Low-Voltage Stressed Inductive WPT System with Pull–Push Class EF2 Inverter

Abstract

1. Introduction

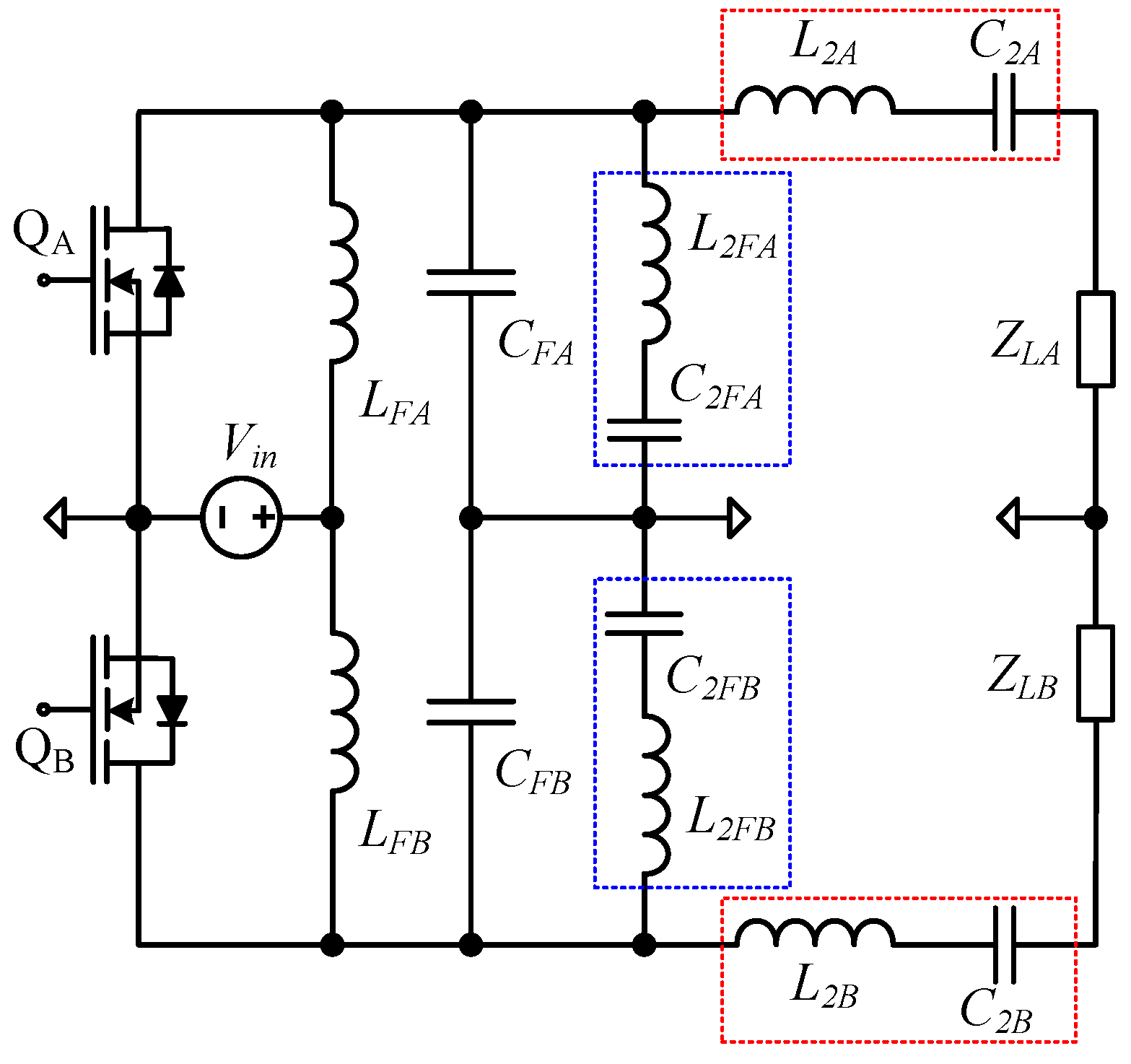

2. Modeling and Analysis of Pull–Push Class EF2 Inverter

2.1. Topology Structure

2.2. Mathematical Model of the Resonant Parameters

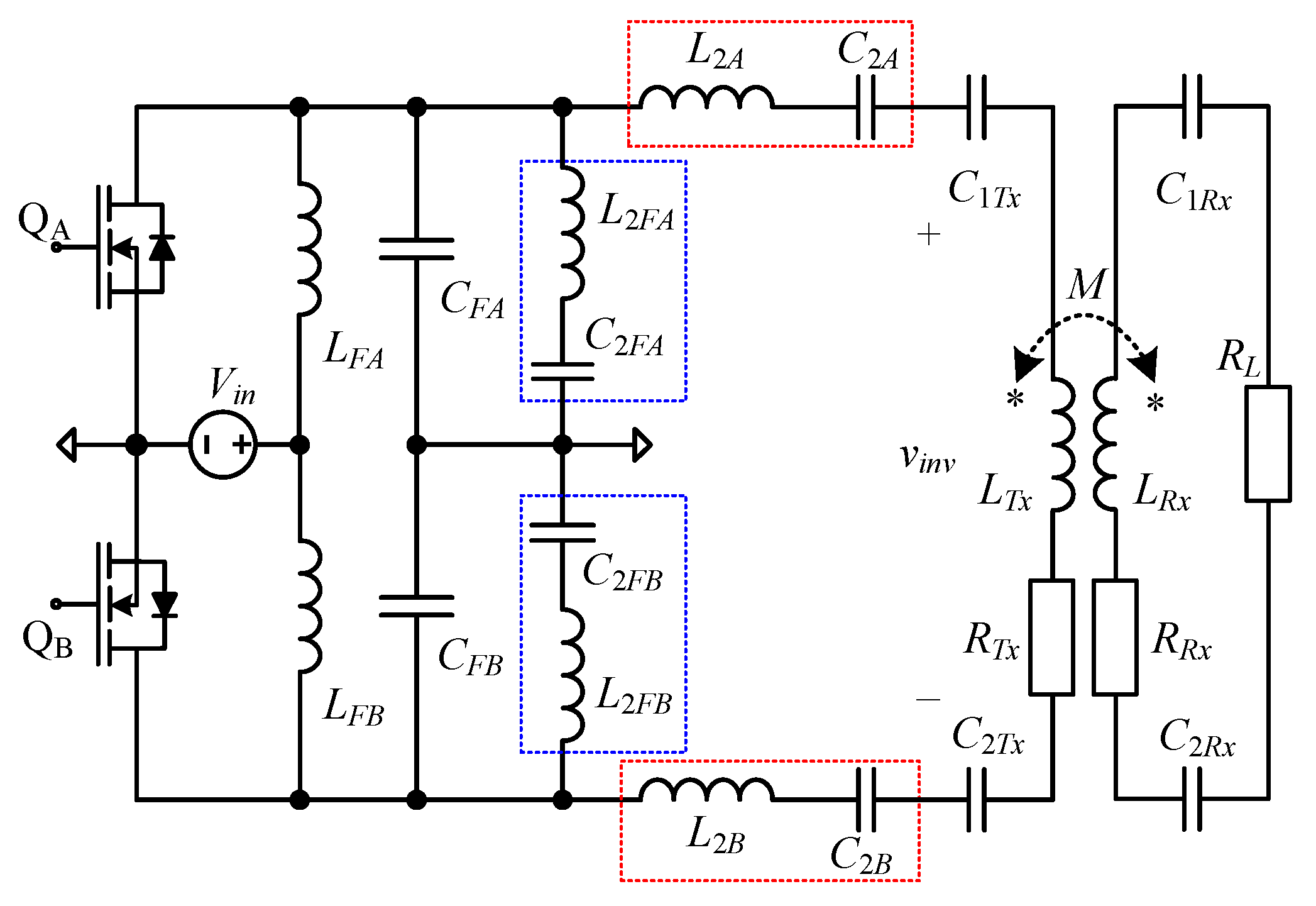

3. Wireless Power Transfer System with Pull–Push Class EF2 Inverter

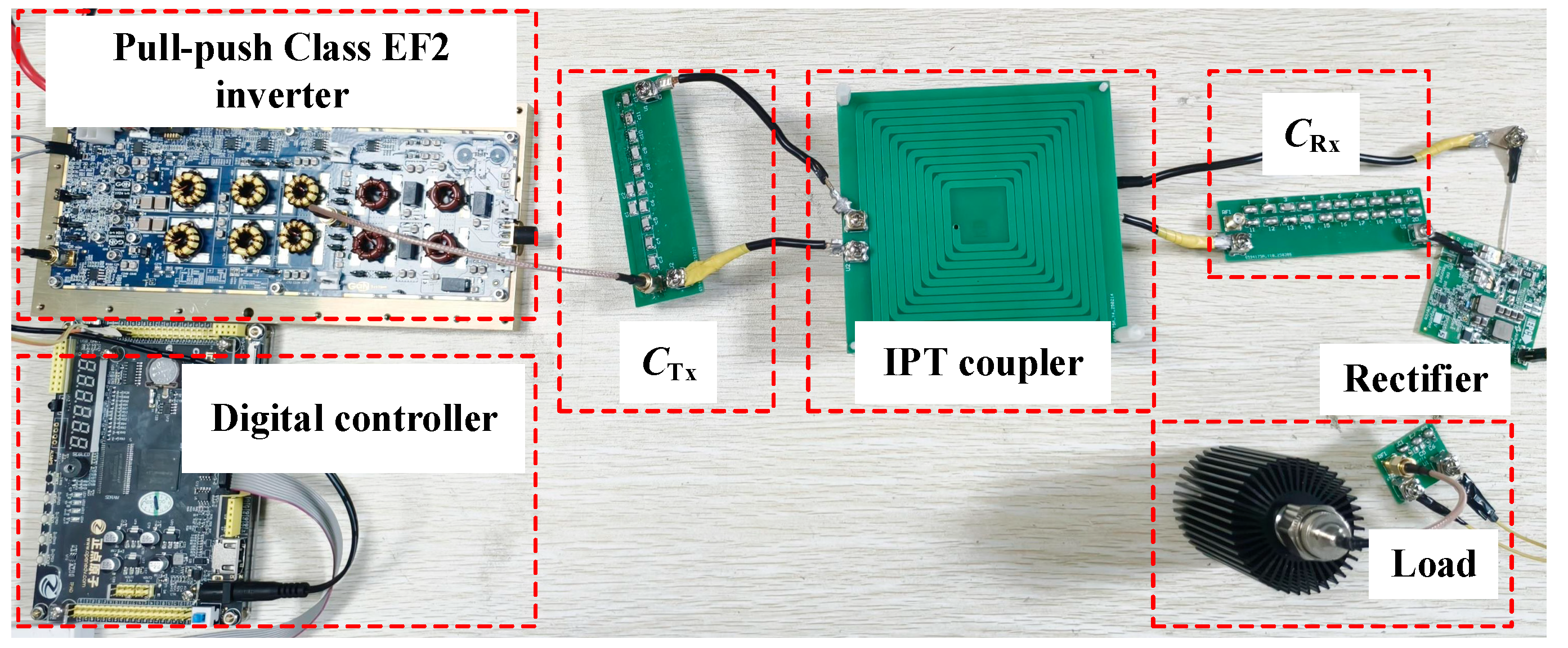

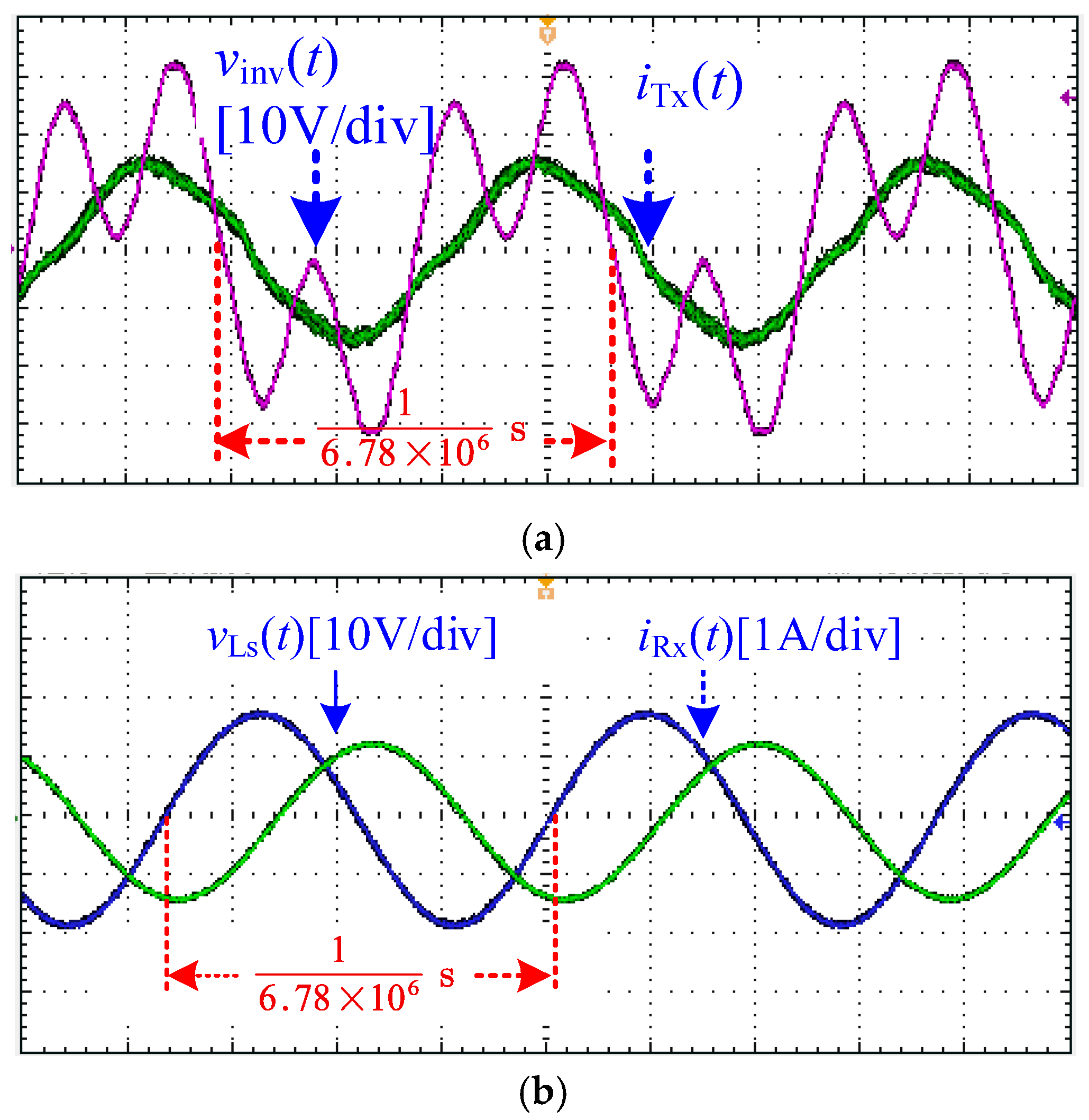

4. System Prototype and Experimental Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alotaibi, F.M. Optimized Coupling Coil Geometry for High Wireless Power Transfer Efficiency in Mobile Devices. J. Low Power Electron. Appl. 2025, 15, 36. [Google Scholar] [CrossRef]

- Niu, S.; Jia, Q.; Hu, Y.; Yang, C.; Jian, L. Safety Management Technologies for Wireless Electric Vehicle Charging Systems: A Review. Electronics 2025, 14, 2380. [Google Scholar] [CrossRef]

- Chai, L.; Song, C.; Lu, J. A Coaxial and Coplanar Wireless Slipring for Multi-Axis Robot Manipulators. Electronics 2022, 11, 2352. [Google Scholar] [CrossRef]

- Liu, M.; Qiao, Y.; Liu, S.; Ma, C. Analysis and Design of a Robust Class E2 DC–DC Converter for Megahertz Wireless Power Transfer. IEEE Trans. Power Electron. 2017, 32, 2835–2845. [Google Scholar] [CrossRef]

- Jawad, A.M.; Nordin, R.; Jawad, H.M.; Gharghan, S.K.; Abu-Samah, A.; Abu-Alshaeer, M.J.; Abdullah, N.F. Wireless Drone Charging Station Using Class-E Power Amplifier in Vertical Alignment and Lateral Misalignment Conditions. Energies 2022, 15, 1298. [Google Scholar] [CrossRef]

- Li, Q.; Duan, S.; Fu, H. Analysis and Design of Single-Ended Resonant Converter for Wireless Power Transfer Systems. Sensors 2022, 22, 5617. [Google Scholar] [CrossRef] [PubMed]

- Detka, K.; Górecki, K. Wireless Power Transfer—A Review. Energies 2022, 15, 7236. [Google Scholar] [CrossRef]

- Ashique, R.H.; Maruf, M.H.; Sourov, K.M.S.H.; Islam, M.M.; Islam, A.; Rabbani, M.; Islam, M.R.; Khan, M.M.; Shihavuddin, A. A Comparative Performance Analysis of Zero Voltage Switching Class E and Selected Enhanced Class E Inverters. Electronics 2021, 10, 2226. [Google Scholar] [CrossRef]

- Ashique, R.H.; Arif, M.S.B.; Bhatti, A.R.; Al Mansur, A.; Maruf, M.H.; Shihavuddin, A. The ZVS Class E/F3 Inverter Using Piezoelectric Transformers for Energy Extraction. Electronics 2023, 12, 2118. [Google Scholar] [CrossRef]

- Xiao, W.; Shen, R.; Zhang, B.; Qiu, D.; Chen, Y.; Li, T. Effects of Foreign Metal Object on Soft-Switching Conditions of Class-E Inverter in WPT. Energies 2018, 11, 1926. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, J.; Wu, Y.; Mao, L.; Xu, J.; Chen, J. Analysis and Implementation of Inverter Wide-Range Soft Switching in WPT System Based on Class E Inverter. Energies 2020, 13, 5187. [Google Scholar] [CrossRef]

- Maji, S.; Etta, D.; Afridi, K.K. Comparison of Resonant Inverter Topologies for Multi-MHz Wireless Power Transfer Systems. In Proceedings of the 2024 IEEE Energy Conversion Congress and Exposition (ECCE), Phoenix, AZ, USA, 20–24 October 2024; pp. 2187–2192. [Google Scholar] [CrossRef]

- Aizawa, S.; Yasuda, T.; Uchida, A.; Luo, W.; Wei, X.; Sekiya, H. Load-Independent Class-E Inverter with a Class-D Rectifier. In Proceedings of the 2023 12th International Conference on Renewable Energy Research and Applications (ICRERA), Oshawa, ON, Canada, 29 August–1 September 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 279–282. [Google Scholar]

- Chen, C.; Wang, H.; Ning, G.; Chen, X.; Su, M. Cascaded resonant RF drive design and soft switching optimization of high-power Class-E power amplifiers. In Proceedings of the 2022 4th International Conference on Smart Power & Internet Energy Systems (SPIES), Beijing, China, 9–12 December 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1539–1543. [Google Scholar]

- Koyama, S.; Mizutani, M.; Ohira, T. Power imbalance compensation of parallel combining twin class-E inverters by DC current detection fed back to gate-signal phase control. In Proceedings of the 2020 IEEE International Conference on Power and Energy (PECon), Penang, Malaysia, 7–8 December 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 89–94. [Google Scholar]

- Huang, X.; Yu, Z.; Dou, Y.; Lin, S.; Ouyang, Z.; Andersen, M.A. Load-independent push–pull Class E2 topology with coupled inductors for MHz-WPT applications. IEEE Trans. Power Electron. 2022, 37, 8726–8737. [Google Scholar] [CrossRef]

- Pezeshkpour, S.; Ahmadi, M.M. Design Procedure for a High-Efficiency Class-E/F3 Power Amplifier. IEEE Trans. Power Electron. 2023, 38, 14388–14399. [Google Scholar] [CrossRef]

- Behera, R.K.; Behera, R.K. Wireless Charging of Electric Vehicles Using Class EF2 Resonant Inverter. In Proceedings of the 2023 11th National Power Electronics Conference (NPEC), Guwahati, India, 14–16 December 2023; pp. 1–6. [Google Scholar]

- Behera, R.K. Wireless Charging of Electric Vehicle Using EF2 Inverter for 3. In 3KW System. In Proceedings of the 2024 IEEE 4th International Conference on Sustainable Energy and Future Electric Transportation (SEFET), Hyderabad, India, 31 July–3 August 2024; pp. 1–6. [Google Scholar]

- Zhou, W.; Chen, Z.; Zhang, Q.; Li, Z.; Huang, L.; Mai, R.; He, Z. Design and Analysis of CPT System with Wide-Range ZVS and Constant Current Charging Operation Using 6.78 MHz Class-E Power Amplifier. IEEE J. Emerg. Sel. Top. Power Electron. 2024, 12, 3211–3225. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, C.; Ouyang, Y.; Xiao, J.; Hu, H.; Chen, F.; Thrimawithana, D.J.; Hu, P.A. An integrated 6.78-MHz Class Φ2 converter using bifurcation phenomenon of resonance between the isolation transformer. IEEE Trans. Power Electron. 2024, 39, 12003–12007. [Google Scholar] [CrossRef]

| Parameters | Symbol | Value (Unit) |

|---|---|---|

| Operating frequency | f | 6.78 MHz |

| Self-inductances of the Tx and Rx coils | 28.13 µH | |

| Coupling factor | k | 0.38 |

| Rated load resistance | 50 Ω | |

| Choke inductances | 180.00 nH | |

| Parallel connected capacitances | 1.45 nF | |

| Parallel resonant network | 185.00 nH | |

| 0.75 nF | ||

| Series resonant network | 6.30 μH | |

| 87.46 nF |

| Topology | Frequency | Efficiency | Output Power | Power Switch Voltage Stress | |

|---|---|---|---|---|---|

| This work | Pull–push class EF2 inverter | 6.78 MHz | 90.1% | 100 W | 1.16 × Vin |

| [10] | Class E inverter | 1 MHz | 85% | ≈130 W | 3.6 × Vin |

| [11] | 100 kHz | 75% | 13 W | Not mentioned | |

| [13] | 1 MHz | 89.2% | Not mentioned | Not mentioned | |

| [14] | Cascaded class E inverter | 13.56 MHz | 80.19% | 2 kW | 3.564 × Vin |

| [15] | Class E inverter | 6.78 MHz | 97.2% | 490 W | 3.5 × Vin |

| [18] | Class EF2 inverter | 1 MHz | Not mentioned | 500 W | 2.5 × Vin |

| [19] | 85 kHz | Not mentioned | 3.3 kW | Not mentioned | |

| [21] | 6.78 MHz | 90.5% | 30 W | 2.54 × Vin |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Kuang, J.; Li, C.; Chen, Z.; Mei, J.; Chen, P.; Lu, J. Low-Voltage Stressed Inductive WPT System with Pull–Push Class EF2 Inverter. Electronics 2025, 14, 3693. https://doi.org/10.3390/electronics14183693

Wang Y, Kuang J, Li C, Chen Z, Mei J, Chen P, Lu J. Low-Voltage Stressed Inductive WPT System with Pull–Push Class EF2 Inverter. Electronics. 2025; 14(18):3693. https://doi.org/10.3390/electronics14183693

Chicago/Turabian StyleWang, Yuting, Jiayue Kuang, Chang Li, Zhidi Chen, Jie Mei, Peng Chen, and Jianghua Lu. 2025. "Low-Voltage Stressed Inductive WPT System with Pull–Push Class EF2 Inverter" Electronics 14, no. 18: 3693. https://doi.org/10.3390/electronics14183693

APA StyleWang, Y., Kuang, J., Li, C., Chen, Z., Mei, J., Chen, P., & Lu, J. (2025). Low-Voltage Stressed Inductive WPT System with Pull–Push Class EF2 Inverter. Electronics, 14(18), 3693. https://doi.org/10.3390/electronics14183693