Research on Train Energy Optimization Based on Dynamic Adaptive Hybrid Algorithms

Abstract

1. Introduction

2. Mathematical Model for Train Optimization

2.1. A Dynamics Model of the Uniform Rod for Trains

- g: gravitational acceleration (unit: );

- : gradient at position l;

- R: curve radius at position l (unit: m);

- L: tunnel length (unit: m).

2.2. Energy Consumption–Time Model Based on Discretization of Grade Resistance of Track

- (1)

- Under traction mode, assuming constant acceleration within the operational step length Δs, the acceleration, running time, and energy consumption within the interval can be expressed as follows:

- (2)

- Under cruising mode, where the traction force equals resistance, the energy consumption within a unit step length Δs corresponds to the work performed against resistance. Consequently, the acceleration, running time, and energy consumption within the interval are defined as follows:

- (3)

- Under coasting mode, the speed begins to decrease, and both the traction force and energy consumption are reduced to 0. Within the interval, the acceleration and running time are defined as follows:

- (4)

- Under braking mode, the train generates regenerative braking energy. Let the feedback efficiency of regenerative braking energy be denoted as . The regenerative braking energy is defined as

2.3. Energy Consumption Model

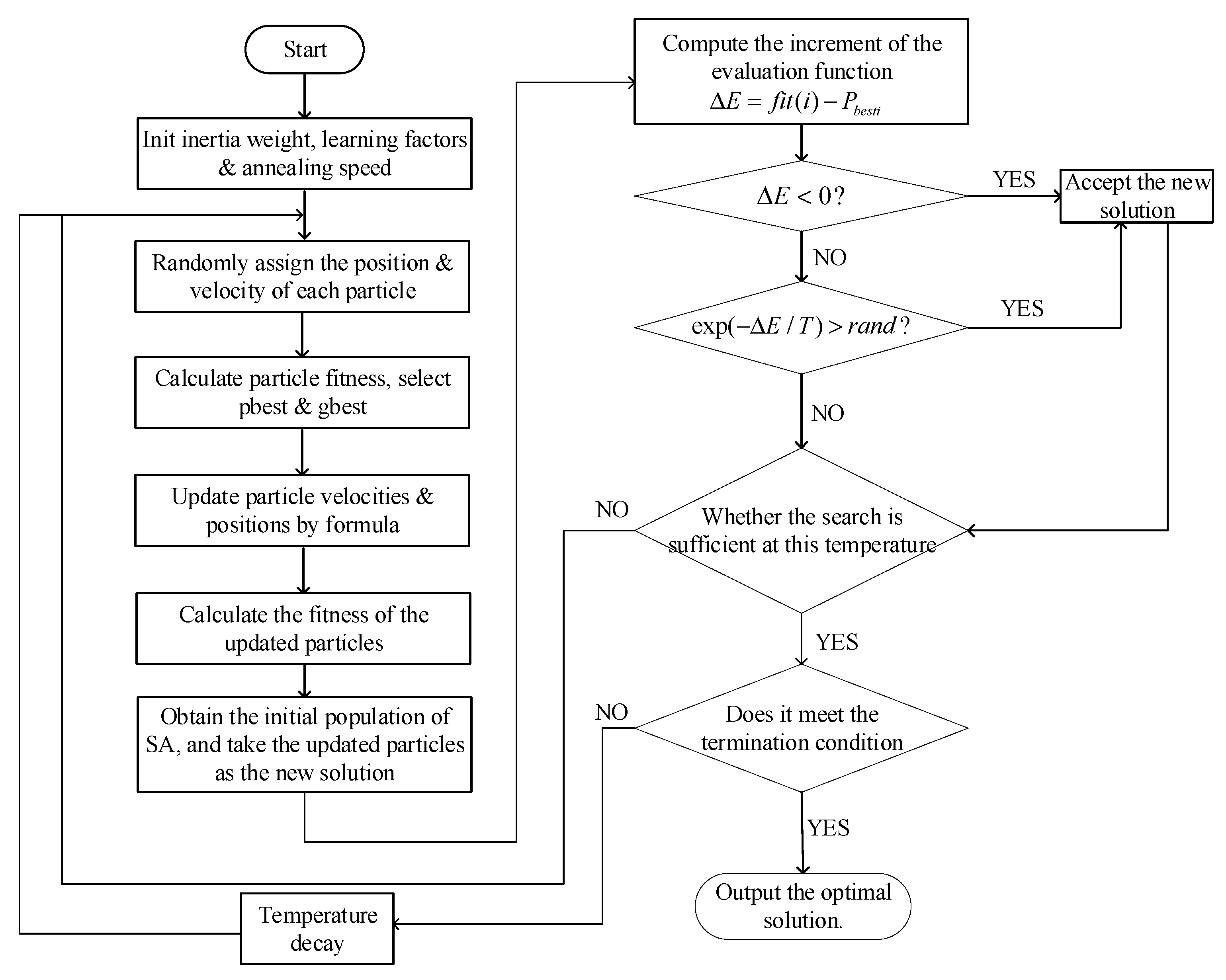

3. Dynamic Adaptive PSO-SA Algorithm for Train Energy Consumption Optimization

- (1)

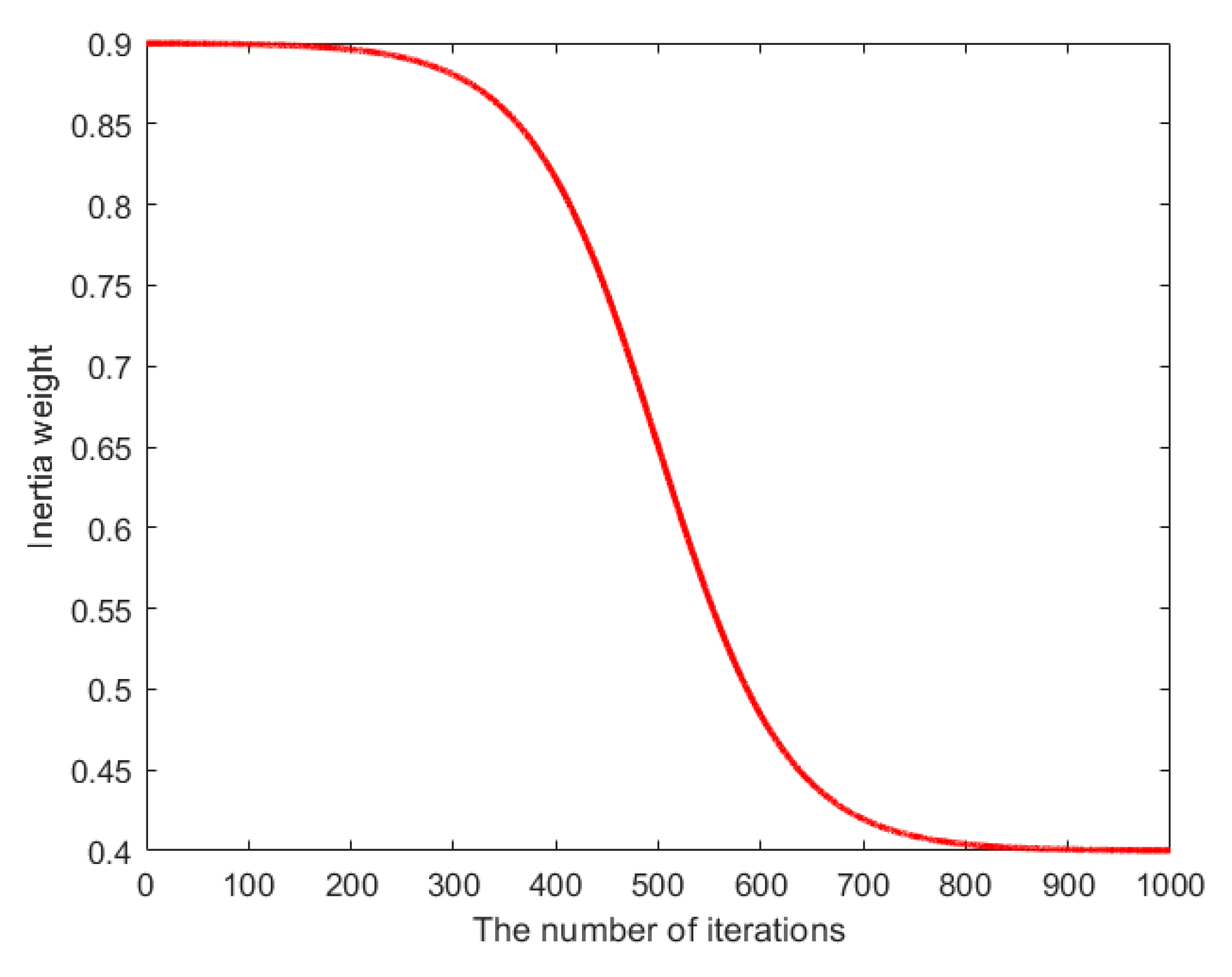

- The dynamic adjustment method for the inertia weight is defined as follows:

- (2)

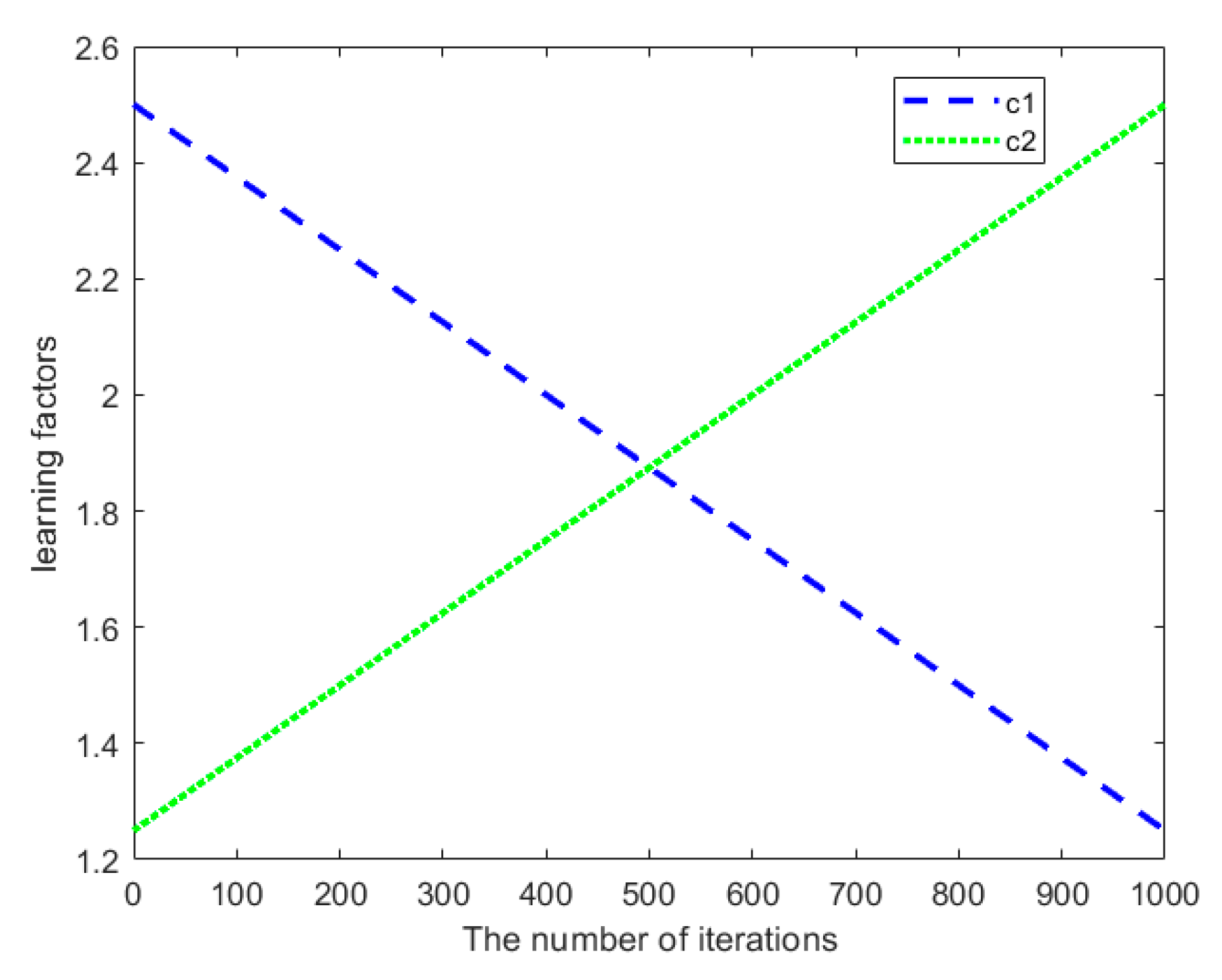

- Learning factors c1 and c2 regulate the flight of population particles towards the personal optimum and the global optimum. Their adjustment methods are as follows:

4. Case Analysis

4.1. Railway Line Information

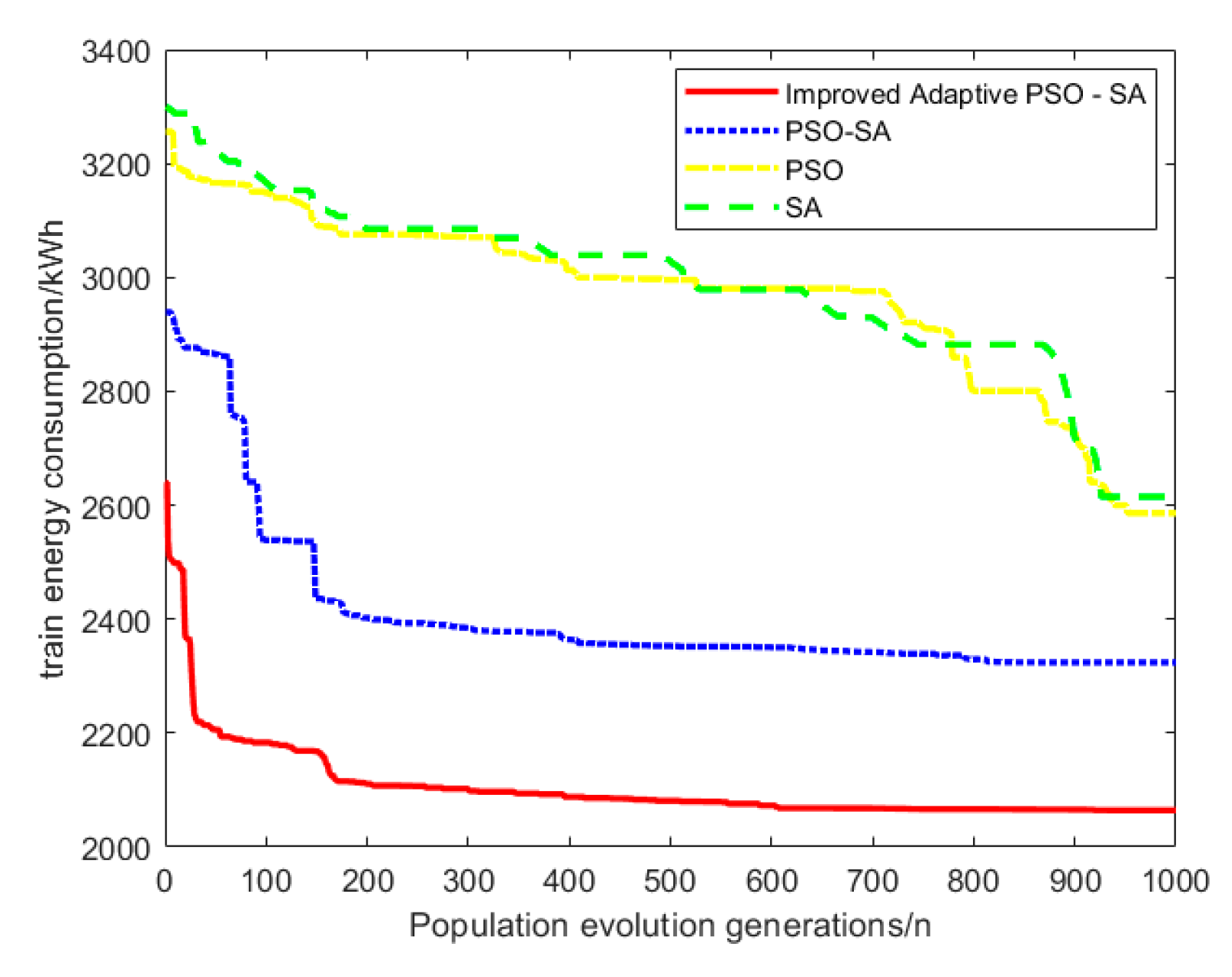

4.2. Evaluation of Dynamic Adaptive PSO-SA Algorithm

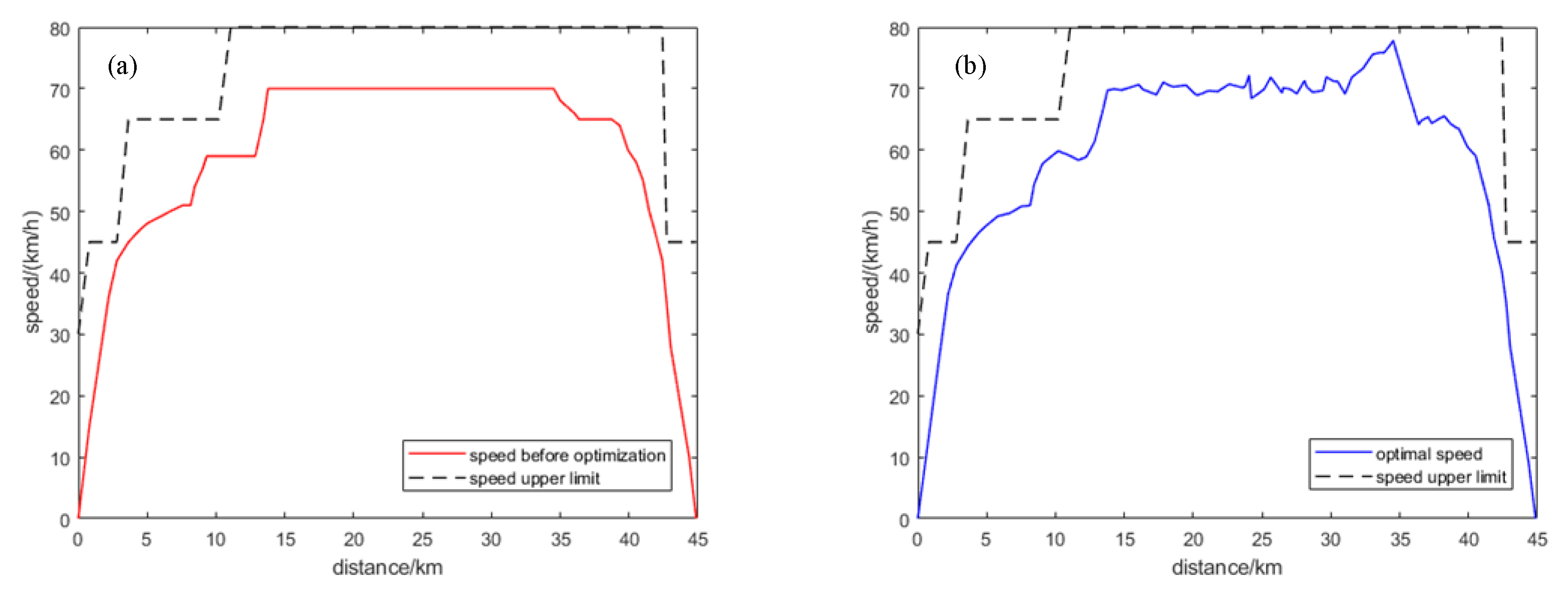

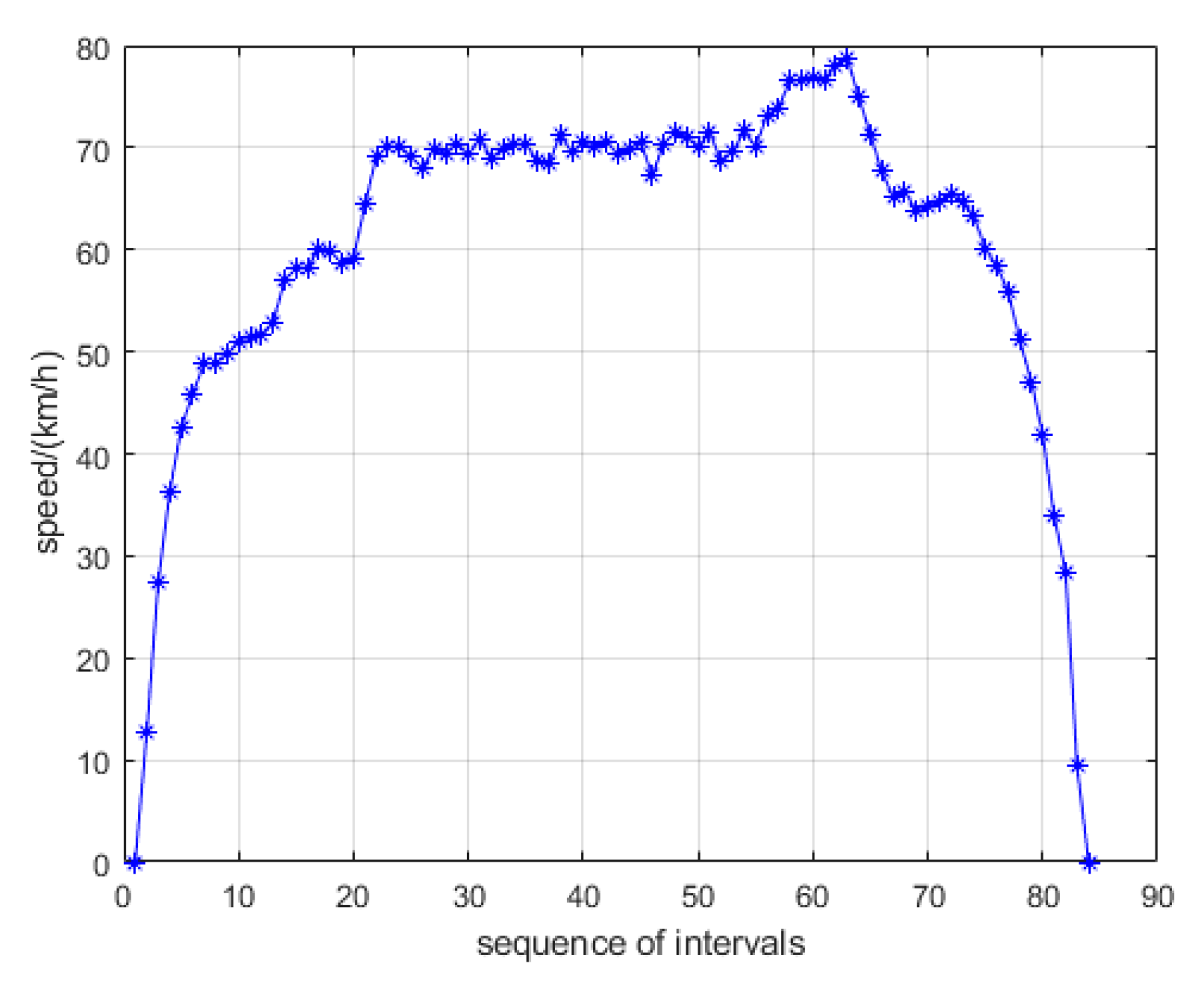

4.3. Comparison of Dynamic Modeling

5. Conclusions

- (1)

- The proposed uniform bar dynamics model resolves the accuracy–efficiency trade-off between single-mass and multi-mass models. By incorporating equivalent slope resistance discretization, it enhances track model precision and, when combined with the uniform bar model, improves the applicability and accuracy of energy consumption models under complex track conditions.

- (2)

- To solve the optimization model, an adaptive PSO-SA algorithm was developed. Building upon the hybrid PSO-SA framework, it improves inertia weights and learning factors, demonstrating excellent optimization performance, a fast convergence speed, and superior solution distribution characteristics—making it particularly suitable for train traction energy optimization.

- (3)

- Validation using the Xinzhun Line showed that the proposed method achieves 19% energy savings compared to conventional approaches, demonstrating strong practical applicability and confirming its correctness and effectiveness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Feng, X.Y.; Huang, D.Q.; Wang, Q.Y.; Sun, P.F.; He, Q. A review of comprehensive energy saving research for transportation trains. J. China Railw. Soc. 2023, 45, 22–34. [Google Scholar]

- Zhou, K.; Song, S.; Xue, A.; You, K.; Wu, H. Smart train operation algorithms based on expert knowledge and reinforcement learning. IEEE Trans. Syst. Man Cybern. Syst. 2022, 52, 716–727. [Google Scholar] [CrossRef]

- Yang, J.; Wu, J.Y.; Wang, B.; Lu, S.F. Research on the optimization algorithm of energy-saving target speed curve for train operation based on heuristic genetic algorithm. J. China Railw. Soc. 2019, 41, 1–8. [Google Scholar]

- Bai, Y.; Zhou, Y.H.; Qiu, Y.; Jia, J.; Mao, B.H. Energy-saving operation method for metro trains on long and steep downhill tracks. China Railw. Sci. 2018, 39, 108–115. [Google Scholar]

- Zhou, Y.L.; Ouyang, R.Q.; Lu, R.X.; Cui, J.F.; Wang, Q.; Yang, H. Maneuvering strategy and operation optimization algorithm for low and medium-speed magnetic levitation trains. J. China Railw. Soc. 2024, 1, 451–470. [Google Scholar]

- Albrecht, A.; Howlett, P.; Pudney, P.; Vu, X.; Zhou, P. The key principles of optimal train control-part 1: Formulation of the model, strategies of optimal type, evolutionary lines, location of optimal switching points. Transp. Res. Part B Methodol. 2016, 94, 482–508. [Google Scholar] [CrossRef]

- Albrecht, A.; Howlett, P.; Pudney, P.; Vu, X.; Zhou, P. Existence of an optimal strategy, the local energy minimization principle, uniqueness, computational techniques. Transp. Res. Part B Methodol. 2016, 94, 509–538. [Google Scholar] [CrossRef]

- Ying, P.; Zeng, X.; Song, H.; Shen, T.; Yuan, T. Energy-efficient train operation with steep track and speed limits: A novel Pontryagin’s maximum principle-based approach for adjoint variable discontinuity cases. IET Intell. Transp. Syst. 2021, 15, 1183–1202. [Google Scholar] [CrossRef]

- Tang, M.N.; Wang, Q.Q. Research on energy-saving optimization of emu trains based on golden ratio genetic algorithm. J. Railw. Sci. Eng. 2020, 17, 16–24. [Google Scholar]

- Zhang, J.T.; Wu, X.C. Multi-objective optimization of high-speed train ATO operation based on improved mh algorithm. J. Railw. Sci. Eng. 2021, 18, 334–342. [Google Scholar]

- Zhao, D.S.; Zhao, P.; Yao, X.M.; Yang, Z.; Zhang, B. Optimization of train energy-saving operation strategy based on working condition sequence optimization. J. Transp. Syst. Eng. Inf. Technol. 2024, 24, 157–165. [Google Scholar]

- Fernández-Rodríguez, A.; Fernández-Cardador, A.; Cucala, A.P. Real time eco-driving of high speed trains by simulation-based dynamic multi-objective optimization. Simul. Model. Pract. Theory 2018, 84, 50–68. [Google Scholar] [CrossRef]

- Cao, J.F.; Liu, B. Simulation research on energy-efficient operation of high-speed trains based on two-stage optimization. J. Railw. Sci. Eng. 2018, 15, 821–828. [Google Scholar]

- Song, Y.D.; Song, W.T. A novel dual speed-curve optimization based approach for energy-saving operation of high-speed trains. IEEE Trans. Intell. Transp. Syst. 2016, 17, 1564–1575. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Z.C.; Liu, F.; Li, P.; Xie, G. Bio-inspired speed curve optimization and sliding mode tracking control for subway trains. IEEE Trans. Veh. Technol. 2019, 68, 6331–6342. [Google Scholar] [CrossRef]

- Zhang, H.R.; Jia, L.M.; Wang, L. Generation of energy-saving driving curve sets for high-speed railway trains based on pareto multi-objective optimization. J. China Railw. Soc. 2021, 43, 85–91. [Google Scholar]

- Zhu, A.H.; Lu, W.; Song, L.M. Research on ATO operation process optimization based on niche particle swarm algorithm. J. Railw. Sci. Eng. 2017, 14, 1998–2004. [Google Scholar]

- Hasanzadeh, S.; Zarei, S.F.; Najafi, E. A train scheduling for energy optimization: Tehran metro system as a case study. IEEE Trans. Intell. Transp. Syst. 2023, 24, 357–366. [Google Scholar] [CrossRef]

- Domínguez, M.; Fernández-Cardador, A.; Cucala, A.P.; Gonsalves, T.; Fernández, A. Multi objective particle swarm optimization algorithm for the design of efficient ATO speed profiles in metro lines. Eng. Appl. Artif. Intell. 2014, 29, 43–53. [Google Scholar] [CrossRef]

- Yan, X.H.; Cai, B.G.; Ning, B.; ShangGuan, W. Moving horizon optimization of dynamic trajectory planning for high-speed train operation. IEEE Trans. Intell. Transp. Syst. 2016, 17, 1258–1270. [Google Scholar] [CrossRef]

- He, D.Q.; Lu, G.C.; Yang, Y.J. Research on optimization of train energy-saving based on improved chicken swarm optimization. IEEE Access 2019, 7, 121675–121684. [Google Scholar] [CrossRef]

- Li, G.N.; Or, S.W.; Chan, K.W. Intelligent energy-efficient train trajectory optimization approach based on supervised reinforcement learning for urban rail transits. IEEE Access 2023, 11, 31508–31521. [Google Scholar] [CrossRef]

- Tao, X.; Wang, Q.; Chen, M.; Sun, P.; Feng, X. Comprehensive optimization of energy consumption and network voltage stability of freight multitrain operation based on amMOPSO algorithm. IEEE Trans. Transp. Electrif. 2024, 10, 4074–4094. [Google Scholar] [CrossRef]

- Xu, K.; Tu, Y.C.; Xu, W.X.; Wu, S.X. Adaptive multi-intelligence body algorithm optimizing deep networks for intelligent train driving. J. Railw. Sci. Eng. 2022, 19, 2820–2832. [Google Scholar]

- Yan, Q.M.; Ma, R.Q.; Ma, Y.X.; Wang, J.J. An Adaptive Simulated Annealing Particle Swarm Optimization Algorithm. J. Xidian Univ. 2021, 48, 120–127. [Google Scholar]

| Category | Parameter |

|---|---|

| Maximum operating speed (km/h) | 160 |

| Full-load weight (t) | 6000 |

| Maximum tractive force (kN) | 580 |

| Maximum braking force (kN) | 400 |

| Electric braking power (kW) | 7200 |

| Total locomotive efficiency | ≥0.85 |

| Basic resistance (kN) | 1.20 + 0.0065v + 0.000279v2 |

| Evaluation Indicators | Improved Adaptive PSO-SA Algorithm | PSO-SA | PSO | SA |

|---|---|---|---|---|

| Average optimal energy consumption (kW·h) | 2139.05 | 2349.48 | 2595.62 | 2606.35 |

| Punctuality error (s) | 8.22 | 20.86 | 31.15 | 33.48 |

| Average number of iterations | 805 | 836 | 906 | 915 |

| Average convergence time (s) | 3.09 | 3.89 | 4.59 | 4.46 |

| Evaluation Indicators | Single Particle Model | Uniform Rod Model | Multi-Particle Model |

|---|---|---|---|

| Energy consumption (kWh) | 2348.24 | 2125.65 | 2103.86 |

| Calculation time (t) | 2.89 | 3.13 | 4.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Shi, Y.; Zhang, T.; Li, X.; Wang, X. Research on Train Energy Optimization Based on Dynamic Adaptive Hybrid Algorithms. Electronics 2025, 14, 1588. https://doi.org/10.3390/electronics14081588

Li J, Shi Y, Zhang T, Li X, Wang X. Research on Train Energy Optimization Based on Dynamic Adaptive Hybrid Algorithms. Electronics. 2025; 14(8):1588. https://doi.org/10.3390/electronics14081588

Chicago/Turabian StyleLi, Jiawei, Yong Shi, Tengya Zhang, Xin Li, and Xiaoxin Wang. 2025. "Research on Train Energy Optimization Based on Dynamic Adaptive Hybrid Algorithms" Electronics 14, no. 8: 1588. https://doi.org/10.3390/electronics14081588

APA StyleLi, J., Shi, Y., Zhang, T., Li, X., & Wang, X. (2025). Research on Train Energy Optimization Based on Dynamic Adaptive Hybrid Algorithms. Electronics, 14(8), 1588. https://doi.org/10.3390/electronics14081588