The Recovery of a Magnetically Dead Layer on the Surface of an Anatase (Ti,Co)O2 Thin Film via an Ultrathin TiO2 Capping Layer

Abstract

:1. Introduction

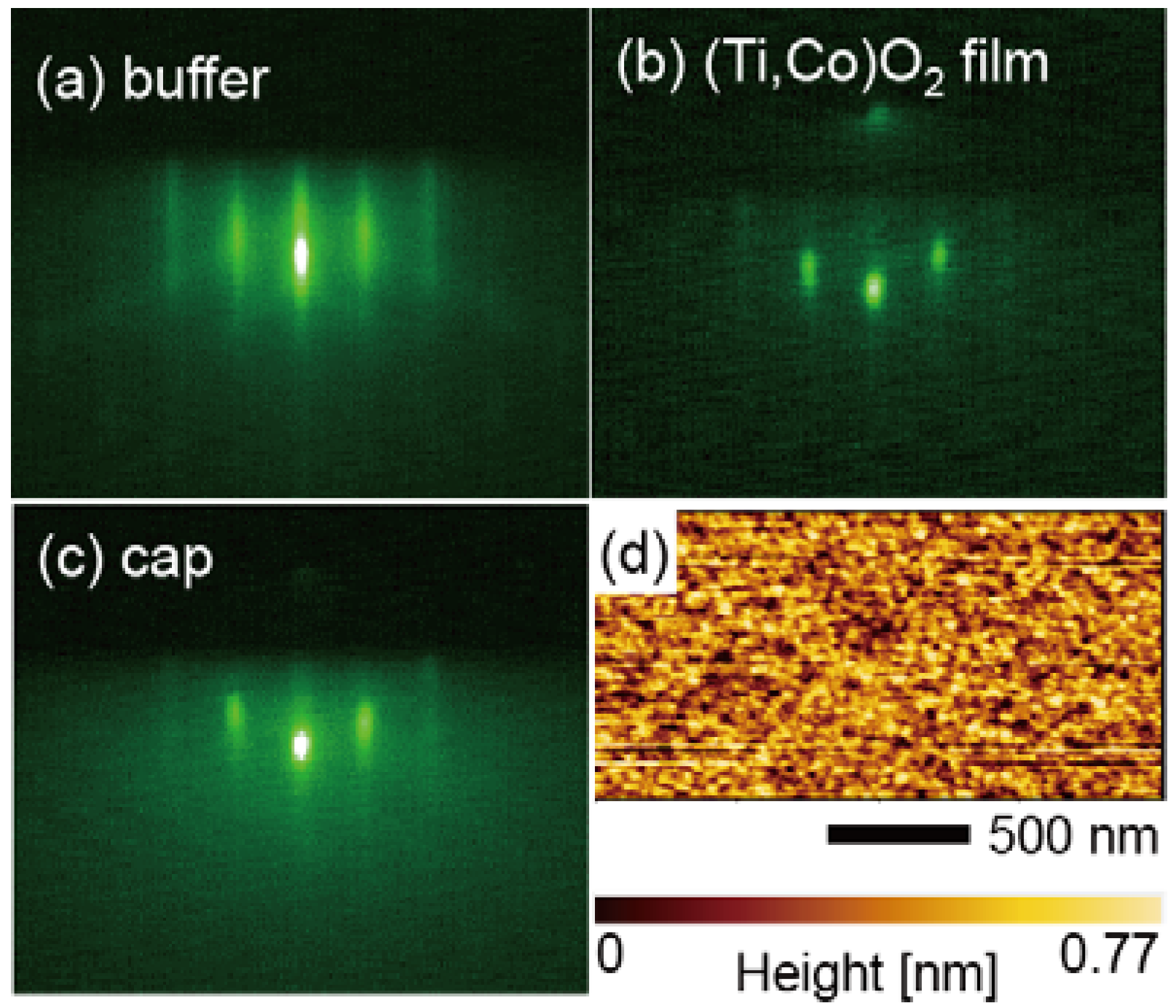

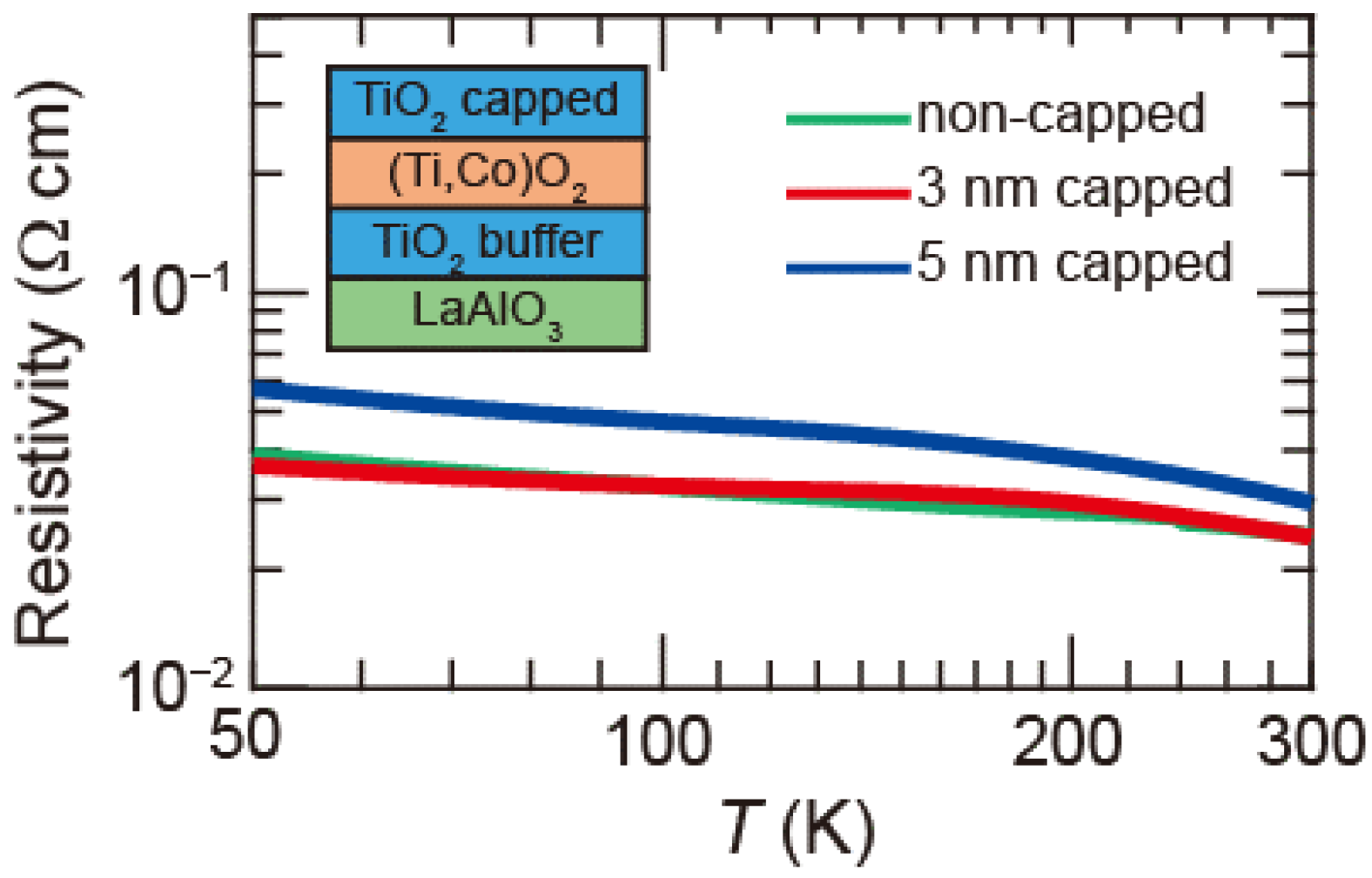

2. Materials and Methods

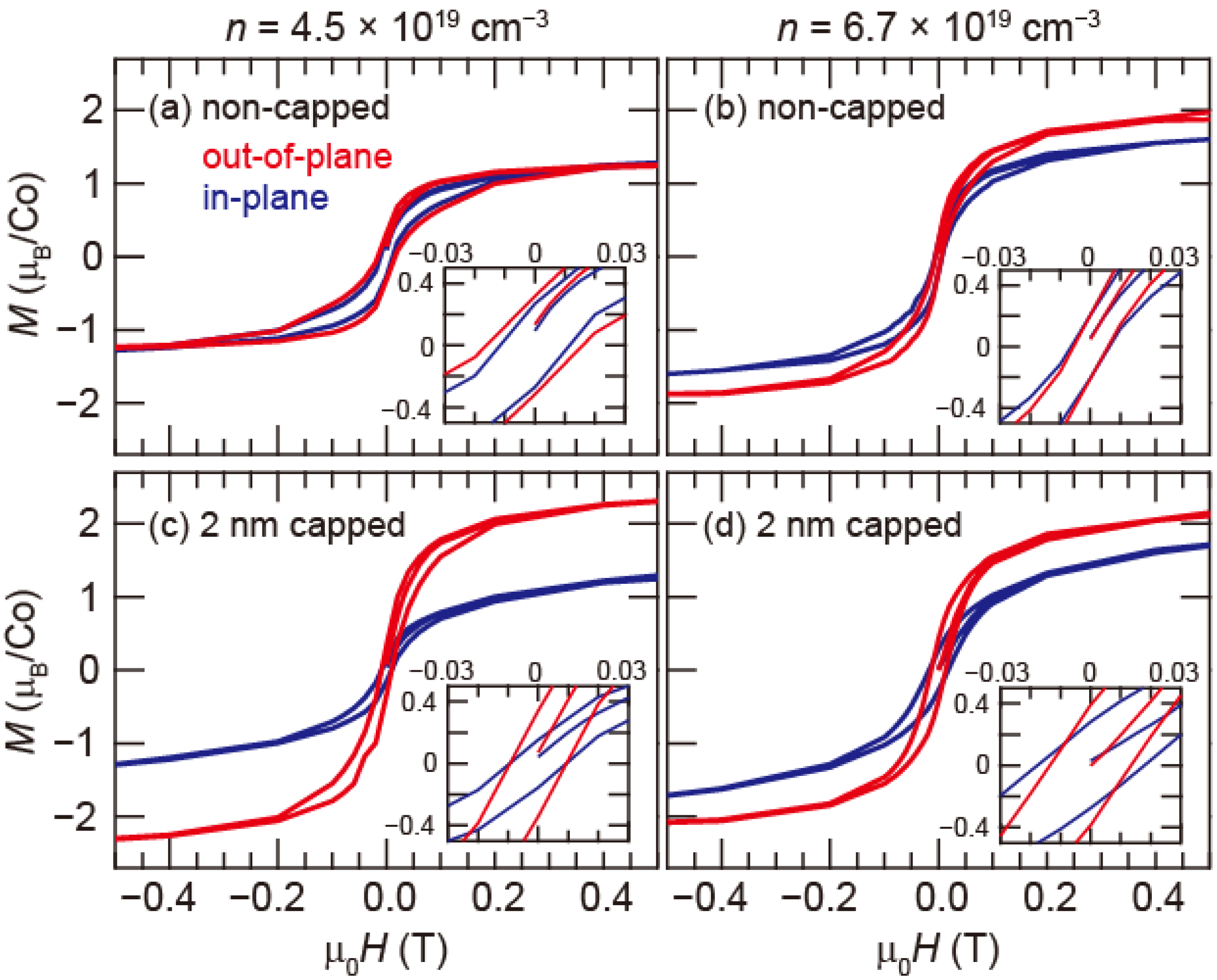

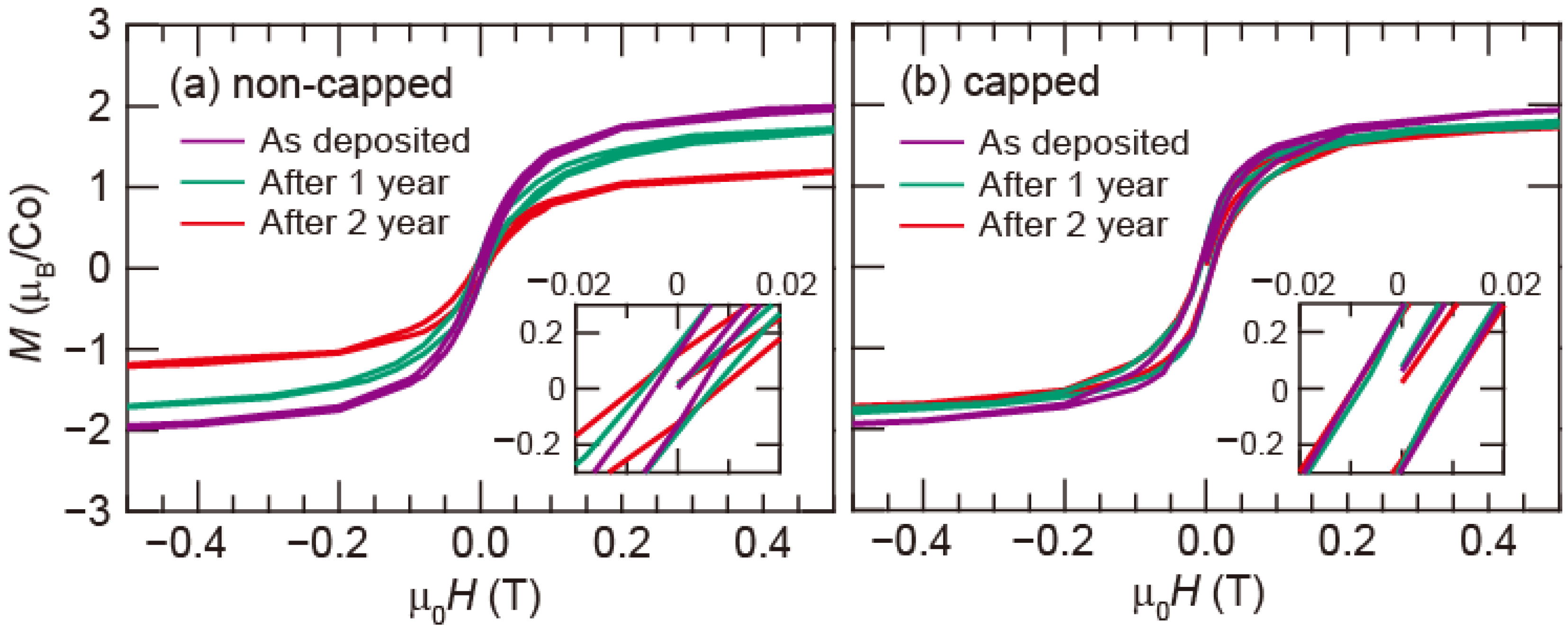

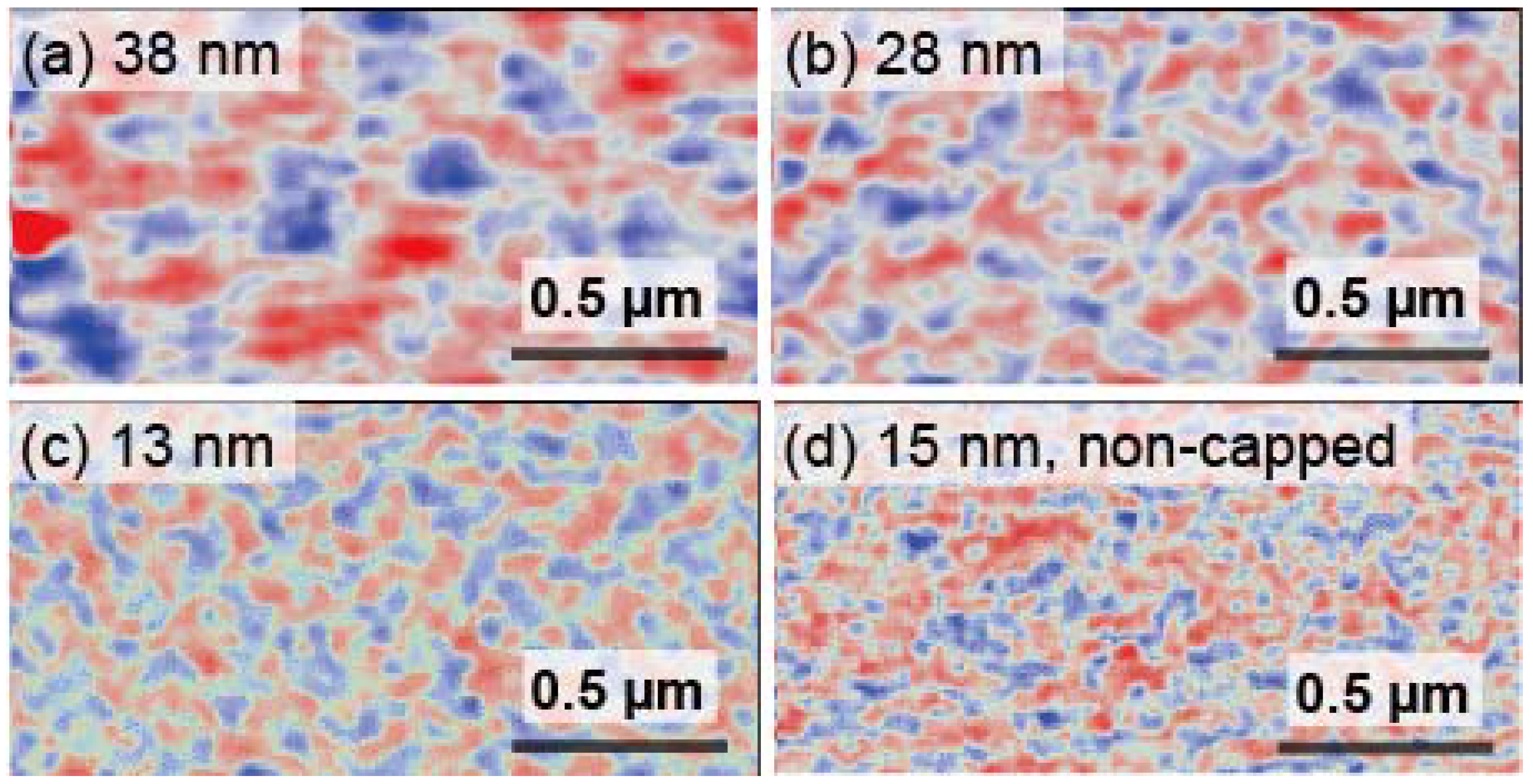

3. Results

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ogale, S.B. Dilute doping, defects, and ferromagnetism in metal oxide systems. Adv. Mater. 2010, 22, 3125–3155. [Google Scholar] [CrossRef] [PubMed]

- Matsumoto, Y.; Murakami, M.; Shono, T.; Hasegawa, T.; Fukumura, T.; Kawasaki, M.; Ahmet, P.; Chikyow, T.; Koshihara, S.; Koinuma, H. Room-temperature ferromagnetism in transparent transition metal-doped titanium dioxide. Science 2001, 291, 854–856. [Google Scholar] [CrossRef] [PubMed]

- Fukumura, T.; Kawasaki, M. Magnetic oxide semiconductors: On the high-temperature ferromagnetism in TiO2- and ZnO-based compounds. In Functional Metal Oxides: New Science and Novel Applications; Ogale, S.B., Venkatesan, T.V., Blamire, M., Eds.; Wiley: Weinheim, Germany, 2013; pp. 91–131. [Google Scholar]

- Saadaoui, H.; Luo, X.; Salman, Z.; Cui, X.Y.; Bao, N.N.; Bao, P.; Zheng, R.K.; Tseng, L.T.; Du, Y.H.; Prokscha, T.; et al. Intrinsic ferromagnetism in the diluted magnetic semiconductor Co:TiO2. Phys. Rev. Lett. 2016, 117, 227202. [Google Scholar] [CrossRef] [PubMed]

- Yamada, Y.; Ueno, K.; Fukumura, T.; Yuan, H.T.; Shimotani, H.; Iwasa, Y.; Gu, L.; Tsukimoto, S.; Ikuhara, Y.; Kawasaki, M. Electrically-induced ferromagnetism at room temperature in cobalt-doped titanium dioxide. Science 2011, 332, 1065–1067. [Google Scholar] [CrossRef] [PubMed]

- Yamada, Y.; Fukumura, T.; Ueno, K.; Kawasaki, M. Control of ferromagnetism at room temperature in (Ti,Co)O2−δ via chemical doping of electron carriers. Appl. Phys. Lett. 2011, 99, 242502. [Google Scholar] [CrossRef]

- Krasienapibal, T.; Fukumura, T.; Hasegawa, T. Curie temperature of Co-doped TiO2 as functions of carrier density and Co content evaluated from electrical transport and magnetization at low temperature regime. AIP Adv. 2016, 6, 055802. [Google Scholar] [CrossRef]

- Krasienapibal, T.S.; Inoue, S.; Fukumura, T.; Hasegawa, T. Observation of magnetic domain structure in anatase Ti1−xCoxO2−δ thin film at room temperature. Appl. Phys. Lett. 2015, 106, 202402. [Google Scholar] [CrossRef]

- Singh, V.R.; Ishigami, K.; Verma, V.K.; Shibata, G.; Yamazaki, Y.; Kataoka, T.; Fujimori, A.; Chang, F.-H.; Huang, D.-J.; Lin, H.-J.; et al. Ferromagnetism of cobalt-doped anatase TiO2 studied by bulk- and surface-sensitive soft X-ray magnetic circular dichroism. Appl. Phys. Lett. 2012, 100, 242404. [Google Scholar] [CrossRef]

- Speriosu, V.S.; Nozieres, J.P.; Gurney, B.A.; Dieny, B.; Huang, T.C.; Lefakis, H. Role of interfacial mixing in giant magnetoresistance. Phys. Rev. B 1993, 47, 11579–11582. [Google Scholar] [CrossRef]

- Borges, R.P.; Guichard, W.; Lunney, J.G.; Coey, J.M.D.; Ott, F.J. Magnetic and electric “dead” layers in (La0.7Sr0.3)MnO3 thin films. J. Appl. Phys. 2001, 89, 3868–3873. [Google Scholar] [CrossRef]

- Ohtsuki, T.; Chainani, A.; Eguchi, R.; Matsunami, M.; Takata, Y.; Taguchi, M.; Nishino, Y.; Tamasaku, K.; Yabashi, M.; Ishikawa, T.; et al. Role of Ti 3d Carriers in Mediating the Ferromagnetism of Co: TiO2 Anatase Thin Films. Phys. Rev. Lett. 2011, 106, 047602. [Google Scholar] [CrossRef] [PubMed]

- Yamashita, N.; Sudayama, T.; Mizokawa, T.; Yamada, Y.; Fukumura, T.; Kawasaki, M. Interplay between magnetic impurities and photo-induced carriers in surface depletion layer of anatase Ti1−xCoxO2−δ thin film probed by X-ray photoemission spectroscopy. Appl. Phys. Lett. 2010, 96, 021907. [Google Scholar] [CrossRef]

- Li, J.; Wang, Z.Y.; Tan, A.; Glans, P.-A.; Arenholz, E.; Hwang, C.; Shi, J.; Qiu, Z.Q. Magnetic dead layer at the interface between a Co film and the topological insulator Bi2Se3. Phys. Rev. B 2012, 86, 054430. [Google Scholar] [CrossRef]

- Wang, Y.-H.; Chen, W.-C.; Yang, S.-Y.; Shen, K.-H.; Park, C.; Kao, M.-J.; Tsai, M.-J. Interfacial and annealing effects on magnetic properties of CoFeB thin films. J. Appl. Phys. 2006, 99, 08M307. [Google Scholar] [CrossRef]

- Krasienapibal, T.S.; Fukumura, T.; Hirose, Y.; Hasegawa, T. Improved room temperature electron mobility in self-buffered anatase TiO2 epitaxial thin film grown at low temperature. Jpn. J. Appl. Phys. 2014, 53, 090305. [Google Scholar] [CrossRef]

- Takahashi, K.S.; Hwang, H.Y. Carrier doping in anatase TiO2 film by perovskite overlayer deposition. Appl. Phys. Lett. 2008, 93, 082112. [Google Scholar] [CrossRef]

- Silvestre, A.J.; Pereira, L.C. J.; Nunes, M.R.; Monteiro, O.C. Ferromagnetic order in aged Co-doped TiO2 anatase nanopowders. J. Nanosci. Nanotechnol. 2012, 12, 6850–6854. [Google Scholar] [CrossRef] [PubMed]

- Hubert, A.; Schafer, R. Magnetic Domains; Springer: Heidelberg, Germanay, 1998. [Google Scholar]

- Pesquera, D.; Herranz, G.; Barla, A.; Pellegrin, E.; Bondino, F.; Magnano, E.; Sánchez, F.; Fontcuberta, J. Surface symmetry-breaking and strain effects on orbital occupancy in transition metal perovskite epitaxial films. Nat. Commun. 2012, 3, 1189. [Google Scholar] [CrossRef] [PubMed]

- Peng, J.J.; Song, C.; Li, F.; Gu, Y.D.; Wang, G.Y.; Pan, F. Restoring the magnetism of ultrathin LaMnO3 films by surface symmetry engineering. Phys. Rev. B 2016, 94, 214404. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krasienapibal, T.S.; Fukumura, T.; Hasegawa, T. The Recovery of a Magnetically Dead Layer on the Surface of an Anatase (Ti,Co)O2 Thin Film via an Ultrathin TiO2 Capping Layer. Electronics 2017, 6, 23. https://doi.org/10.3390/electronics6010023

Krasienapibal TS, Fukumura T, Hasegawa T. The Recovery of a Magnetically Dead Layer on the Surface of an Anatase (Ti,Co)O2 Thin Film via an Ultrathin TiO2 Capping Layer. Electronics. 2017; 6(1):23. https://doi.org/10.3390/electronics6010023

Chicago/Turabian StyleKrasienapibal, Thantip S., Tomoteru Fukumura, and Tetsuya Hasegawa. 2017. "The Recovery of a Magnetically Dead Layer on the Surface of an Anatase (Ti,Co)O2 Thin Film via an Ultrathin TiO2 Capping Layer" Electronics 6, no. 1: 23. https://doi.org/10.3390/electronics6010023

APA StyleKrasienapibal, T. S., Fukumura, T., & Hasegawa, T. (2017). The Recovery of a Magnetically Dead Layer on the Surface of an Anatase (Ti,Co)O2 Thin Film via an Ultrathin TiO2 Capping Layer. Electronics, 6(1), 23. https://doi.org/10.3390/electronics6010023