1. Introduction

Ensuring the normal power supply of numerous islands in China is an inevitable requirement for the long-term stable development of the marine economy [

1,

2]. The traditional power supply method for islands is to use diesel generators, but the long-term use of diesel generators will have a negative impact on the local ecological environment [

3]. The “Island Protection Law of the People’s Republic of China” clearly states that priority should be given to the utilization of abundant renewable energy sources such as wind and solar energy in island areas [

4]. Island microgrids can effectively and flexibly utilize renewable energy, reduce the phenomenon of wind and solar energy curtailment, and reduce the use of fossil fuel units, contributing to the realization of the dual carbon goals [

5,

6,

7].

The grid-connected operation of island microgrids can reduce the power supply pressure within the island, share unstable factors, and ensure power supply security. However, there is a lack of power mutual assistance strategies among island microgrids, and it is necessary to establish coordination and dispatching methods between island power grids to enhance the penetration rate of renewable energy in island microgrid clusters and the reliability of power supply in island operation mode [

8]. Therefore, scholars have conducted relevant research. Cunha et al., 2025 quantitatively demonstrate that clustering three microgrids reduces curtailed energy by 30% and eliminates load shedding during islanded events, thereby highlighting the economic and resilience benefits of collaborative operation [

9]. Cunha et al., 2023 further review multi-microgrid architectures and identify flexible point-of-common-coupling switching, hierarchical/decentralized control, and local energy markets as key enablers for such clusters [

10]. Literature [

11] explored the cooperative operation of shared energy storage in multiple island microgrid systems. To optimize resource allocation and reduce service costs, a two-stage approach is used. The first stage focuses on optimizing profit and energy storage capacity using a modified grey wolf algorithm, while the second stage addresses revenue distribution through a game-theoretic negotiation process and the alternating direction multiplier method. The economic and reliability of the scheme were verified through simulation result. Literature [

12] combined multiple adjacent island microgrids into an island cluster multi-microgrid, where each region supplies power to each other and serves as backup, effectively improving the safety and reliability of power supply. Literature [

13] established an uncertainty optimization dispatching model for island multi-microgrid operation based on reliability and economic indicators, and solved it by combining the particle swarm optimization algorithm with Monte Carlo simulation. The example verified the effectiveness and rationality of the proposed dispatching strategy. The above literature has studied island microgrid clusters to varying degrees, providing important reference value for the construction of island microgrid clusters, but they have not conducted research on the control technology of island microgrid clusters in terms of the efficiency and real-time performance of power dispatching.

Microgrid cluster control technology can be divided into centralized control and distributed control. For centralized control, literature [

14,

15,

16] considered factors such as economy, environmental protection, and voltage stability to construct multi-objective optimization dispatching models for microgrid clusters. Literature [

17] studied the impact of demand response on reducing power generation losses based on economic optimization. Literature [

18] constructed a hierarchical energy optimization management model for active distribution networks with the lowest operating cost of generating units at the active distribution network layer and the lowest economic and environmental costs at the multi-microgrid system layer, and conducted dynamic optimization by introducing adaptive weight coefficients. However, centralized optimization requires processing all the data and variables of the entire system, leading to a significant increase in computational complexity and time, especially when there are many and large-scale microgrids.

For distributed control, it enables independent optimization of scheduling in each region, reducing the demand for computing power and communication resources, especially when the system is large-scale and tightly coupled. References [

19,

20,

21] proposed a dynamic economic decentralized optimization scheduling method based on the alternating direction method of multipliers (ADMM), which decoupled the power grid model into three types: equipment, terminals, and connection points, enabling independent optimization scheduling in each region and reducing the demand for computing and communication resources. Reference [

22] proposed a decentralized scheduling model considering energy storage participation for the problem of high wind power accommodation, based on the synchronous ADMM algorithm, to achieve cross-regional accommodation of wind power. Reference [

23] established a two-layer decentralized scheduling model for a group of microgrids based on the ADMM algorithm, where the upper layer coordinated the scheduling to minimize the total cost of the microgrid group, and the lower layer optimized the management within each microgrid. The two layers were solved alternately, reducing the communication burden of microgrids while maintaining good convergence. However, distributed scheduling based on the alternating multiplier method has a slow convergence speed when the problem scale is large or the coupling relationship of the system is strong, which seriously affects the scheduling results in the case of poor communication conditions in island microgrid groups.

In islanded microgrid clusters, communication conditions may be poor. By utilizing similarity metrics, historical states similar to the current conditions can be quickly identified during the offline optimization phase for initial value setup. Subsequent precise adjustments through online optimization reduce reliance on inter-island communication, ensuring scheduling efficiency and real-time performance. Additionally, each microgrid can rapidly locate the most similar historical data day from offline optimization results using similarity metrics, thereby shortening the solution time for scheduling plans.

In summary, the existing research has the following problems that need to be addressed: The existing methods for island microgrid clusters have not fully considered the efficiency and real-time performance of power dispatching. Centralized control methods have high computational complexity and time consumption, which are not suitable for large-scale and numerous microgrids. Distributed control methods based on ADMM have slow convergence speed when the problem scale is large or the system coupling relationship is strong, which affects the scheduling results under poor communication conditions in island microgrid groups. This paper focuses on the issues of efficiency and real-time performance of energy scheduling in island microgrid groups with long-distance communication, and conducts research on a decentralized inter-island mutual assistance scheduling model for island microgrid groups considering operation costs and carbon emissions. Firstly, the power architecture of island microgrid groups is studied, assuming that the island microgrid group includes two load islands and two resource islands, with transmission channels connecting the load islands and resource islands. Mathematical models are established for different equipment. In the construction of the optimization problem, an optimization problem considering operation costs and carbon emissions is established. In the offline training of the island microgrid group, centralized optimization is conducted with different meteorological resources as boundaries, and the output states of adjustable units under corresponding boundary conditions are stored. In actual operation, each microgrid selects the most similar historical data through similarity measurement and uses the output of controllable units as the initial scheduling value for online optimization. The proposed decentralized scheduling method is compared with independent optimization and centralized optimization methods to verify its effectiveness and reduce the dependence of island microgrid groups on long-distance communication between islands and the mainland.

3. Distributed Scheduling Model of Microgrid Clusters

The distributed scheduling model of island microgrid clusters proposed in this study adopts a combination of offline training and online optimization. In the offline training stage, the microgrid clusters first perform centralized optimization based on a large amount of historical data, and store the output states of the adjustable units and the corresponding natural resource conditions. In the online optimization stage, the similarity between the wind and photovoltaic resources of each microgrid is measured, and the most similar historical data day is found from the offline optimization results. The output of the controllable units is taken as the initial scheduling value, and each microgrid is separately subjected to online optimization. Finally, an optimized scheduling plan for the island microgrid clusters is provided.

Compared with the traditional distributed optimization scheduling method, the method proposed in this paper selects the most similar historical data through similarity measurement in the offline optimization stage as the initial scheduling value for online distributed optimization, which shortens the solution time of the scheduling plan and reduces the dependence on inter-island communication, ensuring the efficiency and real-time performance of the scheduling.

3.1. Offline Training Centralized Optimization Model

In the offline training stage, the historical 365 days of wind speed and photovoltaic power generation data of 4 microgrids are used for centralized optimization to obtain the daily output time series of the controllable units of each microgrid and store them. The optimization objective comprehensively considers the minimization of system operation cost

Feco and carbon emissions

Fco2.

where

CPV,

CW,

CBESS,

Cmgt and

CG are the unit operation costs of photovoltaic equipment, wind turbines, energy storage batteries, micro gas turbines and the distribution network respectively;

aPV,

aW,

aBESS,

amgt and

aG are the carbon emission coefficients of the corresponding equipment;

γ is the proportionality factor for the comprehensive economic and carbon emission optimization;

PPV,i(

t),

PW,i(

t),

,i(

t),

Pmgt,i(

t) and

PG,i(

t) are the power of the

i-th corresponding equipment at time

t. The corresponding values are selected as shown in the following

Table 1 and

Table 2.

3.2. Online Distributed Optimization Model

3.2.1. Similarity Measurement

To quickly retrieve the most analogous historical scenario from the offline library, three widely-used distance measures were evaluated on the 365-day data set: Euclidean distance (ED); Manhattan distance (MD); Dynamic time warping (DTW).

Accuracy was quantified by the day-ahead scheduling-cost error relative to the fully centralized solution, while efficiency was assessed by the average retrieval time on a 3.4 GHz desktop.

Table 3 summarises the results. ED achieves virtually the same accuracy as DTW (error < 0.02%) but consumes only 4.3% of the computation time and requires no parameter tuning or extra storage. MD is marginally faster than ED, yet its error is five times higher. Consequently, ED was selected as the online similarity metric.

The Euclidean distance is calculated as:

where

D is the calculated Euclidean distance;

d is the corresponding day in the offline training data, and the d with the smallest similarity measurement is selected as the reference day;

PW,iref and

PPV,iref are the wind and photovoltaic resources of each day in the offline training data respectively.

3.2.2. Optimization Objective

In actual operation, each microgrid is separately subjected to online optimization. To make the optimization results tend to the centralized optimization results, a penalty function is introduced for the output deviation of the adjustable units (micro gas turbines, electrical energy storage devices) based on the output status of the reference day in the optimization objective function. The optimization objective of each microgrid is as follows:

where

λ is the penalty coefficient for the deviation of the output of the adjustable units (micro gas turbines, electrical energy storage devices) from the reference day operation status;

Pesb and

Pmgt respectively represent the output of the energy storage device and the micro gas turbine;

and

respectively represent the output of the energy storage device and the micro gas turbine on the reference day.

3.3. Two-Stage Decentralized Dispatch Model Solving Process for Island Microgrid Clusters

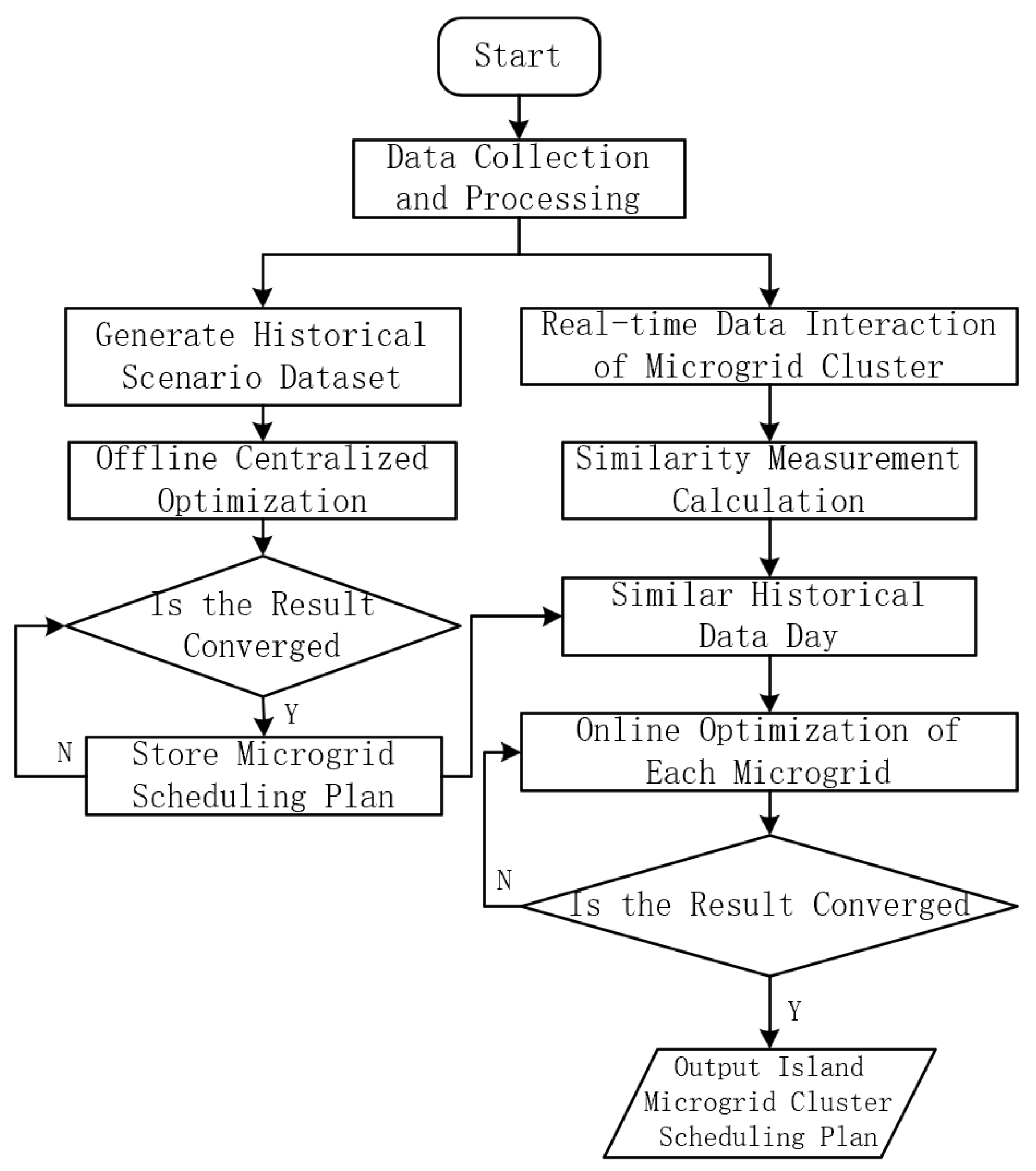

As shown in

Figure 1, the two-stage decentralized dispatch model for the island microgrid cluster starts with the data collection and processing phase. It begins by generating a historical scenario dataset for offline centralized optimization, determining whether the results converge, and storing the microgrid cluster dispatch plan if convergence is achieved. Simultaneously, real-time data interaction within the microgrid cluster is conducted, followed by similarity metric calculations to filter out similar historical datasets. Each microgrid then performs online optimization based on these datasets, reassessing convergence, and ultimately outputs the island microgrid cluster dispatch plan. This process transitions from a global centralized optimization perspective to a localized real-time distributed collaborative optimization, effectively balancing dispatch precision and computational efficiency. It combines scientific rigor with practical feasibility, addressing the complex operational requirements of island microgrid clusters and providing robust support for energy management.

5. Conclusions

To address the issues of efficiency and real-time performance in power mutual assistance of island microgrid groups, this paper proposes a two-stage decentralized dispatching optimization method based on similarity measurement combined with offline training and online optimization. Simulation results demonstrate that compared to independent optimization, the proposed method reduced total carbon emissions by approximately 14.1% (from 21.55 tons to 18.51 tons) and total operating cost by approximately 28.9% (from 20,784 yuan to 14,771 yuan). The distributed optimization method achieved a total cost of 14,771 yuan, deviating from centralized optimization by only 0.17% (14,746 yuan), while reducing solution time from 1.89 s to 0.746 s. The additional tests on 10- and 30-microgrid clusters demonstrate that both computation time and communication burden scale near-linearly with system size, confirming the method’s suitability for large island clusters.

The 4-island system was intentionally sized to match the capacity mix and peak-to-storage ratio reported in IEEE microgrid benchmarks and real island projects (20–60 kW PV, 10–30 kW WT, 15–50 kWh BESS, 1–2 MW tie-line). Because the proposed two-stage scheme only requires local historical data and a lightweight similarity search, its computational burden scales near-linearly with the number of microgrids and can be directly applied to clusters of ten or more islands of similar scale. The conclusions on cost and emission reductions remain valid when (i) the renewable penetration is 60–120% of annual demand and (ii) the inter-island communication delay is below 1 s. For systems with highly skewed resource distribution, large diesel shares, or demand-response programmes, the framework is still applicable; only the cost and carbon coefficients in the offline training model need to be extended accordingly, while the online similarity-plus-ADMM structure remains unchanged.

For future research, we will focus on enhancing similarity measurement algorithms using advanced machine learning techniques to improve accuracy and speed in identifying similar historical data. We will explore the integration of demand response strategies, such as dynamic pricing and incentive schemes for controllable loads, to optimize supply-demand balance.