Data Augmentation and Knowledge Transfer-Based Fault Detection and Diagnosis in Internet of Things-Based Solar Insecticidal Lamps: A Survey

Abstract

1. Introduction

- Since SIL-IoTs are deployed in the wild for a long time and work in a harsh environment, devices are more prone to failure. Multiple faults occurring simultaneously can evolve into compound faults, affecting the accuracy of FDD. Therefore, the accuracy and precision of FDD methods need to be improved.

- SIL-IoTs mainly relies on solar energy for energy supply. Insufficient residual energy during continuous bad weather influences the normal operation of the device. Therefore, a lightweight design is required for FDD methods to save energy.

- Since changes in the device deployment environment will lead to a decrease in the generalization of the FDD method, updating the model will increase the cost of labeling the data. Therefore, data augmentation is needed to reduce the cost of labeling data.

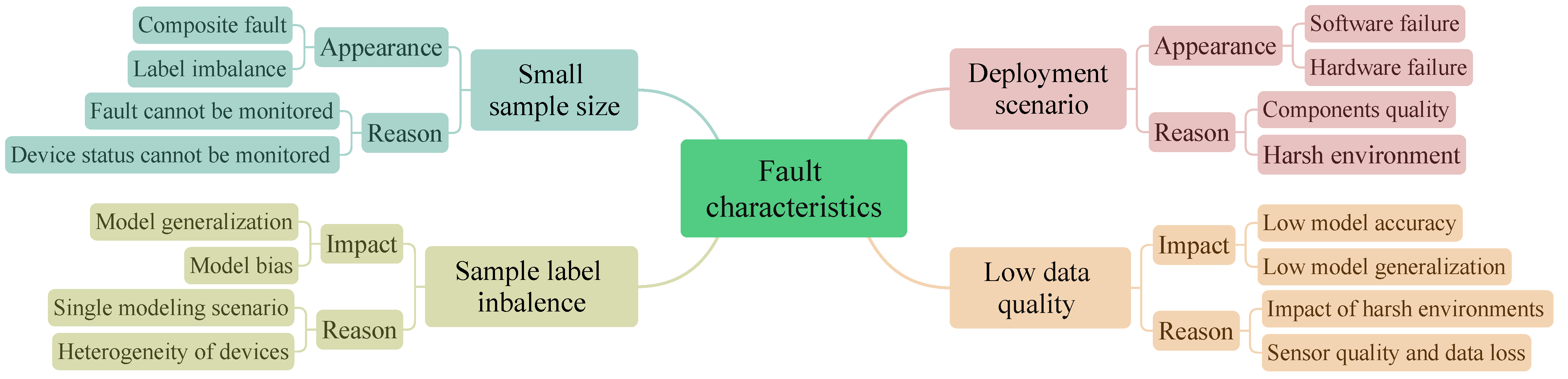

- To investigate the potential issues of FDD of SIL-IoTs, we analyze and categorize the reasons and categories of fault generation.

- To address the current limitations of FDD of SIL-IoTs in practice, we analyze the following issues and point out the corresponding challenges, i.e., compound faults, sample labeling imbalance, single scenarios, computational and energy constraints.

- According to the challenges of FDD of SIL-IoTs, we identify the corresponding countermeasures including data augmentation and TL.

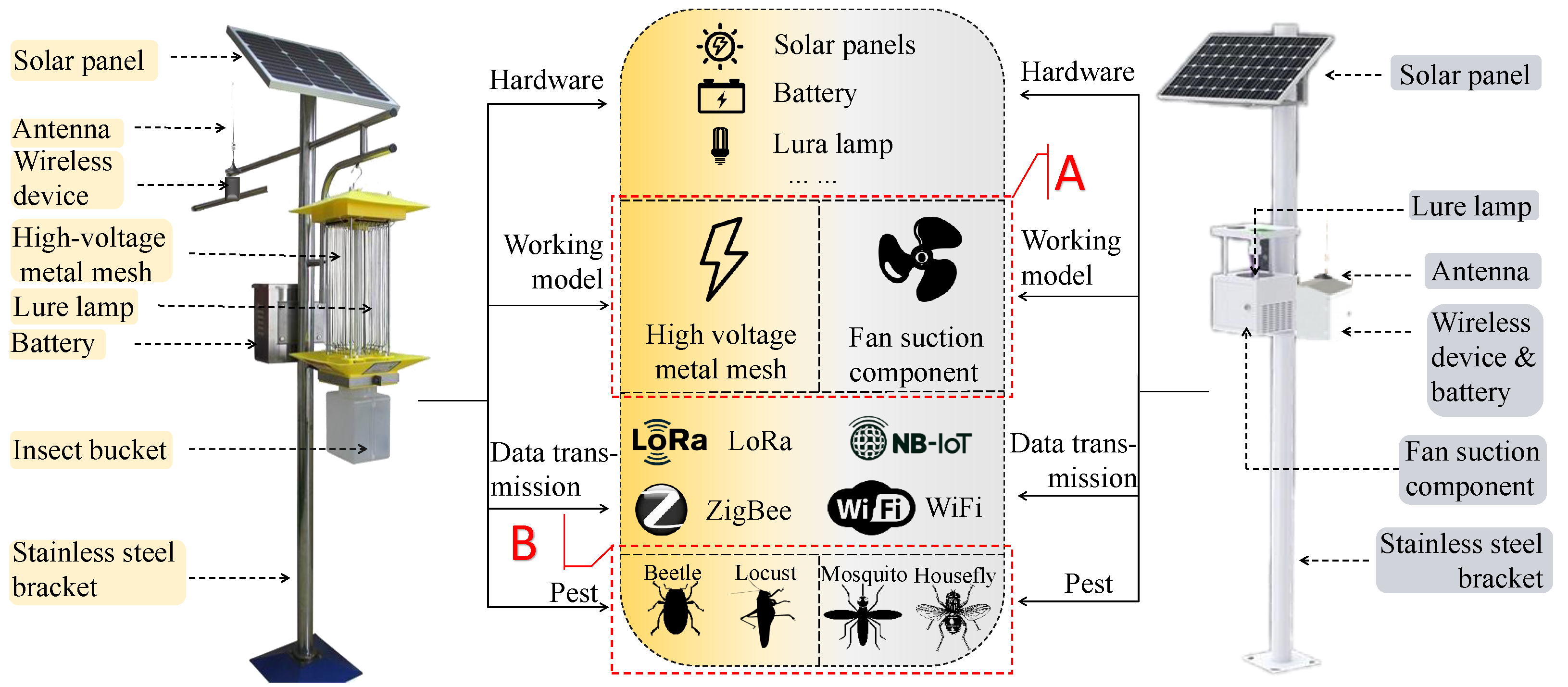

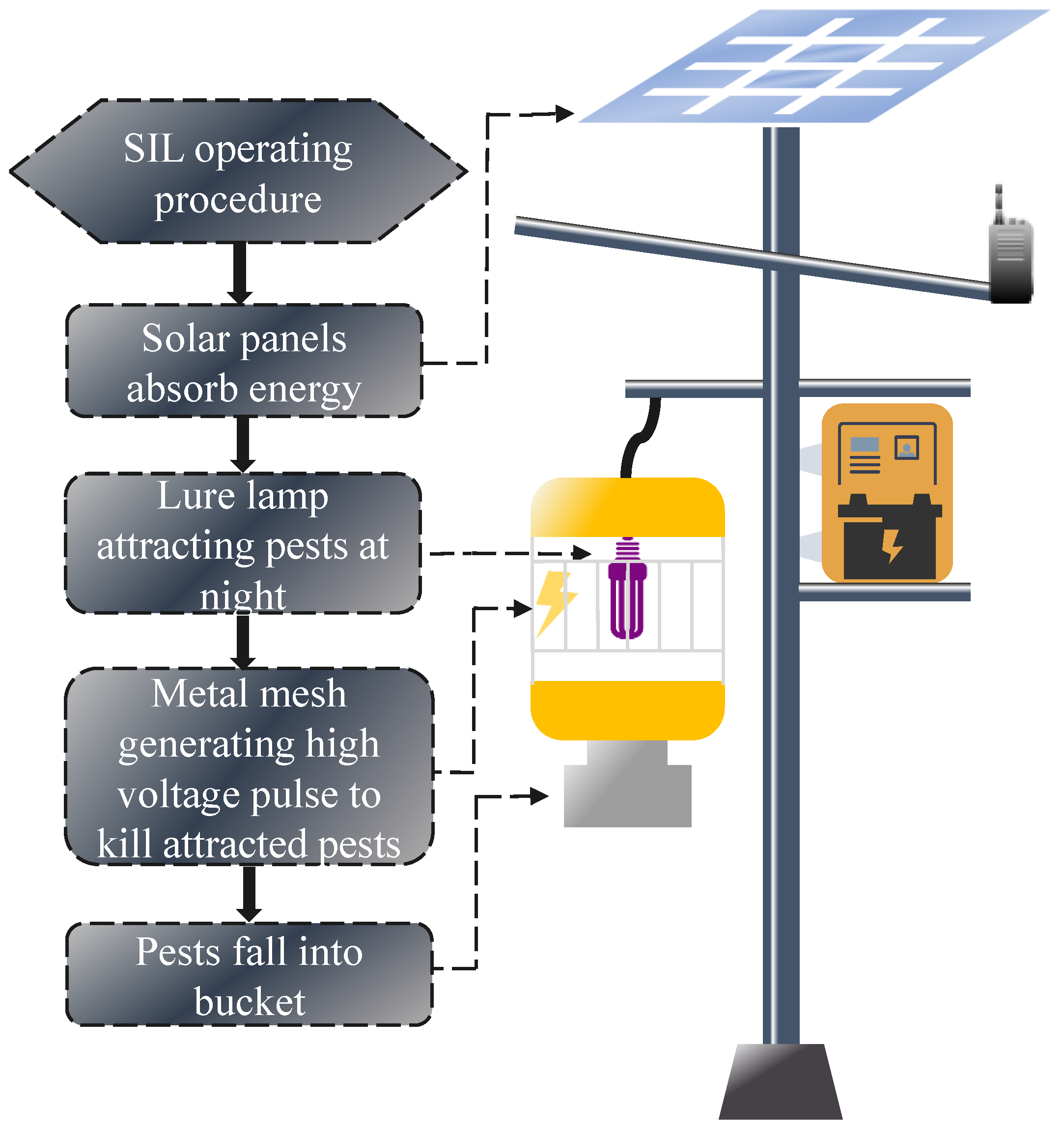

2. Characterization of SIL-IoTs

2.1. Hardware and Software Introduction of SIL-IoTs

2.2. Characterization of SIL-IoTs

- Harsh deployment environment: SIL-IoTs are usually deployed outdoors, where they operate in harsh environments and components are easy to be damaged and aged, resulting in frequent hardware and software failures. Hard faults are defined as faults where a component breaks down and causes the device to fail to work properly. For example, if the lure lamp is broken, SIL-IoTs cannot lure pests. Soft faults are defined as faults where the device is affected by an abnormal state of a component, but is able to maintain operation. For example, sensor misalignment leading to data anomalies.

- Low-quality data: Data quality is a common challenge in IoT applications. As an IoT application scenario, SIL-IoTs requires high-quality data to ensure the accuracy of the FDD model [30]. However, due to the complexity of the environments in which these devices operate, the data often fails to meet expectations or becomes anomalous during transmission. Therefore, the data must be both informative and selective [31].

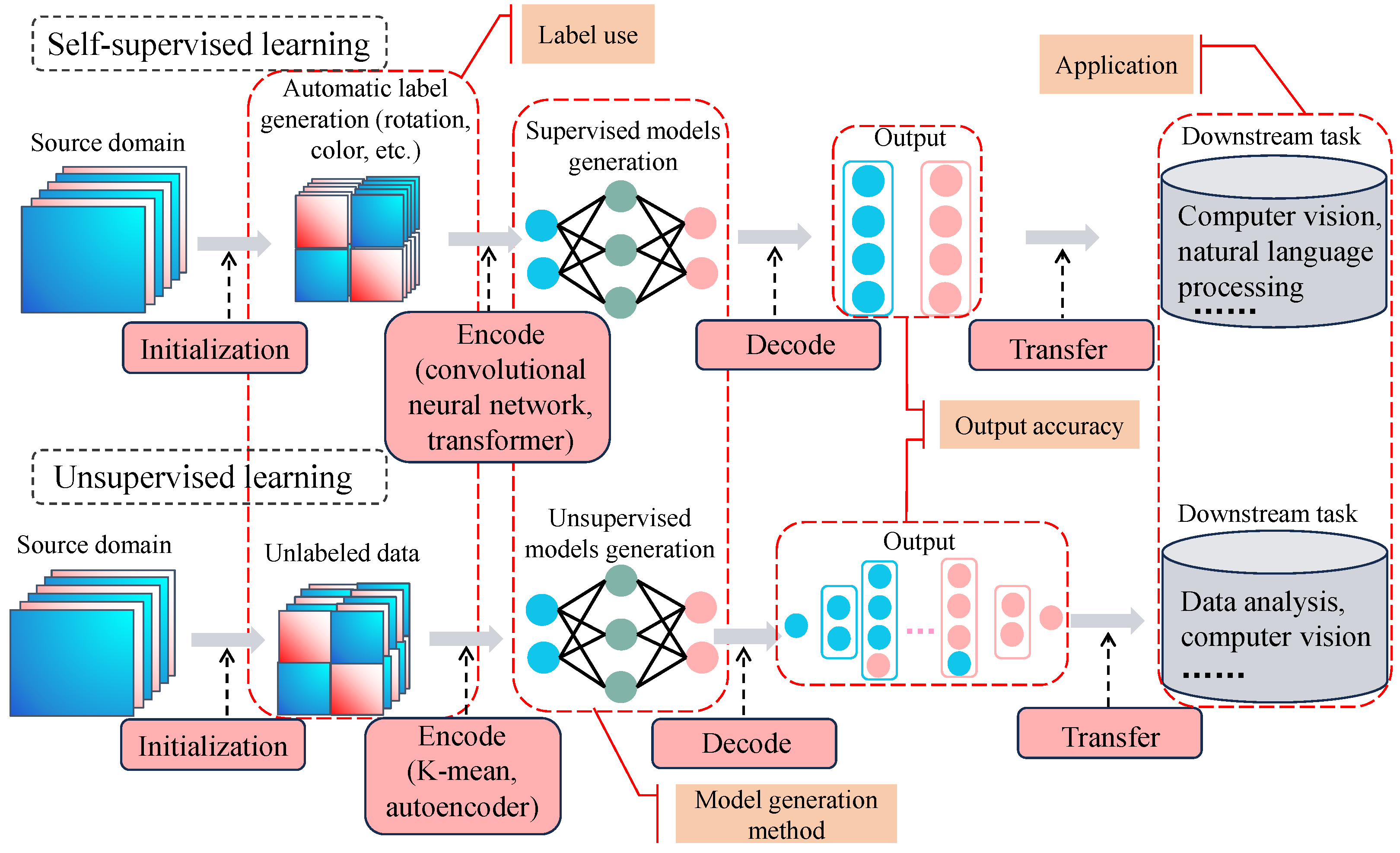

- Few labeled samples: In FDD, the number of labeled samples is usually limited, and samples often contain a large amount of data that does not match expectations [32]. This will lead to a decrease in the accuracy and generalization ability of the FDD model, and even trigger model overfitting or underfitting problems [33]. To solve this problem, data augmentation methods are widely used. Through data augmentation, not only can the number of samples be increased, but various fault characteristics can also be covered, thus ensuring that the FDD model can identify different types of faults.

- Imbalance data category: The FDD of SIL-IoTs needs to identify and analyze the causes of faults to ensure the normal operation of the devices. Thus, constructing effective FDD models requires a sufficient amount of labeled data for both training and evaluation [34]. In addition, to enhance the generalization capability of FDD of SIL-IoTs, it is necessary to label the newly generated data during device operation in different scenarios, allowing the models to adapt to various conditions.Therefore, SSL or TL can effectively solve the problem of labeled data imbalance.

2.3. Summaries

3. Related Method

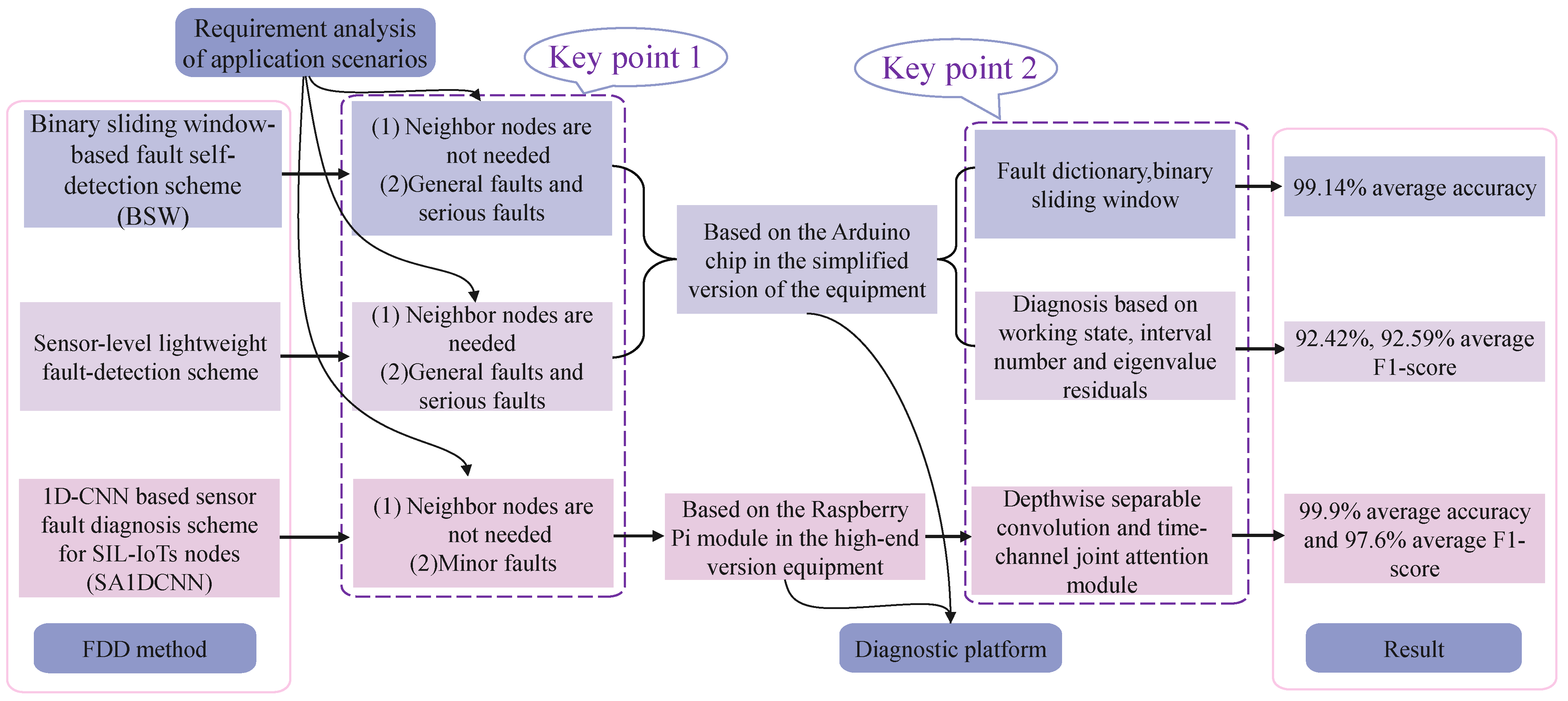

3.1. FDD Methods Targeted to SIL-IoTs

- The BSW method is suitable for addressing critical faults, such as operation unit failures and energy system malfunctions. Sensor-level schemes are typically used to diagnose routine faults, such as equipment operating in abnormal states, whereas SA1DCNN is commonly employed to identify subtle faults, including sensor data inconsistencies.

- Lightweight self-diagnostic techniques such as BSW and SA1DCNN eliminate the need for data from neighboring nodes. In contrast, sensor-level schemes typically involve analyzing the data weights of neighboring nodes to perform fault diagnosis.

- BSW relies on fault dictionaries and binary pattern matching. A sensor-level scheme analyzes working states and calculates feature residuals. The SA1DCNN, a deep learning method, utilizes depthwise separable convolutions and attention mechanisms.

3.2. Data Augmentation-Based FDD Schemes

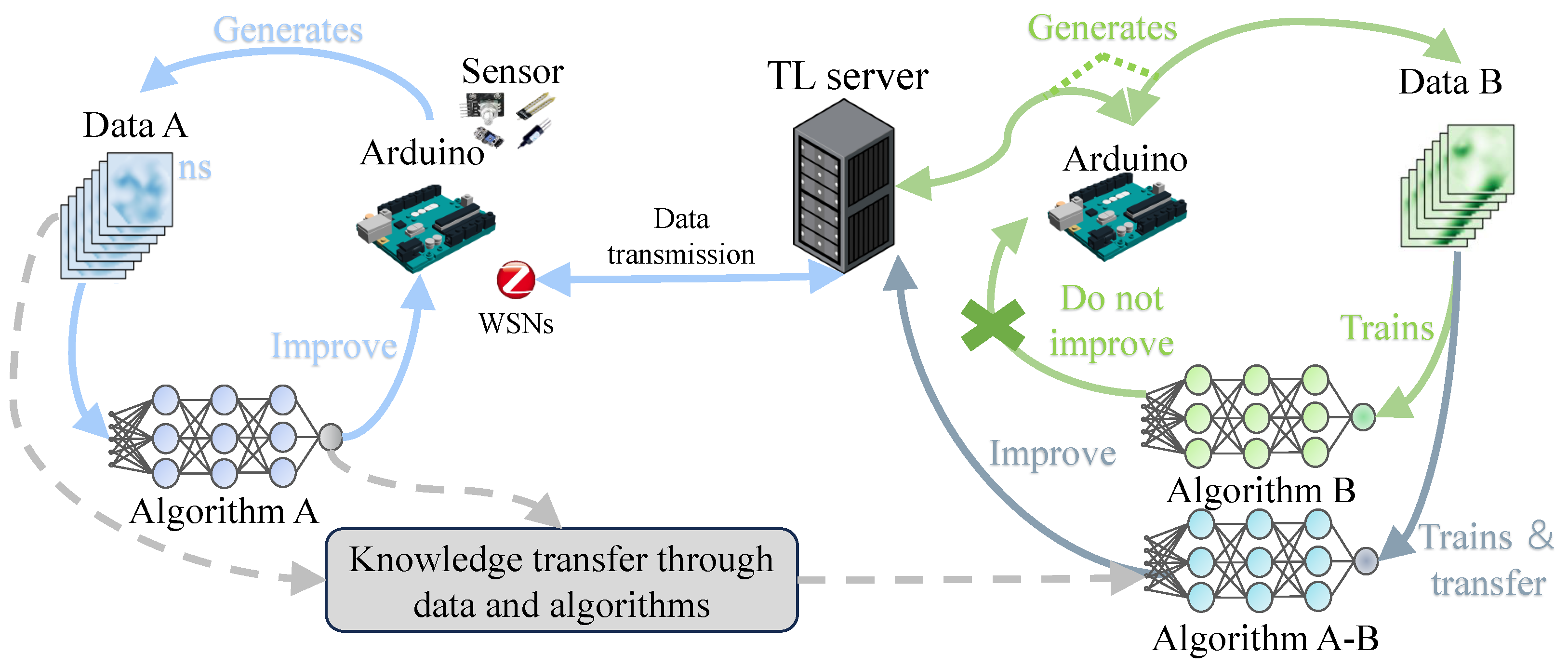

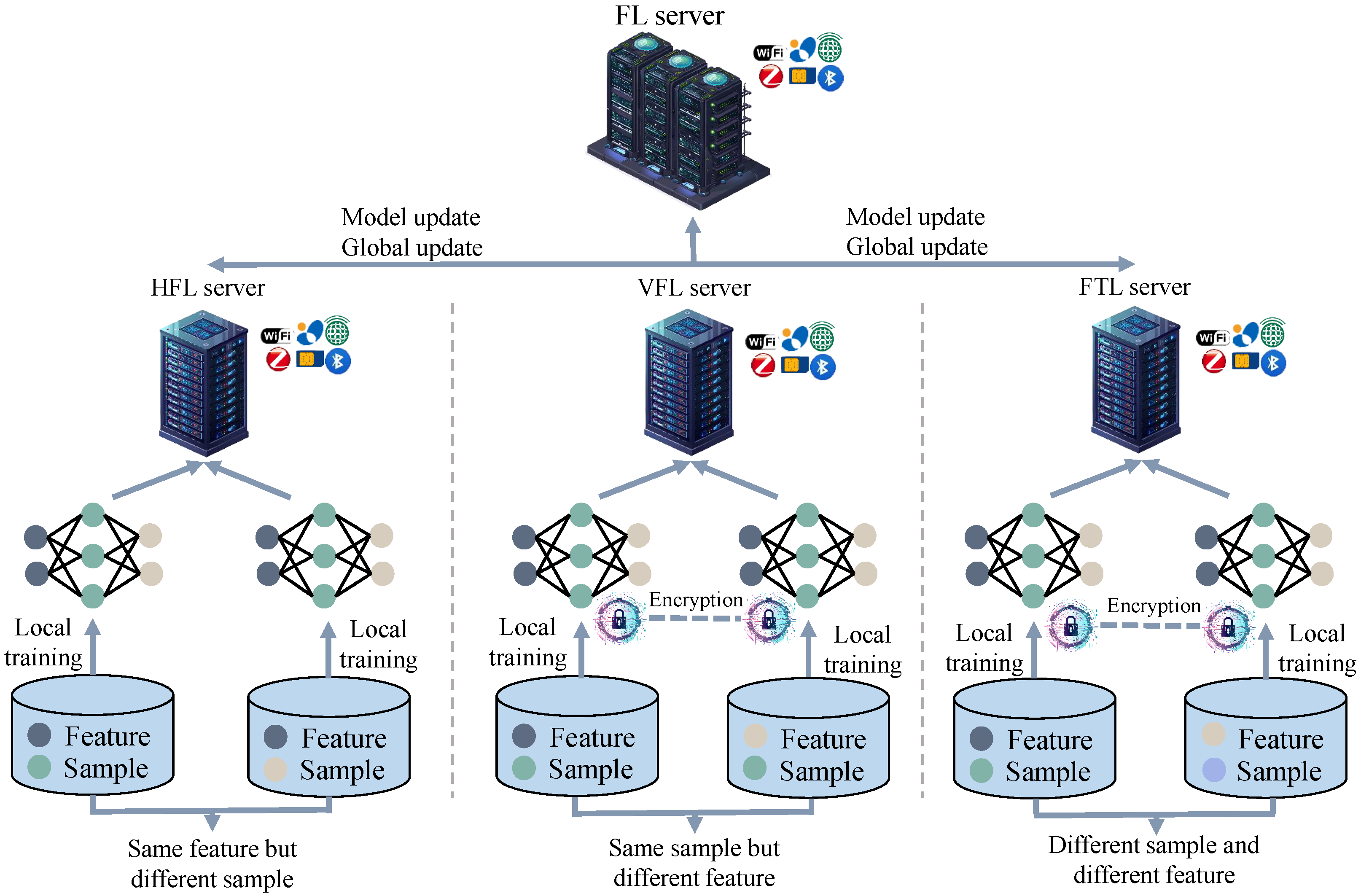

3.3. Knowledge Transfer-Based FDD Schemes

3.4. Failure Mode and Effects Analysis-Based FDD Schemes

3.5. The Limitations of the Above Methods

- Data augmentation and low label dependency related FDD methods require large amounts of high-quality data. However, the datasets for FDD of SIL-IoTs suffer from significant interference and distortion, necessitating the use of appropriate data-preprocessing techniques.

- Although FEMA can effectively evaluate the importance of faults, it usually does not consider differences in deployment environments and does not adjust for data heterogeneity, making it difficult to respond accurately to complex fault information.

- Due to the deployment of SIL-IoTs in various scenarios, there can be differences in terrain, crop types, and target pests. The components of SIL-IoTs in different scenarios will also be different, thus the data between SIL-IoTs nodes varies. For these reasons, applying FL and TL to SIL-IoTs presents challenges, as the data heterogeneity and varying system configurations can affect the accuracy and effectiveness of these methods.

4. Challenges and Future Directions

4.1. Analysis the Challenges of Similar Datasets

4.2. Analysis the Challenges of Relevant Methods

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qiu, B.; Li, H.; Tang, Z.; Chen, C.; Berry, J. How cropland losses shaped by unbalanced urbanization process? Land Use Policy 2020, 96, 104715. [Google Scholar] [CrossRef]

- Luneja, R.L.; Mkindi, A.G. Advances in Botanical-Based Nanoformulations for Sustainable Cotton Insect Pest Management in Developing Countries. Front. Agron. 2024, 7, 1558395. [Google Scholar] [CrossRef]

- Qian, Y.; Xiao, Z.; Deng, Z. Fine-grained Crop Pest Classification based on Multi-scale Feature Fusion and Mixed Attention Mechanisms. Front. Plant Sci. 2025, 16, 1500571. [Google Scholar] [CrossRef]

- Dhanda, S.; Singh, N.; Ikley, J.T.; DeWerff, R.; Werle, R.; Sarangi, D. Dicamba-Based Preemergence Herbicide Tank Mixtures Improved Residual Weed Control in Dicamba-Resistant Soybean. Front. Agron. 2024, 7, 1576547. [Google Scholar] [CrossRef]

- Lykogianni, M.; Bempelou, E.; Karamaouna, F.; Aliferis, K.A. Do pesticides promote or hinder sustainability in agriculture? The challenge of sustainable use of pesticides in modern agriculture. Sci. Total Environ. 2021, 795, 148625. [Google Scholar] [CrossRef]

- Yang, F.; Shu, L.; Huang, K.; Li, K.; Han, G.; Liu, Y. A Partition-Based Node Deployment Strategy in Solar Insecticidal Lamps Internet of Things. IEEE Internet Things J. 2020, 7, 11223–11237. [Google Scholar] [CrossRef]

- Abdollahi, A.; Rejeb, K.; Rejeb, A.; Mostafa, M.M.; Zailani, S. Wireless Sensor Networks in Agriculture: Insights from Bibliometric Analysis. Sustainability 2021, 13, 12011. [Google Scholar] [CrossRef]

- Kelley, J.; McCauley, D.; Alexander, G.A.; Gray, W.F.; Siegfried, R.; Oldroyd, H.J. Using machine learning to integrate on-farm sensors and agro-meteorology networks into site-specific decision support. Trans. ASABE 2020, 63, 1427–1439. [Google Scholar] [CrossRef]

- Singh, A.K.; Balabaygloo, B.J.; Bekee, B.; Blair, S.W.; Fey, S.; Fotouhi, F.; Gupta, A.; Jha, A.; Martinez-Palomares, J.C.; Menke, K.; et al. Smart connected farms and networked farmers to improve crop production, sustainability and profitability. Front. Agron. 2024, 6, 1410829. [Google Scholar] [CrossRef]

- Ge, H.; Zhang, Q.; Shen, M.; Qin, Y.; Wang, L.; Yuan, C. Enhancing yield prediction in maize breeding using UAV-derived RGB imagery: A novel classification-integrated regression approach. Front. Plant Sci. 2025, 16, 1511871. [Google Scholar] [CrossRef] [PubMed]

- Lloret, J.; Sendra, S.; Garcia, L.; Jimenez, J.M. A wireless sensor network deployment for soil moisture monitoring in precision agriculture. Sensors 2021, 21, 7243. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Rai, S.; Krishnan, N.C. Wheat Crop Yield Prediction Using Deep LSTM Model. arXiv 2020, arXiv:2011.01498. [Google Scholar] [CrossRef]

- Puntel, L.A.; Thompson, L.J.; Mieno, T. Leveraging digital agriculture for on-farm testing of technologies. Front. Agron. 2024, 6, 1234232. [Google Scholar] [CrossRef]

- Feng, J.; Blair, S.W.; Ayanlade, T.T.; Balu, A.; Ganapathysubramanian, B.; Singh, A.; Sarkar, S.; Singh, A.K. Robust soybean seed yield estimation using high-throughput ground robot videos. Front. Plant Sci. 2025, 16, 1554193. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Du, B.; Luo, L.; Luo, Y.; Yang, X.; Liu, Y.; Shu, L. A Scheme for Pest-Dense Area Localization with Solar Insecticidal Lamps Internet of Things Under Asymmetric Links. IEEE Trans. AgriFood Electron. 2023, 1, 71–85. [Google Scholar] [CrossRef]

- Yang, X.; Shu, L.; Huang, K.; Li, K.L.; Huo, Z.Q.; Wang, Y.F.; Wang, X.Y.; Lu, Q.L.; Zhang, Y.C. Characteristics analysis and challenges for fault diagnosis in solar insecticidal lamps internet of things. Smart Agric. 2020, 2, 11, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Li, K.L.; Shu, L.; Huang, K.; Sun, Y.H.; Yang, F.; Zhang, Y.; Huo, Z.Q.; Wang, Y.F.; Wang, X.Y.; Lu, Q.L.; et al. Research and prospect of solar insecticidal lamps internet of things. Smart Agric. 2019, 1, 13, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Han, Y.; Song, Z.; Yi, W.; Zhan, C. Design of and Experimentation with a Suction-Based Pest-Capture Machine for the Tea Pest Empoasca vitis. Agriculture 2024, 14, 964. [Google Scholar] [CrossRef]

- Balamurugan, R.; Kandasamy, P. Effectiveness of portable solar-powered light-emitting diode insect trap: Experimental investigation in a groundnut field. J. Asia-Pac. Entomol. 2021, 24, 1024–1032. [Google Scholar] [CrossRef]

- Huang, K.; Li, K.; Shu, L.; Yang, X.; Gordon, T.; Wang, X. High Voltage Discharge Exhibits Severe Effect on ZigBee-Based Device in Solar Insecticidal Lamps Internet of Things. IEEE Wirel. Commun. 2020, 27, 140–145. [Google Scholar] [CrossRef]

- Zhu, T.; Cheng, X.; Li, C.; Li, Y.; Pan, C.; Lu, G. Decoding plant thermosensors: Mechanism of temperature perception and stress adaption. Front. Plant Sci. 2025, 16, 1560204. [Google Scholar] [CrossRef]

- Yang, X.; Shu, L.; Li, K.; Nurellari, E.; Huo, Z.; Zhang, Y. A Lightweight Fault-Detection Scheme for Resource-Constrained Solar Insecticidal Lamp IoTs. Sensors 2023, 23, 6672. [Google Scholar] [CrossRef]

- Yang, F.; Shu, L. A Trajectory-Inspired Node Deployment Strategy in Solar Insecticidal Lamps Internet of Things Under Coverage and Maintenance Cost Considerations. IEEE Trans. AgriFood Electron. 2024, 2, 28–42. [Google Scholar] [CrossRef]

- Ichwana.; Nasution, I.S.; Sundari, S.; Rifky, N. Data Acquisition of Multiple Sensors in Greenhouse Using Arduino Platform. Iop Conf. Ser. Earth Environ. Sci. 2020, 515, 012011. [Google Scholar] [CrossRef]

- Srivastava, D.; Kesarwani, A.; Dubey, S. Measurement of Temperature and Humidity by using Arduino Tool and DHT11. Int. Res. J. Eng. Technol. (IRJET) 2018, 5, 876–878. [Google Scholar]

- Atika, Z.; Leow, W.; Iszaidy, I.; Irwan, Y.; Safwati, I.; Irwanto, M.; Wafi, N.; Saw, S. Development A Portable Solar Energy Measurement System. J. Phys. Conf. Ser. 2021, 1962, 012049. [Google Scholar] [CrossRef]

- Baehaqi, M.; Rosyid, A.; Siswanto, A.; Subiyanta, E. Performance Testing of DHT11 and DS18B20 Sensors as Server Room Temperature Sensors. Mestro J. Tek. Mesin Dan Elektro 2023, 5, 6–11. [Google Scholar] [CrossRef]

- Chen, Y.D.; Wang, J.C.; Zhang, J.H.; Cao, G.Y. Light source for comfortable lighting and trapping pests in tea gardens based on solar-like lighting. Appl. Opt. 2020, 59, 8459–8464. [Google Scholar] [CrossRef]

- Tu, H.; Tang, N.; Hu, X.; Yao, Z.; Wang, G.; Wei, H. LED multispectral circulation solar insecticidal lamp application in rice field. Trans. Chin. Soc. Agric. Eng. 2016, 32, 193–197. [Google Scholar]

- Challa, H.; Niu, N.; Johnson, R. Faulty Requirements Made Valuable: On the Role of Data Quality in Deep Learning. In Proceedings of the 2020 IEEE Seventh International Workshop on Artificial Intelligence for Requirements Engineering (AIRE), Zurich, Switzerland, 1 September 2020; pp. 61–69. [Google Scholar] [CrossRef]

- Serna M., E.; Bachiller S., O.; Serna A., A. Knowledge meaning and management in requirements engineering. Int. J. Inf. Manag. 2017, 37, 155–161. [Google Scholar] [CrossRef]

- Zou, L.; Li, Y.; Xu, F. An adversarial denoising convolutional neural network for fault diagnosis of rotating machinery under noisy environment and limited sample size case. Neurocomputing 2020, 407, 105–120. [Google Scholar] [CrossRef]

- Pothuganti, S. Review on over-fitting and under-fitting problems in Machine Learning and solutions. Int. J. Adv. Res. Electr. Electron. Instrum. Eng. 2018, 7, 3692–3695. [Google Scholar] [CrossRef]

- Bagora, P.; Ebrahimzadeh, A.; Wuhib, F.; Glitho, R.H. Data Labeling for Fault Detection in Cloud: A Test Suite-Based Active Learning Approach. In Proceedings of the 2023 IEEE 9th International Conference on Network Softwarization (NetSoft), Madrid, Spain, 19–23 June 2023; pp. 262–266. [Google Scholar] [CrossRef]

- Yang, X.; Shu, L.; Li, K.; Huo, Z.; Shu, S.; Nurellari, E. SILOS: An Intelligent Fault Detection Scheme for Solar Insecticidal Lamp IoT with Improved Energy Efficiency. IEEE Internet Things J. 2023, 10, 920–939. [Google Scholar] [CrossRef]

- Yang, X.; Shu, L.; Li, K.; Huo, Z.; Zhang, Y. SA1D-CNN: A Separable and Attention Based Lightweight Sensor Fault Diagnosis Method for Solar Insecticidal Lamp Internet of Things. IEEE Open J. Ind. Electron. Soc. 2022, 3, 291–303. [Google Scholar] [CrossRef]

- Chen, H.; Chen, J.; Ding, J. Data Evaluation and Enhancement for Quality Improvement of Machine Learning. IEEE Trans. Reliab. 2021, 70, 831–847. [Google Scholar] [CrossRef]

- Chen, S.; Paul, K.C.; Zhao, T. Enhancing Arc Fault Detection Performance through Data Augmentation with Artificial Intelligence Technology: An Approach to Time Series Dataset Enlargement. In Proceedings of the 2024 IEEE Energy Conversion Congress and Exposition (ECCE), Phoenix, AZ, USA, 20–24 October 2024; pp. 1866–1872. [Google Scholar] [CrossRef]

- Zeng, Q.; Ma, X.; Cheng, B.; Zhou, E.; Pang, W. GANs-Based Data Augmentation for Citrus Disease Severity Detection Using Deep Learning. IEEE Access 2020, 8, 172882–172891. [Google Scholar] [CrossRef]

- Abayomi-Alli, O.O.; Damaševičius, R.; Misra, S.; Maskeliūnas, R. Cassava disease recognition from low-quality images using enhanced data augmentation model and deep learning. Expert Syst. 2021, 38, e12746. [Google Scholar] [CrossRef]

- McDonald, T.; Butler, S.W. Progress and Current Topics of JEDEC JC-70.1 Power GaN Device Quality and Reliability Standards Activity: Or: What is the Avalanche capability of your GaN Transistor? In Proceedings of the 2021 IEEE International Reliability Physics Symposium (IRPS), Monterey, CA, USA, 21–25 March 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Ng, N.; Cho, K.; Ghassemi, M. SSMBA: Self-Supervised Manifold Based Data Augmentation for Improving Out-of-Domain Robustness. arXiv 2020, arXiv:2009.10195. [Google Scholar]

- Liu, Y.; Jin, M.; Pan, S.; Zhou, C.; Zheng, Y.; Xia, F.; Yu, P.S. Graph self-supervised learning: A survey. IEEE Trans. Knowl. Data Eng. 2023, 35, 5879–5900. [Google Scholar] [CrossRef]

- Ding, Y.; Zhuang, J.; Ding, P.; Jia, M. Self-supervised pretraining via contrast learning for intelligent incipient fault detection of bearings. Reliab. Eng. Syst. Saf. 2022, 218, 108126. [Google Scholar] [CrossRef]

- Liu, Y.; Wen, W.; Bai, Y.; Meng, Q. Self-supervised feature extraction via time–frequency contrast for intelligent fault diagnosis of rotating machinery. Measurement 2023, 210, 112551. [Google Scholar] [CrossRef]

- Yang, Z.; Huang, Y.; Nazeer, F.; Zi, Y.; Valentino, G.; Li, C.; Long, J.; Huang, H. A novel fault detection method for rotating machinery based on self-supervised contrastive representations. Comput. Ind. 2023, 147, 103878. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, D.; Xiao, Y.; Yin, H. Semi-Supervised Contrast Learning Based on Multiscale Attention and Multitarget Contrast Learning for Bearing Fault Diagnosis. IEEE Trans. Ind. Inform. 2023, 19, 10056–10068. [Google Scholar] [CrossRef]

- Chaitanya, K.; Erdil, E.; Karani, N.; Konukoglu, E. Contrastive learning of global and local features for medical image segmentation with limited annotations. Adv. Neural Inf. Process. Syst. 2020, 33, 12546–12558. [Google Scholar]

- Sun, S.; Wang, T.; Yang, H.; Chu, F. Condition monitoring of wind turbine blades based on self-supervised health representation learning: A conducive technique to effective and reliable utilization of wind energy. Appl. Energy 2022, 313, 118882. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.; Ge, Y.; Peng, D. Self-supervised signal representation learning for machinery fault diagnosis under limited annotation data. Knowl.-Based Syst. 2022, 239, 107978. [Google Scholar] [CrossRef]

- Fu, D.; Liu, J.; Zhong, H.; Zhang, X.; Zhang, F. A novel self-supervised representation learning framework based on time-frequency alignment and interaction for mechanical fault diagnosis. Knowl.-Based Syst. 2024, 295, 111846. [Google Scholar] [CrossRef]

- Wan, W.; Chen, J.; Zhou, Z.; Shi, Z. Self-Supervised Simple Siamese Framework for Fault Diagnosis of Rotating Machinery with Unlabeled Samples. IEEE Trans. Neural Netw. Learn. Syst. 2024, 35, 6380–6392. [Google Scholar] [CrossRef]

- Wei, M.; Liu, Y.; Zhang, T.; Wang, Z.; Zhu, J. Fault Diagnosis of Rotating Machinery Based on Improved Self-Supervised Learning Method and Very Few Labeled Samples. Sensors 2022, 22, 192. [Google Scholar] [CrossRef] [PubMed]

- Brito, L.C.; Susto, G.A.; Brito, J.N.; Duarte, M.A.V. Fault Detection of Bearing: An Unsupervised Machine Learning Approach Exploiting Feature Extraction and Dimensionality Reduction. Informatics 2021, 8, 85. [Google Scholar] [CrossRef]

- Guo, Z.; Wan, Y.; Ye, H. An Unsupervised Fault-Detection Method for Railway Turnouts. IEEE Trans. Instrum. Meas. 2020, 69, 8881–8901. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, J.; Zheng, L.; Gogu, C. An end-to-end fault diagnostics method based on convolutional neural network for rotating machinery with multiple case studies. J. Intell. Manuf. 2022, 33, 809–830. [Google Scholar] [CrossRef]

- Brito, L.C.; Susto, G.A.; Brito, J.N.; Duarte, M.A. An explainable artificial intelligence approach for unsupervised fault detection and diagnosis in rotating machinery. Mech. Syst. Signal Process. 2022, 163, 108105. [Google Scholar] [CrossRef]

- Su, J.; Yu, X.; Wang, X.; Wang, Z.; Chao, G. Enhanced transfer learning with data augmentation. Eng. Appl. Artif. Intell. 2024, 129, 107602. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, J.; Yang, Z.; Zhang, W.; Wang, J.; Geng, Y.; Srinivasan, D. A Class Alignment Multisource Domain Adaptation for Partial Discharge Condition Assessment with Unknown Faults in GIS. IEEE Internet Things J. 2025, 12, 19955–19971. [Google Scholar] [CrossRef]

- Wang, Q.; Taal, C.; Fink, O. Integrating Expert Knowledge with Domain Adaptation for Unsupervised Fault Diagnosis. IEEE Trans. Instrum. Meas. 2022, 71, 3500312. [Google Scholar] [CrossRef]

- Dai, Y.; Li, J.; Mei, Z.; Ni, Y.; Guo, S.; Li, Z. Self-Supervised Learning for Multimodal Fault Diagnosis with Shapley-Value Weighted Transformers. IEEE Trans. Instrum. Meas. 2025, 74, 3534114. [Google Scholar] [CrossRef]

- Lin, T.; Ren, Z.; Huang, K.; Zhang, X.; Zhu, Y.; Yan, K.; Hong, J. Contribution Imbalance and the Improvement Method in Multisensor Information Fusion-Based Intelligent Fault Diagnosis of Rotating Machinery. IEEE Trans. Instrum. Meas. 2025, 74, 3525614. [Google Scholar] [CrossRef]

- Zhu, H.; Zhao, Y.; Yan, X.; Kang, Y.; Liu, B. Cross-Sensor Generative Self-Supervised Learning Network for Fault Detection Under Few Samples. J. Syst. Sci. Complex. 2025, 38, 1000–1020. [Google Scholar] [CrossRef]

- Li, X.; Deng, W.; Ncube, S.N.; Ming, R.; Duan, C.; Qin, Y.; Liu, F.; Luo, J.; Pu, H. Multi-Source Joint Adaptive Distribution with Online Transfer Learning for Cross-Domain Fault Diagnosis. IEEE Trans. Reliab. 2025, 1–13. [Google Scholar] [CrossRef]

- Xu, X.; Yang, X.; He, C.; Shi, P.; Hua, C. Adversarial Domain Adaptation Model Based on LDTW for Extreme Partial Transfer Fault Diagnosis of Rotating Machines. IEEE Trans. Instrum. Meas. 2024, 73, 3538811. [Google Scholar] [CrossRef]

- Qian, Q.; Wu, F.; Wang, Y.; Qin, Y. Maximum subspace transferability discriminant analysis: A new cross-domain similarity measure for wind-turbine fault transfer diagnosis. Comput. Ind. 2025, 164, 104194. [Google Scholar] [CrossRef]

- Ma, P.; Zhang, H.; Fan, W.; Wang, C. A diagnosis framework based on domain adaptation for bearing fault diagnosis across diverse domains. ISA Trans. 2020, 99, 465–478. [Google Scholar] [CrossRef]

- Li, L.; Fan, Y.; Tse, M.; Lin, K.Y. A review of applications in federated learning. Comput. Ind. Eng. 2020, 149, 106854. [Google Scholar] [CrossRef]

- Yang, D.; Long, Z.; Ma, X.; Xu, B. Wind Power Fault Detection Based on Vertical Federated Learning. In Proceedings of the 2023 Global Reliability and Prognostics and Health Management Conference (PHM-Hangzhou), Hangzhou, China, 12–15 October 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Shen, J.; Yang, S.; Zhao, C.; Ren, X.; Zhao, P.; Yang, Y.; Han, Q.; Wu, S. FedLED: Label-Free Equipment Fault Diagnosis with Vertical Federated Transfer Learning. IEEE Trans. Instrum. Meas. 2024, 73, 3509910. [Google Scholar] [CrossRef]

- Geng, D.; He, H.; Lan, X.; Liu, C. Bearing fault diagnosis based on improved federated learning algorithm. Computing 2022, 104, 1–19. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, Q.; Yu, Q.; Li, Z.; Liu, Y.; Lo, S.K.; Chen, S.; Xu, X.; Zhu, L. Blockchain-Based Federated Learning for Device Failure Detection in Industrial IoT. IEEE Internet Things J. 2021, 8, 5926–5937. [Google Scholar] [CrossRef]

- Liu, Y.; Garg, S.; Nie, J.; Zhang, Y.; Xiong, Z.; Kang, J.; Hossain, M.S. Deep Anomaly Detection for Time-Series Data in Industrial IoT: A Communication-Efficient On-Device Federated Learning Approach. IEEE Internet Things J. 2021, 8, 6348–6358. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Zhu, K.; Bai, C.; Zhang, J. An Effective Federated Learning Verification Strategy and Its Applications for Fault Diagnosis in Industrial IoT Systems. IEEE Internet Things J. 2022, 9, 16835–16849. [Google Scholar] [CrossRef]

- Banabilah, S.; Aloqaily, M.; Alsayed, E.; Malik, N.; Jararweh, Y. Federated learning review: Fundamentals, enabling technologies, and future applications. Inf. Process. Manag. 2022, 59, 103061. [Google Scholar] [CrossRef]

- Wang, L.; Tang, D.; Liu, C.; Nie, Q.; Wang, Z.; Zhang, L. An Augmented Reality-Assisted Prognostics and Health Management System Based on Deep Learning for IoT-Enabled Manufacturing. Sensors 2022, 22, 6472. [Google Scholar] [CrossRef] [PubMed]

- Filz, M.A.; Langner, J.E.B.; Herrmann, C.; Thiede, S. Data-driven failure mode and effect analysis (FMEA) to enhance maintenance planning. Comput. Ind. 2021, 129, 103451. [Google Scholar] [CrossRef]

- Amato, F.; Cirillo, E.; Fonisto, M.; Moccardi, A. Detecting Adversarial Attacks in IoT-Enabled Predictive Maintenance with Time-Series Data Augmentation. Information 2024, 15, 740. [Google Scholar] [CrossRef]

- Liu, H.C.; Liu, L.; Liu, N. Risk evaluation approaches in failure mode and effects analysis: A literature review. Expert Syst. Appl. 2013, 40, 828–838. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.; Wang, K. A deep learning driven method for fault classification and degradation assessment in mechanical equipment. Comput. Ind. 2019, 104, 1–10. [Google Scholar] [CrossRef]

- Kadena, E.; Koçak, S.; Takács-György, K.; Keszthelyi, A. FMEA in Smartphones: A Fuzzy Approach. Mathematics 2022, 10, 513. [Google Scholar] [CrossRef]

- Rastayesh, S.; Bahrebar, S.; Blaabjerg, F.; Zhou, D.; Wang, H.; Dalsgaard Sørensen, J. A system engineering approach using FMEA and Bayesian network for risk analysis—A case study. Sustainability 2019, 12, 77. [Google Scholar] [CrossRef]

- Kim, D.Y.; Kareem, A.B.; Domingo, D.; Shin, B.C.; Hur, J.W. Advanced Data Augmentation Techniques for Enhanced Fault Diagnosis in Industrial Centrifugal Pumps. J. Sens. Actuator Netw. 2024, 13, 60. [Google Scholar] [CrossRef]

- Stivaktakis, R.; Tsagkatakis, G.; Tsakalides, P. Deep Learning for Multilabel Land Cover Scene Categorization Using Data Augmentation. IEEE Geosci. Remote Sens. Lett. 2019, 16, 1031–1035. [Google Scholar] [CrossRef]

- He, Z.; Shao, H.; Zhong, X.; Zhao, X. Ensemble transfer CNNs driven by multi-channel signals for fault diagnosis of rotating machinery cross working conditions. Knowl.-Based Syst. 2020, 207, 106396. [Google Scholar] [CrossRef]

- Shao, S.; McAleer, S.; Yan, R.; Baldi, P. Highly Accurate Machine Fault Diagnosis Using Deep Transfer Learning. IEEE Trans. Ind. Inform. 2019, 15, 2446–2455. [Google Scholar] [CrossRef]

- Shao, J.; Zhong, S.; Tian, M.; Liu, Y. Combining fuzzy MCDM with Kano model and FMEA: A novel 3-phase MCDM method for reliable assessment. Ann. Oper. Res. 2024, 342, 725–765. [Google Scholar] [CrossRef]

- Neupane, D.; Seok, J. Bearing Fault Detection and Diagnosis Using Case Western Reserve University Dataset with Deep Learning Approaches: A Review. IEEE Access 2020, 8, 93155–93178. [Google Scholar] [CrossRef]

- Farag, M.M. Towards a Standard Benchmarking Framework for Domain Adaptation in Intelligent Fault Diagnosis. IEEE Access 2025, 13, 24426–24453. [Google Scholar] [CrossRef]

- Idrees, A.K.; Alhussaini, R.; Salman, M.A. Energy-efficient two-layer data transmission reduction protocol in periodic sensor networks of IoTs. Pers. Ubiquitous Comput. 2023, 27, 139–158. [Google Scholar] [CrossRef]

- Aldhahri, E.A.; Almazroi, A.A.; Alkinani, M.H.; Ayub, N.; Alghamdi, E.A.; Janbi, N.F. Smart Farming: Enhancing Urban Agriculture Through Predictive Analytics and Resource Optimization. IEEE Access 2025, 13, 72375–72388. [Google Scholar] [CrossRef]

- Lynda, D.; Brahim, F.; Hamid, S.; Hamadoun, C. Towards a semantic structure for classifying IoT agriculture sensor datasets: An approach based on machine learning and web semantic technologies. J. King Saud Univ.-Comput. Inf. Sci. 2023, 35, 101700. [Google Scholar] [CrossRef]

- Long, S.; Miao, F. Research on ZigBee wireless communication technology and its application. In Proceedings of the 2019 IEEE 4th Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chengdu, China, 20–22 December 2019; pp. 1830–1834. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, L.; Shu, L.; Jing, X.; Zhang, Z. SILF Dataset: Fault Dataset for Solar Insecticidal Lamp Internet of Things Node. Sensors 2025, 25, 2808. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.; Shu, L.; Li, K.; Feng, Y.; Jiang, Z.; Zhu, Y. Insecticidal counting dataset based on one solar insecticidal lamp and two cameras. Front. Plant Sci. 2022, 13, 995118. [Google Scholar] [CrossRef]

- Nagaraj, D.; Proust, E.; Todeschini, A.; Rulli, M.C.; D’Odorico, P. A new dataset of global irrigation areas from 2001 to 2015. Adv. Water Resour. 2021, 152, 103910. [Google Scholar] [CrossRef]

- Kushal Kumar, B.N.; Balakrishna, R.; Panduranga Rao, M.; Ashok Kumar, P.S. Comprehensive Insights into Machine Learning for Intrusion Detection Systems in IoT and its Datasets. In Proceedings of the 2024 4th International Conference on Data Engineering and Communication Systems (ICDECS), Bangalore, India, 22–23 March 2024; pp. 1–5. [Google Scholar] [CrossRef]

- Wang, L.; Chi, J.; Ding, Y.; Yao, H.; Guo, Q.; Yang, H. Transformer fault diagnosis method based on SMOTE and NGO-GBDT. Sci. Rep. 2024, 14, 7179. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Gu, M. A Bayesian FMEA-Based Method for Critical Fault Identification in Stacker-Automated Stereoscopic Warehouses. Machines 2025, 13, 242. [Google Scholar] [CrossRef]

- Li, Z.; Shen, S.; Liu, Z.; Chen, Y. A Novel Multisource-Domain Adaptation Framework for Bearing Fault Diagnosis Based on Adversarial Network and Feature Enhancement. IEEE Trans. Instrum. Meas. 2025, 74, 3510712. [Google Scholar] [CrossRef]

- Tang, Z.; Zhang, J.; Zhang, K. What-is and how-to for fairness in machine learning: A survey, reflection, and perspective. ACM Comput. Surv. 2023, 55, 1–37. [Google Scholar] [CrossRef]

- Naranjo, J.E.; Alban, J.S.; Balseca, M.S.; Bustamante Villagómez, D.F.; Mancheno Falconi, M.G.; Garcia, M.V. Enhancing Institutional Sustainability Through Process Optimization: A Hybrid Approach Using FMEA and Machine Learning. Sustainability 2025, 17, 1357. [Google Scholar] [CrossRef]

- Gandhare, S.; Narad, S.; Kumar, P.; Madankar, T. Integrating Quantitative Parameters for Automating Medical Equipment Maintenance Using Industry 4.0 and FMEA. In Proceedings of the 2024 2nd DMIHER International Conference on Artificial Intelligence in Healthcare, Education and Industry (IDICAIEI), Wardha, India, 29–30 November 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Wang, H.; Wang, X.; Yang, Y.; Gryllias, K.; Liu, Z. A few-shot machinery fault diagnosis framework based on self-supervised signal representation learning. IEEE Trans. Instrum. Meas. 2024, 73, 3509114. [Google Scholar] [CrossRef]

- Jiang, Q.; Lin, X.; Lu, X.; Shen, Y.; Zhu, Q.; Zhang, Q. Self-supervised learning-based dual-classifier domain adaptation model for rolling bearings cross-domain fault diagnosis. Knowl.-Based Syst. 2024, 284, 111229. [Google Scholar] [CrossRef]

- Hu, H.; Feng, Z.; Li, R.; Ma, Y.; Yang, S. A Novel Cross-Sensor Self-Supervised Learning Method for Rotating Machinery Fault Diagnosis. In Proceedings of the ICASSP 2024—2024 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), Seoul, Republic of Korea, 14–19 April 2024; pp. 7795–7799. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, Z.; Wang, Q.; Cui, D.; Liu, P.; Wang, Z. Toward Electric Vehicle Safe Operation: Unsupervised Learning-Enabled Multiple Fault Diagnosis in Lithium-ion Battery Systems. In Proceedings of the 2024 IEEE 10th International Power Electronics and Motion Control Conference (IPEMC2024-ECCE Asia), Chengdu, China, 17–20 May 2024; pp. 2812–2817. [Google Scholar] [CrossRef]

- Ghosh, A.; Hong, J.; Yin, D.; Ramchandran, K. Robust Federated Learning in a Heterogeneous Environment. arXiv 2019, arXiv:1906.06629. [Google Scholar] [CrossRef]

- Sravani, M.; Purbey, S.; Chakradhar, B.; Kumar Choudhary, A. Design of an Efficient Multidomain Augmented Data Aggregation Model to Solve Heterogeneity Issues for IoT Deployments. In Proceedings of the 2023 2nd International Conference on Applied Artificial Intelligence and Computing (ICAAIC), Salem, India, 4–6 May 2023; pp. 1330–1336. [Google Scholar] [CrossRef]

| Acronym | Description | Acronym | Description |

|---|---|---|---|

| IoT | Internet of Things | SIL | Solar insecticidal lamp |

| FDD | Fault detection and diagnosis | BSW | Binary sliding window-based |

| 1DCNN | 1D convolutional neural network | TL | Transfer learning |

| DA | Domain adaptation | GAN | Generative adversarial networks |

| VAE | Variational autoencoder | FEMA | Failure mode and effects analysis |

| FL | Federated learning | VFL | Vertical federated learning |

| FTL | Federated transfer learning | WSNs | Wireless sensor networks |

| SSL | Self-supervised learning | UL | Unsupervised learning |

| CWRU | Case western reserve university | LSTM | Long short-term memory network |

| AE | Auto-encoder | ML | Machine learning |

| RPN | Risk priority number | CSM-SSL | Cross-sensor multidimensional SSL |

| SLDDA | SSL classification adaptive mode | DGMM | Dual Gaussian mixture Model |

| Hardware | Description |

|---|---|

| Arduino (ATMEGA328PB) | Arduino can carry multiple sensor modules and read the data from the sensors. It has the advantage of high speed, low energy consumption, and cheap price [24]. |

| Sensor module |

|

| High-voltage metal mesh | High-voltage metal mesh discharge 6 kV pulse to eliminate pests by electrical discharge [28]. |

| Lure lamp | 15 W LED lure lamp can effectively lure leaf borer, stem borer, and other types of rice lice [29]. |

| Method | Author | Application Scenarios | F1-Score | Accuracy | Advantage | Disadvantage |

|---|---|---|---|---|---|---|

| Data Augmentation | Zeng et al. [39] | • Smart agriculture | N/A | 92.6% | • Improve generalizability | • High computing cost |

| Abayomi-Alli et al. [40] | • Industrial IoTs | 96.76% | 97.7% | • Increases sample size | • Ineffective sample augment | |

| Kim et al. [83] | • Geographic information systems | 99% | 100% | • Suitable for different tasks | • Data inconsistency | |

| Stivaktakis et al. [84] | 77.7% | 85.7% | ||||

| Self- Supervised Learning | Wang et al. [50] | • Gearbox | N/A | 97.32% | • Reduces label dependency | • High computing cost |

| Wan et al. [52] | • Bearings | 97.85% | 98.41% | • Enhances adaptability | • Low generalization | |

| Wei et al. [53] | • Industrial IoTs | N/A | 93.4% | • Improves robustness | • Data sensitivity | |

| Yang et al. [69] | 87.21% | 99.98% | • Improve feature learning | • Requires unlabeled data | ||

| Unsupervised Learning | Brito et al. [54] | • Railway systems | 92.78% | N/A | • Reduces labeling cost | • No clear objectives |

| Guo et al. [55] | • Gearbox | 96.67% | 99% | • Handles insufficient data | • High complexity | |

| Wang et al. [56] | • Industry IoTs | N/A | 99.5% | • Extensive applications | • Lack of evaluation | |

| Federated Learning | Yang et al. [46] | • Industrial IoTs | N/A | 100% | • Reduces annotation dependency | • High data quality needs |

| Shen et al. [70] | • Bearings | N/A | 98.47% | • Reduces training time | • Negative transfer | |

| Geng et al. [71] | • Power system | 87.76% | 95.56% | • Enhances generalization | • High computing cost | |

| Transfer Learning | Qian et al. [66] | • Power system | N/A | 98% | • Reduces computation | • High-quality data needed |

| He et al. [85] | • Geographic systems | 99% | 100% | • Reduces data needs | • Model negative transfer | |

| Shao et al. [86] | • Rotating machinery | N/A | 98.8% | • Enhances generalization | • Domain mismatch | |

| RPNmin | RPNmax | |||||

| Failure Mode and Effects Analysis | Kadena et al. [81] | • Economic field | 24.3 | 300 | • Risk assessment | • Experience dependent |

| Tarcsay et al. [82] | • Industrial IoTs | 0 | 120 | • Process improvement | • Incomplete risk coverage | |

| Ma et al. [87] | 2.584 | 22.128 |

| Dataset Name | Group/ Sample Size | Temperature & Humidity | Soil Moisture | Sunlight Exposure | Wind Speed & Direction | Component Voltage | Component Current |

|---|---|---|---|---|---|---|---|

| FDD of SIL-IoTs dataset (https://ieee-dataport.org/documents/silf-dataset-faultdataset-solar-insecticidal-lamp-internet-things-node) [94] Accessed on 27 July 2025 | 16/469,916 | ✔ | × | ✔ | ✔ | ✔ | ✔ |

| SIL-IoTs insecticidal count dataset (https://ieee-dataport.org/documents/insecticidal-counting-dataset-based-one-solar-insecticidal-lamp-and-two-cameras) [95] Accessed on 27 June 2025 | 6/708,480 | × | × | ✔ | ✔ | ✔ | ✔ |

| Smart Farming Data 2024 (SF24) (https://www.kaggle.com/datasets/datasetengineer/smart-farming-data-2024-sf24) [91] Accessed on 18 April 2025 | 19/2200 | ✔ | ✔ | ✔ | ✔ | × | × |

| Agriculture and Farming Dataset (https://www.kaggle.com/datasets/bhadramohit/agriculture-and-farming-dataset) [92] Accessed on 18 April 2025 | 9/50 | ✔ | ✔ | ✔ | × | × | × |

| Irrigation machine dataset (https://www.kaggle.com/datasets/mahmoudshaheen1134/irrigation-machine-dataset) [96] Accessed on 18 April 2025 | 22/2000 | ✔ | ✔ | ✔ | × | ✔ | ✔ |

| Intrusion detection systems dataset [97] | 9/2,540,044 | ✔ | × | × | × | ✔ | ✔ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Yang, X.; Li, T.; Shu, L.; Li, K.; Jing, X. Data Augmentation and Knowledge Transfer-Based Fault Detection and Diagnosis in Internet of Things-Based Solar Insecticidal Lamps: A Survey. Electronics 2025, 14, 3113. https://doi.org/10.3390/electronics14153113

Wang Z, Yang X, Li T, Shu L, Li K, Jing X. Data Augmentation and Knowledge Transfer-Based Fault Detection and Diagnosis in Internet of Things-Based Solar Insecticidal Lamps: A Survey. Electronics. 2025; 14(15):3113. https://doi.org/10.3390/electronics14153113

Chicago/Turabian StyleWang, Zhengjie, Xing Yang, Tongjie Li, Lei Shu, Kailiang Li, and Xiaoyuan Jing. 2025. "Data Augmentation and Knowledge Transfer-Based Fault Detection and Diagnosis in Internet of Things-Based Solar Insecticidal Lamps: A Survey" Electronics 14, no. 15: 3113. https://doi.org/10.3390/electronics14153113

APA StyleWang, Z., Yang, X., Li, T., Shu, L., Li, K., & Jing, X. (2025). Data Augmentation and Knowledge Transfer-Based Fault Detection and Diagnosis in Internet of Things-Based Solar Insecticidal Lamps: A Survey. Electronics, 14(15), 3113. https://doi.org/10.3390/electronics14153113