1. Introduction

Boom-type field sprayers are essential for modern crop protection due to their high efficiency and large working width, yet ensuring stable spray performance under real operating conditions remains a major engineering challenge. During high-speed travel, braking, turning, and uneven-terrain operations, the boom is subjected to complex coupled excitations arising from vehicle dynamics, ground–structure interactions, liquid sloshing in the chemical tank, and the pulsating jetting force of the nozzles. Liquid sloshing, driven by acceleration, deceleration, and directional changes, generates strong transient impact forces and moments that are transferred to the boom structure, amplifying low-frequency vibrations and degrading droplet deposition uniformity. Meanwhile, the boom itself is a lightweight, low-stiffness, multi-joint structure with inherently low damping and natural frequencies, making it highly susceptible to resonance. The periodic jetting force from the nozzles further introduces frequency-dependent excitation that may coincide with the natural frequencies of the booms, intensifying structural vibration. Existing studies have examined sloshing dynamics, boom flexibility, and nozzle-induced pulsation separately, yet few have simultaneously considered their coupled effects or the influence of joint stiffness on overall dynamic stability. These vibrations not only compromise spray uniformity but also accelerate structural fatigue, joint wear, and potential failure [

1,

2,

3].

The dynamics of liquids with free surfaces have been studied extensively in naval architecture, aerospace engineering, and automotive fuel-tank design. An actual method to calculate the maximum sloshing force has been proposed by Zheng [

4] through experiments on the sloshing force moments of liquid in a rectangular tank subjected to harmonic excitation. However, the method is obtained through approximate calculation and the accuracy of the calculations requires improvement. The pressure changes in droplets have been investigated by Yu and Surico [

5,

6] during the sloshing process of the inner walls of cylindrical and U-shaped tanks. A numerical work on the liquid sloshing behavior of flexible tanks has been conducted by Kim [

7] under external loads. However, it is only applied to limited shapes of tanks. Meanwhile, versatility is low. The static and dynamic characteristics of field sprayers have been analyzed by Wang [

8] under four typical running conditions. A device known as an elastically constrained floating plate has been proposed by Li [

9] to suppress liquid sloshing, but a detailed analysis of the device’s performance is not provided under extreme conditions. The mechanical characteristics of the tank-liquid sloshing under external excitation has been studied by Wang [

10] through experimental methods, but the tank internal excitation generated is neglected. The forces in three directions have been measured and analyzed by Zhang [

11] under identical running conditions. The force on the tank has been calculated by Lu [

12] under acceleration excitation at various liquid-filling ratios. It has been established that there is an equivalent mechanical model of the liquid under tank translation excitation by the Galerkin method. Li [

13] has simulated both the low-order sloshing mode and high-order local vibration of the liquid. However, the potential effects of the acquired forces on the boom have not been investigated in these studies thoroughly.

The dynamic behavior of boom structures has been widely investigated due to their inherent flexibility. Researchers have employed finite element (FE) models, modal testing, and reduced-order dynamic modeling to identify natural frequencies, mode shapes, and frequency-response functions of boom assemblies. A work on three commonly used boom nozzles has been conducted by Lipiński [

14]. At the same time, the impact of the unstable boom on spray quality has been evaluated. The effects of the nozzle type and the number of nozzles on the boom on the spray quality were studied by Zaffar [

15]. However, the work mainly focuses on the nozzle of the boom. Exploring the vibration characteristics of the boom and establishing the vibration model of the boom are also considered the main research approaches. The effectiveness of active boom suspension has been examined by Jeon [

16] in stabilizing boom motion. A system for measuring displacements related to the stability of booms has been proposed by Kaliniewicz [

17]. In order to determine the dynamic characteristics of the bolted boom, the reduced order model of the bolted boom with a four-parameter Iwan model has been established by Yang [

18]. A model for real-time evaluation of boom stability was proposed by Kaliniewicz [

19]. The vertical sprayer boom movements have been studied with experimental modal analysis by Langenakens [

20]. A hybrid model of spray booms has been developed by Deprez [

21] for the development of a stable boom roll suspension. The discrete element method and finite element method of agricultural spray boom modeling have been compared by Anthonis [

22,

23]. The boom motion of a sprayer with a working width of 12 m has been simulated by Kennes [

24] through a nonlinear finite element method. In the work of the boom model, the boom is used as the main research object. However, the influence factors of the stability of the vehicle with the field sprayer to the boom have not been considered in the actual agricultural operation. The operation stability of the field sprayer is greatly affected by these factors. There is a lack of more comprehensive research on the stability of the boom. In a survey of field spraying operations, it has been found that the rotational motion of the field sprayer is one of the important factors causing the tip motion of the vertical and horizontal booms. In this regard, the influence of the rapid rolling motion of the field sprayer on the stability of the boom has been studied by Nation [

25]. At the same time, it has been concluded that the influence of the rolling can be reduced in the separation of the boom from the rolling motion. In order to realize the isolation between the boom and the rolling motion, a mathematical model of the active tilting linkage boom suspension has been proposed by Frost [

26].

In the field of fluid–solid coupling, there are three mainstream methods. The first is the finite element method [

27,

28], referred to as FE. These are effectively accommodated and include the deformation of solid structures and the interactions with fluids. In order to yield results for stress–strain and temperature distributions, the ability to accurately simulate complex geometric shapes and boundary conditions is considered its primary advantages. The second method is the finite volume method [

29,

30], referred to as FV. It is notable for its adeptness in managing boundary conditions and grid irregularities. Additionally, the implementation of parallel computations is facilitated, therefore computational efficiency is enhanced. The third method is smooth particle hydrodynamics [

31,

32,

33], referred to as SPH. It is considered as a particle-based approach for simulating the behavior of fluids and other continuous media. It excels in addressing free surface and large deformation challenges, making it particularly suitable for applications such as tank sloshing. The FE, FV, and SPH methods are employed comprehensively within the established numerical model of the tank-liquid sloshing to ensure an accurate simulation of the intricate interactions between the fluid and solid components. Yan [

34] comprehensively considers the effects of the vehicle of the field sprayer and boom suspension on the elastic vibrations by the Euler-Bernoulli beam theory. Subsequently, a geometric continuous model of boom vibration is established and the resulting yaw vibration changes in the boom are analyzed grounded by multi-body vibration theory.

The pulsating force generated by spray nozzles, although periodically small in magnitude, can act as a broadband excitation due to the multi-frequency components of pump-driven flow. Researchers have reported correlations between pulsation frequency and boom vibration modes, but only a few studies incorporate both amplitude and frequency effects into structural dynamics simulations [

35,

36,

37]. Despite these advancements, most studies model the external excitation as chassis-induced or ground-induced vibrations, neglecting the contribution of dynamic loads originating from liquid sloshing or nozzle jetting forces. In addition, existing works primarily analyze chassis motion, while the dynamic stability of the boom structure under sloshing excitation remains insufficiently explored. Furthermore, the nonlinear interaction between joint stiffness and fluid-induced excitation has not been adequately quantified, particularly under emergency braking where transient loads are highest. Therefore, a comprehensive multi-physics investigation integrating structural dynamics and fluid–structure interaction is required to fully understand and mitigate the coupled mechanisms governing boom vibration, with the goal of enhancing spraying precision, operational safety, and long-term durability of field sprayers.

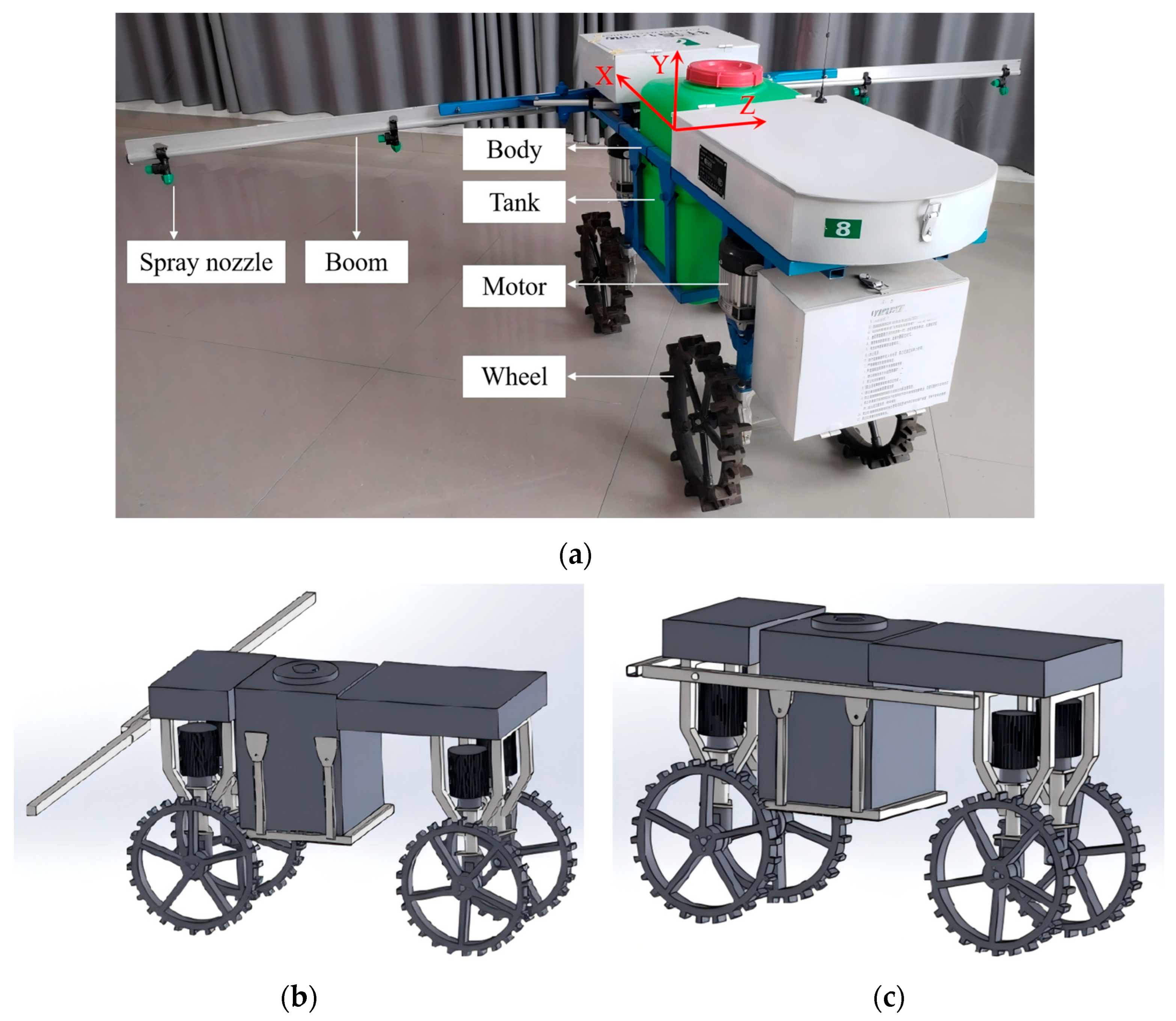

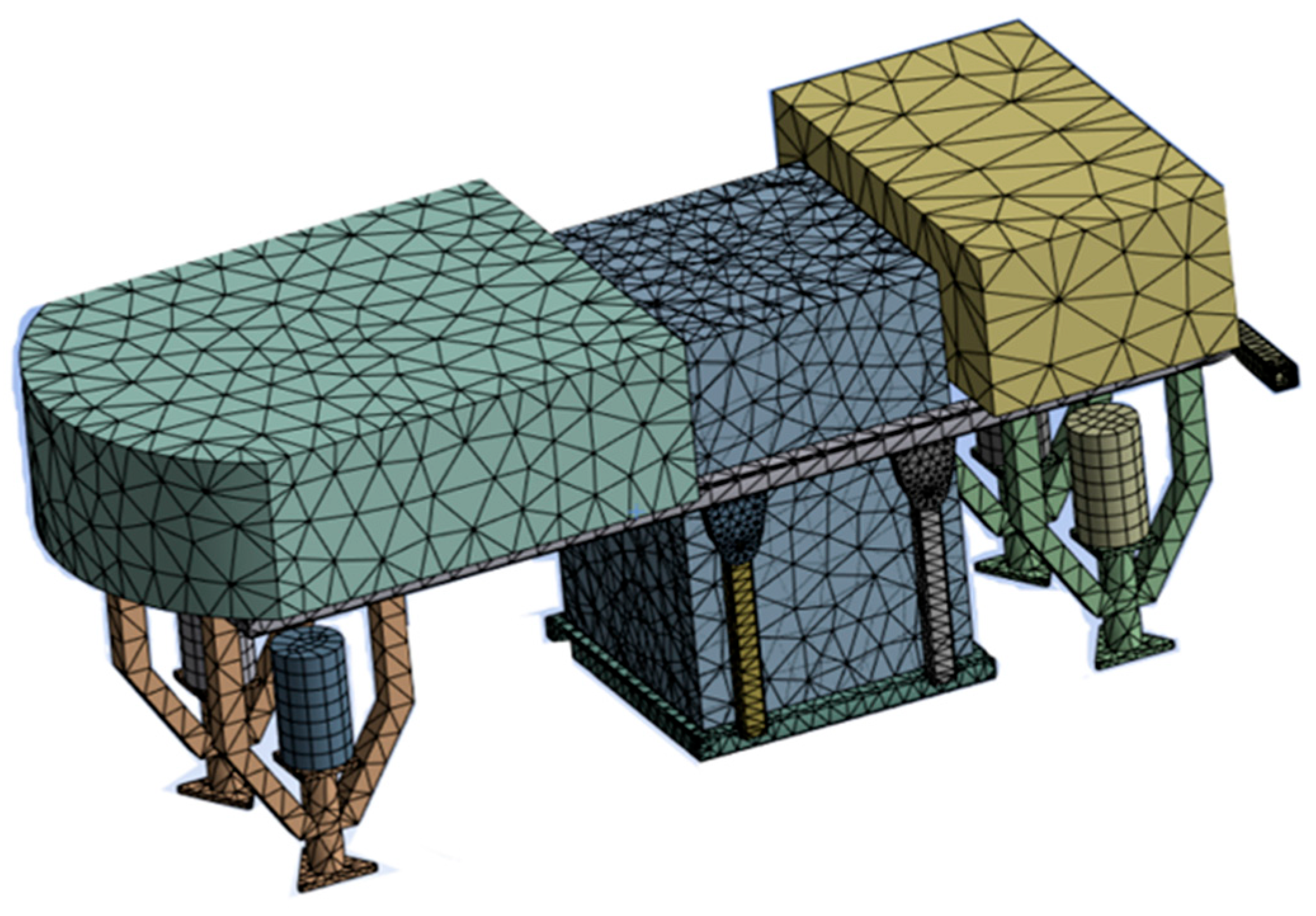

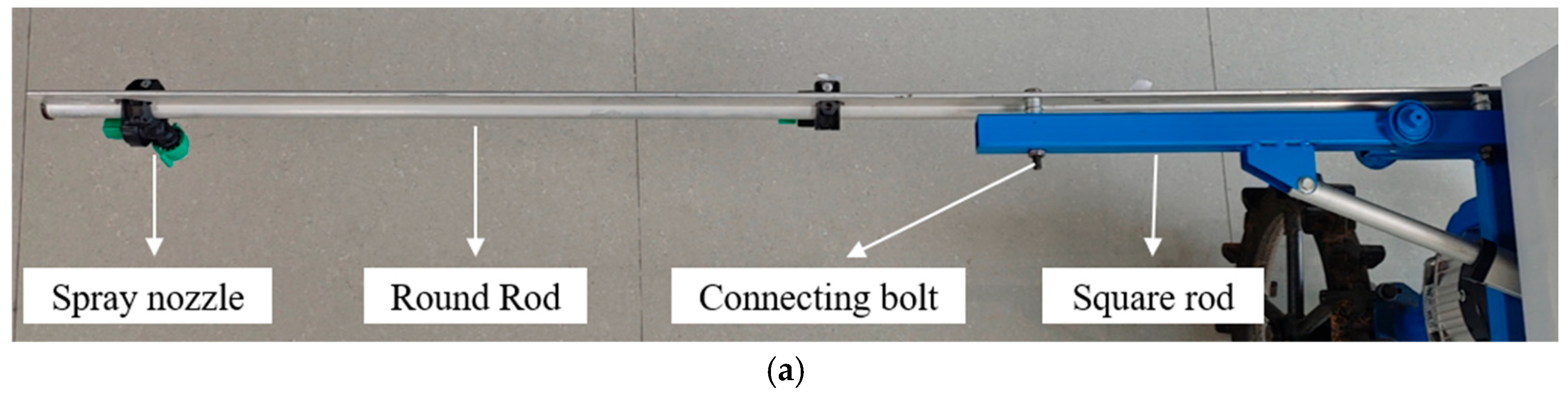

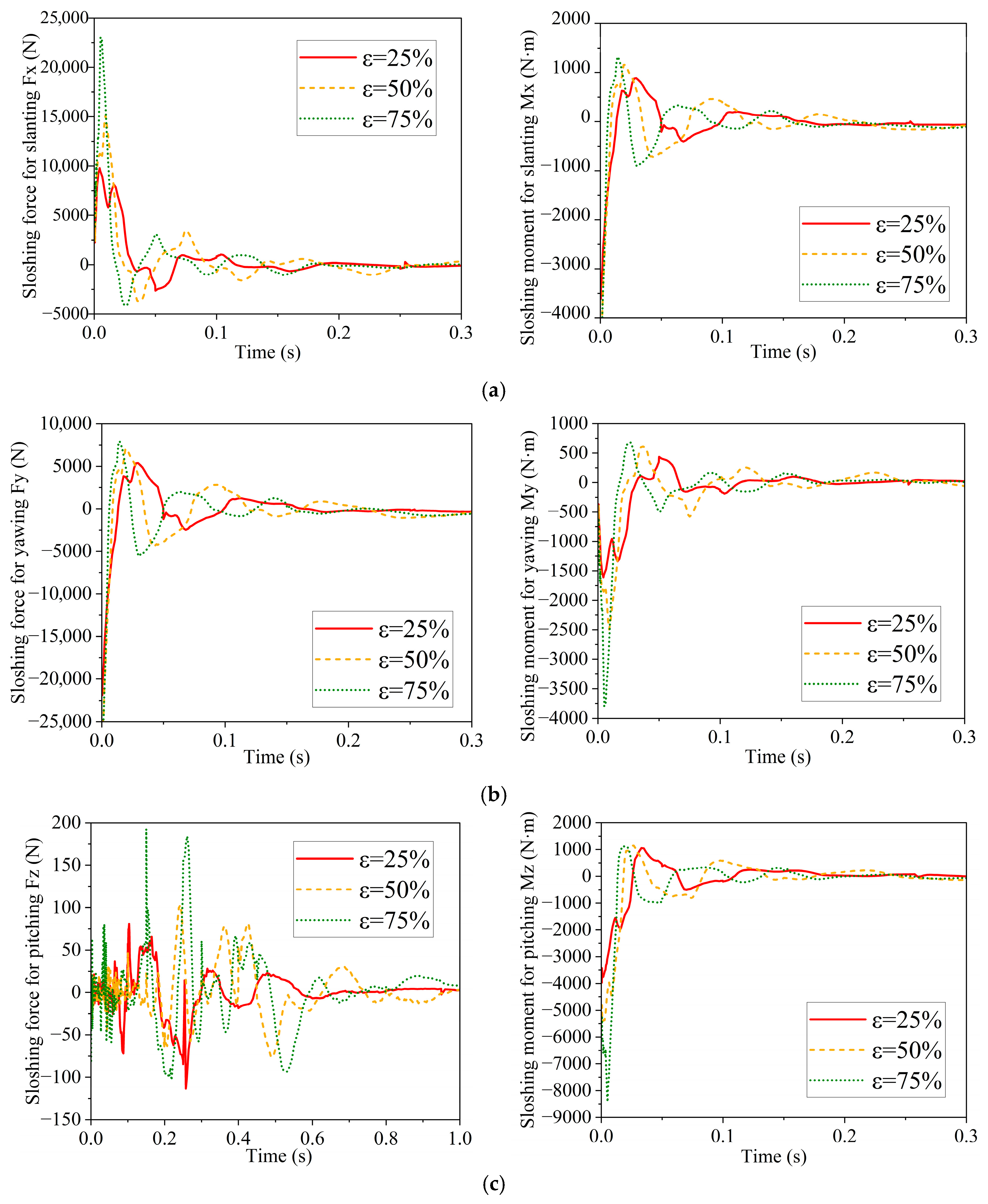

In order to investigate the effect of the tank-liquid sloshing on the stability of the field sprayer, the dynamic characteristics of tank-liquid sloshing, boom-connection stiffness, ground-induced excitation, and nozzle jetting-force characteristics are determined when the field sprayer is braking from 5.4 km/h and swerving at 45°. It should be noted that, although the vibration arising from the wheel–ground interaction has pronounced influences on the dynamic characteristics of the field sprayer, the present study is primarily focused on the analysis of its dynamic characteristics under different running conditions, i.e., braking and swerving, on a specified ground surface. Firstly, based on the experimental test and simulation analysis, the modal parameters of the joint boom are compared and analyzed to determine the most practical connection parameters of the boom so as to establish the finite element model of the vehicle and the joint boom of the field sprayer. Secondly, for the tank with the liquid-filling ratios of 25%, 50%, and 75%, a numerical model of liquid sloshing is developed with the output of the sloshing forces and moments in three directions. Thirdly, considering the tank-liquid sloshing effect, wheel vibration, and the connection characteristics of the joint boom, the tank-liquid sloshing effect on the joint boom is studied through static and dynamic analysis. Fourthly, the brute-force dynamic simulation is carried out to illustrate the influences of connection stiffness, frequencies, and amplitude of the jetting force of the medicinal liquid on the stability of the joint boom. Finally, the conclusions of the work are drawn.

4. Sloshing Effect on the Joint Boom

The slender joint boom in the field sprayer is the weakest component, which is highly susceptible to vehicle vibration and is likely to cause significant swinging of the joint boom. Therefore, the stability of the joint boom is of paramount importance in the dynamic analysis of the field sprayer. Considering the tank-liquid sloshing effect, wheel vibration, and the connection characteristics of the joint boom, the tank-liquid sloshing effect on the joint boom is studied through static and dynamic analysis.

4.1. Static Characteristics

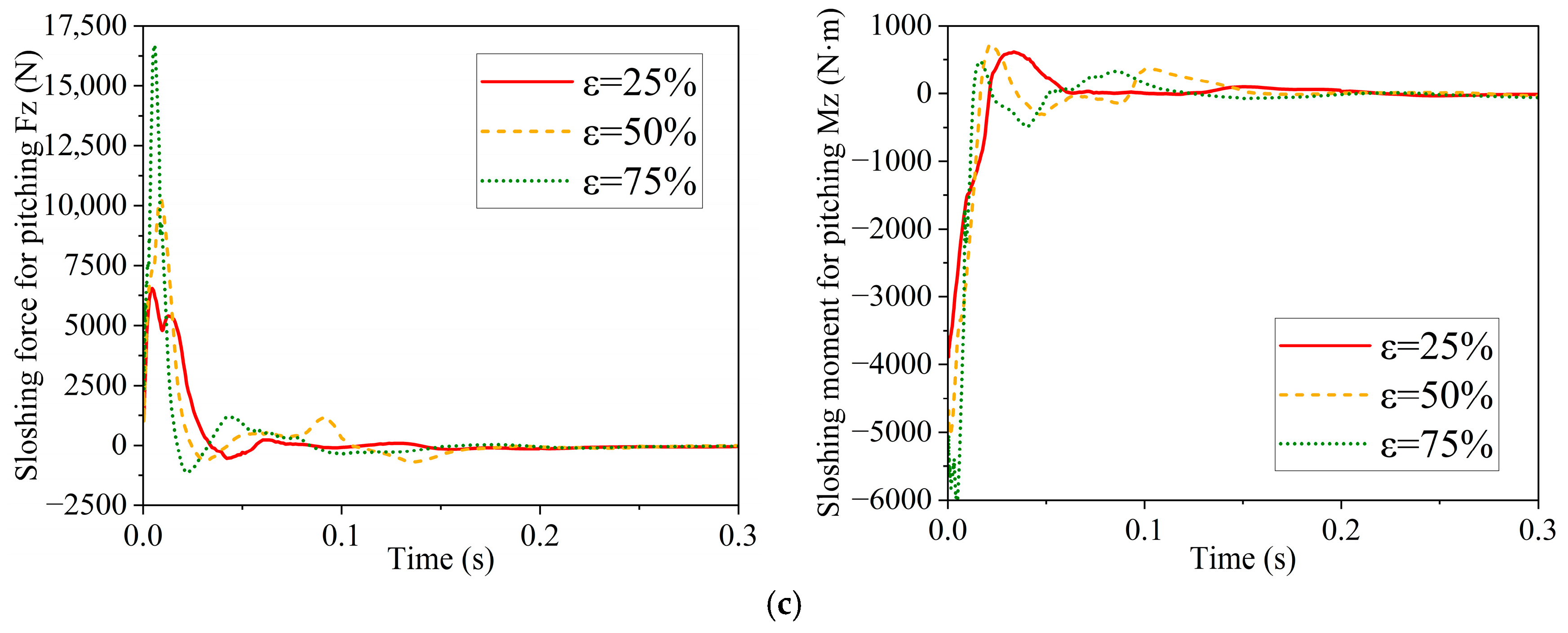

The stress–strain characteristics of the joint boom are obtained through nonlinear simulation. It is indicated that the critical point is forced to occur at the free end of the boom. When the field sprayer is braking from 5.4 km/h, the stress and strain curves of the free end of the joint boom are shown in

Figure 13a. It is indicated that the manifestations of both stress and strain show multimodal oscillation, highlighting the intensity of the impact caused by braking. When the field sprayer is swerving with 45°, the stress and strain curves of the free end of the joint boom are shown in

Figure 13b. It is shown that the stress and strain of the joint boom in the field sprayer with different liquid-filling ratios exhibit different attenuation trends. The variations in stress and strain properties of the joint boom in a field sprayer with varying liquid filling ratios of

,

, and

indicate that the stress and strain of the joint boom during braking are significantly influenced by tank-liquid sloshing. Notably, the maximum stress which is experienced by the joint boom is significantly lower than the allowable one of 158 MPa, which is defined as the standard allowable bending stress of Q235 steel under static loading conditions according to GB/T700-2006 [

39].

4.2. Dynamic Characteristics

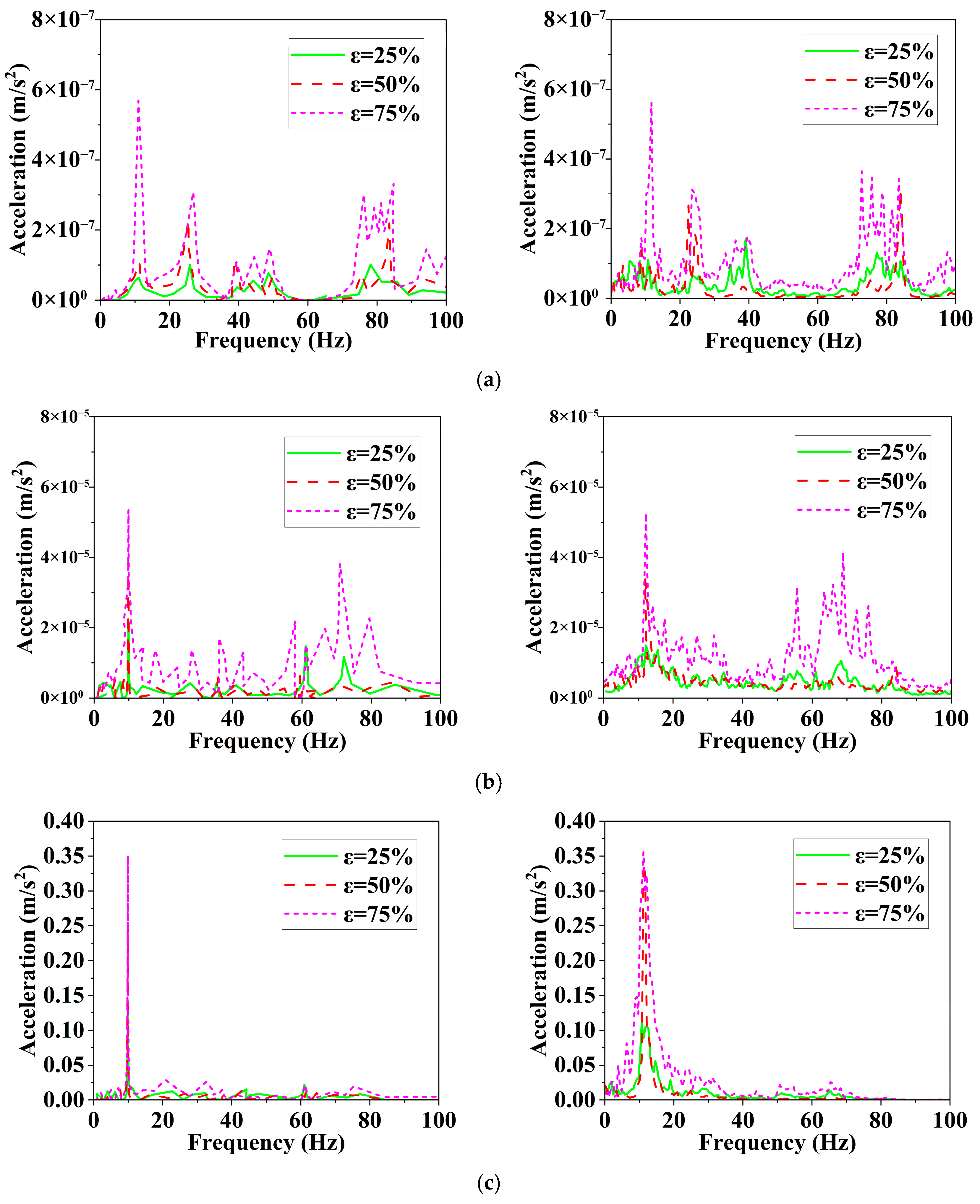

In order to obtain the dynamic characteristics of the wide-amplitude vibration of the joint boom, which is triggered due to its slenderness of the cantilever, the tank-liquid sloshing behaviors of the joint boom in the field sprayer are studied through the stochastic vibration analysis. For the accuracy of comparative analysis, the responses of the free end of the joint boom are obtained by dynamic simulation and experimental testing.

Initially, the vibration behaviors of the joint boom are explained using the principles of structural dynamics. This approach allows for a systematic examination of the random vibrations of the boom by constructing dynamic equations, evaluating frequency response characteristics, and assessing energy allocation. Experiments on the stochastic vibrations of the boom are performed to thoroughly study the impact of tank-liquid sloshing on vibrational mode shapes and energy distribution across varying operational conditions. Frequency-domain cross-validation with a finite element model is carried out, yielding statistically significant profiles of accelerometric amplitude-frequency joint distribution. These profiles are depicted in

Figure 14 and

Figure 15.

In the X direction, it is indicated from the response results in

Figure 14a that at low frequencies, the response amplitude is minimal, escalating sharply at a specific frequency where a clear resonance peak emerges. This suggests the presence of a first-order natural frequency in the X direction. The resonance peaks for both the simulation and experiment occur at nearly identical frequencies, showing that the simulation model accurately represents the dynamic properties. Nonetheless, the experimental peak amplitude is slightly lower, implying additional damping effects in the actual structure.

In the Y direction, the amplitude-frequency responses in

Figure 14b display more notable variations. The simulation results depict a sharper and more ideal resonance peak, whereas the experimental peak is slightly shifted and reduced in amplitude. This discrepancy can be attributed to structural characteristics and material nonlinearity in the real machine, which lead to a less sensitive actual response compared to the simulation prediction. In the Z direction, the simulation and experimental results in

Figure 14c exhibit consistent overall trends, but the vibration amplitude is smaller than that in the X and Y directions, suggesting higher vertical stiffness of the boom. The simulated peak appears sharper, while the experimental curve is smoother, reflecting the impact of higher damping and complex vibration coupling effects in the real system.

Overall, the simulation and experimental amplitude-frequency responses align well concerning the main characteristic frequencies, validating the reliability of the simulation model. The experimental curves are smoother and less pronounced, highlighting that damping and non-ideal boundary conditions in the real machine lessen the vibration response, particularly in the high-frequency domain.

In

Figure 15, both the simulated and experimental results reveal a distinct resonance peak, signifying the primary natural frequency of the joint boom. The resonance frequency observed in the experimental data closely matches that of the simulation, affirming the accuracy of the dynamic model developed. In the Y direction, the response amplitude in

Figure 15b exhibits more significant fluctuations with frequency. The simulation predicts a more pronounced resonance peak, whereas the experimental results show a broader and slightly offset peak, suggesting that nonlinear factors, such as connection looseness, impact the real dynamic behavior of the joint boom during operation. In the Z direction, the overall response amplitude is considerably lower compared to the X and Y directions, indicating that the boom has greater stiffness and improved vibration resistance vertically. Both simulation and experimental data demonstrate similar patterns, although the experimental curve is smoother and less responsive to high-frequency excitation, which further confirms the effects of damping and multi-directional coupling in the actual system. Overall, the comparison between simulation and experimental findings suggests that the developed dynamic model effectively captures the principal vibration characteristics of the joint boom of the field sprayer in all three directions. The minor differences between the two results stem mainly from unmodeled damping and real-world structural complexities, attesting to both the reliability and practical utility of the simulation method.

In addition, the response amplitude of the joint boom caused by tank-liquid sloshing can be magnified as the liquid-filling ratio increases. However, the tank-liquid sloshing has little effect on the vibration frequency of the joint boom, only that the larger the liquid filling ratio, the more frequency components of the vibration responses. It is also indicated that the dynamic responses of the joint boom exhibit strong nonlinearity under the influence of connection characteristics. Furthermore, the comparison of results indicates that the numerical model aligns well with the real measurement in lateral, vertical, and longitudinal direction, although the simulated frequency is about 10 Hz and slightly lower than the testing one of about 12 Hz. The observed discrepancies are mainly attributed to factors such as the flexibility of the rear suspension and the compliance of the modification platform, which are not fully represented in the numerical model. These factors may induce variations in the posture and inertial position of the tank, thereby leading to deviations between the idealized simulation inputs and the actual operating conditions. In addition, variables like sensor accuracy, noise, and external disturbances may combine and intensify during the conversion of liquid sloshing forces and moments, leading to divergence between the converted measurement results and the actual sloshing forces and moments.

In this study, the stability of the sprayer boom refers to its dynamic stability, with motions primarily considered in the vertical plane relative to the vehicle body. The dynamic responses of the sprayer boom under different operating conditions, such as braking and swerving, are analyzed with a focus on the effects induced by liquid sloshing within the tank. Other potential sources of excitation, including motor and pump vibrations and ground-induced vibrations during vehicle movement, are acknowledged but are not explicitly modeled in the present analysis. Based on both numerical simulations and experimental measurements, it is found that the oscillatory movement of the liquid constitutes the dominant factor affecting the dynamic characteristics of the sprayer boom under the considered conditions. The contributions from other sources are comparatively smaller and are considered secondary for the scope of this study.

5. Influences of System Parameters on the Dynamic Responses of the Joint Boom

Based on the validated model and the corresponding method, the brute-force dynamic simulation is carried out to illustrate the influences of connection stiffness, frequencies, and amplitude of the jetting force of the medicinal liquid on the stability of the joint boom. In view of the pronounced vibration of the joint boom during braking, the response amplitude of the joint boom under braking conditions is examined in this study.

The influence of connection stiffness between the joint boom and the vehicle body is analyzed for its impact on the stability of joint boom. The vibrational response amplitudes of the joint boom along three orthogonal directions, i.e., X axis, Y axis, and Z axis, under varying connection stiffness are shown in

Figure 16. It is found that high connection stiffness is demonstrated to increase the response amplitude of the joint boom when the connection stiffness varies from 500 to 3000 N/m. However, excessive stiffness is identified to risk mechanical resonance, which compromises dynamic performance. In addition, an increase in connection stiffness reduces the energy dissipation capacity of the flexible joint connections. Consequently, a larger portion of the vibrational energy is transmitted along the joint boom and accumulates within its structure, leading to an increase in the overall vibration amplitude.

During pesticide spraying, the field sprayer can be significantly impacted by the amplitude and frequency of the jetting force of the medicinal liquid from the dynamic properties of the joint boom. The vibrational response amplitudes of the joint boom along the X axis, Y axis, and Z axis under varying amplitudes of the jetting forces are shown in

Figure 17. As the amplitude of the jetting force ranges from 0 to 1000 N, the vibration responses of the joint boom display distinct directional patterns. In the X direction, the response amplitude decreases almost linearly with increased jetting force, indicating effective suppression of lateral vibration by the jetting force. In contrast, the response amplitude in the Y direction is nearly constant, suggesting the jetting force has little effect on lateral sway. In the Z direction, the vibration amplitude decreases nonlinearly with increased jetting force and stabilizes around 500 N, implying a stabilization of the boom motion beyond this point.

Generally, as the amplitude of the jetting force grows, the overall response of the joint boom declines, with the most notable effect in the vertical direction, i.e., in the Z axis. This observation suggests that the dynamic load generated by liquid-spraying influences both the steady-state control and dynamic characteristics of the joint boom through nonlinear coupling effects. Increasing the amplitude of the jetting force appropriately can enhance the stability of the joint boom. However, excessively high jetting forces might negatively impact damping performance and structural connection stability. Therefore, achieving an optimal balance between the amplitude of the jetting force and the dynamic behavior of the joint boom is crucial in the design of a field sprayer.

The vibrational response amplitudes of the joint boom along the X axis, Y axis, and Z axis under varying frequencies of the jetting forces are shown in

Figure 18. As the frequency of the jetting force rises from 0 to 70 Hz, there are notable differences in the amplitude-frequency responses of the joint boom depending on the directions. In the X direction, the response amplitude decreases steadily from 0 to 45 Hz, with peaks noticeably around 50 Hz, stays relatively elevated between 50 and 60 Hz, and then drops again. This pattern highlights a resonance phenomenon occurring near the third harmonic of the natural frequency, i.e., around 55 Hz, which can be attributed to the interaction between the external excitation frequency components and the inherent modal characteristics of the joint boom. When the frequency content of the applied excitation approaches the natural frequency or its higher-order harmonics, the corresponding vibration mode is preferentially activated, leading to a significant amplification of the vibration response. In the Y direction, the vibration amplitude remains roughly unchanged with varying jetting frequencies, suggesting that the structural damping and joint constraints play a more significant role. In the Z direction, the variation in the response amplitude with frequency is generally similar to that in the X direction but with less fluctuation, indicating some dynamic coupling between the two directions in their vibration responses.

Overall, the effect of the frequency of the jetting force on the dynamic response of the joint boom shows clear frequency-dependent and directional coupling characteristics. The response amplitude decreases in the low-frequency range but shows a noticeable resonance response in the mid-frequency range, i.e., around 50–60 Hz, identified as the most sensitive area for dynamic excitation. The frequency of the jetting force should be appropriately adjusted to avoid resonance zones, effectively lowering the vibration amplitude and improving spraying stability and operational accuracy. These insights are crucial for optimizing the boom structural design and developing vibration control strategies in a field sprayer.

The parametric variations in the jetting force reveal that both its amplitude and frequency govern the vibration response of the joint boom through direction-dependent and frequency-sensitive dynamic coupling mechanisms. An increase in jetting force amplitude generally suppresses boom vibrations by altering the load distribution and enhancing dynamic stabilization, whereas specific excitation frequencies, particularly near higher-order natural harmonics, induce resonance and amplify vibration responses. These trends indicate that the dynamic behavior of the joint boom is controlled by the interplay between external fluid-induced excitation and inherent structural characteristics, providing a physical basis for optimizing jetting parameters to improve operational stability.

6. Conclusions

In the study, a comprehensive fluid–solid coupling framework, combining volume of fluid (VOF) simulation, finite element modeling, and full-scale experimental validation, is developed to investigate the dynamic stability of a field sprayer and its joint boom under the most hazardous operating conditions. The influences of tank-liquid sloshing, connection stiffness, and the jetting force characteristics of the joint boom are systematically quantified. The major conclusions are summarized as follows:

(1) Tank-liquid sloshing significantly affects the dynamic load transmission within the field sprayer. The conditions of braking from 5.4 km/h and swerving with 45° are identified as the most critical operating scenarios. Higher liquid filling ratios produce markedly larger sloshing forces and moments, especially in the X and Z directions, resulting in intensified excitation of both the vehicle body and the joint boom. The simulated liquid surface behavior, including wave flipping and breaking, agrees well with experimentally observed phenomena reported in the literature, confirming the reliability of the adopted fluid–structure interaction model.

(2) The joint boom exhibits strong direction-dependent vibration behavior under fluid-induced and structural excitation. Both simulation and experimental results show good agreement in resonance frequencies and overall amplitude-frequency characteristics. The joint boom demonstrates its highest sensitivity in the X direction, moderate sensitivity in the Y direction, and minimal vibration in the Z direction due to higher vertical stiffness. With increasing liquid filling ratio, nonlinear and multi-frequency components in the vibration response become more prominent, highlighting the complexity of the coupled dynamic behavior.

(3) Connection stiffness plays a crucial role in the dynamic stability of the joint boom. Increasing the stiffness from 500 N/m to 3000 N/m raises the vibration amplitudes in all directions. Excessive stiffness elevates the natural frequencies of the boom and reduces the damping effect of the flexible joints, thereby increasing the likelihood of resonance during braking. This stiffness-induced amplification mechanism indicates that an appropriate stiffness range, rather than maximum stiffness, is critical for vibration mitigation.

(4) The amplitude and frequency of the jetting force strongly influence the dynamics of the joint boom. As the amplitude of the jetting force increases from 0 to 1000 N, the vibration amplitude in the X direction decreases nearly linearly, remains almost unchanged in the Y direction, and decreases nonlinearly in the Z direction, stabilizing beyond approximately 500 N. The jetting frequency produces a pronounced resonance peak near 50–60 Hz in the X and Y directions, consistent with the third harmonic of the natural frequency of the boom. These results demonstrate that jetting force parameters can function as either stabilizing or destabilizing factors, depending on their magnitude and frequency.

(5) The integrated dynamic model provides an accurate prediction of boom vibration and offers guidance for structural optimization. The consistency between simulation and experimental results confirms the effectiveness of the modeling approach, while minor discrepancies are attributed to suspension flexibility, structural deformation of the test platform, and measurement uncertainties.

Overall, this work reveals the complex coupled dynamics governing the stability of a field sprayer and provides a quantitative basis for improving boom design, optimizing connection stiffness, selecting appropriate jetting parameters, and mitigating the adverse effects of tank-liquid sloshing. The findings offer practical engineering guidance for enhancing the operational safety and structural longevity of field sprayers. The potential influences on sprayer uniformity through the reduction in boom vibrations are suggested as a possible implication, to be investigated in future work. It should be noted that, in the present study, water is employed as a surrogate for the medicinal liquid. Consequently, physicochemical properties such as viscosity and surface tension of the actual medicinal liquid are not considered in the analysis of the sloshing effect. In future work, the sloshing dynamics will be investigated with explicit consideration of the physicochemical properties of the medicinal liquid.