Probabilistic Characterization and Machine Learning-Based Modeling of Conducted Emissions of Programmable Microcontrollers

Abstract

1. Introduction

- To obtain the upper and lower bounds within which microcontroller emissions are expected to fall with 95% confidence.

- To accurately obtain the emission peaks of a new program based on the emissions of a set of known programs.

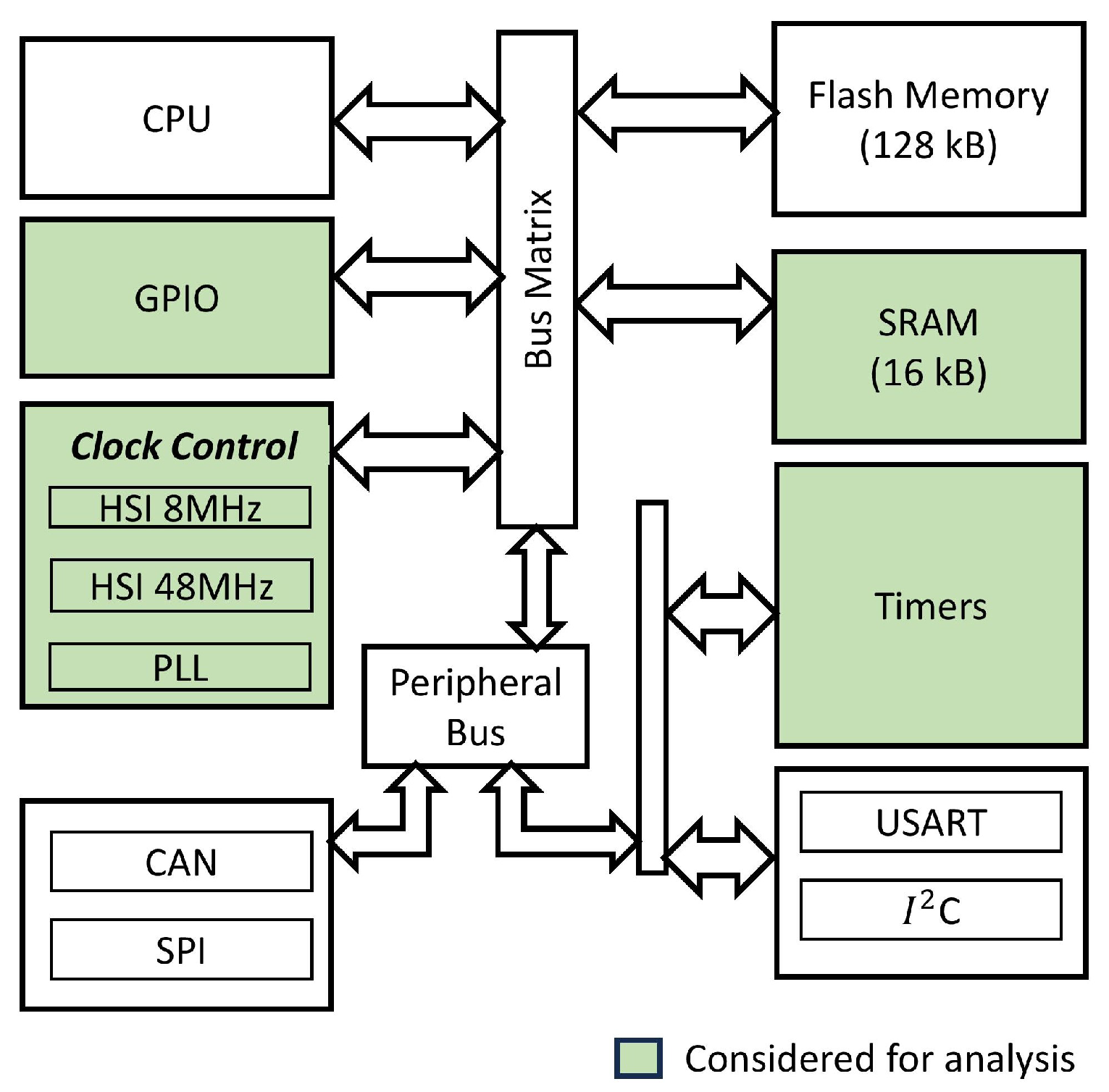

2. Design of Experiments

- To evaluate the impact of RAM utilization on conducted emissions, we execute programs that utilize RAM exclusively, without any I/O port operations or communications, while varying the clock frequency and PLL utilization.

- To capture the effect of GPIO switching caused by timer programs, communication processes, or other similar activities, we conduct GPIO pin switching experiments using different configurations while keeping RAM utilization nearly the same.

3. Measurement Setup

4. Methodology

4.1. Estimation of Emission Bounds

4.2. Prediction of Emissions of a New Program

- Statistically cluster X into distinct groups and justify the assignment of input data to specific clusters.

- Determine the weights associated with each cluster.

- Estimate emissions through a regression model.

- The weight matrix , such that .

- The mixing coefficients , such that .

- The noise variance (also called a precision parameter and considered the same for all clusters).

Determining the Optimal Number of Clusters

5. Results and Discussion

5.1. Emission Band Estimation

5.2. Conditional Mixture Model for Emission Estimation

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Paul, C.R.; Scully, R.C.; Steffka, M.A. Introduction to Electromagnetic Compatibility; John Wiley & Sons: Hoboken, NJ, USA, 2022. [Google Scholar]

- Kharanaq, F.A.; Emadi, A.; Bilgin, B. Modeling of conducted emissions for EMI analysis of power converters: State-of-the-art review. IEEE Access 2020, 8, 189313–189325. [Google Scholar] [CrossRef]

- Trinchero, R.; Stievano, I.S.; Canavero, F.G. Enhanced time-invariant linear model for the EMI prediction of switching circuits. IEEE Trans. Electromagn. Compat. 2020, 62, 2294–2302. [Google Scholar] [CrossRef]

- Stievano, I.S.; Rigazio, L.; Canavero, F.G.; Cunha, T.R.; Pedro, J.C.; Teixeira, H.M.; Girardi, A.; Izzi, R.; Vitale, F. Behavioral modeling of IC memories from measured data. IEEE Trans. Instrum. Meas. 2011, 60, 3471–3479. [Google Scholar] [CrossRef]

- Ghfiri, C.; Durier, A.; Marot, C.; Boyer, A.; Ben Dhia, S. Modeling the internal activity of an FPGA for conducted emission prediction purpose. In Proceedings of the 2018 IEEE International Symposium on Electromagnetic Compatibility and 2018 IEEE Asia-Pacific Symposium on Electromagnetic Compatibility (EMC/APEMC), Suntec City, Singapore, 14–18 May 2018; pp. 309–314. [Google Scholar]

- IEC SC47A/WG9; Models of Integrated Circuits for EMI Behavioral Simulation. International Electrotechnical Commission (IEC): Geneva, Switzerland, 1997.

- Labussière-Dorgan, C.; Bendhia, S.; Sicard, E.; Tao, J.; Quaresma, H.J.; Lochot, C.; Vrignon, B. Modeling the electromagnetic emission of a microcontroller using a single model. IEEE Trans. Electromagn. Compat. 2008, 50, 22–34. [Google Scholar] [CrossRef]

- Leca, J.P.; Froidevaux, N.; Dupré, P.; Jacquemod, G.; Braquet, H. EMI measurements, modeling, and reduction of 32-Bit high-performance microcontrollers. IEEE Trans. Electromagn. Compat. 2014, 56, 1035–1044. [Google Scholar] [CrossRef]

- Serpaud, S.; Levant, J.L.; Poiré, Y.; Meyer, M.; Tran, S. ICEM-CE extraction methodology. In Proceedings of the EMC Compo, Toulouse, France, 17–19 November 2009. [Google Scholar]

- Yuan, S.Y.; Liao, S.S. Automatic conducted-EMI microcontroller model building. In Proceedings of the 2013 9th International Workshop on Electromagnetic Compatibility of Integrated Circuits (EMC Compo), Nara, Japan, 15–18 December 2013; pp. 138–141. [Google Scholar]

- Ghfiri, C.; Boyer, A.; Durier, A.; Dhia, S.B. A new methodology to build the internal activity block of ICEM-CE for complex integrated circuits. IEEE Trans. Electromagn. Compat. 2017, 60, 1500–1509. [Google Scholar] [CrossRef]

- Yuanhao, L.; Shuguo, X.; Yishu, C. A new methodology to build the ICEM-CE model for microcontroller units. In Proceedings of the 2021 IEEE International Workshop on Electromagnetics: Applications and Student Innovation Competition (iWEM), Guangzhou, China, 28–30 November 2021; pp. 1–3. [Google Scholar]

- Ramdani, M.; Sicard, E.; Boyer, A.; Dhia, S.B.; Whalen, J.J.; Hubing, T.H.; Coenen, M.; Wada, O. The electromagnetic compatibility of integrated circuits—Past, present, and future. IEEE Trans. Electromagn. Compat. 2009, 51, 78–100. [Google Scholar] [CrossRef]

- Baharuddin, M.H.; Islam, M.T.; Yuwono, T.; Smartt, C.J.; Thomas, D.W. Impact of Mode of Operations on the Electromagnetic Emissions of a Complex Electronic Device. In Proceedings of the 2020 IEEE International RF and Microwave Conference (RFM), Kuala Lumpur, Malaysia, 14–16 December 2020; pp. 1–4. [Google Scholar]

- Fiori, F.; Musolino, F. Analysis of EME produced by a microcontroller operation. In Proceedings of the Design, Automation and Test in Europe, Conference and Exhibition 2001, Munich, Germany, 13–16 March 2001; pp. 341–345. [Google Scholar]

- Yuan, S.Y.; Tang, Y.C.; Chen, C.C. Software-related EMI test pattern auto-generation for 2-stage pipeline microcontroller. In Proceedings of the 2015 IEEE Symposium on Electromagnetic Compatibility and Signal Integrity, Santa Clara, CA, USA, 15–21 March 2015; pp. 306–309. [Google Scholar]

- Chen, J.; Portillo, S.; Heileman, G.; Hadi, G.; Bilalic, R.; Martínez-Ramón, M.; Hemmady, S.; Schamiloglu, E. Time-varying radiation impedance of microcontroller GPIO ports and their dependence on software instructions. IEEE Trans. Electromagn. Compat. 2022, 64, 1147–1159. [Google Scholar] [CrossRef]

- Wada, O.; Saito, Y.; Nomura, K.; Sugimoto, Y.; Matsushima, T. Power supply current analysis of micro-controller with considering the program dependency. In Proceedings of the 2011 8th Workshop on Electromagnetic Compatibility of Integrated Circuits, Dubrovnik, Croatia, 6–9 November 2011; pp. 93–98. [Google Scholar]

- Yuan, S.Y.; Chung, H.E.; Liao, S.S. A microcontroller instruction set simulator for EMI prediction. IEEE Trans. Electromagn. Compat. 2009, 51, 692–699. [Google Scholar] [CrossRef]

- Sicard, E.; Bouhouch, L. Using ICEM Model Expert to Predict TC1796 Conducted Emission. Available online: http://www.ic-emc.org/appnotes/Ic-Emc-Application-Note-Tricore-v2.pdf (accessed on 7 April 2025).

- Gavai, A.; Hansen, J.; Dhoot, V.; Gope, D. Stochastic modeling of microcontroller emission. In Proceedings of the 2023 IEEE 32nd Conference on Electrical Performance of Electronic Packaging and Systems (EPEPS), Milpitas, CA, USA, 15–18 October 2023; pp. 1–3. [Google Scholar]

- Leoni, J.; Breschi, V.; Formentin, S.; Tanelli, M. Explainable data-driven modeling via mixture of experts: Towards effective blending of gray and black-box models. Automatica 2025, 173, 112066. [Google Scholar] [CrossRef]

- Mulwa, M.M.; Mwangi, R.W.; Mindila, A. GMM-LIME explainable machine learning model for interpreting sensor-based human gait. Eng. Rep. 2024, 6, e12864. [Google Scholar] [CrossRef]

- Alangari, N.; Menai, M.E.B.; Mathkour, H.; Almosallam, I. Intrinsically Interpretable Gaussian Mixture Model. Information 2023, 14, 164. [Google Scholar] [CrossRef]

- Bishop, C.M. Mixture Models and the EM Algorithm; Microsoft Research: Cambridge, UK, 2006. [Google Scholar]

- Bishop, C.M.; Nasrabadi, N.M. Pattern Recognition and Machine Learning; Springer: Berlin/Heidelberg, Germany, 2006; Volume 4. [Google Scholar]

- Gavai, A.; Gope, D.; Dhoot, V.; Hansen, J. Electronic Board Emission Model and its Application for Microcontroller Emission. In Proceedings of the 2024 IEEE Joint International Symposium on Electromagnetic Compatibility, Signal & Power Integrity: EMC Japan/Asia-Pacific International Symposium on Electromagnetic Compatibility (EMC Japan/APEMC Okinawa), Okinawa, Japan, 20–24 May 2024; pp. 587–590. [Google Scholar]

- STMicroelectronics. Arm®-Based 32-Bit MCU, up to 128 KB Flash, Crystal-Less USB FS 2.0, CAN, 12 Timers, ADC, DAC & comm. Interfaces, 2.0–3.6 V. Technical Report, STMicroelectronics, 2019. STM32F072x8/xB Datasheet, Rev 6. Available online: https://www.st.com/resource/en/datasheet/stm32f072c8.pdf (accessed on 7 April 2025).

- CISPR 25:2021; Vehicles, Boats, and Internal Combustion Engines—Radio Disturbance Characteristics—Limits and Methods of Measurement for the Protection of on-Board Receivers Apparatus. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2021.

- Lang, S. Introduction to Linear Algebra; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Dutta, S.; Gandomi, A.H. Design of experiments for uncertainty quantification based on polynomial chaos expansion metamodels. In Handbook of Probabilistic Models; Elsevier: Amsterdam, The Netherlands, 2020; pp. 369–381. [Google Scholar]

- Walpole, R.E.; Myers, R.H.; Myers, S.L.; Ye, K. Probability and Statistics for Engineers and Scientists; Macmillan: New York, NY, USA, 1993; Volume 5. [Google Scholar]

- CISPR 16-4-2; Specification for Radio Disturbance and Immunity Measuring Apparatus and Methods—Part 4-2: Uncertainties, Statistics and Limit Modeling—Measurement Instrumentation Uncertainty. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2011.

| System Clock (MHz) | PLL Status | (R%) | (R%) | (R%) | (R%) | (R%) | (R%) | (R%) |

|---|---|---|---|---|---|---|---|---|

| 8 | OFF | 10 | 15 | 33 | 55 | 75 | 85 | 100 |

| 16 | ON | 10 | 15 | 33 | 55 | 75 | 85 | 100 |

| 24 | ON | 10 | 15 | 33 | 55 | 75 | 85 | 100 |

| 32 | ON | 10 | 15 | 33 | 55 | 75 | 85 | 100 |

| 40 | ON | 10 | 15 | 33 | 55 | 75 | 85 | 100 |

| 48 | ON | 10 | 15 | 33 | 55 | 75 | 85 | 100 |

| 48 | OFF | 10 | 15 | 33 | 55 | 75 | 85 | 100 |

| Auto-Reload Value | Timer Frequency (MHz) | Total Pins | RAM Utilization (R%) |

|---|---|---|---|

| 48 | 1 | 6 | 10.5 |

| 48 | 1 | 12 | 11 |

| 48 | 1 | 17 | 12.75 |

| 24 | 2 | 6 | 10.5 |

| 24 | 2 | 12 | 11 |

| 24 | 2 | 17 | 12.75 |

| 12 | 4 | 6 | 10.5 |

| 12 | 4 | 12 | 11 |

| 12 | 4 | 17 | 12.75 |

| Auto-Reload Value | CCR | Duty Ratio (%) | Total Pins | RAM Utilization (R%) |

|---|---|---|---|---|

| 48 | 5 | 10 | 6 | 10.55 |

| 48 | 5 | 10 | 12 | 11 |

| 48 | 5 | 10 | 17 | 12.75 |

| 48 | 24 | 50 | 6 | 10.55 |

| 48 | 24 | 50 | 12 | 11 |

| 48 | 24 | 50 | 17 | 12.75 |

| 48 | 38 | 80 | 6 | 10.55 |

| 48 | 38 | 80 | 12 | 11 |

| 48 | 38 | 80 | 17 | 12.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gavai, A.; Gope, D.; Dhoot, V.; Hansen, J. Probabilistic Characterization and Machine Learning-Based Modeling of Conducted Emissions of Programmable Microcontrollers. Electronics 2025, 14, 1511. https://doi.org/10.3390/electronics14081511

Gavai A, Gope D, Dhoot V, Hansen J. Probabilistic Characterization and Machine Learning-Based Modeling of Conducted Emissions of Programmable Microcontrollers. Electronics. 2025; 14(8):1511. https://doi.org/10.3390/electronics14081511

Chicago/Turabian StyleGavai, Aishwarya, Dipanjan Gope, Vivek Dhoot, and Jan Hansen. 2025. "Probabilistic Characterization and Machine Learning-Based Modeling of Conducted Emissions of Programmable Microcontrollers" Electronics 14, no. 8: 1511. https://doi.org/10.3390/electronics14081511

APA StyleGavai, A., Gope, D., Dhoot, V., & Hansen, J. (2025). Probabilistic Characterization and Machine Learning-Based Modeling of Conducted Emissions of Programmable Microcontrollers. Electronics, 14(8), 1511. https://doi.org/10.3390/electronics14081511