1. Introduction

Human hands have the unique ability to sense and classify material properties through advanced tactile receptors known as mechanoreceptors. This natural ability inspires the development of tactile sensors for industrial robotics applications for advanced manipulation [

1]. In industrial robotics, replicating this tactile sensitivity is essential for tasks like material handling and object manipulation, but current systems often lack the ability to accurately classify material properties, particularly hardness [

2,

3,

4,

5,

6,

7]. To address this challenge, different types of tactile sensors have been reported for material classification in the literature [

3,

4,

5,

6,

7,

8,

9,

10]. Additionally, customized sensors have been tested in several material classification cases to enhance the accuracy of machine learning (ML) algorithms [

3,

4,

6,

7]. Although these sensors demonstrated comparable accuracy, they did not achieve optimal levels in the case of hardness classification beyond binary classification [

8,

9,

10,

11,

12,

13,

14,

15]. Moreover, they can be costly, time-consuming to produce, and not readily available, limiting their deployment within existing robotic grippers. This highlights the need for readily available tactile sensors that are agile and flexible, for integration into robotics applications to obtain optimum accuracy.

To enhance material classification, research has explored the use of multiple tactile sensors to gather distinct tactile information during grasping [

2,

3,

16,

17]. Although this multi-sensor approach can improve accuracy, it has other challenges, like integration complexity, shape variability, and size. The sensors are often highly customized, expensive, and typically available only on demand. Previous studies have also investigated single-sensor solutions using COTS sensors, noting that combining sensor data as features from multiple sensors can boost ML (Machine learning) accuracy [

7,

8]. Despite these findings, hardness classification using single sensors remains low and impractical for real-time application. Additionally, attempts to emulate the human mechanoreceptor system by layering customized sensors to capture various tactile signals have resulted in improvements in advanced sensor and classification models [

9]. However, these layered sensor systems are often too complex, fragile, or impractical for many robotic grippers, due to factors such as limited lifespan, challenging integration requirements, and the complexities of installation and maintenance [

18,

19,

20,

21,

22,

23].

This study extends the work of a previous investigation [

7] that addressed the challenges associated with utilizing single-sensor data for hardness classification across multiple classes. This work established that aggregating COTS sensors’ data as three features can improve the hardness classification accuracy, but the overall process takes a longer time. Inspired by the layered architecture of human mechanoreceptors [

10], this study explores the integration of multiple COTS sensors in different topological configurations to collect diverse tactile information during robotic grasping. Human mechanoreceptors, which detect a wide range of stimuli, from light touch to deep pressure, provide a biological blueprint for arranging sensors in layers to mimic this functionality. By applying this bio-inspired approach, this aims to improve the accuracy and responsiveness of robotic systems for hardness classification. Previous research [

7] primarily evaluated the performance of individual sensors within a robotic gripper, but the process of collecting and integrating data from a single sensor was not efficient, especially when testing multiple objects. Each test required a separate run for every object and sensor, making the process time-consuming and impractical for real-time applications or larger datasets. This limitation hindered the scalability and adaptability of the system for more complex tasks, such as multi-object or material classification.

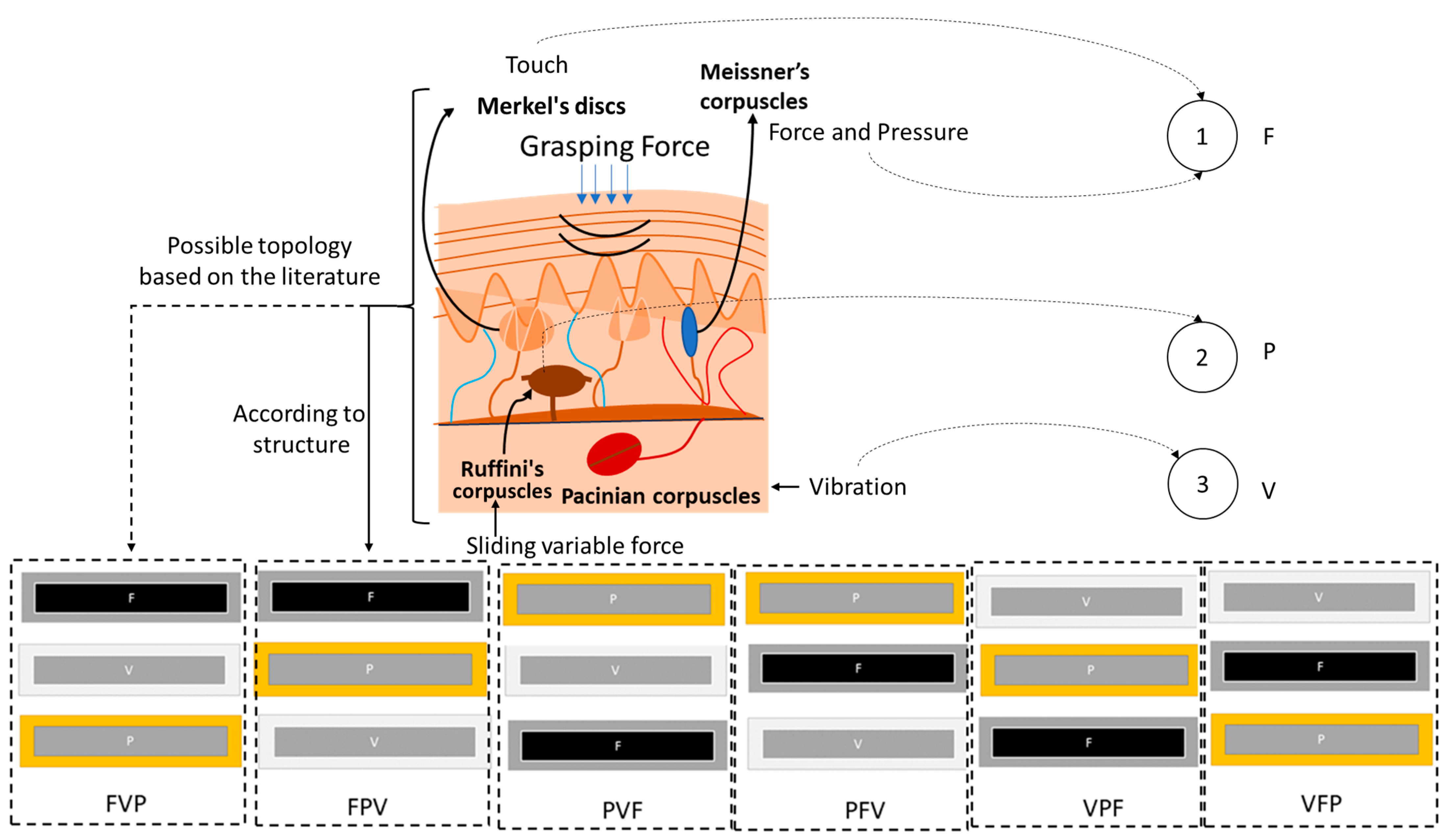

Moreover, as the number of classes increased from binary (two-class) to ternary (three-class) and quaternary (four-class) scenarios, a notable decline in classification accuracy was observed. This drop in accuracy is attributed to the growing complexity of distinguishing between additional classes with a single-sensor setup, which struggles to capture distinctions in tactile information required for more diverse classification tasks. The difficulty increases with each additional class, making it challenging to maintain high accuracy. This paper aims to investigate whether bio-inspired sensor topology configurations from COTS sensors, where tactile information can be collected simultaneously during a grasping action, can be utilized to improve ML outcomes. A multiple topological configuration approach will be employed to identify the optimal topology, which can then be validated through real-time testing. This real-time testing will be conducted using unknown cube-shaped objects within a robotic gripper. The results will assess whether the optimal topologies can accurately classify material properties, showcasing prediction, latency, and accuracy. This will present the use case of COTS tactile sensors topologies in robotic systems for precise material classification and prediction.

This paper is organized into several sections, each detailing the necessary tools, methods, and adaptations required to execute machine learning on the collected data. The sections are structured as follows:

Section 2 provides a detailed review of background literature on the use of COTS sensors in hardness classification, discusses the architecture of mechanoreceptors, and identifies relevant COTS sensors from previous research and exploration of layered sensors/topology configuration in material classification tasks.

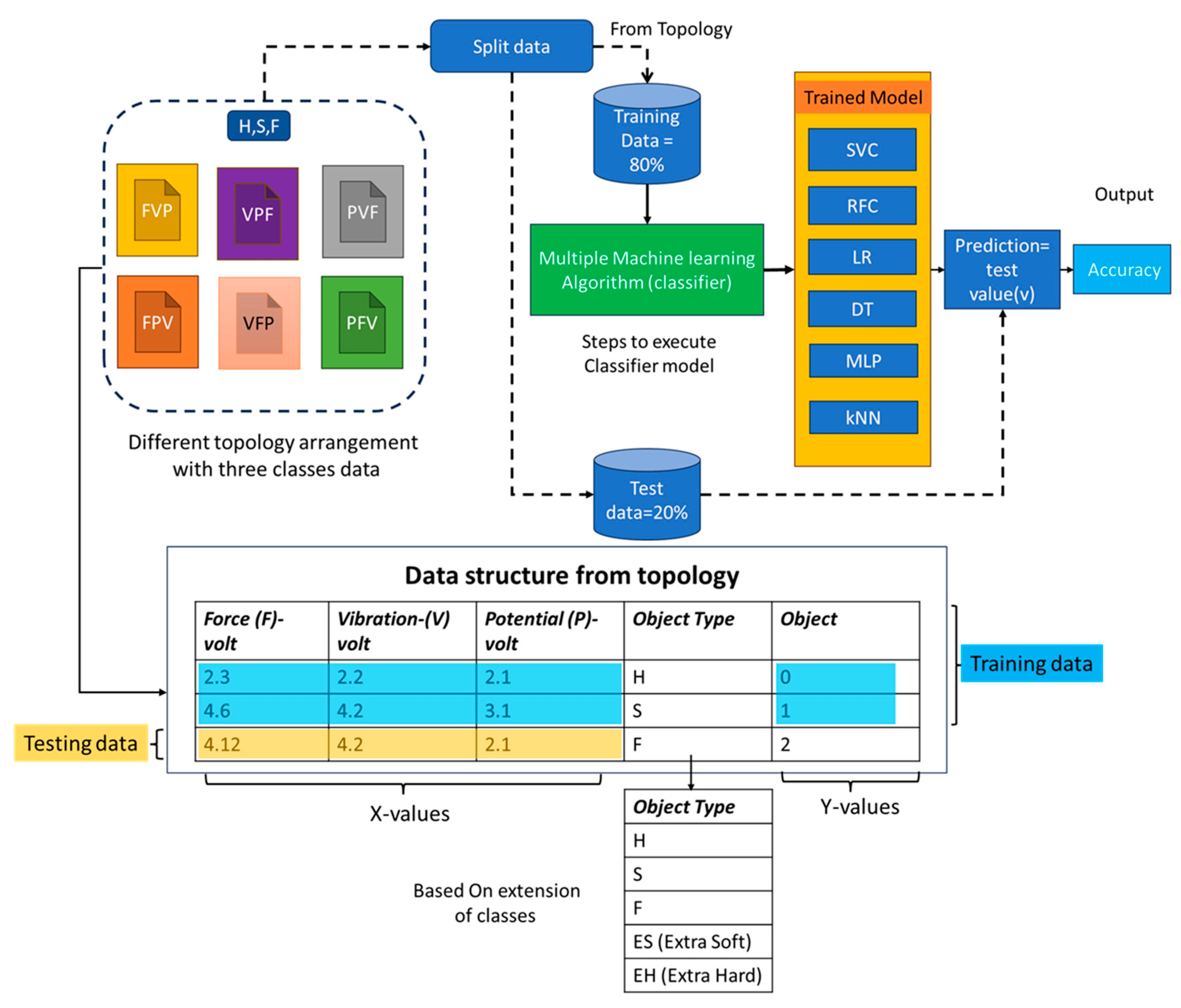

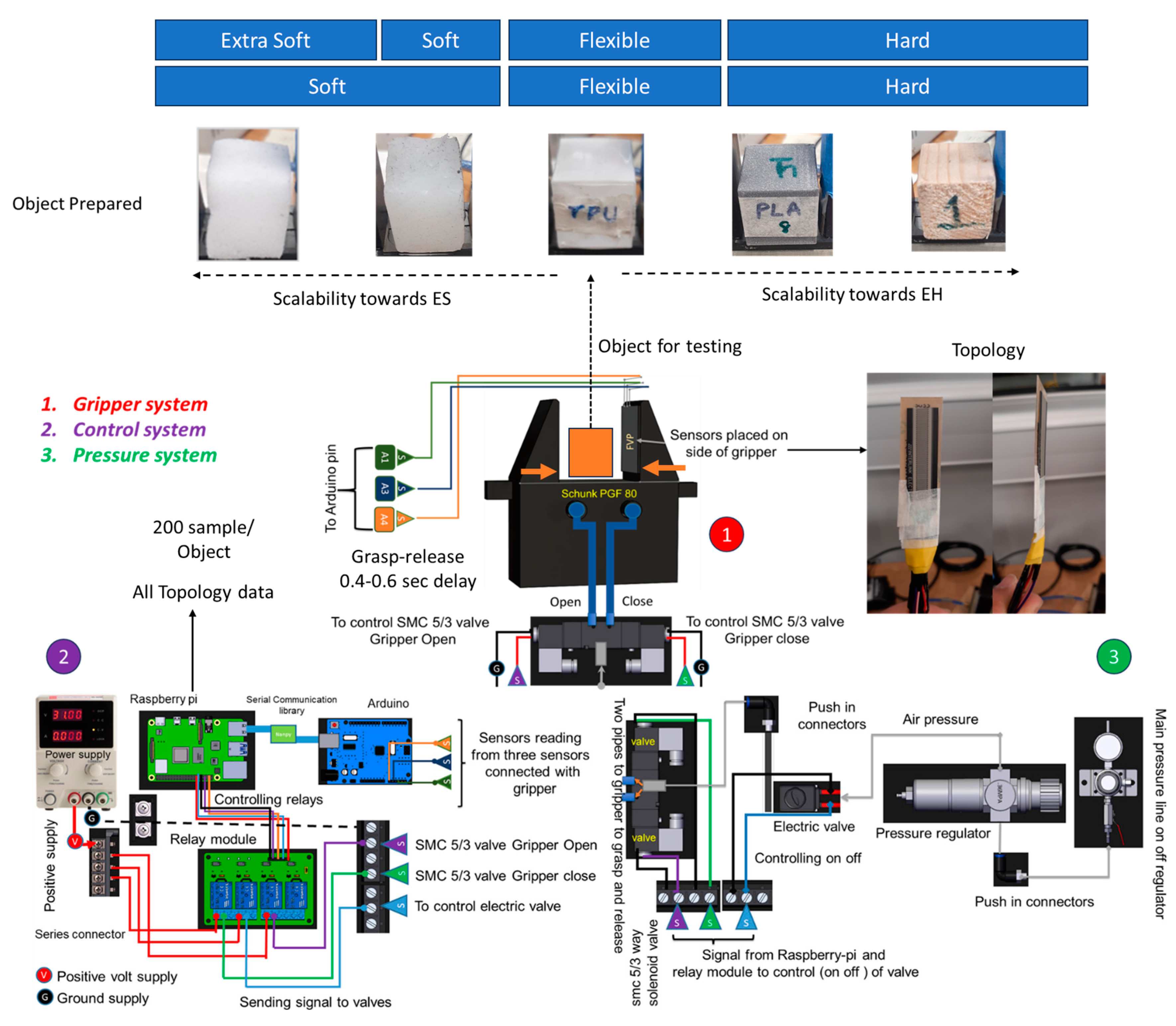

Section 3 outlines the methodology for selecting COTS sensors based on prior research and arranging them in topologies inspired by mechanoreceptors. It details the process of determining the optimal sensor topology from different configurations, the explanation of expanding the Shore scale to four classes for scalability testing, and the future testing scenario. It also presents the machine learning approach applied for hardness classification, which is showcased in testing and training scenarios on data.

Section 4 describes the experimental setup of the robotic gripper, including its control mechanisms and how data were collected from the sensor topologies. It lists the objects used in the experiments and explains steps involved with multiple machine learning algorithms to analyze the collected data.

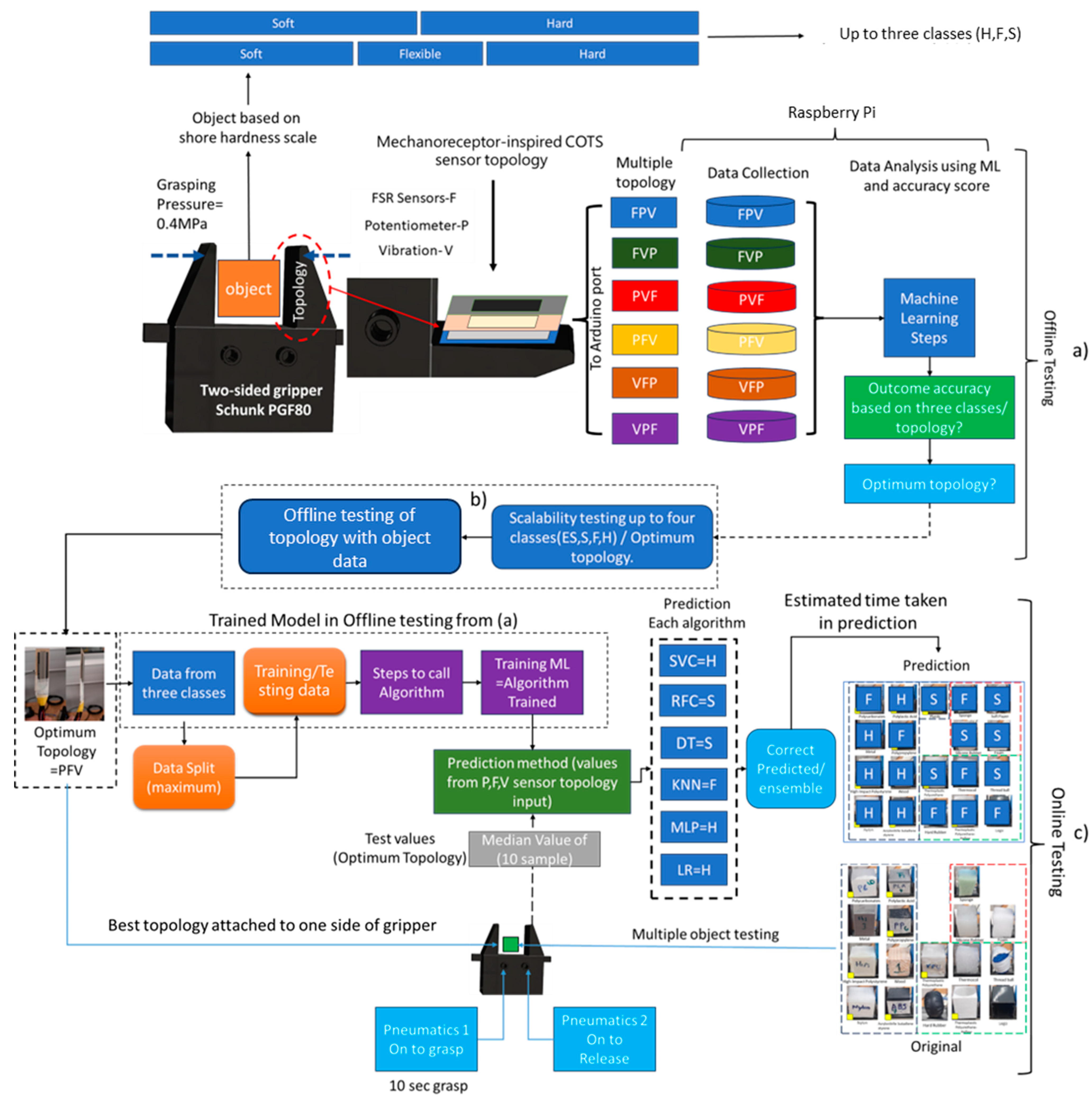

Section 5 presents the analysis outcomes from various machine learning algorithms employed for hardness classification. It identifies the optimal topology from multiple configurations (FVP, FPV, PVF, PFV, VFP, VPF) and extends the analysis to a four-class scenario to determine whether the optimal topology is effective across multiple classification tasks. Additionally, this section includes retesting outcomes, discussing the accuracy of the model when applied to new objects, and its suitability for real-time robotic applications.

2. Background

Tactile sensing refers to the ability of systems, such as robotic grippers or prosthetic hands, to detect and respond to physical touch, pressure, or the tactile properties of objects. It involves the use of sensors that measure various attributes, including force, texture, temperature, and slip, to mimic the human sense of touch. Understanding the tactile or physical properties of objects is crucial in robotics, as it enables robots to recognize and distinguish properties such as texture, hardness, and stiffness. This capability allows robots to perform tasks like hardness classification or material property identification, making them more intelligent and adaptable in interacting with objects.

The natural tactile abilities of human hands, driven by mechanoreceptors, provide crucial inspiration for improving robotic perception. Mechanoreceptors are specialized tactile receptors, located within the human skin, that are capable of detecting various stimuli, including pressure, force, and vibration [

24]. These receptors play a critical role in our ability to perceive and interact with our environment. Understanding the mechanisms by which mechanoreceptors detect hardness is crucial for advancements in robotics research. By utilizing sensors similar to these receptors in robotic systems, it is possible to provide robots with the ability to perceive and interpret tactile information during tasks such as grasping [

2,

15,

17,

24,

25,

26,

27]. This capability may allow robots to more accurately understand object properties and execute tasks that require sensitivity to hardness classification [

9,

11,

15,

18,

28,

29,

30]. The architecture of mechanoreceptors involves a layered arrangement, where different types of receptors are distributed at various depths within the skin, each responding to specific stimuli [

24]. Inspired by this layered architecture, sensors from existing research [

7] can be arranged in a stacked configuration to mimic the mechanoreceptor structure. Sensor arrangement in such topologies can enhance the tactile sensing capabilities of robots, enabling them to perform more precise and nuanced object classification and handling. By adopting this bio-inspired approach, robotic systems can achieve an advanced level of tactile perception and functionality.

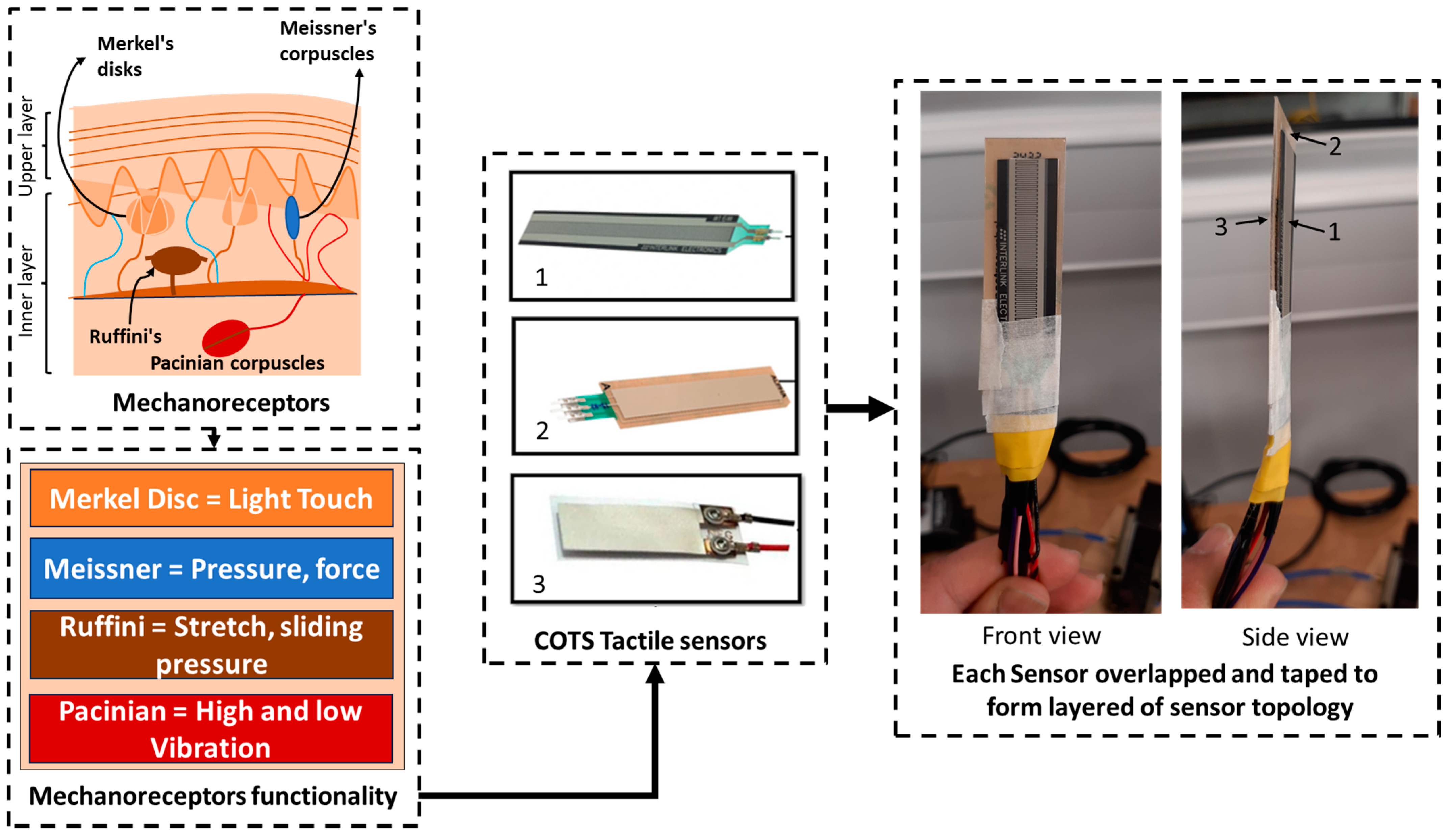

2.1. Mechanoreceptor Architecture

Mechanoreceptors are cells within the human skin that detect different types of tactile information to determine the properties of any material. Firstly, when humans grasp or touch an object, the properties they detect are its hardness or texture. Mechanoreceptors have four important receptors, which are Meissner’s corpuscles, Pacinian corpuscles, Merkel’s discs, and Ruffini’s corpuscles [

24]. Each have their own properties for detecting touch, pressure, and vibration. Each of them is located next to each other at small distances, according to the literature [

7,

19,

24,

26,

27,

28]. Merkel’s discs and Meissner’s corpuscles are located on the upper layers and can precisely localize even gentle touch. The large mechanoreceptors—Pacinian corpuscles and Ruffini endings—are located in the lower layers, and respond to intense pressure and touch, as illustrated in

Figure 1. Previously, based on their functionality, COTS tactile sensors were identified, which were used in performing hardness classification [

7,

17,

24]. In this case, identifying the location of receptors within the architecture of mechanoreceptors was important as a further step in exploring the topology of COTS sensors as mechanoreceptors.

2.2. Identification of Tactile Sensors

From a previous research paper [

7], COTS tactile sensors were categorized based on their functional similarity to human mechanoreceptors. Force-sensing resistors (FSRs) were assigned as the primary (first) layer to detect force, while potentiometer sensors functioned as the secondary (second) layer to measure position, displacement, or deformation. Lastly, vibration sensors were placed as the tertiary (third) layer to detect vibrations, as illustrated in

Figure 1. These sensors are standard, widely used components in various applications, and they have a thin film. They are commercially available and documented, including the FSR [

31], vibration sensor [

32], and potentiometer membrane [

33]. In this study, these sensors were further examined in a multilayer topology to analyze performance in hardness classification. This aimed to compare accuracy between single-sensor configurations and multilayered sensor configurations. Additionally, the sensors were arranged in topological configurations to mimic mechanoreceptor structures, allowing the investigation of the effects of varying topological factors on classification accuracy in hardness classification.

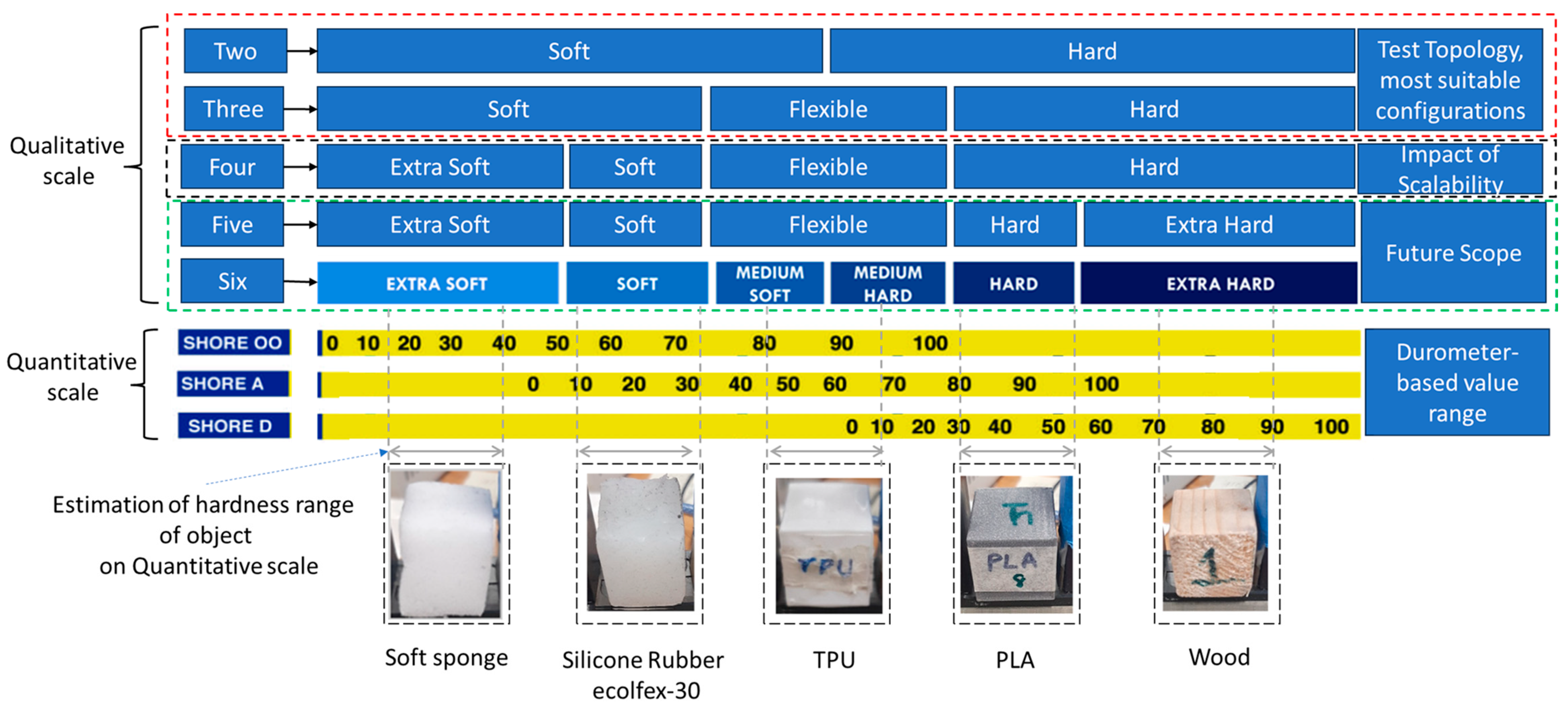

2.3. Shore Hardness Scale

Previous literature has demonstrated that the Shore hardness scale plays a crucial role in selecting objects for testing or experimentation [

7]. The Shore hardness scale, which includes two different types (Shore A and Shore D), helps users to determine the appropriate scale for various objects based on their material properties. The previous study utilized a qualitative Shore hardness scale to categorize objects into six different categories, facilitating the selection of objects for hardness classification experiments [

7]. This approach allowed for a more nuanced understanding of how objects can be grouped according to their Shore hardness qualitative scale, which could include extra-soft (ES), soft (S), medium-soft (MS), medium-hard (MH), hard (H) and extra-hard (EH); this is further described in

Section 3.2. Consequently, a Shore hardness scale based on qualitative criteria was adopted in this study, following methodologies outlined in previous research [

4,

5,

6,

7].

2.4. Layered Tactile Sensors in Hardness Classification

Layered tactile sensors have been previously explored and mentioned in object-material classification across different studies demonstrating their effectiveness and complexity [

18,

19,

20,

21,

22,

23,

27,

28,

29,

30,

34]. These sensors are typically composed of diverse chemical structures and developed using intricate fabrication processes, often featuring grid-type configurations. Despite their potential, these sensors are not yet commercially available. Research has demonstrated the integration of quadruple tactile sensors on a robotic hand [

18], enabling precise object recognition through advanced tactile information processing. The layered approach in this study allowed the detection of different object properties and showed the potential of enhancing the robot’s ability to classify materials based on hardness. This methodology underscores the effectiveness of multilayered sensors in replicating the nuanced sensing capabilities of human skin. Similarly, a study on multi-parameter electronic skin (e-skin) explored the use of biomimetic mechanoreceptors and stress field sensing to achieve high-fidelity material classification [

28,

34]. This e-skin incorporated various sensing layers that worked together simultaneously to emulate the depth and responsiveness of human mechanoreceptors, facilitating accurate hardness classification. Moreover, previous research [

7] investigated the use of COTS sensors inspired by human mechanoreceptors for hardness classification.

Research has shown that aggregating data from multiple sensors can significantly enhance classification accuracy, achieving results comparable to those of customized sensors. This study will highlight the advantages of using readily available COTS sensors in a layered configuration for multiclass hardness classification and introduce one case of their use in real-time robotics applications. By utilizing bio-inspired sensors based on human mechanoreceptors, the outcomes of this research will demonstrate how COTS sensors can be arranged in stacks, emulating the functionality of receptors. It will also explore how different sensor configurations form topologies, and how these can be compared to assess the accuracy of material hardness classification outcomes.

2.5. Summary

In different studies, multilayered custom sensors have been used in robotic applications for texture and material classification [

25,

28]. However, these layered sensors are not easily available, and their development is complex, making them difficult to install and integrate into existing gripper systems. Additionally, general sensors like COTS sensors have not been fully explored in terms of topological configuration and integration for different cases of use in robotic applications. While inspiration from mechanoreceptor architecture has led to the development of sensors with useful capabilities, COTS-based topologies inspired by human mechanoreceptors have not been systematically studied. This gap in the research prompts the exploration of how multiple topological configurations, inspired by mechanoreceptors and different arrangements of COTS sensors, can improve hardness classification accuracy based on the Shore hardness scale. This approach may provide a cost-effective solution for readily available industrial robotic applications. The study will use general machine learning methods and minimal data to identify the optimal topology that can achieve high accuracy across the different classes addressed in the previous paper [

7]. However, challenges have been noted in different studies, particularly regarding different configurations of the layered sensor [

25,

26,

27,

28]. Further investigation will show how the sensors identified were arranged in different topologies, and how they were integrated on one side of robotic gripper to perform hardness classification.

5. Results and Analysis

5.1. Identification of Optimal Topologies by Accuracy

Figure 8 illustrates the performance of different topologies and machine learning algorithms used for material hardness classification across three categories: hard, soft, and flexible. The analysis aims to identify the optimal combination of topology and machine learning model for analyzing the data and providing reliable, thoroughly tested results. The accuracy results for each topology and algorithm are compared to a benchmark from a previous study, where the aggregation of data from individual sensors—force (F), potentiometer (P), and vibration (V)—achieved an accuracy of approximately 81%. This baseline is shown in

Figure 8 by a red dashed line, with the green region representing the benchmark for comparison.

Performance Analysis of Machine Learning Models: Figure 8 highlights the performance trends of various ML models in terms of accuracy. Accuracy was chosen as the primary evaluation metric to assess the performance of the classification models in predicting material categories. Default settings were applied to all machine learning models to establish a consistent baseline for comparison, and to incorporate a larger number of classes in further exploration. The parameters described in [

35,

36,

37,

38] provide a clear basis for comparing model performance, and align well with the actual data patterns, offering a reliable means to evaluate the models against existing results [

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15]. Among all the machine learning models, RFC achieved optimal accuracy, while the accuracy was 98.7% in PFV, 97.5% in FVP, 96.25% in FPV, 95.62% in VPF, 93.75% in VPF, and 90% in PVF. RFC achieved high accuracy, likely due to its ability to capture different material patterns across the three classes in the tactile feature dataset. After RFC, the trends show that models like DT, KNN, and ANN-MLP achieved accuracies between 94% and 96% for FPV, PFV, and FVP. However, for VFP, VPF, and PVF, a decline in accuracy was observed, with values falling below 90%, but staying above 85%. Additionally, it is crucial to assess whether RFC experiences any overfitting issues in subsequent tests. SVC with the linear kernel achieved an accuracy of 86%, while SVC with the RBF kernel performed better, at 95%. The difference in performance between the two models could be attributed to their ability to capture data relationships; the linear kernel assumes a simpler, linear relationship, while the RBF kernel is suited for handling non-linear relationships, making it more effective for the complex patterns in the sensor data [

35,

36,

37,

38]. Across all topologies, both LR and SVC with a linear kernel achieved accuracies ranging from 55% to 84%. This indicates that linear models struggle to capture the complexity of the material tactile data, particularly for hardness classification. Hyperparameter optimization could be explored in future studies to improve the performance of ML models where accuracy drops below 90%. In conclusion, RFC was used at this stage to identify the optimal topologies, which were PFV, FVP, and FPV.

Performance Analysis of Sensor Topologies: Based on the analysis, the topologies PFV, FVP, and FPV were identified as optimal for three-class material classification. Among these, two bio-inspired topologies, FPV and FVP, demonstrated effective performance, achieving accuracies of 96.25% and 97.5%, respectively. These configurations, where the top layer consisted of force sensors, likely contributed to their effectiveness. The highest accuracy of 97.5%, achieved by FVP, supports the hypothesis that bio-inspired topologies can perform optimally in material classification. However, this hypothesis was not fully validated, as the alternative topology, PFV, outperformed all others, with the highest accuracy of 98.75%. In PFV, the P sensor was positioned at the top, which may have been a critical factor in its better performance. In contrast, PVF, which also had the P sensor at the top, achieved an accuracy of 93%, the second-lowest among all topologies. In configurations where the vibration sensor was placed on top, such as VFP and VPF, accuracies dropped further to 90% and 95%, respectively. This decline may be due to the vibration sensor’s position on top, which could interfere with capturing accurate force values and essential tactile information. Notably, in VPF, when the P sensor was moved from the last to the second layer, accuracy improved, as observed in PFV. Additionally, in topologies like PVF, VFP, and VPF, which achieved accuracies of 93%, 90%, and 95%, respectively, the arrangement and placement of sensors significantly influenced the machine learning outcomes. Overall, PFV emerged as the most effective configuration, achieving the highest accuracy of 98.75%. These findings highlight the critical role of topology design in optimizing tactile information capture, emphasizing the importance of sensor arrangement in achieving accurate material classification. Further testing of optimal topologies such as FPV, FVP, and PFV in both offline and online cases was conducted in the next step to assess the stability of the outcomes for multiclass hardness classification.

5.2. Performance of Optimal Topologies Across Multiclass Scenarios

To assess the scalability of the optimal topologies, FVP, FPV, and PFV configurations were evaluated with expanded material classes, including four-class and five-class classifications. The fourth class introduced an extra-soft (ES) material, such as sponge, while the fifth class added an extra-hard (EH) material, such as wood. Each topology was trained using datasets that incorporated these new materials, following the same methodology as in earlier tests.

For the fourth and fifth classes, the FVP topology experienced a slight decline in accuracy, dropping from 89.38% to 88% (

Table 1). In contrast, the PFV and FPV topologies, which feature vibration sensors in the last layer, maintained consistently high accuracy. PFV achieved 98.0% and 97.5%, while FPV recorded 95.6% and 96% accuracy for the fourth and fifth classes, respectively. These findings indicate that placing vibration sensors in the last layer enhances the ability to capture tactile features, contributing to improved classification performance as the complexity of the task increases.

However, the difficulty in distinguishing overlapping material types, such as ES, S, and F, likely contributed to the decline in accuracy observed across the topologies. Additionally, misclassifications may have been influenced by the uneven distribution of objects in the dataset (2-H, 2-S, 1-F). To explore these challenges further, offline and online testing were conducted to evaluate the scalability and robustness of the FPV and PFV topologies. These tests provide valuable insights into how these configurations perform under varying testing conditions.

5.3. Offline Validation of PFV Topology: Accuracy with New and Unseen Data

Offline validation or testing involved evaluating the performance of the ML model, utilizing data from a topology previously identified as optimal—PFV or FPV—against new and unseen data from objects of different material types. This process used a trained model and prediction methods, where newly collected values from the PFV topology were fed into the model to predict material types. In this study, offline validation was crucial for assessing the generalization capabilities of the PFV topology, recognized earlier as optimal for hardness classification. Previously, RFC maintained consistent accuracy, which was utilized in offline testing scenarios to validate the results. Initially, RFC was applied to evaluate the PFV topology using new object data, collected from 20 samples for each material type. These samples were then input into the trained model to predict the material type, as shown in

Table 2. While RFC exhibited relatively high accuracy overall, it correctly predicted only 6 out of the 15 material types. This highlights the limitation of RFC in generalizing to unseen data, with over 50% of predictions being incorrect. Variability in the new object data likely made it difficult for a single classifier to capture complex features, and overfitting may have further contributed to its inability to generalize effectively, leading to this underperformance.

To address these challenges, an Ensemble approach was implemented. This method integrated multiple algorithms—RFC, SVC, LR, DT, MLP, and KNN—to collaboratively predict material types. By aggregating predictions from these diverse models, the ensemble approach provided a more robust and accurate prediction mechanism. Consequently, the ensemble correctly predicted 13 out of 15 material types, as shown in

Table 2, with and accuracy range from 60 to 100%. The enhanced performance of the ensemble approach underlines its ability to mitigate the limitations of individual RFC classifiers by leveraging their collective prediction, making it a more reliable approach for material classification in diverse and unseen datasets. In the next step, online testing was conducted using real-time data to evaluate the capability of the trained model with the ensemble approach.

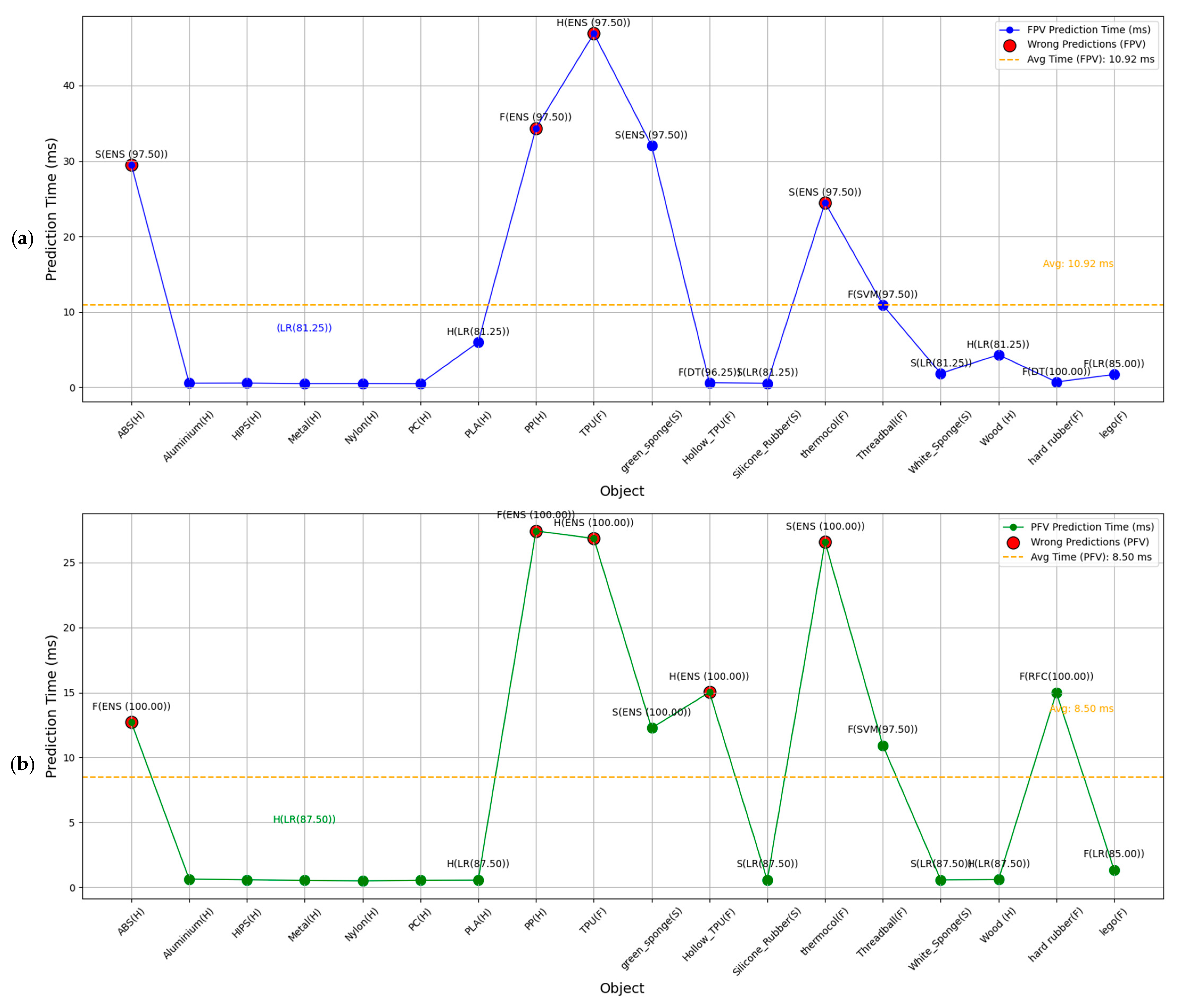

5.4. Online Testing: Validation of Optimum Topology in Real-Time Robotic Application

For real-time application in robotic systems, 18 objects were tested using a robotic gripper, which grasped each object for 10 s while collecting sensor data. The median values from these data were input into a pre-trained model that included data from three classes (H, S, F). The model utilized trained algorithms and new objects to predict material properties, with accuracy results shown in the accompanying plot in

Figure 9. This comparison between the two topologies, PFV and FPV, as illustrated in

Figure 9, highlights that 12 out of 18 for PFV and 13 out of 18 for FPV objects were correctly predicted, detailing prediction times for each object with accuracy. The following is also described in

Table 3: overall, PFV has an average prediction time of approximately 8.31 milliseconds, making it faster compared to FPV, which has an average prediction time of around 10 to 13.3 milliseconds. In terms of prediction speed, the data indicate that PFV topology outperforms FPV for most materials. For hard materials, PFV achieves an average prediction time of 4.35 milliseconds, compared to 7.2 milliseconds for FPV. For soft materials, PFV maintains a faster average prediction time of 4.46 milliseconds, while FPV requires 11.47 milliseconds. However, for flexible materials, PFV has an average prediction time of 16.13 milliseconds, which is slower compared to FPV’s 21.50 milliseconds. The faster response time of PFV makes it suitable for real-time robotic automation tasks, such as industrial material sorting, automated packaging, or assembly lines or medical robotic applications, where quick decision-making is crucial. Also, PFV and FPV take less time in prediction, in comparison to the 43 milliseconds described in [

18]. In contrast, FPV, with its longer latency, may be more suitable for less time-sensitive tasks, or scenarios where precision can outweigh speed. Specifically, PFV’s speed and accuracy for hard, soft, and flexible materials make it more ideal than FPV for industries needing fast, precise, three-class classification of objects. Real-time robotic systems using FPV might face delays, making them less suitable for tasks requiring high throughput or rapid adaptation to object property changes. Overall, PFV emerges as the faster and more adaptable topology for most materials, though FPV can be valuable in applications where tactile precision is essential.

7. Conclusions and Future Work

Based on the results, it is concluded that topology configurations based on mechanoreceptor architectures can improve accuracy in hardness classification across various Shore hardness scales. The findings confirm that mechanoreceptor-based COTS topology configurations enhance classification accuracy when compared to previous studies [

7] and a single-sensor approach. Furthermore, the research highlights that some topologies, including mechanoreceptor-based configurations (FPV), can achieve optimal accuracy and deliver real-time predictions with lower latency, comparably to existing customized sensors [

18]. Additionally, other configurations, like PFV, demonstrate even lower latency than FPV, indicating future potential for testing with multiple objects and materials to understand further class testing. These results suggest potential for further applications in robotic systems and other real-time scenarios. Topology-based approaches hold promise for obtaining optimum accuracy at lower cost (using COTS), which could be useful for medical applications like prosthetics, enhancing sensor configurations to enable faster predictions and reduced latency for improved real-time responsiveness. In robotics, they can support precise object manipulation and adaptive decision-making, increasing efficiency and versatility.

However, certain limitations were identified in this investigation. The limited sample size of four to five objects may have constrained the generalizability of the results. Increasing the number of data points or replicates per material object could improve accuracy and robustness. Future work will address this limitation by expanding the dataset and exploring the impact of sample size on performance. The rationale for the current sample size was based on practical constraints, but a larger dataset will be considered in future studies. During offline testing, RFC showed high accuracy, but its performance dropped during online testing. This issue was addressed by using an ensemble approach, which combined predictions from multiple algorithms to improve accuracy and reliability, but in online testing, these dropped. Additionally, this study primarily focused on hardness classification, and other material properties (texture) were not extensively explored. The current study focuses on lab-based testing, with limitations in real-world applications. The current setup also lacks environmental variability, which is critical for assessing the practical applicability of the sensors in dynamic and uncontrolled settings. Future work will involve deploying models in such environments, including the UR10 robot or others, to evaluate scalability and performance.

Currently, the use of only a single gripper limits the broader applicability of the approach, highlighting the need for further exploration in this area. Future investigations will include a broader range of objects to further validate the findings and improve the robustness of the models. Additionally, exploring sensors compatible with industrial robotics, particularly those used with three-finger grippers, could unlock new potential. Multidimensional grippers incorporating topologies such as PFV, VPF, and FVP would enable simultaneous assessment of texture, hardness, and slip, enhancing the system’s capability to adapt to diverse and intricate real-world scenarios.

Future work can explore deep learning models and hyperparameter optimization to see if they improve the performance of a specific topology or enhance other topologies and algorithms that did not achieve optimal results. A comparison of these improvements could provide further insights. Expanding the dataset to include various materials with different properties can help in understanding the broader applicability of the sensor topologies. Specifically, testing should be conducted on materials with varying textures, elasticity, and thermal properties to evaluate the sensors’ versatility in classifying different material attributes. Real-time testing with uncertain objects is also a next step. Deploying these sensor topologies in real-world scenarios with unknown objects (bottle, uneven objects) will provide valuable insights into their practical performance and reliability. This includes integrating the sensors into robotic systems and testing their ability to classify materials on-the-fly during robotic operations. Also, a single type of robotic gripper was deployed; there is scope for future exploration based on different robotic grippers and different classifications. These topologies may also help to improve prosthetics’ sensing capabilities, enhancing sensor configurations to enable faster predictions and reduced latency for improved real-time responsiveness. In robotics, they can support precise object manipulation and adaptive decision-making, increasing efficiency and versatility. Sensor topology might also play a crucial role in fruit handling and classification, by optimizing sensor placement for the accurate detection of properties such as texture and firmness, enabling precise grip control, real-time feedback, and efficient classification across diverse fruit types, while minimizing damage during handling.

Another area of interest is the development of miniaturized and more robust COTS sensors that can withstand harsh environments and continuous use in industrial settings. Furthermore, further studies should explore other bio-inspired topologies and configurations to discover new possibilities for optimizing tactile sensing and material classification. By addressing these limitations and exploring these future research directions, the field of tactile sensing and material classification using COTS sensors can be suggestively advanced, leading to more reliable and versatile applications in robotics.

Silicone rubber could be added between the sensors to emulate the complete architecture of the mechanoreceptor-skin. Accuracy scores for retesting outcomes can showcase, in parallel, a prediction set, which may help to identify real-time prediction scenarios if used in the future and may improve latency. For further development, a feedback loop can be set, based on sensors which may be able to control pressure and perform the self-adjustment task of handling sensitive objects, alongside prediction.

Untested topology can be explored in terms of different applications. VPF or VFP can be used in texture detection, based on vibration as the top layer; PFV or PVF for slip detection, with the potentiometer as the top layer; and FPV or FVP in general touch, force, and pressure understanding. For future testing, different topologies, such as VPFV and other four-sensor combinations, can be explored to gather more tactile information for hardness classification and beyond. Furthermore, single- (FFF, VVV, PPP) or dual-functionality (FFVV, VVPP, FFPP) sensor topologies and other combinations can also form part of future exploration. In addition, temperature-based sensors can also be integrated to create a TFPV topology, along with other configurations, to further explore and analyze the behaviour and functionality of these topologies in sensing and classification tasks using COTS sensors for robotic applications. Also, classes could be extended to include up to five to six classes ((ES, S, F, H, EH) or (ES, S, MS, MH, H, EH)), MS (medium-soft), or MH (medium-hard). Additionally, building on a previous study on spike patterns [

15], these patterns could be aggregated as new features to explore whether the sensor topology behaves similarly, or if a fully developed artificial mechanoreceptor configuration can further enhance real-time prediction accuracy. This could broaden the study of COTS sensor topologies in classification tasks, providing deeper insights into their potential applications. Also, temperature sensors can be used as thermoreceptors to make complete artificial mechanoreceptor sub-layers and test different combinations of topologies, and can be used in-real time prediction, considering temperature among the material properties.