Abstract

Following the development of the Industrial Revolution 4.0, many new types of systems are being designed, introduced, or attempted, even in almost every traditional industry. The clothing industry is no exception. The use of continuously developing production equipment and Information and Communication Technology (ICT) has a single objective, providing a customized service to all customers. Thus, in this study, the primary research task was to identify ill-balanced aspects or disadvantages of the services previously analyzed to construct a more complete online customized service. This was accomplished by analyzing an automated Computer-Aided Design (CAD) output file containing customer requirements regarding individual clothing items. The secondary research task was to plan and design a clothing manufacturing process to which a one-person one-item mass production system has been applied to achieve a customized service. As a result, for the primary research task, the customers’ requirements for each dress were reflected in attributes, such as color, pattern, or size, and it was possible to obtain an automated CAD output file for each element. Such CAD output files can be used in the production process directly. To find the possibility of upgrading the existing dressmaking process and implement the one-person one-item system, the entire manufacturing process was simulated for the test.

1. Introduction

In the midst of the Industry 4.0 Revolution, even traditional industries are introducing new system designs when attempting new ventures. The clothing industry is no exception to this. Clothes are a one of our basic human necessities and the clothing industry’s contribution to employment and the national economy cannot be ignored. The constantly changing production equipment and the current IT-based services have one aim: Delivering a customized service to all customers.

The Industry 4.0 revolution refers to the establishment of a flexible and efficient production system through the convergence of the manufacturing system and ICT (Information and Communication Technology). For instance, Germany has started the Industry 4.0 project to strengthen their manufacturing industry, while the US is operating and actively investing in a smart factory research and development consortium. Also, influenced by Germany’s Industry 4.0 project, China’s Ministry of Industry and Information Technology has launched ‘The Year 2025 Chinese Manufacturing Strategy’ to prepare for the new industrial revolution by intensively fostering ten sectors and partially promoting an additional four sectors. Meanwhile, the government of the Republic of Korea (ROK) is also constructing a special program for the innovation of the small and medium manufacturing industry, aiming to construct 10,000 smart factories by 2020. Due to the rapid changes in the manufacturing industry, the ICT central to the Fourth Industrial Revolution must quickly respond to various types of customer demands and changes in the manufacturing process to apply improvements to new systems [1,2].

Currently, the commercialized garment customizing services are largely divided into the Made-To-Measure (MTM)-type services and the customer-participating-type services, and the latter is a high-value service, which can express the customer’s individuality as his/her idea can be put into the design, which allows the elements, such as images, colors, etc., to be digitally printed for production [3,4,5,6]. Although many more customer-participating garment customizing services adopting the digital printing technology is emerging, there are still some problems to be solved. These problems are not only related to the method of solving a series of issues in the communications with the customers, but also closely associated with the production process, specifically, the customized mass production process.

However, there are very few studies that propose a solid hypothesis for mass customization in the clothing industry. This study attempts to establish a detailed plan for the subsequent platform development and service provision for the custom clothing sector in response to the Fourth Industrial Revolution, whereby said platform would become an innovative exemplar. The proposed platform is a garment shopping mall where customers participate with their own designs. The platform has many advantages over previous customized fashion services that have been studied. The first discussion topic in this study is the implementation of a more complete service, which corresponds with the Fourth Industrial Revolution by adding an image automation module for the clothing size to the platform. The second topic is the planning of a process where the customized clothes attached with customer-required conditions (i.e., ordered through the proposed platform) can be mass produced to serve the customers. This includes a process design of the smart factory for the clothes.

The contribution of this study is that the efficiency of clothing service and production process has been achieved through the methods being proposed. To improve the service and respond to one of the ultimate goals of the Industry 4.0 revolution ‘Individualized Service’, both the information of the customers who placed an order and the manufacturing information of the products are sent to the factory simultaneously through a means of online communication based on the online software being implemented. This provides a solution to the ordering, manufacturing, or the distribution process in terms of management for the individualized service. The entire process of the sewing solution distinct to the garment manufacturing process described in this study demonstrates the garment ordering and information transmission processes that are the most basic processes of a smart factory. The Author hopes that this research will be a reference for configuring an efficient smart factory in time of the Industry 4.0 revolution.

2. Related Research

Starting with Internet of Things (IoT), new technologies are in the limelight, and a new technology is being introduced each year. Also, the application methodologies for these technologies are being studied to find a way into individual industries and businesses. This is why the current era is being called the era of the Fourth Industrial Revolution. The novel technologies of this era are gaining potential in a high-value service or business, as well as in traditional industries involving food, housing, and clothing. As one of the major traditional industries, the clothing industry has greatly contributed to many countries’ economy in the previous industrial era. The superior productivity of the mass production system is still considered as a primary element in the current production systems. Thus, organic research works should be conducted for the rapidly changing clothing service and industry. In ‘A Research on Policy for Implementation of ICT-Based Smart Factory’ by Hyung-Joon Hahm (2017) [3], the concept of the smart factory originated from Industry 4.0 and it does not necessarily refer to mass production or efficiency, but is instead related to ‘personalized products’. Many examples of the smart factory can be found in Germany. One of these examples, associated with fashion, is the smart factory where Adidas customized sneakers are manufactured. The smart factory also suggests the necessity of a new platform that has introduced such a concept. That is, a smart factory for a personalized service and personalized products was proposed [7,8,9,10]. Meanwhile, Pan, B., and Holland, R. (2006) [11] explained their way of reflecting consumer preferences and requirements on the process of synthesis of design, production, and approval while reducing the entire production process in their research work ‘A Mass Customized Supply Chain for Fashion System with Design-Production Interface’. Therefore, the operation process in a smart factory reflects customer requirements on the production process from the time of order entry for mass production.

2.1. Characteristics of Clothing Service in the Industry

The ultimate objective of a clothing service in the Fourth Industry is to provide a customized service to the customers. In the research work of Štefko, R. and Steffek, V. (2018) [12], ‘Key Issues in Slow Fashion: Current Challenges and Future Perspectives’ was emphasized claiming that having the knowledge, skills, and competence based on that choices will allow one to actively participate in an actual production system. They also pointed out that the business models that allow an individual or a group to participate are suitable for small businesses and although they do not aim for the popular fashion market, they actually are a shared learning-based business, which provides a new meaning to the customers.

Currently, IoT-based customized services are divided into two types: A participating-type service, and an MTM service. The former mainly considers design elements (visual), such as colors or patterns as participating factors whereas the latter usually considers and customizes the sizes using automated custom-made pattern development technology. This is to provide customers with physically comfortable clothes rather than emphasizing visual effects.

2.1.1. Participating-Type Service

Concerning the participating-type service, Yoon-Jung Kim, Jong-Yeon Na, and Yuri Lee [4] analyzed five fashion services, and their common characteristics were as follows. First, all the design elements were included. They all provided an online platform to make the participating process easier. Such a method aimed to allow customers to ultimately produce their own item(s). Although the above researchers expected that there would be a limit in achieving this objective as these services were using a voting method, they also expected that the development of ICT would allow the range and the utilization of these services to be expanded further [4]. In 2009, Sanders and Simons distinguished the starting point of the participating-type services into the following four stages: First, the Design Stage where customer requirements are presented from the start, intervening in the design process. Second, the Fabrication Stage where a standardized product can be partially fabricated according to the personal preferences. Third, the Assembly Stage where options are provided when assembling the product. Finally, the Post Production Stage where additional modification can be made reflecting the buyer’s preferences after purchase [5]. Meanwhile, Hye-Jung Shin and Hye-yeon Kim (2015) analyzed eight design-participating cases and found some problems: Lack of a sustainable process in the production phase, design simulation function, and design modification function; deficiency in image editing; difficulty in assuring quality; less appealing environment; and limited designs [6]. Furthermore, mostly free size or simple clothes were used for the service with a simulation function, as this simplified the complicated manufacturing process. Using these types of clothes is quite common in the participating-type services, but it can be a weakness as well. For formal fashion, even a small personal brand has a specification for each size. On the other hand, low-priced clothes in a wholesale market without any brand usually use free sizes. The situation in which sizes are not being specified even for high-value services should be corrected.

2.1.2. MTM-Type Service

As a customized mass production service is provided in an MTM service, customers are able to purchase well-fitting clothes at a more reasonable price [5,6,7], and such a service is being used for men’s suits [6]. The technicalization of adding variety to the size of the basic patterns is key to MTM services, and Kim et al. (2011) classified such a back-end technique into three categories. First, programming the pattern drafting process and displaying the pattern automatically once the measurements are entered. Second, deploying data on a 3D-scanned body surface. Third, grading the deviations in the measurements to be applied to a base form [9]. The MTM services are provided based on 3D virtual clothing technology and data utilization technology [10,11]. However, such a service is not as accurate as a manual clothing system where a person actually takes measurements and cuts out clothes. In the last Fourth Industry Fashion Exhibition, many cases of inaccurately-sized clothes were produced during the demonstration of making 3D scan-based customized clothes [12,13,14]. This was due to inadequate scanning of the body of a person who was already wearing clothes, even if they were very thin. Also, a service related to a data-based body type classification option often encounters an error as the selected option sometimes does not match the customer’s body size [15,16,17,18,19]. This is because although the data is subdivided more than the existing standardized size data, this data also uses standardized measurements [20,21]. IWODE (Guangzhou, China) and Korea’s Stripes also provide ICT-based MTM clothing services for men, but in the end they had to use a visiting service for measurement. As this case shows, the most efficient way to achieve an MTM service is using manually measured values, rather than using standardized data or a high-tech scanning technique [22,23,24,25]. Applying ICT-based technology to an actual service just for its convenience would lead to a greater risk of a large volume of returned sales [26,27,28]. This may be riskier than having to choose the clothes from the standardized sizes. For this reason, the Author considers that it would be more reasonable to select one’s own clothes from the standardized ready-made items rather than from the MTM service. It would be better if a specialist consults with the customer to recommend a suitable size, but if it is not possible, selecting the correct size from a greater number of size categories is a reasonable alternative [29,30,31]. In summary, participating-type clothing services tend to offer rather simple sizes, and MTM services also have some problems in offering proper sizes. Thus, it is possible to think that adding more standardized sizes to a participating-type clothing service would be more appropriate for the ideal objective of the Fourth Industry.

2.1.3. 3D Clothing Simulation

In a study related to digital fashion textile products using 3D and virtual space technologies, Junghwan Sung and Heewon Sung mainly discussed 3D technology along with ICT to support consumer-centered purchase and consumption in the 21st century [32]. They suggested a digital communication technology where these two discussed technologies were converged. They wrote that digital communication refers to the actions of 3D-based body measuring and modeling, parametric human body modeling for producing clothes, drape simulations, modeling of raw materials, virtual dressmaking and wearing, texture mapping reflecting the exterior and the pattern of the product, and dynamic simulation and animation. In other words, customers need to know how to use these technologies on the internet to receive a corresponding service, or a hired expert has to show the result to the customer after reflecting the customer demands and using the available technologies. In a way, for the former, the complicated operation requirements would cause much inconvenience to the customers whereas the latter would lead to a large labor cost. They also claimed that a personalized pattern, which could replace the grading concept can be created with a virtual body developed with customer body data. This idea can be considered as the method developed by Kim et al. (2011) [9], who deployed the data on a 3D-scanned body surface.

A company in China [33] just happened to sell that product at the time so that the Author conducted an interview on the phone and discovered some problems. That is, this method is effective when making a tight-fitting party dress or a suit, but is not adequate for loose-fitting dresses or ones with frilly fabric. Thus, this system uses a method that makes a tight original pattern for each customer in advance and then cuts a pattern following the main design based on the original pattern again [34,35,36,37]. For this reason, it is impossible for this method to rapidly implement the stage in which the pattern will be instantly generated automatically like the grading method, which was introduced by Dae-Hee Lee, Jae-Yong Lee, Gyu-Hyeon Bae [38]. These two also described the cooperation and the shopping system in a virtual space, but it is not clear that such research would actually affect the customer purchase interest even though it certainly has some significance in terms of technological development.

Also, from a technological perspective, some customers responded that there might a problem as their computer specifications would not be adequate for the transmission speed when they use the 3D shopping malls. Therefore, they speculated that such a 3D-based internet shopping mall may become an obstacle to the purchase decision. That is, although implementation of a 3D-based internet shopping mall requiring some expensive high-end technologies and high-end specifications may have been an attempt to provide more detailed information to the customers, the research result showed that a few photos of a dress could have delivered the information better and more accurately. On the other hand, Hye-Jung Shin and Hye-Yeon Kim (2015) and Yoon-Jeong Kim, Jong-Yeon-Na and Yuri Lee (2015) found that there was only one case where an MTM-type customizing service was used for simple clothing (bottom underwear) among the commercialized customized fashion services [32,33,34,35]. There were no other examples of a 3D-based simulation using real-time 3D rendering technology. Meanwhile, some cases of 3D-mapping simulations were conducted, but as they were actually very similar to 2D image-based manipulation, they should be regarded as 2D-based simulations. When commercializing an online customized fashion service, 3D-based designs would certainly interest the customers, but it is doubtful that they would have much effect on the purchase decision. By contrast, 2D-based customized shopping malls are still very active on the market as they can offer faster information delivery speed and easier operation.

2.2. The Studies Related to the Process and Equipment of Smart Factory in the Fourth Clothing Industry

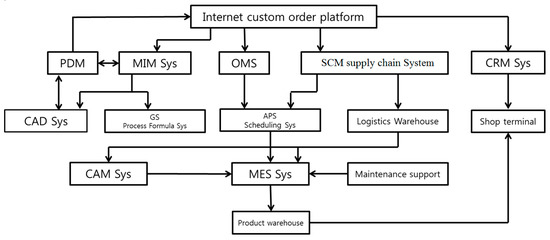

The new garment manufacturing equipment and their novel applications, along with the emerging ICT-based clothing services and relevant technologies allow researchers to design a new innovative type of smart factory suitable for the Fourth Industrial Revolution. Xian ting He (2018) [10] has designed a flexible supply chain and its digital system for clothing customization, as shown in Figure 1, which describes an online customer ordering platform. The elements, such as the software dealing with design development, production, management, and sales, as well as the order management system, including production process, factory, and sales shops, are flexibly organized in the design.

Figure 1.

A flexible supply chain and digital system.

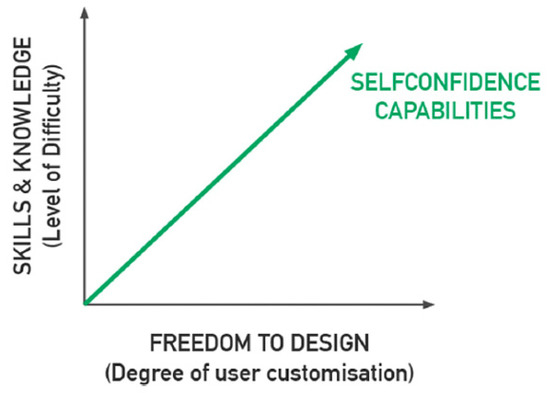

A proposal was made in relation to the creation of new value through the ‘Social manufacturing’ promoted by DIY (do-it-yourself), DIT (do-it-together), and some participating-type design strategies. They distinguished ‘design’ and ‘professional design’ by stage to assess the degree of freedom allowed to a participant giving a definition. In other words, a test was conducted from the stage where only the details a beginner or a user can define had been given, because some of the clothes have been made almost ready as if a designer has prepared them to the stage where more freedom of design was given to the customer, but higher skills were required, despite the fact that much preparation had to be made. Figure 2 shows increased skill-level results in greater self-confidence and capabilities.

Figure 2.

Increased skill-level results in greater self-confidence and capabilities.

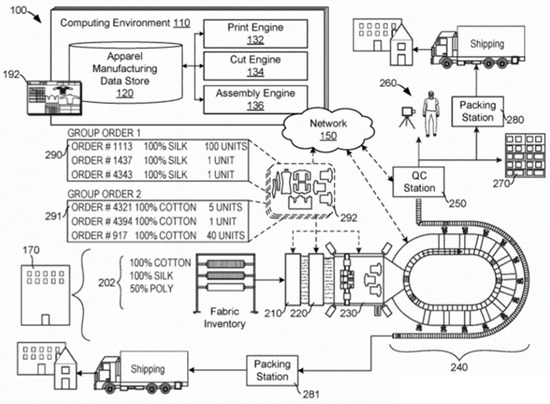

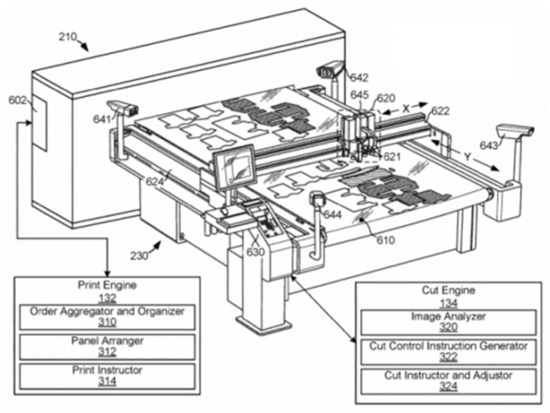

In April 2017, Amazon acquired a patent related to the on-demand apparel manufacturing system [34]. The related typical process is described in Figure 3. Although all the ordering and production processes are included in the system, the two most emphasized parts of this system are the panel printing and cutting of the textiles. The details pertaining to how the orders will be received, the user interface for ordering, what should be prepared prior to printing, and how the needlework should be performed (in line or one-by-one) are not described.

Figure 3.

An automated apparel production and distribution system.

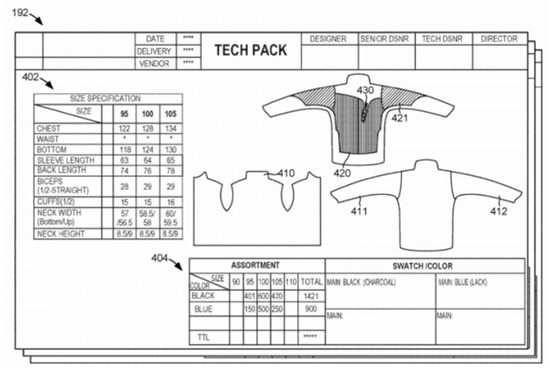

In Figure 3, it is possible to observe that the digital printing and cutting processes [34] are sequentially carried out together. However, in the printing process, the internet user interface that allows a customer to select the garment’s surface area is not described in detail. This is due to the possibility that the production equipment and the processes could change according to the order-receiving flow of the user interface being used. Figure 4 shows the Tech Packs [34], and a technician who can read it to design a production process is required. Then, in the ‘automatic generation of needlework instruction’ mentioned in patent 330 (Figure 5), was the instruction based on the analysis? When there is just one dress, a single sewing process is applied, but if there are multiple clothing items, according to patent 330, a swing instruction is given to each panel and another instruction is for the next one. It is not clear whether, in a manual process, a new process would be generated as a secondary plan to fix the mistake made by not following the instruction. It is explained that patent 330 includes many data and even generates the information pertaining to sewing sequence that includes the combination of processes. However, an exact generation method for the sewing sequence is not introduced. This patent does not cover detailed solutions to all the possibilities and their descriptions are still lacking. This paper attempts to study this part more concretely while focusing on the process in the smart factory.

Figure 4.

Tech packs for manufacturing.

Figure 5.

Textile printer and textile cutter.

The garment industry is a traditional industry that still cannot escape the labor-intensive environment, due to the flexible characteristics of textiles. Such flexible materials are quite different from the hard objects, which can be conveniently moved or joined together, making a robotic arm inefficient. Also, the flexible textiles can transform into 2 or 3-dimensional forms (physical characteristic). It is therefore safe to say that if the needlework can be automated, the majority of the garment production process has been automated as well. The patent acquired by Amazon [34] shows that the needlework is actually carried out by workers. Nevertheless, there have been a series of studies and hypotheses on the process of automated needlework.

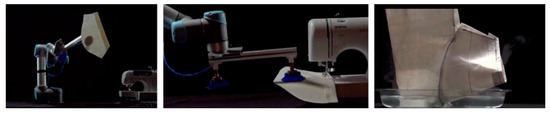

Jonathan Zornow (US) invented a sewing robot named Sewbo in 2017 claiming that a single item like a t-shirt can be produced within half an hour. Figure 6 depicts the automated sewing process of Sewbo [15]. In this invention, a robotic arm was used to carry out automated movement and for this reason, the flexible textile was processed stiffly. That is, a stiffly processed fabric was used for the assembling process and after that, it was soaked in water to restore it to its natural form. Such a textile stiffening method has its own disadvantage in that it is difficult to use the technique for materials which have a high waterproofing property, such as waterproofed wools or leathers. Currently, most of the automation attempts in the clothing industry are made for simple-construction items like t-shirts. However, even if the attempts have been successful, it does not guarantee success in actual production sites, as other clothing items require 5 or 10 times more steps to process in the production line.

Figure 6.

Sewbo sewing clothes.

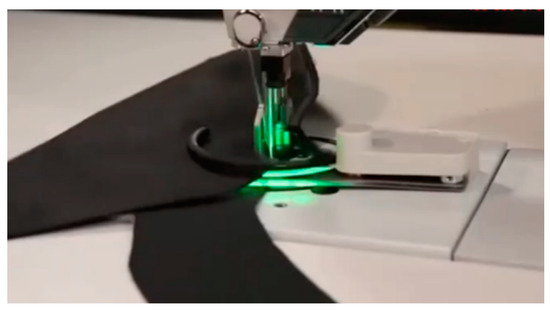

Meanwhile, a software company in the US developed another automated sewing robot [37]. Each workstation linked to the production line is quite precise, simple, and efficient so that the line can be operated independently with just one worker. Figure 7 shows a process where differently curved patterns are being sewed together. Such a process requires the human skills of being able to uniformly sew and match both ends of the patterns. Those with fewer skills or know-how would not be able to perform such tasks. If automation can be achieved in this field, it will be a ground-breaking technology that brings new hope to the clothing industry.

Figure 7.

Automatic sewing.

Figure 8 shows an automatic sewing line. The plate on the belt automatically transfers the dress to be sewn sequentially by each machine.

Figure 8.

Automatic sewing production live.

This company is applying this production system to produce shoes, pillows, mattresses, t-shirts, and towels. An order can be placed on the company homepage by drawing up a tech pack(s). This system might be the most excellent example in the current field of needlework automation. However, it is slightly disappointing that the system is being mostly used for the mass-production of a single product. If the system can be applied to the mass production line for customized (one-item one-person) clothes, its value will be appreciated further. The processes should be organized efficiently and sequentially to achieve such a concept. Also, if a command that instructs a combined process in a specific process zone can be entered with just a simple touch method, the system could be used for various types of clothes [38]. Soon Oh and Jin-Seon Kim (2016) [39] rounded up the needlework process for the production of a coat with 53 processes in their research study ‘A Comparative Study on Needleworks for Female Coat’. This is a process excluding the post-processing work. However, there are only about 10 processes involved in manufacturing a t-shirt, which is often tested in a smart factory for clothes. If the commands between each process can be conveniently programmed for needlework, the above system will allow mass production of customized clothes based on the faster automated sewing process. In addition to these studies, Dae-Hee Lee et al. (2017) [38] designed and tested a system that senses the remaining thread in a bobbin usable at smart sewing factories.

3. Research Contents: Customized CAD (Computer-Aided Design) Framework and Design of Production Process

The aim of this study is to provide a solution for an on-demand CAD framework for the mass production of customized (one-item one-person) clothes and design a production process. These are the two main objectives of the study.

A customer-participating clothing platform was used as an example for the research as this platform was a sort of web platform, including the service that best corresponds to the ultimate objective of such a service, proposed by Yun Jeong Kim et al. (2015) [4], a service without ‘limitations’. The characteristics of this service are that customers can participate in the design process and all the designs developed by each customer will be produced, instead of producing small quantities of a single design selected by vote. That is, aside from customer participation, a service that allows the production of customized clothes (one-item one-clothing design) is quite innovative and its concept completely corresponds with the production potential of the smart factories explained.

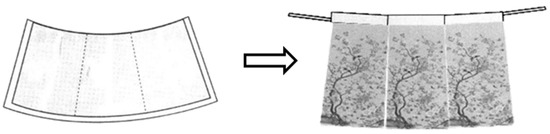

Also, it can cover all the limitations in the existing fashion design participation cases analyzed by Hye Jeong Shin and Hye Yeon Kim (2015) [6], making it the most suitable example of the proposed platform. The grounds for the proposed platform, which is able to provide all the customers with clothes of different designs, are associated with the automated printing image generation technology for back-end production [40,41,42]. In this regard, Eun Gyeong Han [43] proposed a production method in 2006 where the design was performed in a CAD-based pattern for printing, as shown in Figure 9 [43]. Following the development of the digital printing industry, such a design R&D method has been commercialized. S Kim (2011) [44,45] extended this production method into a study about customized service (Figure 10). It was possible to obtain a panel on which a customer-designed 3D design was automatically printed within the pattern.

Figure 9.

Design inside the panel.

Figure 10.

From 3D scan to automated customer designed panel.

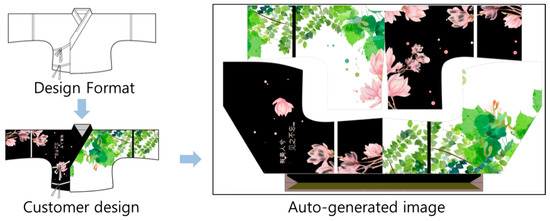

The proposed service also follows a similar production method and the printing image automatically generated is shown in Figure 11. This image is one that the design provider can see from his/her end for the order(s) designed and placed by him/her. Additionally, the input system, which allows various types of clothes to be converted into a design format, can be used for the design of various fashion items, not just for simple-design clothes [40].

Figure 11.

Design U platform’s service process and technical.

Further, the design simulations can be performed with 2D simulations, which are fast and convenient for the customers. Nevertheless, the automatic image generation should be prepared for printing every image size. This is because the printing task for the printing process of customized clothes requires more complex preparation and management than free-sized clothing. However, if a management system, which can control the size of the patterns conveniently by adding a module that controls the pattern sizes like ‘IWODE’, a relatively complete customer participating fashion IoT service can be achieved.

Therefore, the first research task is to develop an automated panel image generation system where a size-control module has been adopted. Through this developing process, a service that provides 2D-based simulations to customers by including a panel-grouping function will be possible as well. The second research task involves a mass-production method with which various types of clothes with different designs ordered by each customer using the Design U system.

4. Research Method

4.1. Size Control Pattern

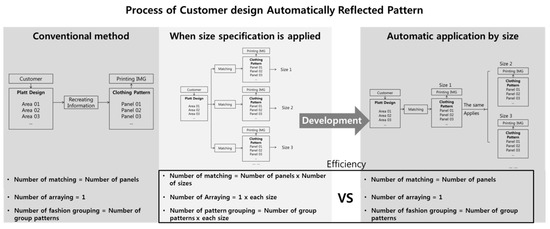

The following method is used to add a size control module. When adding the module, it is preferable for the customer to set the size(s) and methods. This is mainly due to the questionable accuracy of MTM. Also, for the CAD, the objective is to generate an automated image on a pattern whose size may vary depending on the customers. The automated pattern generation is implemented on the web. Existing automated area matching technology follows the process shown in Figure 12. An area of flat design is matched to one panel. Two PNG files are overlapped in an opaque status. It is a match between one flat design PNG file and one PNG pattern piece. The matched pattern is one piece of pattern in a specific cloth. However, regular brands in a fashion market provide clothing by size. Therefore, even if there is one flat design, the matching pattern must match N times if there is N number of size, as does the pattern array. To reduce the amount of labor required to do repetitive behavior up to the number of size, it maps to all other sizes if there is one which matches a specific size. Also, Figure 13 automatic application by size UML (Unified Modeling Language).

Figure 12.

Development concept flow chart.

Figure 13.

Automatic application by size Java UML (Unified Modeling Language).

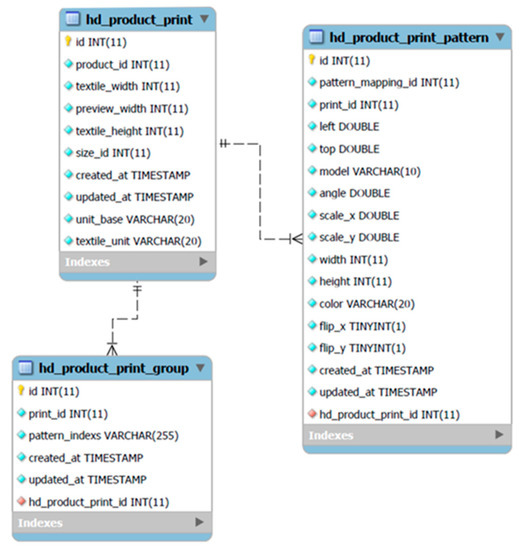

4.2. Panel Grouping

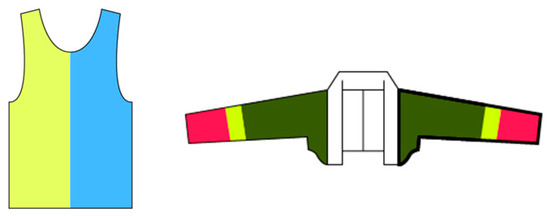

Parts controlled in another pattern Array is a development of pattern grouping technology. One area of existing flat design is relevant to one pattern. If one background color is applied to a flat design, the matched pattern becomes that color. However, this one pattern may show various background colors. For example, it includes the sleeve color of a traditional costume and color of sportswear (Figure 14). It makes it as if there are many areas in one piece of pattern. For example, if one pattern is divided into three areas, it must be actually three patterns, and these three pieces must be attached as if they are one. However, in the Array process, the largest size pattern can be arranged. Also, if it moves to smaller sizes, it makes a gap between the three array patterns, which makes size automation difficult. Therefore, it is necessary to develop grouping technology. A related idea is shown in Figure 15. It makes one group have the same size of three patterns. In the next place, it overlaps the selected patterns at the central area, and if three images of the same size that are divided by parts are grouped, it looks like one pattern. The “transparent area of the image” is actually represented by the white part of each image.

Figure 14.

Example of one pattern with one more area.

Figure 15.

Pattern grouping concept.

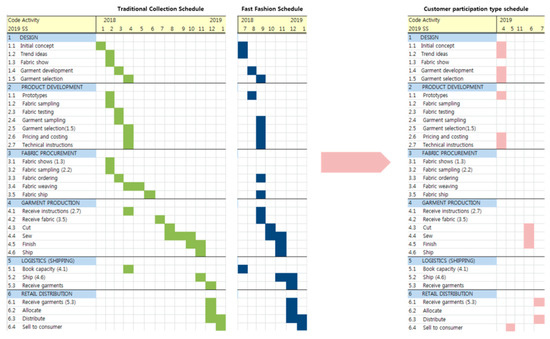

4.2.1. A Mass-Production System Process for ‘One-Person One-Item’ Based Customization

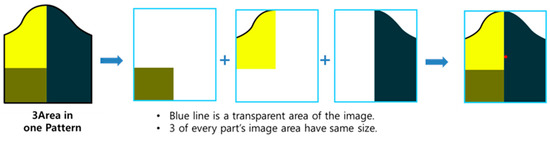

A common garment production process cycle starting from design planning to manufacturing presented by KOFOTI (Korea Federation of Textile Industries, Gangnam-gu, Seoul, Korea) in 2017 is shown in Figure 16 [45]. Based on this table, an attempt is made to create a supply chain cycle, which includes all the processes involving garment planning and production for the one-item one-person customer-participating service. The conventional production scheduling had to be started about 13 months prior to starting their sales, but this period has moved back to six months, due to the emergence of fashion brands who have their own supply chains. Currently, there is even a system that has shortened the supply deadline from five days, to three days. Considering the delivery time, it is possible to guess that such a method may have drastically shortened or skipped the time necessary for design development or the tests. The cycle becomes shorter for fast fashion brands and many consumers often wear these brands no more than one time. This may be due to the fact that these brands value the similarity to current trends over the quality, fitness, or architecture of the clothing. In the Design U service, each customer is able to participate in designing the clothes so that these clothes would hold a higher value for them than other customized clothing items that have been produced for special occasions. Also, holding a higher value does not necessarily mean that its trendiness will last long. Customers tend to reflect their design personality each time following the trend. This might be their way of representing themselves as a creator rather than being a trend follower. With the Design U service, the inventories can be reduced markedly as only the ordered products are produced, and by doing so, each item’s value could be increased. In this regard, the schedules for product planning and manufacturing and between customers and producers are developed along with a customer cloud funding system.

Figure 16.

Fashion planning and production process supply chain schedule.

4.2.2. Design of One-Person One-Clothing Mass Production Smart Factory

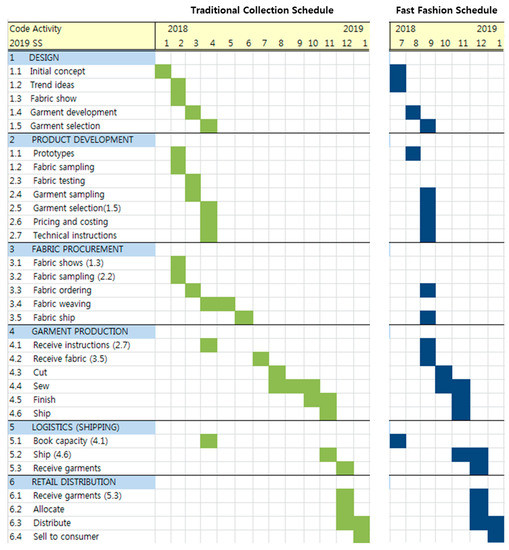

Observing the service characteristics of the Design U service, the first is its method of starting the production only for the order placed by the customer through cloud funding. Such a method is suitable for mass production as it allows the production of several items in a single style. However, these mass-produced clothes are actually different clothes as each clothing item contains an individual customer’s own visual design (colors and/or patterns). It is just that since each panel belongs to a different customer, they must not be mixed with other panels when proceeding with the needlework. Thus, in addition to a tech pack for each clothing style, a mapping work order that lists the outputs of the designs of each different customer should be given as well. Such an additional order is used to check the errors of misplacing/misusing the pieces belonging to another customer when performing the needlework.

There are two sewing methods: Single sewing and line sewing. For the former, as shown in the upper section of Figure 17, each clothing item is counted as a sole unit so that they are sewn one by one. At this moment, a needleworker is required to have deep knowledge of clothing composition, as well as skillfulness. To perform line sewing as shown in the lower section of Figure 17, the panels of the same shapes are grouped from the same clothing styles for sewing. Here, the worker is not required to have a good understanding of the clothing compositions so that he/she just needs to repeat direct or curved-line sewing for the panels given to him/her. The Design U service adopts a method where a garment is produced repeatedly by way of cloud funding, but there is one caution that the user should make note of. That is, there are no differences between the top panel and the bottom panel when the panels are piled up. However, in the one-person one-item production method, the panels must be sewn in order to produce a dress accurately. This means that the way of piling up the panels is also important.

Figure 17.

Panel classification scheme by sewing method: Line sewing and single piece flow production.

The second characteristic is that a DTP [41] (Digital Textile Printing) process is required to print separate visual designs prepared by the customers so that DTP equipment must be included in the production line. The panel pieces have to be cut continuously in the cutting process [42], but it is more preferable to cut them one by one rather than cutting all of them at the same time.

5. Result

The clothing produced in the test has validated that the suggested customized service and the production process design for the clothing industry in the Fourth Industrial Revolution can efficiently provide each customer with a different type of clothing, adding higher value through an efficient production process and management system.

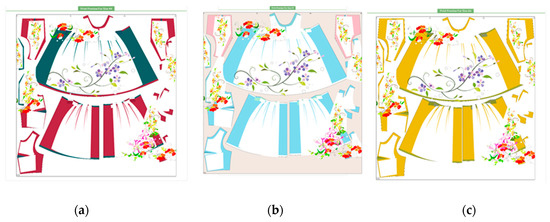

5.1. Mapping Result by Size

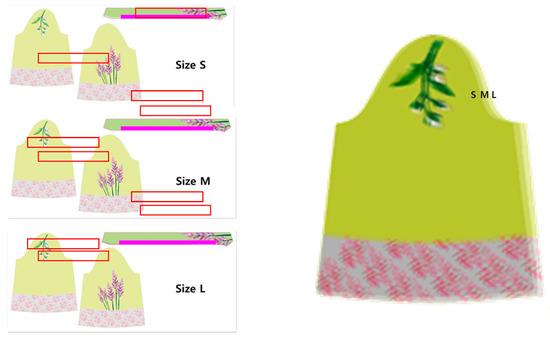

As a result of mapping by size, the customer area becomes larger or smaller by size, and it has the same results in terms of size proportion, rotation proportion and position (Figure 18).

Figure 18.

Apply size result. (a) Size S (b) Size M (c) Size L.

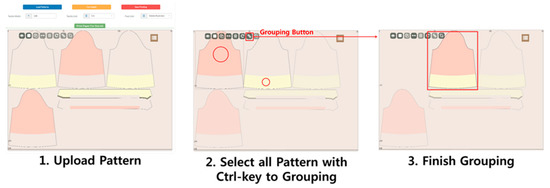

5.2. Result of Grouping Setting Function

Figure 19 shows a panel array screen. At the top are the function buttons necessary for arraying the panels. A grouping button has been added here.

Figure 19.

Result of grouping setting function.

5.2.1. Design Result of One Person One Item Mass Production Process

A plan and production schedule for a customer design participating product has been established (Figure 20). The supply chain cycle of Design U customer-participating service is considered to be five to six months. The period in which a customer can participate in the design process is estimated at 1.5 months and is included in the cycle. The clothing company can start the design R&D, five months prior to sales. At this time, the supplier is ready to respond to the customers with just the garment design selection, fabric selection, and samples. The difference with the existing mass production is that the sales activity starts prior to the production.

Figure 20.

A supply chain schedule suitably changed for the production method of the Design U service.

The schedule between the customer and the producer is shown in Figure 21. The design suggested above and its sample are registered until the middle of April for the dress, which will be provided in the first week of July. The customer participates in the design process for a period of 1.5 months followed by its production for a month. An additional seven days are used for the delivery. The period of R&D varies by design company, but if there is a usable previous R&D source, its format can be registered. Although the production period was set as a maximum of one month, it can change depending on each company’s production and supply chain so that the supply cycle may change as well. However, the entire process follows the sequence shown in Figure 21. A company with a short production cycle and many customers will be able to proceed with cloud funding several times for a single design in one season.

Figure 21.

The customer-participated scheduling.

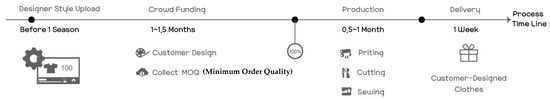

Figure 22 shows a scheduling roadmap of a customer-participating service performed by the customer cloud funding. The customer can receive the dress 1.5 to 3 months after participating in its design. The companies that have a short production cycle can plan the production schedule within 1.5 months so that the customers’ waiting cycles will become shorter and shorter as their number increases.

Figure 22.

Crowdfunding process of customer design participation.

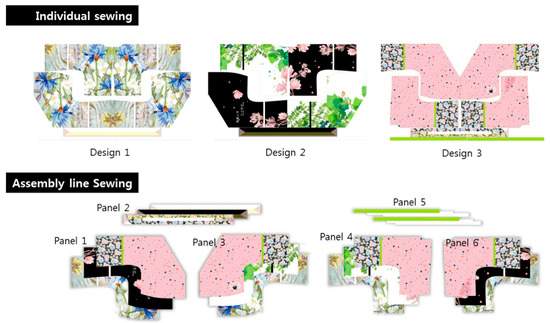

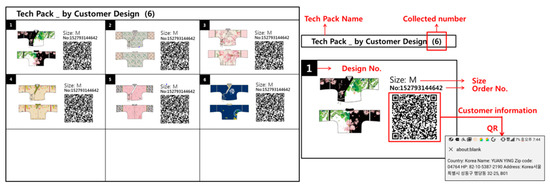

5.2.2. Design Result of Smart Factory Using One Person One Item Mass Production

The Tech Pack used here is an additional individual customer Tech Pack, as the design of each dress is different and each design has a fixed customer. The additional Tech Packs are basically outputted in color as the visual information of the participating customers must be distinguished. The number next to the name of a tech pack is the number of dresses collected through cloud funding. For each customer, the minimum information, including size and customer order number, is briefly filled in along with the starting and ending color for color mapping. The size is indicated, as a size tech should be attached when manufacturing the dress. The order number is used to track the product in case some problems occur, or just for mailing. The customer information embedded in a QR code is mostly a delivery address. Simply by scanning the QR code and attaching the printed address sticker on a delivery box, it is ready for shipping. Also, the numbers next to the designs are for the communication between producers. Instead of marking each design as XXX Customer’s Design or Order Number XXX Design, it is more convenient to indicate each of them as No. 1 Design, No. 2 Design and so on. Depending on the Tech pack, it is possible to include 6 to 16 kinds of customer information in each Tech Pack. Figure 23 shows additional tech pack for one person one item mass production.

Figure 23.

Additional tech pack for one person one item mass production.

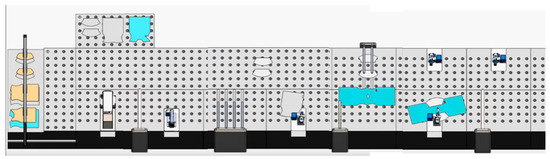

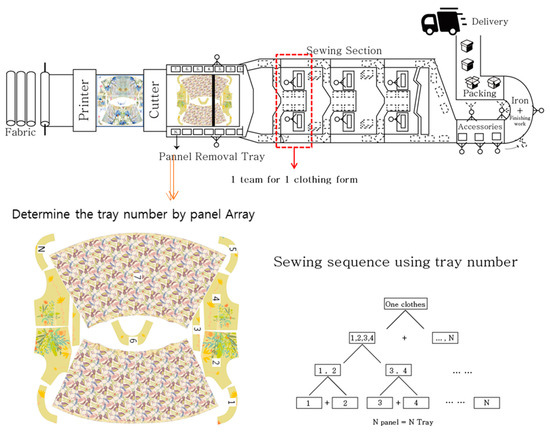

Figure 24 is the configuration of the smart factory for the customer-participating one-person one-item mass production system. A design method involving a sewing sequence using a tray is proposed as well. Observing the factory configuration, the fabrics necessary for printing are set in array. Each fabric could completely cover a single dress, or two or three fabrics have to be printed in sequence as a set. In many cases, outer fabric, inner lining, and pads constitute a set and they are processed individually and sequentially. The factory process is organized in such a way that the printing and cutting tasks are carried out on the outer fabric whereas only the cutting task is applied to the inner lining and pads, skipping the printing task. Once the fabrics have been cut, the panels are moved to a tray marker with a single number. In the one-person one-item system, it is expected that the total number of dresses collected through cloud funding for a single style would remain between 30 and 200, but would not exceed 200. A group of two or three to four undertakes the orders for a single style. The workers are divided into the tasks of fabric sorting, sewing line, and accessorizing/post-treatment/delivery, with a single leader. At this time, the workers other than the leader can be replaced by mechanical arms or an unmanned sewing system in the future. The fabric sorting team sorts out all the fabrics by panel and delivers them to the sewing team on the conveyor belt. The delivery can be routed to each sewing team separately. The finishing team performs the accessorizing, ironing, and delivering tasks in sequence. The configuration of this factory is suitable for a small quantity batch production system or a one-person one-item mass production system so that it is not comparable to the existing systems of producing thousands to hundreds of thousands of clothing items in a single style, and it can minimize the space required for production. Also, as the factory starts production as soon as an order is placed, a warehouse for the finished products is not necessary.

Figure 24.

Design of smart factory for one person one item production.

The planning of the sewing sequence is shown at the bottom of Figure 24 as follows: Considering only the sewing process, one of the sequences is to sew only one line or one curve. That is, by sewing one line, two panels will become one so that, for a single style, the method of preparing as many trays as the number of panels and assigning individual numbers to the trays for sequential sewing is quite useful to unskilled workers. For one clothing style, each identical panel will be placed in the same location for all the dresses (Cf. two color pictures in Figure 24). Thus, when performing the panel arraying task 3, months prior to the production, the sewing process can be carried out more conveniently by assigning the numbers to the trays considering the locations of the panels to be placed. The tray numbers are given according to the panel’s locations and the printing/cutting locations, but the numbering formulas will be different depending on the panel sewing sequence. Figure 24 shows that trays 1 and 2 are sewn first and 3 and 4 are next. Finally, the former and the latter are sewn together. This means that the sewing sequence does not follow the number sequence, but is carried out according to the formula.

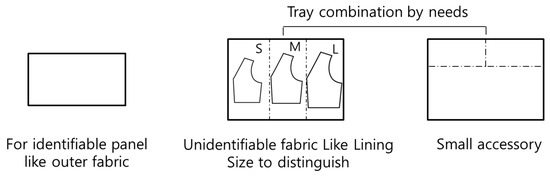

The sizes are distinguished for the panels that have not been assigned any customized designs. The several small pieces, such as inner linings or accessories can be put in a single tray. Also, the trays used for distinguishing the patterns can be manually combined (Figure 25).

Figure 25.

Tray combination by needs.

6. Test Evaluation

6.1. Evaluation of Automated Pattern and Panel Grouping Test

The result of mapping the customer design information to the relevant size is shown in Figure 26. All the sizes excluding the largest one, which is a reference size, in the array are perfectly grouped. The right side of Figure 26 shows that a customer-designed flower pattern applied only once before has been adjusted automatically according to the sizes. This can be confirmed by the differences in sizes. For the evaluation of the grouping test, the picture on the left shows the result obtained from performing a grouping process just one time for a single size. If the grouping has been equally successful for the other sizes, a crack will be generated at the boundary of the area indicated with a red box. As the crack was not generated for any other sizes, the grouping was equally successful.

Figure 26.

After customer design mapping.

6.2. Result of One-Person One-Item Mass Production Test

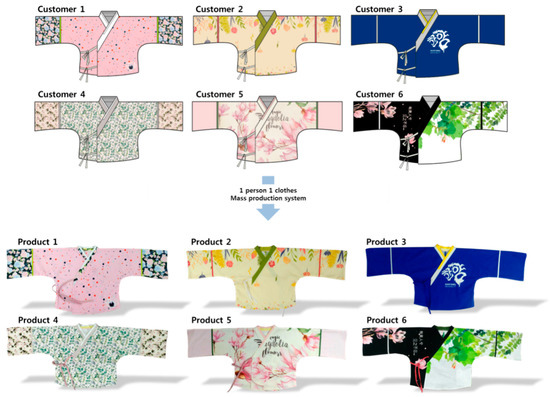

The top part of Figure 27 shows the result of a design created by the customer participation through Design U. The lower part shows the actual dress provided through the one-person one-item mass production method. As the picture shows, a dress very similar to the dress the customer wanted can be produced and this test shows that this method can be applied to the actual production service.

Figure 27.

The product of one person one item mass production system.

7. Conclusions

In this study, a customer-participating design service was studied along with the process customized to a one-person one-item mass production system to provide such a service from clothing plan, to design, to production. The process has been designed and proposed in order to develop a relatively complete service, which can be commercialized rapidly with currently available technologies. The Design U platform is a platform that allows customers to participate in the designing process with some visual elements. By adding a sizing technique to this platform, back-end technology, which automatically generates individual customer designs by size was developed. With this technology, customers will be able to not only select the clothes based on their visual interests, but also create a well-fitting dress in their own design by utilizing the added size selection function, adding more values to it.

The test result of the front-end service plan and back-end production process plan extends the possibility of achieving an efficient one-person one-clothing mass production system and developing the related services, as well as proving that the garment customizing services can be applied to more popular clothes.

Also, by using the major function of the Design U service ‘automatic image generation’, the designers can reduce the time required for reproducing their designs on the patterns repeatedly. The Author hopes that the smart factory structure design utilizing such technology and the processes involved in the entire production system could become another reference material that differentiates them from the existing ready-made production technologies for clothing companies who are planning a similar service. Further, such a one-person one-item customer-participating design system can be mixed with other general mass-production systems. For instance, the Design U service allows a customer to view and select the designs already paid for by other customers so that the new customer would not have to go through any design process, by simply choosing a design he/she prefers and proceeding to the production phase. The selected design could be used for mass production as ready-made clothes in the end.

Providing the viable methods of improving the efficiency in the clothing service and the manufacturing processes is the main objective of this study and a contribution has been made to that regard. An efficient service can be achieved by implementing an online software, which allows efficient and effective online communications—through which the customer information is delivered to the manufacturing factory along with the manufacturing requirements. This type of the process indeed follows the one major characteristic of the fourth industrial revolution namely ‘individualization’ or ‘customization’. The management solution proposed in the study promotes the efficiency in ordering/information delivery/distribution process whereas the proposed sewing solution focuses on the basic, but efficient performance in the production line of the smart factory. It is expected that this study will be a useful reference in establishing an efficient smart factory for the clothing industry in the era of the fourth industrial revolution.

The main feature of the platform and the production process developed in this study is that they make it possible to provide an individualized service for the customers by offering them different clothes. In the future, it is expected that such a nature of directly connecting an order system with an appropriate production process will be applied to the studies pertaining to the authentication systems using blockchain.

Author Contributions

Conceptualization, Y.Y.; Data curation, Y.Y.; Formal analysis, Y.Y. and J.-H.H.; Funding acquisition, Y.Y.; Investigation, Y.Y.; Methodology, Y.Y.; Project administration, J.-H.H.; Resources, Y.Y. and J.-H.H.; Software, J.-H.H.; Supervision, J.-H.H.; Validation, J.-H.H.; Visualization, J.-H.H.; Writing–original draft, Y.Y. and J.-H.H.; Writing–review and editing, J.-H.H.

Funding

This work was supported by the research fund of Hanyang University (HY-2014).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Park, S.; Huh, J.-H. Effect of Cooperation on Manufacturing IT Project Development and Test Bed for Successful Industry 4.0 Project: Safety Management for Security. Processes 2018, 6, 88. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Murino, T.; Gallo, M. Layout and material flow optimization in digital factory. Int. J. Simul. Model. 2016, 15, 223–235. [Google Scholar] [CrossRef]

- Hahm, H.J. A Study of Smart Factory Policy for ICT-Based. e-Bus. Stud. 2017, 18, 363–380. (In Korean) [Google Scholar] [CrossRef]

- Kim, Y.J.; Rha, J.Y.; Lee, Y. ICT Development and Customer Participation in Fashion Industry-Case studies using Value Co-creation of Business Model. Fash. Text. Res. J. 2015, 17, 907–918. (In Korean) [Google Scholar] [CrossRef]

- Sanders, L.; Simons, G. A Social Vision for Value Co-creation in Design. Available online: http://timreview.ca/article/310,2009 (accessed on 30 June 2018).

- Shin, H.J.; Kim, H.Y. A Study of the Development of Fashion Design for Enhancing Sustainable Participation of User. J. Basic Des. Art 2015, 16, 253–268. (In Korean) [Google Scholar]

- Chun, J.S.; Lim, H.S. A Study on the Use of MTM CAD Program for Mass Customization of Men’s Suit. Res. J. Costume Cult. 2003, 11, 647–656. [Google Scholar]

- Jang, S.O. Optimized Automation of Men’s Suit Pattern for MTM Production. Fiber Technol. Ind. 2006, 10, 259–266. [Google Scholar]

- Kim, I.H.; Nam, Y.J.; Kim, S.M. Development of Air Force Winter Service Uniform Shirt Pattern and Automatic Pattern Drafting Program for MTM Production. J. Korean Soc. Cloth. Text. 2011, 35, 1271–1284. [Google Scholar] [CrossRef]

- He, X. Digital Technology Drives the Customized Transformation of the Apparel Industry. Basic Sci. J. Text. Univ. 2018, 31, 19–24. (In Chinese) [Google Scholar]

- Pan, B.; Holland, R. A Mass Customised Supply Chain for the Fashion System at the Design-Production Interface. J. Fash. Mark. Manag. 2006, 10, 345–359. [Google Scholar] [CrossRef]

- Štefko, R.; Steffek, V. Key Issues in Slow Fashion: Current Challenges and Future Perspectives. Sustainability 2018, 10, 2270. [Google Scholar] [CrossRef]

- Sinha, P. The mechanics of fashion. In Fashion Marketing: Contemporary Issues; Hines, T., Bruce, M., Eds.; Butterworth-Heinemann: Oxford, UK, 2001; pp. 65–189. [Google Scholar]

- Hinds, B.K.; McCartney, J. Interactive garment design. Vis. Comput. 1990, 6, 53–61. [Google Scholar] [CrossRef]

- Okabe, H.; Imaoka, H.; Tomiha, T.; Niwaya, H. Three dimensional apparel CAD system. ACM SIGGRAPH 1992, 26, 105–110. [Google Scholar] [CrossRef]

- Luo, Z.G.; Yuen, M.M.F. Reactive 2D/3D garment pattern design modification. Comput.-Aided Des. 2005, 37, 623–630. [Google Scholar] [CrossRef]

- Durupynar, F.; Gudukbay, U. A virtual garment design and simulation system. In Proceedings of the 11th International Conference Information Visualization, Zurich, Switzerland, 4–6 July 2007; pp. 862–870. [Google Scholar]

- Volino, P.; Cordier, F.; Thalmann, N.M. From early virtual garment simulation to interactive fashion design. Comput.-Aided Des. 2004, 37, 593–608. [Google Scholar] [CrossRef]

- Kang, T.J.; Kim, S.M. Development of three-dimensional apparel CAD system: Part II: Prediction of garment drape shape. Int. J. Cloth. Sci. Technol. 2000, 12, 26–38. [Google Scholar] [CrossRef]

- Mok, P.Y.; Xu, J.; Wang, X.X.; Fan, J.T.; Kwok, Y.L.; Xin, H. An IGA-based design support system for realistic and practical fashion designs. Comput.-Aided Des. 2013, 45, 1442–1458. [Google Scholar] [CrossRef]

- Wan, X.; Mok, P.Y.; Jin, X. Shape deformation using skeleton correspondences for realistic posed fashion flat creation. IEEE Trans. Autom. Sci. Eng. 2014, 11, 409–420. [Google Scholar] [CrossRef]

- Xu, J.; Mok, P.Y.; Yuen, C.W.M.; Yee, R.W.Y. A web-based design support system for fashion technical sketches. Int. J. Cloth. Sci. Technol. 2016, 28, 130–160. [Google Scholar] [CrossRef]

- Lu, J.; Wang, M.; Chen, C.; Wu, J. The development of an intelligent system for customized clothing making. Expert Syst. Appl. 2010, 37, 799–803. [Google Scholar] [CrossRef]

- Chen, Y.; Zeng, X.; Happiette, M.; Bruniaux, P.; Ng, R.; Yu, W. Optimisation of garment design using fuzzy logic and sensory evaluation techniques. Eng. Appl. Artif. Intell. 2009, 22, 272–282. [Google Scholar] [CrossRef]

- Guo, Z.X.; Wong, W.K.; Leung, S.Y.S.; Li, M. Applications of artificial intelligence in the apparel industry: A review. Text. Res. J. 2011, 81, 1871–1892. [Google Scholar] [CrossRef]

- Huh, J.-H. Big Data Analysis for Personalized Health Activities: Machine Learning Processing for Automatic Keyword Extraction Approach. Symmetry 2018, 10, 93. [Google Scholar] [CrossRef]

- Metaaphanon, N.; Kanongchaiyos, P. Real-time cloth simulation for garment CAD. In Proceedings of the 3rd International Conference on Computer Graphics and Interactive Techniques in Australasia and South East Asia, Dunedin, New Zealand, 30 November–2 December 2005; pp. 83–89. [Google Scholar]

- Han, F.; Stylios, G.K. 3D modelling, simulation and visualisation techniques for drape textiles and garments. In Modelling and Predicting Textile Behaviour; Chen, X., Ed.; Woodhead Publishing Ltd.: Cambridge, UK, 2009; Volume 94, pp. 388–421. [Google Scholar]

- Terozopoulos, D.; Platt, J.; Barr, A.; Fleischer, K. Elastically deformable models. ACM SIGGRAPH 1987, 21, 205–214. [Google Scholar] [CrossRef]

- Volino, P.; Magnenat-Thalmann, N. Versatile and efficient techniques for simulating cloth and other deformable objects. In Proceedings of the 22nd Annual Conference on Computer Graphics and Interactive Techniques, Los Angeles, CA, USA, 6–11 August 1995; pp. 137–144. [Google Scholar]

- Sze, K.Y.; Liu, X.H. Fabric drape simulation by solid-shell finite element method. Finite Elements Anal. Des. 2007, 43, 819–838. [Google Scholar] [CrossRef]

- Sung, J.; Sung, H. A Study of the Influence of Consumer’s Decision Making Process in Internet Shopping of Clothing Product Using Virtual Reality (Web 3D). Arch. Des. Res. 2004, 17, 289–298. [Google Scholar]

- Available online: http://www.iqiyi.com/w_19rtcc6tlp.html (accessed on 30 June 2018).

- Aminpour, R.S.; Barnet, A.T.; Liang, N.Y.; Alexander, A.N.; Wilson, J.R.; Mata, J.G. On Demand Apparel Manufacturing. U.S. Patent No. 9,623,578, 18 April 2017. [Google Scholar]

- Available online: http://www.sewbo.com (accessed on 30 June 2018).

- Available online: http://softwearautomation.com (accessed on 30 June 2018).

- Available online: http://www.sohu.com/a/218611889_810202 (accessed on 30 June 2018).

- Lee, D.-H.; Lee, J.-Y.; Bae, G.-Y. A Study on the Sewing Yarn Sensing Detector System of Sewing Machine for Smart Manufacturing. Proc. Inst. Electron. Inf. Eng. 2017, 1430–1433. [Google Scholar]

- Oh, S.; Kim, J. The Productivity Comparison of Women’s Coats Sewing Process—Focused on Line-worker Team & Time-worker Team. Des. Forum 2016, 53, 117–126. [Google Scholar]

- Available online: www.designusysapp.designu.shop (accessed on 30 June 2018).

- Available online: www.qfc.cn/company/d4452687 (accessed on 30 June 2018).

- Available online: https://detail.1688.com/offer/549100296504.html?spm=a261b.2187593.1998088710.236.316b71a2Ev7Vac (accessed on 30 June 2018).

- Han, E.G. The Application of Digital Textile Printing to Apparel Design: The Manipulation on Apparel Pattern. J. Korean Soc. Des. Cult. 2006, 12, 295–304. [Google Scholar]

- Kim, S. Development of Mass Production Processes for Custom-Made Digital Textile Printing (DTP) Garments on Demand. Master’s Thesis, Konkuk University Graduate School, Seoul, Korea, 2011; pp. 1–30. [Google Scholar]

- KOFOTI. New Fashion Business Model “Speed”. Glob. Issue Rep. 2017, 17, 1–18. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).