A Novel Hierarchical Optimal Scheduling and Coordination Control Method for Microgrid Based on Multi-Energy Complementarity

Abstract

1. Introduction

Paper Organization

2. Construction of a Three-Layer Coordinated Scheduling Model

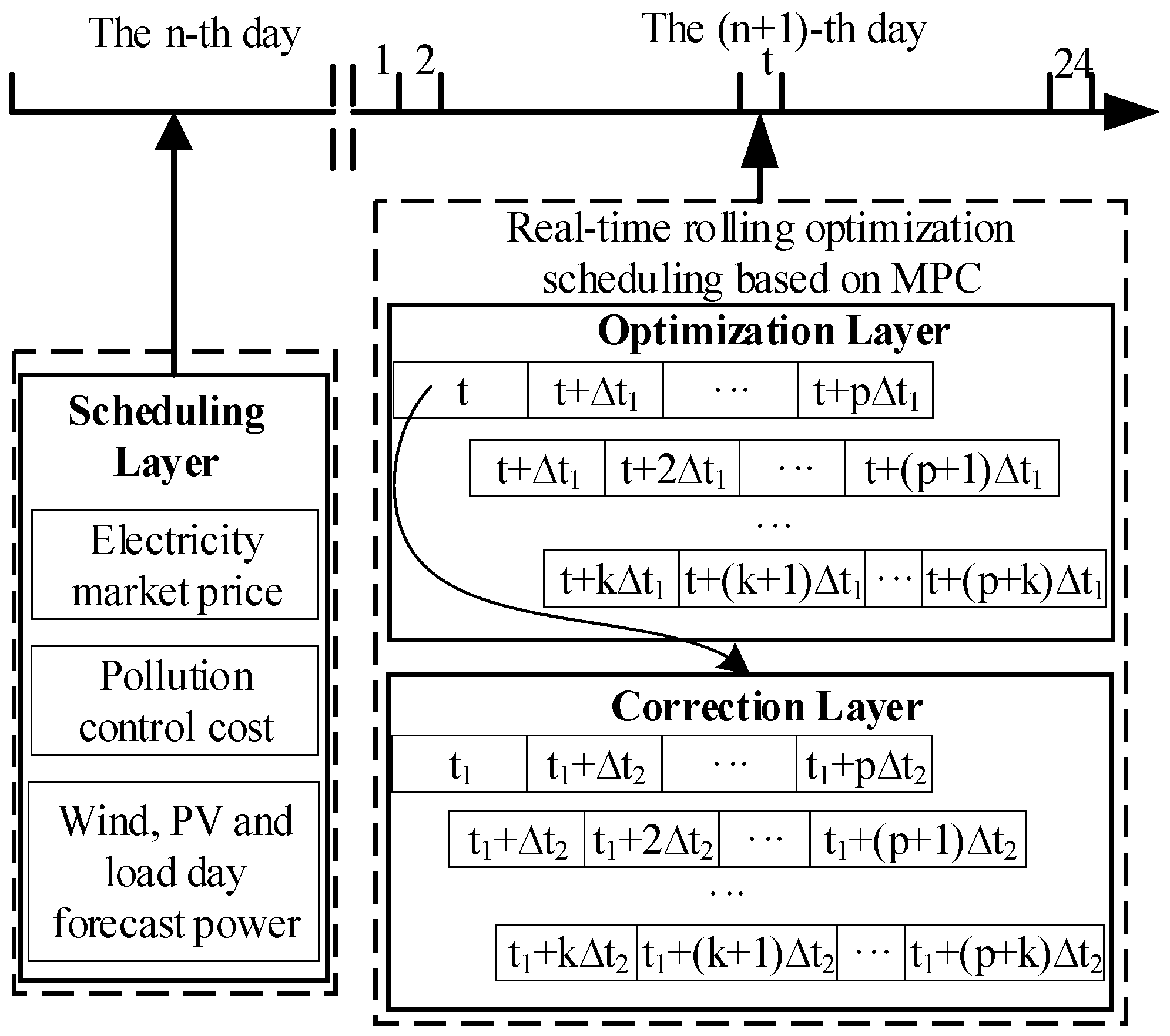

2.1. Three-Tier Coordinated Movement Control Framework

- (a)

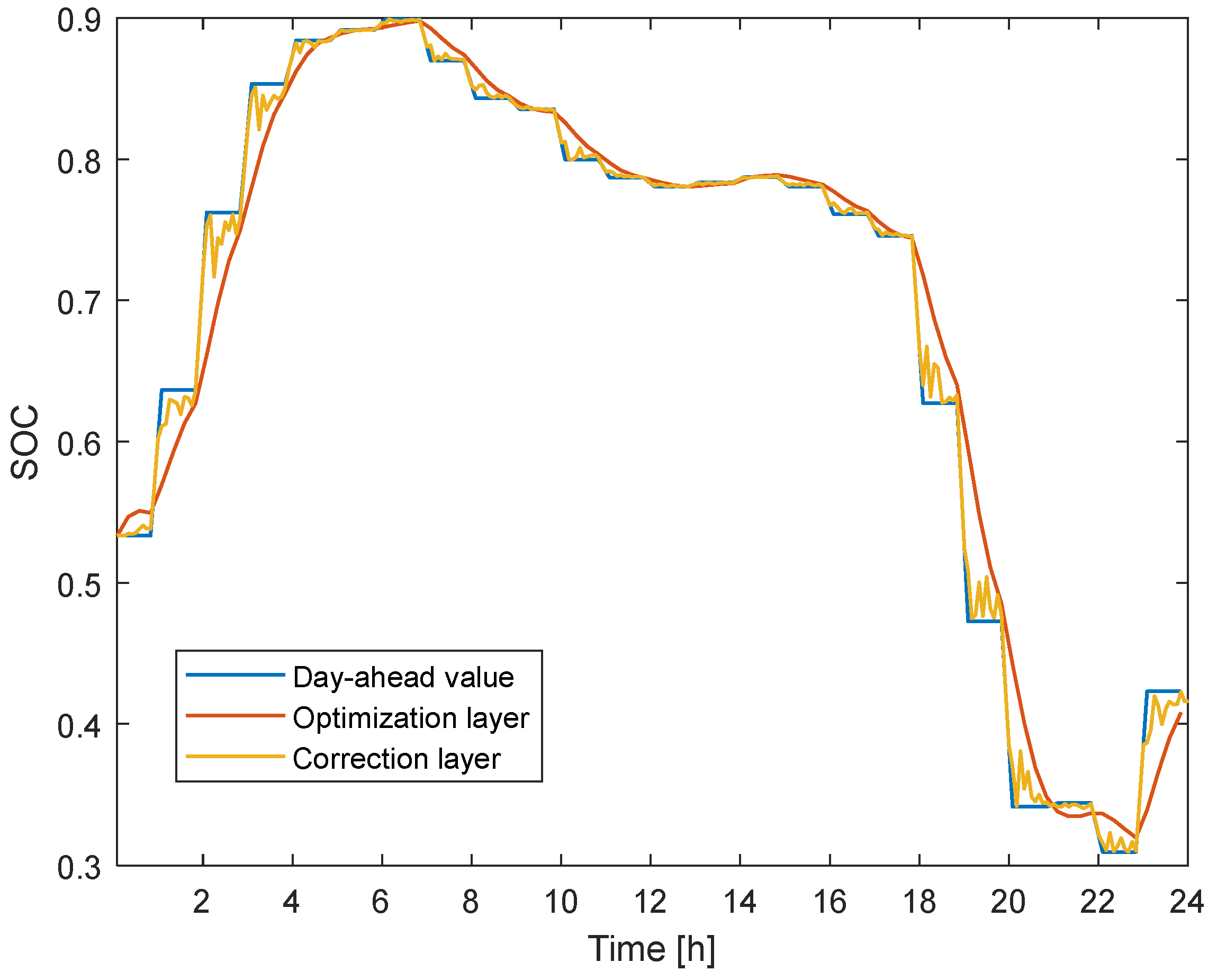

- First Layer—Scheduling Layer: This layer operates on a “day-ahead” time scale and is based on forecasts of renewable energy and load demand. A 24 h planning cycle (Δt = 1 h) is defined at the dispatch level, covering the co-optimization of PV, wind turbines, storage (SOC 0.2–0.9), gas turbine, diesel generator, and grid interconnections. It comprehensively considers time-varying electricity prices and environmental management costs, aiming to minimize the system’s economic costs. By optimizing control variables such as micro-source power, charge, and discharge adjustments, and the output ratio of interconnection lines, a generation plan for each hour of the following day is established.

- (b)

- Second Layer—Optimization Layer: This layer functions on an “intraday” time scale, managing units according to the day-ahead generation plan. The optimization layer uses a 4 h rolling window (Δt = 15 min) to dynamically adjust the control variables: energy storage charging and discharging power, gas turbine, and diesel generator output power. The objective is to minimize tracking errors for the interconnection line power and the state of charge (SOC) of energy storage based on the day-ahead plan, solving for the optimal control sequence for each unit. The power state values of the units, energy storage, and interconnection lines derived from this sequence are then used as initial values for the next time segment in the optimization layer.

- (c)

- Third Layer—Correction Layer: This layer operates on a “real-time” time scale, using the scheduling values obtained from the optimization layer as a reference for the real-time management of units. The optimization cycle is refined into three periods, with rolling corrections occurring every 5 min. Using an MPC controller, the inputs of the system are gas turbine, diesel generator, and energy storage charging and discharging power. The output is the exchanged power of the contact line and the energy storage system. The objective function is to minimize the input variables by tracking the contact line power and the energy storage SOC day-ahead schedule value. A closed loop system is formed by the difference between the output power and the actual power as a feedback regulation.

2.2. Construction of Scheduling Layer

- (1)

- Power balance constraint

- (2)

- Distributed power constraints

- (3)

- Power climb constraint of distributed power supply

- (4)

- Constraints on the transmission power of the tie line

- (5)

- Capacity constraint of energy storage unit

- (6)

- The constraints on the charging and discharging power of energy storage are as follows:

2.3. Construction of Optimization Layer and Correction Layer

3. Improvement of the Dung Beetle Optimization Algorithm

3.1. The Problem of Traditional DBO Algorithm

- (a)

- Lack of Information Exchange: Individuals do not communicate with one another, which makes the algorithm susceptible to becoming trapped in local optima.

- (b)

- Inflexible Step Size: The absence of adaptive changes in step size during individual position updates leads to an imbalance between global exploration and local exploitation capabilities.

- (c)

- Random Distribution in Initialization: The overly random distribution of individuals during population initialization results in a limited search range.

- (d)

- Low Precision in Complex Problems: When confronted with complex problems, the algorithm exhibits low solution accuracy and slow convergence speed.

3.2. Improvement Process

3.2.1. Improved Population Initialization

3.2.2. Improvement of Ball Rolling Behavior

3.2.3. Improved Foraging Behavior

3.2.4. Variation Perturbation to the Optimal Solution

3.3. OTcmDBO Performance Testing

4. Optimization and Solution of a Three-Layer Coordinated Optimal Scheduling Model Based on OTcmDBO

- (1)

- Input the optimization metric and relevant constraints, initialize the dung beetle population using Equation (16), and calculate the fitness value for each individual, selecting the optimal individual.

- (2)

- Use the random number Rand from the dung beetle algorithm to determine whether to update the position using Equation (17) or the dancing behavior; Rand is a random number in the interval [0, 1], with the original algorithm set to λ = 0.9.

- (3)

- After updating the positions of the nurturing ball and the small dung beetles through reproductive and foraging behaviors, compare the new random number Rand with the adaptive selection probability p in Equation (19). If the criteria are met, update the positions of the small dung beetles using Equation (18), and finally, update the positions of the stealing dung beetles to increase diversity.

- (4)

- Calculate the fitness value and extract the optimal solution. Apply mutation disturbance to the optimal solution using Equation (20) and compute its fitness value, selecting the best solution.

- (5)

- Check if the algorithm has reached the maximum number of iterations. If not, repeat steps (2)–(5); if yes, end the loop, and the optimal solution represents the optimal output or control sequence for each unit.

5. Analysis and Verification of Numerical Examples

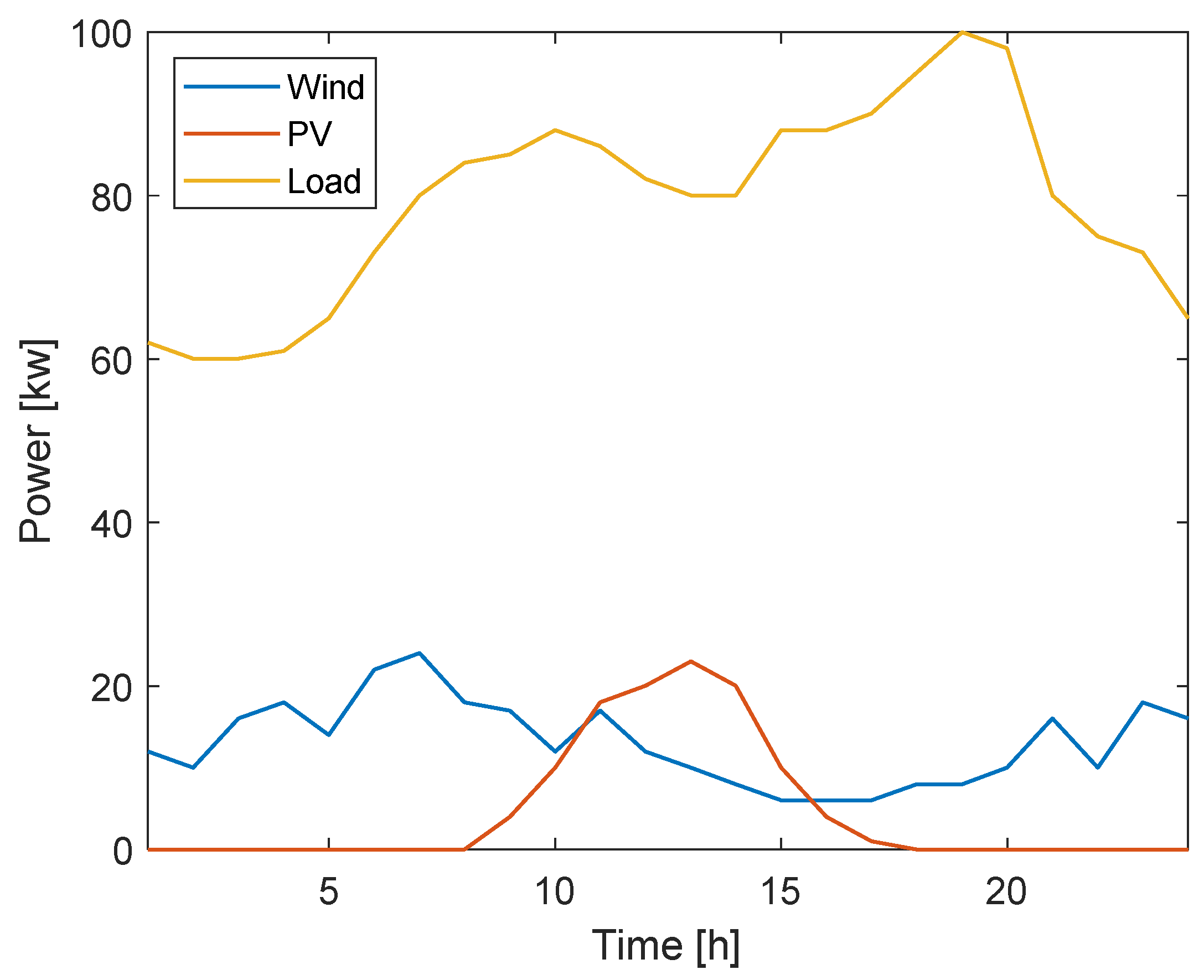

5.1. Example Parameter

5.2. Interpretation of Result

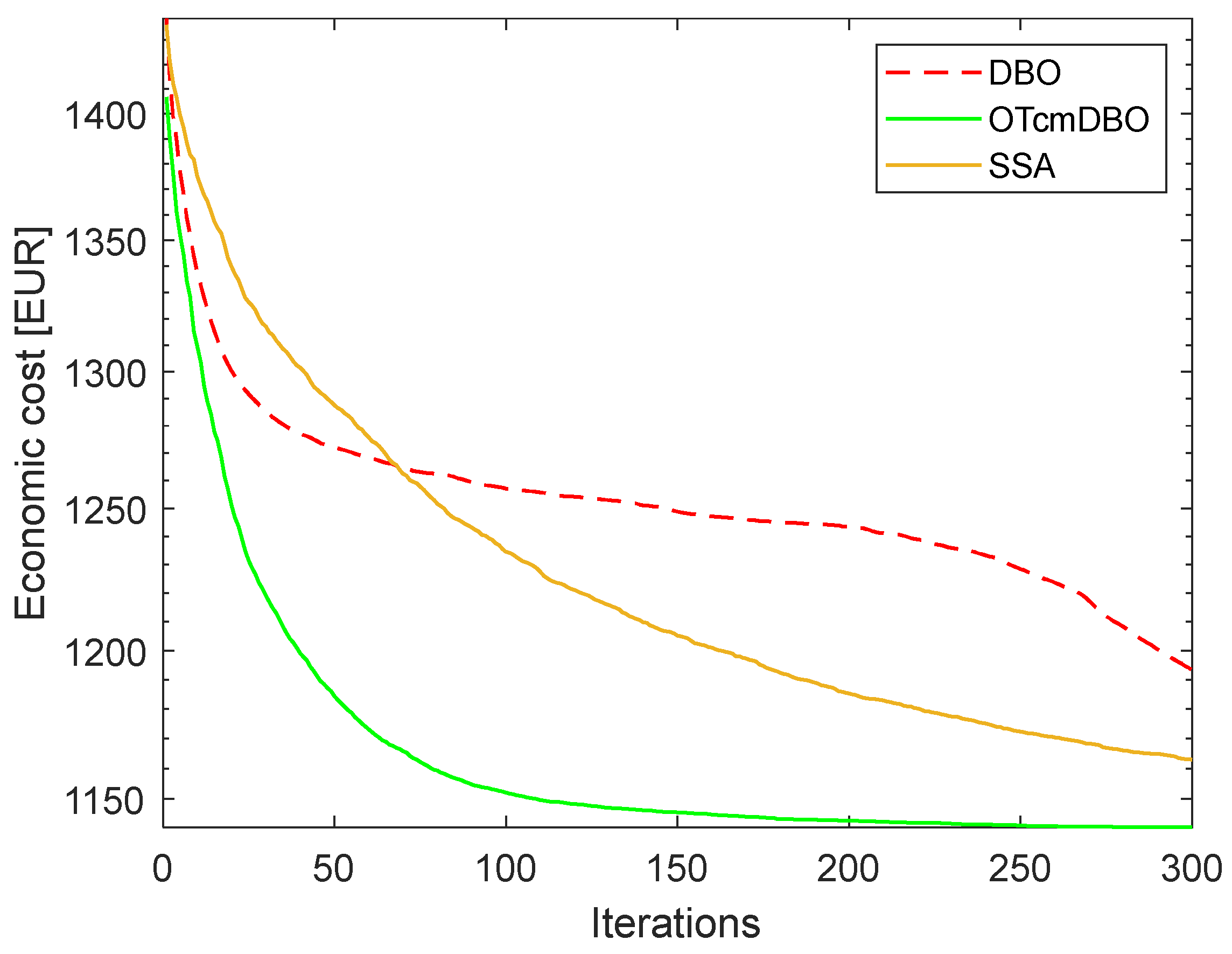

5.2.1. Comparative Analysis of Day-Ahead Scheduling Economy

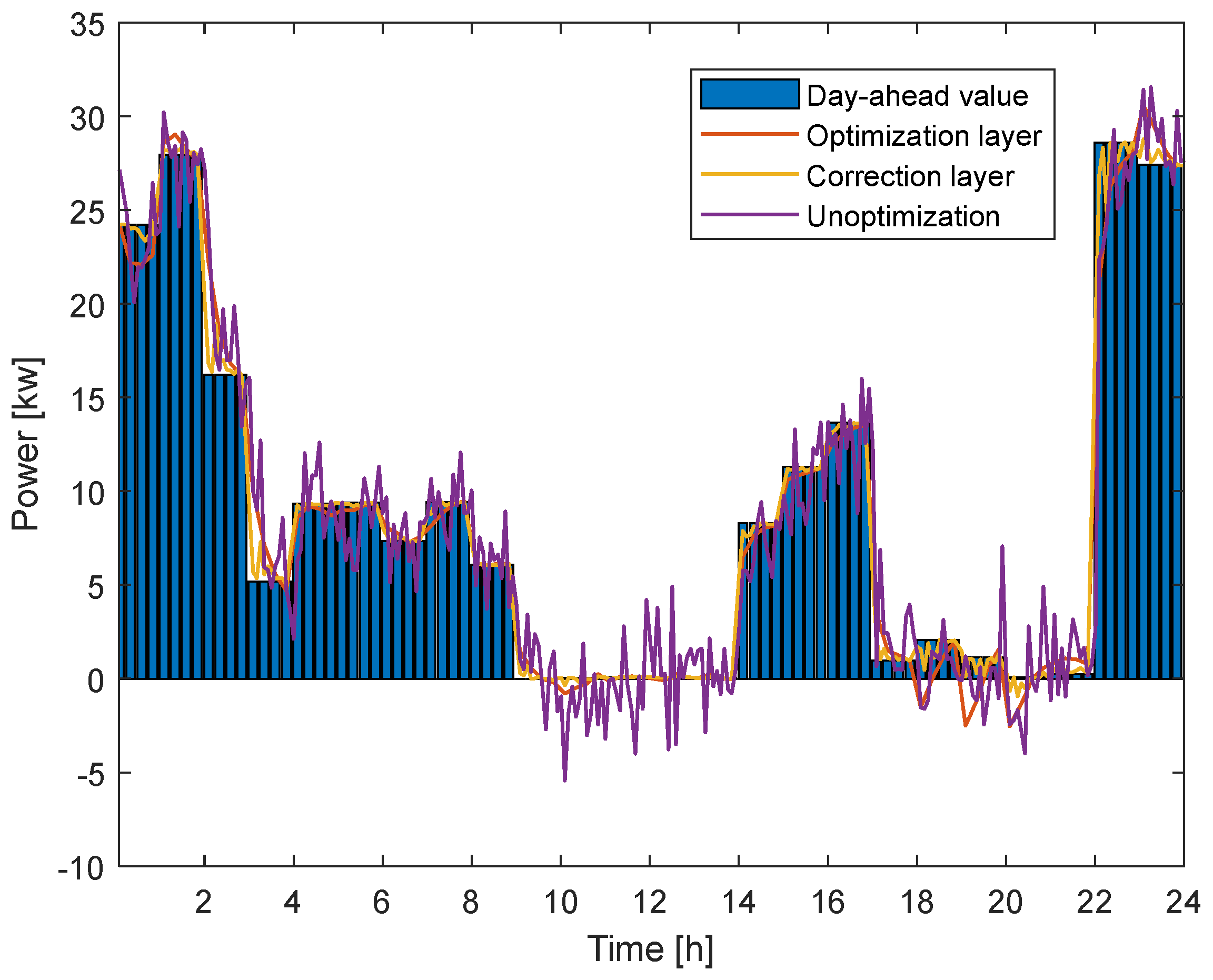

5.2.2. Intraday Rolling Optimization Scheduling Analysis

5.2.3. Comparative Analysis of Control Effect

6. Conclusions

- The proposed three-layer predictive control model effectively improves the scheduling performance of the microgrid, stabilizing and controlling interconnection line power. It also considers time-varying electricity prices and environmental pollution costs, contributing to economic efficiency and sustainable development.

- Improvements to the traditional dung beetle optimizer algorithm, including population initialization, rolling behavior, and foraging behavior, along with mutation perturbations for the optimal solution, were compared through simulation experiments with other optimization algorithms. The results indicate that the OTcmDBO algorithm yields superior optimization results and converges more rapidly.

- The results of this study confirm the applicability of the proposed three-layer predictive control model and OTcmDBO algorithm to addressing renewable energy and load demand uncertainties in microgrids. While the findings demonstrate reductions in operating costs and improvements in volatility management, it is important to acknowledge limitations in the study. These include: (a) simplified assumptions in modeling (e.g., static energy storage parameters and deterministic load profiles); (b) dependence on day-ahead forecasting accuracy, which may degrade under extreme weather conditions; and (c) limited scalability for multi-microgrid collaborative scenarios.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chu, C.-C.; Wu, Y.-K.; Lian, K.-L.; Liu, J.-H. Guest Editorial Towards Resilient Power Grids Integrated With High-Penetrated Renewable Energy Sources: Challenges, Opportunities, Implementation Strategies, and Future Perspectives. IEEE Trans. Ind. Applicat. 2024, 60, 1960–1962. [Google Scholar] [CrossRef]

- Rhodes, E.; Scott, W.A.; Jaccard, M. Designing flexible regulations to mitigate climate change: A cross-country comparative policy analysis. Energy Policy 2021, 156, 112419. [Google Scholar] [CrossRef]

- Hu, J.; Shan, Y.; Yang, Y.; Parisio, A.; Li, Y.; Amjady, N.; Islam, S.; Cheng, K.W.; Guerrero, J.M.; Rodríguez, J. Economic Model Predictive Control for Microgrid Optimization: A Review. IEEE Trans. Smart Grid 2024, 15, 472–484. [Google Scholar] [CrossRef]

- Babayomi, O.; Zhang, Z.; Dragicevic, T.; Hu, J.; Rodriguez, J. Smart grid evolution: Predictive control of distributed energy resources—A review. Int. J. Electr. Power Energy Syst. 2023, 147, 108812. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, X.; Li, G.; Feng, J.; Yang, A. Model Predictive Control Method of Multi-Energy Flow System Considering Wind Power Consumption. IEEE Access 2023, 11, 86697–86710. [Google Scholar] [CrossRef]

- Hu, Z.; Liu, S.; Luo, W.; Wu, L. Intrusion-Detector-Dependent Distributed Economic Model Predictive Control for Load Frequency Regulation With PEVs Under Cyber Attacks. IEEE Trans. Circuits Syst. I 2021, 68, 3857–3868. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, C.; Liu, Z.; Wang, T.; Ke, F.; Yang, D.; Zhang, D.; Miao, S. A Hierarchical Cooperative Frequency Regulation Control Strategy of Wind-Storage-Load in a Microgrid Based on Model Prediction. Energies 2023, 16, 1886. [Google Scholar] [CrossRef]

- He, Y.; Li, Z.; Zhang, J.; Shi, G.; Cao, W. Day-ahead and intraday multi-time scale microgrid scheduling based on light robustness and MPC. Int. J. Electr. Power Energy Syst. 2023, 144, 108546. [Google Scholar] [CrossRef]

- Zhang, J.; Qin, D.; Ye, Y.; He, Y.; Fu, X.; Yang, J.; Shi, G.; Zhang, H. Multi-Time Scale Economic Scheduling Method Based on Day-Ahead Robust Optimization and Intraday MPC Rolling Optimization for Microgrid. IEEE Access 2021, 9, 140315–140324. [Google Scholar] [CrossRef]

- Hou, J.; Yu, W.; Xu, Z.; Ge, Q.; Li, Z.; Meng, Y. Multi-time scale optimization scheduling of microgrid considering source and load uncertainty. Electr. Power Syst. Res. 2023, 216, 109037. [Google Scholar] [CrossRef]

- Zhang, N.; Ren, Q.; Liu, G.; Guo, L.; Li, J. Short-term PV Output Power Forecasting Based on CEEMDAN-AE-GRU. J. Electr. Eng. Technol. 2022, 17, 1183–1194. [Google Scholar] [CrossRef]

- Fu, S.; Sun, H.; Liu, Z.; Han, H.; Zhang, Y. Model Predictive Control for Nonlinear Systems With Two-Time Scales. IEEE Trans. Automat. Sci. Eng. 2024, 21, 5088–5098. [Google Scholar] [CrossRef]

- Lin, Y.; Wending, C.; Zhuo, L. Hierarchical Prediction Control Strategy of Active Power for Photovoltaic Cluster. Dianli Xitong Zidonghua/Autom. Electr. Power Syst. 2023, 47, 42–52. [Google Scholar] [CrossRef]

- Hu, K.; Wang, B.; Cao, S.; Li, W.; Wang, L. A novel model predictive control strategy for multi-time scale optimal scheduling of integrated energy system. Energy Rep. 2022, 8, 7420–7433. [Google Scholar] [CrossRef]

- Dey, B.; Misra, S.; Marquez, F.P.G. Microgrid system energy management with demand response program for clean and economical operation. Appl. Energy 2023, 334, 120717. [Google Scholar] [CrossRef]

- Xue, J.; Shen, B. Dung beetle optimizer: A new meta-heuristic algorithm for global optimization. J. Supercomput. 2023, 79, 7305–7336. [Google Scholar] [CrossRef]

- Dehghani, M.; Trojovský, P. Osprey optimization algorithm: A new bio-inspired metaheuristic algorithm for solving engineering optimization problems. Front. Mech. Eng. 2023, 8, 1126450. [Google Scholar] [CrossRef]

- Gao, Z.-M.; Zhao, J.; Zhang, Y.-J. Review of chaotic mapping enabled nature-inspired algorithms. Math. Biosci. Eng. 2022, 19, 8215–8258. [Google Scholar] [CrossRef]

- Aryani, D.R.; Song, H. A Review on Power System Security Issues in the High Renewable Energy Penetration Environment. J. Electr. Eng. Technol. 2024, 19, 4649–4665. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, Q.; Ma, L.; Zhang, Z. Sparrow search algorithm with adaptive t distribution for multi-objective low-carbon multimodal transportation planning problem with fuzzy demand and fuzzy time. Expert Syst. Appl. 2024, 238, 122042. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, L.; He, D. Application of Variable Universe Fuzzy PID Controller Based on ISSA in Bridge Crane Control. Electronics 2024, 13, 3534. [Google Scholar] [CrossRef]

- Ou, X.; Wu, M.; Pu, Y.; Tu, B.; Zhang, G.; Xu, Z. Cuckoo search algorithm with fuzzy logic and Gauss–Cauchy for minimizing localization error of WSN. Appl. Soft Comput. 2022, 125, 109211. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Q.; Li, G.; Wu, J.; Wang, C.; Li, Z. Hybrid Model for Renewable Energy and Load Forecasting Based on Data Mining and EWT. J. Electr. Eng. Technol. 2022, 17, 1517–1532. [Google Scholar] [CrossRef]

| Function | Range | Minimum Value |

|---|---|---|

| F1 | [−10, 10] | 0 |

| F2 | [−100, 100] | 0 |

| F3 | [−5.12, 5.12] | 0 |

| F4 | [−32, 32] | 0 |

| F5 | [−65, 65] | 1 |

| F6 | [−2, 2] | 3 |

| Test Function | F1 | F2 | F3 | F4 | F5 | F6 | |

|---|---|---|---|---|---|---|---|

| OTcmDBO | M | 0 | 0 | 0 | 4.44 × 10−16 | 1.16 | 3 |

| Std | 0 | 0 | 0 | 0 | 0.53 | 2.9 × 10−15 | |

| GA-PSO | M | 1.89 × 10−48 | 9.36 × 10−48 | 0 | 9.18 × 10−16 | 10.55 | 10.98 |

| Std | 1.58 × 10−48 | 1.05 × 10−47 | 0 | 1.23 × 10−15 | 3.19 | 11.31 | |

| GWO | M | 0.02 | 1.31 | 32.75 | 0.02 | 5.72 | 3 |

| Std | 0.01 | 0.55 | 9.51 | 0.01 | 4.93 | 9.08 × 10−4 | |

| PSO | M | 24.28 | 8.31 | 146.55 | 5.81 | 2.74 | 3.02 |

| Std | 6.88 | 1.98 | 47.33 | 0.58 | 1.86 | 0.02 | |

| SSA | M | 2.48 × 10−21 | 2.49 × 10−20 | 0 | 5.81 × 10−16 | 7.56 | 4.8 |

| Std | 1.06 × 10−20 | 1.11 × 10−19 | 0 | 4.01 × 10−16 | 5.48 | 6.85 | |

| DBO | M | 7.49 × 10−10 | 4.58 × 10−8 | 0.95 | 3.89 × 10−10 | 2.54 | 3 |

| Std | 3.65 × 10−9 | 1.71 × 10−7 | 3.81 | 1.73 × 10−9 | 2.26 | 6.73 × 10−15 | |

| Name of Parameter | Gas Turbine | Diesel Generator | Wind | PV | Grid |

|---|---|---|---|---|---|

| Upper power limit [kW] | 30 | 30 | 100 | 50 | 30 |

| Lower power limit [kW] | 3 | 6 | 0 | 0 | −30 |

| Upper limit of climbing power [kW/min] | 1.5 | 1.5 | 0 | 0 | 0 |

| Operation and maintenance unit price [EUR/kW·h] | 0.0293 | 0.128 | 0 | 0 | 0 |

| Pollutant Type | Treatment Cost [EUR/kg] | Pollutant Discharge Coefficient [g/kW·h] | ||||

|---|---|---|---|---|---|---|

| MT | DE | WT | PV | Grid | ||

| CO2 | 0.023 | 724 | 680 | 0 | 0 | 889 |

| SO2 | 6 | 0.0036 | 0.306 | 0 | 0 | 1.8 |

| NOX | 8 | 0.2 | 10.09 | 0 | 0 | 1.6 |

| Type | Parameter | Value |

|---|---|---|

| Storage battery | Maximum capacity [kW·h] | 150 |

| Minimum capacity [kW·h] | 5 | |

| Maximum input power [kW] | 30 | |

| Initial storage capacity [kW·h] | 80 | |

| Maximum power output [kW] | 30 | |

| Charge and discharge rate | 0.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Ma, Z.; Jia, C.; Zhang, T.; Zhang, H. A Novel Hierarchical Optimal Scheduling and Coordination Control Method for Microgrid Based on Multi-Energy Complementarity. Electronics 2025, 14, 1829. https://doi.org/10.3390/electronics14091829

Zhang L, Ma Z, Jia C, Zhang T, Zhang H. A Novel Hierarchical Optimal Scheduling and Coordination Control Method for Microgrid Based on Multi-Energy Complementarity. Electronics. 2025; 14(9):1829. https://doi.org/10.3390/electronics14091829

Chicago/Turabian StyleZhang, Li, Zeyuan Ma, Chenhao Jia, Tao Zhang, and Hongwei Zhang. 2025. "A Novel Hierarchical Optimal Scheduling and Coordination Control Method for Microgrid Based on Multi-Energy Complementarity" Electronics 14, no. 9: 1829. https://doi.org/10.3390/electronics14091829

APA StyleZhang, L., Ma, Z., Jia, C., Zhang, T., & Zhang, H. (2025). A Novel Hierarchical Optimal Scheduling and Coordination Control Method for Microgrid Based on Multi-Energy Complementarity. Electronics, 14(9), 1829. https://doi.org/10.3390/electronics14091829