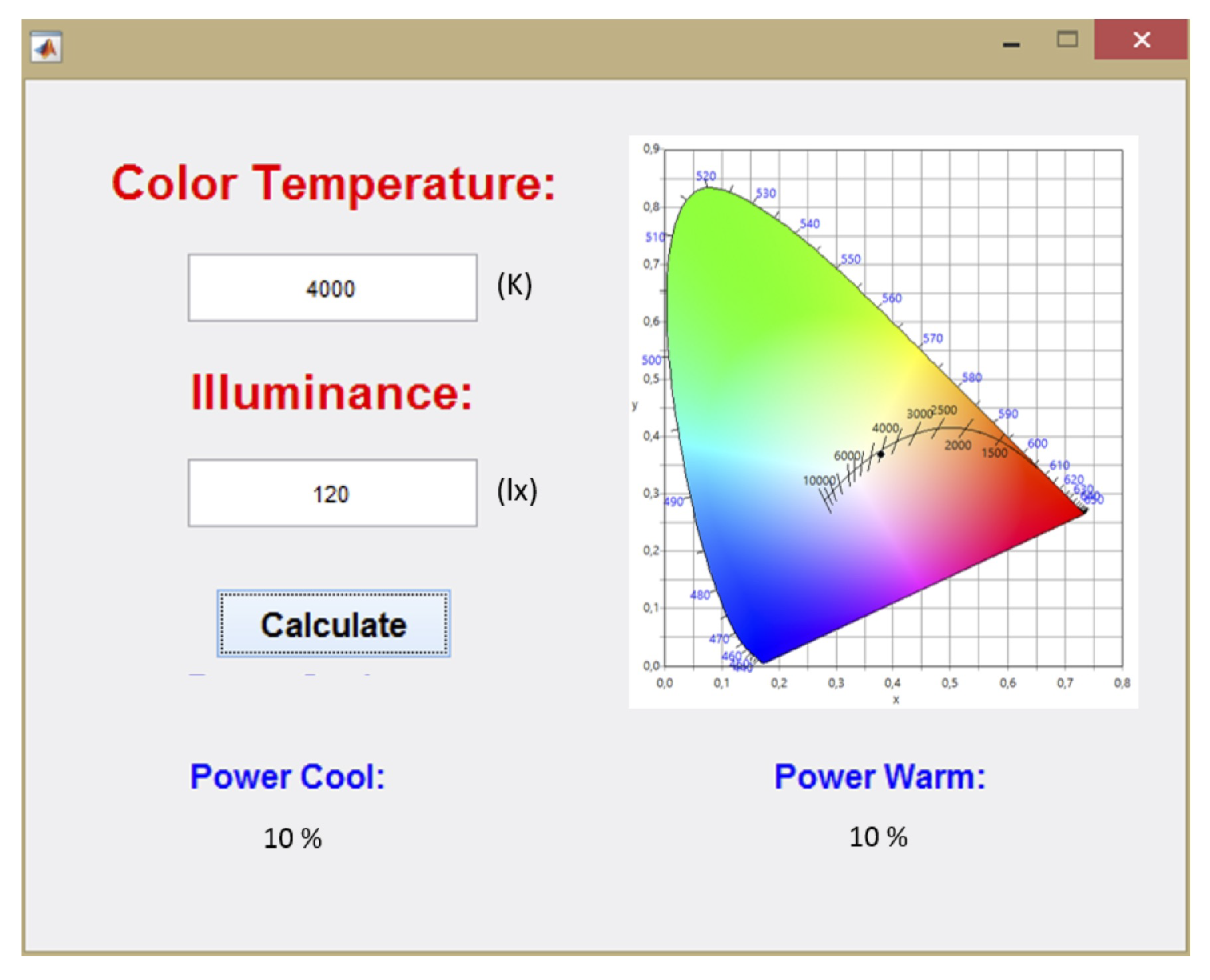

In this paper, a new efficient method for LED light sources characterization is presented. The developed mathematical model was achieved from CCT and illuminance average curves obtained during the training phase. These curves are summarized in

Figure 7, where CCT (

Figure 7a) and illuminace trend (

Figure 7b) as a function of dimming are illustrated. The CCT surface curve has an irregular trend, when the power of the cool channel increases, keeping the warm channel constant, the CCT moves towards high values and vice versa for the warm channel. Instead by increasing the power the illuminance’s curve has a linear trend. The level sets for CCT and illuminance projected on the x-y plane are also illustrated in both figures (

Figure 7), identifying the iso-CCT and iso-illuminance points. Moving along those lines we have all the power inputs

that keep CCT or illuminance constant. From the intersection between CCT and illuminance level sets it is possible to find the corresponding values of warm and cool channel which allow us to obtain the desired lighting parameters values. In

Figure 7a it is shown how the level sets of the CCT are a beam of fan curves. Starting from the center, with the same power for the warm and cool channel, we have a natural CCT, moving towards the low power of the warm channel dominates a cool CCT, while increasing the power of the warm channel leads to a warmer CCT. In

Figure 7b the level sets are lines on which to maintain a constant illuminance the powers of the warm and cool channel must always be compensated.

In the testing phase, a comparison between the expected CCT and illuminance values and those measured by illuminance spectrophotometer were carried out. For a more accurate analysis, the distributions of the relative percentage differences of the CCT and illuminance values were calculated as follows:

where P

and P

are the values of the generic lighting parameters P (CCT or illuminance) for the measured and expected value.

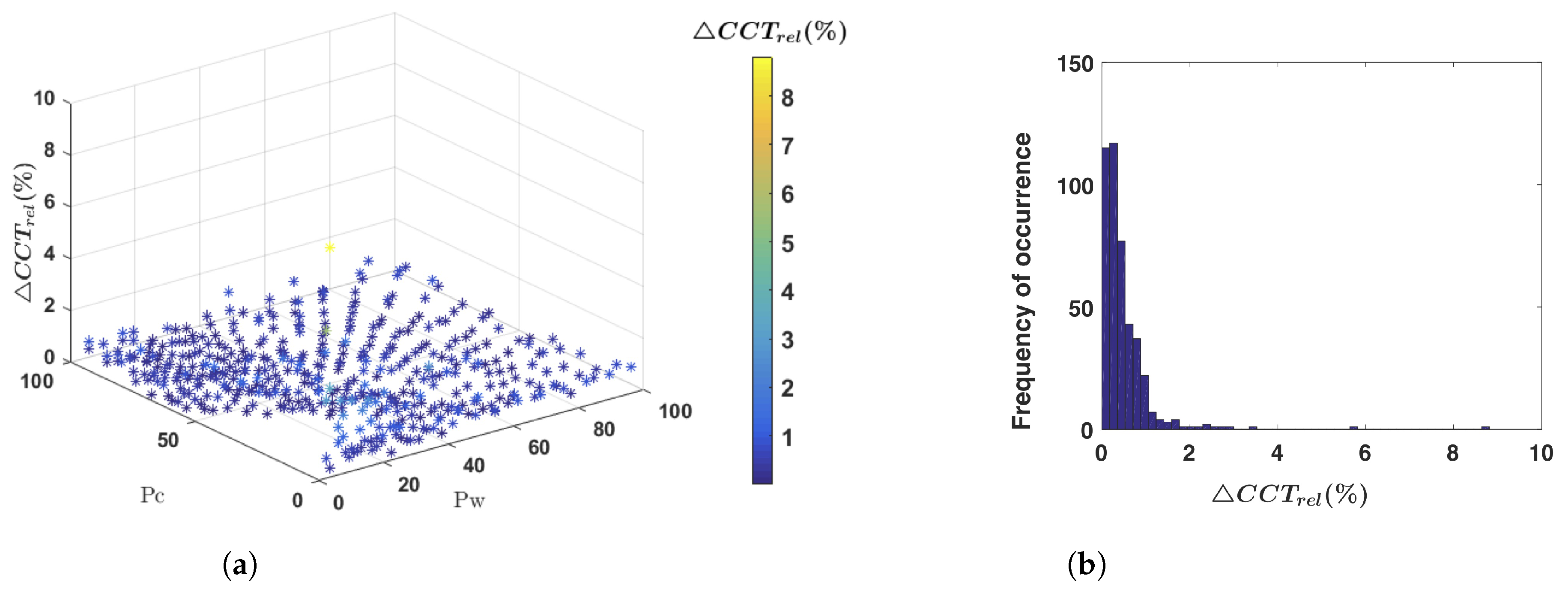

Figure 9a shows the distribution of the relative percentage differences of the CCT for a LED light source used in the testing phase. It shows the distribution as a function of power, highlighting slightly greater errors for low values; while

Figure 9b loses the link with the input power of the LED light source and it shows the final results of both LED light sources. Anyway, it is possible to observe how the distribution converges to 0%, with a maximum of 0.3% for CCT.

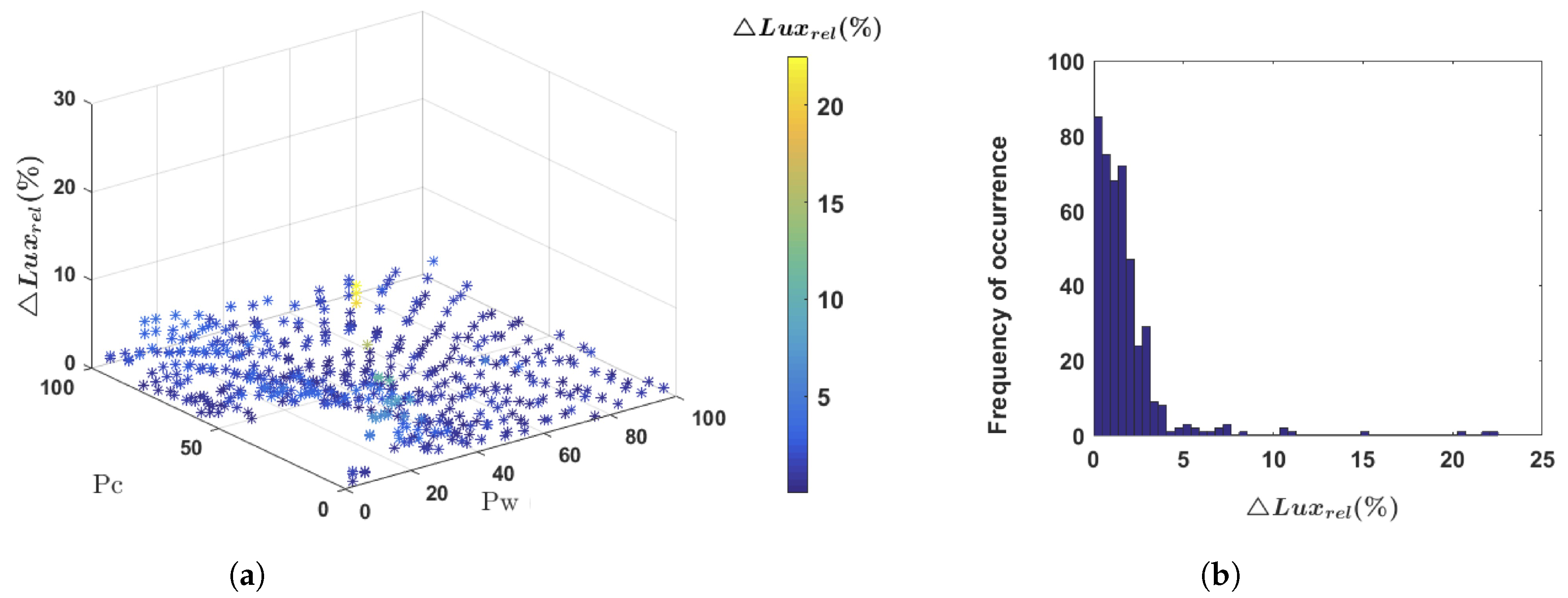

The obtained results for the illuminance are shown in

Figure 10.

Figure 10a shows the space distribution of the relative percentage values of the illuminance for a LED light source, reaching a maximum error percentage of 23% at low input power supply. The

Figure 10b shows the overall results of both LED light sources used for the model validation. The results show a maximum error of 1.5%. Unlike the CCT, for illuminance, greater errors at low power values were obtained (

Figure 10a). The higher error rate at low input powers is justified by the low reflection of the sphere at low light intensities and by the sensitivity of Minolta at low power values.

In

Figure 11 the response of the LED light source in CIE 1931 graph as a function of input powers is illustrated, in particular the regions of uncertainty (3-step MacAdam as reported in the LED’s datasheet), and so the error that can be committed with the developed model has been reported.

5. Conclusions

This paper presents an efficient method for characterizing the LED light sources used in the new lighting system installed in the Scrovegni Chapel, Padua, Italy. These LED light sources are based on Tunable White technology in which the LED drivers are generally controlled in power without knowing the exact values of illuminance and Correlated Color Temperature emitted by the LEDs. The work represents the first world example of LED light source characterization based on illuminance and Correlated Color Temperature measurements. In order to find a mathematical model to describe the response of the LED light source as a function of the expected values of CCT and illuminance, a series of measures has been performed in the training phase. Based on the least squares method, a mathematical model has been developed to estimate the right power supply of the warm and cool channels to obtain the desired values of illuminance and CCT. Subsequently, the model has been validated through a testing phase verifying the correspondence of CCT and illuminance values measured and those set in the mathematical model. Results show a low error rate between expected and measured values. The proposed mathematical model can be used to find the power values to be set to warm and cool channels of the LED light sources, obtaining an accurate characterization of the light emitted quality. Based on this study, the combined control of warm and cool LEDs generates the expected lighting performance, creating a system capable of controlling light in real-time, maintaining the lighting parameters at the expected constant values without exceeding the thresholds imposed by standards in cultural heritage applications. Therefore, using the developed mathematical model, it is possible to offer compliance with the specifications in lighting systems and the best visual perception in cultural heritage applications, such as the Scrovegni Chapel one. Moreover, the proposed method for model development can be useful and applicable in any other scenarios or to any other LED light source.