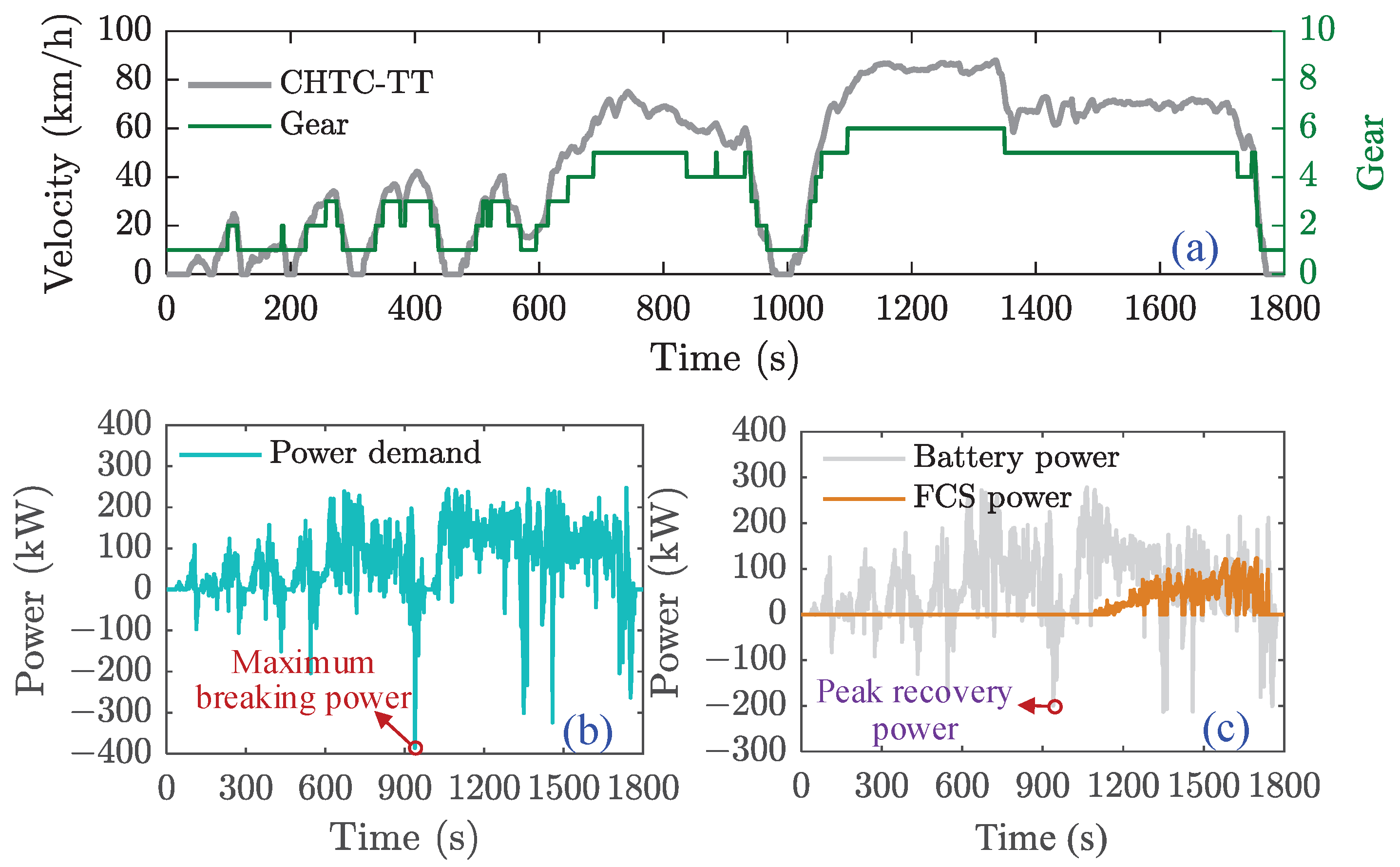

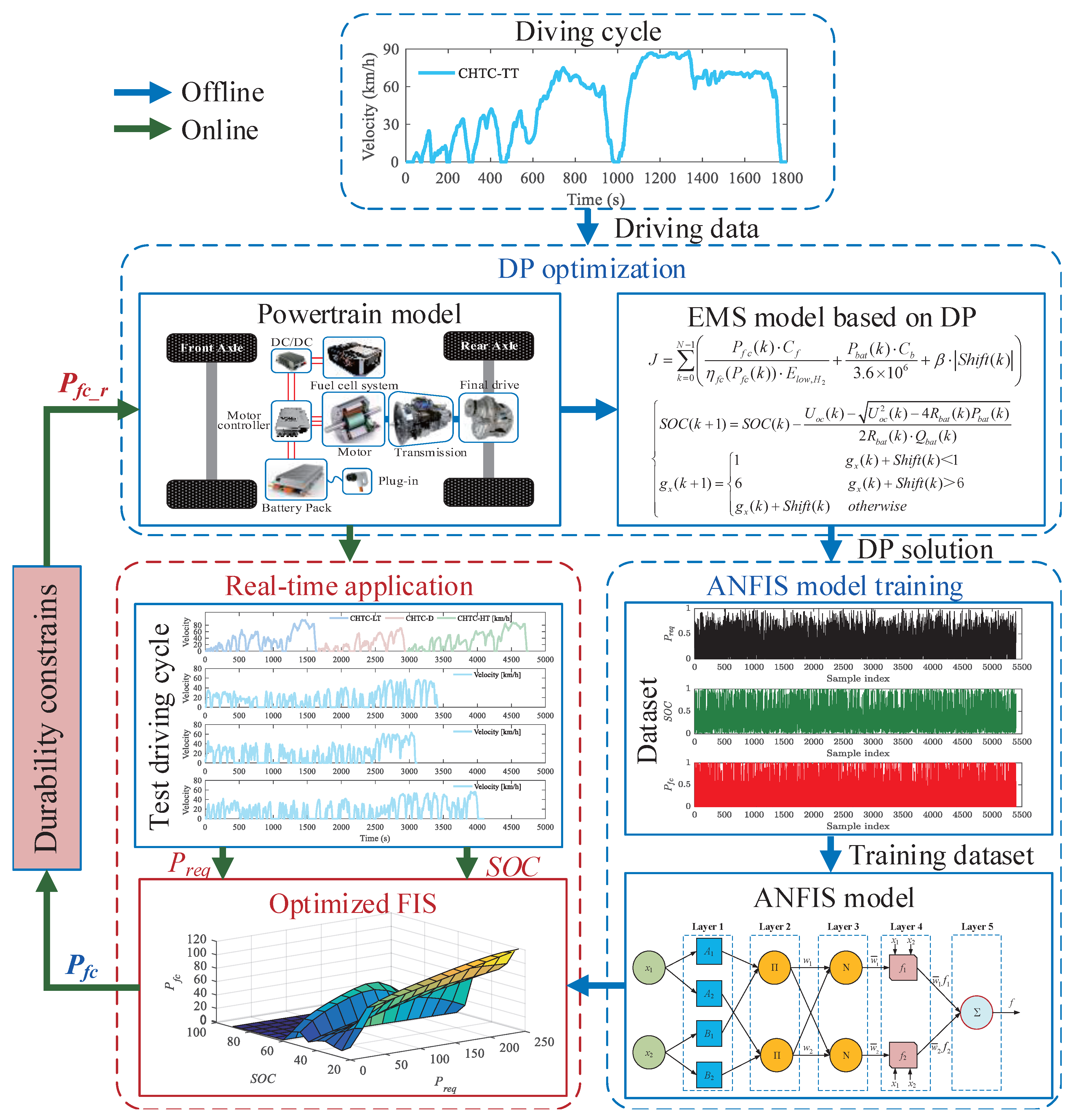

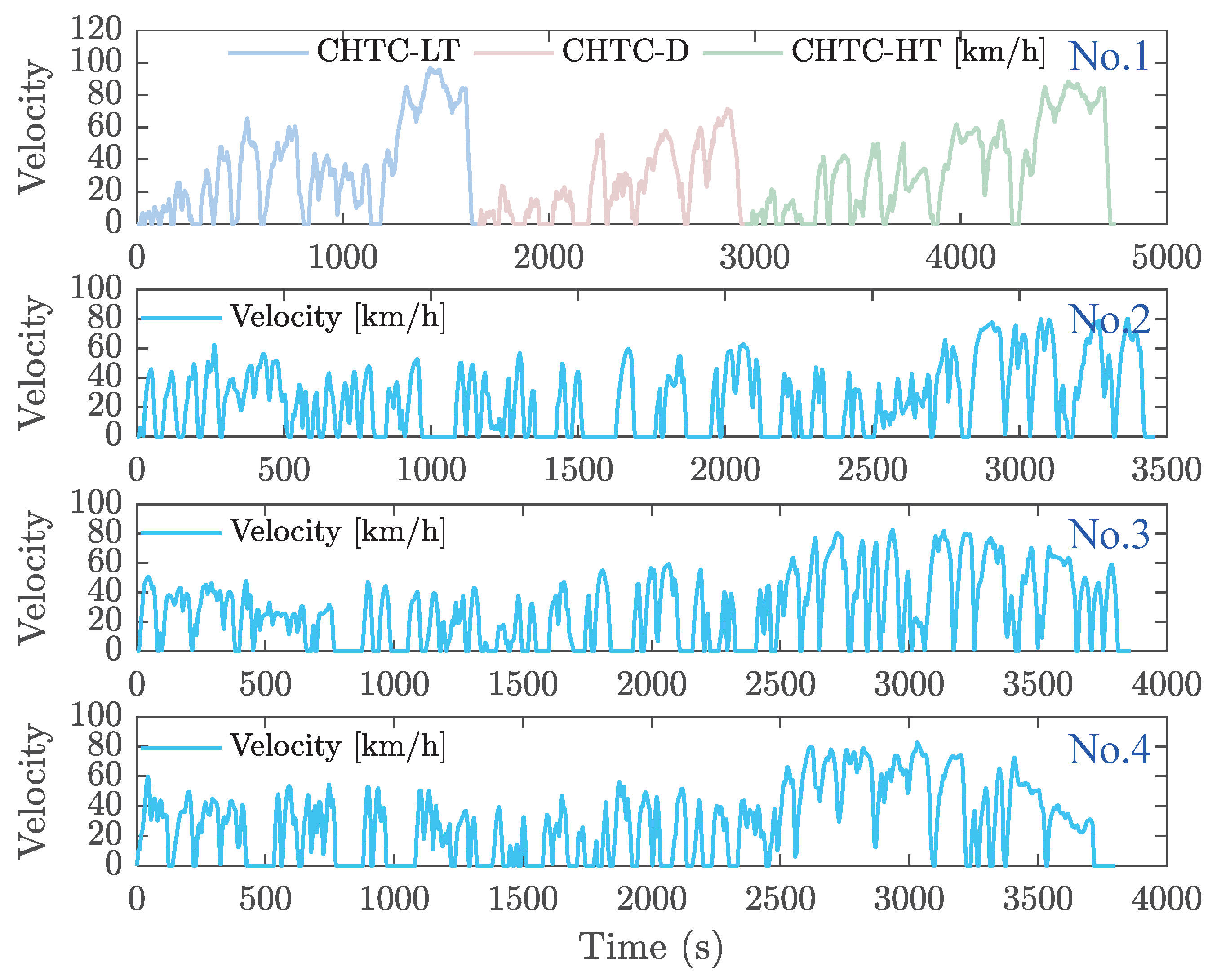

5.1. CHTC-TT

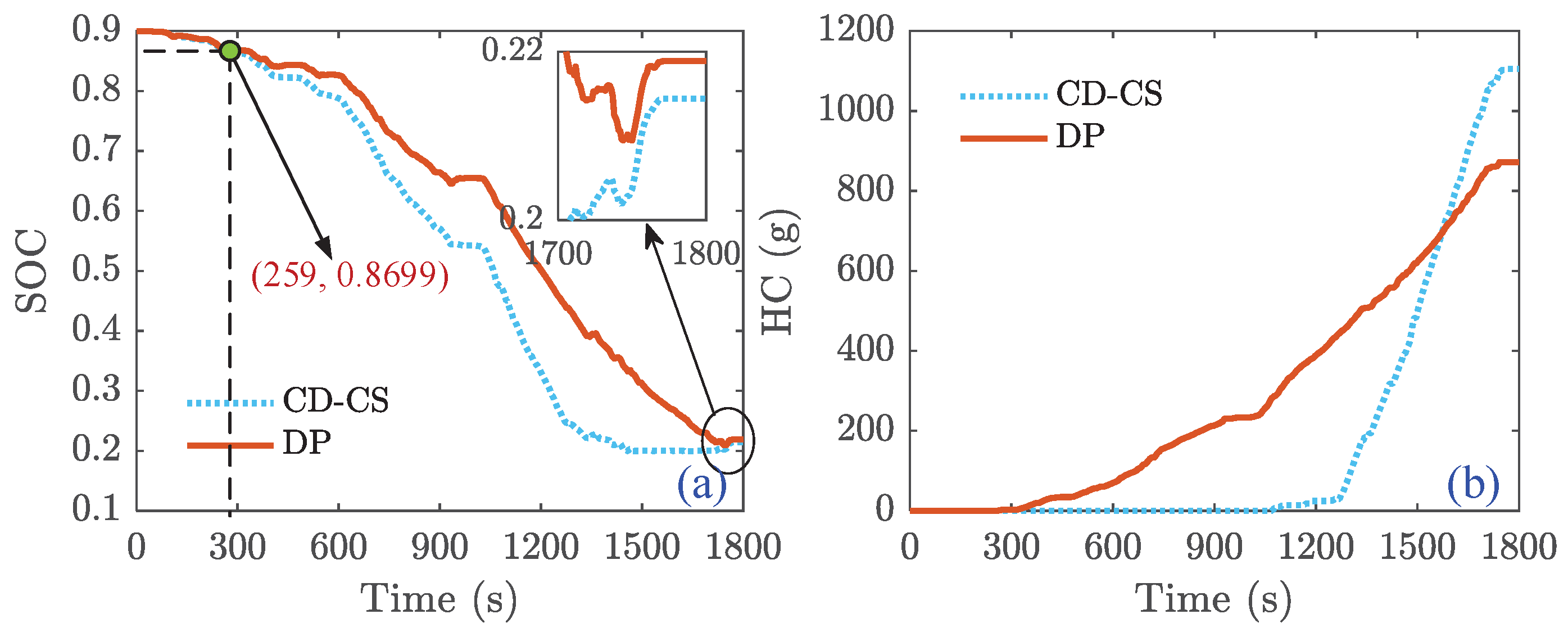

The well-trained FIS was first used for CHTC-TT to evaluate the performance of ANFIS-DP energy management. Furthermore, the DP and CD-CS strategies were utilized as benchmarks to comprehensively evaluate the energy-saving potential and effectiveness of the proposed ANFIS-based strategy in mitigating FCS degradation. To ensure a fair comparison of HC across the strategies, all three strategies aimed to completely deplete the battery energy by the end of the simulation, ideally achieving a battery SOC of 0.2. Additionally, to investigate the performance of the ANFIS-DP strategy at various SOC levels, this study analyzes its effectiveness under different initial SOC conditions.

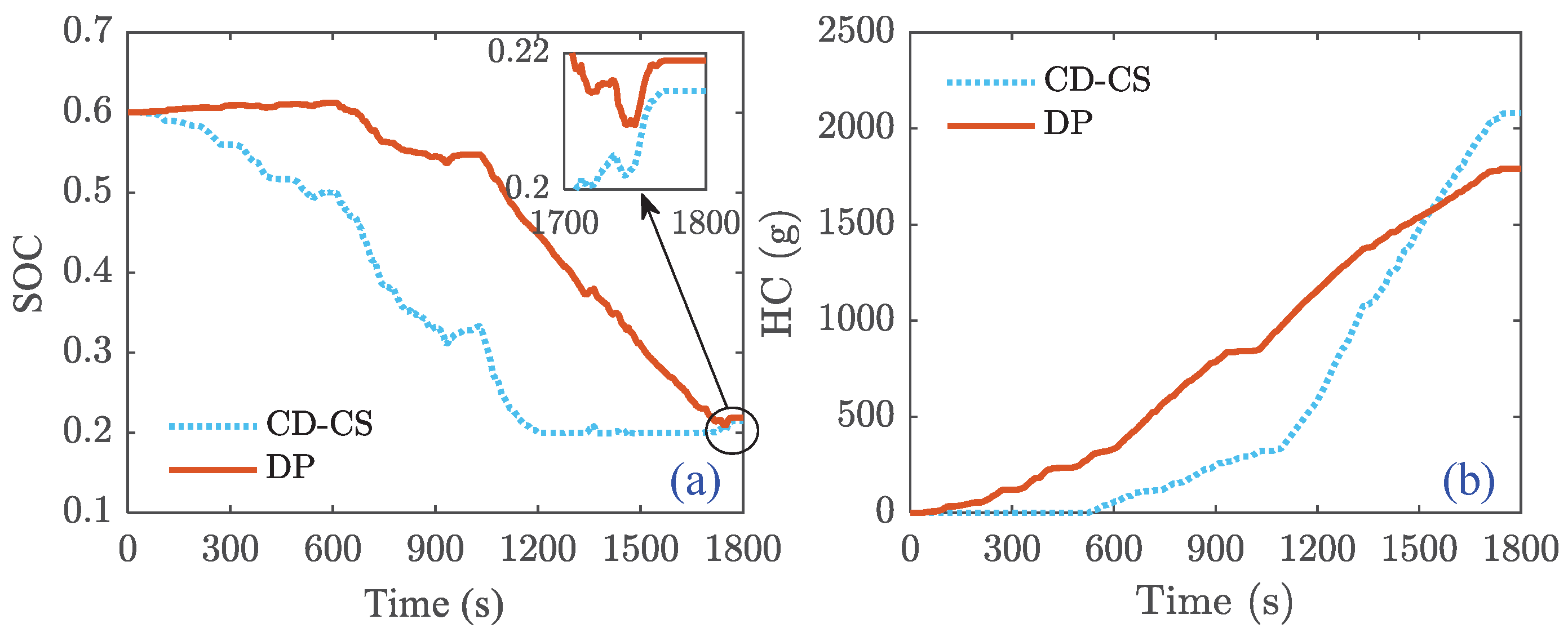

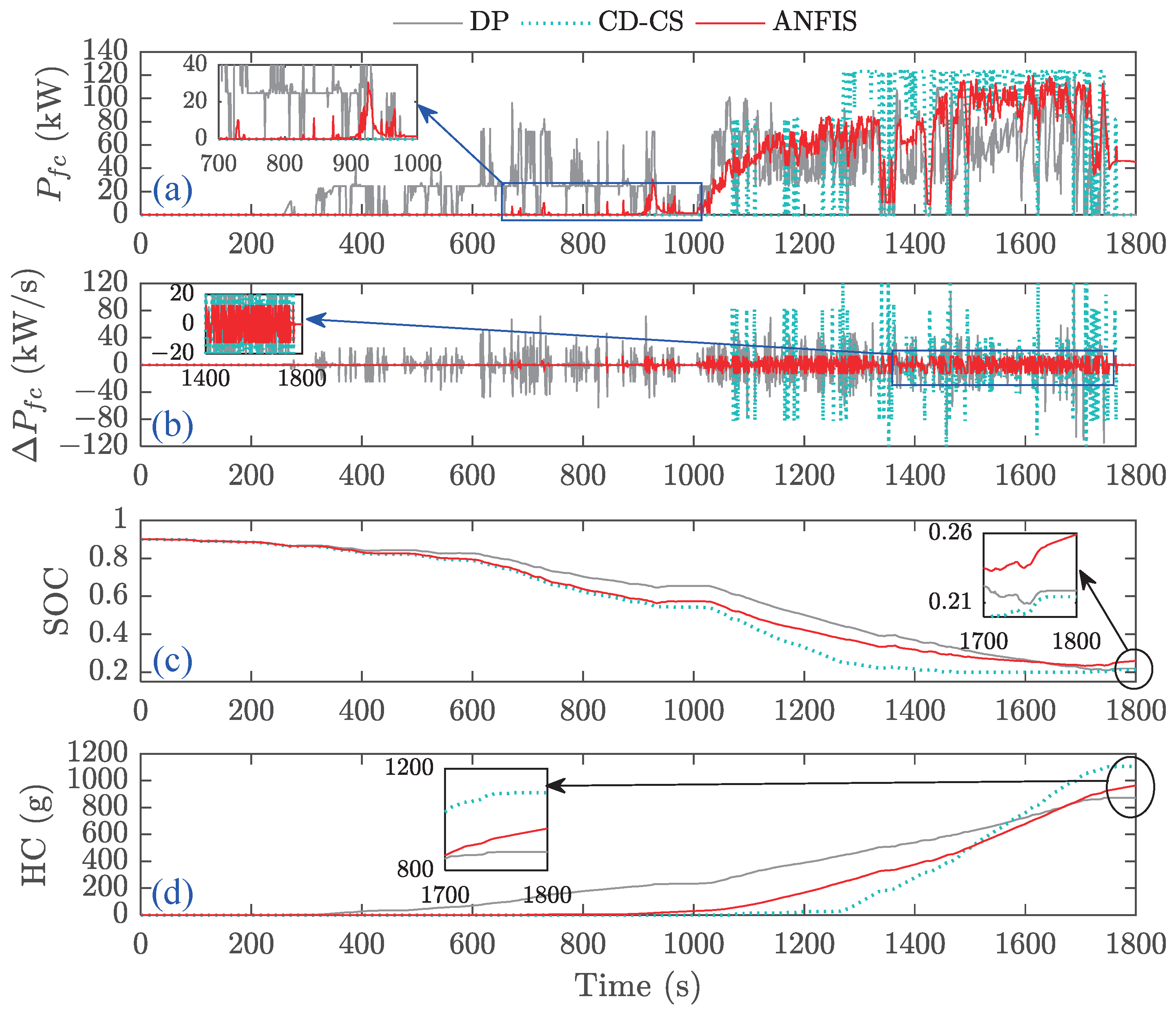

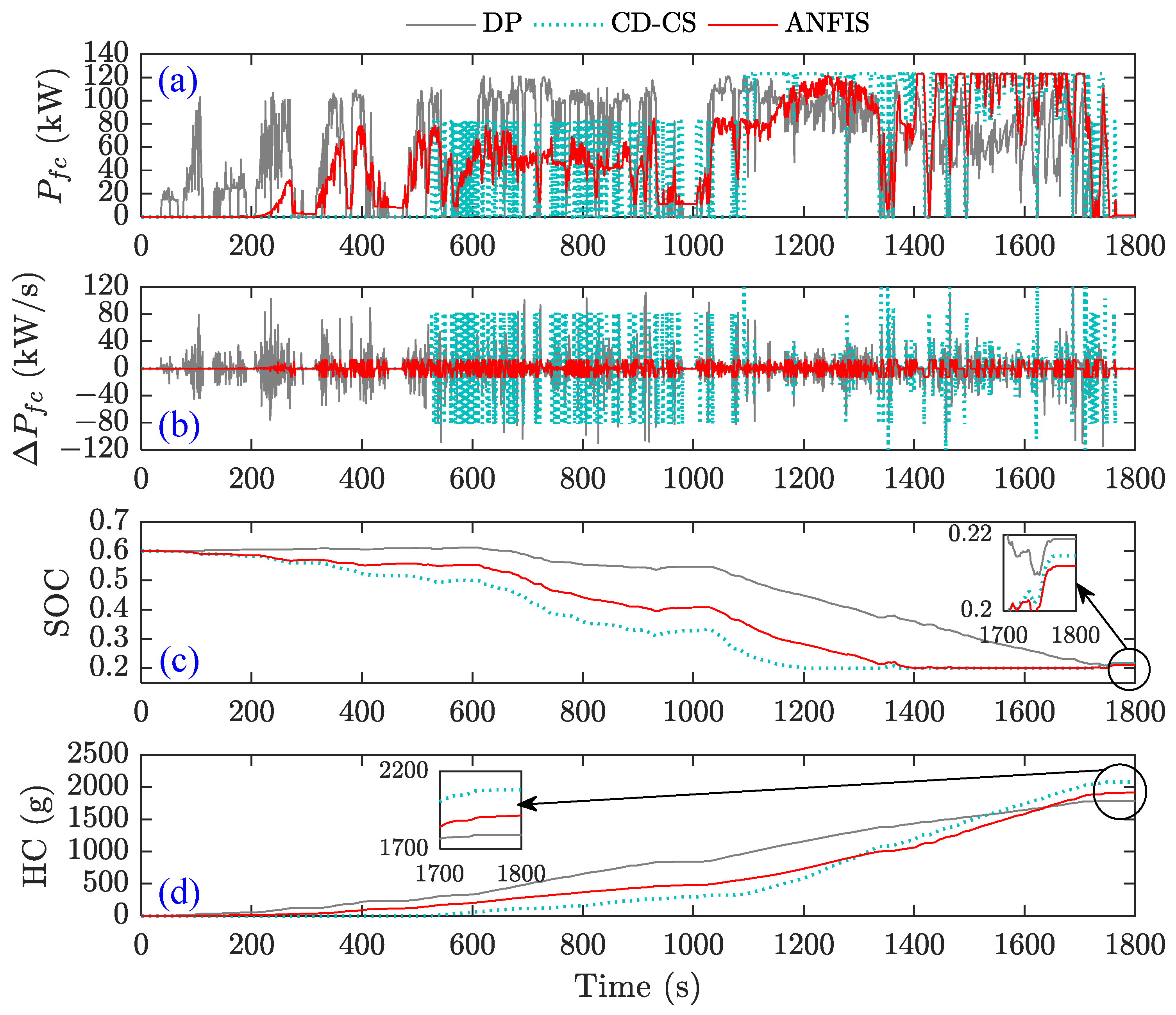

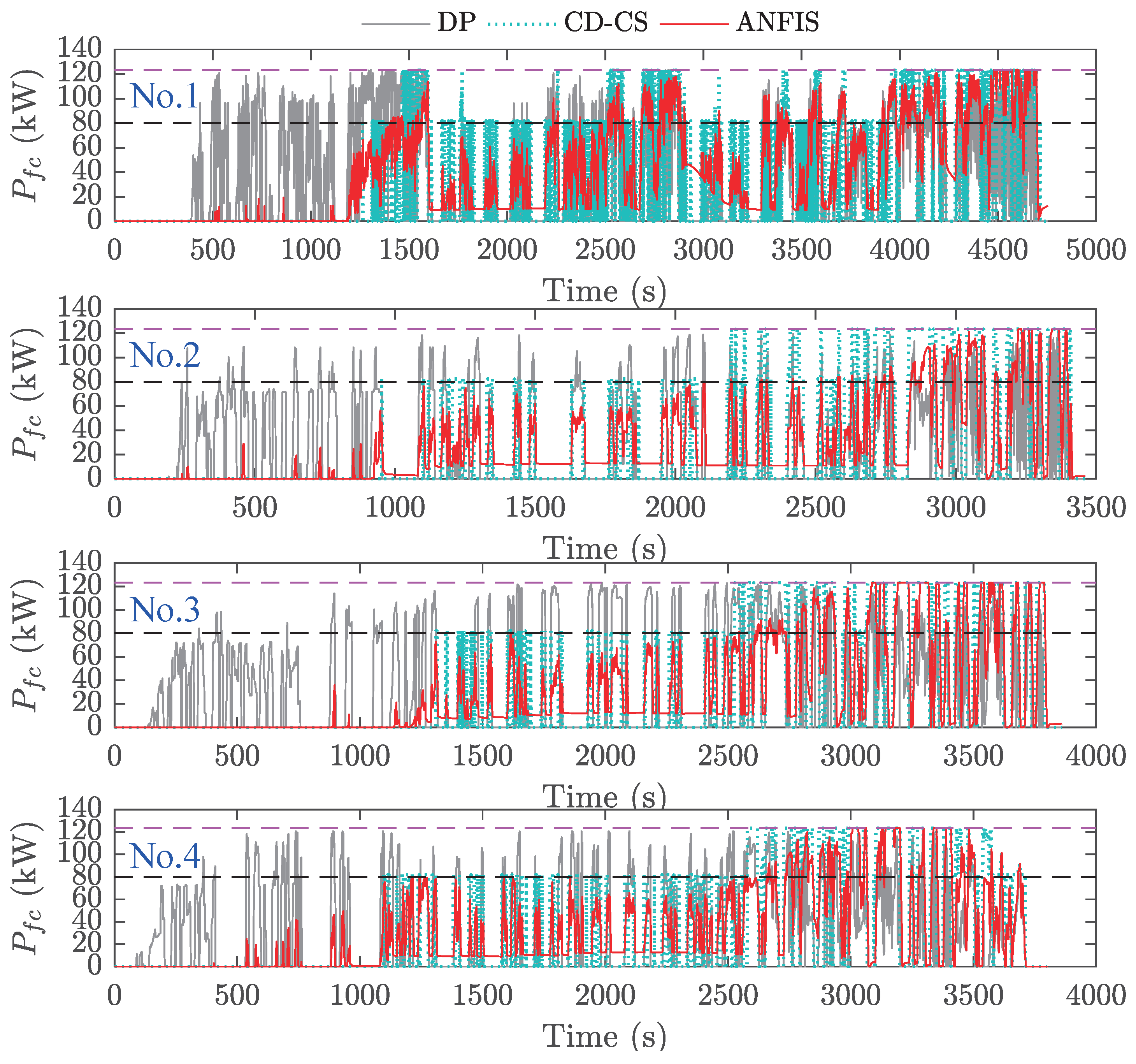

Figure 20,

Figure 21 and

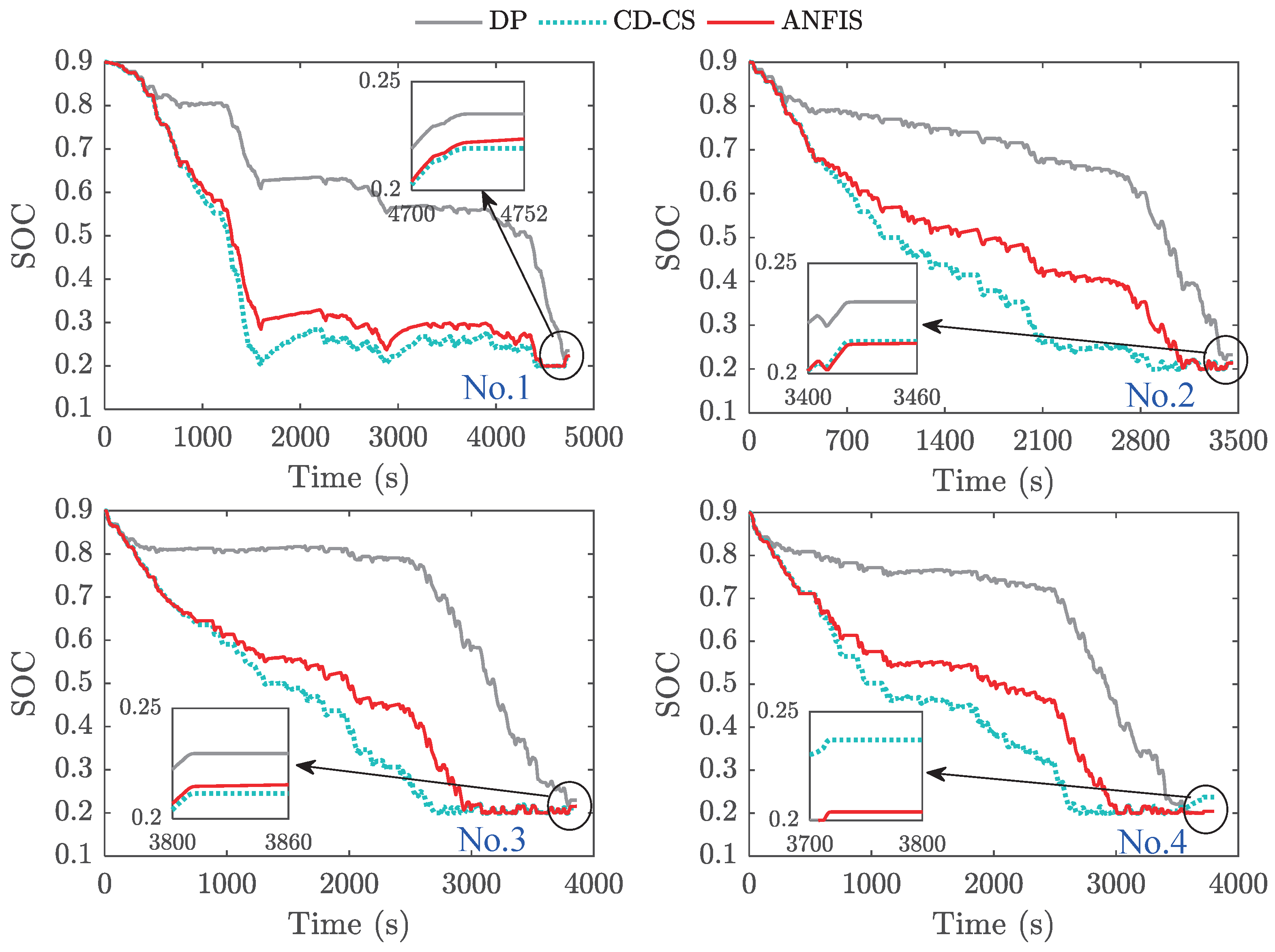

Figure 22 illustrate the corresponding outcomes for initial battery SOC values of 0.9, 0.6, and 0.3. In the figures, (a), (b), (c), and (d) respectively represent the power of the FCS, the change rate of the FCS’s power, battery SOC, and HC. The DP algorithm is designed to achieve global optimization, resulting in the FCS having the earliest working time.

In contrast, the CD-CS strategy involves depleting the power battery energy before entering the FCS working mode, leading to a later working time. As for the ANFIS-DP strategy, its FCS working time primarily depends on factors such as the ANFIS model and training results, as well as battery SOC and power demand. Consequently, when the battery’s SOC reaches a certain threshold, it will be activated with a working time falling between the DP and CD-CS strategies (

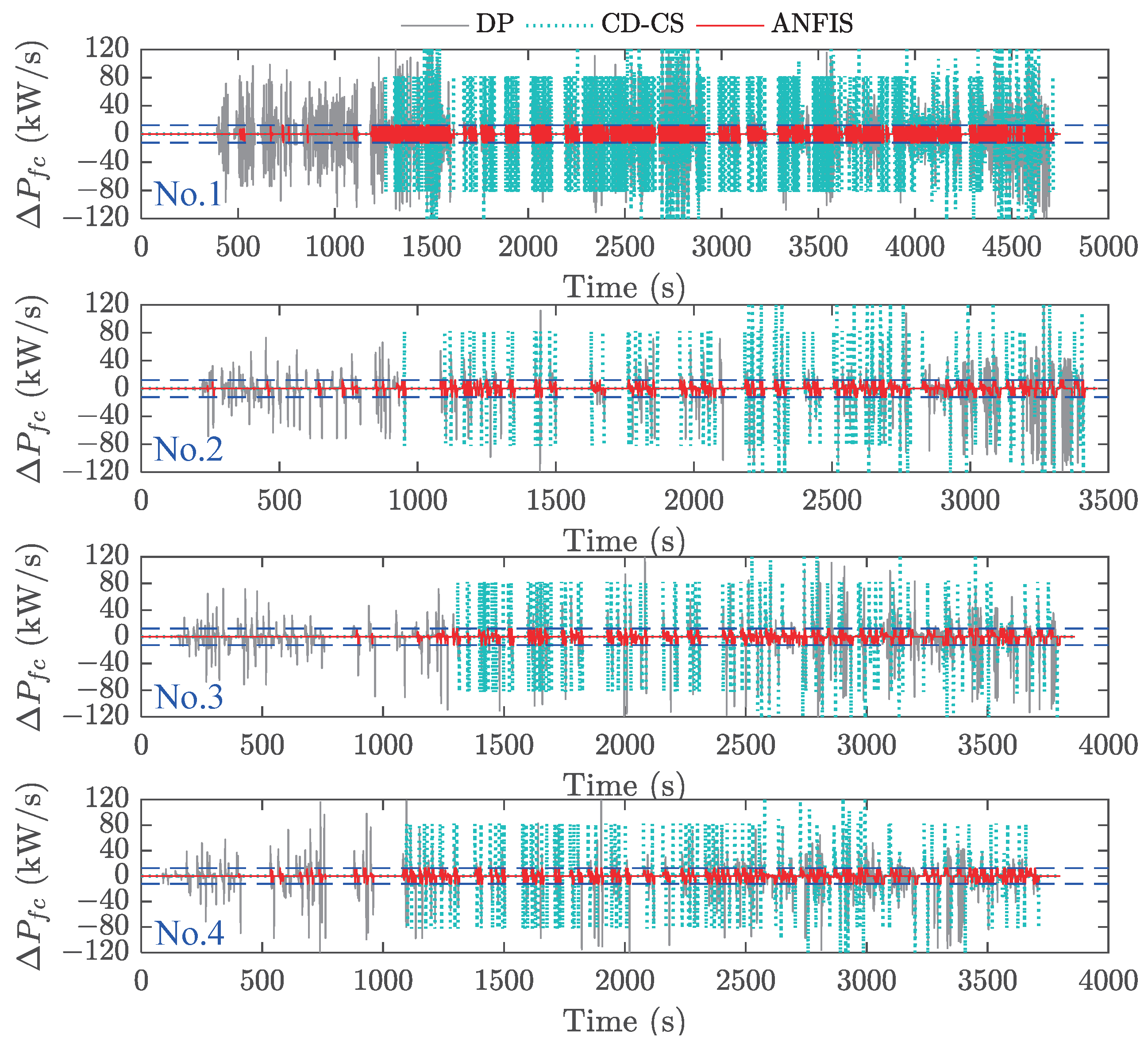

Figure 20a). The lifespan of fuel cells is significantly influenced by the rate of change in FCS output power. In this study, the ANFIS-DP strategy imposes restrictions on the power output of FCS, resulting in exceptional performance and maintaining a controlled rate of power change even at high power output levels. Conversely, DP and CD-CS have no limitations, leading to an unreasonable variation in their FCS’s output power (

Figure 20b). All three strategies can achieve the intended terminal SOC when considering variations in battery SOC. However, slight deviations were observed between the strategy (see

Figure 20c). As the battery SOC has reached its predetermined lower discharge limit, it can be considered effectively depleted. Therefore, only HC was considered when assessing the economic aspects of these three strategies. It is evident that DP is the optimal strategy, and ANFIS is suboptimal compared to CD-CS (see

Figure 20d).

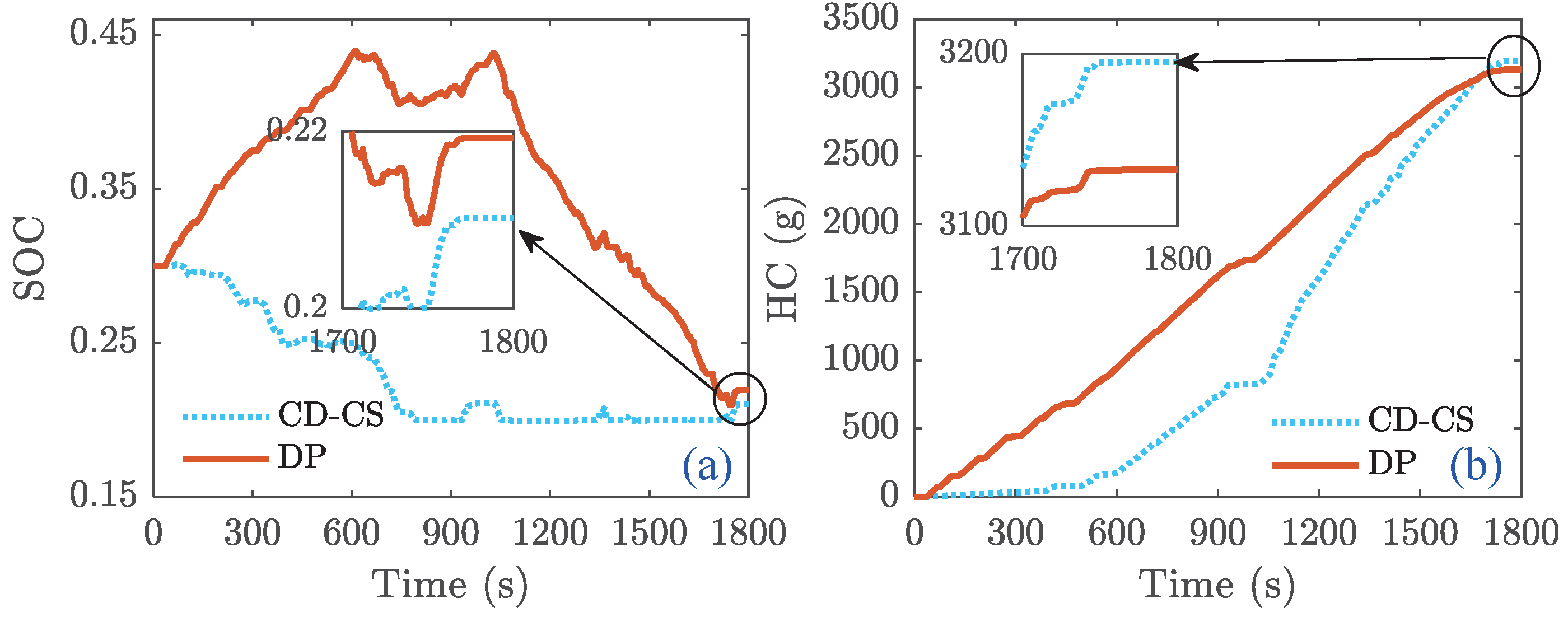

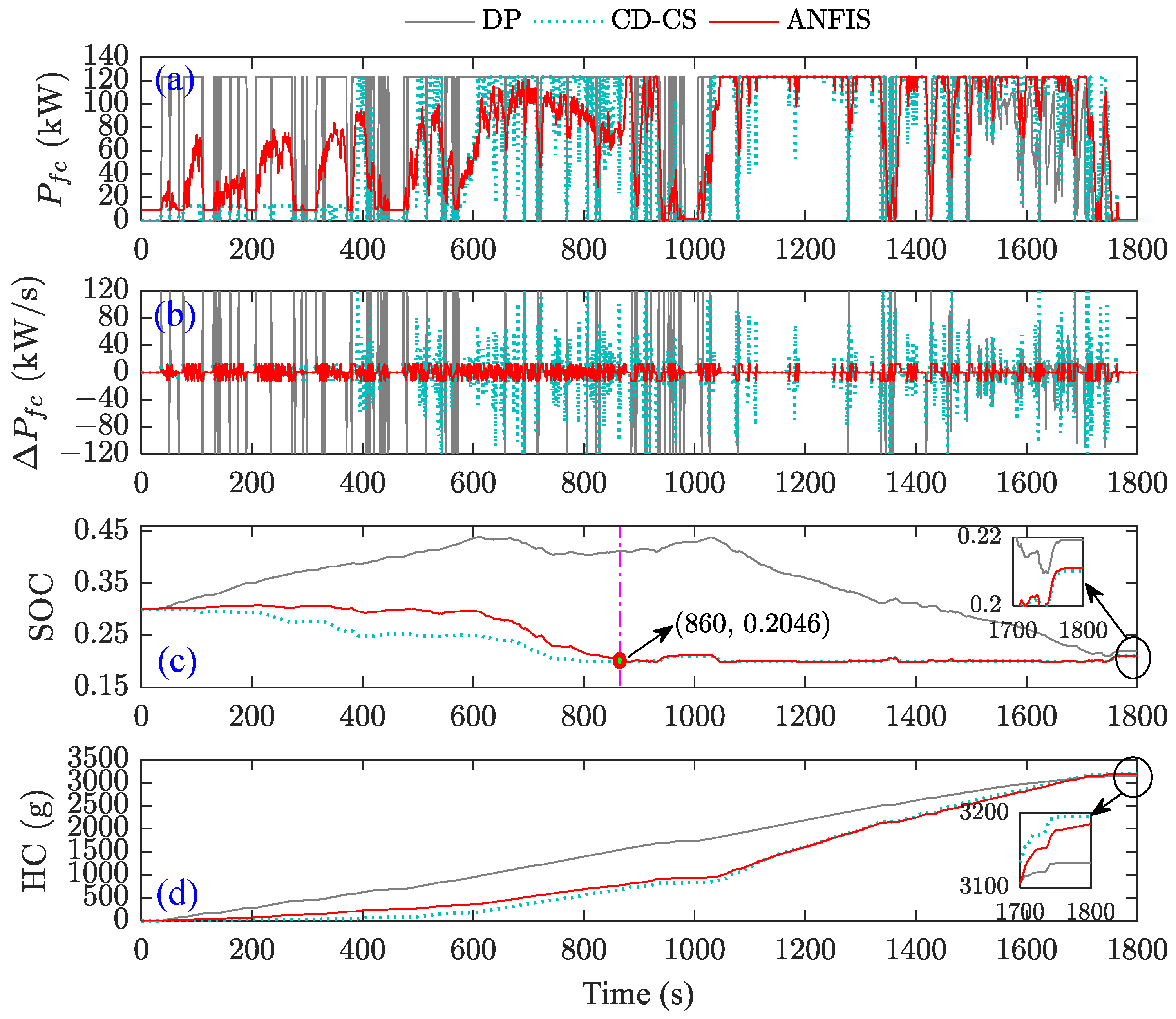

Figure 21 and

Figure 22 show that reducing the battery’s initial SOC increases the FCS’s operating time across all three strategies. The start-up time of FCS is earlier than in the case where the initial battery SOC is 0.9, not only for the DP strategy but also for the ANFIS and CD-CS strategies. This phenomenon is particularly pronounced when the initial SOC of the battery is 0.3, as shown in

Figure 21a and

Figure 22a. On the other hand, decreasing the initial battery SOC also increases the power demand from the FCS. However, the power change rate of the FCS in the ANFIS-DP strategy remains acceptable.

In contrast, both DP and CD-CS exhibit an unsatisfactory power change rate (as shown in

Figure 21b and

Figure 22b). The battery’s SOC reflects its power consumption. When the initial SOC of the battery is 0.6, the SOC trajectories for all three strategies exhibit similarities to those shown for the battery with an initial SOC of 0.9. As shown in

Figure 21c, the DP strategy involves early engagement of the FCS, resulting in a slower decline in battery SOC. Conversely, CD-CS entails engaging the FCS later, leading to a faster decline in battery SOC. However, the ANFIS-DP strategy involves earlier intervention by the FCS compared to CD-CS, resulting in a slower decline in battery SOC and offering more significant potential for operating within high-efficiency zones.

Notably, the SOC trajectories under the DP strategy exhibit an initial increase followed by a subsequent decrease when the battery’s initial SOC is 0.3 (see

Figure 22c). This phenomenon arises because DP represents a globally optimal strategy, ensuring compliance with terminal constraints while achieving optimal performance within the broader context. As a result, the FCS charges the power battery first and then collaborates with the battery. In contrast, the ANFIS-DP and the CD-CS strategies maintained their previous changing characteristics. The CD-CS strategy declined rapidly, whereas the ANFIS-DP strategy declined slowly. However, due to the low initial battery SOC, the ANFIS and CD-CS strategies quickly reached the lower SOC limits, causing their SOC trajectories to always coincide after 860 s. Fortunately, regardless of whether the initial SOC is 0.6 or 0.3, the power battery’s energy is depleted by the end of the driving cycle. Therefore, evaluating the FCECV’s economy by HC is reasonable. The ANFIS-DP strategy exhibits a superior energy-saving effect when the initial SOC is 0.6, as depicted in

Figure 21d. However, at an initial SOC of 0.3, its HC is comparable to CD-CS, as illustrated in

Figure 22d, due to premature battery energy depletion. It is essential to note that the energy-saving effect of the DP strategy is less pronounced when the battery’s initial SOC is 0.3. This is due to insufficient initial energy in the power battery, limiting the energy conservation potential of the hybrid power system.

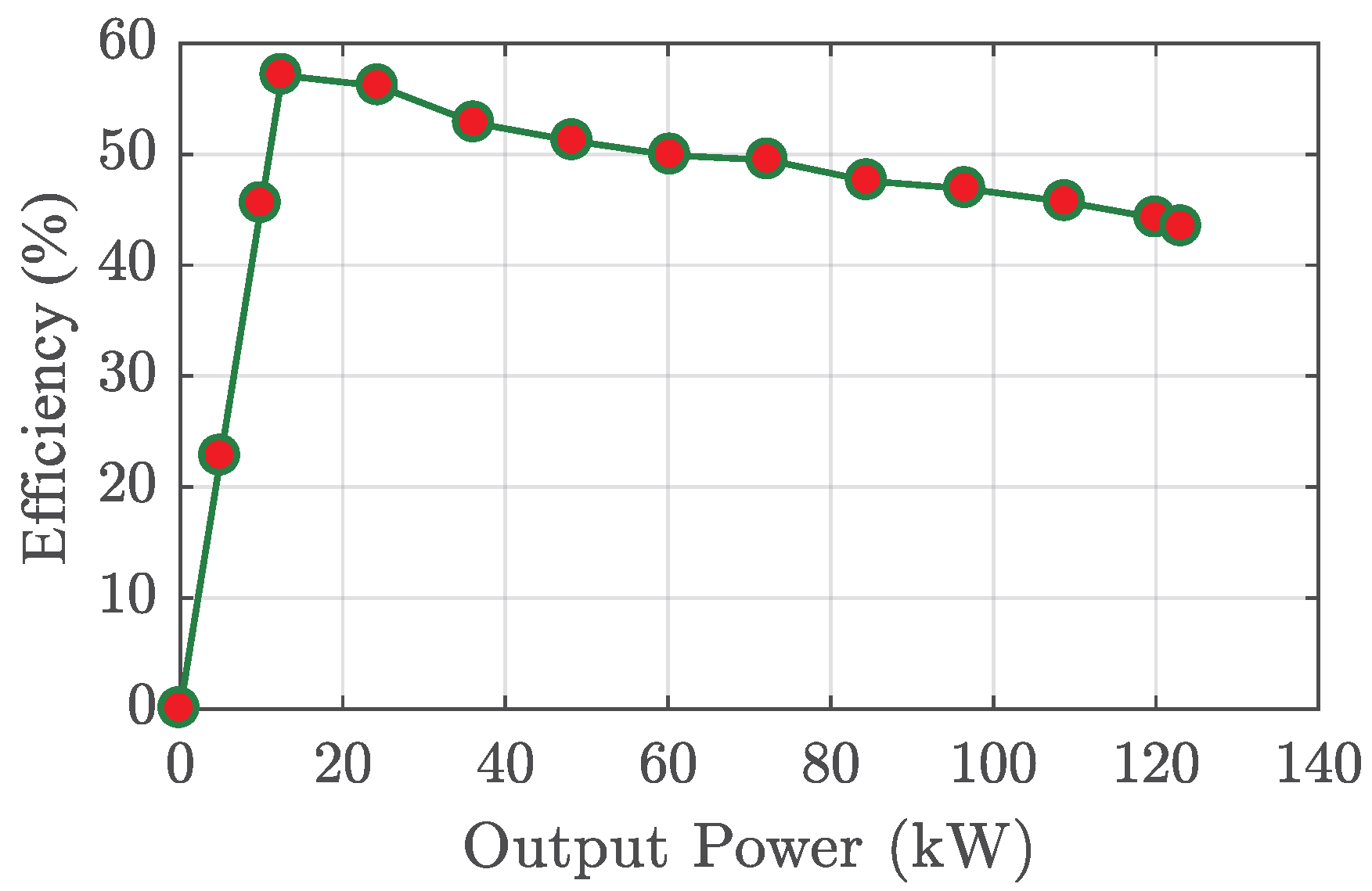

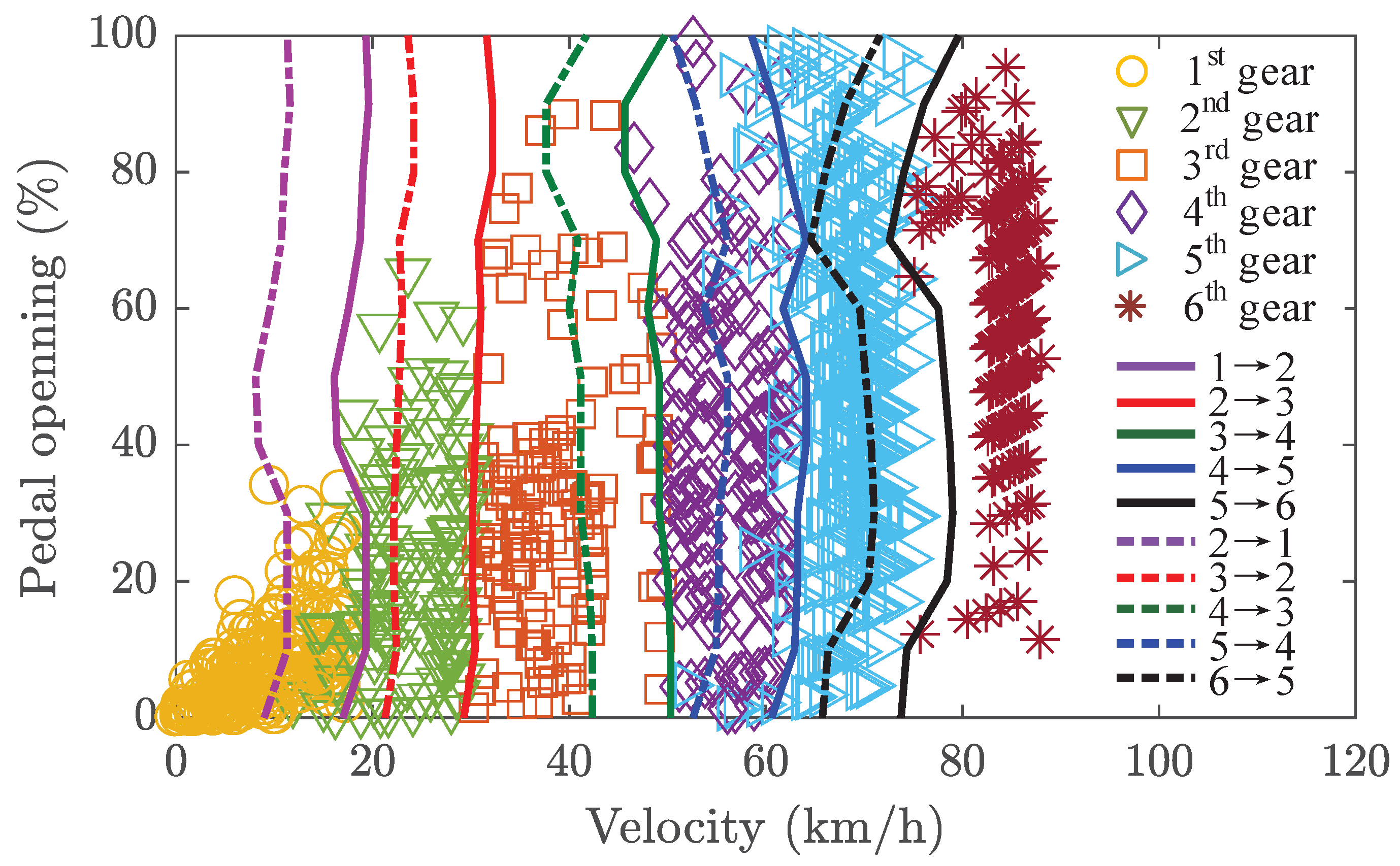

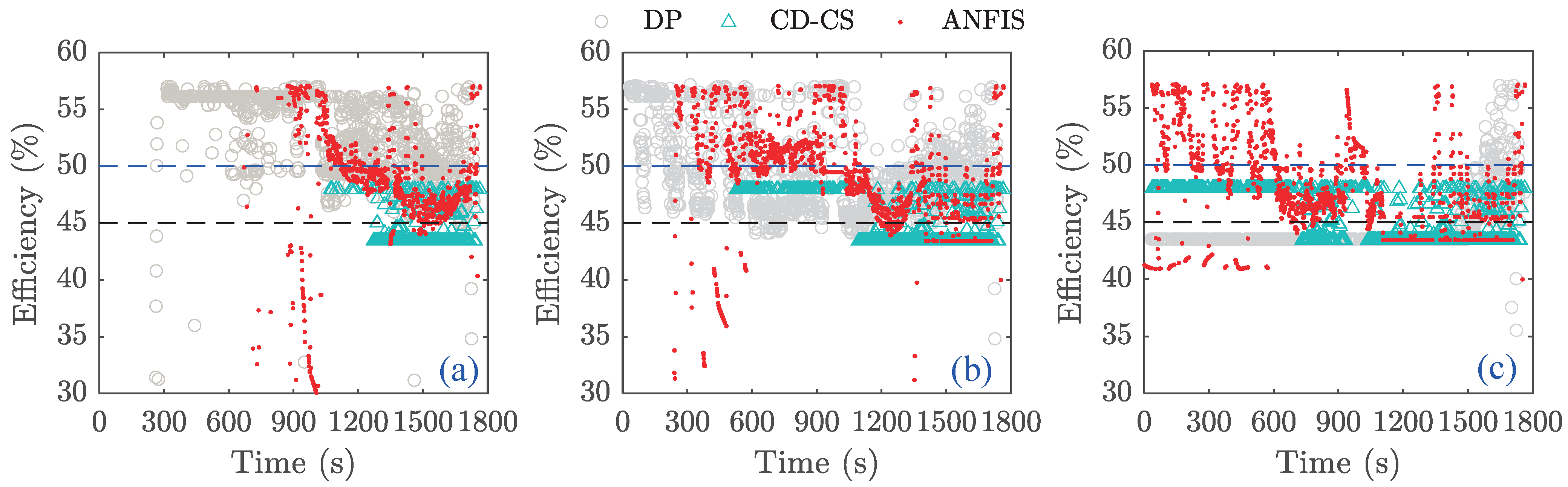

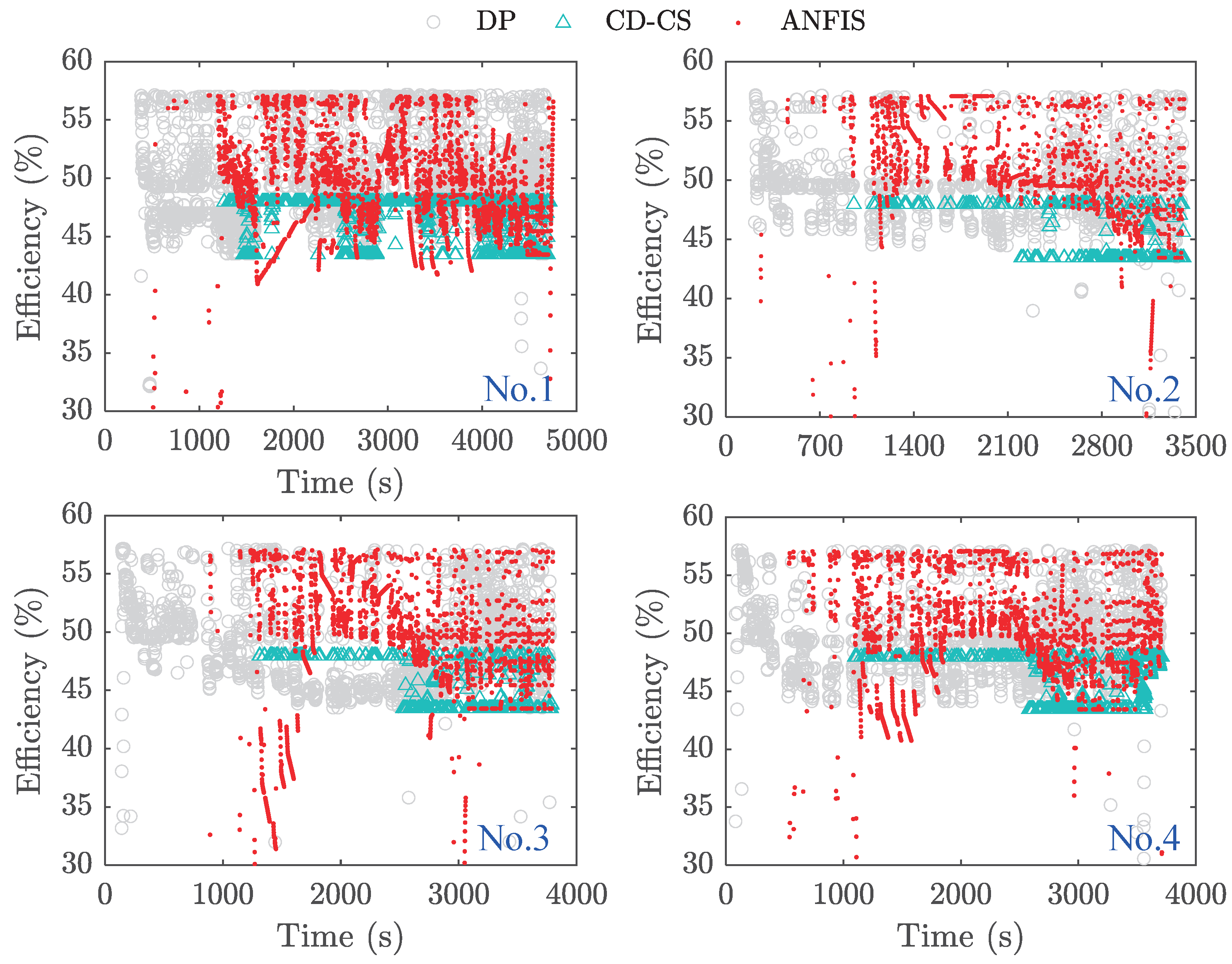

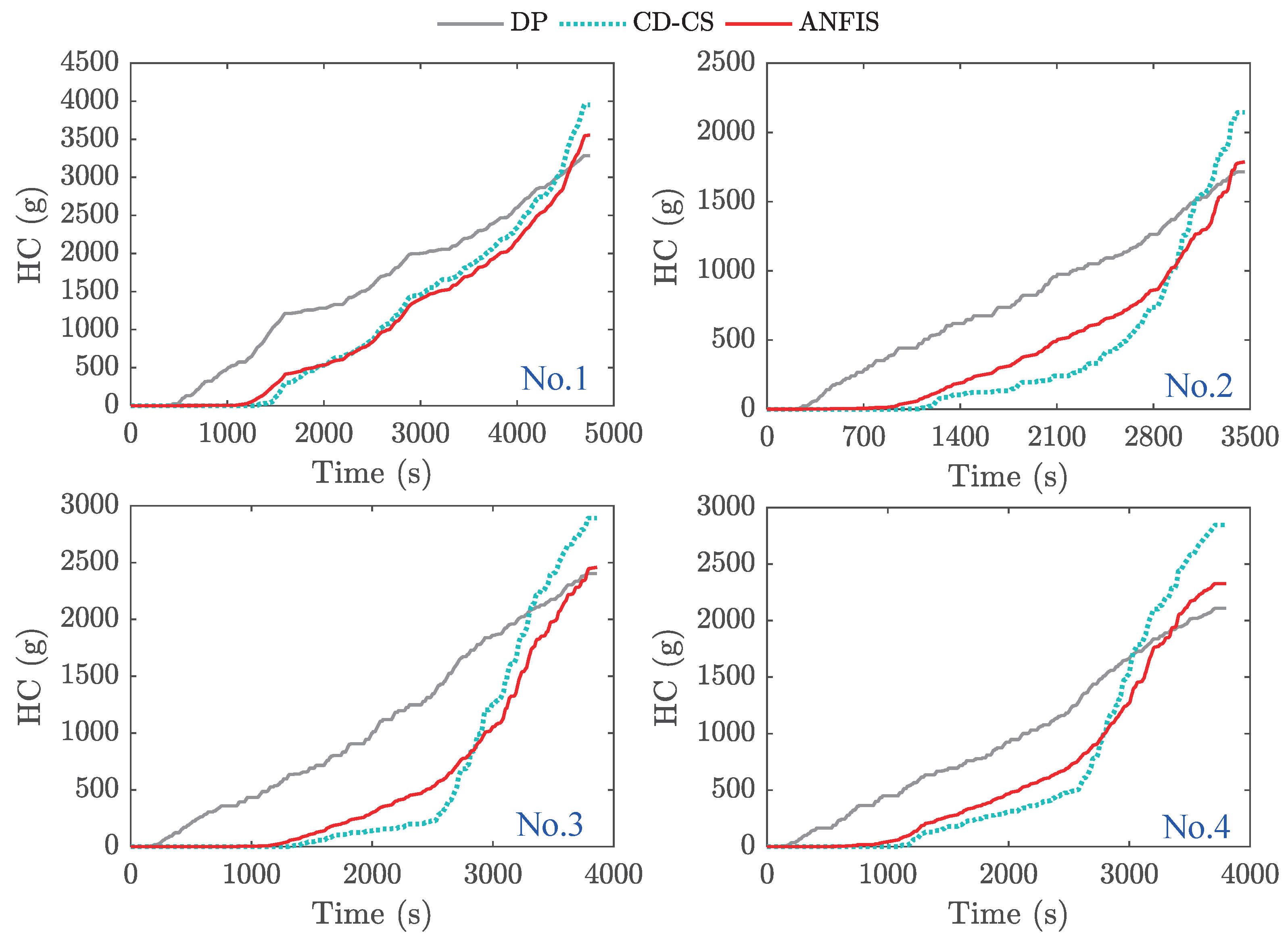

The efficiency distribution of FCS operating points under the three strategies is shown in

Figure 23. When the initial SOC is 0.9, the DP strategy leads to an earlier transition of FCS into the operational state; however, its working efficiency is not satisfactory. This can be attributed to the fact that the DP strategy in this paper considers both optimal energy consumption of FCS and battery, which may result in specific operating points of FCS falling within non-efficient zones. Furthermore, since the ANFIS-DP strategy is based on DP results, low-efficiency FCS operating points may also exist, as shown in

Figure 23a,b. Conversely, under the CD-CS strategy, FCS operates later with a shorter working time when the initial SOC is 0.9 or 0.6. Due to its regular nature, this strategy demonstrates a higher concentration of working efficiency. However, the working efficiencies of both cases are below 50%, leading to an increase in HC.

Remarkably, the FCS intervention of all three strategies occurred earlier in

Figure 23c due to depleted battery energy levels. However, the DP strategy exhibits a higher frequency of FCS operation within low-efficiency zones, particularly before the 1200 s. In contrast, the ANFIS-DP strategy demonstrated superior FCS efficiency during this period. Nevertheless, the DP algorithm ensures global optimization, thereby enhancing the efficiency of its FCS beyond the 1500 s and thus guaranteeing its energy-saving advantage.

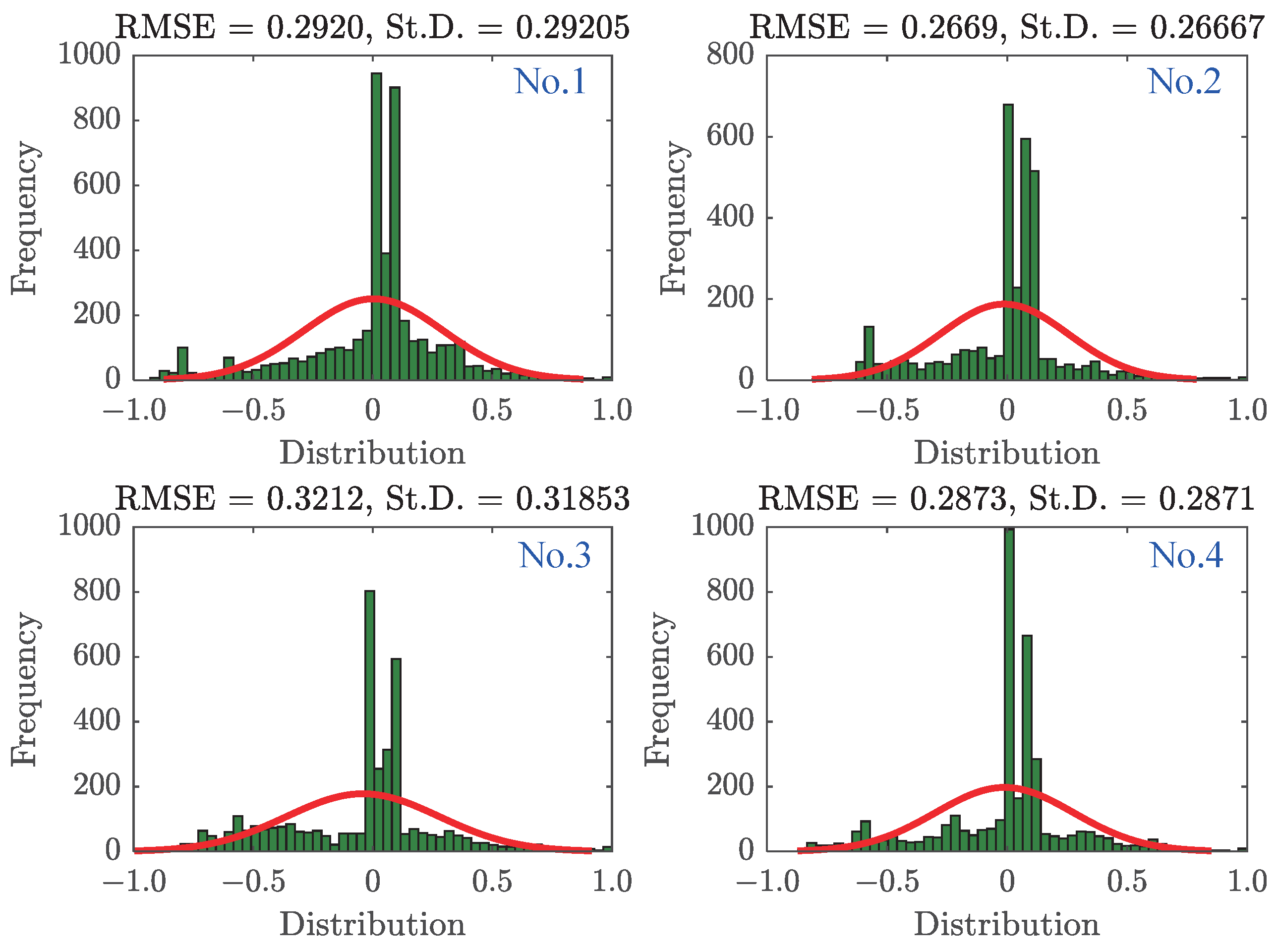

Table 4 below shows the change rate of the FCS power under three strategies, displaying the maximum, minimum, and standard deviation of the change rate. The power change rate for FCS is notably high under the DP and CD-CS strategies, exceeding the safe range for FCS power variation. Additionally, the standard deviation suggests that these two strategies lead to less stable and more volatile power fluctuations, presenting substantial challenges to the service life of FCS. In contrast, the ANFIS-DP strategy effectively regulates the power change rate of the FCS within a reasonable range of [

, 12.3] kW, thus better meeting the power variation limit requirements of the FCS. Notably, the battery’s initial SOC does not affect this characteristic. Despite a higher standard deviation of the power change rate at initial SOC levels of 0.6 and 0.3, the stable power change rate remains consistent. This is expected to benefit the durability of the fuel cell significantly.

Table 5 exhibits the energy consumption for three different strategies. The results indicate that the DP strategy achieves a terminal SOC of 0.219 for various initial SOC levels within the specified range of

. The CD-CS strategy yields a terminal SOC below 0.22 for various initial SOC values, thereby ensuring more comprehensive battery energy utilization. When the battery’s initial SOC is set at 0.9, the terminal SOC for the ANFIS-DP strategy reaches 0.259, which is slightly higher than those obtained with initial SOCs of 0.6 and 0.3, effectively meeting the battery power depletion requirements. Regarding HC, the DP strategy emerges as the globally optimal approach across various initial SOC scenarios. However, it is worth noting that the ANFIS-based strategy also exhibits energy conservation advantages compared to the CD-CS, reducing HC by 13.20%, 7.97%, and 0.31% under different initial SOC conditions. While ANFIS falls short of matching the energy efficiency improvements achieved by the DP strategy, it can still be effectively employed for real-time applications when operating conditions are unknown. Although both DP and ANFIS enhance the energy efficiency of FCECVs, their advantage becomes less significant when the battery’s initial SOC is low. However, when the battery is fully charged, the ANFIS-based strategy can lead to substantial energy savings in real-time implementation.

Table 6 presents the operating characteristics of FCS to facilitate a comprehensive analysis of the energy-saving mechanism of the ANFIS-DP strategy. The peak operating power, average power, operating frequency (i.e., percentage of the working points for the entire driving cycle), and distribution of working point efficiency for the three strategies under different initial SOC scenarios are statistically analyzed. It is essential to note that the distribution of working point efficiency excludes cases where the FCS’s output power is zero, resulting from the varying operating frequency of the FCS associated with different strategies. Based on the findings, when the battery’s SOC is at 0.9, the DP and ANFIS strategies do not need to achieve the FCS’s peak power. As the initial SOC decreases, the maximum power of the ANFIS-DP strategy reaches its peak power at SOC levels of 0.6 and 0.3, whereas the DP strategy only achieves peak power at the 0.3 SOC level. Regarding mean power, the ANFIS-DP strategy performs similarly to the DP strategy, except for a higher mean power at an initial SOC of 0.3.

Additionally, it has been observed that the CD-CS strategy consistently achieves peak power and exhibits a similar trend in mean power variation compared to the DP and ANFIS-DP strategies. Moreover, the CD-CS strategy consistently shows lower mean power than the other two. This can be attributed to the fact that the FCS operating frequency of the CD-CS strategy is consistently lower than that of the other strategies. In contrast, the ANFIS-DP strategy generally operates at higher frequencies of FCS than the DP strategy, except when the SOC is 0.9. In other words, when the SOC is low, the ANFIS-DP strategy will prolong the FCS’s operating time. Despite this, it is more efficient than the CD-CS strategy across different initial SOC scenarios. In addition, when the battery’s initial SOC is 0.9 or 0.6, the proportion of operating point efficiencies exceeding 45% is lower than that of the DP strategy. However, the FCS of the DP strategy experiences a dramatic decrease in operating point efficiency when the initial SOC is 0.3, resulting in poor energy-saving performance. Similarly, although the ANFIS-DP strategy has better operating point efficiency than DP, its energy-saving effectiveness still requires improvement due to increased operational frequency.

The findings suggest that when the battery is fully charged (i.e., the initial SOC = ), the ANFIS-DP strategy is comparable to DP in terms of maximum operating power and average power, with a lower operating frequency of FCS than DP. However, it slightly lags behind DP in terms of operating point efficiency. Therefore, the energy-saving effect is marginally inferior to DP. Furthermore, the ANFIS-DP strategy exhibits a slightly higher operating frequency compared to DP when the initial SOC of the battery is . However, a noticeable disparity exists in operating point efficiency, particularly for , indicating that its energy-saving effectiveness still falls short of DP. Nevertheless, the ANFIS-DP strategy remarkably surpasses the existing strategies for CD-CS real-time applications in terms of energy conservation and enhancement of FCS durability.