A Multi-Mode Wireless Power Transfer System Based on a Reconfigurable Transmitter for Charging Electric Bicycles

Abstract

1. Introduction

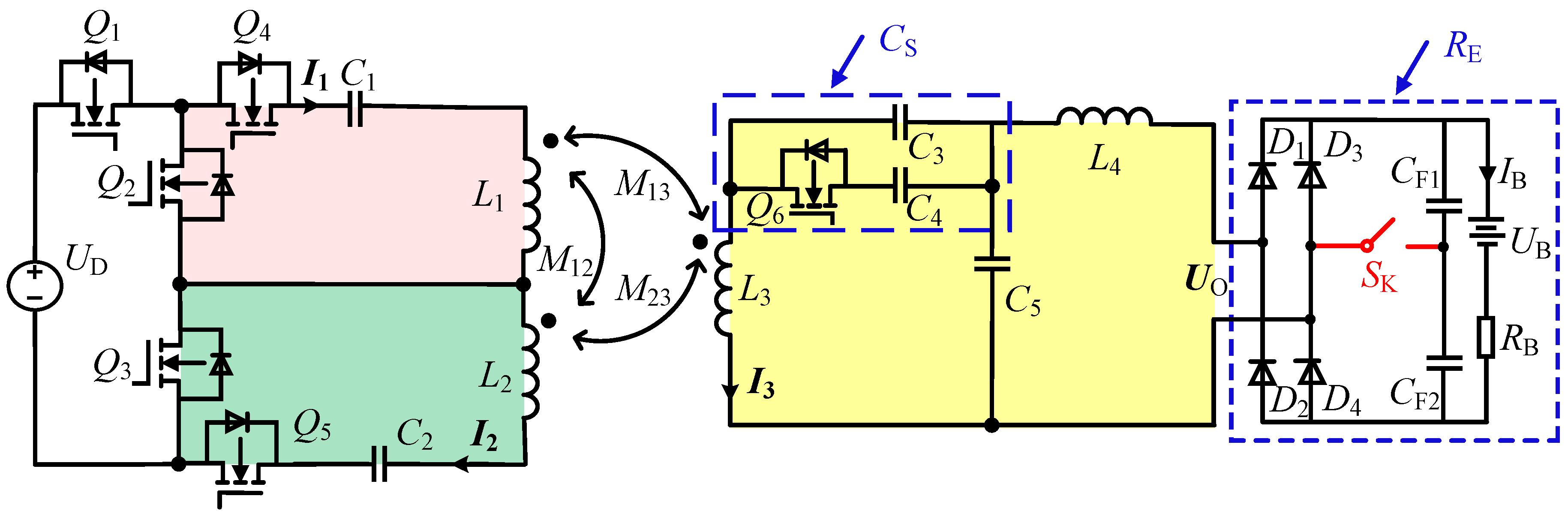

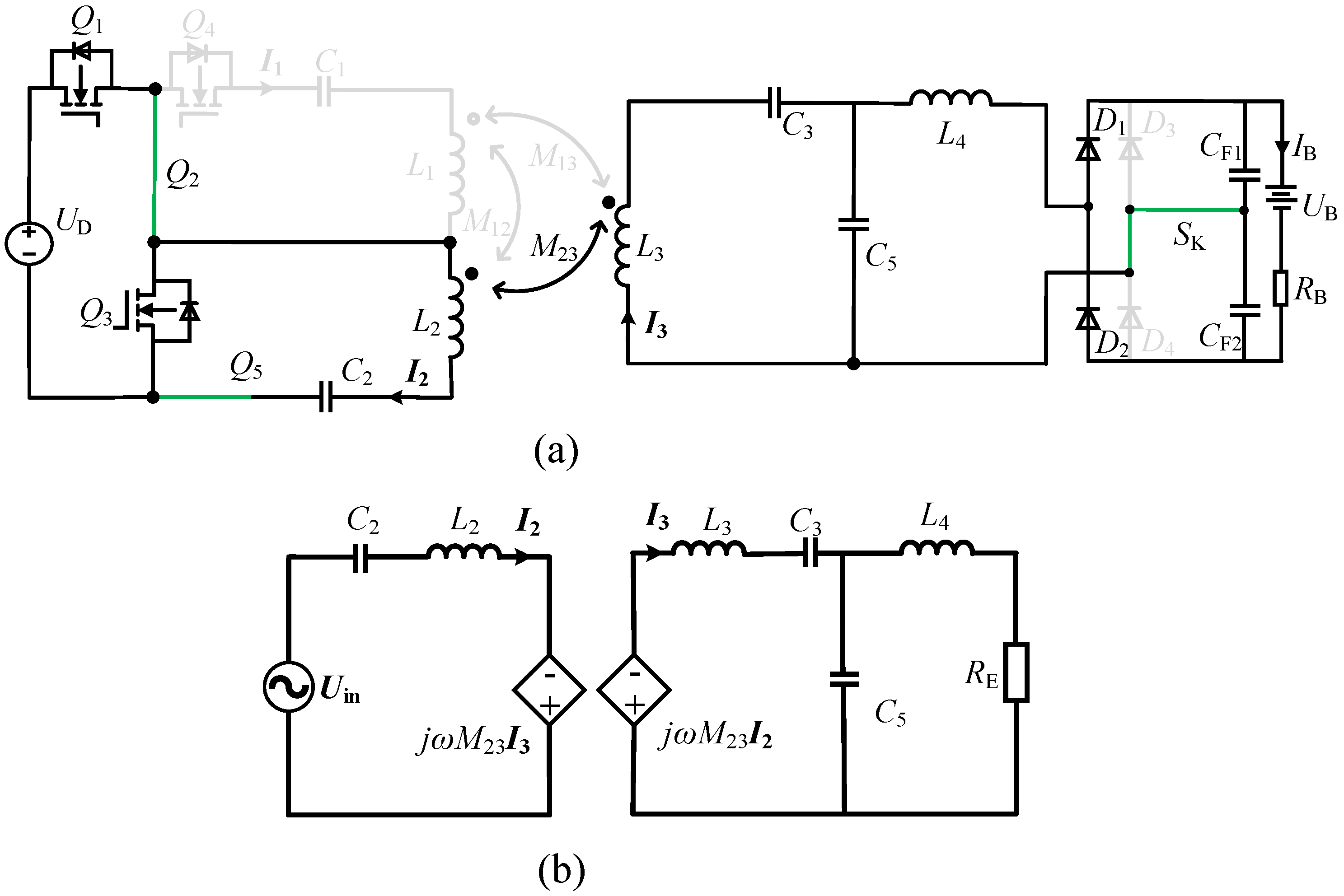

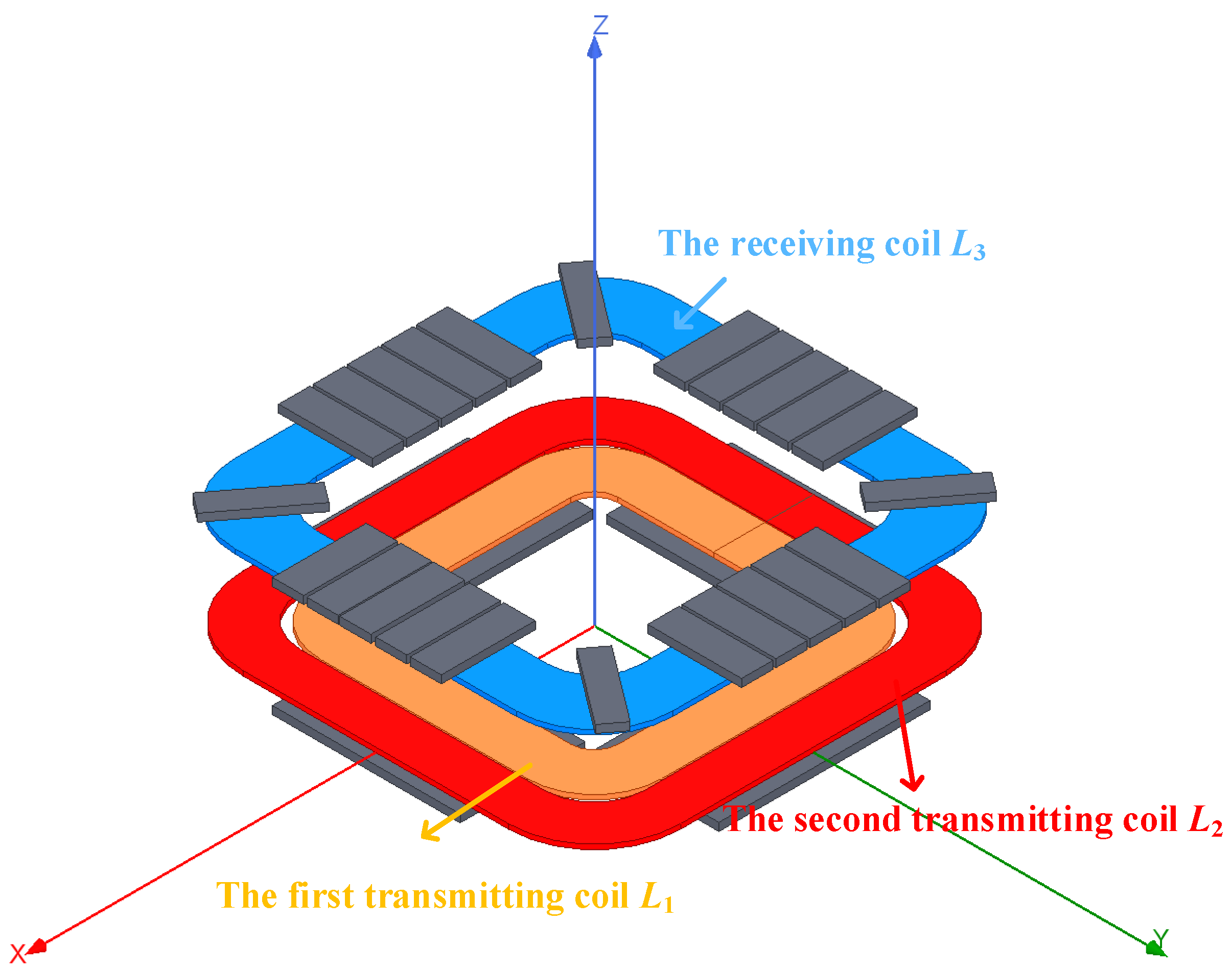

2. Theoretical Analysis

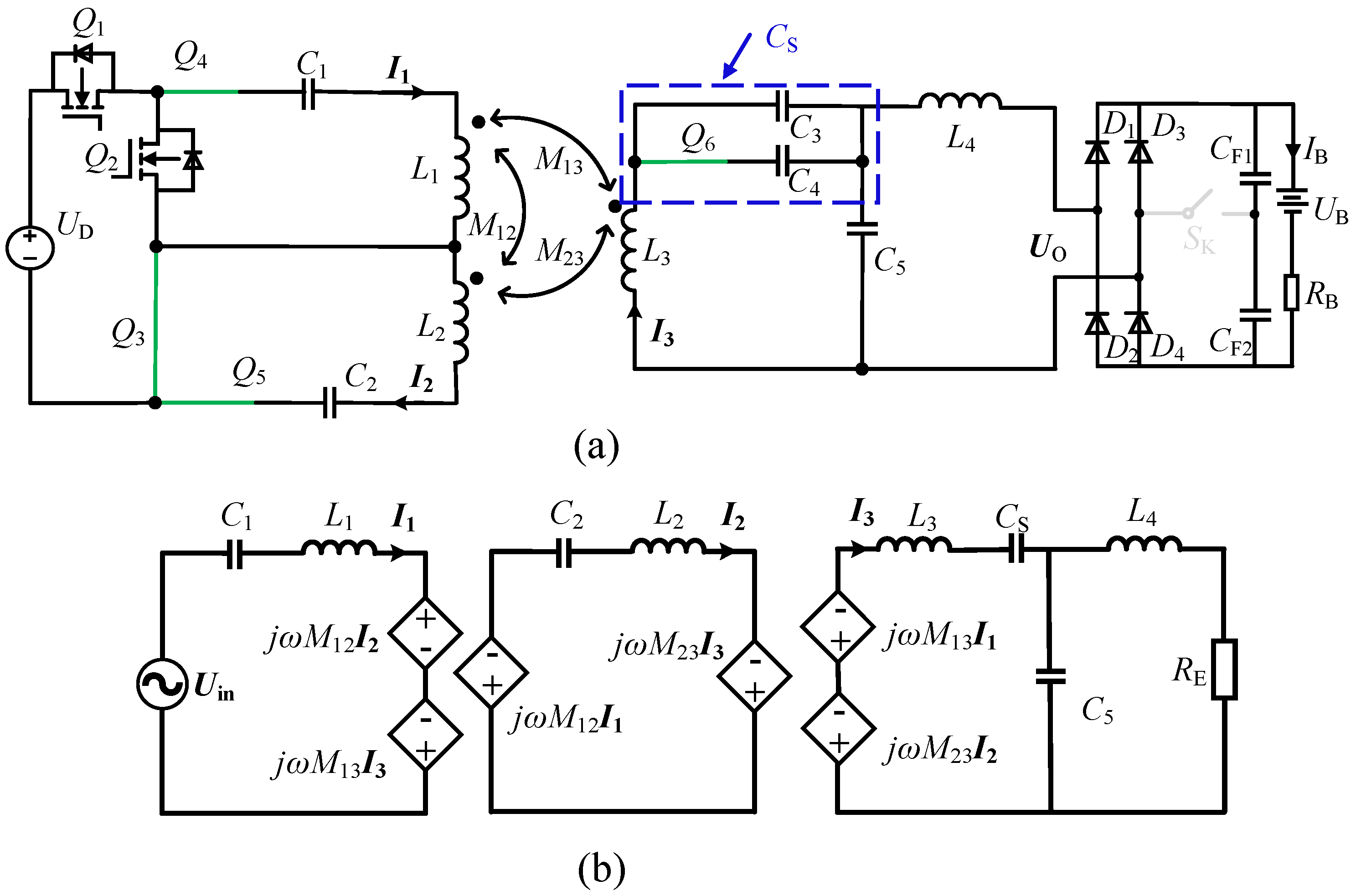

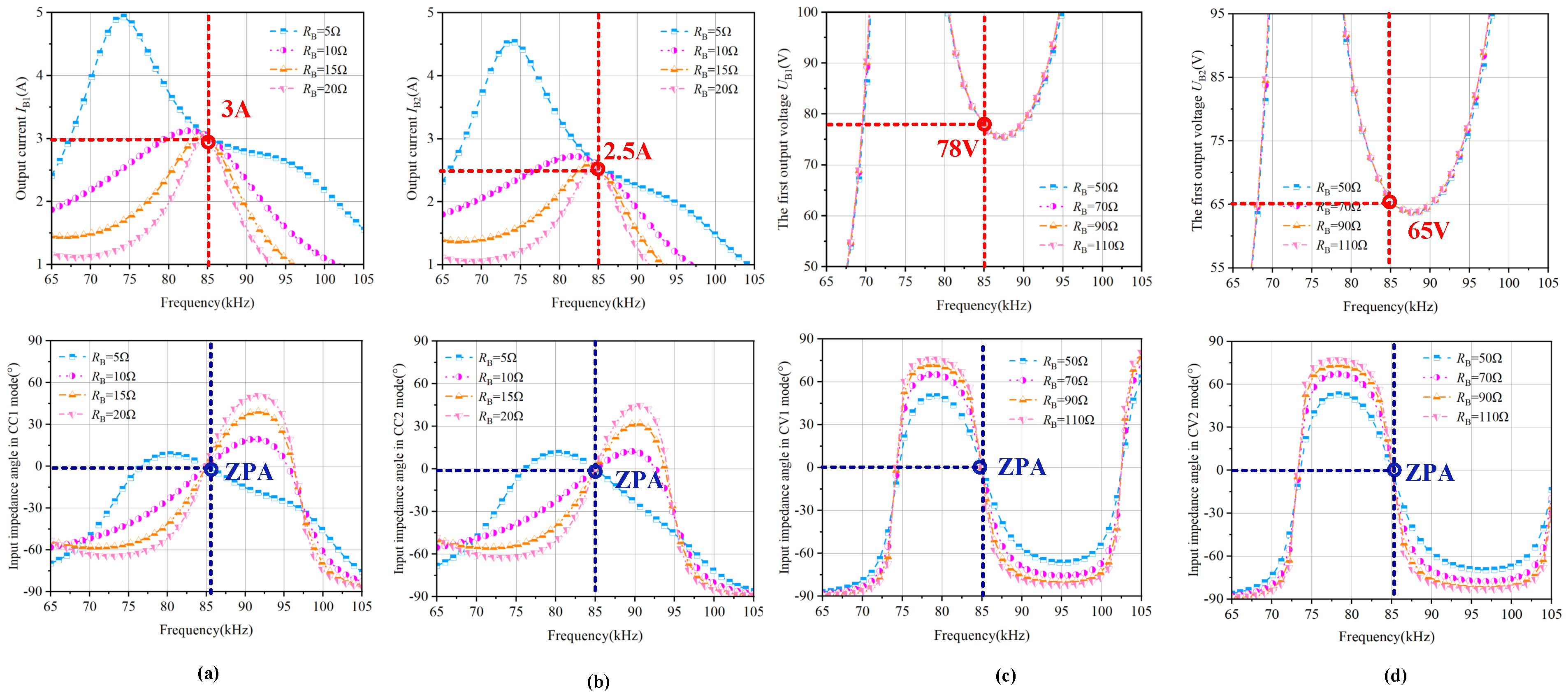

2.1. CC1 Mode

2.2. CC2 Mode

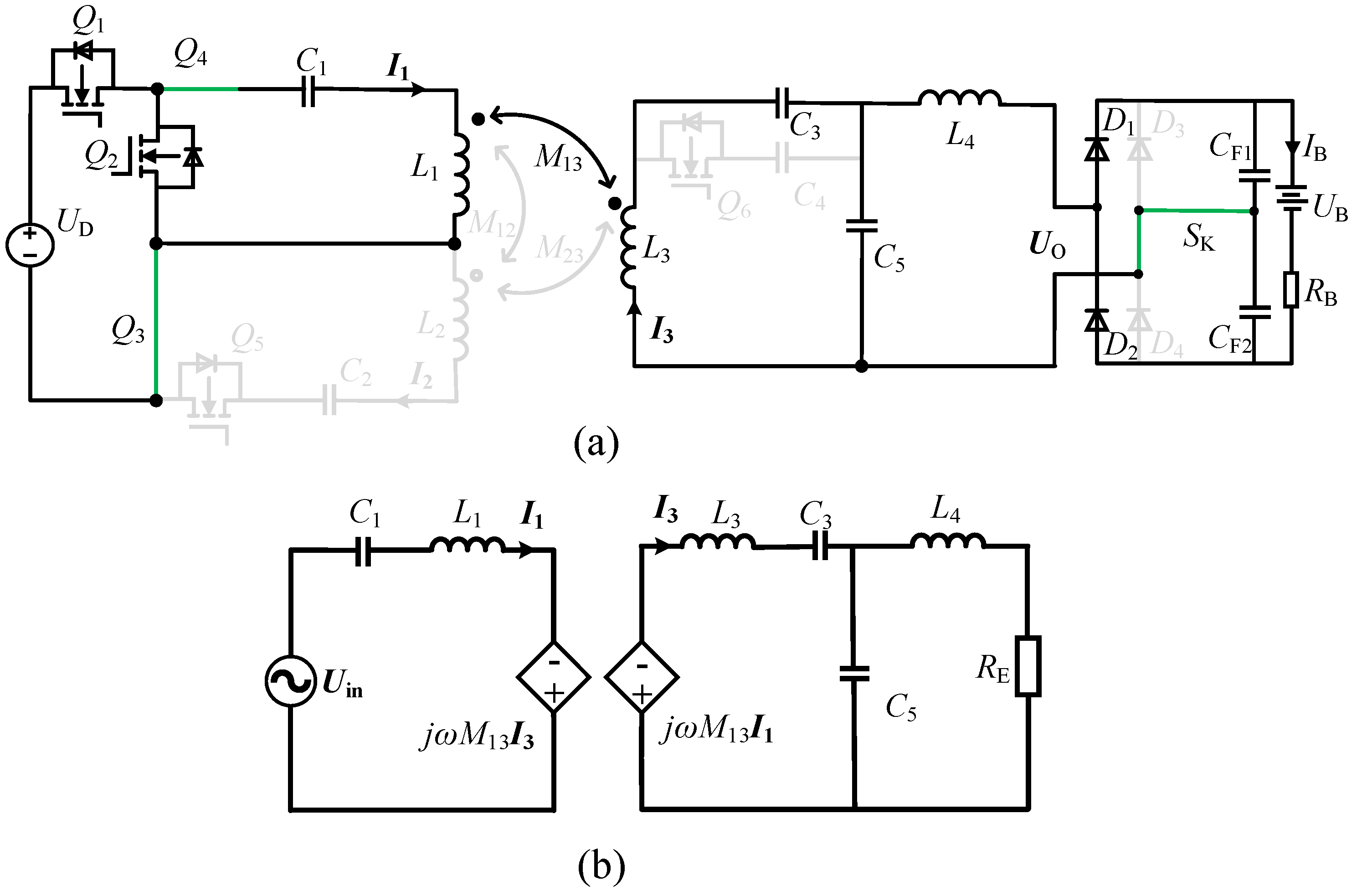

2.3. CV1 Mode

2.4. CV2 Mode

3. Simulation Analysis

4. Experimental Verification

4.1. Experimental Prototype and Experimental Parameters

4.2. Experimental Waveforms

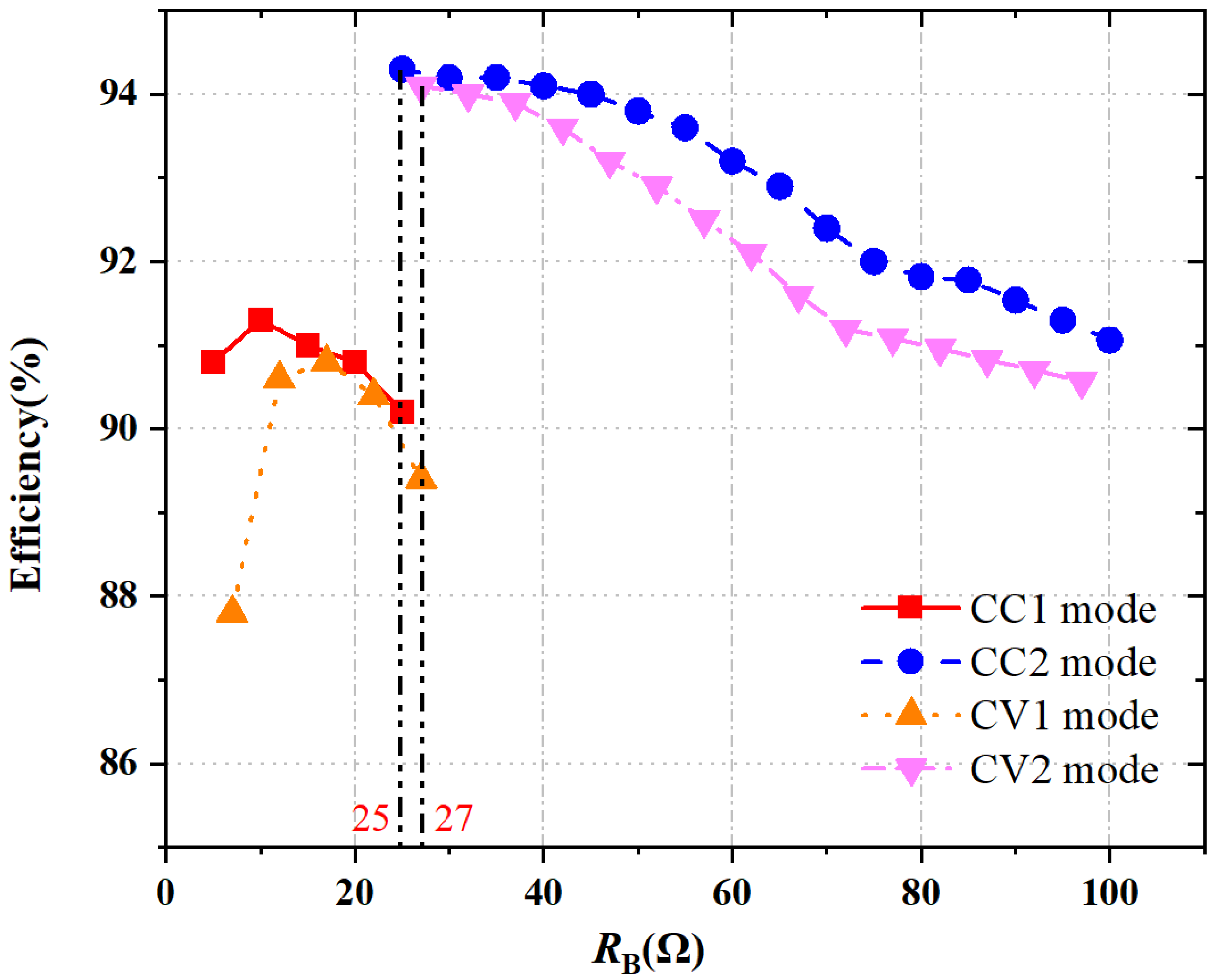

4.3. Experimental Efficiency

5. The Comprehensive Comparison Results

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.; Zhang, Z.; Yang, B.; Zhang, B.; Fu, L.; He, Z.; Mai, R. A Clamp Circuit-Based Inductive Power Transfer System with Re-configurable Rectifier Tolerating Extensive Coupling Variations. IEEE Trans. Power Electron. 2024, 39, 1942–1946. [Google Scholar] [CrossRef]

- Rong, E.; Sun, P.; Qiao, K.; Zhang, X.; Yang, G.; Wu, X. Six-plate and hybrid-dielectric capacitive coupler for underwater wireless power transfer. IEEE Trans. Power Electron. 2023, 39, 2867–2881. [Google Scholar] [CrossRef]

- Li, J.; Chen, F.; Zhu, R.; Chen, Y.; Mai, R. 3-D Embedded Receiving Coil Positioning Based on Decoupled Transformer for Wireless Sensor Power Supply System. IEEE Trans. Power Electron. 2025, 10, 14222–14227. [Google Scholar] [CrossRef]

- Liang, Z.; Zhu, L.; Sun, Y.; Li, J.; Qin, R.; Arka, B.; Costinett, D.; Bai, H. Full Integration of On-Board Charger, Auxiliary Power Module, and Wireless Charger for Electric Vehicles Using Multipurpose Magnetic Couplers. IEEE Trans. Ind. Electron. 2024, 71, 9962–9967. [Google Scholar] [CrossRef]

- Liu, X.; Gao, F.; Wang, W.H. A Series–Parallel Transformer-Based WPT System for 400-V and 800-V Electric Vehicles with Z1 or Z2 Class. IEEE Trans. Power Electron. 2024, 39, 1749–1761. [Google Scholar] [CrossRef]

- Li, G.; Ma, H. A Hybrid IPT System with High-Misalignment Tolerance and Inherent CC–CV Output Characteristics for EVs Charging Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 3152–3160. [Google Scholar] [CrossRef]

- Li, M.; Khaleghi, A.; Hasanvand, A.; Narayanan, R.P.; Balasingham, I. A New Design and Analysis for Metasurface-Based Near-Field Magnetic Wireless Power Transfer for Deep Implants. IEEE Trans. Power Electron. 2024, 39, 6442–6454. [Google Scholar] [CrossRef]

- Mukherjee, D.; Rainu, S.K.; Singh, N.; Mallick, D.; Miniaturized, A. Low-Frequency Magnetoelectric Wireless Power Transfer System for Powering Biomedical Implants. IEEE Trans. Biomed. Circuits Syst. 2024, 18, 438–450. [Google Scholar] [CrossRef] [PubMed]

- Shah, I.A.; Zada, M.; Shah, S.A.; Basir, A.; Yoo, H. Flexible Metasurface-Coupled Efficient Wireless Power Transfer System for Implantable Devices. IEEE Trans. Microw. Theory Tech. 2024, 72, 2534–2547. [Google Scholar] [CrossRef]

- Yang, L.; Dong, K.; Wang, Y.; Cai, C. Analysis and Design of a Dual-Receiver WPT System with Constant Current and Constant Voltage Dual-Type Outputs. IEEE Trans. Transp. Electrif. 2025, 11, 4060–4069. [Google Scholar] [CrossRef]

- Mai, R.; Luo, Y.; Yang, B.; Song, Y.; Liu, S.; He, Z. Decoupling circuit for automated guided vehicles IPT charging systems with dual receivers. IEEE Trans. Power Electron. 2020, 35, 6652–6657. [Google Scholar] [CrossRef]

- Cai, C.; Wang, J.; Saeedifard, M.; Zhang, P.; Chen, R.; Zhang, J. Gyrator-Gain Variable WPT Topology for MC-Unconstrained CC Output Customization Using Simplified Capacitance Tuning. IEEE Trans. Ind. Electron. 2025, 71, 3594–3605. [Google Scholar] [CrossRef]

- Yang, L.; Wang, Y.; Guo, P.; Dong, K.; Cai, C. A Reconfigurable Rectifier Based Communication-Free Wireless LED Driver with Dual-Customization CC Outputs. IEEE Trans. Power Electron. 2025, 40, 2680–2684. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Z.; Yang, B.; Lu, Y.; Mai, R.; He, Z.; Chen, Y. Inductive Power Transfer System with Constant Current-Constant Voltage Charging Tolerating Misalignment Based on Multiobjective Optimization for Compensation Topology. IEEE Trans. Power Electron. 2024, 40, 4581–4591. [Google Scholar] [CrossRef]

- Yang, L.; Xu, S.; Wang, Y.; Jiang, J.; Shi, Y.; Wang, M.; Cai, C. A Reconfigurable Magnetic Integrated Transmitter-Based Multimode WPT System for Electric Bicycle Charging. IEEE Trans. Transp. Electrif. 2025, 11, 11805–11815. [Google Scholar] [CrossRef]

- Xie, R.; Wu, Y.; Tang, H.; Zhuang, Y.; Zhang, Y. A Strongly Coupled Vehicle-to-Vehicle Wireless Charging System for Emergency Charging Purposes with Constant-Current and Constant-Voltage Charging Capabilities. IEEE Trans. Power Electron. 2024, 39, 3985–3989. [Google Scholar] [CrossRef]

- Colak, K.; Asa, E.; Bojarski, M.; Czarkowski, D.; Onar, O.C. A Novel Phase-Shift Control of Semibridgeless Active Rectifier for Wireless Power Transfer. IEEE Trans. Power Electron. 2015, 30, 6288–6297. [Google Scholar] [CrossRef]

- Song, K.; Li, Z.; Jiang, J.; Zhu, C. Constant current/voltage charging operation for series-series and series-parallel compensated wireless power transfer systems employing primary-side controller. IEEE Trans. Power Electron. 2018, 33, 8065–8080. [Google Scholar] [CrossRef]

- Liu, N.; Habetler, T.G. Design of a Universal Inductive Charger for Multiple Electric Vehicle Models. IEEE Trans. Power Electron. 2015, 30, 6378–6390. [Google Scholar] [CrossRef]

- Gati, E.; Kampitsis, G.; Manias, S. Variable Frequency Controller for Inductive Power Transfer in Dynamic Conditions. IEEE Trans. Power Electron. 2017, 32, 1684–1696. [Google Scholar] [CrossRef]

- Huang, Z.; Wong, S.; Tse, C. Comparison of Basic Inductive Power Transfer Systems with Linear Control Achieving Optimized Efffciency. IEEE Trans. Power Electron. 2020, 35, 3276–3286. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, C.; Jiang, J.; Song, K.; Chan, K.; Wei, G. A 3-kW wireless power transfer system for sightseeing car supercapacitor charge. IEEE Trans. Power Electron. 2017, 32, 3301–3316. [Google Scholar] [CrossRef]

- Qu, X.; Han, H.; Wong, S. Hybrid IPT topologies with constant current or constant voltage output for battery charging applications. IEEE Trans. Power Electron. 2015, 30, 6329–6337. [Google Scholar] [CrossRef]

- Li, Y.; Hu, J.; Liu, M.; Chen, Y.; Chan, K.; He, Z.; Mai, R. Reconfigurable Intermediate Resonant Circuit Based WPT System with Load-Independent Constant Output Current and Voltage for Charging Battery. IEEE Trans. Power Electron. 2019, 34, 1988–1992. [Google Scholar] [CrossRef]

- Mai, R.; Li, Q.; Chen, Y.; Yang, B.; He, Z. Variable parameter and variable frequency-based IPT charging system with configurable charge current and charge voltage. IET Power Electron. 2020, 13, 751–757. [Google Scholar] [CrossRef]

- Vu, V.-B.; Tran, D.-H.; Choi, W. Implementation of the constant current and constant voltage charge of inductive power transfer systems with the double-sided LCC compensation topology for electric vehicle battery charge applications. IEEE Trans Power Electron. 2018, 33, 7398–7410. [Google Scholar] [CrossRef]

- Chen, Y.; Kou, Z.; Zhang, Y.; He, Z.; Mai, R.; Cao, G. Hybrid Topology with Configurable Charge Current and Charge Voltage Output-Based WPT Charger for Massive Electric Bicycles. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 1581–1594. [Google Scholar] [CrossRef]

- Yang, L.; Shao, S.; Zhou, X. A Three-Coil IPT Charger with CC and CV Outputs Through Circuit Reconfiguration. IEEE Trans. Circuits Syst. II Express Briefs 2024, 71, 3558–3562. [Google Scholar] [CrossRef]

| Parameters | Value | Parameters | Value | Parameters | Value |

|---|---|---|---|---|---|

| f | 85 kHz | 100 V | 3 A | ||

| 2.5 A | 78 V | 65 V | |||

| 66.2 | 73.8 | 102.85 | |||

| 20 | 52.96 n | 47.51 n | |||

| 42.32 n | 41.88 n | 175.3 n | |||

| 38 | 25.8 | 30.35 |

| Parameters | Value | Parameters | Value | Parameters | Value |

|---|---|---|---|---|---|

| f | 85 kHz | 100 V | 3 A | ||

| 2.5 A | 78 V | 65 V | |||

| 67.1 | 73.92 | 102.65 | |||

| 20.3 | 51.96 n | 47.71 n | |||

| 41.82 n | 41.38 n | 175.72 n | |||

| 38.23 | 25.98 | 30.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, D.; Zang, Y.; Chen, X.; Xu, S. A Multi-Mode Wireless Power Transfer System Based on a Reconfigurable Transmitter for Charging Electric Bicycles. Electronics 2025, 14, 4315. https://doi.org/10.3390/electronics14214315

Ding D, Zang Y, Chen X, Xu S. A Multi-Mode Wireless Power Transfer System Based on a Reconfigurable Transmitter for Charging Electric Bicycles. Electronics. 2025; 14(21):4315. https://doi.org/10.3390/electronics14214315

Chicago/Turabian StyleDing, Dongshuai, Yongqi Zang, Xiteng Chen, and Shujia Xu. 2025. "A Multi-Mode Wireless Power Transfer System Based on a Reconfigurable Transmitter for Charging Electric Bicycles" Electronics 14, no. 21: 4315. https://doi.org/10.3390/electronics14214315

APA StyleDing, D., Zang, Y., Chen, X., & Xu, S. (2025). A Multi-Mode Wireless Power Transfer System Based on a Reconfigurable Transmitter for Charging Electric Bicycles. Electronics, 14(21), 4315. https://doi.org/10.3390/electronics14214315