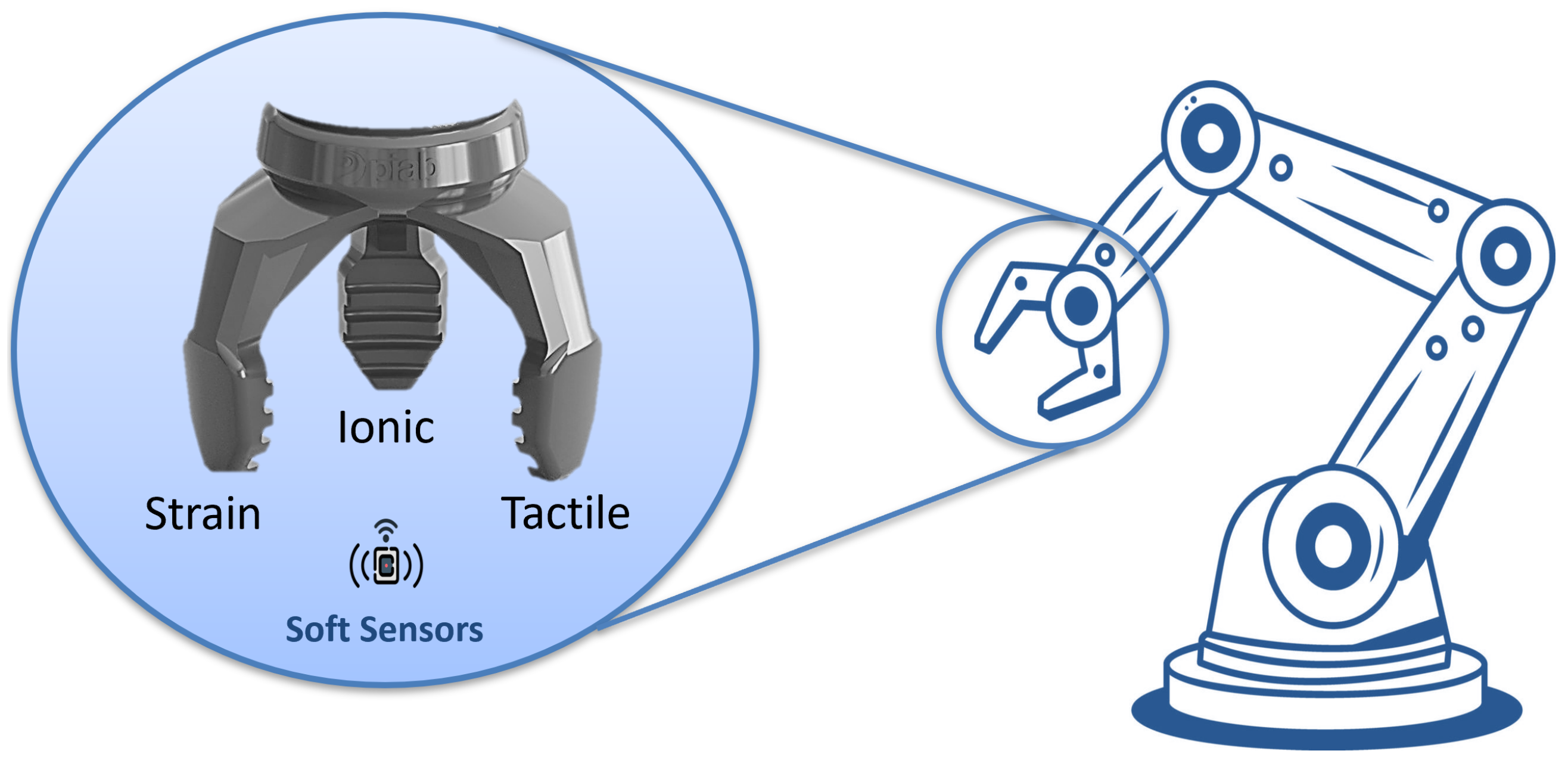

Resistive Sensing in Soft Robotic Grippers: A Comprehensive Review of Strain, Tactile, and Ionic Sensors

Abstract

1. Introduction

1.1. Robotic Grippers: Definition and Importance

1.2. Soft Robotics and Soft Grippers

1.3. The Role of Sensing in Robotic Grippers

1.4. Flexible and Resistive Sensors: An Overview

1.5. Classification of Resistive Sensors

1.6. Applications of Resistive Sensors in Soft Grippers

1.7. Materials and Fabrication Considerations

1.8. Challenges and Future Directions

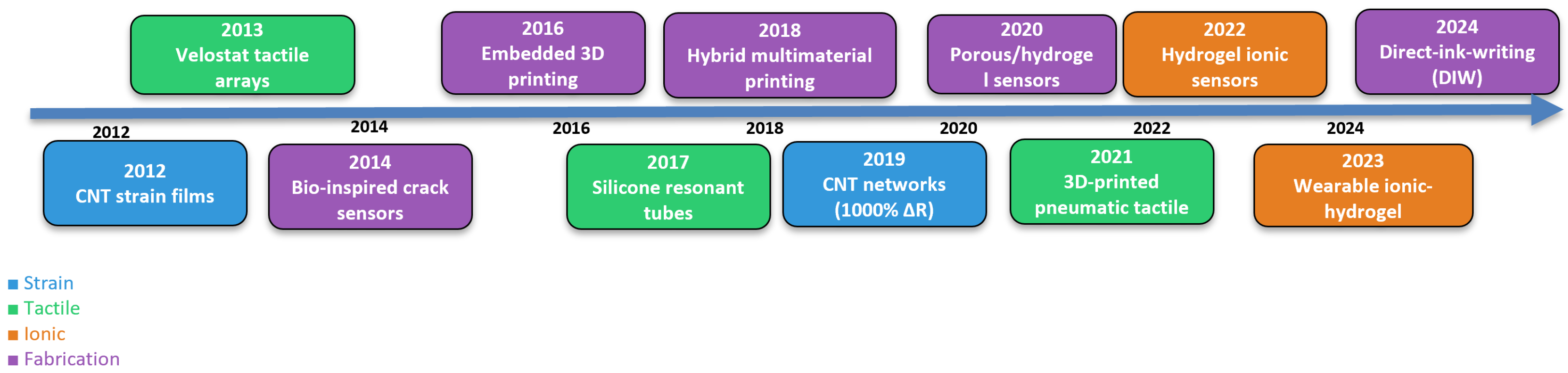

1.9. Roadmap of This Review

2. Background and Working Principles of Resistive Sensors

2.1. Fundamentals of Resistive Sensing

2.2. Relevance to Soft Robotic Grippers

2.3. Integration Considerations

3. Strain Sensor

3.1. Working Principle

3.2. Materials and Fabrication Techniques

| Material System | Structure / Fabrication | Electrical Range | Dimensions | Linearity | Ref. |

|---|---|---|---|---|---|

| Dragon Skin 30 elastomer + MWCNTs (non-conductive elastic pillar) | Spiral conductive fiber wound on an elastic base pillar | – | Spiral fiber ⌀ 0.6 mm | Linearity | [137] |

| Conductive PLA | Direct 3D printing | ∼15–27 k | 52 × 19 mm; track thickness 0.3 mm | Most | [144] |

| Carbon Nanotubes (CNTs) | Serpentine-shaped stretchable interconnects (curved arc of 260°) | Resistance changes up to 1300% at 11% strain | CNT density: 3 CNT/m2 @ 5 V; 5.67 CNT/m2 @ 15 V | Linear behavior up to 9% strain | [145] |

| Conductive TPU-based filament | Piezoresistive layer-by-layer FDM printing on TPU substrate | – | 130 × 10 × 0.3 mm | Linear up to 5% strain | [103] |

| Conductive TPU (CTPU) | 3D printing | 14.48 k (rest) → 12.45 k (at 300 kPa) | 130 × 10 × 0.3 mm | Linear up to 5% strain | [146] |

| Soft silicone elastomers | Molded air-filled microchannels (pneumatic strain gauge) | Supply pressure 60 kPa; resistance 0.71–1.2 (normalized) | 183 mm length; channel 200 m × 200 m | Nonlinear behavior | [147] |

3.3. Representative Sensor Materials and Structures

3.4. Discussion of Trends

- Sensitivity (Gauge Factor, GF): (GF stands for gauge factor, which is the ratio of applied strain to relative resistance change ) The gauge factor is commonly expressed asrepresenting the capacity to detect minute deformations. Due to conductive network rearrangements, CNT-based sensors exhibit maximum sensitivity, with resistance variations of 1000% under strains of only 10–11% [137,145]. On the other hand, sensors built on PLA and TPU have moderate sensitivity but offer consistent performance across a wider range of strains [103,144,146].

- Linearity: Conductive PLA sensors demonstrate excellent linearity across bending motions [144], and TPU-based sensors maintain predictable linear responses up to 30% strain [103,146]. By comparison, CNT and silicone-based systems often exhibit nonlinear behavior, especially at higher strains [137,145,147].

- Hysteresis: Adjusting the conducting network and elastic relaxation in the polymer matrix are common ways to introduce hysteresis. While TPU-based sensors often exhibit reduced hysteresis, ensuring repeatability across cycles [103,146], CNT composites and silicone elastomers generally show higher hysteresis [145,147].

- Durability: TPU-based printed sensors demonstrate strong cycle stability and tolerate repeated bending without significant drift [103,146]. Although CNT sensors are extremely sensitive, they might fail if stretchy interconnects are not used to support them [145]. Long-term operation is demonstrated by pneumatic silicone gauges, although extended usage may cause signal drift [147].

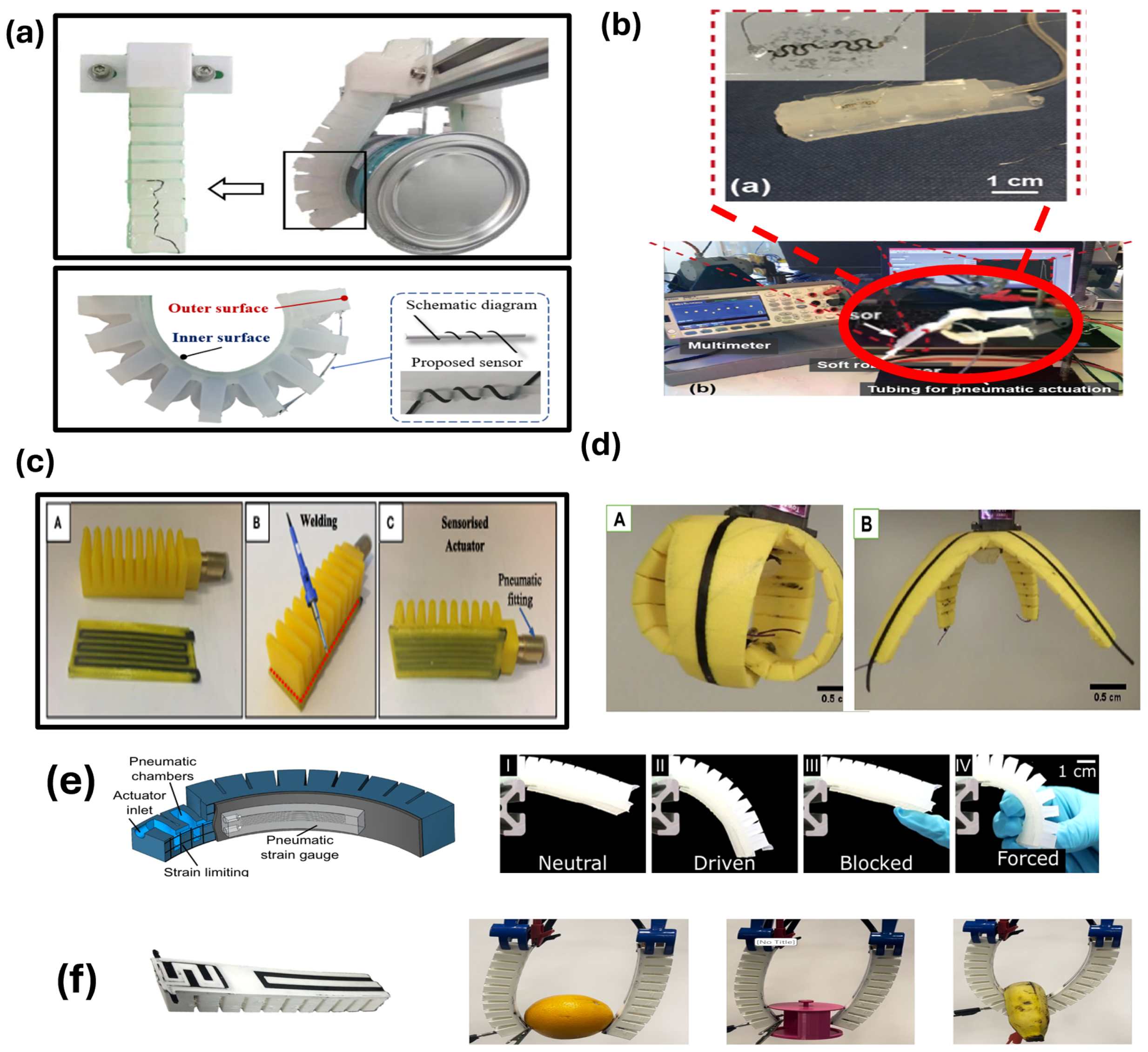

3.5. Integration with Soft Robotic Grippers

3.6. Applications, Challenges, and Future Directions

4. Tactile Sensor

4.1. Transduction Mechanisms of Tactile Sensing in Soft Robotic Grippers

4.2. Materials, Fabrication, and Structural Considerations of Tactile Sensors

4.3. Performance Metrics and Sensor Characteristics

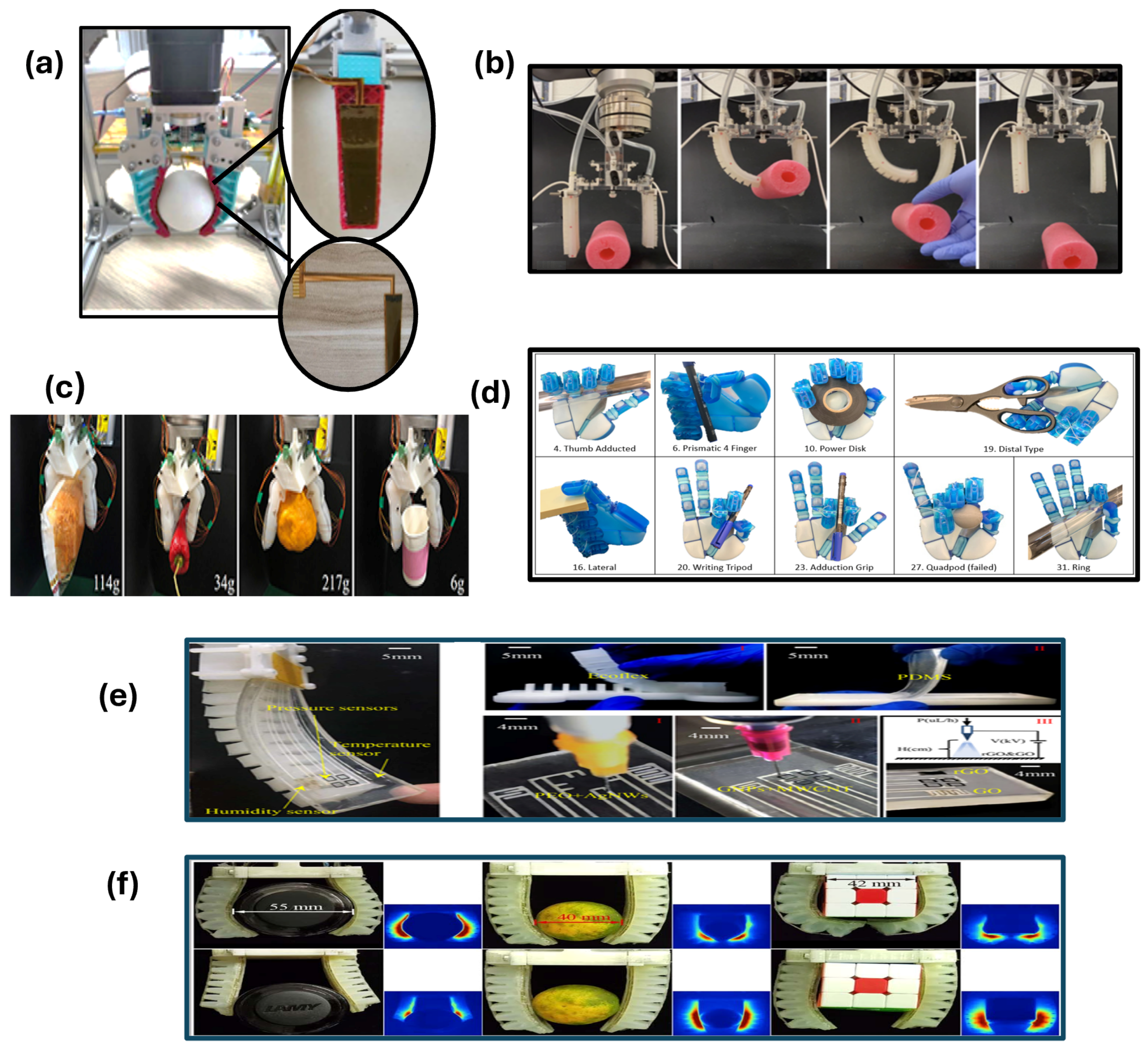

4.4. Integration with Soft Robotic Grippers

4.5. Applications and Emerging Directions of Tactile Sensors for Soft Robotic Manipulation

5. Ionic Sensor

5.1. Multimodal Sensing Principles of Ionic Sensor

5.2. Materials, Fabrication, and Structural Considerations

Materials

Hydrogels and ionogels are the two main types of materials. Ionic liquids (like EMIM-ES) are distributed throughout a silica matrix to form ionogels, like those created by Truby et al. [178,179]. They are appropriate for embedding into soft actuators because they combine mechanical compliance with high ionic conductivity. Double-network architectures and glycerol-based additives are used in hydrogels, like the Alg-PAAm networks described by Zhou et al. [180], to improve their stretchability, water retention, and antifreezing characteristics. Given that poor adhesion can result in delamination under cyclic strain, the hydrogel–elastomer interface is especially crucial.

Fabrication

One popular method for adding ionogels straight into elastomeric matrices is embedded 3D printing, or EMB3D. In order to enable complex sensor geometries (such as U-shaped curvature sensors, inflation sensors, and fingertip tactile pads), Truby et al. [179] showed how to precisely deposit ionogel inks into pre-cast silicone channels. This method ensures that electrical pathways stay compliant with actuator deformation by enabling direct multimaterial integration. Simultaneously, Zhou et al. [180] created hydrogel sensors by encapsulating them in EcoFlex layers after in situ polymerization within elastomeric molds. This approach strikes a balance between ionic mobility preservation over wide temperature ranges and mechanical robustness.

Structural considerations

The sensing function determines the device architecture. Pressure sensors are inserted around pneumatic chambers to measure internal pressure, whereas curvature sensors usually use long tracks aligned along the bending axis. Since mechanical deformation is concentrated at the fingertip, tactile sensors frequently employ localized pads there. By varying electrode thickness and dielectric spacing, multilayer stacking (hydrogel electrodes + EcoFlex dielectric) in capacitive hydrogel sensors offers tunable sensitivity. Structural compliance and durability under repeated actuation continue to be major challenges in all designs, especially when it comes to preserving stable interfaces and preventing ionic liquid leakage. These material and fabrication strategies for ionic sensors are summarized in Table 7, which compares different ionogel and hydrogel sensor types, their compositions, fabrication methods, and structural configurations for soft robotic applications.

| Sensor Type | Material Composition | Fabrication Method | Structural Configuration | Ref. |

|---|---|---|---|---|

| Curvature Sensor (Ionogel) | Ionogel (EMIM-ES + silica) in silicone elastomer | Embedded 3D printing (EMB3D) | U-shaped printed trace along bending axis | [178] |

| Inflation Sensor (Ionogel) | Ionogel matrix (same as above) | EMB3D deposition in pneumatic chamber wall | Circumferential trace around actuator chamber | |

| Tactile Sensor (Ionogel) | Ionogel fingertip pads | EMB3D deposition at fingertip regions | Localized fingertip pads integrated in fingertip | [179] |

| Strain Sensor (Hydrogel) | Double-network Alg-PAAm hydrogel + glycerol additive | In situ polymerization + EcoFlex encapsulation | U-shaped bonded hydrogel trace | |

| Capacitive Tactile Sensor (Hydrogel) | Hydrogel electrodes + EcoFlex dielectric layer | Multilayer assembly | Stacked capacitive sandwich structure | [180] |

5.3. Performance Metrics and Sensor Characteristics

Curvature and inflation sensing

Ionogel-based curvature and inflation sensors integrated into pneumatic actuators were demonstrated by Truby et al. [179]. They demonstrated dependable pressure detection over tens of kPa and linear resistance changes with bending angles up to approximately 90°. Because of their low hysteresis during cyclic bending, the sensors can be used to continuously monitor actuator deformation.

Tactile sensing

Truby et al. [178] reported fingertip-integrated ionogel pads that can distinguish between slip, deep compression, and fine touch. Although the tactile sensors’ resistance response was nonlinear, this nonlinearity helped them distinguish between different surface textures and force levels. The system demonstrated the potential of tactile sensing for intelligent manipulation tasks by enabling object recognition through machine learning.

Hydrogel strain and capacitive sensors

Hydrogel-based strain sensors with stretchable and antifreezing qualities were created by Zhou et al. [180] and maintained a steady electrical response at −20 °C. Strong adherence of the double-network hydrogel to elastomer substrates permitted repeated strain cycles without delamination. Additionally, linear capacitance–pressure relationships were offered by capacitive hydrogel tactile sensors, which demonstrated consistent performance over a broad load range.

General trends

Ionic sensors provide a unique edge in mechanical compliance and multifunctionality across all designs, allowing for simultaneous tactile, pressure, and curvature detection in a single device. Long-term stability, especially for hydrogel-based systems that are subject to dehydration, and achieving high signal-to-noise ratios in practical manipulation are still difficulties, in any case. A schematic overview of the structural configurations, fabrication strategies, and comparative performance of these ionic sensors is illustrated in Figure 9.

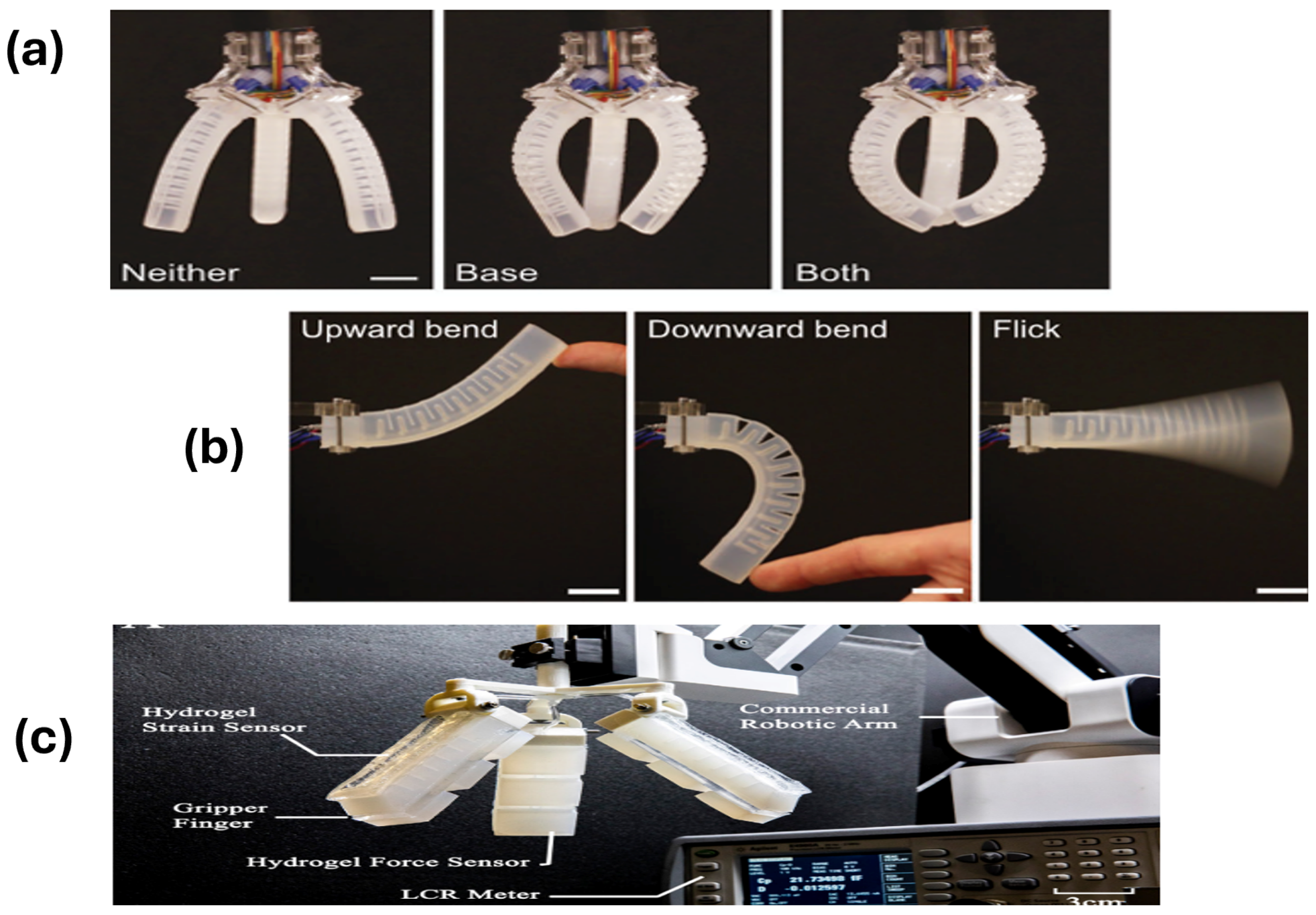

5.4. Integration with Soft Robotic Grippers

Challenges and outlook

Despite these advances, integration challenges remain. Long-term stability is hindered by water loss in hydrogels and interfacial degradation under cyclic loading. Moreover, routing multiple sensing channels through compact grippers complicates electrical interconnect design. Future work should focus on robust encapsulation strategies, wireless data transmission, and modular architectures that balance sensing density with mechanical compliance.

5.5. Applications and Emerging Directions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cortinovis, S.; Vitrani, G.; Maggiali, M.; Romeo, R.A. Control methodologies for robotic grippers: A review. Actuators 2023, 12, 332. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Z. Review of robotic grippers for high-speed handling of fragile foods. Adv. Robot. 2025, 39, 1054–1070. [Google Scholar] [CrossRef]

- Hernandez, J.; Sunny, M.S.H.; Sanjuan, J.; Rulik, I.; Zarif, M.I.I.; Ahamed, S.I.; Ahmed, H.U.; Rahman, M.H. Current designs of robotic arm grippers: A comprehensive systematic review. Robotics 2023, 12, 5. [Google Scholar] [CrossRef]

- Dubey, V.N.; Crowder, R.M. Grasping and control issues in adaptive end effectors. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Salt Lake City, UT, USA, 28 September–2 October 2004; ASME: New York, NY, USA, 2004; Volume 46954, pp. 327–335. [Google Scholar]

- Monkman, G.J. Robot Grippers; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar]

- Zhu, W.; Lu, C.; Zheng, Q.; Fang, Z.; Che, H.; Tang, K.; Zhu, M.; Liu, S.; Wang, Z. A soft–rigid hybrid gripper with lateral compliance and dexterous in-hand manipulation. IEEE/ASME Trans. Mechatron. 2022, 28, 104–115. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft robotic grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef]

- Shembekar, S.; Kamezaki, M.; Zhang, P.; He, Z.; Tsunoda, R.; Otsuki, K.; Sakamoto, H.; Sugano, S. Preliminary development of a powerful and backdrivable robot gripper using magnetorheological fluid. In Proceedings of the International Symposium on Automation and Robotics in Construction (ISARC), Kitakyushu, Japan, 27–28 October 2020; IAARC Publications: Singapore, 2020; Volume 37, pp. 1458–1463. [Google Scholar]

- Dontu, S.; Kanhere, E.; Stalin, T.; Dharmawan, A.G.; Hegde, C.; Su, J.; Chen, X.; Magdassi, S.; Soh, G.S.; Valdivia, Y.; et al. Applications of a vacuum-actuated multi-material hybrid soft gripper: Lessons learnt from RoboSoft manipulation challenge. Front. Robot. 2024, 11, 1356692. [Google Scholar] [CrossRef]

- Phanomchoeng, G.; Pitchayawetwongsa, P.; Boonchumanee, N.; Lin, S.; Chancharoen, R. Grasping profile control of a soft pneumatic robotic gripper for delicate gripping. Robotics 2023, 12, 107. [Google Scholar] [CrossRef]

- Visentin, F.; Castellini, F.; Muradore, R. A soft, sensorized gripper for delicate harvesting of small fruits. Comput. Electron. Agric. 2023, 213, 108202. [Google Scholar] [CrossRef]

- Rahman, M.M.; Shahria, M.T.; Sunny, M.S.H.; Khan, M.M.R.; Islam, E.; Swapnil, A.A.Z.; Bedolla-Martínez, D.; Rahman, M.H. Development of a three-finger adaptive robotic gripper to assist activities of daily living. Designs 2024, 8, 35. [Google Scholar] [CrossRef]

- Bruzzone, L.; Nodehi, S.E.; De Domenico, D.; Fanghella, P. Whetlhloc: Small-scale hybrid locomotion robot with stair climbing capability. J. Mech. Robot. 2024, 16, 021007. [Google Scholar] [CrossRef]

- Nodehi, S.E.; Bruzzone, L.; Fanghella, P. Porcospino, spined single-track mobile robot for inspection of narrow spaces. Robotica 2023, 41, 3446–3462. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, X.; Zhang, S.; Nie, J. Development of a novel shape memory alloy-actuated resettable locking device for magnetic bearing reaction wheel. Rev. Sci. Instrum. 2014, 85, 015006. [Google Scholar] [CrossRef]

- AboZaid, Y.A.; Aboelrayat, M.T.; Fahim, I.S.; Radwan, A.G. Soft robotic grippers: A review on technologies, materials, and applications. Sens. Actuators A Phys. 2024, 372, 115380. [Google Scholar] [CrossRef]

- Liu, M.; Hao, L.; Zhang, W.; Zhao, Z. A novel design of shape-memory alloy-based soft robotic gripper with variable stiffness. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420907813. [Google Scholar] [CrossRef]

- Correll, N.; Kriegman, D.; Otto, S.; Watson, J. A versatile robotic hand with 3D perception, force sensing for autonomous manipulation. arXiv 2024, arXiv:2402.06018. [Google Scholar] [CrossRef]

- Bruzzone, L.; Nodehi, S.E.; Berselli, G.; Fanghella, P. Energy efficiency of a SCARA-like manipulator with elastic balancing. In Proceedings of the International Workshop IFToMM for Sustainable Development Goals, Bilbao, Spain, 22–23 June 2023; Springer: Cham, Switzerland, 2023; pp. 65–72. [Google Scholar]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef] [PubMed]

- Yasa, O.; Toshimitsu, Y.; Michelis, M.Y.; Jones, L.S.; Filippi, M.; Buchner, T.; Katzschmann, R.K. An overview of soft robotics. Annu. Rev. Control. Robot. Auton. Syst. 2023, 6, 1–29. [Google Scholar] [CrossRef]

- Trivedi, D.; Rahn, C.D.; Kier, W.M.; Walker, I.D. Soft robotics: Biological inspiration, state of the art, and future research. Appl. Bionics Biomech. 2008, 5, 99–117. [Google Scholar] [CrossRef]

- Kim, S.; Laschi, C.; Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef]

- Laschi, C.; Mazzolai, B.; Cianchetti, M. Soft robotics: Technologies and systems pushing the boundaries of robot abilities. Sci. Robot. 2016, 1, eaah3690. [Google Scholar] [CrossRef]

- Okamura, A.M.; Matarić, M.J.; Christensen, H.I. Medical and health-care robotics. IEEE Robot. Autom. Mag. 2010, 17, 26–37. [Google Scholar] [CrossRef]

- Morar, C.A.; Doroftei, I.-A.; Doroftei, I.; Hagan, M.G. Robotic applications on agricultural industry: A review. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 9th International Conference on Advanced Concepts in Mechanical Engineering—ACME 2020, Iași, Romania, 4–5 June 2020; IOP Publishing: Bristol, UK, 2020; Volume 997, p. 012081. [Google Scholar]

- Wang, Z.; Hirai, S.; Kawamura, S. Challenges and opportunities in robotic food handling: A review. Front. Robot. 2022, 8, 789107. [Google Scholar] [CrossRef]

- Bogue, R. The role of robots in environmental monitoring. Ind. Robot. Int. J. Robot. Res. Appl. 2023, 50, 369–375. [Google Scholar] [CrossRef]

- Zhang, Z.; Fan, W.; Long, Y.; Dai, J.; Luo, J.; Tang, S.; Lu, Q.; Wang, X.; Wang, H.; Chen, G. Hybrid-driven origami gripper with variable stiffness and finger length. Cyborg Bionic Syst. 2024, 5, 0103. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Li, Y.; Wang, Q.; Lyu, Z. Integrated actuation and sensing: Toward intelligent soft robots. Cyborg Bionic Syst. 2024, 5, 0105. [Google Scholar] [CrossRef]

- Hughes, J.; Culha, U.; Giardina, F.; Guenther, F.; Rosendo, A.; Iida, F. Soft manipulators and grippers: A review. Front. Robot. 2016, 3, 69. [Google Scholar] [CrossRef]

- Deimel, R.; Brock, O. A novel type of compliant and underactuated robotic hand for dexterous grasping. Int. J. Robot. Res. 2016, 35, 161–185. [Google Scholar] [CrossRef]

- Polygerinos, P.; Correll, N.; Morin, S.A.; Mosadegh, B.; Onal, C.D.; Petersen, K.; Cianchetti, M.; Tolley, M.T.; Shepherd, R.F. Soft robotics: Review of fluid-driven intrinsically soft devices; manufacturing, sensing, control, and applications in human-robot interaction. Adv. Eng. Mater. 2017, 19, 1700016. [Google Scholar] [CrossRef]

- Ying, B.; Liu, X. Skin-like hydrogel devices for wearable sensing, soft robotics and beyond. iScience 2021, 24, 111. [Google Scholar] [CrossRef]

- Xiong, J.; Chen, J.; Lee, P.S. Functional fibers and fabrics for soft robotics, wearables, and human–robot interface. Adv. Mater. 2021, 33, 2002640. [Google Scholar] [CrossRef]

- Takács, K.; Mason, A.; Christensen, L.B.; Haidegger, T. Robotic grippers for large and soft object manipulation. In Proceedings of the 2020 IEEE 20th International Symposium on Computational Intelligence and Informatics (CINTI), Budapest, Hungary, 5–7 November 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 133–138. [Google Scholar]

- Santiago, J.L.C.; Godage, I.S.; Gonthina, P.; Walker, I.D. Soft robots and kangaroo tails: Modulating compliance in continuum structures through mechanical layer jamming. Soft Robot. 2016, 3, 54–63. [Google Scholar] [CrossRef]

- Billard, A.; Kragic, D. Trends and challenges in robot manipulation. Science 2019, 364, eaat8414. [Google Scholar] [CrossRef]

- Saudabayev, A.; Varol, H.A. Sensors for robotic hands: A survey of state of the art. IEEE Access 2015, 3, 1765–1782. [Google Scholar] [CrossRef]

- Murray, M.; Gupta, A.; Cakmak, M. Learning to grasp in clutter with interactive visual failure prediction. In Proceedings of the 2024 IEEE International Conference on Robotics and Automation (ICRA), Yokohama, Japan, 13–17 May 2024; pp. 18172–18178. [Google Scholar]

- Kumra, S.; Joshi, S.; Sahin, F. Gr-convnet v2: A real-time multi-grasp detection network for robotic grasping. Sensors 2022, 22, 6208. [Google Scholar] [CrossRef]

- Huang, X.; Halwani, M.; Muthusamy, R.; Ayyad, A.; Swart, D.; Seneviratne, L.; Gan, D.; Zweiri, Y. Real-time grasping strategies using event camera. J. Intell. Manuf. 2022, 33, 593–615. [Google Scholar] [CrossRef]

- Ivanov, V.; Andrusyshyn, V.; Pavlenko, I.; Pitel’, J.; Bulej, V. New classification of industrial robotic gripping systems for sustainable production. Sci. Rep. 2024, 14, 295. [Google Scholar] [CrossRef]

- Dou, W.; Zhong, G.; Cao, J.; Shi, Z.; Peng, B.; Jiang, L. Soft robotic manipulators: Designs, actuation, stiffness tuning, and sensing. Adv. Mater. Technol. 2021, 6, 2100018. [Google Scholar] [CrossRef]

- Takács, K.; Takács, B.; Garamvölgyi, T.; Tarsoly, S.; Alexy, M.; Móga, K.; Rudas, I.J.; Galambos, P.; Haidegger, T. Sensor-Enhanced Smart Gripper Development for Automated Meat Processing. Sensors 2024, 24, 4631. [Google Scholar] [CrossRef]

- Dilibal, S.; Sahin, H.; Danquah, J.O.; Emon, M.O.F.; Choi, J.W. Additively Manufactured Custom Soft Gripper with Embedded Soft Force Sensors for an Industrial Robot. Int. J. Precis. Eng. Manuf. 2021, 22, 709–718. [Google Scholar] [CrossRef]

- Saleem, Z.; Gustafsson, F.; Furey, E.; McAfee, M.; Huq, S. A Review of External Sensors for Human Detection in a Human Robot Collaborative Environment. J. Intell. Manuf. 2025, 36, 2255–2279. [Google Scholar] [CrossRef]

- Pagoli, A.; Chapelle, F.; Corrales-Ramon, J.-A.; Mezouar, Y.; Lapusta, Y. Large-Area and Low-Cost Force/Tactile Capacitive Sensor for Soft Robotic Applications. Sensors 2022, 22, 4083. [Google Scholar] [CrossRef] [PubMed]

- Mun, H.; Diaz Cortes, D.S.; Youn, J.-H.; Kyung, K.-U. Multi-Degree-of-Freedom Force Sensor Incorporated into Soft Robotic Gripper for Improved Grasping Stability. Soft Robot. 2024, 11, 628–638. [Google Scholar] [CrossRef] [PubMed]

- Sabir, H.M.S.; Mehmood, A.; Tahir, M.H.; Tahir, M.S.; Elahi, H.; Tayyab, M.A. Materials Classification via Piezoelectric Sensors for Robotic Grippers. In Proceedings of the 2024 International Conference on Robotics and Automation in Industry (ICRAI), Rawalpindi, Pakistan, 18–19 December 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–5. [Google Scholar]

- MostaghniYazdi, D.; Khalid, M.U.; Frascio, M.; Zoppi, M. Design and fabrication of resistive sensor using additive manufacturing techniques for robotic application. Int. J. Adv. Manuf. Technol. 2025, 139, 1711–1721. [Google Scholar] [CrossRef]

- Lee, H.K.; Chang, S.I.; Yoon, E. A flexible polymer tactile sensor: Fabrication and modular expandability for large area deployment. J. Microelectromech. Syst. 2006, 15, 1681–1686. [Google Scholar] [CrossRef]

- Dahiya, R.S.; Metta, G.; Valle, M.; Sandini, G. Tactile sensing—From humans to humanoids. IEEE Trans. Robot. 2009, 26, 1–20. [Google Scholar] [CrossRef]

- Yang, M.; Liu, Q.; Naqawe, H.S.; Fok, M.P. Movement detection in soft robotic gripper using sinusoidally embedded fiber optic sensor. Sensors 2020, 20, 1312. [Google Scholar] [CrossRef]

- Kim, M.; Jang, K.W.; Yoo, W.J.; Lee, B. Development of a flexible variable-view angioscopy system using face-angled GRIN lenses to enhance field of vision. Sens. Actuators A Phys. 2017, 263, 259–263. [Google Scholar] [CrossRef]

- Amjadi, M.; Kyung, K.-U.; Park, I.; Sitti, M. Stretchable, skin-mountable, and wearable strain sensors and their potential applications: A review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Shih, B.; Christianson, C.; Gillespie, K.; Lee, S.; Mayeda, J.; Huo, Z.; Tolley, M.T. Design considerations for 3D printed, soft, multimaterial resistive sensors for soft robotics. Front. Robot. AI 2019, 6, 30. [Google Scholar] [CrossRef]

- Tarhan, B.; Asif, S.; Webb, P.; Chacin, M. A review of flexible robotic gripping systems. Front. Manuf. Technol. 2025, 5, 1517727. [Google Scholar] [CrossRef]

- Landi, E.; Baldi, T.L.; Papenbrock, J.; Facello, A.; Prato, A.; Schiavi, A.; Prattichizzo, D.; Fort, A. Sensorizing Flexible Joints for Soft Robots: A Feasibility Study. In Proceedings of the 2025 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Padua, Italy, 19–22 May 2025; pp. 1–6. [Google Scholar]

- Shu, Q.; Pang, Y.; Li, Q.; Gu, Y.; Liu, Z.; Liu, B.; Li, J.; Li, Y. Flexible Resistive Tactile Pressure Sensors. J. Mater. Chem. A 2024, 12, 9296–9321. [Google Scholar] [CrossRef]

- Zhou, X.; Cao, W. Flexible and Stretchable Carbon-Based Sensors and Actuators for Soft Robots. Nanomaterials 2023, 13, 316. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, G.; Xue, Y.; Duan, Q.; Liang, X.; Lin, T.; Wu, Z.; Tan, Y.; Zhao, Q.; Zheng, W.; et al. Fatigue-Resistant Conducting Polymer Hydrogels as Strain Sensor for Underwater Robotics. Adv. Funct. Mater. 2023, 33, 2305705. [Google Scholar] [CrossRef]

- Wang, S.; Sun, Z.; Zhao, Y.; Zuo, L. A Highly Stretchable Hydrogel Sensor for Soft Robot Multi-Modal Perception. Sens. Actuators A Phys. 2021, 331, 113006. [Google Scholar] [CrossRef]

- Hegde, C.; Su, J.; Tan, J.M.R.; He, K.; Chen, X.; Magdassi, S. Sensing in Soft Robotics. ACS Nano 2023, 17, 15277–15307. [Google Scholar] [CrossRef]

- Butt, M.A. Photonics on a budget: Low-cost polymer sensors for a smarter world. Micromachines 2025, 16, 813. [Google Scholar] [CrossRef]

- Goh, G.L.; Yeong, W.Y.; Altherr, J.; Tan, J.; Campolo, D. 3D Printing of Soft Sensors for Soft Gripper Applications. Mater. Today Proc. 2022, 70, 224–229. [Google Scholar] [CrossRef]

- Rana, M.T.; Islam, M.S.; Rahman, A. Human-Centered Sensor Technologies for Soft Robotic Grippers: A Comprehensive Review. Sensors 2025, 25, 1508. [Google Scholar] [CrossRef]

- Saxena, A.; Patra, K. Fabrication and Characterization of Human Finger Ridge-Inspired Soft Elastomeric Pressure Sensor with Liquid Metal-Embedded Microchannels. Polym. Int. 2024, 73, 970–980. [Google Scholar] [CrossRef]

- Pyo, S.; Eun, Y.; Sim, J.; Kim, K.; Choi, J. Carbon Nanotube–Graphene Hybrids for Soft Electronics, Sensors, and Actuators. Micro Nano Syst. Lett. 2022, 10, 9. [Google Scholar] [CrossRef]

- Homberg, B.S.; Katzschmann, R.K.; Dogar, M.R.; Rus, D. Haptic Identification of Objects Using a Modular Soft Robotic Gripper. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; pp. 1698–1705. [Google Scholar]

- Chen, W.; Khamis, H.; Birznieks, I.; Lepora, N.F.; Redmond, S.J. Tactile Sensors for Friction Estimation and Incipient Slip Detection—Toward Dexterous Robotic Manipulation: A Review. IEEE Sens. J. 2018, 18, 9049–9064. [Google Scholar] [CrossRef]

- Huang, J.; Guo, Y.; Jiang, Y.; Wang, F.; Pan, L.; Shi, Y. Recent Advances and Future Prospects in Tactile Sensors for Normal and Shear Force Detection, Decoupling, and Applications. J. Semicond. 2024, 45, 121601. [Google Scholar] [CrossRef]

- Suchal, S.; Arezzo, A.; Miodownik, M.; Spurgeon, S.; Wurdemann, H. Towards Actuating Soft Robotic Manipulators for MIS Using Stiffness-Controllable Low Melting Point Material. In Proceedings of the CRAS 2018 Workshop Program, London, UK, 10–11 September 2018; Volume 14, p. e1875. [Google Scholar]

- Zhang, Q.; Li, N.; Song, Y.; Hua, C.; Guan, T.; Ma, Y.; Cheng, C.; Liu, J. Liquid Metal Sensors for Soft Robots. Adv. Robot. Res. 2025, 1, 202500057. [Google Scholar] [CrossRef]

- Alexandre, E.B. Complex-Structured 3D Printed Electronic Skin for Artificial Tactile Sensing. Master’s Thesis, King Abdullah University of Science and Technology, Thuwal, Saudi Arabia, 2022. [Google Scholar]

- Larson, C.; Peele, B.; Li, S.; Robinson, S.; Totaro, M.; Beccai, L.; Mazzolai, B.; Shepherd, R. Highly Stretchable Electroluminescent Skin for Optical Signaling and Tactile Sensing. Science 2016, 351, 1071–1074. [Google Scholar] [CrossRef]

- Zuo, R.; Zhou, Z.; Ying, B.; Liu, X. A Soft Robotic Gripper with Anti-Freezing Ionic Hydrogel-Based Sensors for Learning-Based Object Recognition. In Proceedings of the 2021 IEEE International Conference on Robotics and Automation (ICRA), Xi’an, China, 30 May–5 June 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 12164–12169. [Google Scholar]

- Liu, Z.; Wang, Y.; Ren, Y.; Jin, G.; Zhang, C.; Chen, W.; Yan, F. Poly (Ionic Liquid) Hydrogel-Based Anti-Freezing Ionic Skin for a Soft Robotic Gripper. Mater. Horiz. 2020, 7, 919–927. [Google Scholar] [CrossRef]

- Lei, Z.; Wang, Q.; Sun, S.; Zhu, W.; Wu, P. A Bioinspired Mineral Hydrogel as a Self-Healable, Mechanically Adaptable Ionic Skin for Highly Sensitive Pressure Sensing. Adv. Mater. 2017, 29, 1700321. [Google Scholar] [CrossRef] [PubMed]

- Wan, S.; Wan, P.; Li, S.; Wang, J.; Huang, H.; Jin, J.; Li, S.; He, X.; Su, S.; Bi, H.; et al. A Highly Sensitive Iontronic Pressure Sensor for High Pressure Range Monitoring. IEEE Sens. J. 2025, 25, 10766–10774. [Google Scholar] [CrossRef]

- Hao, Y.; Zhang, S.; Fang, B.; Sun, F.; Liu, H.; Li, H. A Review of Smart Materials for the Boost of Soft Actuators, Soft Sensors, and Robotics Applications. Chin. J. Mech. Eng. 2022, 35, 37. [Google Scholar] [CrossRef]

- Ros, R.; Baroni, I.; Demiris, Y. Adaptive Human–Robot Interaction in Sensorimotor Task Instruction: From Human to Robot Dance Tutors. Robot. Auton. Syst. 2014, 62, 707–720. [Google Scholar] [CrossRef]

- Yamaguchi, A.; Atkeson, C.G. Recent Progress in Tactile Sensing and Sensors for Robotic Manipulation: Can We Turn Tactile Sensing into Vision? Adv. Robot. 2019, 33, 661–673. [Google Scholar] [CrossRef]

- Kappassov, Z.; Corrales, J.-A.; Perdereau, V. Tactile Sensing in Dexterous Robot Hands. Robot. Auton. Syst. 2015, 74, 195–220. [Google Scholar] [CrossRef]

- Liu, Y.; Hou, J.; Li, C.; Wang, X. Intelligent Soft Robotic Grippers for Agricultural and Food Product Handling: A Brief Review with a Focus on Design and Control. Adv. Intell. Syst. 2023, 5, 2300233. [Google Scholar] [CrossRef]

- Nnadi, S.N.; Aliyu, A.; Elgeneidy, K.; Rahmani, A.; Sohani, B. Versatile Multimodal Strain Sensors for Responsive Soft Robot Applications. In Proceedings of the 2024 10th International Conference on Electrical Engineering, Control and Robotics (EECR), Guangzhou, China, 29–31 March 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 124–128. [Google Scholar]

- Zhao, C.; Wang, Y.; Tang, G.; Ru, J.; Zhu, Z.; Li, B.; Guo, C.F.; Li, L.; Zhu, D. Ionic Flexible Sensors: Mechanisms, Materials, Structures, and Applications. Adv. Funct. Mater. 2022, 32, 2110417. [Google Scholar] [CrossRef]

- Giovanelli, D.; Farella, E. Force Sensing Resistor and Evaluation of Technology for Wearable Body Pressure Sensing. J. Sens. 2016, 2016, 9391850. [Google Scholar] [CrossRef]

- Romeo, R.A.; Zollo, L. Methods and Sensors for Slip Detection in Robotics: A Survey. IEEE Access 2020, 8, 73027–73050. [Google Scholar] [CrossRef]

- Pohtongkam, S.; Srinonchat, J. Object Recognition for Humanoid Robots Using Full Hand Tactile Sensor. IEEE Access 2023, 11, 20284–20297. [Google Scholar] [CrossRef]

- Scholz, C.; Cao, H.-L.; Imrith, E.; Roshandel, N.; Firouzipouyaei, H.; Burkiewicz, A.; Amighi, M.; Menet, S.; Sisavath, D.W.; Paolillo, A.; et al. Sensor-Enabled Safety Systems for Human-Robot Collaboration: A Review. IEEE Sens. J. 2024, 25, 65–88. [Google Scholar] [CrossRef]

- Rademaekers, S.T.J.; Kuling, I.A.; van Beek, F.E.; Fattori, M.; Overvelde, J.T.B. Soft Sensors for a Pneumatic Gripper. Master’s Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2022. [Google Scholar]

- Lv, J.; Luo, L.; Chen, J.; Liu, S.; Chen, M.; Wang, J.; Wei, H.; Lu, Q. Design and Fabrication of Flexible Composite Tactile Sensors for Robotic Soft Grippers. IEEE Sens. J. 2023, 24, 2482–2490. [Google Scholar] [CrossRef]

- Qu, J.; Cui, G.; Li, Z.; Fang, S.; Zhang, X.; Liu, A.; Han, M.; Liu, H.; Wang, X.; Wang, X. Advanced Flexible Sensing Technologies for Soft Robots. Adv. Funct. Mater. 2024, 34, 2401311. [Google Scholar] [CrossRef]

- Sun, Y.; Sang, M.; Xu, Y.; Zhang, Z.; Duan, S.; Wang, Y.; Gong, X. Conductive Magnetorheological Fluid (cMRF)-Based Flexible Sensor with Adjustable Stiffness for Magneto-Mechanical Dual-Response and Soft Actuator. Chem. Eng. J. 2024, 489, 151229. [Google Scholar] [CrossRef]

- Chen, C.; Zheng, L.; Chen, L.; Liu, X. Recent Progress and Challenges of Flexible Supercapacitor-Sensor Integrated Systems Based on Conductive Polymers. J. Mater. Chem. C 2025, 13, 16320–16349. [Google Scholar]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Mengüç, Y.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D Printing of Strain Sensors within Highly Stretchable Elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef]

- Nodehi, S.E.; Bruzzone, L.; Fanghella, P. SnakeTrack: A bio-inspired, single-track mobile robot with compliant vertebral column for surveillance and inspection. In Proceedings of the International Conference on Robotics in Alpe-Adria Danube Region (RAAD), Klagenfurt, Austria, 8–10 June 2022; Springer: Berlin/Heidelberg, Germany, 2022; pp. 513–520. [Google Scholar]

- Cho, G.-S.; Park, Y.-J. Soft Gripper with eGain Soft Sensor for Detecting Grasp Status. Appl. Sci. 2021, 11, 6957. [Google Scholar] [CrossRef]

- Ren, J.; Wu, F.; Shang, E.; Li, D.; Liu, Y. 3D Printed Smart Elastomeric Foam with Force Sensing and Its Integration with Robotic Gripper. Sens. Actuators A Phys. 2023, 349, 113998. [Google Scholar] [CrossRef]

- VG, M.C.; Paul, B. Wearable Fabric Tactile Sensors for Robotic Elderly Assistance. In Proceedings of the 2022 Smart Technologies, Communication and Robotics (STCR), Sathyamangalam, India, 10–11 December 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–5. [Google Scholar]

- Su, J.; He, K.; Li, Y.; Tu, J.; Chen, X. Soft Materials and Devices Enabling Sensorimotor Functions in Soft Robots. Chem. Rev. 2025, 125, 5848–5977. [Google Scholar] [CrossRef] [PubMed]

- Georgopoulou, A.; Vanderborght, B.; Clemens, F. Fabrication of a Soft Robotic Gripper with Integrated Strain Sensing Elements Using Multi-Material Additive Manufacturing. Front. Robot. AI 2021, 8, 615991. [Google Scholar] [CrossRef]

- Zhong, L.; Yu, R.; Hong, X. Review of Carbon-Based Electromagnetic Shielding Materials: Film, Composite, Foam, Textile. Text. Res. J. 2021, 91, 1167–1183. [Google Scholar] [CrossRef]

- Truby, R.L.; Lewis, J.A. Printing Soft Matter in Three Dimensions. Nature 2016, 540, 371–378. [Google Scholar] [CrossRef]

- Annabestani, M.; Shabani, M.; Magalhaes, S.V.; Mondini, A.; Mazzolai, B. A Plant-Inspired Multifunctional, Two Way, and Fiberless Soft Gripper with Sensorized Kinaesthesia. arXiv 2022, arXiv:2203.01611. [Google Scholar] [CrossRef]

- Vogt, D.M.; Park, Y.-L.; Wood, R.J. Design and Characterization of a Soft Multi-Axis Force Sensor Using Embedded Microfluidic Channels. IEEE Sens. J. 2013, 13, 4056–4064. [Google Scholar] [CrossRef]

- Gurusckaran, A.; Rasheed, A.; Xu, R.; Ciocca, M.; Vidoni, R.; Lugli, P.; Makarov, D.; Petti, L. Stretchable, Self-Healable, Carbon-Based Strain Sensor for Soft Robotic Applications. In Proceedings of the 2024 IEEE International Flexible Electronics Technology Conference (IFETC), Bologna, Italy, 15–18 September 2024; pp. 1–4. [Google Scholar]

- Asutkar, S.; Korrapati, M.; Singh, S.; Gupta, D.; Tallur, S. Performance evaluation of post-curing method for sensitivity enhancement of elastomer vibration sensors. Sens. Actuators A Phys. 2022, 334, 113313. [Google Scholar] [CrossRef]

- Porte, E.; Eristoff, S.; Agrawala, A.; Kramer-Bottiglio, R. Characterization of temperature and humidity dependence in soft elastomer behavior. Soft Robot. 2024, 11, 118–130. [Google Scholar] [CrossRef]

- Park, S.; Mondal, K.; Treadway, R.M., III; Kumar, V.; Ma, S.; Holbery, J.D.; Dickey, M.D. Silicones for stretchable and durable soft devices: Beyond Sylgard-184. ACS Appl. Mater. Interfaces 2018, 10, 11261–11268. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.; Li, D.; Salim, T.; Li, Y.; Cheng, G.; Lam, Y.M.; Ding, J. Electrically driven hydrogel actuators: Working principle, material design and applications. J. Mater. Chem. 2024, 12, 1565–1582. [Google Scholar] [CrossRef]

- Lovett, E.; Hammond, M.; Seyfi, N.; Golestaneh, A.F.; Cichella, V.; Lamuta, C. A Review on Sensor Technologies, Control Approaches, and Emerging Challenges in Soft Robotics. Adv. Robot. Res. 2025, 1, 202500085. [Google Scholar] [CrossRef]

- Ambaye, G.; Boldsaikhan, E.; Krishnan, K. Soft Robot Design, Manufacturing, and Operation Challenges: A Review. J. Manuf. Mater. Process. 2024, 8, 79. [Google Scholar] [CrossRef]

- Abdul-Hussain, G.; Holderbaum, W.; Theodoridis, T.; Wei, G. Modified Nonlinear Hysteresis Approach for a Tactile Sensor. Sensors 2023, 23, 7293. [Google Scholar] [CrossRef]

- Xu, M.; Liu, Y.; Li, J.; Xu, F.; Huang, X.; Yue, X. Review of Flexible Robotic Grippers, with a Focus on Grippers Based on Magnetorheological Materials. Materials 2024, 17, 4858. [Google Scholar] [CrossRef]

- Ge, G.; Wang, Q.; Zhang, Y.-Z.; Alshareef, H.N.; Dong, X. 3D Printing of Hydrogels for Stretchable Ionotronic. Adv. Funct. Mater. 2021, 31, 2107437. [Google Scholar] [CrossRef]

- Cole, T. Exploring Applications of Liquid Metals in Robotic Systems. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2025. [Google Scholar]

- Zhao, Z.; Tang, J.; Yuan, J.; Li, Y.; Dai, Y.; Yao, J.; Zhang, Q.; Ding, S.; Li, T.; Zhang, R.; et al. Large-Scale Integrated Flexible Tactile Sensor Array for Sensitive Smart Robotic Touch. ACS Nano 2022, 16, 16784–16795. [Google Scholar] [CrossRef]

- Li, R.; Qiao, H. A Survey of Methods and Strategies for High-Precision Robotic Grasping and Assembly Tasks—Some New Trends. IEEE/ASME Trans. Mechatron. 2019, 24, 2718–2732. [Google Scholar] [CrossRef]

- Khoshmanesh, K.; Tang, S.-Y.; Zhu, J.Y.; Schaefer, S.; Mitchell, A.; Kalantar-Zadeh, K.; Dickey, M.D. Liquid metal enabled microfluidics. Lab Chip 2017, 17, 974–993. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Li, J.; Zhu, Z.; Zhao, L.; Wang, H.; Song, C.; Chen, Y.; Zhao, Q.; Yang, J.; Pei, Y. A comprehensive review on synergy of multi-modal data and AI technologies in medical diagnosis. Bioengineering 2024, 11, 219. [Google Scholar] [CrossRef] [PubMed]

- Song, C.; Gong, J.; Yang, C.; Xu, M. Flexible multimode sensors: Structural design, signal decoupling, and emerging applications. Adv. Mater. Technol. 2025, 10, e01368. [Google Scholar] [CrossRef]

- Dudurairajrairaj, S.; Durairaj, S. Advancements and challenges in self-healing coatings for sustainable smart materials in industry applications. Zast. Mater. 2025. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Kouzani, A.Z.; Khoo, S.Y.; Amiri, A.A.; Gibson, I.; Kaynak, A. Evolution of 3D printed soft actuators. Sens. Actuators A Phys. 2016, 250, 258–272. [Google Scholar] [CrossRef]

- Dincer, C.; Bruch, R.; Costa-Rama, E.; Fernández-Abedul, M.T.; Merkoçi, A.; Manz, A.; Urban, G.A.; Güder, F. Disposable sensors in diagnostics, food, and environmental monitoring. Adv. Mater. 2019, 31, 1806739. [Google Scholar] [CrossRef]

- Zhang, Y.; Ni, F.; Liu, H. Design and optimization of Wheatstone bridge adjustment circuit for resistive sensors. IEEE Sens. J. 2023, 23, 14330–14338. [Google Scholar] [CrossRef]

- Chung, D.D.L. A Critical Review of Piezoresistivity and Its Application in Electrical-Resistance-Based Strain Sensing. J. Mater. Sci. 2020, 55, 15367–15396. [Google Scholar] [CrossRef]

- Zhang, X.; Chai, J.; Zhan, Y.; Cui, D.; Wang, X.; Gao, L. Design, Fabrication, and Application of Large-Area Flexible Pressure and Strain Sensor Arrays: A Review. Micromachines 2025, 16, 330. [Google Scholar] [CrossRef]

- Bruzzone, L.; Nodehi, S.E.; Belotti, V.; Fanghella, P. Actuation and Control Layout of the Hybrid Locomotion Ground Mobile Robot WheTLHLoc. In Proceedings of the International Conference of IFToMM ITALY, Online, 8–9 September 2022; Springer: Cham, Switzerland, 2022; pp. 677–684. [Google Scholar]

- Medina, O.; Shapiro, A.; Shvalb, N. Resistor-Based Shape Sensor for a Spatial Flexible Manifold. IEEE Sens. J. 2016, 17, 46–50. [Google Scholar] [CrossRef]

- Dahiya, R.S.; Mittendorfer, P.; Valle, M.; Cheng, G.; Lumelsky, V.J. Directions Toward Effective Utilization of Tactile Skin: A Review. IEEE Sens. J. 2013, 13, 4121–4138. [Google Scholar] [CrossRef]

- Mandil, W.; Rajendran, V.; Nazari, K.; Ghalamzan-Esfahani, A. Tactile-sensing technologies: Trends, challenges and outlook in agri-food manipulation. Sensors 2023, 23, 7362. [Google Scholar] [CrossRef] [PubMed]

- Ren, Z.; Liu, N. Zhang, Q.; Yin, J.; Jia, P.; Lu, W.; Yao, Q.; Deng, M.; Gao, Y. Ionic flexible mechanical sensors: Mechanisms, structural engineering, applications, and challenges. Adv. Sens. Res. 2023, 2, 2200099. [Google Scholar] [CrossRef]

- Liu, T.; Liu, L.; Gou, G.-y.; Fang, Z.; Sun, J.; Chen, J.; Cheng, J.; Han, M.; Ma, T.; Liu, C.; et al. Recent advancements in physiological, biochemical, and multimodal sensors based on flexible substrates: Strategies, technologies, and integrations. ACS Appl. Mater. Interfaces 2023, 15, 21721–21745. [Google Scholar] [CrossRef]

- Yong, S.; Chapman, J.; Aw, K. Soft and flexible large-strain piezoresistive sensors: On implementing proprioception, object classification and curvature estimation systems in adaptive, human-like robot hands. Sens. Actuators A Phys. 2022, 341, 113609. [Google Scholar] [CrossRef]

- Liu, R.; Wang, S.; Yang, H.; Shi, C. Highly stretchable strain sensor with spiral fiber for curvature sensing of a soft pneumatic gripper. IEEE Sens. J. 2021, 21, 23880–23888. [Google Scholar] [CrossRef]

- Awada, Z.; Haddab, Y.; Gouttefarde, M. PneuNet actuators design: Trade-offs between deformation, force, and resistance to buckling. Sens. Actuators A Phys. 2025, 386, 116307. [Google Scholar] [CrossRef]

- Cook, J.N.; Sabarwal, A.; Clewer, H.; Navaraj, W. Tactile sensor array laden 3D-printed soft robotic gripper. In Proceedings of the 2020 IEEE SENSORS Conference, Rotterdam, The Netherlands, 25–28 October 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–4. [Google Scholar]

- Ghosh, P.K.; Sundaravadivel, P. Stretchable sensors for soft robotic grippers in edge-intelligent IoT applications. Sensors 2023, 23, 4039. [Google Scholar] [CrossRef]

- Cha, L.; Groß, S.; Mao, S.; Braun, T.; Haddadin, S.; He, L. Stretchable capacitive and resistive strain sensors: Accessible manufacturing using direct ink writing. In Proceedings of the 2025 IEEE 8th International Conference on Soft Robotics (RoboSoft), Lausanne, Switzerland, 22–26 April 2025; IEEE: Piscataway, NJ, USA, 2025; pp. 1–6. [Google Scholar]

- Cafiso, D.; Lantean, S.; Pirri, C.F.; Beccai, L. Soft mechanosensing via 3D printing: A review. Adv. Intell. Syst. 2023, 5, 2200373. [Google Scholar] [CrossRef]

- Duan, L.; D’hooge, D.R.; Cardon, L. Recent progress on flexible and stretchable piezoresistive strain sensors: From design to application. Prog. Mater. Sci. 2020, 114, 100617. [Google Scholar] [CrossRef]

- Elgeneidy, K.; Neumann, G.; Jackson, M.; Lohse, N. Directly printable flexible strain sensors for bending and contact feedback of soft actuators. Front. Robot. 2018, 5, 2. [Google Scholar] [CrossRef]

- Dang, W.; Hosseini, E.S.; Dahiya, R. Soft robotic finger with integrated stretchable strain sensor. In Proceedings of the 2018 IEEE Sensors Conference, New Delhi, India, 28–31 October 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–4. [Google Scholar]

- Lalegani Dezaki, M.; Sales, R.; Zolfagharian, A.; Yazdani Nezhad, H.; Bodaghi, M. Soft pneumatic actuators with integrated resistive sensors enabled by multi-material 3D printing. Int. J. Adv. Manuf. Technol. 2023, 128, 4207–4221. [Google Scholar] [CrossRef]

- Koivikko, A.; Lampinen, V.; Pihlajamäki, M.; Yiannacou, K.; Sharma, V.; Sariola, V. Integrated stretchable pneumatic strain gauges for electronics-free soft robots. Commun. Eng. 2022, 1, 14. [Google Scholar] [CrossRef]

- Blanco, K.; Navas, E.; Emmi, L.; Fernandez, R. Manufacturing of 3D printed soft grippers: A review. IEEE Access 2024, 12, 30434–30451. [Google Scholar] [CrossRef]

- Xu, S.; Vogt, D.M.; Hsu, W.-H.; Osborne, J.; Walsh, T.; Foster, J.R.; Sullivan, S.K.; Smith, V.C.; Rousing, A.W.; Goldfield, E.C.; et al. Biocompatible soft fluidic strain and force sensors for wearable devices. Adv. Funct. Mater. 2019, 29, 1807058. [Google Scholar] [CrossRef]

- Bruzzone, L.; Nodehi, S.E. Application of half-derivative damping to Cartesian space position control of a SCARA-like manipulator. Robotics 2022, 11, 152. [Google Scholar]

- Li, J.; Yao, Z.; Meng, X.; Zhang, X.; Wang, Z.; Wang, J.; Ma, G.; Liu, L.; Zhang, J.; Niu, S.; et al. High-fidelity, low-hysteresis bionic flexible strain sensors for soft machines. ACS Nano 2024, 18, 2520–2530. [Google Scholar]

- Pinto, T.; Cai, L.; Wang, C.; Tan, X. CNT-based sensor arrays for local strain measurements in soft pneumatic actuators. Int. J. Intell. Robot. Appl. 2017, 1, 157–166. [Google Scholar] [CrossRef]

- Zhang, Y.; Zeng, J.; Wang, Y.; Jiang, G. Flexible three-dimensional force tactile sensor based on velostat piezoresistive films. Micromachines 2024, 15, 486. [Google Scholar] [CrossRef]

- Li, M.S.; Huh, T.M.; Yahnker, C.R.; Stuart, H.S. Resonant pneumatic tactile sensing for soft grippers. IEEE Robot. Autom. Lett. 2022, 7, 10105–10111. [Google Scholar] [CrossRef]

- Liang, L.; Li, C.; Yang, X.; Chen, Z.; Zhang, B.; Yang, Y.; Ji, G. Pneumatic structural deformation to enhance resonance behavior for broadband and adaptive radar stealth. Nano Lett. 2024, 24, 2652–2660. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, H.; Li, G.; Peng, M.; Ma, X.; Li, M.; Yan, S. Construction of liquid metal-based soft microfluidic sensors via soft lithography. J. Nanobiotechnol. 2022, 20, 246. [Google Scholar]

- Pannen, T.J.; Puhlmann, S.; Brock, O. A low-cost, easy-to-manufacture, flexible, multi-taxel tactile sensor and its application to in-hand object recognition. In Proceedings of the 2022 International Conference on Robotics and Automation (ICRA), Philadelphia, PA, USA, 23–27 May 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 10939–10944. [Google Scholar]

- Suprapto, S.S.; Setiawan, A.W.; Zakaria, H.; Adiprawita, W.; Supartono, B. Low-cost pressure sensor matrix using velostat. In Proceedings of the 2017 5th International Conference on Instrumentation, Communications, Information Technology, and Biomedical Engineering (ICICI-BME), Bandung, Indonesia, 6–7 November 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 137–140. [Google Scholar]

- Dong, S.; Cai, L.; Wei, Y.; She, J. Design and tactile classification of flexible tactile sensor for soft gripper. Meas. Sci. Technol. 2023, 34, 125155. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Li, Y. Pre-charged pneumatic soft gripper with closed-loop control. IEEE Robot. Autom. Lett. 2019, 4, 1402–1408. [Google Scholar] [CrossRef]

- Deng, L.; Shen, Y.; Fan, G.; He, X.; Li, Z.; Yuan, Y. Design of a soft gripper with improved microfluidic tactile sensors for classification of deformable objects. IEEE Robot. Autom. Lett. 2022, 7, 5607–5614. [Google Scholar] [CrossRef]

- Shorthose, O.; Albini, A.; He, L.; Maiolino, P. Design of a 3D-printed soft robotic hand with integrated distributed tactile sensing. IEEE Robot. Autom. Lett. 2022, 7, 3945–3952. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Z.; Zeng, G.; Xu, Z.; Hai, Z.; Chen, Z.; Zhao, Y.; Wu, D. Printing of tactile sensors upon the surface of pneumatic soft gripper by direct writing and electrospraying to enable intelligent grasping. Adv. Eng. Mater. 2022, 24, 2200704. [Google Scholar] [CrossRef]

- Hao, Y.; Liu, Z.; Liu, J.; Fang, X.; Fang, B.; Nie, S.; Guan, Y.; Sun, F.; Wang, T.; Wen, L. A soft gripper with programmable effective length, tactile and curvature sensory feedback. Smart Mater. Struct. 2020, 29, 035006. [Google Scholar] [CrossRef]

- Park, Y.-L.; Majidi, C.; Kramer, R.; Bérard, P.; Wood, R.J. Hyperelastic pressure sensing with a liquid-embedded elastomer. J. Micromech. Microeng. 2010, 20, 125029. [Google Scholar] [CrossRef]

- He, L.; Lu, Q.; Abad, S.-A.; Rojas, N.; Nanayakkara, T. Soft fingertips with tactile sensing and active deformation for robust grasping of delicate objects. IEEE Robot. Autom. Lett. 2020, 5, 2714–2721. [Google Scholar] [CrossRef]

- Yuan, L.; Qu, H.; Li, J. Velostat sensor array for object recognition. IEEE Sens. J. 2021, 22, 1692–1704. [Google Scholar] [CrossRef]

- Dzedzickis, A.; Sutinys, E.; Bucinskas, V.; Samukaite-Bubniene, U.; Jakstys, B.; Ramanavicius, A.; Morkvenaite-Vilkonciene, I. Polyethylene-carbon composite (Velostat®) based tactile sensor. Polymers 2020, 12, 2905. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Sun, X.; Liu, J. Advances in liquid metal-enabled flexible and wearable sensors. Micromachines 2020, 11, 200. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Totaro, M.; Beccai, L. Toward perceptive soft robots: Progress and challenges. Adv. Sci. 2018, 5, 1800541. [Google Scholar] [CrossRef]

- dos Santos, S.R.; Rohmer, E. Soft sensory-motor system based on ionic solution for robotic applications. Sensors 2024, 24, 2900. [Google Scholar] [CrossRef]

- He, X.; Zhang, B.; Liu, Q.; Chen, H.; Cheng, J.; Jian, B.; Yin, H.; Li, H.; Duan, K.; Zhang, J.; et al. Highly conductive and stretchable nanostructured ionogels for 3D printing capacitive sensors with superior performance. Nat. Commun. 2024, 15, 6431. [Google Scholar] [CrossRef]

- Jiang, H.; Cheng, Y.; Zhang, X.; Li, M.; Wang, Q.; Yang, L.; Shuai, C. Progress of ionogels in flexible pressure sensors: A mini-review. Polymers 2025, 17, 1093. [Google Scholar] [CrossRef]

- Kim, T.; Lee, S.; Hong, T.; Shin, G.; Kim, T.; Park, Y.-L. Heterogeneous sensing in a multifunctional soft sensor for human-robot interfaces. Sci. Robot. 2020, 5, eabc6878. [Google Scholar] [CrossRef]

- Nodehi, S.E.; Bruzzone, L.; Lalegani Dezaki, M.; Zolfagharian, A.; Bodaghi, M. Porcospino flex: A bio-inspired single-track robot with a 3D-printed, flexible, compliant vertebral column. Robotics 2024, 13, 76. [Google Scholar]

- Zhao, G.; Lv, B.; Wang, H.; Yang, B.; Li, Z.; Ren, J.; Gui, G.; Liu, W.; Yang, S.; Li, L. Ionogel-based flexible stress and strain sensors. Int. J. Smart Nano Mater. 2021, 12, 307–336. [Google Scholar] [CrossRef]

- Ying, B.; Chen, R.Z.; Zuo, R.; Li, J.; Liu, X. An anti-freezing, ambient-stable and highly stretchable ionic skin with strong surface adhesion for wearable sensing and soft robotics. Adv. Funct. Mater. 2021, 31, 2104665. [Google Scholar] [CrossRef]

- Truby, R.L.; Katzschmann, R.K.; Lewis, J.A.; Rus, D. Soft robotic fingers with embedded ionogel sensors and discrete actuation modes for somatosensitive manipulation. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Republic of Korea, 14–18 April 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 322–329. [Google Scholar]

- Truby, R.L.; Wehner, M.; Grosskopf, A.K.; Vogt, D.M.; Uzel, S.G.M.; Wood, R.J.; Lewis, J.A. Soft somatosensitive actuators via embedded 3D printing. Adv. Mater. 2018, 30, 1706383. [Google Scholar] [CrossRef]

- Zhou, Z.; Zuo, R.; Ying, B.; Zhu, J.; Wang, Y.; Wang, X.; Liu, X. A sensory soft robotic gripper capable of learning-based object recognition and force-controlled grasping. IEEE Trans. Autom. Sci. Eng. 2022, 21, 844–854. [Google Scholar] [CrossRef]

- Chen, X.; Xia, X.; Guo, C.F. Flexible Iontronic Sensing: Ionic Materials, Electrodes, and Encapsulation. Adv. Funct. Mater. 2025, 35, e12920. [Google Scholar] [CrossRef]

- Sarker, A.; Ul Islam, T.; Islam, M.R. A Review on Recent Trends of Bioinspired Soft Robotics: Actuators, Control Methods, Materials Selection, Sensors, Challenges, and Future Prospects. Adv. Intell. Syst. 2025, 7, 2400414. [Google Scholar] [CrossRef]

- Wang, T.; Jin, T.; Lin, W.; Lin, Y.; Liu, H.; Yue, T.; Tian, Y.; Li, L.; Zhang, Q.; Lee, C. Multimodal sensors enabled autonomous soft robotic system with self-adaptive manipulation. ACS Nano 2024, 18, 9980–9996. [Google Scholar] [CrossRef]

- Wang, H.; Du, J.; Mao, Y. Hydrogel-based continuum soft robots. Gels 2025, 11, 254. [Google Scholar] [CrossRef]

- Amoli, V.; Kim, J.S.; Kim, S.Y.; Koo, J.; Chung, Y.S.; Choi, H.; Kim, D.H. Ionic tactile sensors for emerging human-interactive technologies: A review of recent progress. Adv. Funct. Mater. 2020, 30, 1904532. [Google Scholar] [CrossRef]

| Material Type | Examples | Key Properties | Advantages | Limitations/Typical Use |

|---|---|---|---|---|

| Carbon-based Composites | CNTs, Graphene, Carbon black | High conductivity, tunable sensitivity, flexible | High sensitivity, versatile fabrication | Hysteresis, nonlinear response; used for strain sensors and curvature monitoring |

| Conductive Polymers | PEDOT:PSS, Polypyrrole | Stretchable, processable, chemically stable | Good integration with soft substrates | Lower conductivity vs metals; used in flexible strain/tactile pads |

| TPU/PLA Elastomers | Thermoplastic polyurethane (TPU), PLA blends | 3D-printable, customizable geometries | Additive manufacturing compatibility | Limited durability under cyclic strain; used in custom 3D-printed strain sensors |

| Textiles and Fabrics | Velostat, EeonTex | Low-cost, conformable, scalable | Scalable for large-area tactile skins | Low sensitivity, durability issues; used for low-cost tactile arrays |

| Conductive Foams | PU foams, CNT foams | Compressible, pressure-sensitive, porous | Simple fabrication, good pressure response | Hysteresis, mechanical fatigue; used in pressure pads for contact detection |

| Hydrogels/Ionogels | Polyacrylamide hydrogels, Ionogels | Stretchable, transparent, antifreezing, self-healing | Multimodal sensing, biocompatibility | Dehydration, mechanical fragility; used in multimodal strain/tactile sensors |

| Liquid Metals | EGaIn, Galinstan | Highly conductive, liquid phase, deformable | Excellent stretchability, wide strain range | Leakage, oxidation, stability issues; used in stretchable strain and tactile sensors |

| Material/Composite | Structure and Fabrication | Range/Output | Sensitivity | Size/Geometry | Response Time | Durability | Cross-Sensitivity | Ref. |

|---|---|---|---|---|---|---|---|---|

| Velostat + FPC | Matrix-shaped Velostat between two flexible printed circuits | Resistance up to 50 k | – | 5 × 10 array (∼50 sensing points), ∼1 mm thick | – | Moderate; requires calibration | Moderate temperature sensitivity | [159] |

| Silicone (Dragon Skin™ 30) | Pneumatic resonant tube with lateral opening | Frequency-based measurement via resonance | – | Ø 6 mm × 10 cm | Tens of ms (reported qualitatively) | High, robust | Low mechanical cross-sensitivity | [154] |

| Silicone Elastomers + EGaIn | Microfluidic channels with an indenter layer | Resistivity of EGaIn: · m | Higher with narrow indenters (2 mm best) | Length 6 mm; Widths 2–6 mm | <100 ms | Moderate; risk of leakage | Low mechanical cross-sensitivity | [161] |

| Silicone Rubber (Shore A40) | 3D-printed pneumatic chambers | Pressure sensing | 2.31 kPa/N | Raised 4 mm; Thickness 1.5 mm | – | High cycle stability | Low cross-sensitivity | [162] |

| GNPs/MWCNT/PEO + rGO/GO | Printed multimodal sensors on PDMS (pressure, temperature, humidity) | Pressure: 0–100 kPa; Temp: 20–65 °C; Humidity: 25–90% RH | Pressure: 1.1 MPa−1; Temp: 0.65% °C−1; Humidity: 3.5–5.8 pF | 2 × 2 array (pressure); Thin films (temperature/humidity) | 50–60 ms | ≥100 cycles | Moderate cross-talk between modalities | [163] |

| Silicone + EGaIn Microchannels | Spiral microchannel (tactile) + linear channels (curvature) | Tactile: up to ∼0.5 mV; Curvature: 0.6–2.4 mV | High | Tip diameter 9 mm | <50 ms | Moderate; stable but fatigue sensitive | Low mechanical cross-sensitivity | [164] |

| Tactile Sensor | Merits | Demerits | Cost |

|---|---|---|---|

| Velostat-based resistive sensor arrays | Low-cost, simple, flexible, suitable for classification | Nonlinearity, drift, limited durability | Low |

| Resonant pneumatic sensor | Robust, mechanically protected, stable response | Bulky, low spatial resolution | Medium |

| Programmable soft gripper | Adaptive, programmable length, versatile | Structural complexity, slower response | Medium–High |

| Direct-writing nanocomposite e-skin | Conformal, multimodal, scalable, fast response | Mechanical stability issues, durability concerns | Medium |

| 3D-printed hand with distributed sensor | Integrated, scalable, customizable | Moderate sensitivity, design-dependent | Medium |

| Microfluidic liquid metal | High sensitivity, flexibility, conforms to complex geometry | Leakage risk, fatigue, complex fabrication | Medium–High |

| Integration Method | Advantages | Limitations | Reference |

|---|---|---|---|

| Velostat lamination | Low-cost, easy to apply, distributed contact sensing | Reduces compliance, wiring complexity | [159] |

| Pneumatic resonant tube | Robust, mechanically protected, near-linear response | Low spatial resolution | [154] |

| EGaIn microchannels | Highly flexible, conformal, high sensitivity | Leakage, fatigue over cycles | [161] |

| 3D-printed chambers | Directly integrated, robust, scalable | Design-dependent, moderate sensitivity | [162] |

| Printed nanocomposite e-skin | Multimodal sensing, fast response | Long-term stability issues | [163] |

| Principle | Sensing Function | Required Characteristics | Forming of Ionogel/Hydrogel | Device Structure | Ref. |

|---|---|---|---|---|---|

| Resistive sensing (ionogel curvature sensor) | – | High ionic conductivity, stretchability, linear response | Embedded 3D printing (EMB3D) of ionogel in elastomer channels | U-shaped traces inside bending actuator | [178] |

| Resistive sensing (inflation sensor) | Pressure sensitivity, repeatability, stable, resistance under deformation | High ionic conductivity, stretchability, linear response | EMB3D of ionogel along actuator chamber | Ionogel channel integrated into pneumatic actuator wall | |

| Resistive tactile sensing (ionogel contact sensor) | Measures fingertip compression (fine/deep touch) and slip | High compliance, surface sensitivity, nonlinear but discriminative | EMB3D traces at fingertip regions | Ionogel pads at anterior fingertip | [179] |

| Resistive strain sensing (hydrogel) | Tracks bending/strain during grasping | Antifreezing, stretchability, strong adhesion | Double-network hydrogel (Alg-PAAm) with glycerol | U-shaped hydrogel bonded to EcoFlex elastomer | [180] |

| Capacitive tactile sensing (hydrogel) | Detects applied pressure through capacitance change | Stable dielectric properties, encapsulation for durability | Hydrogel electrodes with EcoFlex dielectric encapsulation | Multilayer stacked capacitive element in fingertip |

| Sensor Type | Material/Structure | Electronic Range/Signal | Dynamic Profile | Actuation Coupling | Ref. |

|---|---|---|---|---|---|

| Curvature Sensor (Ionogel) | Ionogel (EMIM-ES + silica) printed as U-shaped traces inside the bending actuator | Resistance increases linearly with curvature ( vs. angle) | Minimal hysteresis; stable under repeated cycles; good linearity | Bending angles up to ∼90° measurable with linear response | [178] |

| Inflation Sensor (Ionogel) | Ionogel embedded in pneumatic actuator chamber wall | Resistance correlates with internal pneumatic pressure | Slight viscoelastic hysteresis due to the elastomer matrix | Detects actuation pressure ranges (tens of kPa typical for soft grippers) | |

| Tactile/Contact Sensor (Ionogel) | Ionogel traces embedded in the fingertip regions of soft fingers | Resistance change nonlinear vs. applied force | Sensitive to surface texture; distinguishes fine vs. deep touch | Force range up to ∼10 N; enables slip detection and texture discrimination | [179] |

| Resistive Strain Sensor (Hydrogel) | Double-network Alg-PAAm hydrogel with glycerol; bonded to EcoFlex elastomer | Large resistance variation with strain; maintains function at −20 °C | Linear vs. bending; antifreezing (−95 °C); stable under repeated cycles | Bending angle measurement (proprioception) during grasping | |

| Capacitive Tactile Sensor (Hydrogel) | Hydrogel electrodes with EcoFlex dielectric; encapsulated multilayer structure | Capacitance increases linearly with applied pressure | Stable tactile feedback at ambient and subzero (−20 °C) | Pressure sensing across mN–N range; supports closed-loop force control | [180] |

| Sensor Type | Benefits | Limitations | Cost Considerations |

|---|---|---|---|

| Curvature Sensor (Ionogel) | Linear response to bending; reliable proprioception; easy embedding in actuator | Requires EMB3D fabrication; limited scalability | Moderate—depends on 3D printing process and ionogel synthesis |

| Inflation Sensor (Ionogel) | Differentiates internal actuation from external load; stable pressure sensing | Viscoelastic hysteresis from elastomer matrix; less precise under high cycles | Moderate—similar cost to curvature sensors with added fabrication complexity |

| Tactile Sensor (Ionogel) | Sensitive to surface contact, slip, and texture; supports ML-based recognition | Nonlinear signal complicates calibration; fabrication at fingertip regions is complex | Higher—multiple embedded traces increase fabrication and assembly cost |

| Strain Sensor (Hydrogel) | High stretchability; antifreezing down to −95 °C; strong adhesion to elastomer | Risk of dehydration without additives; long-term stability issues | Low to moderate—hydrogels are inexpensive, but encapsulation adds cost |

| Capacitive Tactile Sensor (Hydrogel) | Linear capacitance–pressure response; robust tactile feedback even at subzero | Encapsulation and multilayer assembly increase fabrication complexity | Moderate to high—fabrication is costlier than resistive hydrogels |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mostaghniyazdi, D.; Nodehi, S.E. Resistive Sensing in Soft Robotic Grippers: A Comprehensive Review of Strain, Tactile, and Ionic Sensors. Electronics 2025, 14, 4290. https://doi.org/10.3390/electronics14214290

Mostaghniyazdi D, Nodehi SE. Resistive Sensing in Soft Robotic Grippers: A Comprehensive Review of Strain, Tactile, and Ionic Sensors. Electronics. 2025; 14(21):4290. https://doi.org/10.3390/electronics14214290

Chicago/Turabian StyleMostaghniyazdi, Donya, and Shahab Edin Nodehi. 2025. "Resistive Sensing in Soft Robotic Grippers: A Comprehensive Review of Strain, Tactile, and Ionic Sensors" Electronics 14, no. 21: 4290. https://doi.org/10.3390/electronics14214290

APA StyleMostaghniyazdi, D., & Nodehi, S. E. (2025). Resistive Sensing in Soft Robotic Grippers: A Comprehensive Review of Strain, Tactile, and Ionic Sensors. Electronics, 14(21), 4290. https://doi.org/10.3390/electronics14214290