The common conventional FSPM machines with composite phases are four-, six-, nine-, and twelve-phase machines, which can be considered as a combination of multiple machines with prime phases. For example, four-phase conventional FSPM machines can be deduced from two-phase machines, and six-, nine-, and twelve-phase conventional FSPM machines can be deduced from three-phase machines.

2.1. Six-Phase Conventional FSPM Machines

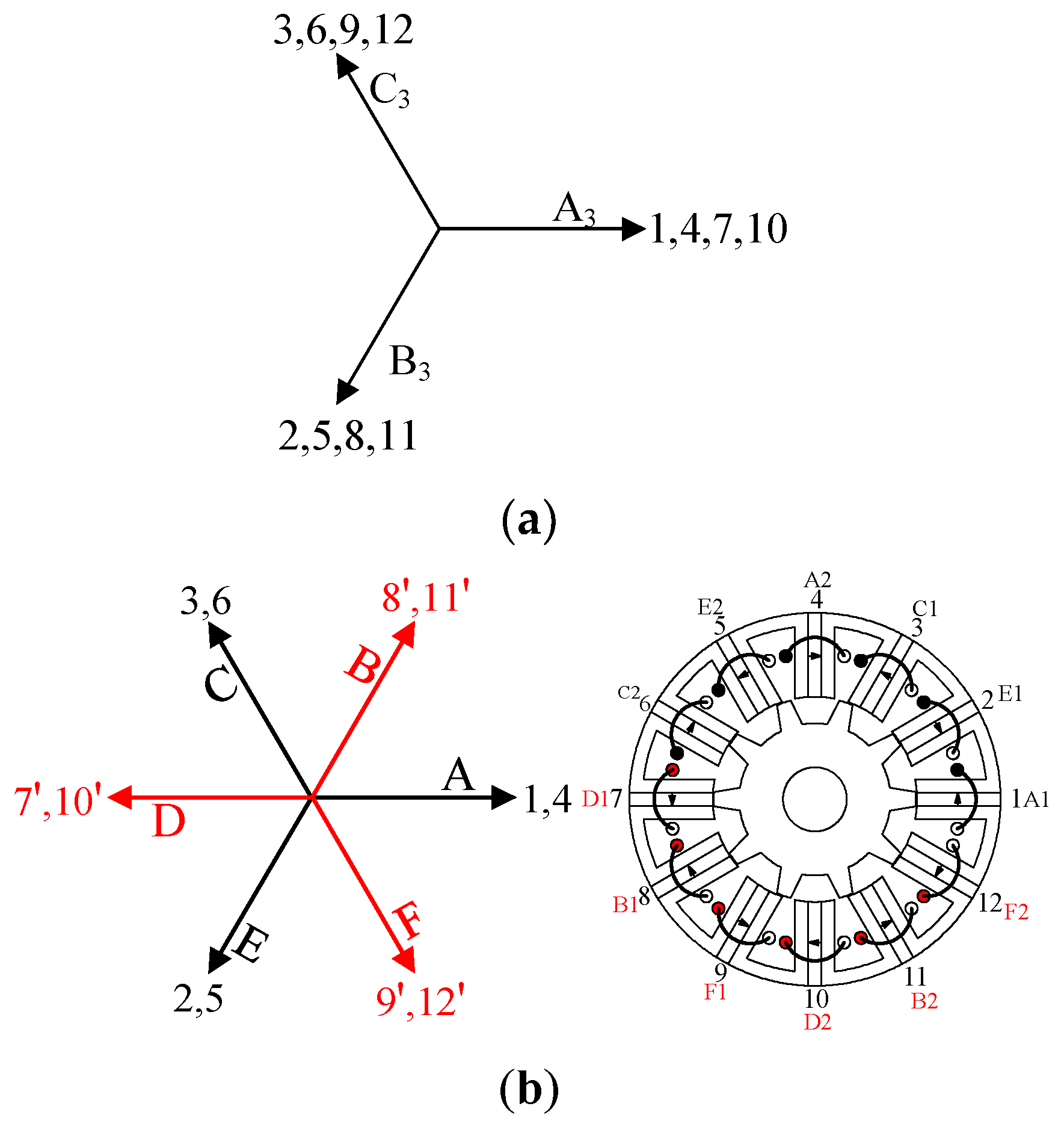

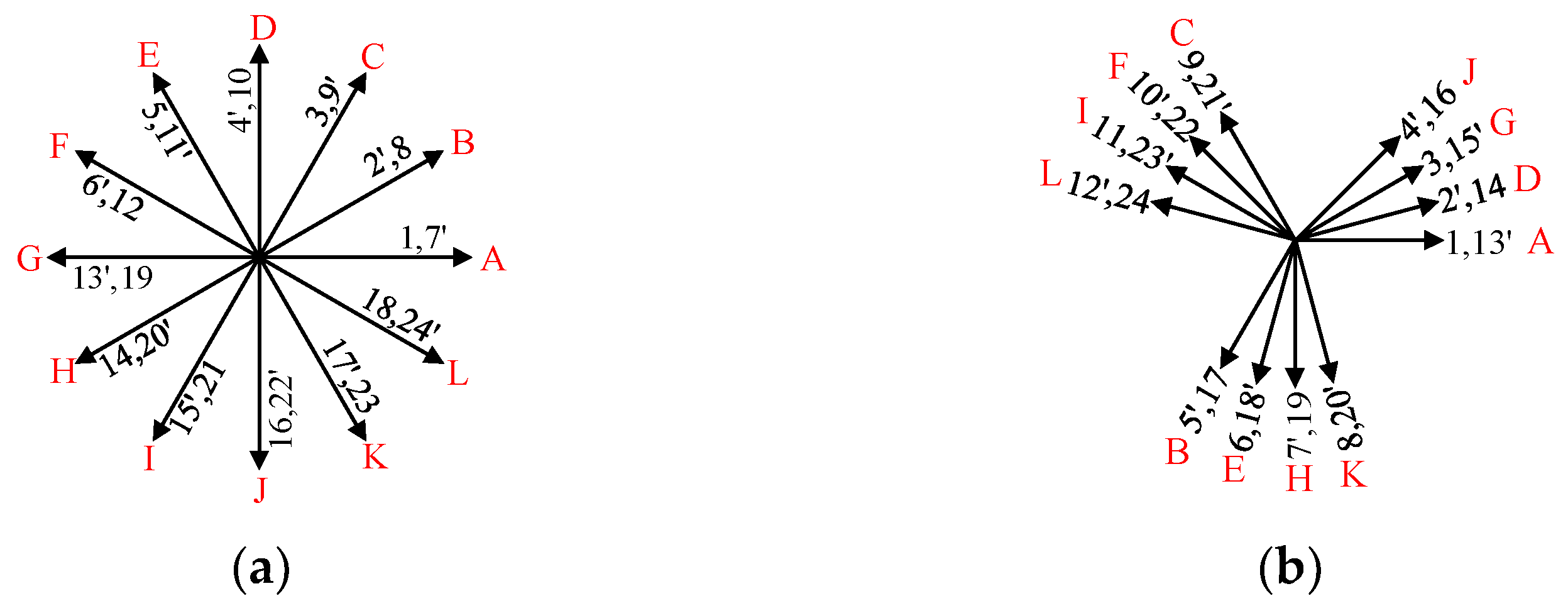

According to different connection styles, the machines with prime phase numbers could be connected into symmetrical and asymmetrical topologies with composite phases. For six-phase conventional FSPM machines, the standard six-phase machine has a symmetrical structure, and the dual three-phase machine has an asymmetrical structure, as shown in

Figure 1.

Both the symmetrical and asymmetrical six-phase structures can be obtained by combining three-phase machines. The parameter

q′ is the equivalent number of coils per pole per phase, i.e., the number of the consecutively adjacent coils belonging to the same phase, and

K is the number of coil pairs having complementarity for the three-phase machines. Similarly,

q6′ and

K6 are the corresponding parameters of six-phase machines, i.e., the numbers of the consecutively adjacent stator coils belonging to the same phase and coil-pairs having complementarity for six-phase machines. For the three-phase machines with

q′ being an odd number and

K being an even number, including 12/10, 12/14, 24/20, 24/28, 36/34, and 36/38 topologies, if half of the stator coils connect in opposite polarity, the machines could be connected into a standard six-phase machine. Taking a 12/10 topology shown in

Figure 2 as an example, the 12/10 topology shown in

Figure 2a is a three-phase structure with

q′ = 1 and

K = 2, where coils 1, 4, 7, and 10, coils 2, 5, 8, and 11, and coils 3, 6, 9, and 12 belong to phases A

3, B

3, and C

3, respectively (A

3, B

3, and C

3 represent the three phases of three-phase machines). However, the structure can be connected into a standard six-phase 12/10 machine shown in

Figure 2b by half coils connected in opposite polarity to A

3, B

3, and C

3. Coils 1 and 4, coils 2 and 5, and coils 3 and 6 remain the same polarity with A

3, B

3, and C

3, composing phases A, E, and C. Coils 7 and 10 are connected in opposite polarity, composing phase D. Similarly, the phases B and F are composed of coils 8 and 11 and coils 9 and 12 in opposite polarity, respectively. It should be noted that the coils connected in reverse are marked with prime indices, such as 7′ in

Figure 2b. For the reconnected standard six-phase machine, the number of the consecutively adjacent stator coils belonging to the same phase and coil-pairs having complementarity are both 1, namely,

q6′ = 1 and

K6 = 1.

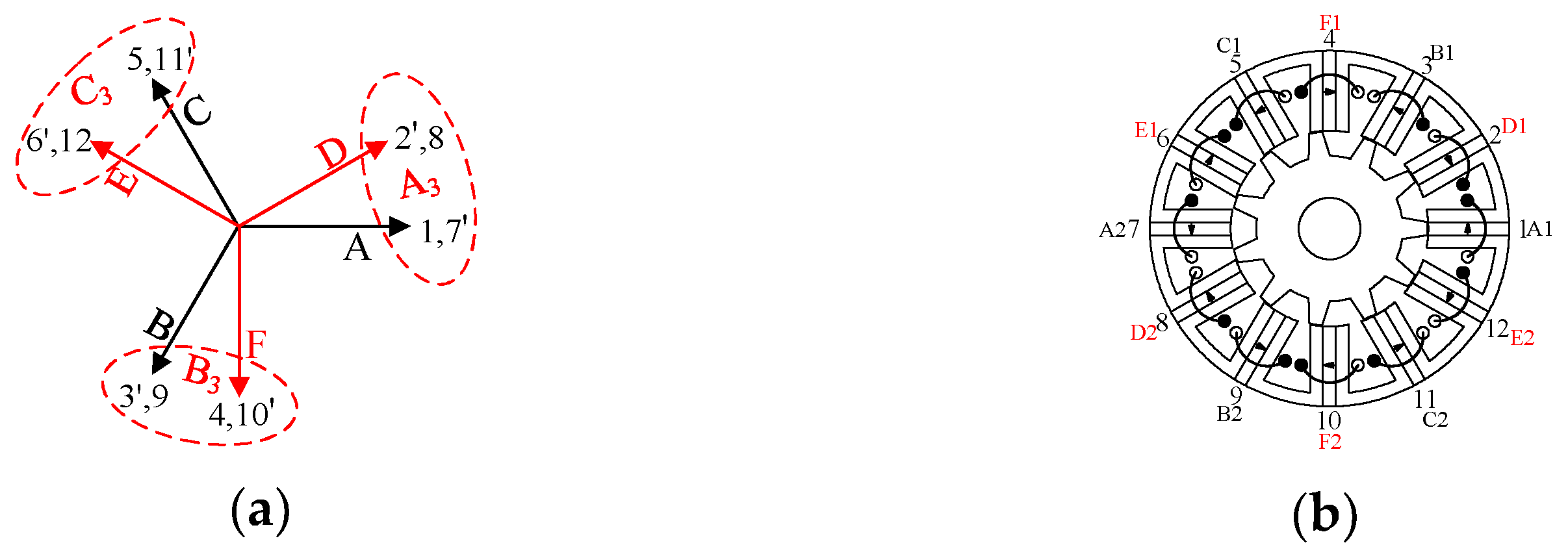

The three-phase machines, with

q′ being an even number, such as 12/11, 12/13, 24/22, 24/26, 24/23, 24/25, etc., could be reconnected into dual three-phase machines. Taking the three-phase 12/11 topology (

q′ = 2 and

K = 1) as an example, phases A

3, B

3, and C

3 are, respectively, composed of coils 1, 2, 7, and 8, coils 3, 4, 9, and 10, and coils 5, 6, 11, and 12, as is illustrated in

Figure 3a, where winding-EMF vectors of phases A

3, B

3, and C

3 are, respectively, synthesized from two coil-EMF vectors. Hence, if the coils of the same coil-EMF vector connect into a phase winding, i.e., coils 1 and 7, coils 3 and 9, coils 5 and 11, coils 2 and 8, coils 6 and 12, and coils 4 and 10, respectively, connect into phases A, B, C, D, E, and F; the three-phase 12/11 machine then turns into a dual three-phase 12/11 machine, as is shown in

Figure 3, where

q6′ = 1 and

K6 = 1.

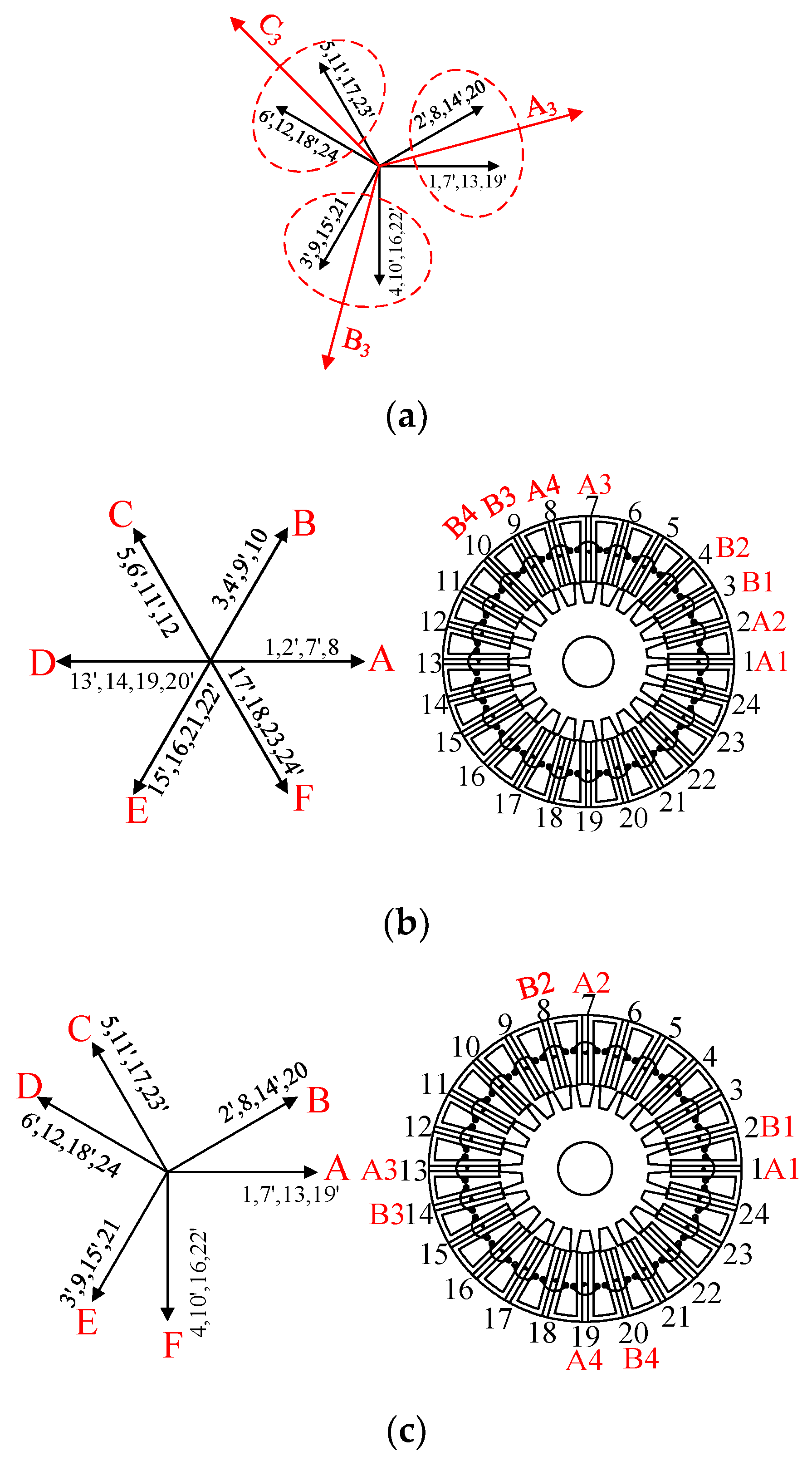

It should be noted that when

q′ is an even number, on the one hand, the machines can all be connected into dual three-phase machines, whatever the parameter

K is. On the other hand, if

K is also an even number, the machines could also be connected to standard six-phase machines. Taking a three-phase 24/22 structure shown in

Figure 4a as an example, where

q′ = 2 and

K = 2, phase A

3 consists of coils 1, 2, 7, 8, 13, 14, 19, and 20, and phases B

3 and C

3 are, respectively, composed of coils 3, 4, 9, 10, 15, 16, 21, and 22 and coils 5, 6, 11, 12, 17, 18, 23, and 24. Winding vectors of phases A

3, B

3, and C

3 are, respectively, synthesized from two coil vectors. If half of the coils in phases A

3, B

3, and C

3 are connected in opposite polarity, it turns out to be a standard six-phase 24/22 machine with

q6′ = 2 and

K6 = 1 shown in

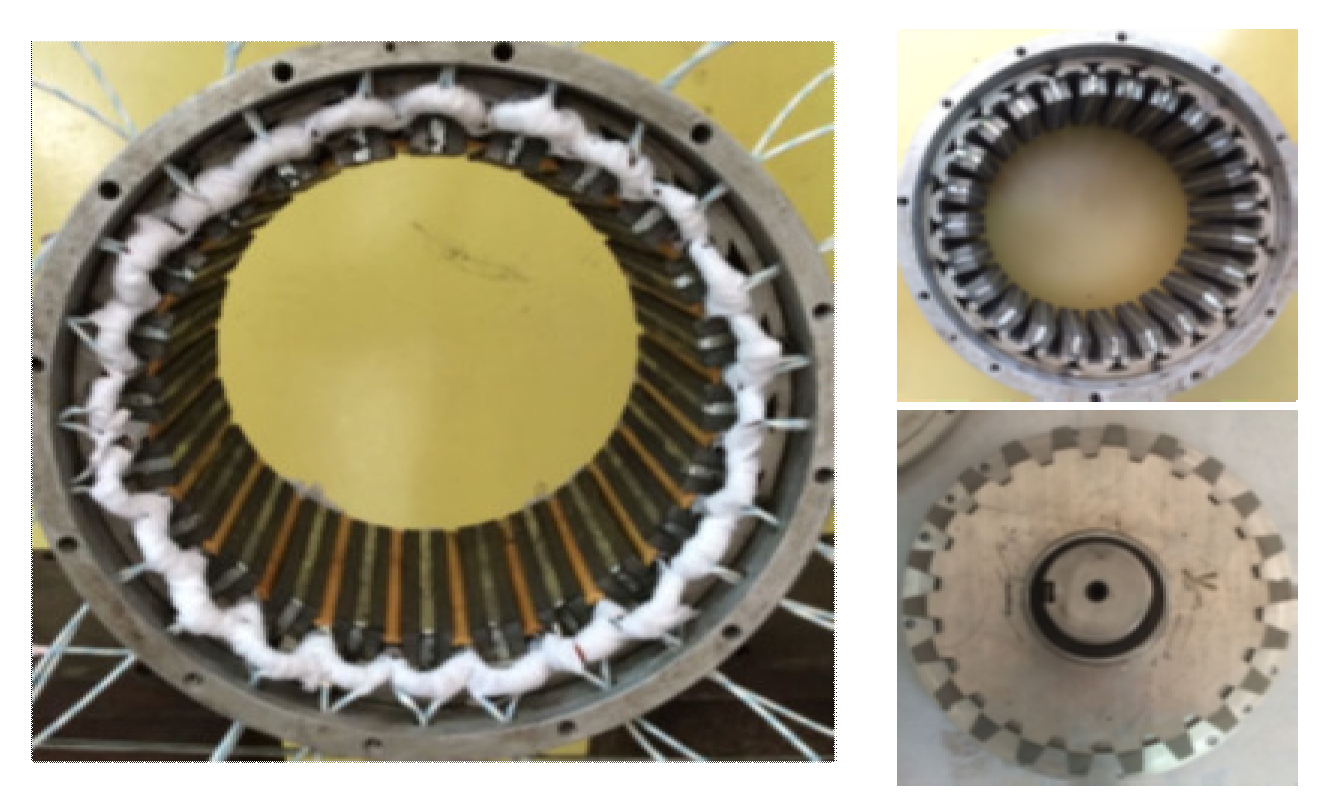

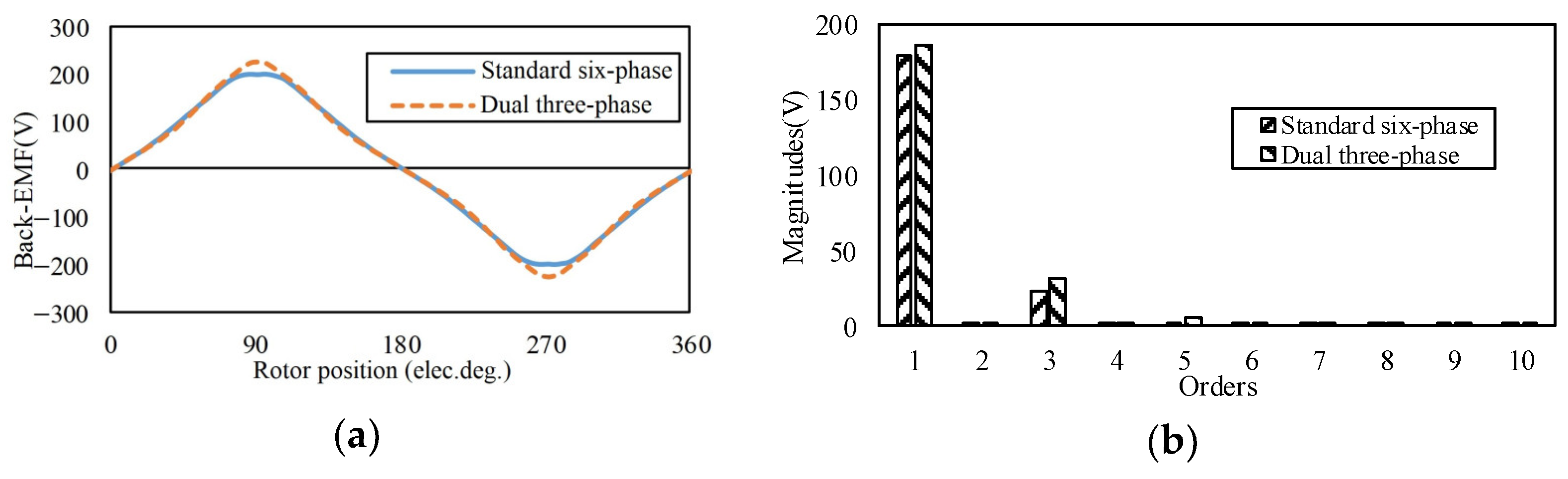

Figure 4b, where the coil connections of phases A and B are exhibited. If the coils of the same coil-EMF vector connect into a phase winding, the three-phase machine changes into a dual three-phase 24/22 machine with

q6′ = 1 and

K6 = 2, as is presented in

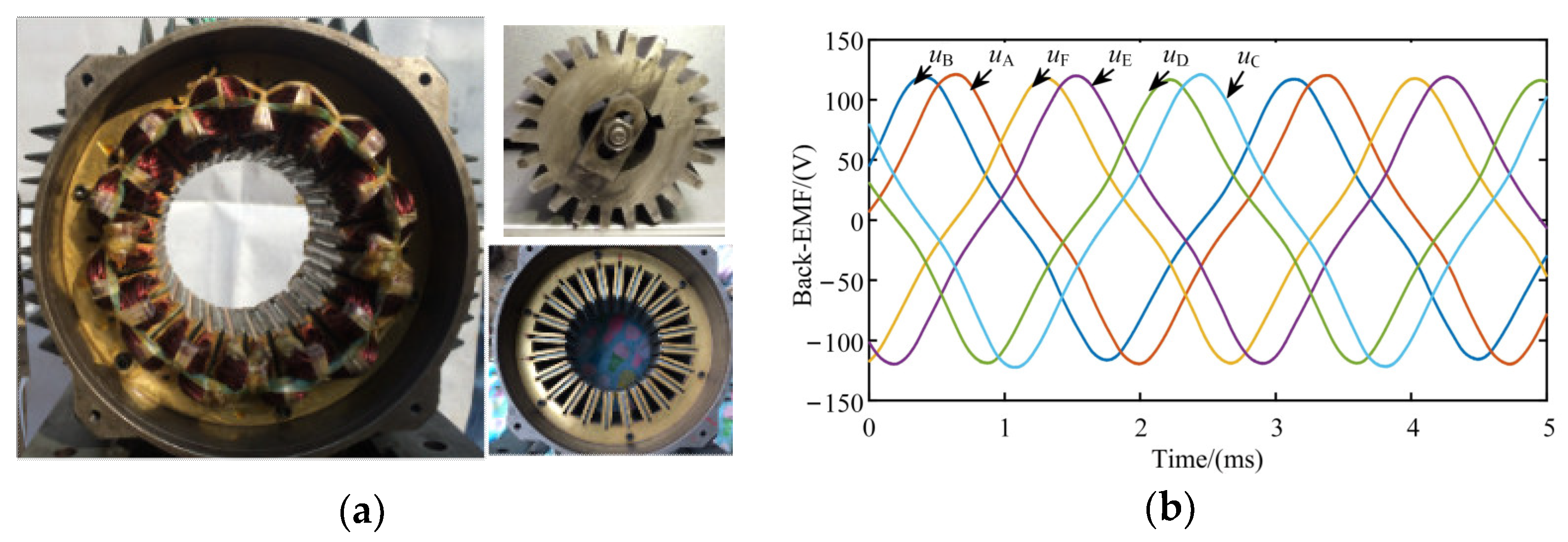

Figure 4c, where the coil connection of phases A and B is shown. A dual three-phase 24/22 conventional FSPM prototype has been manufactured and measured, as presented in

Figure 5a, and the specific parameters are listed in

Table 1. The measured back-EMF waveforms at 1000 r/min are presented in

Figure 5b. It can be seen that the back-EMF waveforms are exactly symmetrical.

Based on the above analysis, some conclusions can be drawn. At first, when

q′ is an odd number and

K is an even number, or

q′ is an even number, the corresponding three-phase machines can be reconnected into six-phase machines. Secondly, among the three-phase machines that can be connected into six-phase machines, some machines, where

K is an even number, can be reconnected into standard six-phase machines (symmetrical structure); meanwhile, the machines with

q′ being an even number can be connected into dual three-phase machines (asymmetrical structure). That is to say, the three-phase combinations with

q′ being an even number and

K being an even number not only could be connected into standard six-phase structures but also could be connected into dual three-phase structures. Thirdly, if the three-phase structures are connected into six-phase structures, the parameters

q′,

K,

q6′, and

K6 must satisfy Equation (2). In addition, for standard six-phase machines,

K6 is half of

K and

q6′ is the same as

q′, namely Equation (3), while for dual three-phase machines,

K6 is equal to

K and

q6′ is half of

q′, namely Equation (4), i.e., when three-phase machines are connected into six-phase machines, one of the parameters,

q′ or

K will be reduced to half. The types of six-phase structures and the relationship of parameters

q′,

K,

q6′, and

K6 are concluded and listed in

Table 2. Taking the combination of three-phase 24/22 where

K = 2 and

q′ = 2 as an example, this machine could be connected into a standard six-phase machine (

K6 =

K/2 and

q6′ =

q′) and can also be connected into a dual three-phase machine (

K6 =

K and

q6′ =

q′/2). The specific performance comparisons between the 24/22 standard six-phase machine and the 24/22 dual three-phase machine will be conducted in

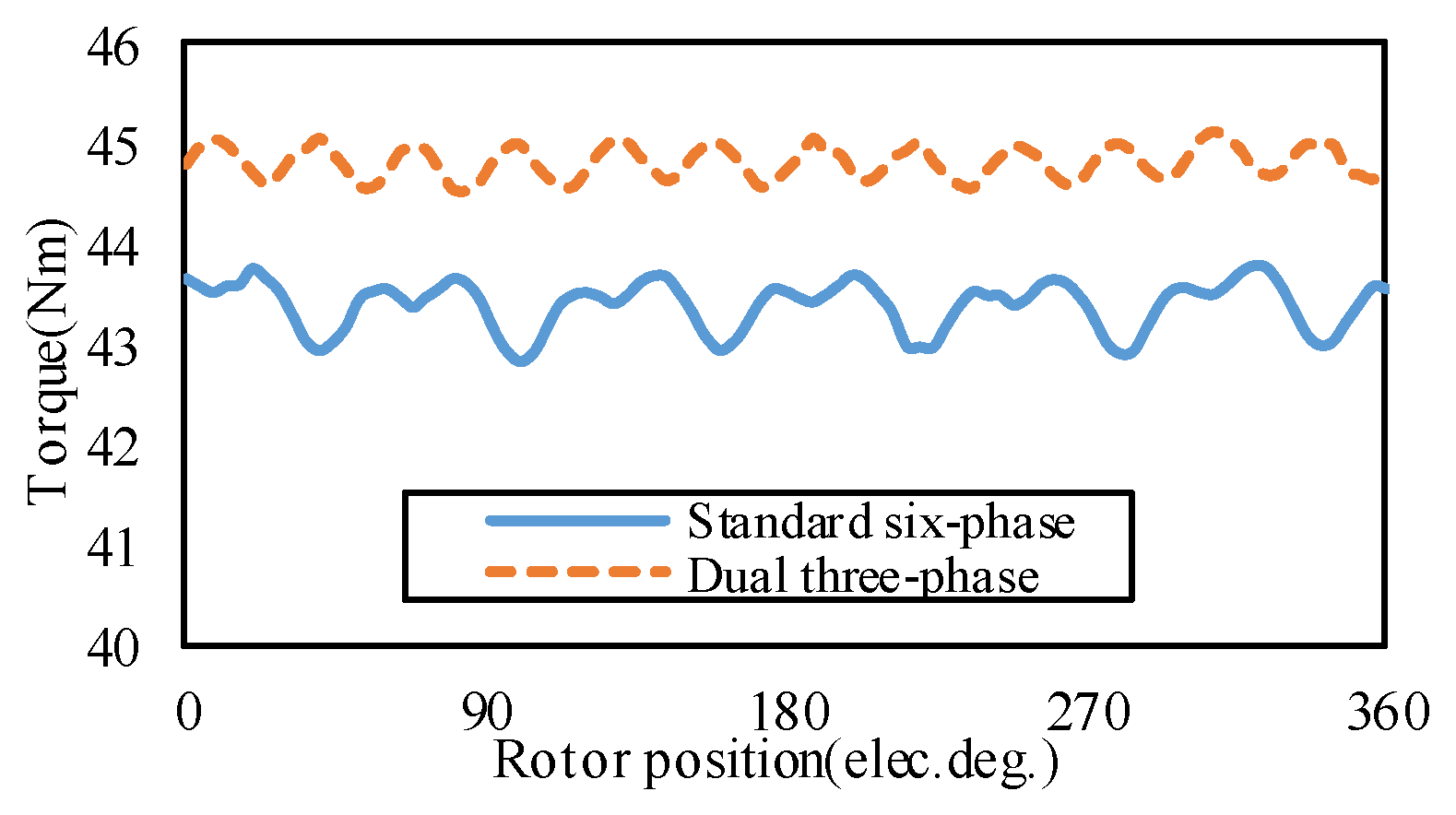

Section 4. The combinations of stator poles and rotor teeth for six-phase conventional FSPM machines, including symmetrical and asymmetrical structures, are listed in

Table A1 in

Appendix A.

2.2. Nine-Phase Conventional FSPM Machines

Like six-phase machines,

q9′ and

K9 are, respectively, the number of the consecutively adjacent stator coils belonging to the same phase and the number of coil-pairs having complementarity for nine-phase machines coils per pole per phase and the number of coil-pairs having complementarity for nine-phase machines. Nine-phase conventional FSPM machines can also be deduced from three-phase machines where

q′ is a multiple of three. For example, 18/17, 18/19, 36/34, 36/38 (

q′

= 3), and 36/35, 36/37 (

q′

= 6) three-phase machines can be reconnected to nine-phase machines. Taking an 18/17 structure (

q′ = 3,

K = 1) as an example, each phase winding of the three-phase 18/17 machine shown in

Figure 6a is composed of six coils, covering three coil-EMF vectors, and if the coils with the same coil-EMF vector connect into a phase winding and the coils connect in positive polarity, the three-phase 18/17 machine turns into a standard nine-phase 18/17 machine (symmetrical structure), as is shown in

Figure 6b, where

q9′ = 1 and

K9 = 1. The three-phase machines, being able to be connected to standard nine-phase machines, can also be reconnected into triple three-phase machines. Like the standard nine-phase machine in

Figure 6b, if coils 2 and 11, coils 5 and 14, and coils 8 and 17 connect in opposite polarity, the standard nine-phase machine turns into a triple three-phase 18/17 machine with

q9′ = 1 and

K9 = 1, shown in

Figure 6c.

Overall, at first, when

q′ is a multiple of three, the corresponding three-phase conventional FSPM machines can be reconnected into nine-phase machines, and in addition, the three-phase topologies cannot only be connected into symmetrical structures (standard nine-phase machines) but also can be connected into asymmetrical structures (triple three-phase machines). Then, if the three-phase structures are connected into nine-phase structures, regardless of symmetrical structures or asymmetrical structures, the parameters

q′,

K,

q9′, and

K9 all satisfy Equation (5). The types of nine-phase structures and the relationship of parameters

q′,

K,

q9′, and

K9 are listed in

Table 3. The specific stator pole and rotor teeth combinations for nine-phase machines are all listed in

Table A1 in

Appendix A.

In addition, a standard nine-phase 36/34 conventional FSPM prototype was manufactured and presented in

Figure 7, which was detailedly described in the reference [

24]. From the measured no-load EMF waveforms at 500 r/min shown in reference [

24], it can be seen that the EMF waveforms are exactly symmetrical.

2.3. Twelve-Phase Conventional FSPM Machines

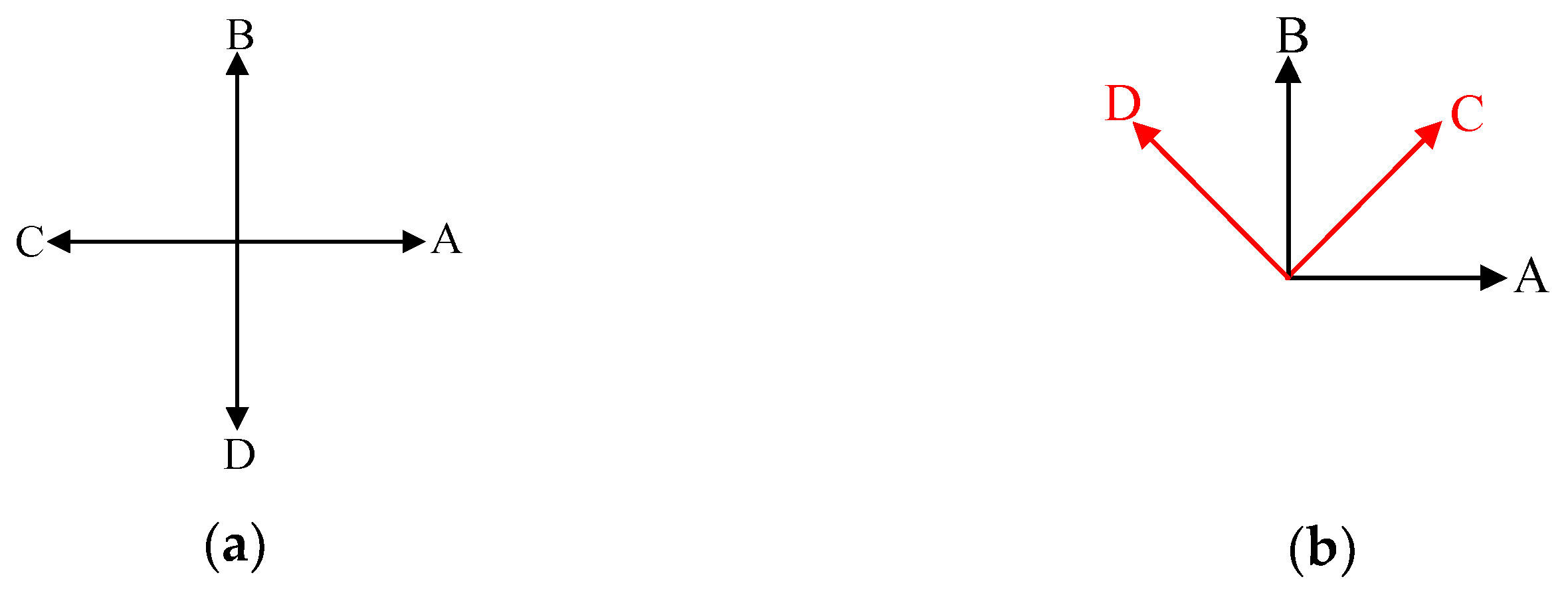

Twelve-phase conventional FSPM machines, including symmetrical structure (standard twelve-phase machine) and asymmetrical structure (four three-phase machines), as shown in

Figure 8, can be derived from three-phase structures.

When

q′ is an even number and

K is also an even number, such as 24/22, 24/26, 48/46, 48/50, etc., the corresponding three-phase structure can be connected into a standard twelve-phase machine. For example, if

q′ = 2 and

K = 2, the corresponding three-phase 24/22 structure shown in

Figure 4a will turn into a standard twelve-phase machine exhibited in

Figure 9a if half of the coils change their polarity, and for the obtained machine, the parameters satisfy

q12′ = 1 and

K12 = 1, where

q12′ and

K12 represent, respectively, the number of the consecutively adjacent stator coils belonging to the same phase and the number of coil-pairs having complementarity for twelve-phase machines.

All the three-phase structures, where

q′ is a multiple of 4 and

K is not restricted, could be reconnected into four three-phase machines, shown in

Figure 8b, such as 24/23, 24/25, 48/46, 48/50 (

q′ = 4), etc. For example, a three-phase 24/23 structure (

q′ = 4,

K = 1) can be connected into a four three-phase machine shown in

Figure 9b, where

q12′ = 1 and

K12 = 1.

In addition, the machines where q′ is a multiple of 4 and K is an even number, such as 48/46 and 48/50 (q′ = 4, K = 2), can not only be connected into standard twelve-phase machines but also can be connected into four three-phase machines.

Overall, the parameters

q′,

K,

q12′, and

K12 must satisfy Equation (6). For standard twelve-phase machines,

q12′ and

K12 are half of

q′ and

K, namely Equation (7); meanwhile, for four three-phase machines,

q12′ is a quarter of

q′ and

K12 is equal to

K, namely Equation (8). The types of twelve-phase structures and the relationship of parameters

q′,

K,

q12′, and

K12 are concluded and listed in

Table 4. The combinations of stator poles and rotor teeth for twelve-phase conventional FSPM machines, including symmetrical and asymmetrical structures, are listed in

Table A1 in

Appendix A.

A standard twelve-phase 24/22 FSPM prototype was manufactured and presented in

Figure 10, which was described in the reference [

25]. From the measured no-load EMF waveforms at 500 r/min shown in reference [

25], it can be seen that the EMF waveforms are exactly symmetrical.

2.4. Four-Phase Conventional FSPM Machines

Similar to six-phase machines deduced from three-phase machines, four-phase machines could be deduced from two-phase structures.

When

K is an even number, the corresponding machines, such as 8/6, 8/10, 16/12, 16/20, 24/18, 24/30, 24/22, 24/26, etc., can be connected into standard four-phase machines (symmetrical structure) as is shown in

Figure 11a by half of the coils connecting in opposite polarity, such as the standard six-phase topologies.

All the two-phase machines, where

q′ is an even number and

K is not restricted, such as 8/7, 8/9, 16/14, 16/18, 24/21, 24/27, 32/28, and 32/36, etc., could be reconnected into dual two-phase machines (asymmetrical structure) shown in

Figure 11b, such as the dual three-phase topologies. In addition, the machines where

q′ and

K are all even numbers, such as 16/14, 16/18 (

q′ = 2,

K = 2), 32/28, and 32/36 (

q′ = 2,

K = 4), can be connected into standard four-phase machines and also can be connected into dual two-phase machines.

q4′ and

K4, respectively, represent the number of the consecutively adjacent stator coils belonging to the same phase and the number of coil-pairs having complementarity for four-phase machines. Parameters

q′,

K,

q4′, and

K4 must satisfy Equation (9). For standard four-phase machines, they satisfy Equation (10); meanwhile, for dual two-phase machines, they satisfy Equation (11). The types of four-phase structures and the relationship of parameters

q′,

K,

q4′, and

K4 are concluded and listed in

Table 5. The specific combinations of stator and rotor poles for four-phase conventional FSPM machines, including symmetrical and asymmetrical structures, are listed in

Table A1 in

Appendix A.