1. Introduction

In recent years, the industrial utilization of electrical equipment and household appliances has proliferated [

1]. However, with the passage of time, prolonged overload operations and aging of electrical circuits have led to insulation breakdowns, consequently triggering arc faults, which in turn result in safety hazards [

2]. Arc faults manifest in various forms including series, parallel, and ground fault arcs [

3]. Particularly, when the latter two types occur, the circuit’s current typically exceeds 75 A. To address this issue, circuit breakers equipped with isolation protection capabilities have been developed. It is worth noting that series arc faults stand out as the primary culprits behind electrical fires [

4]. Unlike other fault types, series arc faults occur under load conditions where the presence of these loads tends to limit the fault current, rendering it similar to normal current flow. This presents a challenge for conventional line protection methodologies [

5].

Thus, the detection of series arc faults emerges as a pivotal focus of ongoing research. There are three principal research directions concerning series fault arcs.

Firstly, when an arc occurs, it gives rise to light, sound, electromagnetic waves, pressure and other phenomena, which can be utilized for identification. For instance, in reference [

6], an electromagnetic acoustic sensing system is employed to detect and identify series fault arcs. In the literature [

7], internal sound signals of the switchgear are collected in real time via MEMS sound sensors. Subsequently, after wavelet packet decomposition, noise reduction and reconstruction based on singularity spectrum analysis, purer sound signals are obtained and applied to arc fault classification, effectively diminishing casualties and property losses caused by switchgear failures. In the literature [

8], a multi-sensor data fusion algorithm is proposed to enhance the detection accuracy of arc faults, achieving the fusion of sensing signals acquired from temperature sensors, acoustic sensors and arc intensity sensors. The adaptive weighted fusion algorithm overcomes the uncertainty of individual sensors, realizes the extraction of arc fault features from homogeneous sensors, and provides accurate test sample data for the neural network fusion algorithm. In the literature [

9], a synchronous fusion detection method for fault arc optics, electricity and magnetism is invented: using the increment of ultraviolet light intensity within a specific band and the voltage gradient composition or logic generated during the arc starting stage as a starting criterion; using the correlation similarity between the increment of visible light intensity and the zero-sequence transient current trend increment during the arc ignition stage as an exit, thereby realizing the synchronous photoelectric and magnetic detection of grounding fault arcs in switchgear and breaking through the bottleneck of detecting grounding weak current fault components. The detection of series fault arcs based on physical phenomena has the merits of simplicity and rapidity in operation. However, it demands high field environment conditions and cannot be deployed on a large scale. Most of the protection devices are only suitable for installation in distribution cabinets [

10].

Secondly, the arcing phenomenon is modeled and analyzed. Mary’s model, Cassie’s model and Schwarz’s model are widely adopted methods for detecting series arc faults. In the literature [

11], an improved Mayr arc modeling method based on dual-temperature magnetohydrodynamic arc simulation is proposed. The relative error between the VFTO simulation results of the improved Mayr arc model and the measured results is small, and the computational accuracy is high. In the literature [

12], the Schwarz arc model is used to simulate and compare nonlinear load circuits, and the characteristics of voltage and current waveforms during fault circuits are analyzed. The wavelet analysis algorithm is utilized to decompose the current and calculate the energy in different frequency bands, achieving favorable detection results. In the literature [

13], a Mayr–Cassie combinatorial model with arc current as the variable is constructed. Through experimental verification, this model can accurately reflect the arc characteristics and identify the fault arc. Although the use of arc mathematical models for arc identification offers high identification accuracy, in practical engineering, this arc model scheme, due to a large number of parameters, leads to a longer detection time, which is not conducive to accident prevention and is mostly used for theoretical research.

Thirdly, normal and fault voltage and current signals are collected, and the collected signals are processed by various methods. Subsequently, fault arc features are sought for detection and identification, and numerous new algorithms are emerging in this research direction. In the literature [

14], an arc segmentation simulation model is established to analyze the effect of arc resistance on the fault characteristics of the load terminal voltage. From the selection of the optimal number of wavelet decomposition layers and wavelet basis functions, an arc fault detection method using wavelet energy spectrum entropy is proposed. This method makes use of the aberration caused by the fault arc voltage on the load terminal voltage to detect the fault and overcomes the problem of the difficulty in determining the fault characteristic frequency band by using the wavelet energy spectrum entropy. In the literature [

15], an arc identification method based on the absolute difference between the current neighboring wave and randomness is proposed according to the arc stochastic characteristics of the fault’s current mutation amplitude and current variation. This method can effectively detect series arc faults with good adaptability. In the literature [

16], a series arc fault detection method based on multi-feature fusion and improved SVM is proposed. The collected current signals are analyzed in the time domain, frequency domain and time–frequency domain to construct the series arc feature index set. Then, the series arc feature index set is used as the input vector of the SVM, and the SVM is optimized using the particle swarm algorithm to improve the accuracy of the classification model. The detection method based on the voltage and current waveforms or time–frequency domain feature changes during the occurrence of series fault arcs is the current mainstream research method [

17].

In addition, it is worthwhile to learn from the troubleshooting methods used in different fields. The literature [

18] presents a novel acoustic emission (AE)-based pipeline monitoring approach, integrating empirical wavelet transform (EWT) for adaptive frequency decomposition with customized one-dimensional DenseNet architecture to achieve precise leak detection and size classification. The literature [

19] presents a fault diagnosis technique for milling machines based on acoustic emission (AE) signals and a hybrid deep learning model optimized with a genetic algorithm.

Traditional electrical protection devices, such as fuses and circuit breakers, are only capable of detecting large currents resulting from short circuits, overloads, ground faults, or parallel arc faults. For series arc faults, these devices are often ineffective, and effective detection is difficult to achieve. So, series arc fault detection devices need to be further investigated. This paper proposes a method that combines a multi-feature fusion of Markov transition field (MTF) with an enhanced residual neural network (ResNet18). While MTF has shown excellent results in bearing fault detection, its application in arc fault detection is less explored. This method utilizes fast Fourier transform to compute magnitude and phase data, which are then converted into images using MTF. The resulting three MTF images—representing the original data, magnitude, and phase—are fused via weighted averaging to create new recognition features for each current signal. The improved ResNet18, enhanced with the convolutional block attention module (CBAM), is employed for recognition to boost learning speed and accuracy. The method effectively detects series arcs and achieves high recognition accuracy.

2. Data Collection and Analysis

Series arc faults can occur in both AC and DC systems. In AC systems, the primary arc signatures originate from rapid extinguishing and/or re-ignition events at voltage zero crossings. By contrast, DC series faults are more challenging to detect due to the absence of zero crossing points. Although 220/380 V AC dominates low-voltage distribution networks, DC systems are employed in specialized applications such as photovoltaic installations and electric vehicle charging stations. Consequently, this paper focuses on low-voltage (LV) AC series arc fault detection.

This study primarily focuses on household loads, which operate under relatively mild environmental conditions. The testing apparatus was constructed in compliance with the GB/T 31143-2014 ‘Electrical Fire Monitoring System Part IV: Arc Fault Detector’ standard [

20]. Specifically, the environmental parameters include:a temperature range of −5 °C to +40 °C, a maximum relative humidity of 50% at 40 °C, and an external magnetic field intensity not exceeding five times the Earth’s geomagnetic field in any direction.

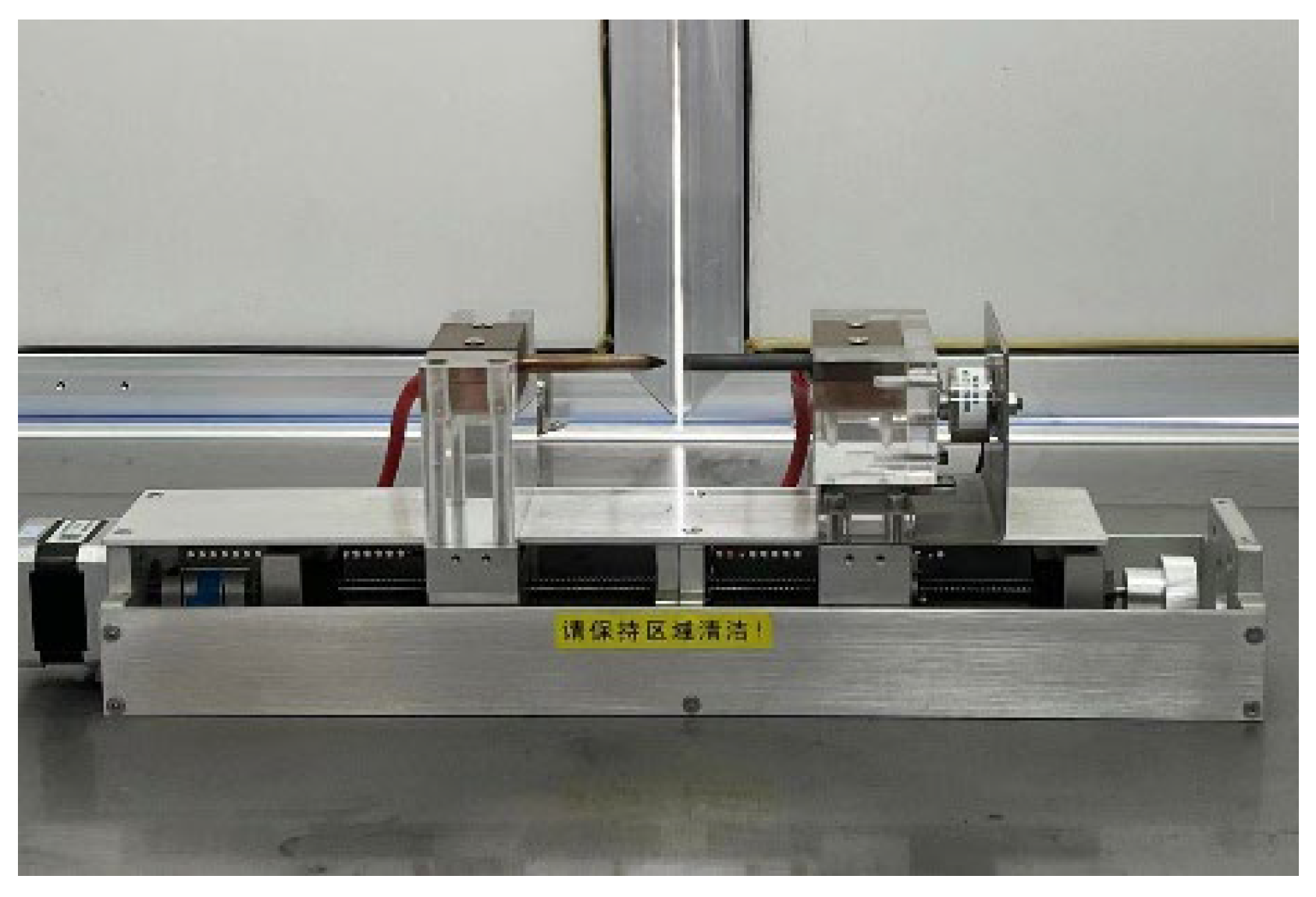

The arc fault generation unit comprises a carbon rod and a copper rod connected to a stepper motor. Upon initiating the power supply, the stepper motor separates the two rod poles, creating an arc between them due to air breakdown. The arc fault generator is illustrated in

Figure 1.

The oscillographic recorder captures loop current signals during both normal operation and arc faults, which are subsequently transmitted to a computer for in-depth analysis. Given that arc fault protection primarily targets residential environments, various household appliances were chosen as experimental loads. Following tests conducted on the experimental platform, circuit current signals from eight types of typical loads (refer to

Table 1) were recorded. These loads encompass most scenarios of low-voltage electrical appliance usage in daily life and adhere to the specifications outlined in the GB/T 31143-2014 standard.

These loads are grouped into four categories based on their characteristics. Resistive loads are categorized as such because their current closely resembles a sine wave. Motor-type loads include air compressors (capacitor start), electric hand drills, and vacuum cleaners due to their large inrush currents during startup. Gas discharge lamp loads, represented by halogen and fluorescent lamps, exhibit arc-like current characteristics. Lastly, electronic lamp dimmer and switching mode power supply loads fall into the power electronics enabled load category due to their wide bandwidth harmonics.

Based on the constructed platform, current signals from eight loads are gathered, including resistors, capacitor-started air compressors, electric hand drills, vacuum cleaners, halogen lamps, fluorescent lamps, electronic dimmer lamps, and switching power supplies. The time domain signals of these loads are shown in

Figure 2,

Figure 3,

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8 and

Figure 9, where the blue waveforms indicate the normal state and the red waveforms indicate the arc-fault state.

Figure 2 illustrates the current waveform of a purely resistive load. Under normal circuit conditions, the resistive load current exhibits a standard sinusoidal waveform, with the current changing continuously and smoothly over time without distortion or abnormal fluctuations, indicating circuit stability. During an arc fault, the current waveform demonstrates a distinct “zero rest” phenomenon at the current zero crossing. This “zero rest” characteristic serves as a key basis for series arc fault detection, aiding in the identification of fault states in practical circuits.

Figure 3,

Figure 4 and

Figure 5 illustrate the current waveforms of motor-type loads.

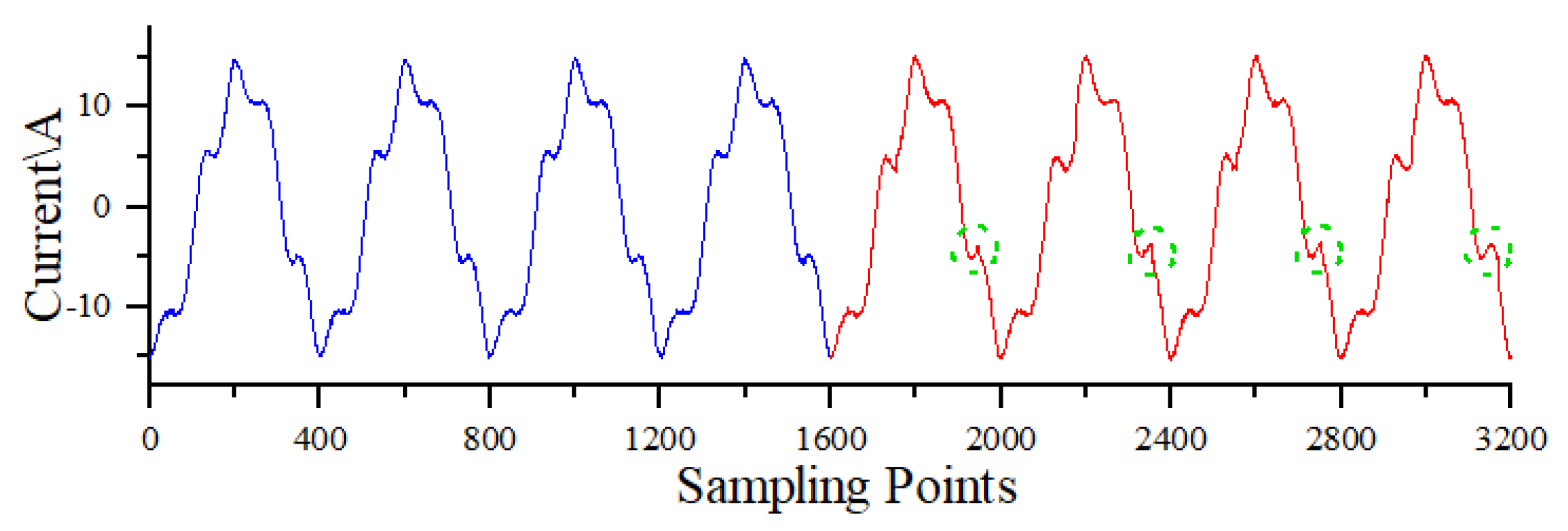

Figure 3 illustrates the current waveforms of an air compressor under normal operation and during an arcing fault. The blue normal current waveform exhibits a periodic “multi-peak” pattern, attributed to the nonlinear characteristics of the single-phase induction motor in the air compressor and the influence of its internal electromagnetic field, causing multiple current fluctuations within a cycle. When an arc fault occurs in the line, the current waveform’s peaks deviate from the normal cyclic pattern; the green dotted line in the figure marks the “spikes”, demonstrating abrupt current changes at these positions distinct from the normal waveform.

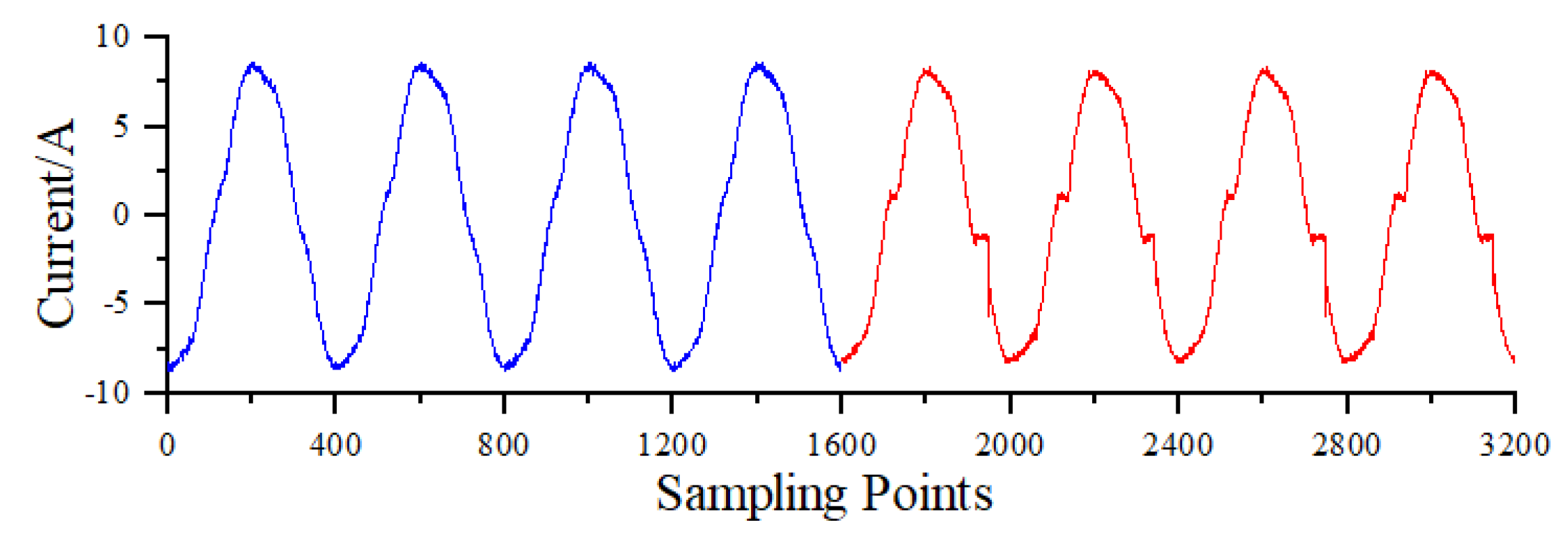

Figure 4 illustrates the current waveform of a handheld drill load. As an inductive load, the handheld drill’s inductive components impede current changes, causing slight distortion at the current zero crossing while maintaining an overall regular sinusoidal form. During a line arcing fault, the waveform exhibits a distinct “zero rest” phenomenon at the zero crossing, accompanied by severe distortion.

Figure 5 illustrates the current waveform of a vacuum cleaner’s load. With an AC motor inside the vacuum cleaner, carbon brushes separate from the commutator during each phase change, generating a “benign arc” that creates a “zero rest” characteristic similar to fault arcs. This waveform typifies the vacuum cleaner’s normal operation, reflecting a regular motor operation and phase change process. During a line arc fault, the current waveform exhibits numerous “burrs” at the zero crossing on top of the normal waveform, accompanied by unstable current amplitude fluctuations. The term “benign arc” refers to arcs that do not disrupt normal load operation.

Figure 6 and

Figure 7 illustrate the current waveforms of fluorescent and halogen lamps, respectively. The gas discharge process in these lamps introduces current interference, causing slight waveform aberration even under normal line conditions—resulting in non-perfect sinusoidal waveforms. During an arc fault, while the “zero rest” phenomenon at the zero crossing is less pronounced, the current waveform exhibits more severe distortion compared to the normal state.

Figure 8 illustrates the current waveforms of a 60° dimming lamp load under normal operation and during an arc fault. Operating at a 60° conduction angle, the thyristor in the dimmable lamp conducts and cuts off at specific angles, resulting in rapid current rise during 60–180° of the first half-cycle and steep current fall during 240–360° of the second half-cycle. This forms a symmetrical chopper-like waveform—characteristic of the dimmable lamp’s normal operation under 60° dimming. During a line arc fault, the waveform exhibits a “flat shoulder” at the zero crossing atop the original symmetrical chopper pattern, with aggravated overall distortion.

Figure 9 depicts the current waveforms of an electronic switching power supply under normal load and arcing fault conditions. Inside the electronic switching power supply, high-frequency power electronics continuously perform on–off operations to regulate the output voltage. This high-frequency action leads to severe distortion of the current waveform. Nevertheless, despite the distortion, the current waveform still maintains periodicity. When an arc fault occurs, two significant changes take place. Firstly, the distortion of the current waveform is further exacerbated, and a distinct “zero rest” phenomenon emerges at the zero-crossing point. Secondly, the current waveform loses its original periodic nature, with the current peaks fluctuating irregularly.

5. Conclusions

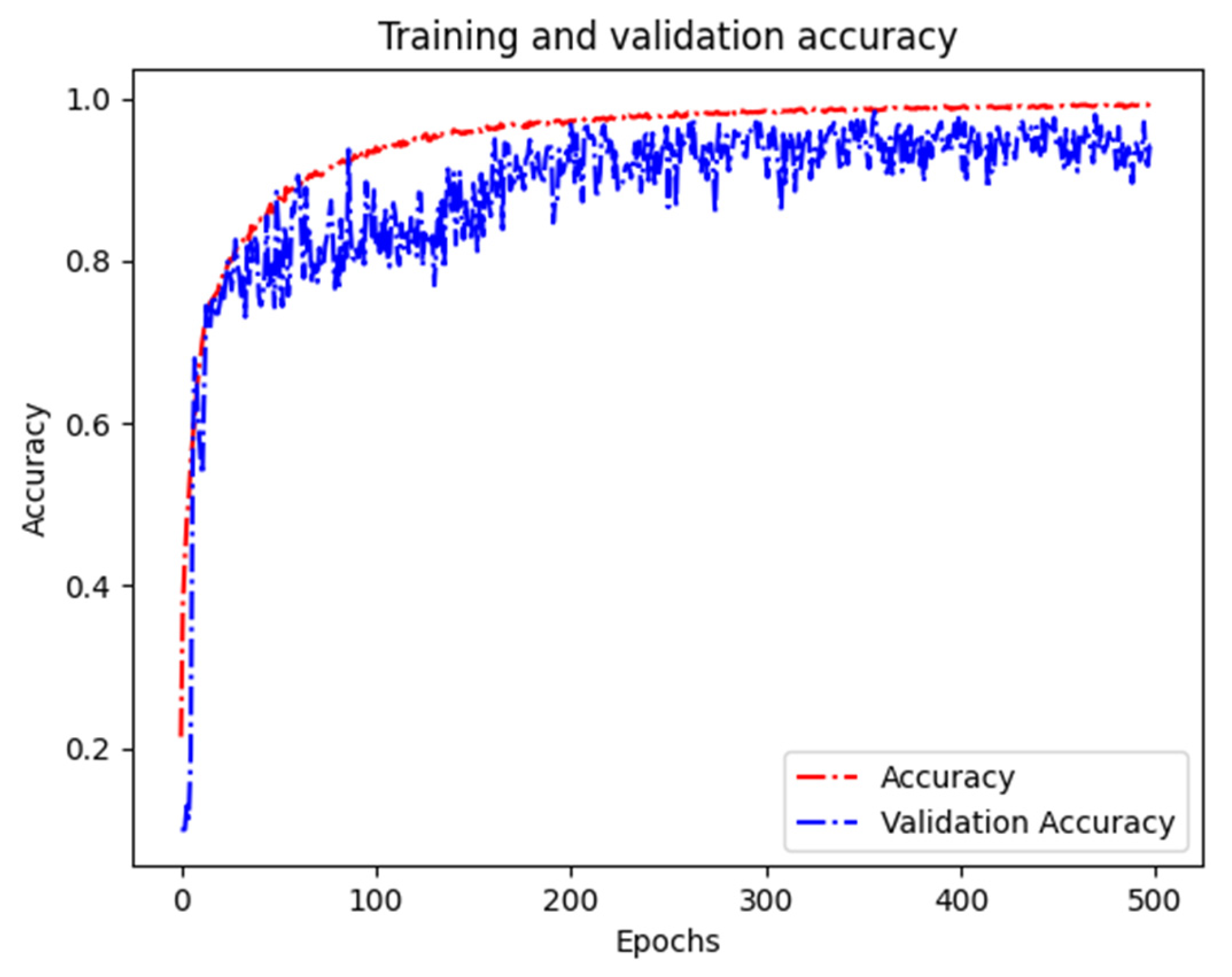

This paper delves into a multi-feature fusion method and puts forward a low-voltage series arc fault identification approach grounded in MTF and an enhanced ResNet18 model. By leveraging the fast Fourier transform to extract the amplitude and phase features of the original signal, and computing Markov matrices for raw data, amplitude, and phase, we create a fused image by averaging and weighting these matrices. This not only enhances the recognition of signals with similar currents but also provides a more comprehensive representation of the fault characteristics.

Furthermore, the integration of the CBAM attention mechanism into the ResNet18 model significantly boosts the model’s recognition rate and accuracy. In practical applications, this enhanced method can play a crucial role in safeguarding low-voltage electrical systems. It can effectively prevent potential electrical fires caused by series arc faults, thereby ensuring the safety of electrical equipment and personnel.

Compared with existing common identification methods, the methodology in this paper not only achieves a higher recognition rate and accuracy but also demonstrates advantages in terms of computational efficiency and cost-effectiveness. This could potentially lead to more widespread adoption in the industry, promoting the development of more reliable and cost-efficient arc fault detection systems.

In the academic realm, this study enriches the research on low-voltage series arc fault identification methods, providing new ideas and references for future research in this field.