Simulation Study on P-Shaped Process Layout for Automated Container Terminals

Abstract

1. Introduction

1.1. Research Background

1.2. Existing Problems

1.3. Methods and Contributions

2. Literature Review

2.1. Layout Research of Container Terminals

2.2. Simulation Research of Container Terminals

2.3. Research Gaps

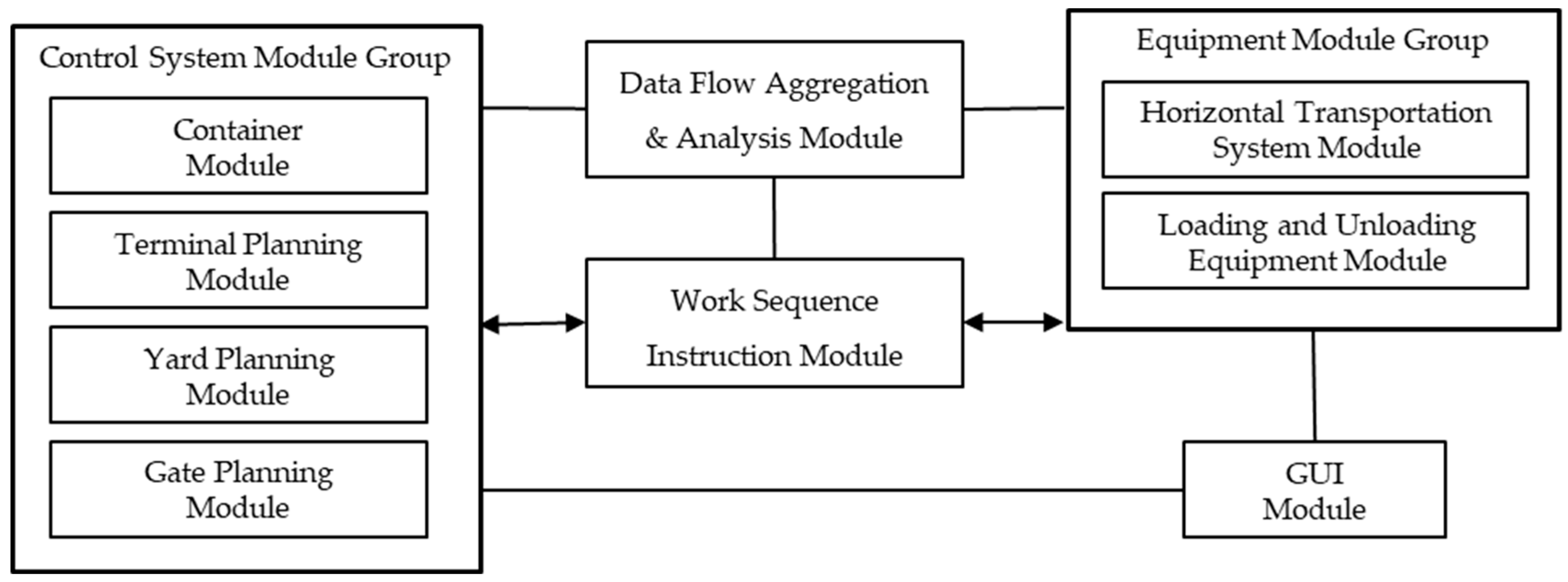

3. Simulation Design for Container Terminal Operations

3.1. Operational Parameter Design for Container Terminals

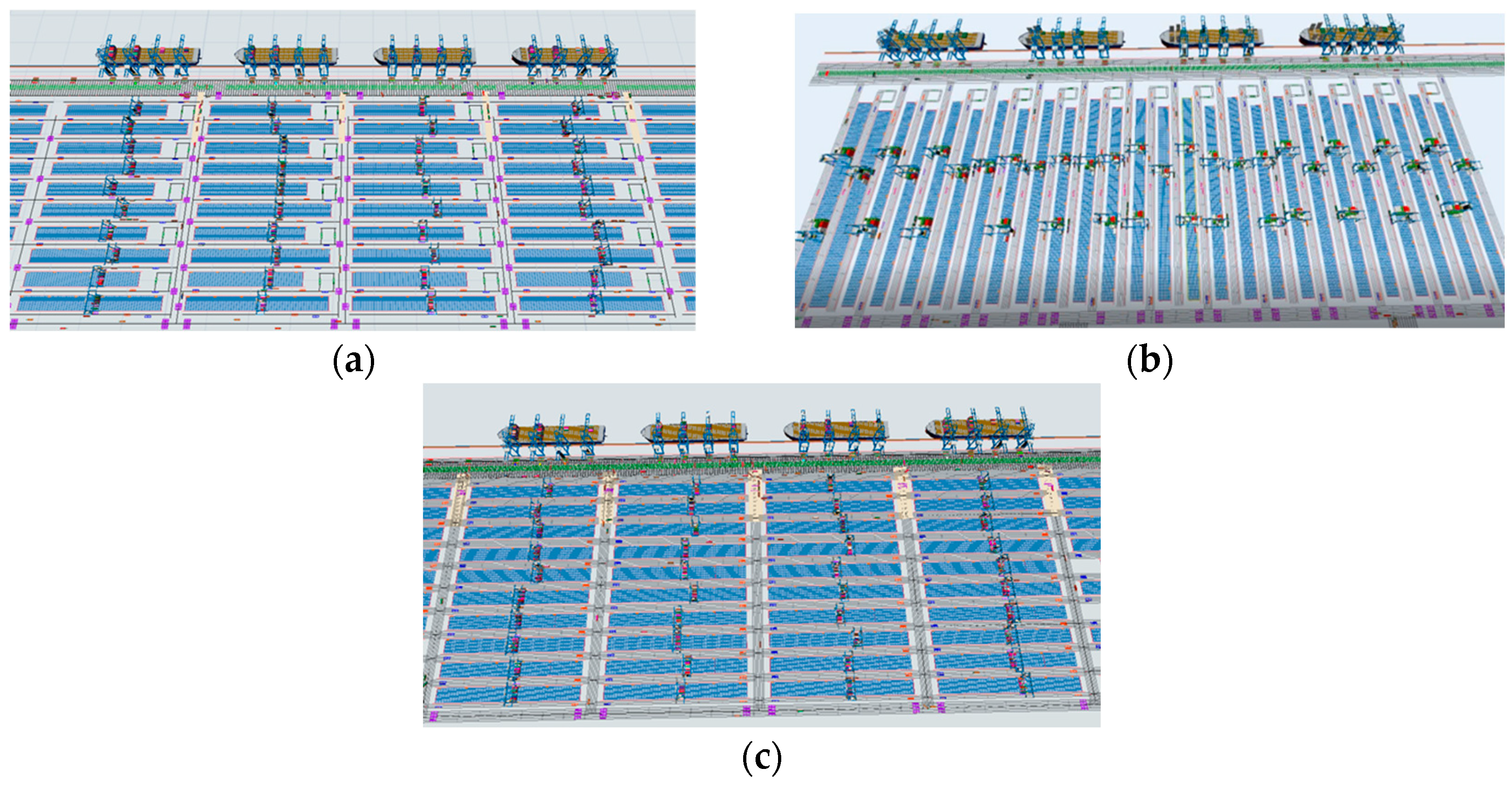

3.2. Simulation Modeling

- This study was conducted under ideal conditions, ignoring equipment failures and all kinds of unexpected factors that cause work interruptions;

- The inbound and outbound containers are evenly distributed in the yard;

- The storage locations of the containers are selected randomly.

3.3. Simulation Experiment Setup

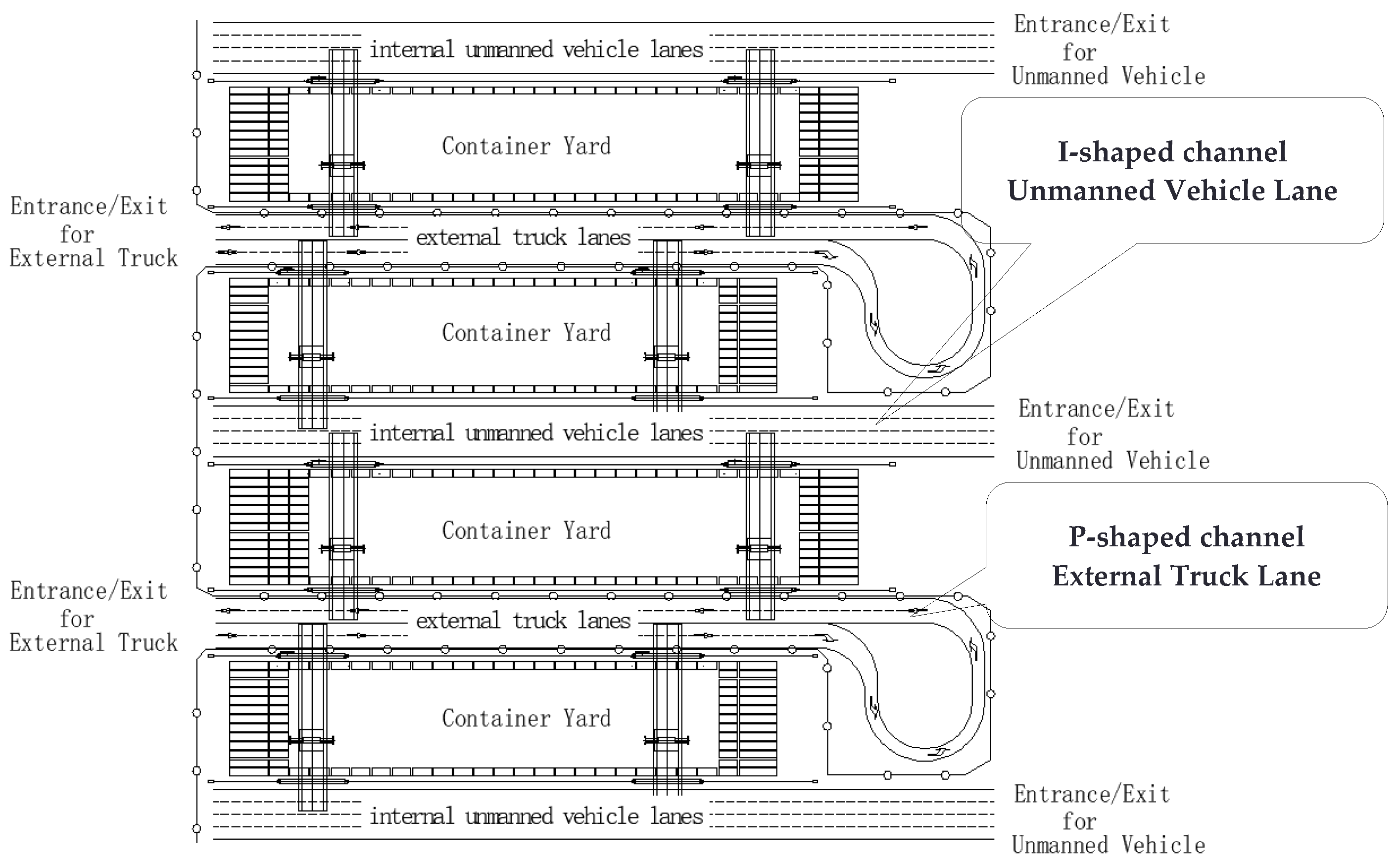

4. P-Shaped Container Terminal Handling Process Scheme

4.1. Scheme One: P-Shaped Layout with Yard Parallel to Shoreline

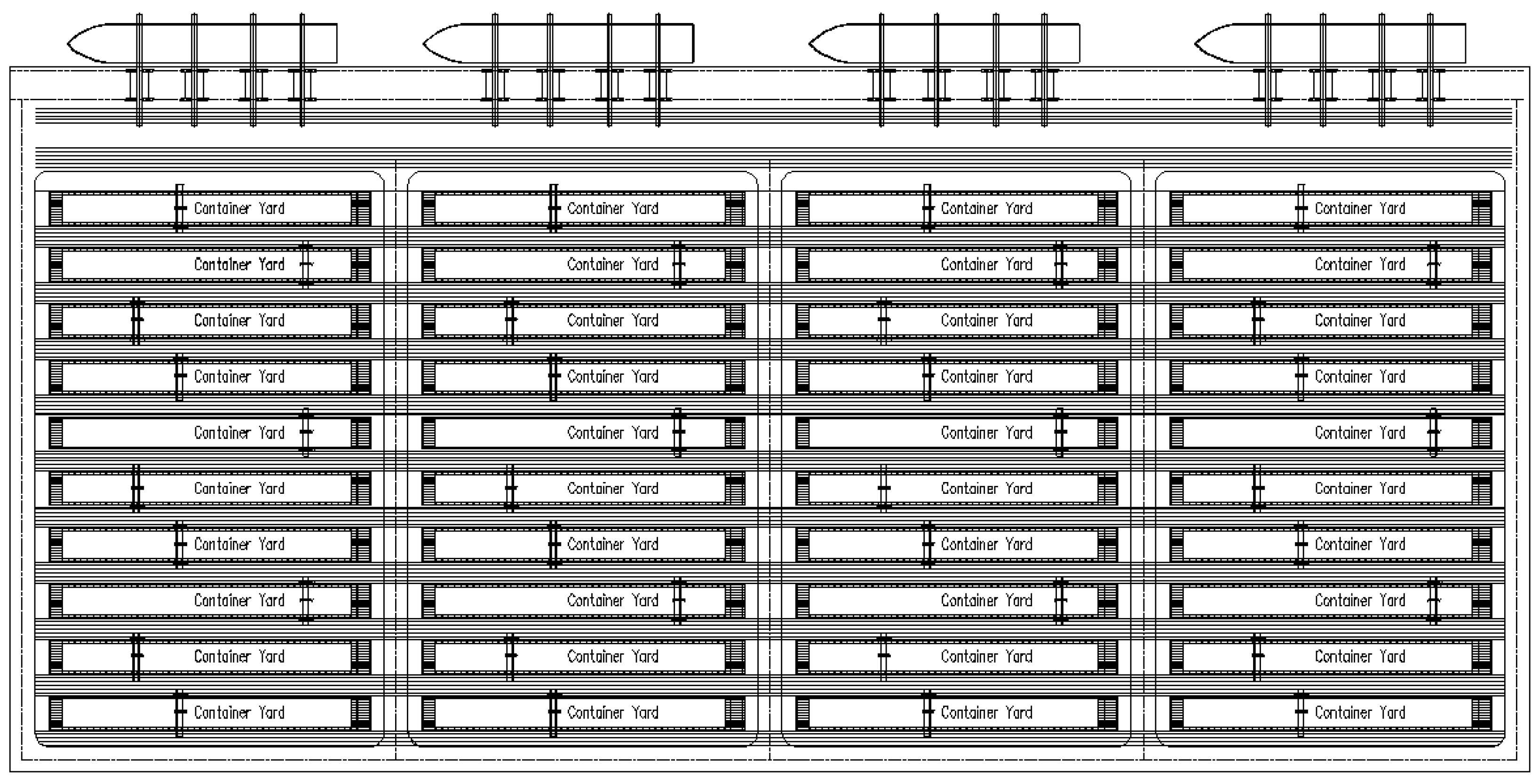

4.2. Scheme Two: P-Shaped Layout with Yard Perpendicular to Shoreline

4.3. Scheme Three: Mixed-Traffic Layout with Yard Parallel to Shoreline

4.4. Comparison of Handling Equipment Configuration and Ground Slot Capacity

5. Simulation Data Analysis

5.1. Evaluation Metrics

- : Quay crane operation time, unit: h

- : Quay crane handling time, unit: h

- : Quay crane waiting time, unit: h

- : Quay crane idle time, unit: h

- : Quay crane efficiency, unit: box/h

- : Number of containers handled by the quay crane, unit: box

- : Quay crane operation time, unit: h

- : Quay crane utilization rate, unit: %

- : Quay crane handling time, unit: h

- : Quay crane operation time, unit: h

- : Average cycle distance of unmanned vehicle, unit: m/cycle

- : Total travel distance of unmanned vehicles, unit: m

- C: Number of operational cycles completed by unmanned vehicles, unit: cycle

- : Average speed of unmanned vehicles, unit: m/s

- : Total travel distance of unmanned vehicles, unit: m

- : Total travel time of unmanned vehicles, unit: s

- : Average cycle time of unmanned vehicles, unit: h

- : Travel time, unit: h

- : Time spent operatings at the quay crane, unit: h

- : Time spent operatings in the yard, unit: h

- : Waiting time at the quay crane, unit: h

- : Waiting time in the yard, unit: h

- : Time spent in traffic congestion within the road system, unit: h

- : Congestion rate of unmanned vehicles, unit: %

- : Traffic congestion time per cycle within the road system, unit: h

- : Total cycle time of unmanned vehicles, unit: h

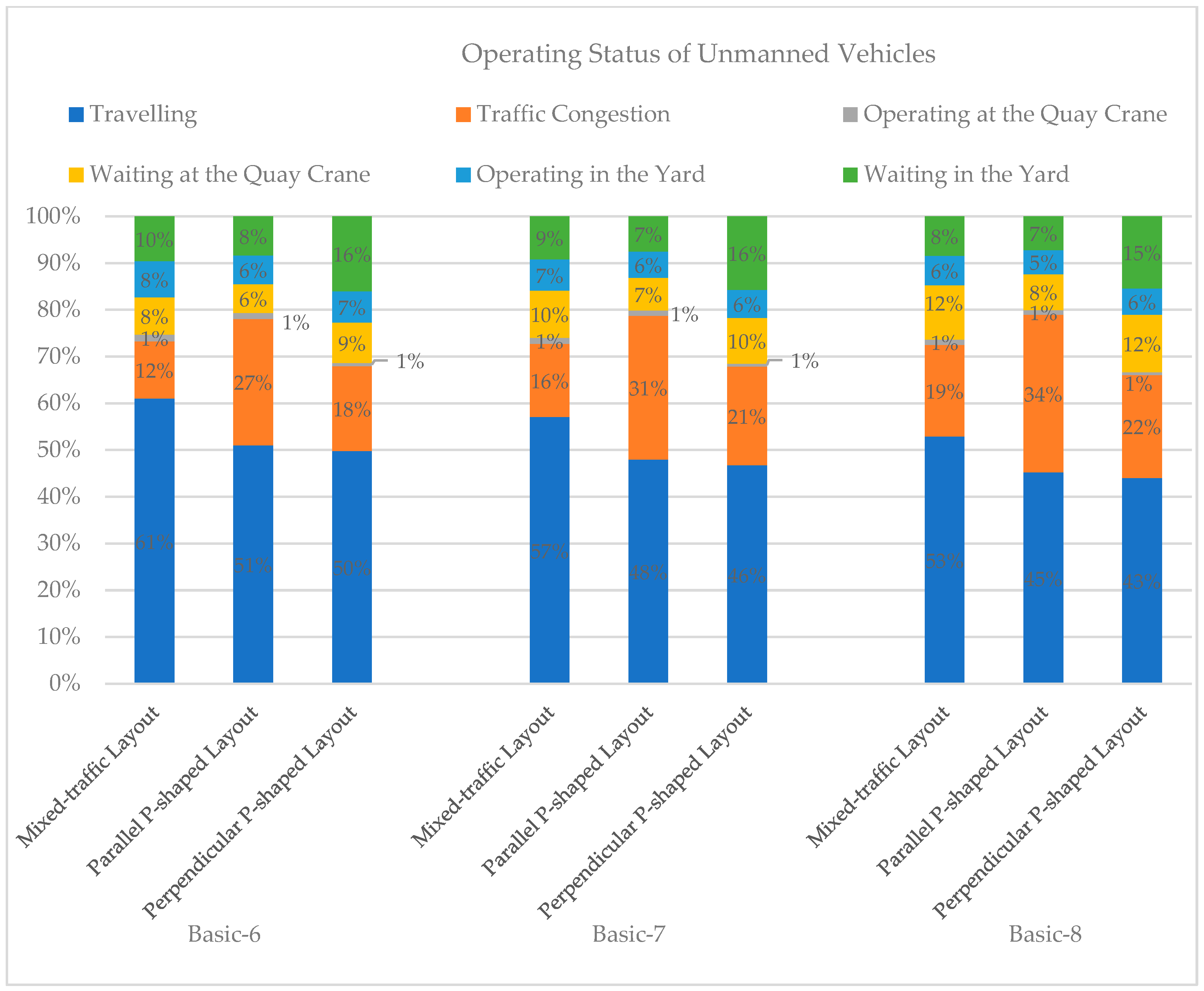

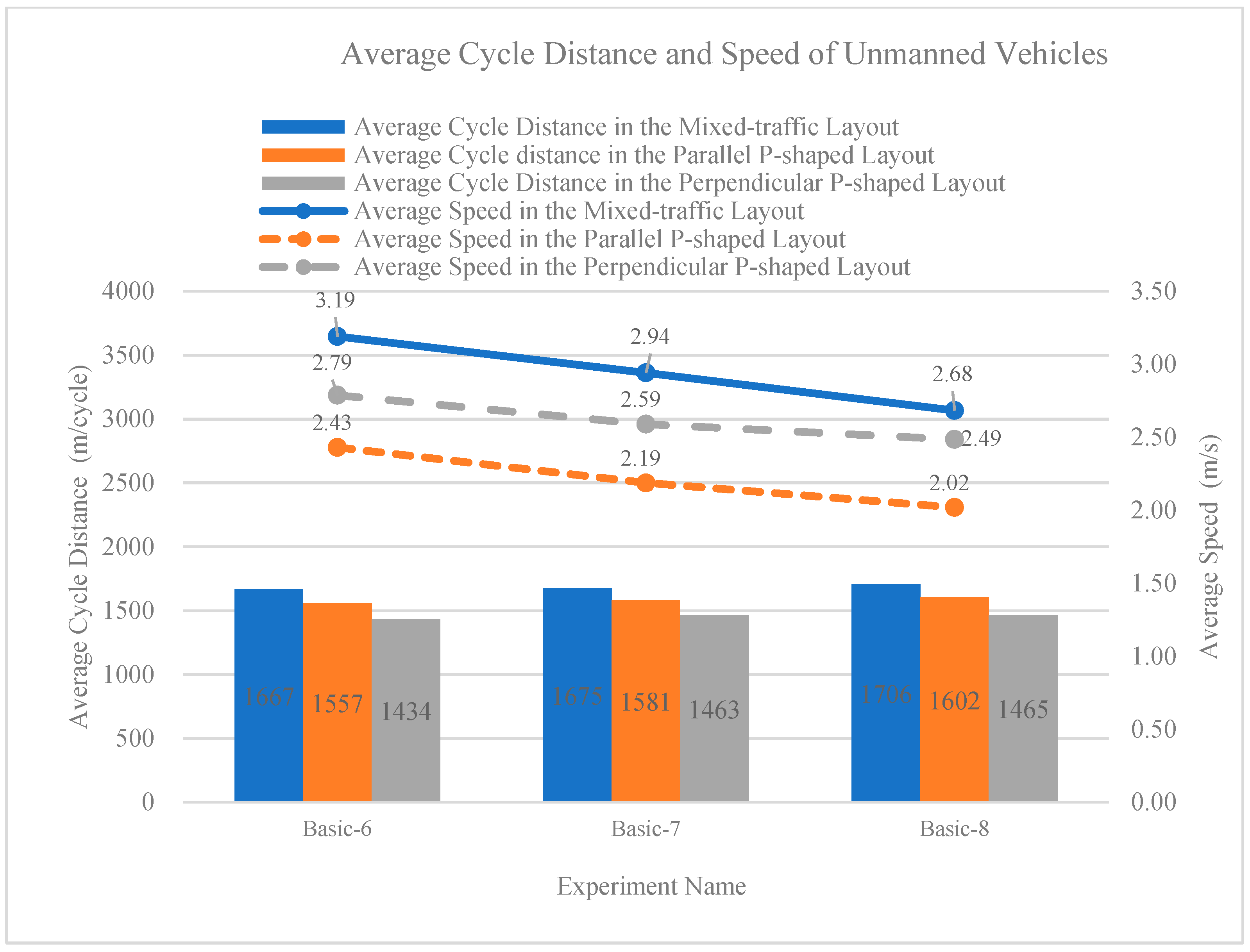

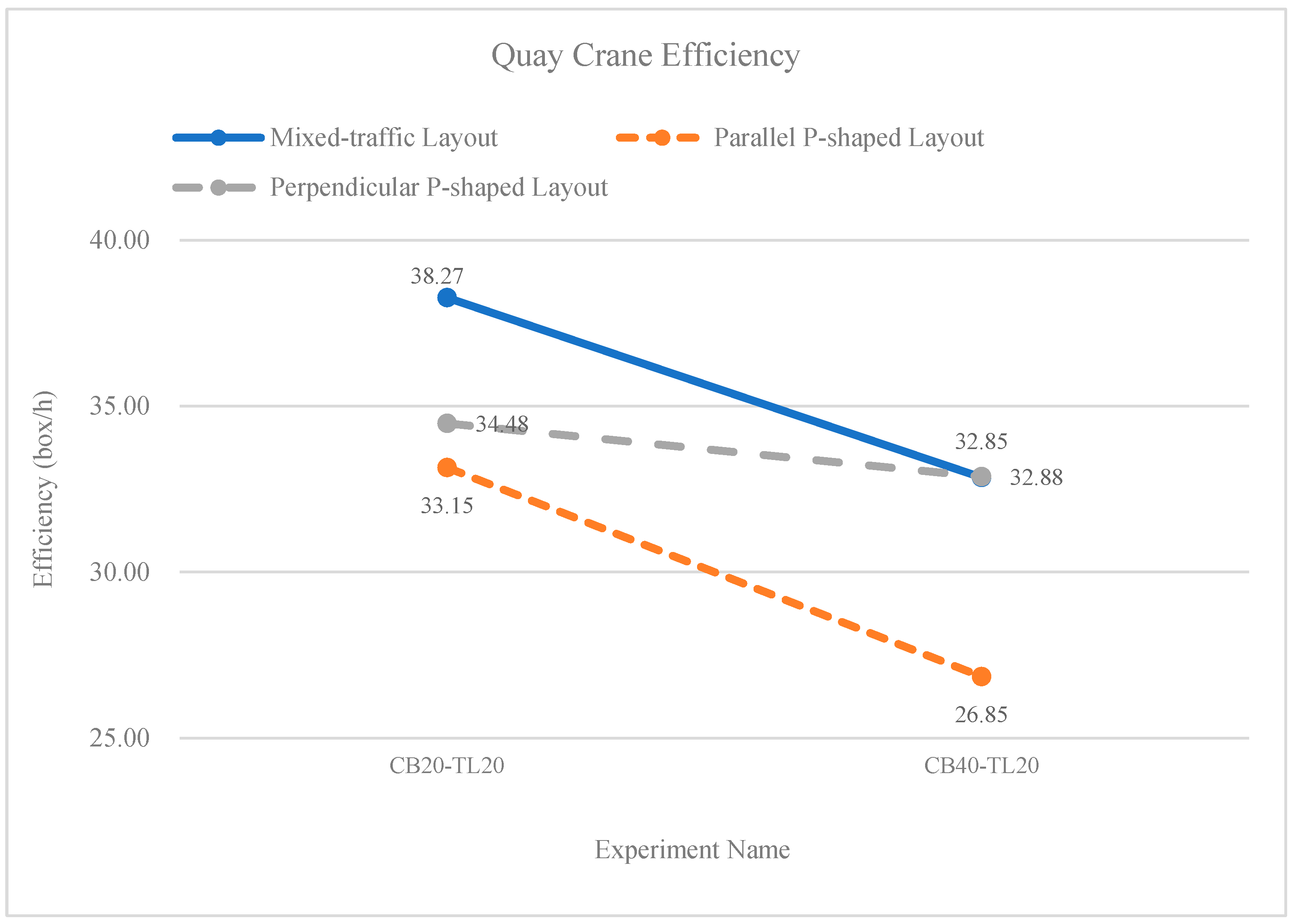

5.2. Basic Experimental Results

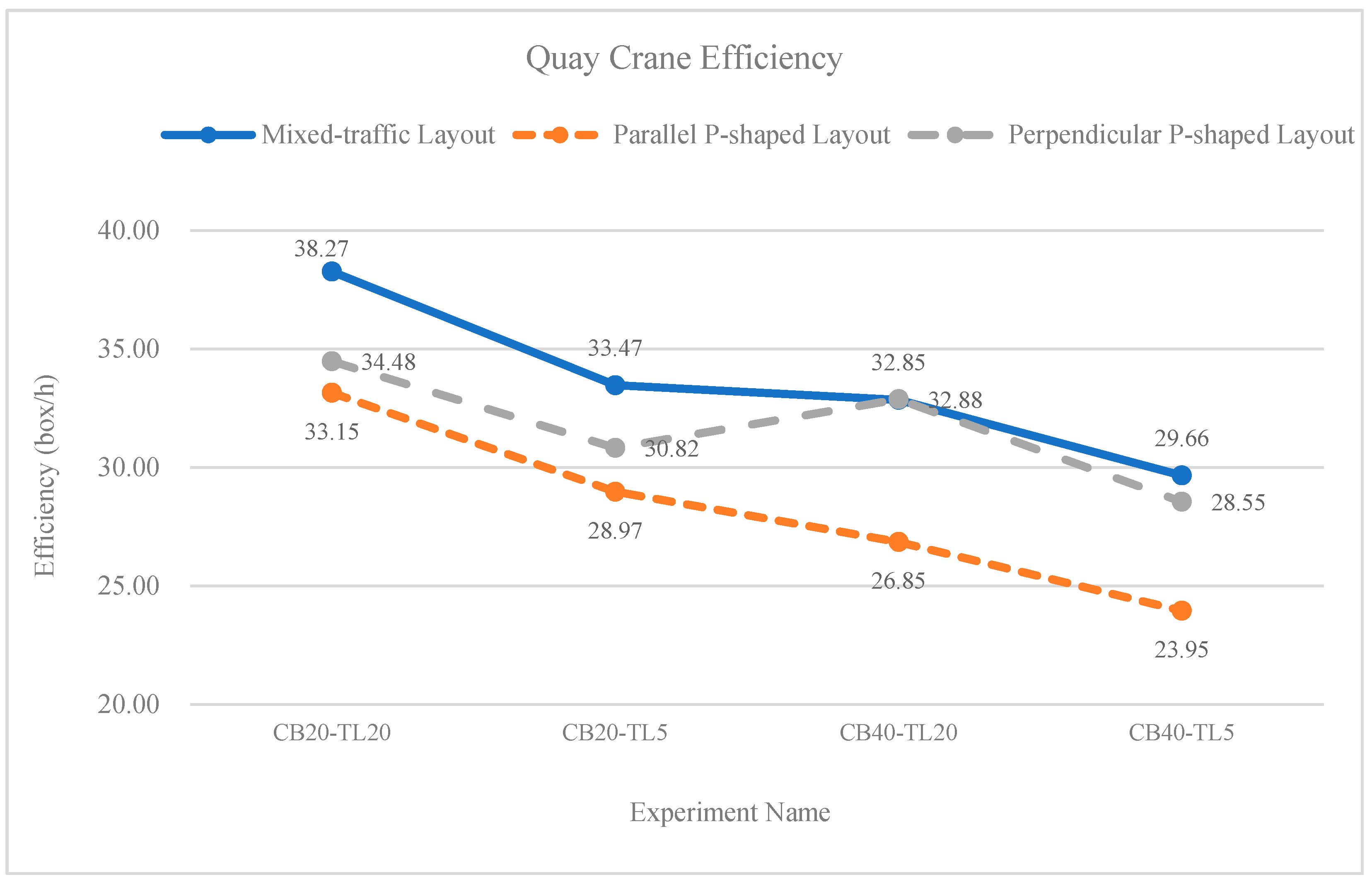

- The quay crane efficiency for the parallel P-shaped layout is 33.15 box/h.

- The perpendicular P-shaped layout improves quay crane efficiency by approximately 4% compared to the parallel P-shaped layout.

- The mixed-traffic layout improves quay crane efficiency by approximately 11% compared to the perpendicular P-shaped layout and 15% compared to the parallel P-shaped layout.

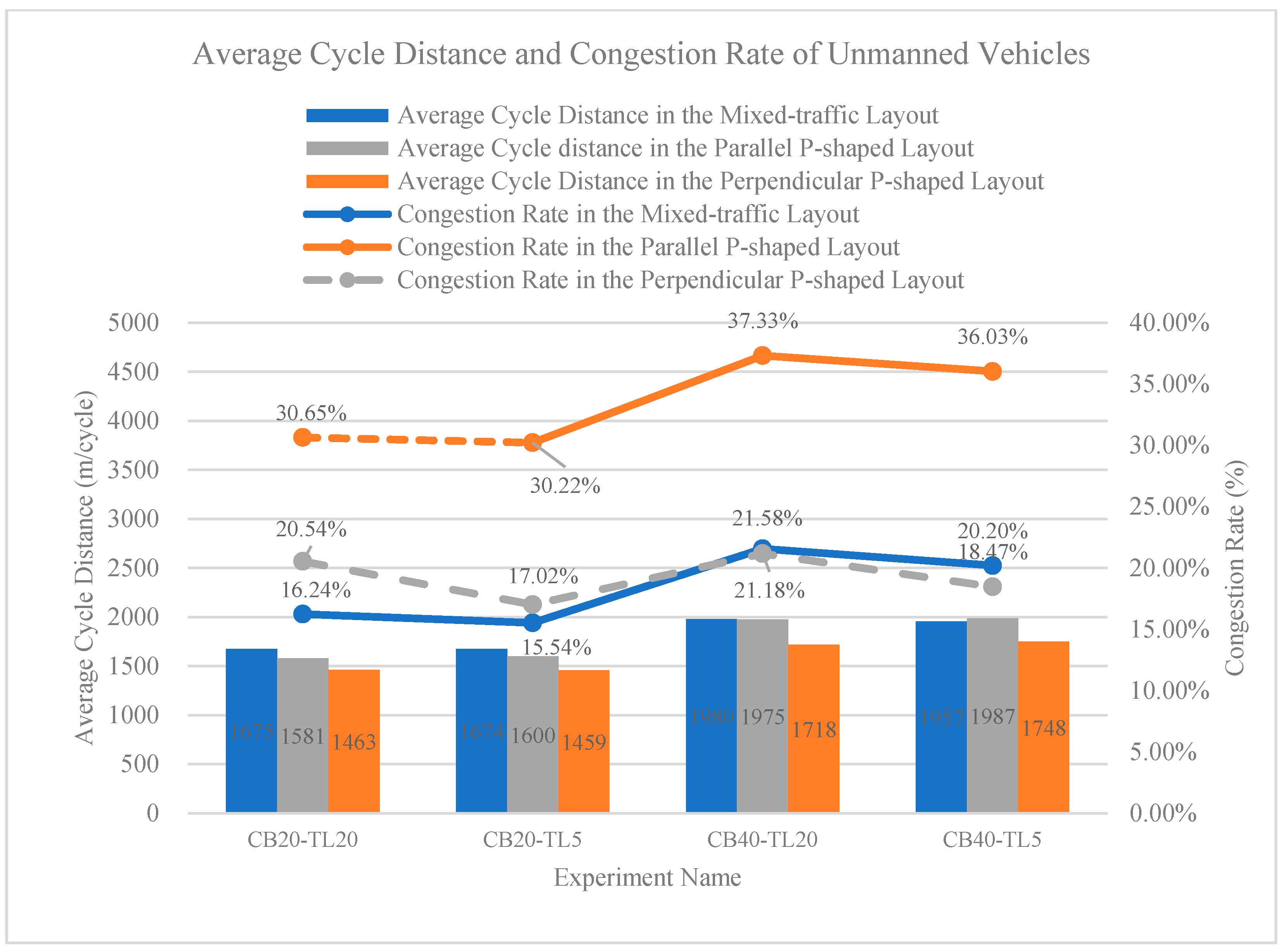

- The congestion rate for the mixed-traffic layout is approximately 16%.

- The congestion rate for the perpendicular P-shaped layout is 21%, and for the parallel P-shaped layout, it is 31%.

- The average speed for the parallel P-shaped layout is 2.19 m/s.

- The average speed for the perpendicular P-shaped layout is 2.59 m/s, representing an increase of approximately 18% compared to the parallel P-shaped layout.

- The average speed for the mixed-traffic layout is 2.94 m/s, which is approximately 14% higher than the perpendicular P-shaped layout and 34% higher than the parallel P-shaped layout.

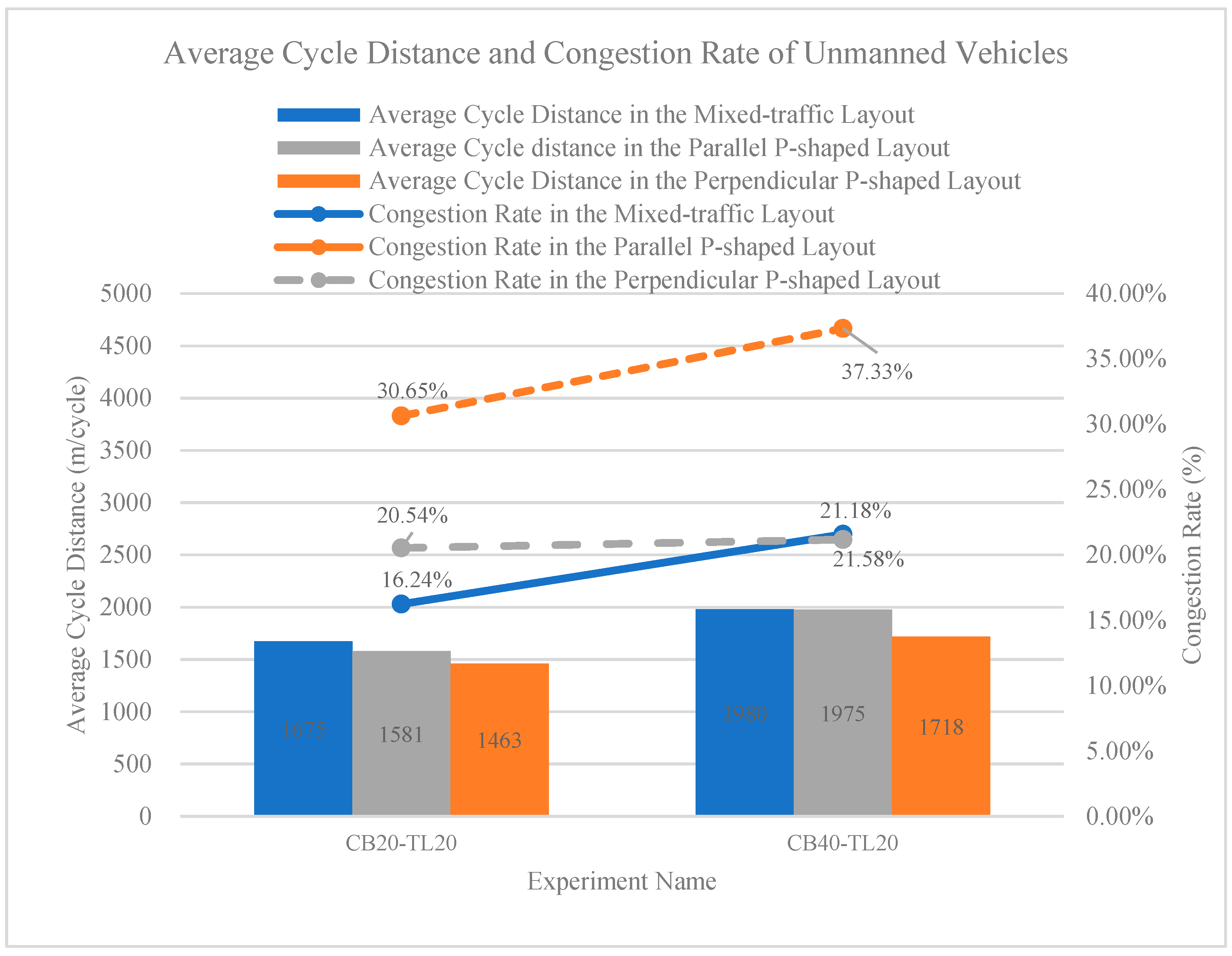

5.3. Sensitivity Analysis of Operation Plans

- For the mixed-traffic layout, the average cycle distance of unmanned vehicles increases by approximately 300 m, representing an increase of about 18%.

- For the perpendicular P-shaped layout, the average cycle distance of unmanned vehicles increases by approximately 250 m, representing an increase of about 17%.

- For the parallel P-shaped layout, the average cycle distance of unmanned vehicles increases by approximately 400 m, representing an increase of about 25%.

- For the mixed-traffic layout, the congestion rate of unmanned vehicles increases by approximately 33%.

- For the perpendicular P-shaped layout, the congestion rate of unmanned vehicles increases by approximately 3%.

- For the parallel P-shaped layout, the congestion rate of unmanned vehicles increases by approximately 22%.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ACT | Automated Container Terminal |

| AGV | Automated Guided Vehicle |

| ARMG | Automated Rail-Mounted Gantry Crane |

| ASC | Automated Stacking Crane |

| GUI | Graphical User Interface |

| IGV | Intelligent Guided Vehicle |

| QC | Quay Crane |

| TEU | Twenty-feet Equivalent Unit |

References

- Liu, Q.; Ni, X.; Liu, H.; Wang, J.; Wang, K. Optimization of Reclaiming–Loading Scheduling in Dry Bulk Terminals Based on Knowledge-Driven Memetic Algorithm. Electronics 2024, 13, 4558. [Google Scholar] [CrossRef]

- Li, X.-J.; Zhou, R.; Zhu, L.-Q.; Wang, Y.-S. The Influence of High Operation Platform Mode on U-Shaped Automated Container Terminal Efficiency. IEEE Access 2024, 12, 46616–46625. [Google Scholar] [CrossRef]

- Kong, L.R.; Ji, M.J. Mathematical modeling and optimizing of yard layout in automated container terminals. Expert Syst. Appl. 2024, 258, 125117. [Google Scholar] [CrossRef]

- Rodriguez, L.; Loyo, J.; Silva, U. Layout evaluation with the Industry 4.0 approach for a manufacturing laboratory. Int. J. Simul. Model. 2023, 22, 551–561. [Google Scholar] [CrossRef]

- Gharehgozli, A.; Zaerpour, N.; de Koster, R. Container terminal layout design: Transition and future. Marit. Econ. Logist. 2020, 22, 610–639. [Google Scholar] [CrossRef]

- Li, X.Y.; Zhou, R.; Zhu, L.Q. Research on energy saving effect of parallel and perpendicular yard layouts under different proportions of transshipment at the automated container terminal. Sustainability 2024, 16, 7387. [Google Scholar] [CrossRef]

- Liu, W.; Zhu, X.; Wang, L.; Wang, S. Multiple equipment scheduling and AGV trajectory generation in U-shaped sea-rail intermodal automated container terminal. Measurement 2023, 206, 112262. [Google Scholar] [CrossRef]

- Yang, A.; Liu, Y.; Xin, C.; Chen, Q.; Wang, L. Towards intuitive visualisation goals for the operation optimisation of automated container terminal based on digital twin technology. Marit. Policy Manag. 2024, 51, 631–652. [Google Scholar] [CrossRef]

- Wang, X.; Jin, Z. Collaborative Optimization of Multi-Equipment Scheduling and Intersection Point Allocation for U-Shaped Automated Sea-Rail Intermodal Container Terminals. IEEE Trans. Autom. Sci. Eng. 2024, 22, 7373–7393. [Google Scholar] [CrossRef]

- Xu, B.; Jie, D.; Li, J.; Yang, Y.; Wen, F.; Song, H. Integrated scheduling optimization of U-shaped automated container terminal under loading and unloading mode. Comput. Ind. Eng. 2021, 162, 107695. [Google Scholar] [CrossRef]

- Shan, J.; Jin, J.; Zhang, Y. A new container yard handling process based on flyover technology. Port Waterw. Eng. 2023, 617, 64–69. [Google Scholar] [CrossRef]

- Ni, M.; Shan, J. Handling technology of automatic tridimensional yard. Port Waterw. Eng. 2020, 574, 82–86. [Google Scholar] [CrossRef]

- Ni, M.; Xia, J. General layout and handling technology design of automated container terminal for multimodal transport under multishoreline. Port Waterw. Eng. 2023, 612, 95–100. [Google Scholar] [CrossRef]

- Liang, Y.; Chen, Y.; Jin, J. Simulation of layout technology of twist lock station with single trolley quay cranes in automated container terminal. Port Waterw. Eng. 2024, 2024, 175–179+185. [Google Scholar] [CrossRef]

- Li, X.; Peng, Y.; Huang, J.; Wang, W.; Song, X. Simulation study on terminal layout in automated container terminals from efficiency, economic and environment perspectives. Ocean Coast. Manag. 2021, 213, 105882. [Google Scholar] [CrossRef]

- Li, X.; Peng, Y.; Guo, Y.; Wang, W.; Song, X. An integrated simulation and AHP-entropy-based NR-TOPSIS method for automated container terminal layout planning. Expert Syst. Appl. 2023, 225, 120197. [Google Scholar] [CrossRef]

- Lee, B.K.; Lee, L.H.; Chew, E.P. Analysis on high throughput layout of container yards. Int. J. Prod. Res. 2018, 56, 5345–5364. [Google Scholar] [CrossRef]

- Budiyanto, M.A.; Huzaifi, M.H.; Sirait, S.J.; Prayoga, P.H.N. Evaluation of CO2 emissions and energy use with different container terminal layouts. Sci. Rep. 2021, 11, 5476. [Google Scholar] [CrossRef]

- Ma, N.; Zhou, C.H.; Stephen, A. Simulation model and performance evaluation of battery-powered AGV systems in automated container terminals. Simul. Model. Pract. Theory 2021, 106, 102146. [Google Scholar] [CrossRef]

- Wan, Z.; Zhang, T.; Sha, M.; Guo, W.; Jin, Y.; Guo, J.J.; Liu, Y.T. Evaluation of emission reduction strategies for berthing containerships: A case study of the Shekou Container Terminal. J. Clean. Prod. 2021, 299, 126820. [Google Scholar] [CrossRef]

- Cho, G.; Lee, S.H. Cloud-Based Virtual Port-Container Terminal Establishment and Operation Analysis. Electronics 2020, 9, 1615. [Google Scholar] [CrossRef]

- Tuncel, G.; Deniz, E. Optimization of container terminal operations using Response Surface Methodology. Int. J. Simul. Model. 2024, 23, 563–574. [Google Scholar] [CrossRef]

- Yang, Y.S.; Liang, J.Y.; Feng, J.K. Simulation and optimization of automated guided vehicle charging strategy for U-shaped automated container terminal based on improved proximal policy optimization. Systems 2024, 12, 472. [Google Scholar] [CrossRef]

- Guo, P.; Chen, Z.; Yang, Y.; Miao, R. A multistage simulation-optimization-integrated methodology framework for user-oriented electric vehicle carsharing reallocation under dynamic price subsidy. Energy 2024, 290, 130207. [Google Scholar] [CrossRef]

- Guo, P.; Yang, Y.; Su, Y.; Chen, Z.; Miao, R. Incentive-based customer-oriented rebalancing strategy for one-way shared electric vehicles in sustainable urban governance. J. Clean. Prod. 2024, 469, 143192. [Google Scholar] [CrossRef]

| Parameter Name | Unit | Value |

|---|---|---|

| Quay Length | Meters | 1600 |

| Double-Trollley Quay Cranes (QCs) | Units | 16 |

| Ratio of Unmanned Vehicles to Quay Cranes | Vehicles | 6/7/8 |

| Dual-Cantilever Automated Rail-Mounted Gantry Cranes (ARMGs) | Units | 40 |

| Twin-Lift Operation Ratio | % | 20 |

| Cross-Berth Operation Ratio | % | 20 |

| External Truck Arrival Frequency | Trucks/Hour | 120 |

| Equipment Name | No-Load Max Speed (m/s) | Full-Load Max Speed (m/s) | No-Load Acceleration (m/s2) | Full-Load Acceleration (m/s2) |

|---|---|---|---|---|

| Double-Trolley Quay Crane | ||||

| -Gantry | 0.83 | 0.83 | 0.1 | 0.1 |

| -Front/Rear Trolley | 4/2 | 4/2 | 0.67/0.67 | 0.67/0.67 |

| -Front/Rear Spreader | 3/2 | 1.5/1 | 0.6/0.6 | 0.6/0.6 |

| Dual-Cantilever ARMG | ||||

| -Gantry | 2.5 | 2.5 | 0.21 | 0.21 |

| -Trolley | 2 | 2 | 0.5 | 0.5 |

| -Spreader | 1.5 | 0.75 | 0.38 | 0.38 |

| Unmanned Vehicles | ||||

| -Straight Movement | 8.33 | 8.33 | 0.9 | 0.35 |

| -Turning | 2 | 1.67 | 0.9 | 0.35 |

| Experiment Type | Experiment Name | Unmanned Vehicle Ratio | Cross-Berth Operation Ratio | Twin-Lift Operation Ratio |

|---|---|---|---|---|

| Basic Analysis | Basic-6 | 6 | 20% | 20% |

| Basic-7 | 7 | 20% | 20% | |

| Basic-8 | 8 | 20% | 20% | |

| Sensitivity Analysis | CB20-TL20 | 7 | 20% | 20% |

| CB20-TL5 | 7 | 20% | 5% | |

| CB40-TL20 | 7 | 40% | 20% | |

| CB40-TL5 | 7 | 40% | 5% |

| Parameter Name | Unit | Scheme One: Parallel Yard Layout (P-Shaped) | Scheme Two: Perpendicular Yard Layout (P-Shaped) | Scheme Three: Parallel Yard Layout (Mixed-Traffic) |

|---|---|---|---|---|

| Double-Trolley Quay Cranes | Units | 16 | 16 | 16 |

| Automated Rail-Mounted Gantry Cranes (ARMGs) | Units | 40 | 40 | 40 |

| Ground Slot Capacity | TGS | 21,240 | 24,336 | 24,960 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Y.; Jin, J.; Guo, Z.; Chen, Y.; Bao, J. Simulation Study on P-Shaped Process Layout for Automated Container Terminals. Electronics 2025, 14, 3356. https://doi.org/10.3390/electronics14173356

Liang Y, Jin J, Guo Z, Chen Y, Bao J. Simulation Study on P-Shaped Process Layout for Automated Container Terminals. Electronics. 2025; 14(17):3356. https://doi.org/10.3390/electronics14173356

Chicago/Turabian StyleLiang, Yan, Jianming Jin, Zhaohua Guo, Yang Chen, and Jinsong Bao. 2025. "Simulation Study on P-Shaped Process Layout for Automated Container Terminals" Electronics 14, no. 17: 3356. https://doi.org/10.3390/electronics14173356

APA StyleLiang, Y., Jin, J., Guo, Z., Chen, Y., & Bao, J. (2025). Simulation Study on P-Shaped Process Layout for Automated Container Terminals. Electronics, 14(17), 3356. https://doi.org/10.3390/electronics14173356