Solution-Processable ZnO Thin Film Memristive Device for Resistive Random Access Memory Application

Abstract

:1. Introduction

2. Experimental Details

2.1. Materials and Method

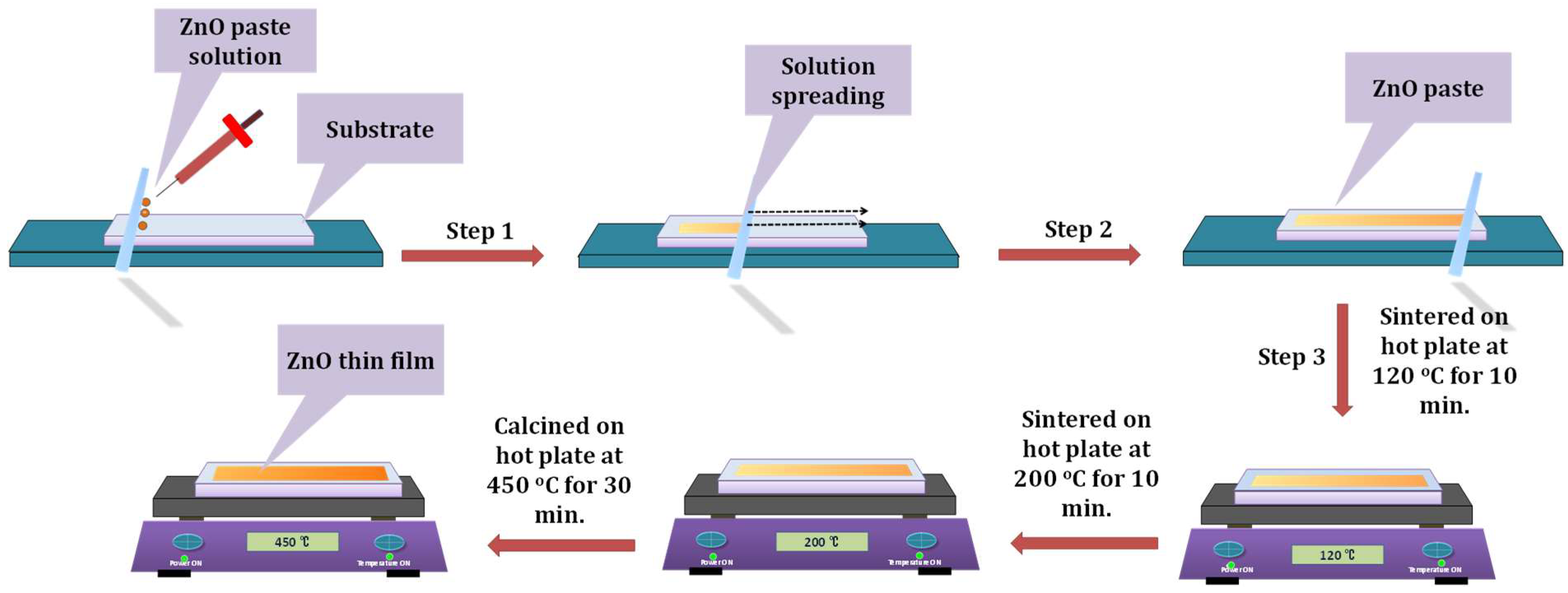

2.2. Synthesis of ZnO Powder and Development of ZnO Thin Film Using the Doctor Blade Method

2.3. Development and Characterizations of ZnO Memristive Device

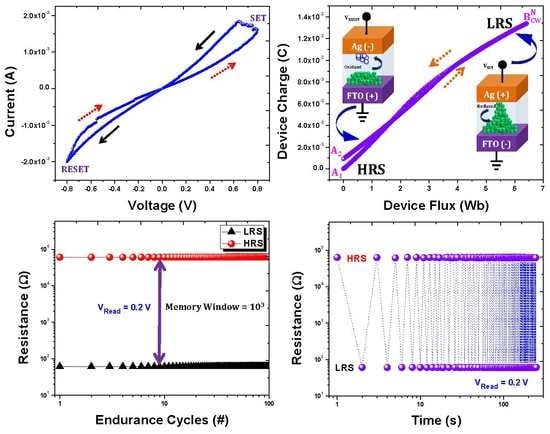

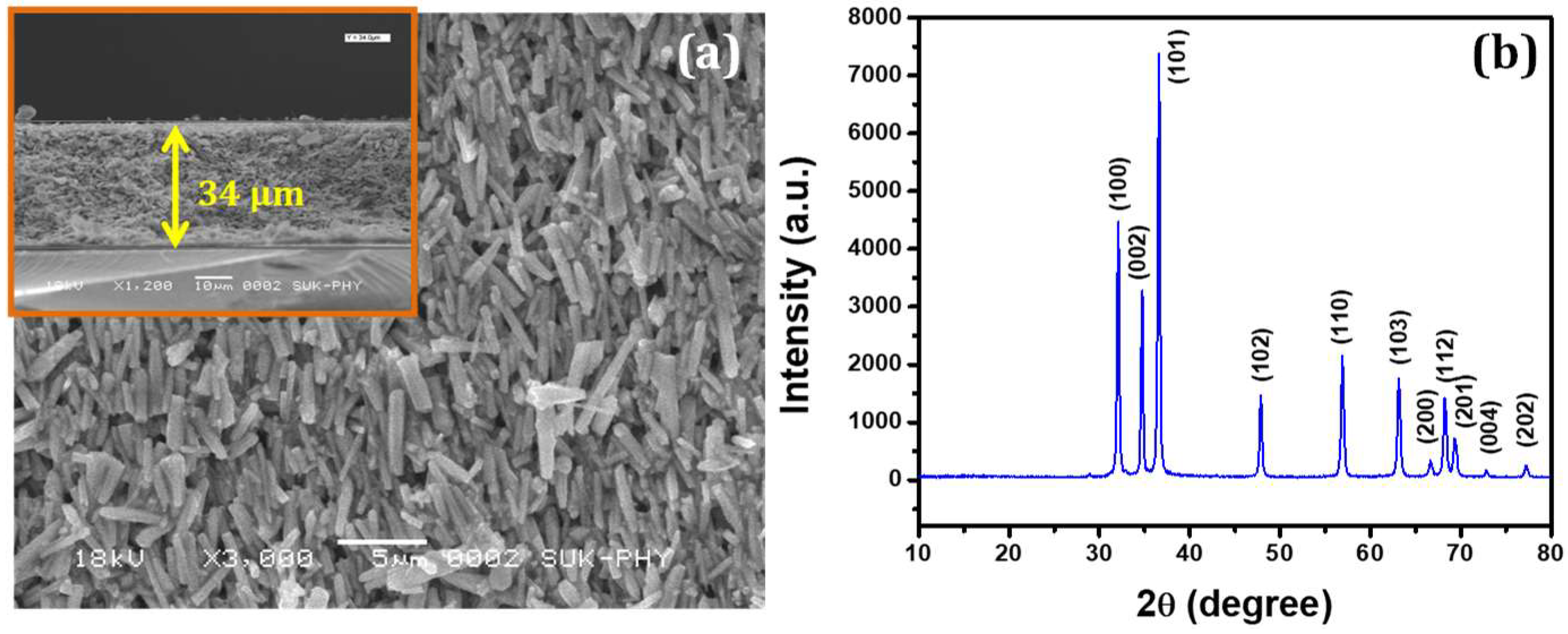

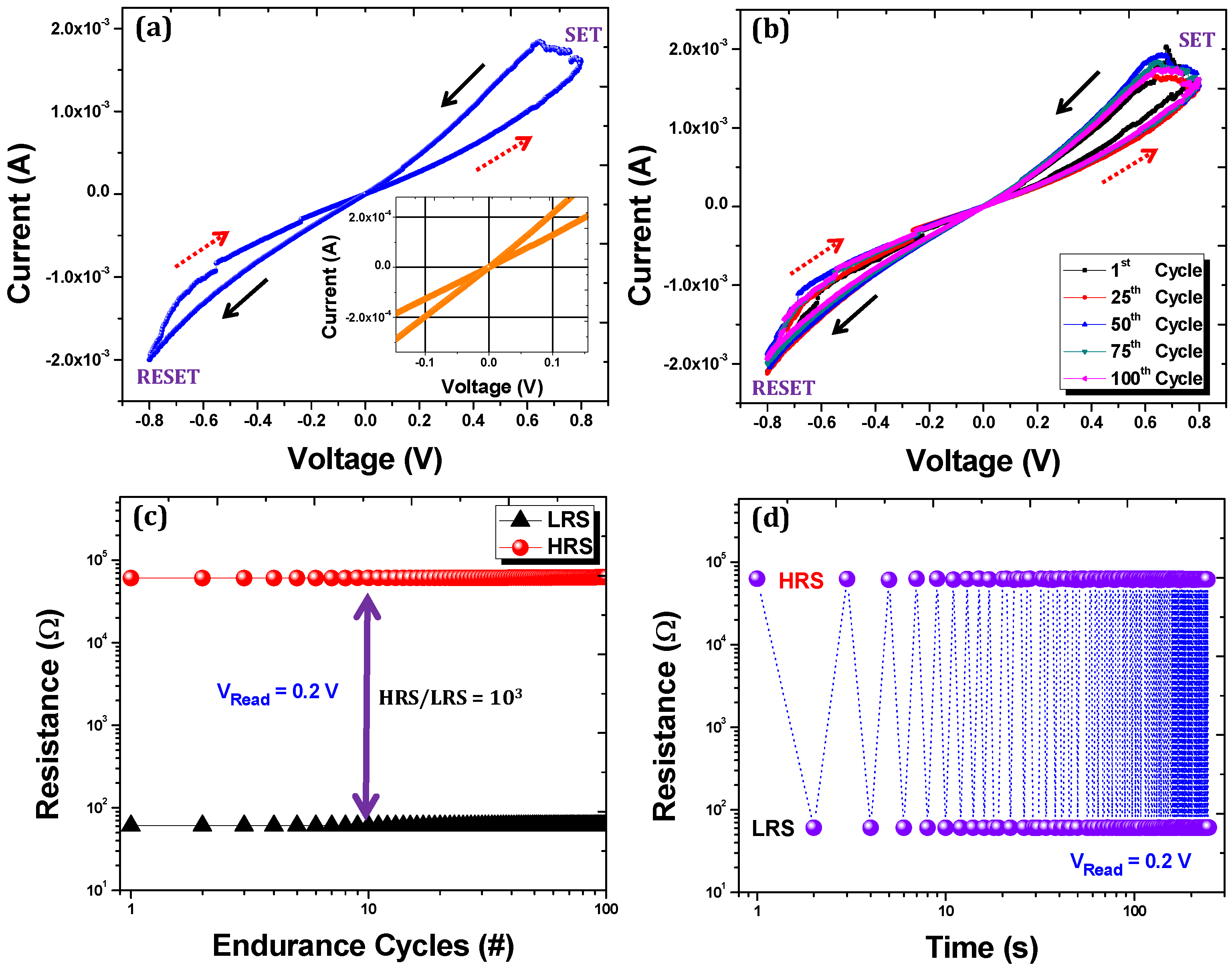

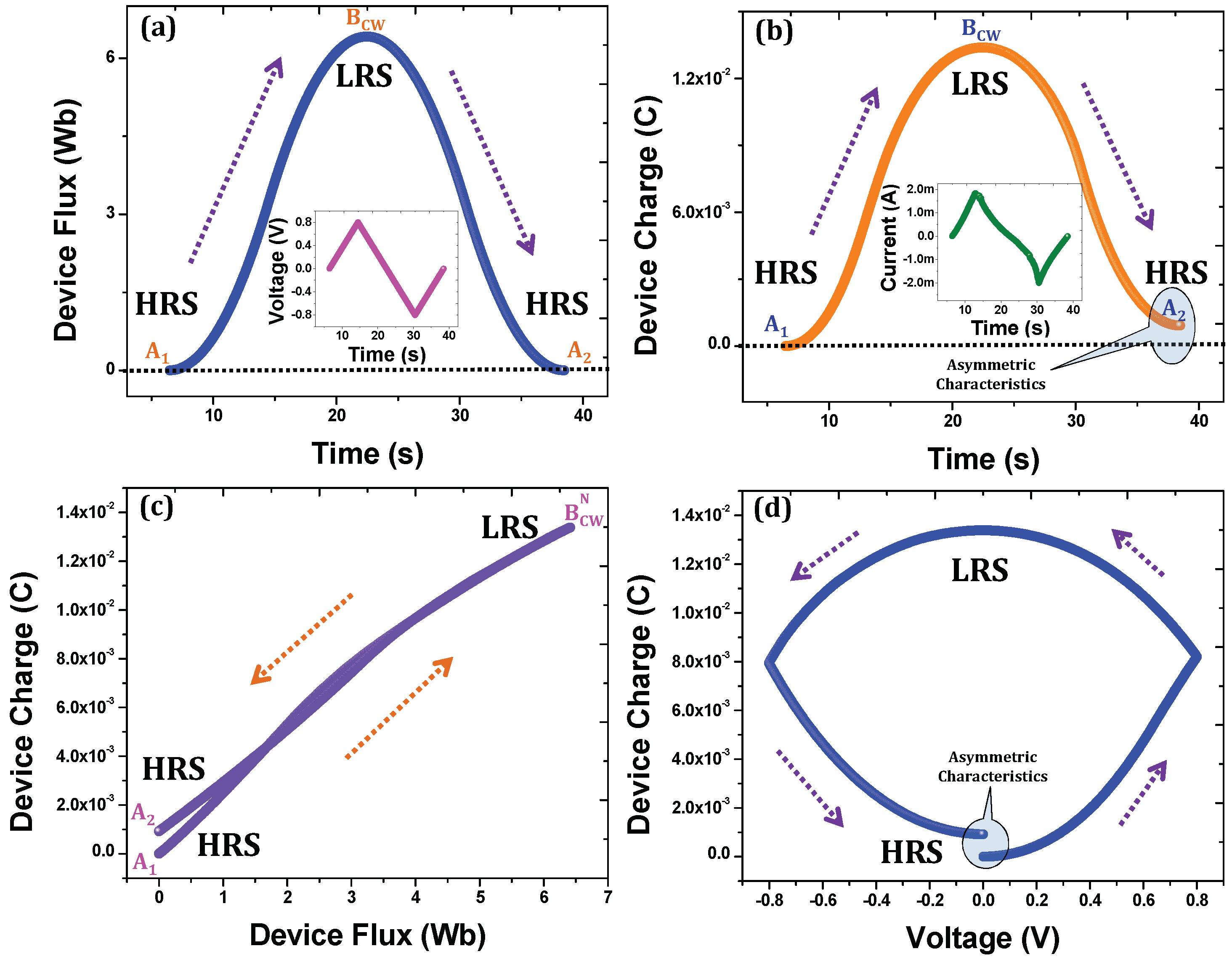

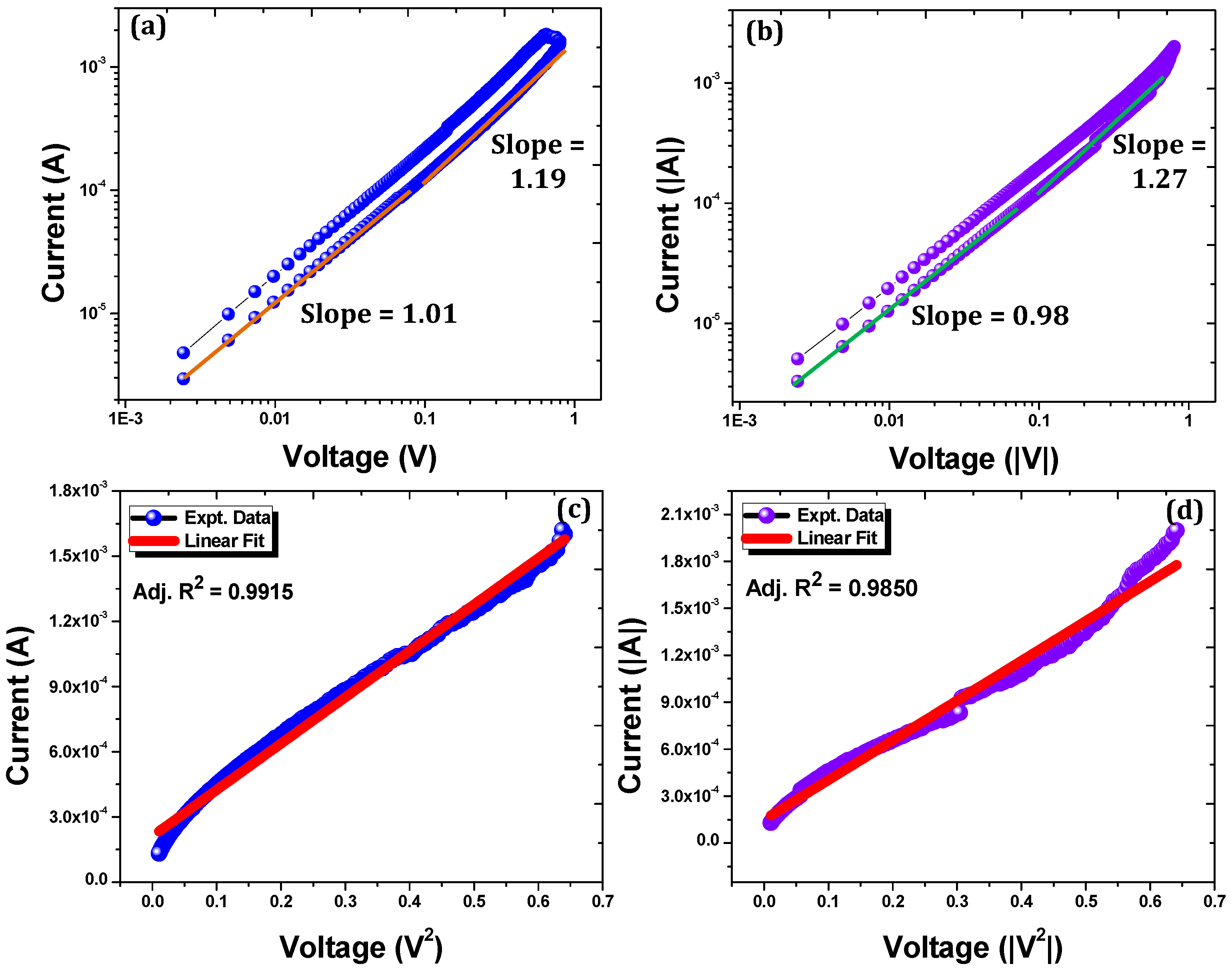

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Salaoru, I.; Khiat, A.; Li, Q.; Berdan, R.; Prodromakis, T. Pulse-Induced Resistive and Capacitive Switching in TiO2 Thin Film Devices. Appl. Phys. Lett. 2017, 103, 233513. [Google Scholar] [CrossRef]

- Dongale, T.D.; Pawar, P.S.; Tikke, R.S.; Mullani, N.B.; Patil, V.B.; Teli, A.M.; Khot, K.V.; Mohite, S.V.; Bagade, A.A.; Kumbhar, V.S.; et al. Mimicking the Synaptic Weights and Human Forgetting Curve Using Hydrothermally Grown Nanostructured CuO Memristor Device. J. Nanosci. Nanotechnol. 2018, 18, 984–991. [Google Scholar] [CrossRef] [PubMed]

- Dongale, T.D.; Mohite, S.V.; Bagade, A.A.; Kamat, R.K.; Rajpure, K.Y. Bio-Mimicking the Synaptic Weights, Analog Memory, and Forgetting Effect Using Spray Deposited WO3 memristor Device. Microelectron. Eng. 2017, 183–184, 12–18. [Google Scholar] [CrossRef]

- Waser, R.; Dittmann, R.; Staikov, C.; Szot, K. Redox-Based Resistive Switching Memories-Nanoionic Mechanisms, Prospects, and Challenges. Adv. Mater. 2009, 21, 2632–2663. [Google Scholar] [CrossRef]

- Kim, K.H.; Gaba, S.; Wheeler, D.; Cruz-Albrecht, J.M.; Hussain, T.; Srinivasa, N.; Lu, W. A Functional Hybrid Memristor Crossbar-Array/CMOS System for Data Storage and Neuromorphic Applications. Nano Lett. 2012, 12, 389–395. [Google Scholar] [CrossRef] [PubMed]

- Duan, S.K.; Hu, X.F.; Wang, L.D.; Li, C.D. Analog Memristive Memory with Applications in Audio Signal Processing. Sci. China Inf. Sci. 2014, 57, 1–15. [Google Scholar] [CrossRef]

- Hong, Y.; Lian, Y. A Memristor-Based Continuous-Time Digital FIR Filter For Biomedical Signal Processing. IEEE Trans. Circuits Syst. 2015, 62, 1392–1401. [Google Scholar] [CrossRef]

- Chua, L.O. Memristor-the missing circuit element. IEEE Trans. Circuit Theory 1971, 18, 507–519. [Google Scholar] [CrossRef]

- Strukov, D.B.; Snider, G.S.; Stewart, D.R.; Williams, R.S. The Missing Memristor Found. Nature 2008, 453, 80–83. [Google Scholar] [CrossRef]

- Kim, K.M.; Kim, G.H.; Song, S.J.; Seok, J.Y.; Lee, M.H.; Yoon, J.H.; Hwang, C.S. Electrically Configurable Electroforming and Bipolar Resistive Switching in Pt/TiO2/Pt Structures. Nanotechnology 2010, 21, 305203. [Google Scholar] [CrossRef]

- Szot, K.; Speier, W.; Bihlmayer, G.; Waser, R. Switching the Electrical Resistance of Individual Dislocations in Single-Crystalline SrTiO3. Nat. Mater. 2006, 5, 312–320. [Google Scholar] [CrossRef] [PubMed]

- Liao, Z.M.; Hou, C.; Zhang, H.Z.; Wang, D.S.; Yu, D.P. Evolution of Resistive Switching over Bias Duration of Single Ag2S Nanowires. Appl. Phys. Lett. 2010, 96, 20–23. [Google Scholar] [CrossRef]

- Berzina, T.; Smerieri, A.; Bernab, M.; Pucci, A.; Ruggeri, G.; Erokhin, V.; Fontana, M.P. Optimization of an Organic Memristor as an Adaptive Memory Element. J. Appl. Phys. 2009, 105, 124515. [Google Scholar] [CrossRef]

- Song, J.; Zhang, Y.; Xu, C.; Wu, W.; Wang, Z.L. Polar Charges Induced Electric Hysteresis of ZnO Nano/Microwire for Fast Data Storage. Nano Lett. 2011, 11, 2829–2834. [Google Scholar] [CrossRef] [PubMed]

- Dongale, T.D.; Khot, K.V.; Mali, S.S.; Patil, P.S.; Gaikwad, P.K.; Kamat, R.K.; Bhosale, P.N. Development of Ag/ZnO/FTO Thin Film Memristor Using Aqueous Chemical Route. Mater. Sci. Semicond. Process. 2015, 40, 523–526. [Google Scholar] [CrossRef]

- Hu, S.G.; Liu, Y.; Chen, T.P.; Liu, Z.; Yu, Q.; Deng, L.J.; Yin, Y.; Hosaka, S. Emulating the Ebbinghaus Forgetting Curve of the Human Brain with a NiO-Based Memristor. Appl. Phys. Lett. 2013, 103, 133701. [Google Scholar] [CrossRef]

- Shinde, S.S.; Dongle, T.D. Modelling of nanostructured TiO2-based memristors. J. Semiccond. 2015, 36, 034001. [Google Scholar] [CrossRef]

- Dongale, T.D.; Shinde, S.S.; Kamat, R.K.; Rajpure, K.Y. Nanostructured TiO2 Thin Film Memristor Using Hydrothermal Process. J. Alloys Compd. 2014, 593, 267–270. [Google Scholar] [CrossRef]

- Dongale, T.D.; Mohite, S.V.; Bagade, A.A.; Gaikwad, P.K.; Patil, P.S.; Kamat, R.K.; Rajpure, K.Y. Development of Ag/WO3/ITO Thin Film Memristor Using Spray Pyrolysis Method. Electron. Mater. Lett. 2015, 11, 944–948. [Google Scholar] [CrossRef]

- Sindhu, H.S.; Joishy, S.; Rajendra, B.V.; Rao, A.; Gaonkar, M.; Kulkarni, S.D.; Babu, P.D. Tuning Optical, Electrical and Magnetic Properties of Fiber Structured ZnO Film by Deposition Temperature and Precursor Concentration. Mater. Sci. Semicond. Process. 2017, 68, 97–107. [Google Scholar] [CrossRef]

- Wang, Y.L.; Ren, F.; Kim, H.S.; Norton, D.P.; Pearton, S.J. Materials and Process Development for ZnMgO/ZnO Light-Emitting Diodes. IEEE J. Sel. Top. Quantum Electron. 2008, 14, 1048–1052. [Google Scholar] [CrossRef]

- Gul, F.; Efeoglu, H. Bipolar Resistive Switching and Conduction Mechanism of an Al/ZnO/Al-Based Memristor. Superlattices Microstruct. 2017, 101, 172–179. [Google Scholar] [CrossRef]

- Choi, K.H.; Mustafa, M.; Rahman, K.; Jeong, B.K.; Doh, Y.H. Cost-Effective Fabrication of Memristive Devices with ZnO Thin Film Using Printed Electronics Technologies. Appl. Phys. A Mater. Sci. Process. 2012, 106, 165–170. [Google Scholar] [CrossRef]

- Park, J.; Lee, S.; Lee, J.; Yong, K. A Light Incident Angle Switchable ZnO Nanorod Memristor: Reversible Switching Behavior between Two Non-Volatile Memory Devices. Adv. Mater. 2013, 25, 6423–6429. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.T.; Dai, Y.W.; Xu, J.; Chen, L.; Sun, Q.Q.; Zhou, P.; Wang, P.F.; Ding, S.J.; Zhang, D.W. Resistive Switching and Synaptic Behaviors of TaN/Al2O3/ZnO/ITO Flexible Devices with Embedded Ag Nanoparticles. IEEE Electron Device Lett. 2016, 37, 878–881. [Google Scholar] [CrossRef]

- Paul, S.; Harris, P.G.; Pal, C.; Sharma, A.K.; Ray, A.K. Low Cost Zinc Oxide for Memristors with High On-Off Ratios. Mater. Lett. 2014, 130, 40–42. [Google Scholar] [CrossRef]

- Chew, Z.J.; Li, L. A Discrete Memristor Made of ZnO Nanowires Synthesized on Printed Circuit Board. Mater. Lett. 2013, 91, 298–300. [Google Scholar] [CrossRef]

- Wang, J.; Sun, B.; Gao, F.; Greenham, N.C. Memristive Devices Based on Solution-Processed ZnO Nanocrystals. Phys. Status Solidi Appl. Mater. Sci. 2010, 207, 484–487. [Google Scholar] [CrossRef]

- Dongle, V.S.; Dongare, A.A.; Mullani, N.B.; Pawar, P.S.; Patil, P.B.; Heo, J.; Park, T.J.; Dongale, T.D. Development of Self-Rectifying ZnO Thin Film Resistive Switching Memory Device Using Successive Ionic Layer Adsorption and Reaction Method. J. Mater. Sci. Mater. Electron. 2018, 29, 18733–18741. [Google Scholar] [CrossRef]

- Rananavare, A.P.; Kadam, S.J.; Prabhu, S.V.; Chavan, S.S.; Anbhule, P.V.; Dongale, T.D. Organic Non-Volatile Memory Device Based on Cellulose Fibers. Mater. Lett. 2018, 232, 99–102. [Google Scholar] [CrossRef]

- Pawar, P.S.; Tikke, R.S.; Patil, V.B.; Mullani, N.B.; Waifalkar, P.P.; Khot, K.V.; Teli, A.M.; Sheikh, A.D.; Dongale, T.D. A Low-Cost Copper Oxide Thin Film Memristive Device Based on Successive Ionic Layer Adsorption and Reaction Method. Mater. Sci. Semicond. Process. 2017, 71, 102–108. [Google Scholar] [CrossRef]

- Itoh, M.; Chua, L.O. Duality of Memristor Circuits. Int. J. Bifurc. Chaos 2013, 23, 1330001. [Google Scholar] [CrossRef]

- Shuai, Y.; Du, N.; Ou, X.; Luo, W.; Zhou, S.; Schmidt, O.G.; Schmidt, H. Improved Retention of Nonvolatile Bipolar BiFeO3 Resistive Memories Validated by Memristance Measurements. Phys. Status Solidi Curr. Top. Solid State Phys. 2013, 10, 636–639. [Google Scholar] [CrossRef]

- Qingjiang, L.; Khiat, A.; Salaoru, I.; Papavassiliou, C.; Hui, X.; Prodromakis, T. Memory Impedance in TiO2 based Metal-Insulator-Metal Devices. Sci. Rep. 2014, 4, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Shen, Z.; Wu, Y.; Wang, X.; Zhang, S.; Shi, X.; Zeng, H. Amorphous ZnO Based Resistive Random Access Memory. RSC Adv. 2016, 6, 17867–17872. [Google Scholar] [CrossRef]

- Kim, A.; Song, K.; Kim, Y.; Moon, J. All solution-processed, fully transparent resistive memory devices. ACS Appl. Mater. Interfaces 2011, 3, 4525–4530. [Google Scholar] [CrossRef] [PubMed]

- Kathalingam, A.; Kim, H.S.; Kim, S.D.; Park, H.C. Light induced resistive switching property of solution synthesized ZnO nanorod. Opt. Mater. 2015, 48, 190–197. [Google Scholar] [CrossRef]

- Hu, W.; Zou, L.; Chen, X.; Qin, N.; Li, S.; Bao, D. Highly uniform resistive switching properties of amorphous InGaZnO thin films prepared by a low temperature photochemical solution deposition method. ACS Appl. Mater. Interfaces 2014, 6, 5012–5017. [Google Scholar] [CrossRef]

- Xu, J.; Yang, Z.; Zhang, Y.; Zhang, X.; Wang, H. Bipolar resistive switching behaviours in ZnMn2O4 film deposited on p+-Si substrate by chemical solution deposition. Bull. Mater. Sci. 2014, 37, 1657–1661. [Google Scholar] [CrossRef]

- Wu, X.; Xu, Z.; Yu, Z.; Zhang, T.; Zhao, F.; Sun, T.; Ma, Z.; Li, Z.; Wang, S. Resistive switching behavior of photochemical activation solution-processed thin films at low temperatures for flexible memristor applications. J. Phys. D Appl. Phys. 2015, 48, 115101. [Google Scholar] [CrossRef]

| Device Structure | Resistive Switching Voltage | Memory Window | Endurance (Cycles) | Retention (Seconds) | Reference |

|---|---|---|---|---|---|

| ITO/GaZnO/ITO | +5/−7.5 V | 15 | 300 | - | [36] |

| Au/ZnO/Au | ±4 V | 102 | - | - | [37] |

| Pt/a-IGZO/Pt | +1.7/−1 V | 102 | - | 104 | [38] |

| Ag/ZnMn2O4/p+−Si | +8/−10 V | 102 | 100 | 105 | [39] |

| Ag/ZnO/ITO | +3/−1.5 V | 10 | 120 | 4 × 103 | [40] |

| Ag/ZnO/FTO | ±0.8 V | 103 | 100 | 102 | Present Work |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patil, S.R.; Chougale, M.Y.; Rane, T.D.; Khot, S.S.; Patil, A.A.; Bagal, O.S.; Jadhav, S.D.; Sheikh, A.D.; Kim, S.; Dongale, T.D. Solution-Processable ZnO Thin Film Memristive Device for Resistive Random Access Memory Application. Electronics 2018, 7, 445. https://doi.org/10.3390/electronics7120445

Patil SR, Chougale MY, Rane TD, Khot SS, Patil AA, Bagal OS, Jadhav SD, Sheikh AD, Kim S, Dongale TD. Solution-Processable ZnO Thin Film Memristive Device for Resistive Random Access Memory Application. Electronics. 2018; 7(12):445. https://doi.org/10.3390/electronics7120445

Chicago/Turabian StylePatil, Swapnil R., Mahesh Y. Chougale, Tushar D. Rane, Sagar S. Khot, Akshay A. Patil, Ojus S. Bagal, Sagar D. Jadhav, Arif D. Sheikh, Sungjun Kim, and Tukaram D. Dongale. 2018. "Solution-Processable ZnO Thin Film Memristive Device for Resistive Random Access Memory Application" Electronics 7, no. 12: 445. https://doi.org/10.3390/electronics7120445

APA StylePatil, S. R., Chougale, M. Y., Rane, T. D., Khot, S. S., Patil, A. A., Bagal, O. S., Jadhav, S. D., Sheikh, A. D., Kim, S., & Dongale, T. D. (2018). Solution-Processable ZnO Thin Film Memristive Device for Resistive Random Access Memory Application. Electronics, 7(12), 445. https://doi.org/10.3390/electronics7120445