A Laser-Induced Audible Metal Defect Detection Method Based on Spectral Discriminative Weights

Abstract

1. Introduction

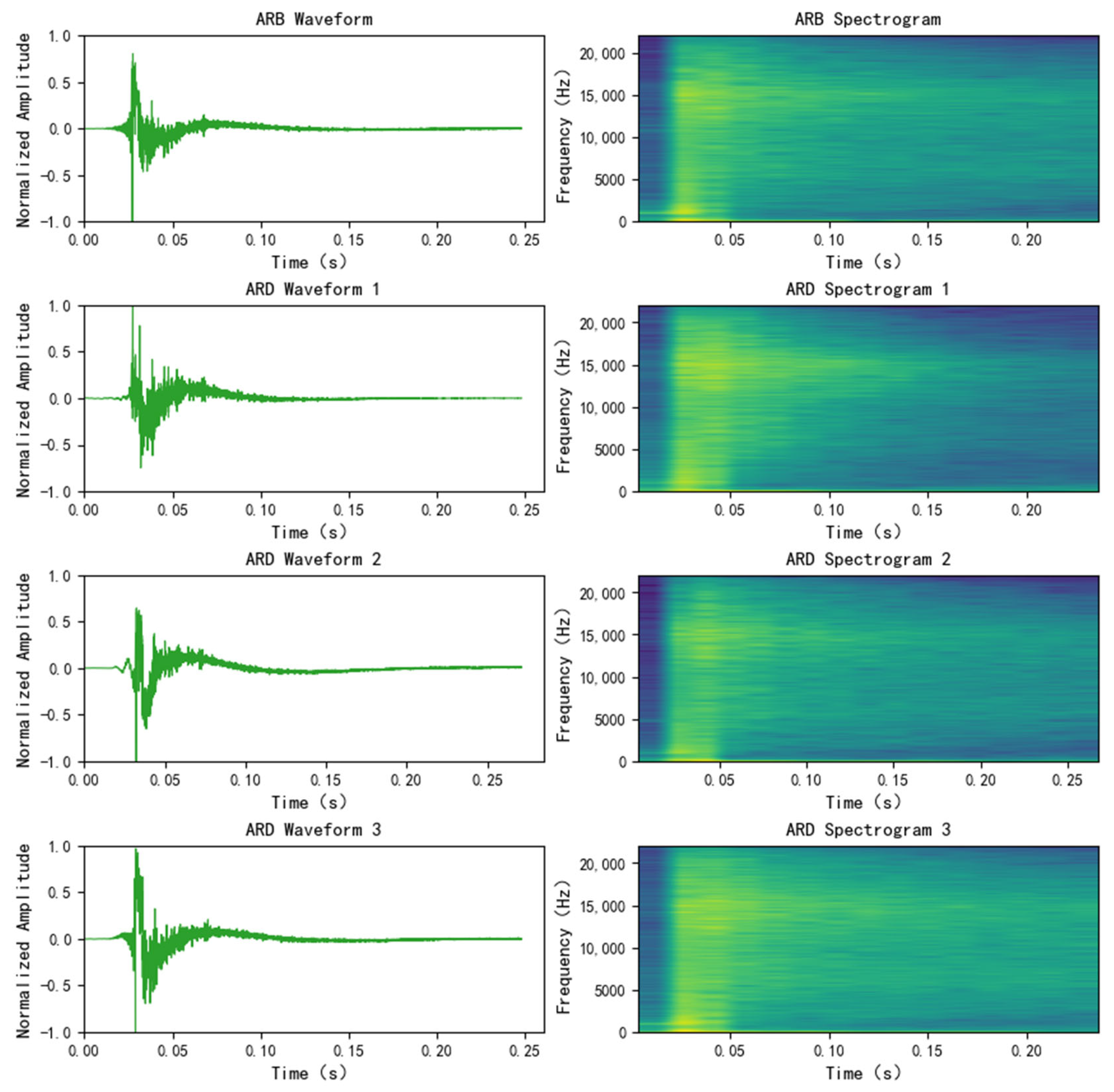

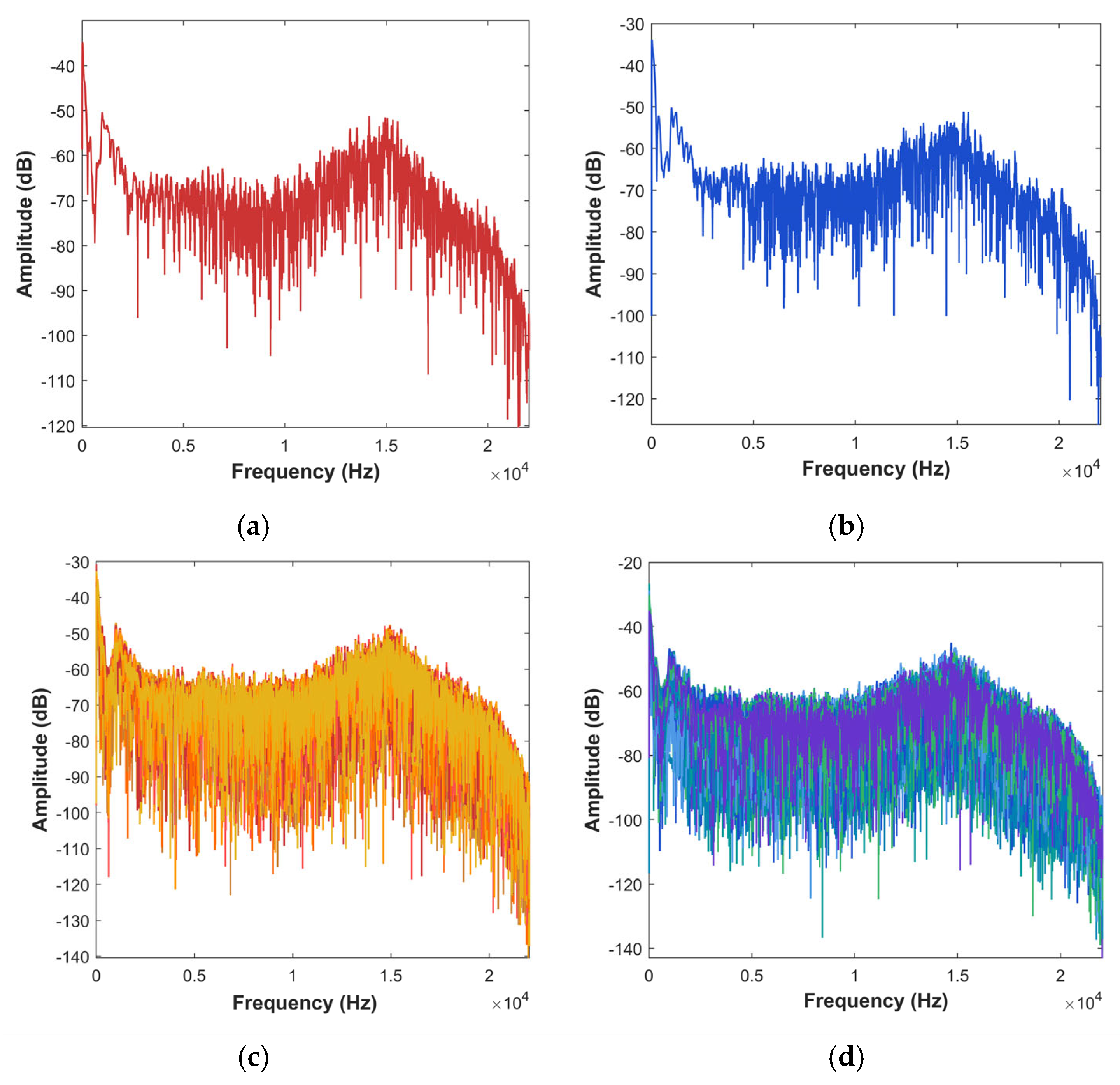

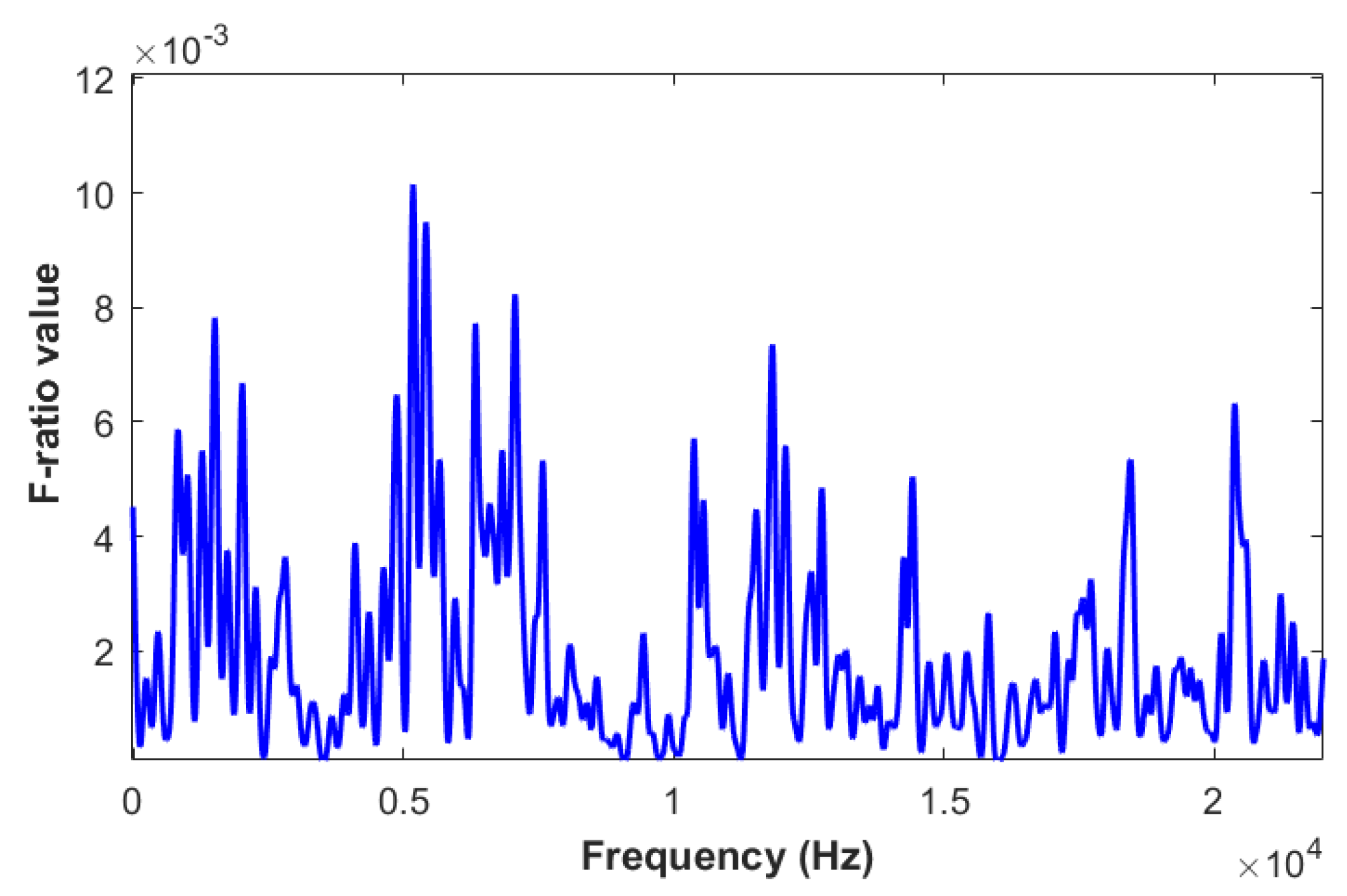

2. Spectral Discrimination Analysis of Laser-Induced Audible Sound

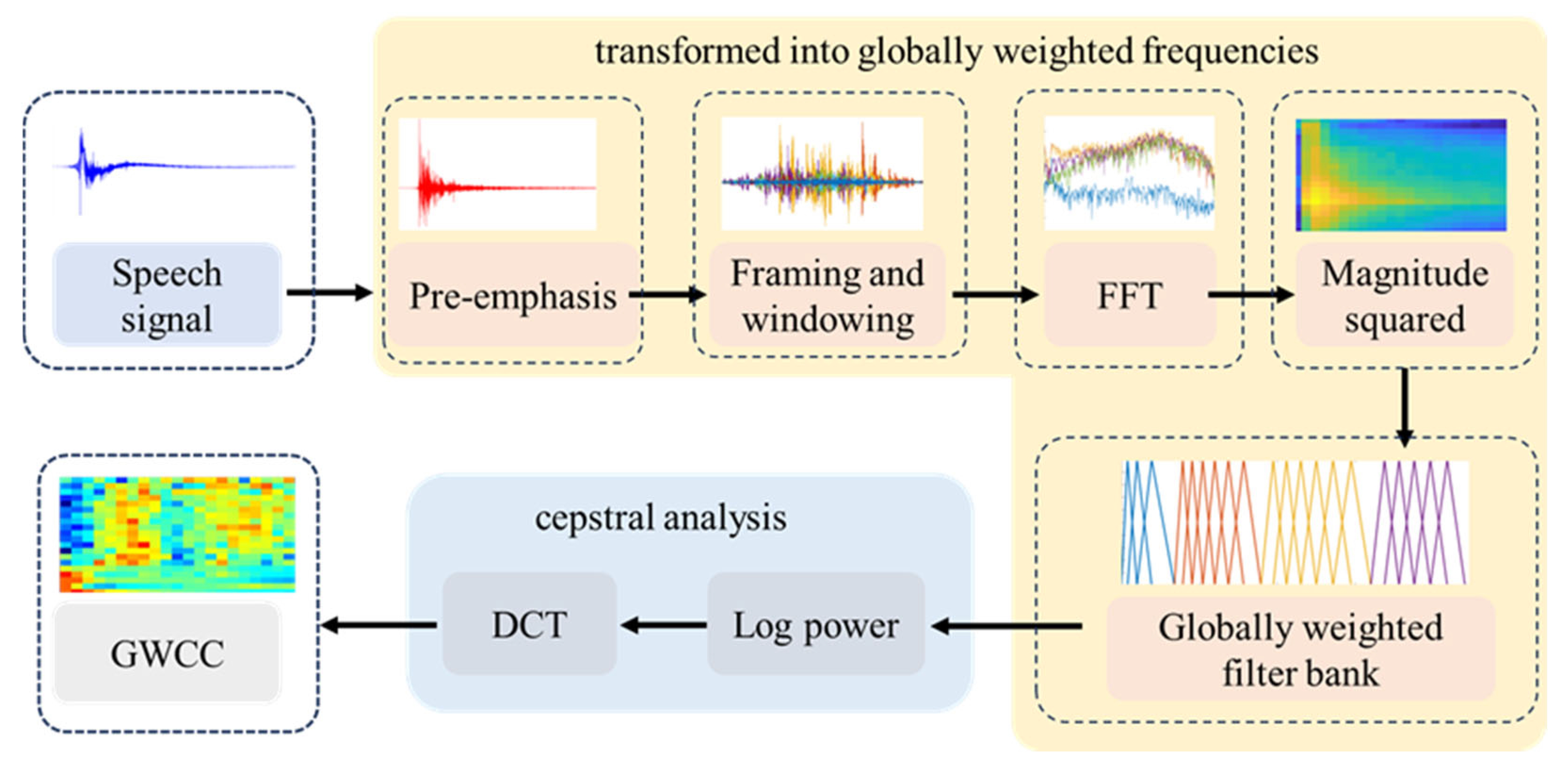

3. GWCC Feature Extraction

3.1. Feature Extraction Scheme

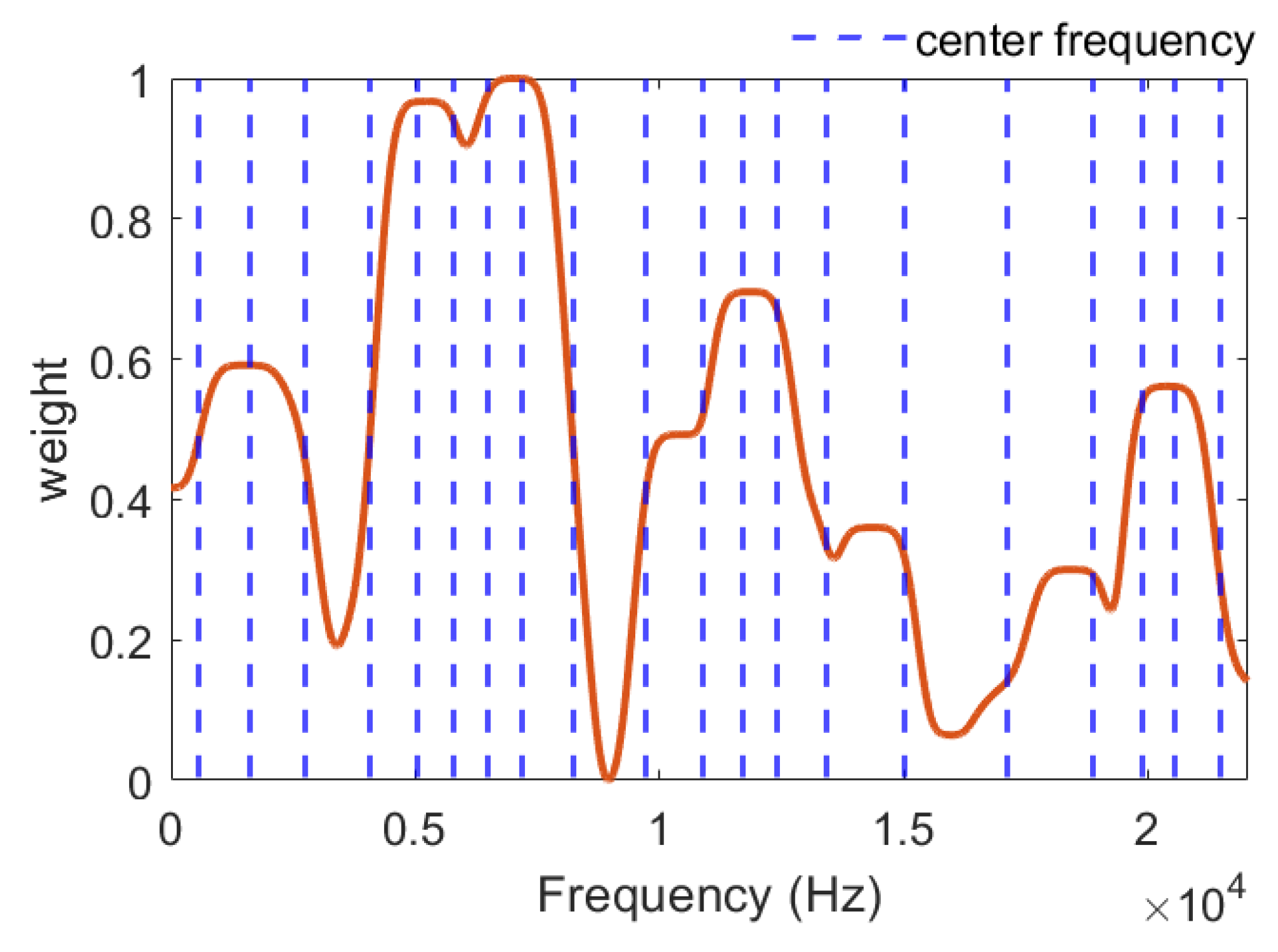

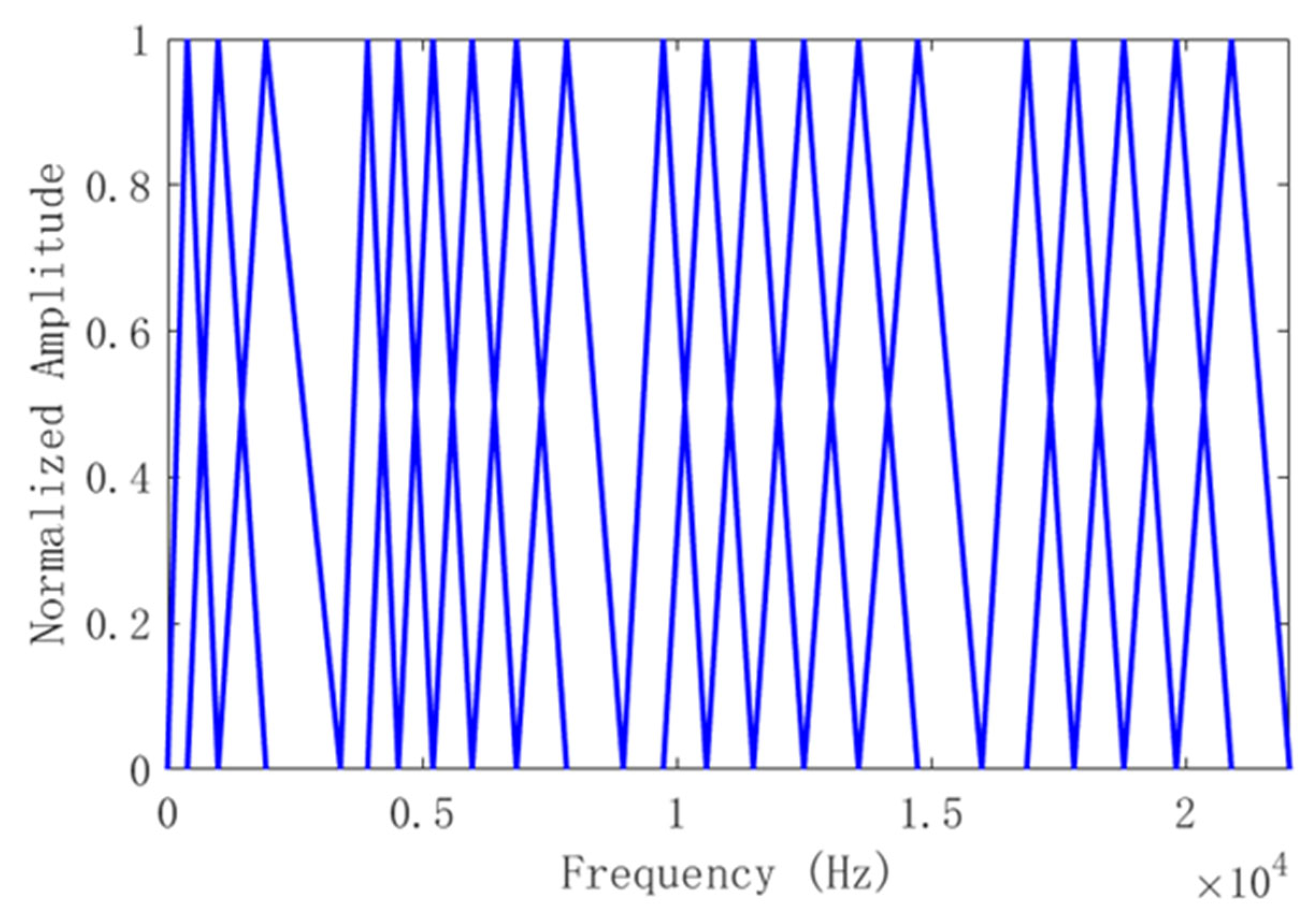

3.2. Design of Frequency-Band Weights

4. Experiment and Analysis

4.1. Experimental Setup

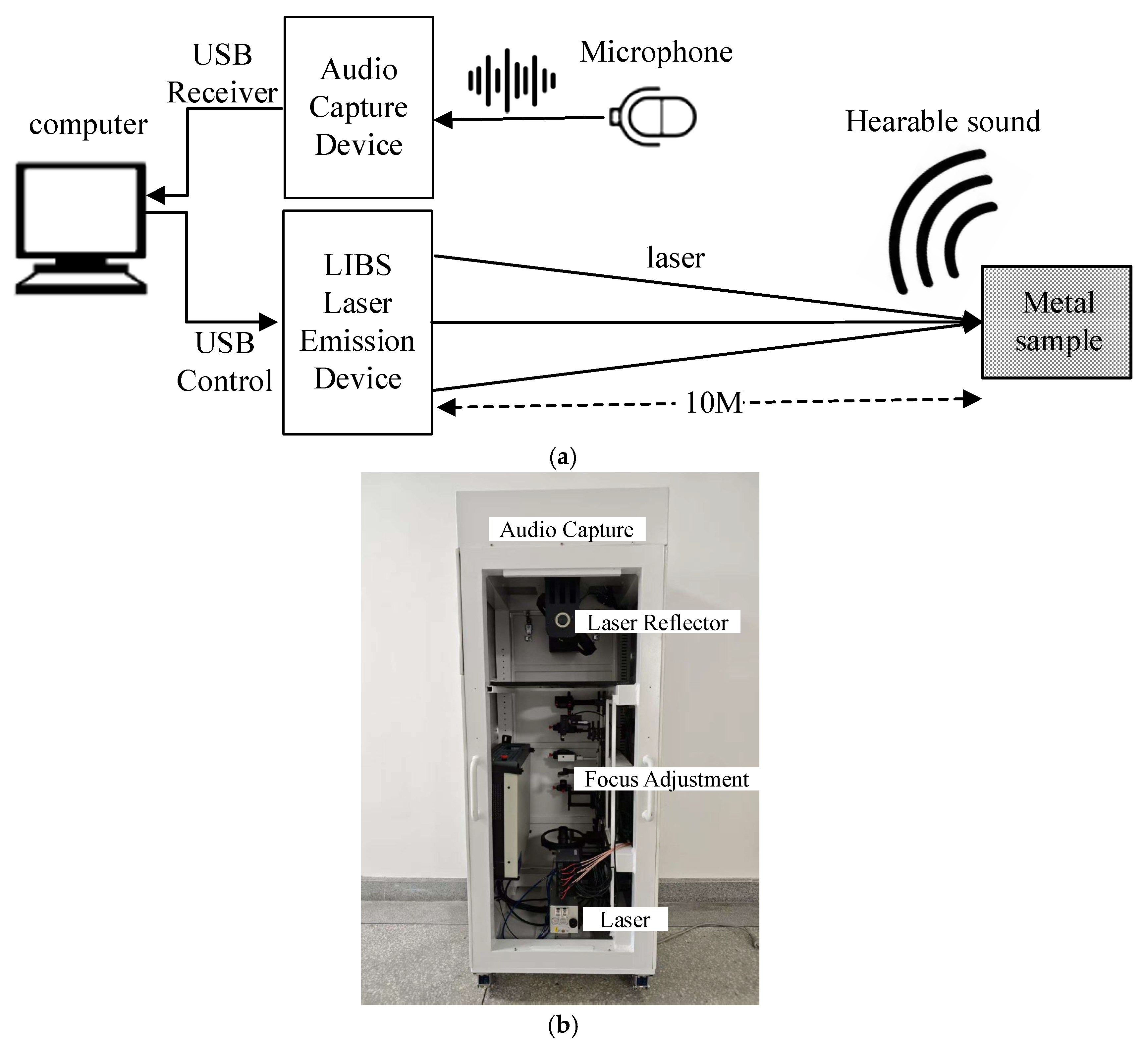

4.1.1. Laser–Acoustic Inspection System

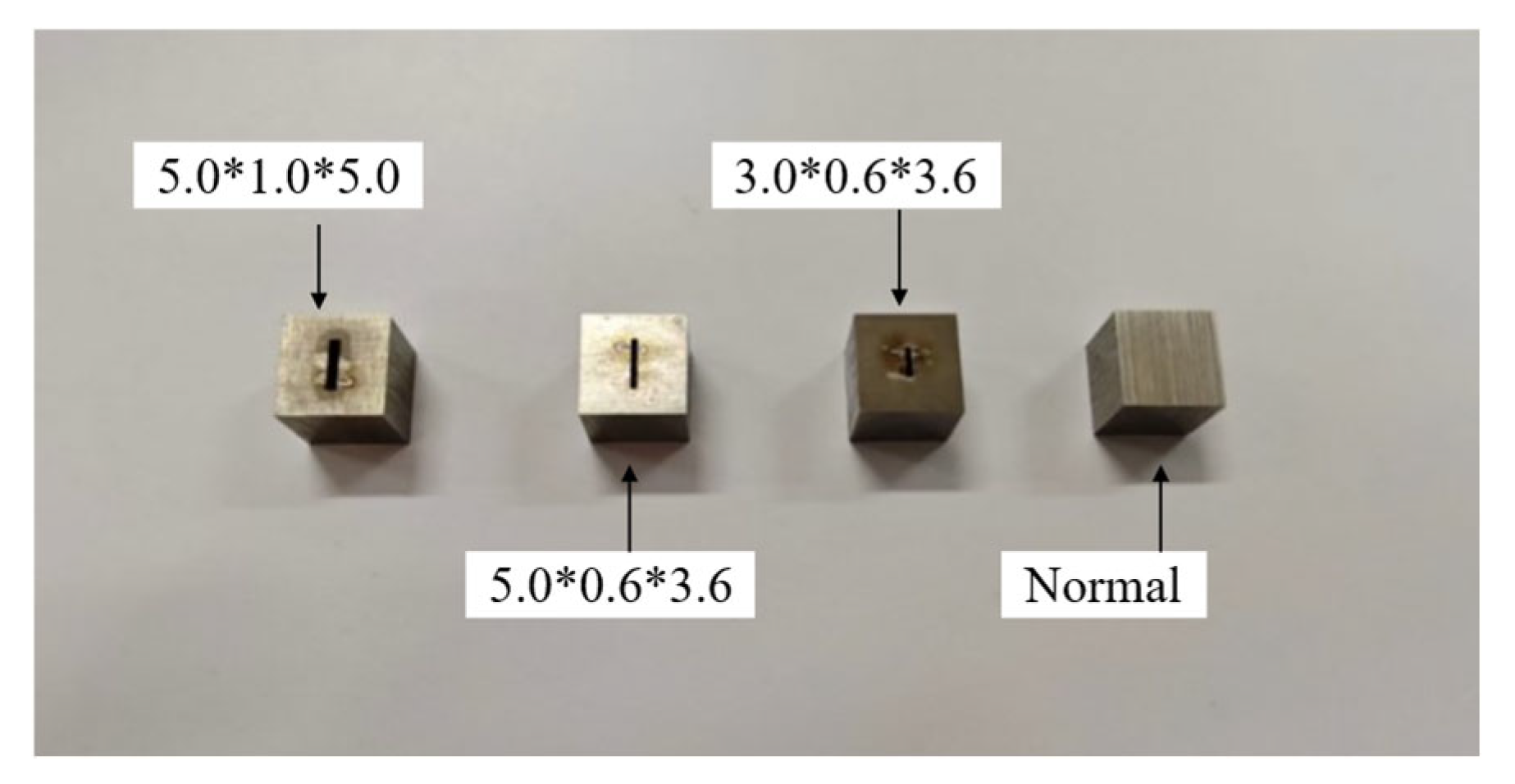

4.1.2. Experimental Dataset

4.2. Experimental Results and Analysis

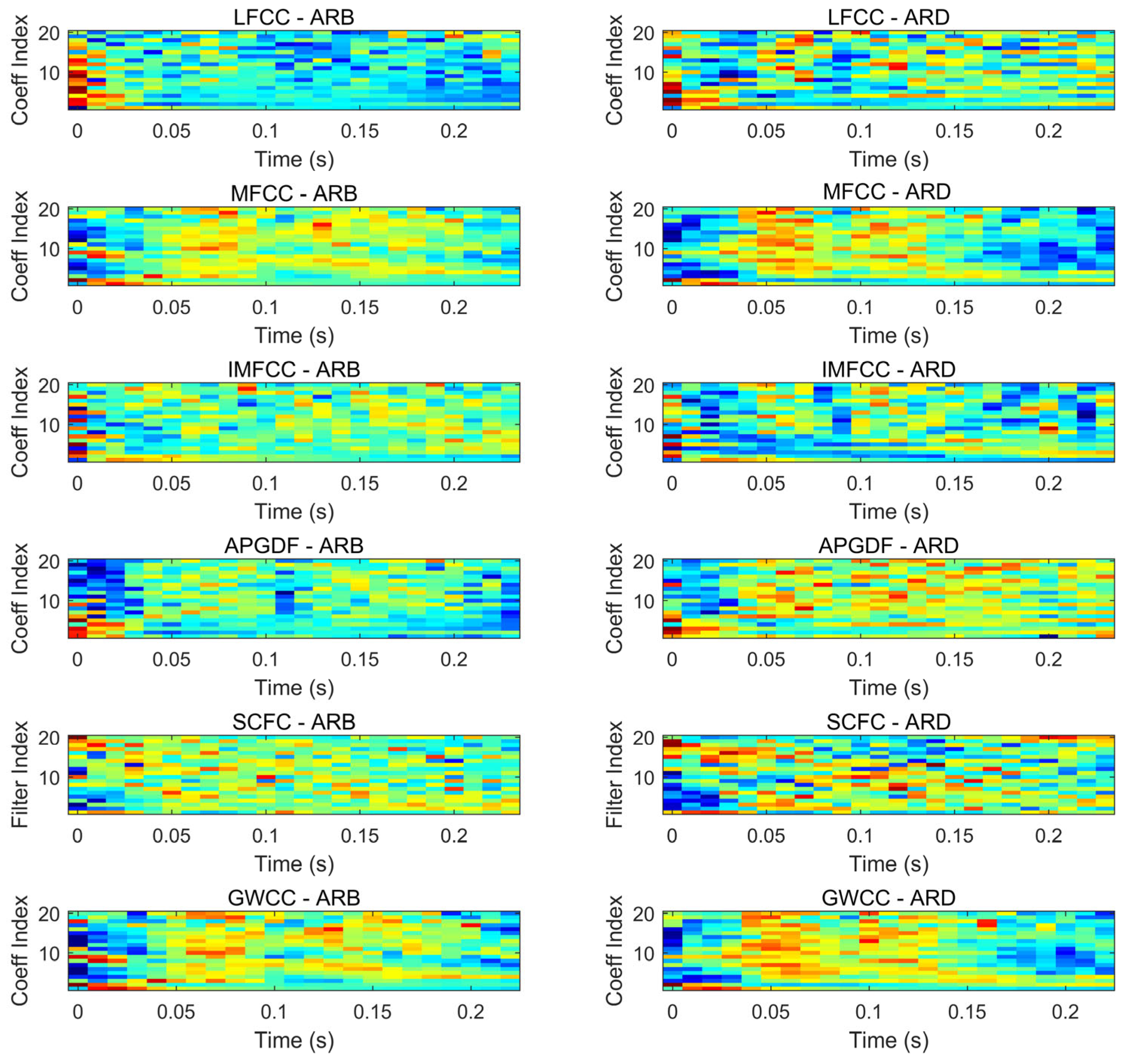

4.2.1. Feature Visualization Analysis

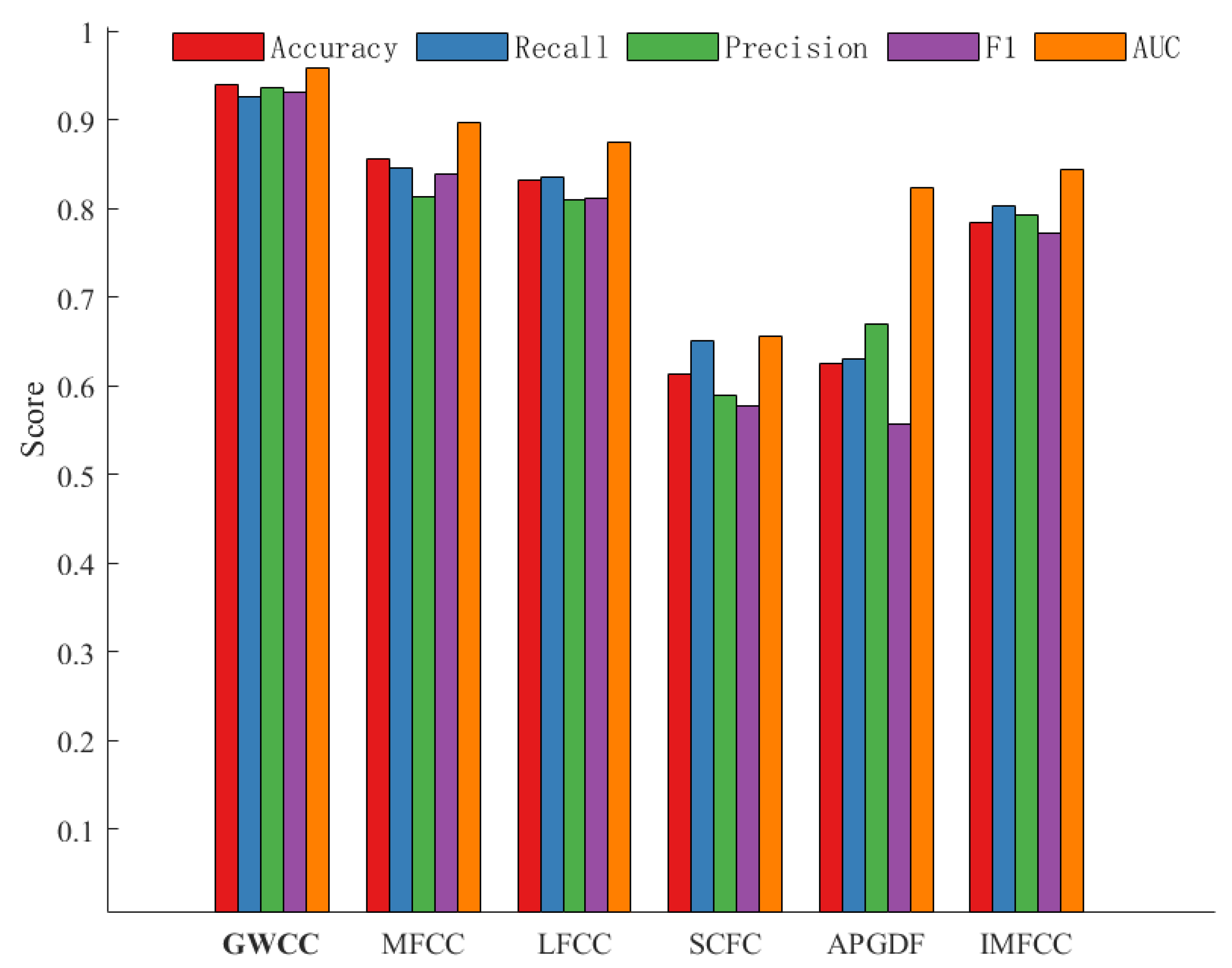

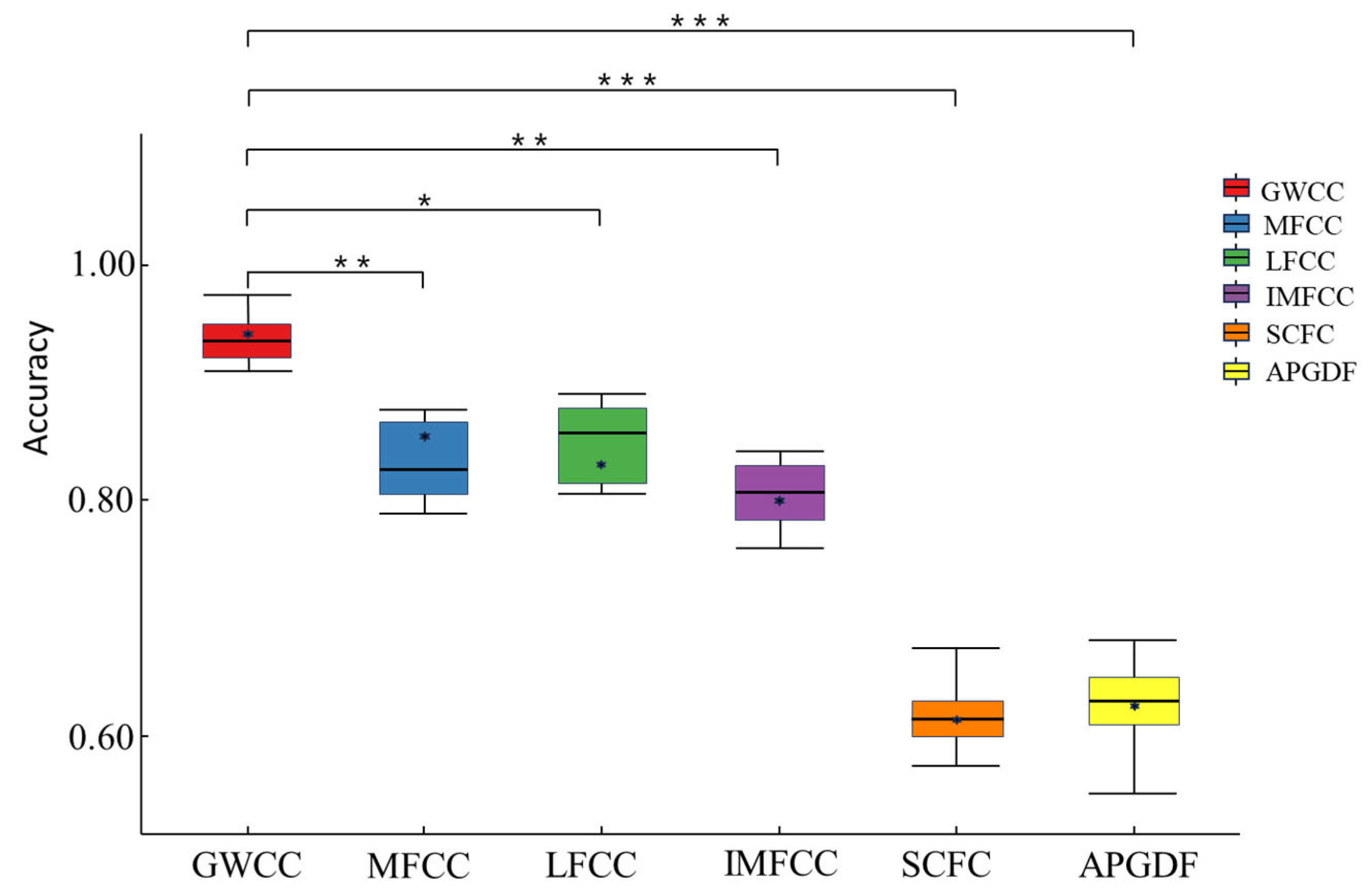

4.2.2. Feature Performance Comparison

5. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| LAST | Laser-Induced Audible Sound Testing |

| GWCC | Globally Weighted Cepstral Coefficients |

| LUT | Laser Ultrasonics |

| NDT | Non-Destructive Testing |

| UT | Ultrasonic Testing |

| CEEMD | Complementary Ensemble Empirical Mode Decomposition |

| EMAT | Electromagnetic Acoustic Testing |

| RT | Radiographic Testing |

| LIBS | Laser-Induced Breakdown Spectroscopy |

| ARD | Acoustic Response From Baseline Defective Metal Blocks |

| ARB | Acoustic Response From Baseline Defect-free Metal Blocks |

| SVM | Support Vector Machine |

| MFCC | Mel Frequency Cepstral Coefficients |

| LFCC | Linear Frequency Cepstral Coefficients |

| IMFCC | Inverted MFCC |

| SCFC | Spectral Centroid Frequency Coefficients |

| APGDF | All-Pole Group Delay Function |

References

- Lu, M.; Ding, L.; Yan, X.; Chen, Y. Application and prospect of laser ultrasonic nondestructive testing technology in advanced manufacturing. J. Vibration Meas. Diagnos. 2021, 41, 631–643. [Google Scholar]

- Fu, L.; Han, J.; Long, J. Application of ultrasonic nondestructive testing and evaluation on metal additive manufacture parts. J. Appl. Acoust. 2023, 42, 434–442. [Google Scholar]

- Liso, A.; Patruno, C.; Renò, V. A deep learning based probabilistic approach for non-destructive testing of aircraft components using laser ultrasonic data. IEEE Access 2025, 13, 66761–66773. [Google Scholar] [CrossRef]

- Joh, J.; Choi, Y.; Lee, J.R. Reverberation-based high-speed guided-wave ultrasonic propagation imager for structural inspection of thick composites. Compos. Struct. 2021, 259, 113446. [Google Scholar] [CrossRef]

- Kim, D.Y.; Cho, Y.H.; Lee, J.H. Assessment of wall-thinning in carbon steel pipe by using laser-generated guided wave. Nucl. Eng. Technol. 2010, 42, 546–551. [Google Scholar] [CrossRef]

- Selim, H.; Delgado-Prieto, M.; Trull, J.; Picó, R.; Romeral, L.; Cojocaru, C. Defect reconstruction by non-destructive testing with laser induced ultrasonic detection. Ultrasonics 2020, 101, 106000. [Google Scholar] [CrossRef] [PubMed]

- Zang, Y.; Zhang, H.; Zhu, L.; Li, Q.; Yuan, J. Application of in-situ static non-destructive testing technology in aviation equipment. Nondestr. Test. Technol. 2024, 48, 1–5. [Google Scholar]

- Zhou, H.; Gao, F.; Gu, P. Research on laser ultrasonic propagation characteristics and quantitative detection of delamination of carbon fiber composite. Optik 2022, 271, 170173. [Google Scholar] [CrossRef]

- Zhuang, B.Z.; Arcaro, A.; Gencturk, B.; Meyer, R.; Oberai, A.; Sinkov, A.; Good, M. Non-destructive evaluation and machine learning methods for inspection of spent nuclear fuel canisters: A state-of-the-art review. Prog. Nucl. Energy 2025, 185, 105697. [Google Scholar] [CrossRef]

- Voitovich, D.; Kurnikov, A.; Orlova, A.; Petushkov, A.; Shimolina, L.; Komarova, A.; Shirmanova, M.; Liu, Y.H.; Razansky, D.; Subochev, P. Local laser fluence estimation in optical resolution optoacoustic angiography employing calibrated ultrasound detector. Photoacoustics 2024, 44, 100734. [Google Scholar] [CrossRef] [PubMed]

- Hui, P.; Wei, Z. Laser ultrasonic weak defect signal detection based on Duffing oscillator. Russ. J. Nondestr. Test. 2025, 61, 23–31. [Google Scholar] [CrossRef]

- Yang, M. The Research on Ultrasonic Non-Destructive Testing Algorithm. Ph.D. Dissertation, Nanjing University of Posts and Telecommunications, Nanjing, China, 2019. [Google Scholar]

- Ma, Q. Research on Electromagnetic Eddy Current Methods and Multi-Parameter Evaluation for In-Line Detection of Pipeline Defects. Ph.D. Dissertation, University of Electronic Science and Technology of China, Chengdu, China, 2023. [Google Scholar]

- Liu, Z.; Deng, L.; Zhang, Y.; Li, A.; Bin, W.; He, C. Development of an omni-directional magnetic-concentrator-type electromagnetic acoustic transducer. NDT E Int. 2020, 109, 102193. [Google Scholar] [CrossRef]

- Kim, K.; Choi, J.; Lee, Y. Effectiveness of non-local means algorithm with an industrial 3 MeV LINAC high-energy X-ray system for non-destructive testing. Sensors 2020, 20, 2634. [Google Scholar] [CrossRef] [PubMed]

- Wang, J. Research on Automatic Defect Detection Algorithms for X-Ray Weld Images. Ph.D. Thesis, Xi’an University of Technology, Xi’an, China, 2018. [Google Scholar]

- Wang, Z.; Li, S.; Xuan, J.; Shi, T. Biologically inspired compound defect detection using a spiking neural network with continuous time–frequency gradients. Adv. Eng. Inform. 2025, 65, 103132. [Google Scholar] [CrossRef]

- Moros, J.; Gaona, I.; Laserna, J.J. Remotely exploring deeper-into-matter by non-contact detection of audible transients excited by laser radiation. Sensors 2017, 17, 2960. [Google Scholar] [CrossRef] [PubMed]

- Miyazaki, T.; Tanaka, Y. Monitoring Q-swithed YAG laser drilling process by generated sound. Int. J. Jpn. Soc. Precis. Eng. 1991, 25, 142–147. [Google Scholar]

- Chen, M.; Chen, X. Detection of replay spoof speech using global self-attentive Teager energy features. Acta Acust. 2024, 49, 1122–1130. [Google Scholar]

- Zheng, L. Research on Water Seepage Detection of Concrete Based on Percussion Method with MFCC as the Sound Feature. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2020. [Google Scholar]

- Wang, L.; Zhao, Z. Marine Mechanical Noise Monitoring System Based on MFCC-SVM. Automat. Instrum. 2020, 35, 54–58. [Google Scholar]

- Davis, S.; Mermelstein, P. Comparison of parametric representations for monosyllabic word recognition in continuously spoken sentences. IEEE Trans. Acoust. Speech Signal Process. 1980, 28, 357–366. [Google Scholar] [CrossRef]

| No. | Fixed Dimensions of Defect Region (mm) | Variable Dimension of Defect Region (mm) |

|---|---|---|

| 1-1 to 1-5 | Length = 5.0, Height = 5.0 | Width: 0.2, 0.4, 0.5, 0.6, 1.0 |

| 2-1 to 2-5 | Length = 5.0, Width = 0.6 | Height: 1.2, 2.4, 3.6, 4.8, 6.0 |

| 3-1 to 3-5 | Width = 0.6, Height = 3.6 | Length: 3.0, 4.0, 5.0, 6.0, 7.0 |

| Feature | Mean Recognition Rate | ±Standard Deviation |

|---|---|---|

| LFCC | 0.832 | ±0.035 |

| MFCC | 0.855 | ±0.043 |

| IMFCC | 0.783 | ±0.035 |

| SCFC | 0.613 | ±0.044 |

| APGDF | 0.624 | ±0.044 |

| GWCC | 0.940 | ±0.029 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, B.; Liu, T.; Hou, W.; Wang, S.; Hang, Y.; Shao, L.; Cai, Z.; Mei, J.; Chen, X. A Laser-Induced Audible Metal Defect Detection Method Based on Spectral Discriminative Weights. Electronics 2025, 14, 4175. https://doi.org/10.3390/electronics14214175

Zhu B, Liu T, Hou W, Wang S, Hang Y, Shao L, Cai Z, Mei J, Chen X. A Laser-Induced Audible Metal Defect Detection Method Based on Spectral Discriminative Weights. Electronics. 2025; 14(21):4175. https://doi.org/10.3390/electronics14214175

Chicago/Turabian StyleZhu, Bin, Tao Liu, Wuyue Hou, Sirui Wang, Yuhua Hang, Lei Shao, Zhen Cai, Jinna Mei, and Xueqin Chen. 2025. "A Laser-Induced Audible Metal Defect Detection Method Based on Spectral Discriminative Weights" Electronics 14, no. 21: 4175. https://doi.org/10.3390/electronics14214175

APA StyleZhu, B., Liu, T., Hou, W., Wang, S., Hang, Y., Shao, L., Cai, Z., Mei, J., & Chen, X. (2025). A Laser-Induced Audible Metal Defect Detection Method Based on Spectral Discriminative Weights. Electronics, 14(21), 4175. https://doi.org/10.3390/electronics14214175