The renewable energy system contains a variety of converters, each serving different functions. For instance, there are renewable energy converters for power transfer from renewable sources, as well as devices that enhance the system’s power quality, such as SVGs and active power filters. To measure the output impedance of converters, this paper proposes using the SVG with redundant capacity as the perturbation current injection device. This approach significantly reduces the investment required for impedance measurement equipment. Based on this setup, the key issue in impedance measurement lies in how to accurately inject the perturbation signal into the system while satisfying the requirements for spectral controllability, logarithmic uniform distribution of frequency points, and avoiding frequency coupling. This section therefore presents the control strategy and design process for the perturbation signal to address this key challenge.

3.1. Multi-Functional Controller

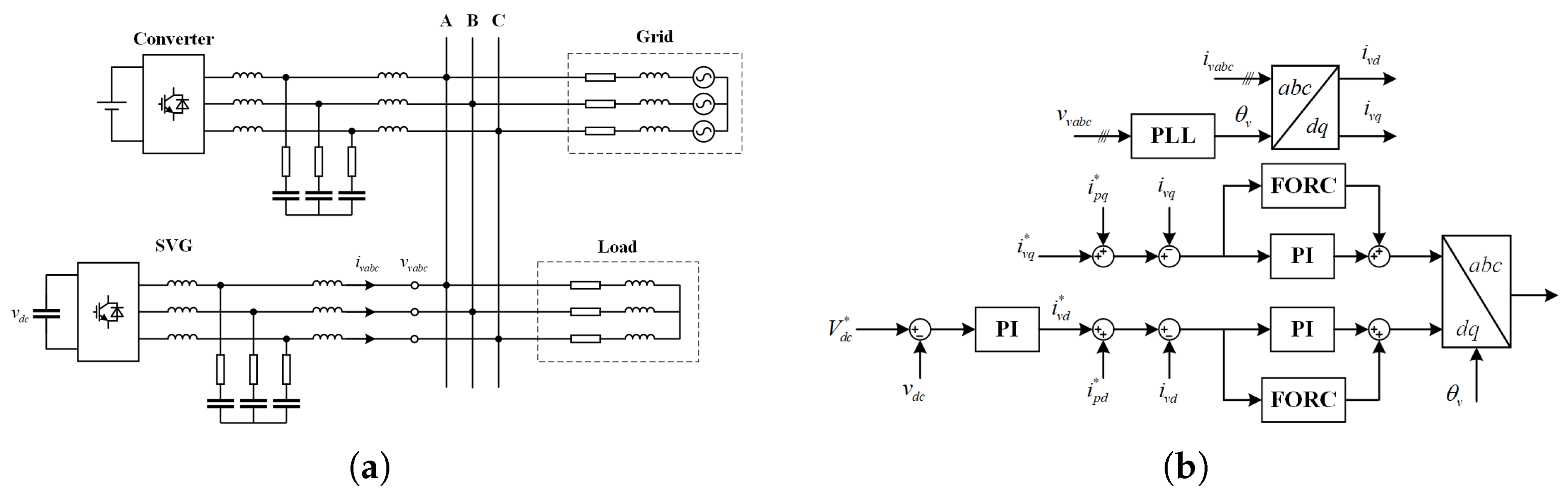

Figure 3a shows a simplified renewable energy system, where a renewable energy converter is connected to the point of common coupling (PCC), with its control structure is presented later.The load

represents a three-phase inductive load. An SVG is employed to compensate for the system’s reactive power and is connected to an LCL filter. Moreover, the SVG also serves to inject perturbation currents into the system. To fulfill these dual roles, the control strategy of the SVG needs to be optimized, as detailed in

Figure 3b.

In this paper, perturbation signals with multiple frequencies are injected simultaneously. To achieve precise control of multi-frequency sinusoidal signals, the perturbation controller must have appropriate control characteristics. For this purpose, FORC is employed as the perturbation controller.

In the figure, denotes the DC-side capacitor voltage, while and represent the voltage and current at the output port of the SVG, respectively. The controller comprises a voltage loop and a current loop. The voltage loop regulates the DC-side voltage via Proportional–Integral (PI) control, with serving as the reference voltage value. The current loop is designed to control reactive power and the perturbation current. Here, and represent the reference values of the d-axis and q-axis currents, respectively. These reference values are derived by summing the DC reference values and with the perturbation signal reference values and . Specifically, determines the output reactive power. and denote the d-axis and q-axis currents, respectively. represents the synchronous phase obtained from the phase-locked loop (PLL). The control structure of the current loop combines a PI controller and a perturbation controller, used to regulate the DC reference signal and the perturbation signal, respectively.

Based on this control strategy, the sensitivity of the dominant poles to various parameters is analyzed in

Figure 4. Sensitivity is defined as the per-unit value of the variation in the modulus of the dominant pole divided by the per-unit value of the variation in the parameter.

Figure 4 analyzes the degree of influence of each control parameter in the SVG controller and the grid inductance

on the dominant poles. The control parameters include the proportional gain

and integral gain

of the voltage control loop, the proportional gain

and integral gain

of the current control loop, the proportional gain

and integral gain

of the PLL, and the proportional gain

of FORC. As shown in the figure, the primary factors influencing the dominant poles are

and

, while

has a relatively minor impact. This indicates that FORC exhibits favorable robustness in terms of parameter adjustment, and variations in its parameters do not significantly affect the stability of the system.

3.2. Impedance Measurement Method

The output impedance or admittance of the power converters is a crucial parameter for identifying the state of the system. The three-phase converter shown in

Figure 5 is widely utilized in distributed energy systems.

is the three-phase voltage at the PCC, and

refers to the output current. The converter adopts a current control strategy and utilizes a PLL to maintain phase synchronization between the output current and the PCC voltage. The controller is implemented in the dq domain, where PI controllers are used to track the reference signal, and pulse width modulation (PWM) is used to generate control signals.

Given the inherent nonlinearity of the converter shown in

Figure 5, impedance measurement should be performed around a stable operating point of the converter. Therefore, when implementing impedance measurement techniques, a small-amplitude perturbation signal is typically injected into the system while it is operating in a stable state. The output impedance of the converter is then determined by measuring the corresponding voltage and current responses to this perturbation signal.

As depicted in

Figure 6, there are two types of perturbation signals. One is the current perturbation signal injected in parallel, and the other is the voltage perturbation signal injected in series. Thus, the output impedance of the converter at the frequency

can be computed in accordance with the voltage

and current

. In this paper, the parallel injection method is employed. Firstly, the parallel injection method is more straightforward to implement in engineering applications, as it avoids changing the system’s connection configuration. Secondly, this perturbation injection approach can be integrated into the existing equipment in the system.

Owing to the inherent structural asymmetry of the three-phase converter, its impedance model is characterized by a matrix. This paper employs the impedance model in the d-q frame as an implementation case for impedance measurement. As described in [

19], the d-q frame of the three-phase converter system is distinguished into two sets: the system d-q frame that tracks the phase angle of the grid voltage and the controller d-q frame that follows the phase of the PLL. The impedance model is constructed on the system d-q frame. Consequently, to accurately measure the impedance model of the converter, it is essential to capture the voltage and current responses on the system d-q frame. An illustration of measuring the converter’s output impedance using parallel current disturbances is depicted in

Figure 7. Variables marked with the superscript ’s’ denote the system d-q frame variables. To ensure that these variables remain aligned with the system d-q frame, the disturbance current source in

Figure 7 is synchronized with the grid voltage via an improved PLL. During impedance measurement, orthogonal current disturbances are injected. The disturbances on the d-q frame, as indicated by

and

in the figure, can be represented by the following expressions:

where

,

, and

represent the amplitude, frequency, and phase angle of the perturbation signal, respectively. Through coordinate transformation, the system will be subjected to injection with three-phase perturbation currents. In

Figure 7, two phases are required to perform impedance measurement. One is the phase for disturbance signal injection, denoted as

. In this paper, the SVG is used to inject the disturbance signal. Therefore, this phase is obtained via the PLL in the SVG controller, i.e., phase

in

Figure 3b. The other phase is used for impedance calculation: it converts the three-phase voltage and current data into the data in the system dq frame. This phase is derived from the improved PLL described in this paper.

The impedance can be calculated by measuring the components of voltage and current at the disturbance frequency. The impedance is represented by four elements. To determine the impedance at a given frequency, at least two independent perturbations must be injected into the system. Denoting the measurement results of the first and second injections with subscripts 1 and 2, respectively, the impedance at frequency

can then be calculated as follows:

3.3. Design for Disturbance Signal

The input of the FORC is the difference between the reference value of the perturbation signal and its actual measured value. The design of this reference value is crucial in determining the efficiency and accuracy of impedance measurements. The reference value of the perturbation signal with multiple frequencies is expressed as

,

, and

represent the frequency, amplitude, and phase angle of the k-th component of the multi-sine signal, respectively. These three parameters need to be designed to improve the accuracy of impedance measurements and to minimize the impact of the perturbation signal on the system.

When selecting the frequency of the perturbation signal, the frequency coupling characteristics of the system should be considered to avoid. Specifically, the coupling phenomena appear as follows: injecting a perturbation current signal with a frequency of

into the d-q frame results in the generation of current signals with frequencies

and

in the three-phase stationary coordinate system, where

is the grid frequency. These two frequencies are known as sideband frequencies. Therefore, in choosing the frequency of the perturbation signal, the following three conditions should be considered and balanced: (1) Avoid interference from background harmonics and between different perturbation signals. Specifically, the sideband frequencies of each perturbation signal should not be equal to the harmonic frequencies of the system. In addition, the sideband frequencies should not be equal to each other. (2) The perturbation frequencies should maintain a certain integer multiple relationship to leverage the advantages of FORC and enhance measurement efficiency. (3) The perturbation frequencies should be distributed as uniformly as possible on a logarithmic scale to align with spectral characteristics. After selecting the perturbation frequencies, the indicator

U can be used to quantify the degree of uniformity of the frequencies on a logarithmic scale, and its calculation process is given in (

8) and (

9). Here,

n is the total number of selected frequency points. Values of

U closer to 1 indicate more uniform distribution on a logarithmic scale. When designing the frequencies, it is advisable to ensure that

.

To fulfill the aforementioned conditions, this paper employs the following method to set the perturbation frequencies: The frequency range is divided into several logarithmically spaced intervals, and the number of measurement frequencies per zone are specified. Next, several base frequencies are chosen in each interval, and subsequent frequencies are generated by integer multiples of these base frequencies. The selected fundamental frequencies and the subsequent frequencies generated must meet the first condition. Lastly, appropriate frequencies are chosen from the generated frequencies to ensure that U is sufficiently large. As an example, consider a measurement frequency range from 10 Hz to 1000 Hz, which is divided into three logarithmically spaced intervals. The frequency intervals are [10 Hz, 46.4 Hz], [46.4 Hz, 215.4 Hz], and [215.4 Hz, 1000 Hz]. In each zone, seven measurement frequency points are set. For the first zone, the fundamental frequencies of the perturbation signal can be selected as 5.2 Hz and 12.9 Hz. The selected frequencies for the first zone are [10.4, 12.9, 15.6, 20.8, 25.8, 31.2, 38.7] Hz. For the second and third frequency zones, the frequencies within these two zones should be multiples of the frequencies in the first zone, with the multiple coefficients being 5.01 and 25.1, respectively.

For perturbation signals at the same frequency, two independent perturbations should be injected to determine the converter’s output impedance. This is accomplished by changing the phase of the perturbation signal. Specifically, in this paper, the phases of the two perturbations are set to 0 and , respectively.

The design of the perturbation signal amplitude should take into account two factors. First, it should satisfy the small-signal assumption, meaning the amplitude should be sufficiently small to ensure the system remains linear around the steady-state operating point. Second, the amplitude needs to be large enough to overcome internal system harmonic distortions and noise, ensuring that the response signal can be accurately extracted. In the frequency design of the perturbation signal discussed earlier, the perturbation signal is designed to avoid background harmonic interference. This enables the use of smaller perturbation amplitude. Based on these considerations, the amplitude of the perturbation signal is determined based on the following principles: The amplitude of a single-frequency perturbation signal should be less than 5% of the steady-state operating point, and the combined amplitude of multiple perturbation signals should be less than 10% of the steady-state operating point. Within these constraints, the perturbation amplitude is maximized to ensure reliable and accurate system response measurements.

In the context of the aforementioned design, multiple reference values for perturbation signals are generated. It should be noted that each reference value of the perturbation signal contains multiple sinusoidal frequency components. These frequencies are all multiples of a specific fundamental frequency within a given frequency range.

Based on the control strategy and measurement method, the impedance measurement process is illustrated in

Figure 8. Initially, the reference value of the perturbation signal is designed. Subsequently, the control parameters of the FORC are updated based on this reference value. Specifically, the order of the delay link and the coefficients of the Lagrange interpolation formula are determined according to the fundamental frequency of the reference value, as given in (

4). Next, two independent disturbance currents are injected into the system. The three-phase voltage and current data at the test port are then collected and transformed into the d-q coordinate system. Finally, the components of the voltage and current signals in the d-q coordinate system at the disturbance frequencies are extracted, and the impedance at these frequencies is calculated. By iterating through the perturbation signals across all frequencies and repeating the aforementioned steps, the wideband impedance of the system under test can be obtained.

3.4. Improved PLL

To obtain the impedance model of the three-phase converter, it is necessary to perform a coordinate transformation to shift the response signals from the abc frame to the system d-q frame, not the controller d-q frame. This requires the use of a phase angle, which is typically estimated using a PLL or other mathematical algorithms. However, since disturbance signals are injected, dynamic synchronization effects caused by the phase angle estimation method may be introduced. Essentially, the d-q frame components calculated through this phase angle are those of the controller d-q frame. This leads to inaccurate impedance model measurements below the PLL bandwidth. To mitigate the impact of phase angle dynamics on impedance measurement, an improved PLL is adopted to compensate for the dynamic effects of the PLL.

The structure of the PLL is depicted in

Figure 9, and the output is the phase angle of the controller d-q frame, denoted by

. To track grid fluctuations, the bandwidth of the PLL needs to be sufficiently high. This, however, may result in a difference between the angles of the two d-q frames [

19], denoted as

, due to the injected disturbance. It can be shown that the relationship between the angles of the two frames is as follows:

where

represents the phase angle in the system d-q frame.

To accurately determine the system d-q frame components, it is essential to accurately determine the phase difference

.

is derived as shown in

Figure 9. Specifically, the PLL frequency small-signal component is extracted using a high-pass filter (HPF) and then integrated to obtain

. The expression for the high-pass filter is given by

Here, is the damping factor, typically set to 0.707, and is the cut-off frequency of the HPF. Its value should be less than the minimum frequency of the disturbance signal to accurately extract the angle difference.

Using this improved PLL, the system d-q frame components can be derived through two methods. One is to transform coordinates with

to directly compute the system d-q frame components. The other is to use

for an initial coordinate transformation to obtain the controller d-q frame components, which are then converted to the system d-q frame components using the following equation:

where

and

represent the voltage of the system d-q frame, and

and

represent the voltage of the controller d-q frame. The dq axis current can be calculated by the same method.