Grain Boundary Engineering for High-Mobility Organic Semiconductors

Abstract

1. Background and Introduction

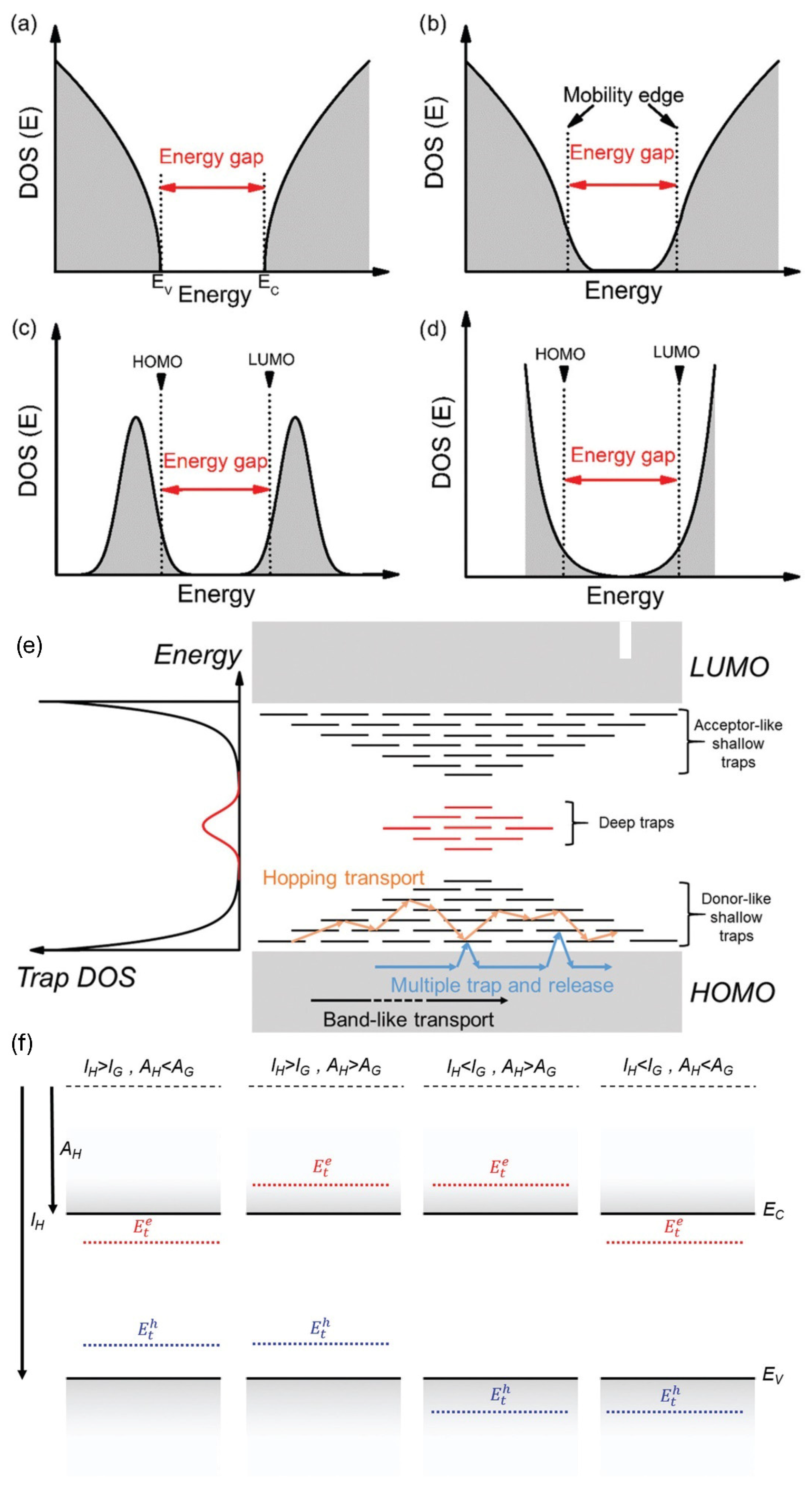

1.1. Grain Boundaries as Charge Carrier Traps

1.2. Grain Boundaries as Potential Barriers

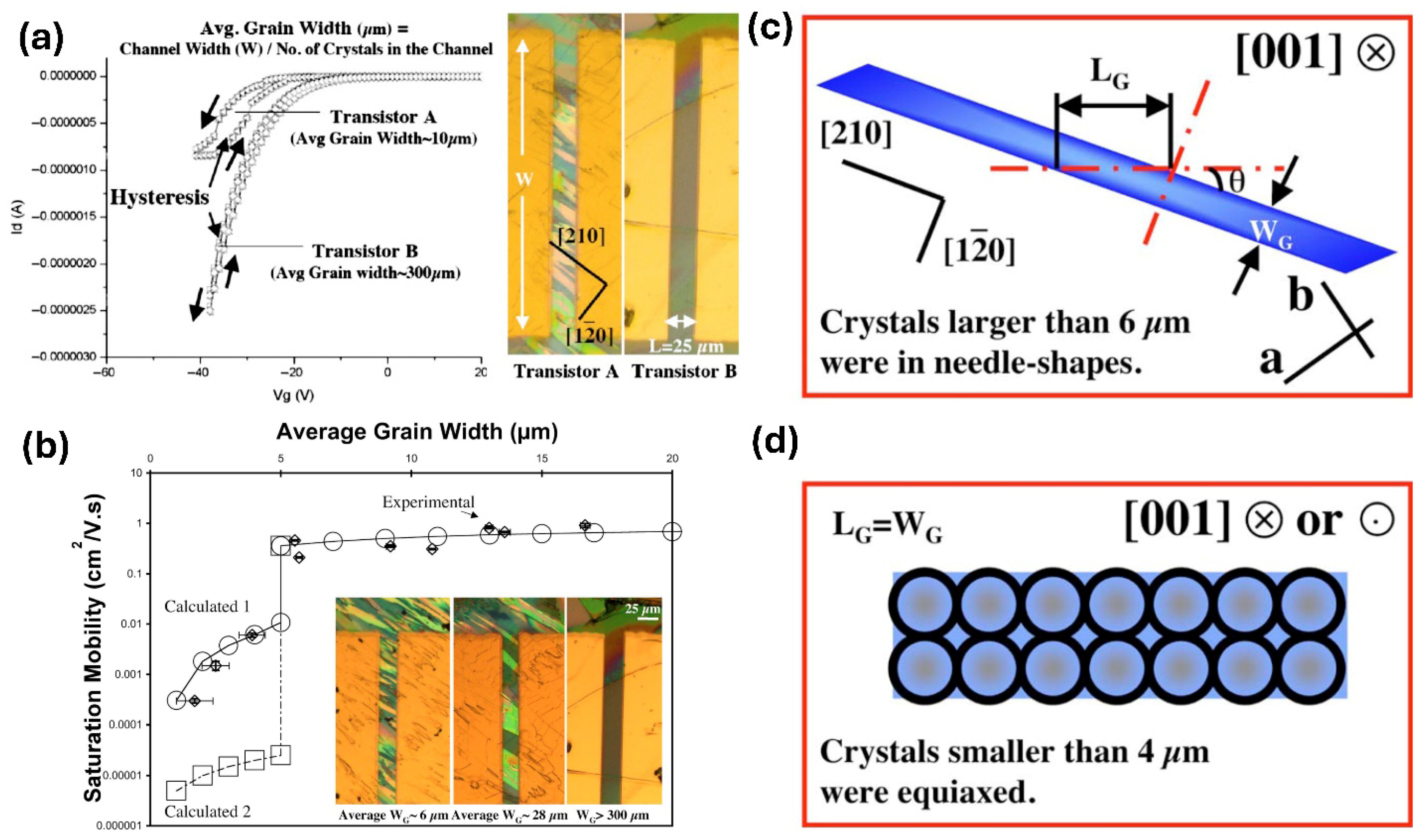

1.3. Grain Width-Dependent Model

1.4. Impact of Grain Boundary on Electrical Performance of OTFTs

2. Methods for Grain Boundary Engineering

2.1. Solvent Choices

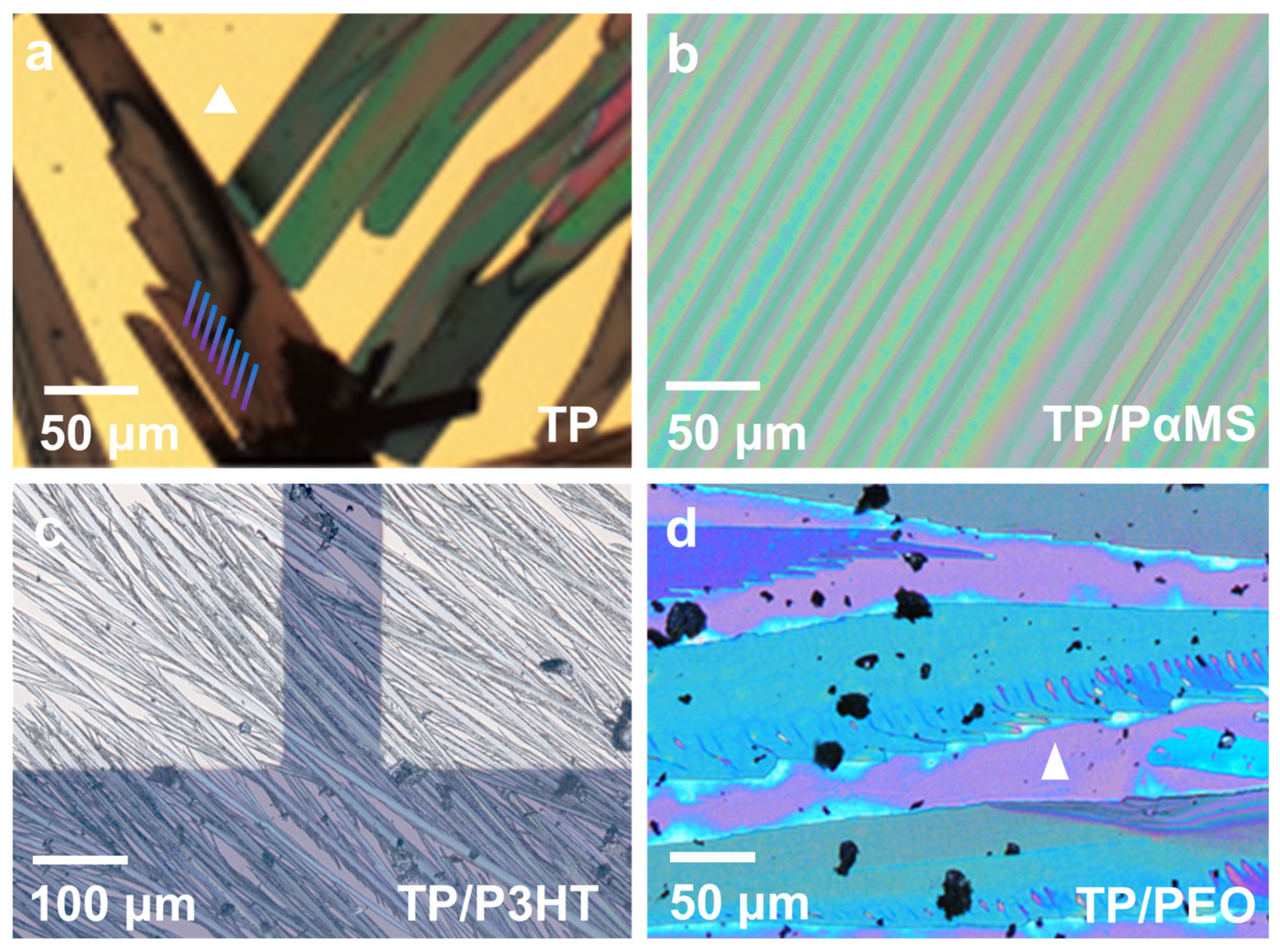

2.2. Polymer Additives

2.3. External Alignment

3. Case Studies of Grain Boundary Engineering

3.1. Pentacene

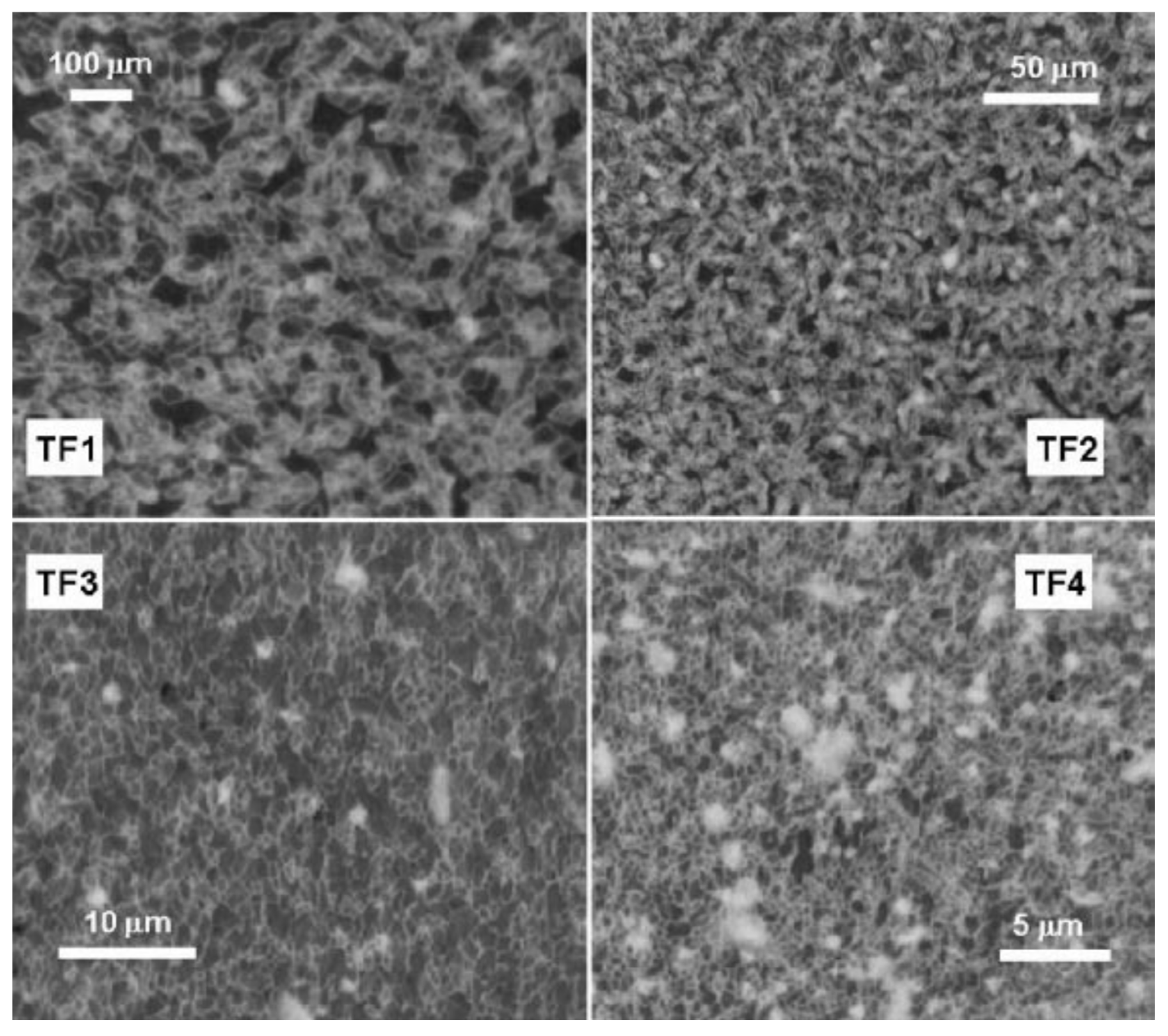

3.2. TIPS Pentacene

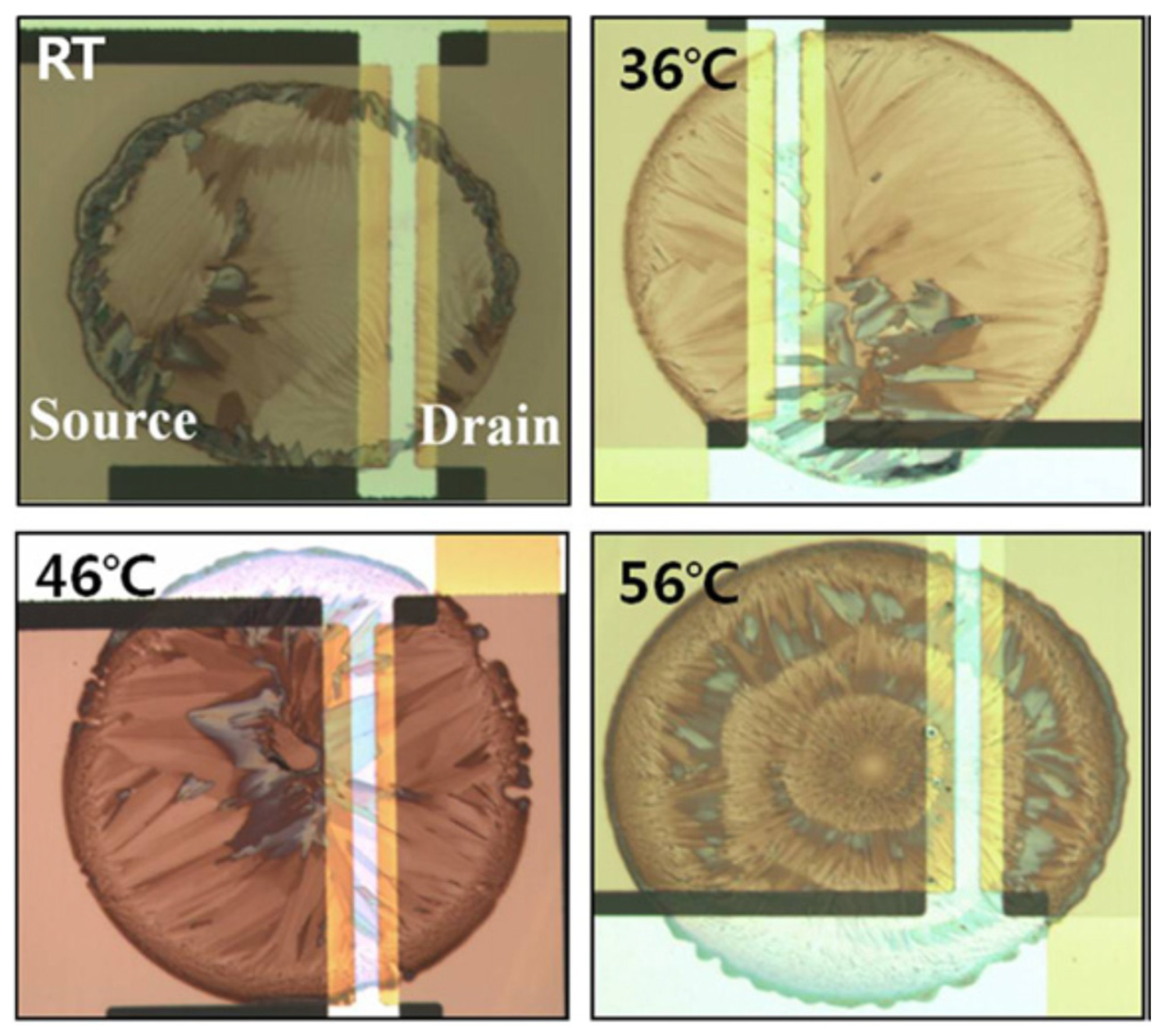

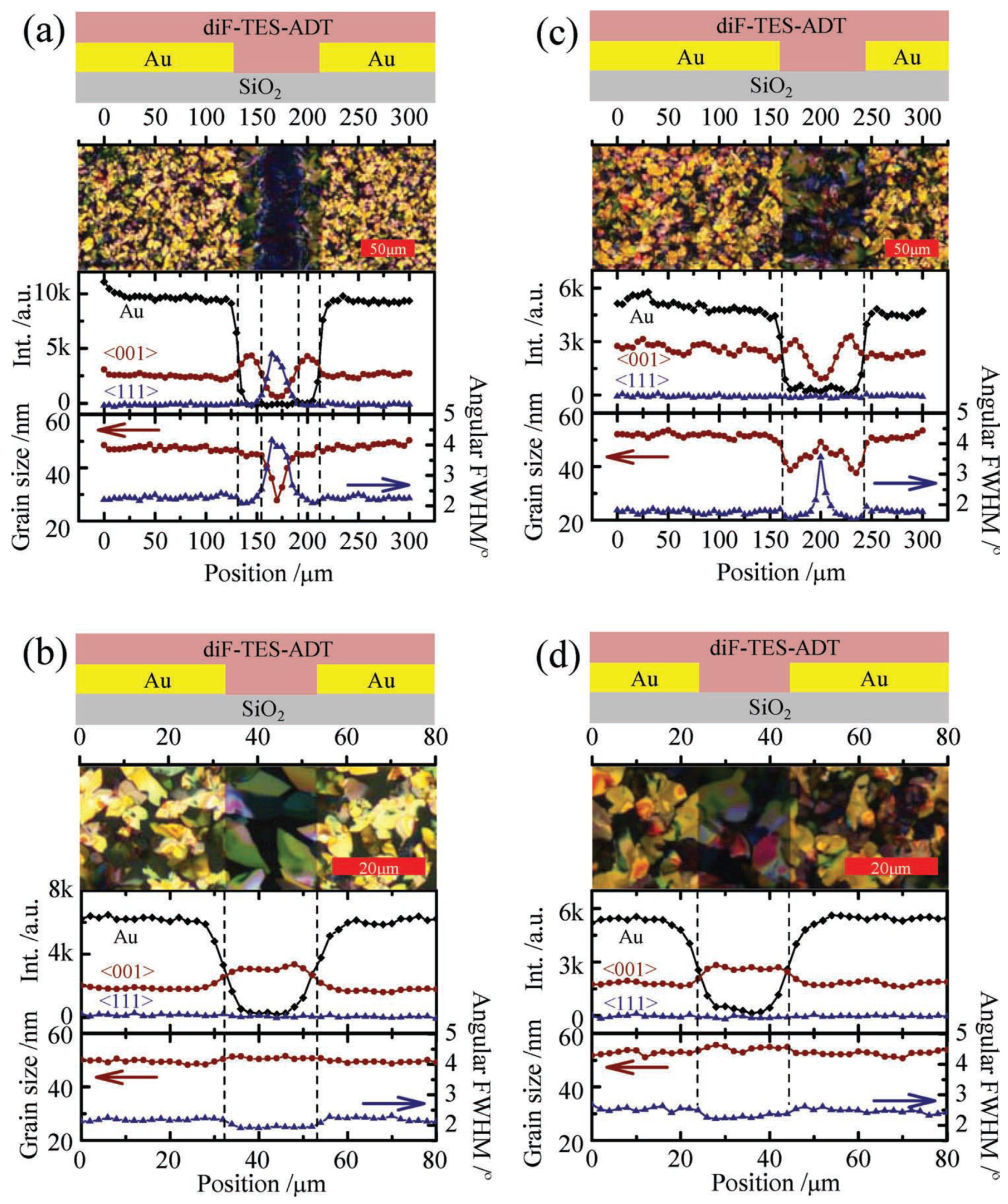

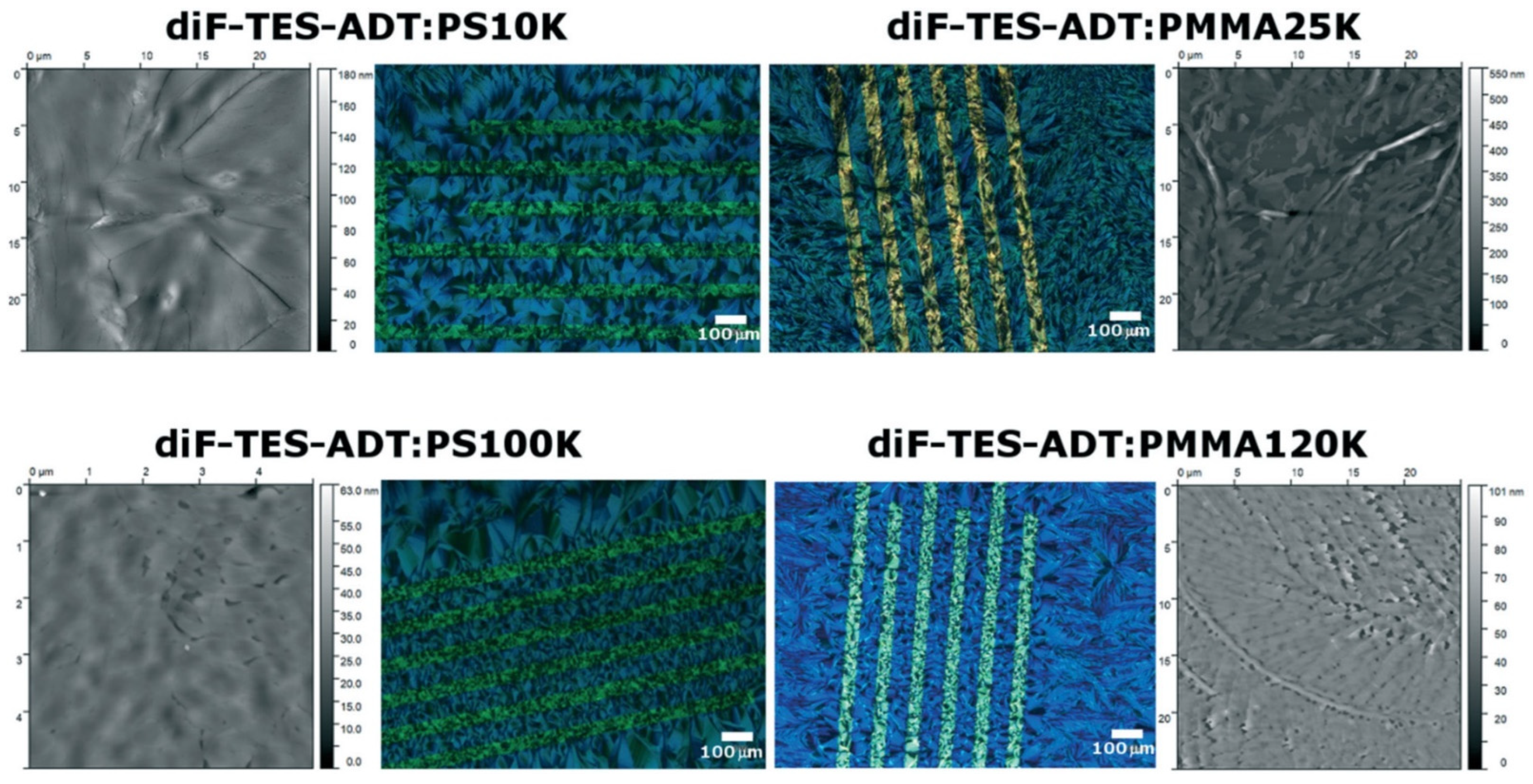

3.3. diF-TES-ADT

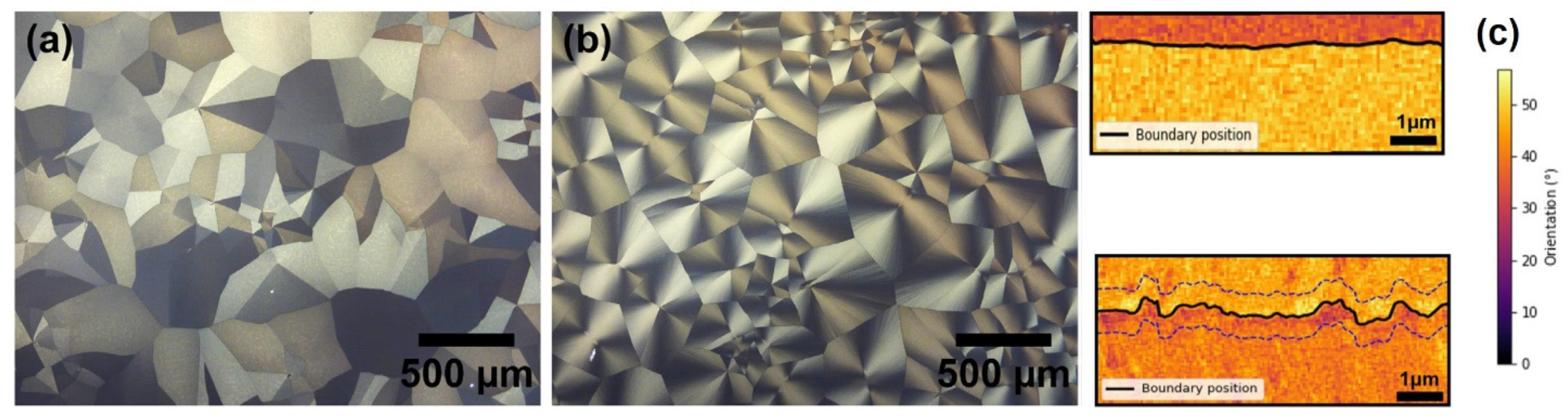

3.4. Rubrene

4. Conclusions and Outlook

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, L.; Tang, L.; Ma, H.; Gu, W.; Liu, C.; Jia, X.; Tao, T.; Liu, S.; Chen, Y.; Wang, X.; et al. Application of Highly Spatially Resolved Area Array Velocity Measurement in the Cracking Behavior of Materials. Electronics 2025, 14, 1732. [Google Scholar] [CrossRef]

- Sancho-García, J.C.; Pérez-Jiménez, A.J.; Olivier, Y.; Cornil, J. Molecular packing and charge transport parameters in crystalline organic semiconductors from first-principles calculations. Phys. Chem. Chem. Phys. 2010, 12, 9381–9388. [Google Scholar] [CrossRef]

- Nelson, J.; Kwiatkowski, J.J.; Kirkpatrick, J.; Frost, J.M. Modeling Charge Transport in Organic Photovoltaic Materials. Acc. Chem. Res. 2009, 42, 1768–1778. [Google Scholar] [CrossRef]

- Šiljegović, M.; Cvejić, Ž.; Jankov, S.; Toth, E.; Herceg, D.; Odry, P.; Tadic, V. Impedance and Dielectric Analysis of Nickel Ferrites: Revealing the Role of the Constant Phase Element and Yttrium Doping. Electronics 2024, 13, 1496. [Google Scholar] [CrossRef]

- Ryno, S.M.; Risko, C.; Brédas, J.-L. Impact of Molecular Orientation and Packing Density on Electronic Polarization in the Bulk and at Surfaces of Organic Semiconductors. ACS Appl. Mater. Interfaces 2016, 8, 14053–14062. [Google Scholar] [CrossRef]

- Li, L.; Hu, W.; Fuchs, H.; Chi, L. Controlling Molecular Packing for Charge Transport in Organic Thin Films. Adv. Energy Mater. 2011, 1, 188–193. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, X.; Ma, F.; Li, J.; Wang, S. A Semi-Supervised Method for Grain Boundary Segmentation: Teacher–Student Knowledge Distillation and Pseudo-Label Repair. Electronics 2024, 13, 3529. [Google Scholar]

- Grozema, F.C.; Siebbeles, L.D.A. Mechanism of charge transport in self-organizing organic materials. Int. Rev. Phys. Chem. 2008, 27, 87–138. [Google Scholar] [CrossRef]

- Zuo, G.; Abdalla, H.; Kemerink, M. Impact of doping on the density of states and the mobility in organic semiconductors. Phys. Rev. B 2016, 93, 235203. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, L.; Wang, X.; You, W. Exploring the Odd–Even Effect, Current Stabilization, and Negative Differential Resistance in Carbon-Chain-Based Molecular Devices. Electronics 2024, 13, 1764. [Google Scholar] [CrossRef]

- Roelofs, W.S.C.; Mathijssen, S.G.J.; Janssen, R.A.J.; de Leeuw, D.M.; Kemerink, M. Accurate description of charge transport in organic field effect transistors using an experimentally extracted density of states. Phys. Rev. B 2012, 85, 085202. [Google Scholar] [CrossRef][Green Version]

- Eisensmith, J.D.; Dholabhai, P.P.; Xu, K. Critical Considerations for Observing Cross Quantum Capacitance in Electric-Double-Layer-Gated Transistors Based on Two-Dimensional Crystals. Electronics 2025, 14, 1811. [Google Scholar] [CrossRef]

- Baranovskii, S.D. Theoretical description of charge transport in disordered organic semiconductors. Phys. Status Solidi. B 2014, 251, 487–525. [Google Scholar] [CrossRef]

- Kasap, S.; Koughia, C.; Berashevich, J.; Johanson, R.; Reznik, A. Charge transport in pure and stabilized amorphous selenium: Re-examination of the density of states distribution in the mobility gap and the role of defects. J. Mater. Sci. Mater. Electron. 2015, 26, 4644–4658. [Google Scholar] [CrossRef]

- Morab, S.; Sundaram, M.M.; Pivrikas, A. Charge Transport Characteristics in Doped Organic Semiconductors Using Hall Effect. Electronics 2024, 13, 4223. [Google Scholar] [CrossRef]

- Stoneham, A.M.; Gavartin, J.; Shluger, A.L.; Kimmel, A.V.; Muñoz Ramo, D.; Rønnow, H.M.; Aeppli, G.; Renner, C. Trapping, self-trapping and the polaron family. J. Phys. Condens. Matter 2007, 19, 255208. [Google Scholar] [CrossRef]

- Thouless, D.J. Electrons in disordered systems and the theory of localization. Phys. Rep. 1974, 13, 93–142. [Google Scholar] [CrossRef]

- Jin, H.; Debroye, E.; Keshavarz, M.; Scheblykin, I.G.; Roeffaers, M.B.J.; Hofkens, J.; Steele, J.A. It’s a trap! On the nature of localised states and charge trapping in lead halide perovskites. Mater. Horiz. 2020, 7, 397–410. [Google Scholar] [CrossRef]

- Li, G.; Blake, G.R.; Palstra, T.T.M. Vacancies in functional materials for clean energy storage and harvesting: The perfect imperfection. Chem. Soc. Rev. 2017, 46, 1693–1706. [Google Scholar] [CrossRef]

- Pezzé, L.; Sanchez-Palencia, L. Localized and Extended States in a Disordered Trap. Phys. Rev. Lett. 2011, 106, 040601. [Google Scholar] [CrossRef]

- Doherty, T.A.S.; Winchester, A.J.; Macpherson, S.; Johnstone, D.N.; Pareek, V.; Tennyson, E.M.; Kosar, S.; Kosasih, F.U.; Anaya, M.; Abdi-Jalebi, M.; et al. Performance-limiting nanoscale trap clusters at grain junctions in halide perovskites. Nature 2020, 580, 360–366. [Google Scholar] [CrossRef]

- Bai, X.-M.; Uberuaga, B.P. The Influence of Grain Boundaries on Radiation-Induced Point Defect Production in Materials: A Review of Atomistic Studies. JOM 2013, 65, 360–373. [Google Scholar] [CrossRef]

- Geng, X.; Vega-Paredes, M.; Wang, Z.; Ophus, C.; Lu, P.; Ma, Y.; Zhang, S.; Scheu, C.; Liebscher, C.H.; Gault, B. Grain boundary engineering for efficient and durable electrocatalysis. Nat. Comm. 2024, 15, 8534. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, D.; Chu, W.; Wang, B.; Vasenko, A.S.; Prezhdo, O.V. Point defects at grain boundaries can create structural instabilities and persistent deep traps in metal halide perovskites. Nanoscale 2025, 17, 2224–2234. [Google Scholar] [CrossRef]

- Chen, Y.-S.; Lu, H.; Liang, J.; Rosenthal, A.; Liu, H.; Sneddon, G.; McCarroll, I.; Zhao, Z.; Li, W.; Guo, A.; et al. Observation of hydrogen trapping at dislocations, grain boundaries, and precipitates. Science 2020, 367, 171–175. [Google Scholar] [CrossRef]

- Sherkar, T.S.; Momblona, C.; Gil-Escrig, L.; Ávila, J.; Sessolo, M.; Bolink, H.J.; Koster, L.J.A. Recombination in Perovskite Solar Cells: Significance of Grain Boundaries, Interface Traps, and Defect Ions. ACS Energy Lett. 2017, 2, 1214–1222. [Google Scholar] [CrossRef]

- Li, C.; Duan, L.; Li, H.; Qiu, Y. Universal Trap Effect in Carrier Transport of Disordered Organic Semiconductors: Transition from Shallow Trapping to Deep Trapping. J. Phys. Chem. C 2014, 118, 10651–10660. [Google Scholar] [CrossRef]

- Saarinen, K.; Hautojärvi, P.; Vehanen, A.; Krause, R.; Dlubek, G. Shallow positron traps in GaAs. Phys. Rev. B 1989, 39, 5287–5296. [Google Scholar] [CrossRef]

- Shuttle, C.G.; Treat, N.D.; Douglas, J.D.; Fréchet, J.M.J.; Chabinyc, M.L. Deep Energetic Trap States in Organic Photovoltaic Devices. Adv. Energy Mater. 2012, 2, 111–119. [Google Scholar] [CrossRef]

- Haneef, H.F. Dynamics of Charge Carrier Traps in Organic Semiconductors. Ph.D. Thesis, Wake Forest University, Winston-Salem, NC, USA, 2021. [Google Scholar]

- Dundas, K.; Shears, M.J.; Sun, Y.; Hopp, C.S.; Crosnier, C.; Metcalf, T.; Girling, G.; Sinnis, P.; Billker, O.; Wright, G.J. Alpha-v–containing integrins are host receptors for the Plasmodium falciparum sporozoite surface protein, TRAP. Proc. Natl. Acad. Sci. USA 2018, 115, 4477–4482. [Google Scholar] [CrossRef]

- Haneef, H.F.; Zeidell, A.M.; Jurchescu, O.D. Charge carrier traps in organic semiconductors: A review on the underlying physics and impact on electronic devices. J. Mater. Chem. C 2020, 8, 759–787. [Google Scholar] [CrossRef]

- Wang, F.; Landau, D.P. Determining the density of states for classical statistical models: A random walk algorithm to produce a flat histogram. Phys. Rev. E 2001, 64, 056101. [Google Scholar] [CrossRef]

- Lacroix, C. Density of states for the Anderson model. J. Phys. F Met. Phys. 1981, 11, 2389. [Google Scholar] [CrossRef]

- Singh, S.; Chopra, M.; de Pablo, J.J. Density of States–Based Molecular Simulations. Annu. Rev. Chem. Biomol. Eng. 2012, 3, 369–394. [Google Scholar] [CrossRef]

- Novikov, S.V. Density of states in locally ordered amorphous organic semiconductors: Emergence of the exponential tails. J. Chem. Phys. 2021, 154, 124711. [Google Scholar] [CrossRef]

- Zanatta, A.R.; Chambouleyron, I. Absorption edge, band tails, and disorder of amorphous semiconductors. Phys. Rev. B 1996, 53, 3833–3836. [Google Scholar] [CrossRef]

- Tsitrin, S.; Williamson, E.P.; Amoah, T.; Nahal, G.; Chan, H.L.; Florescu, M.; Man, W. Unfolding the band structure of non-crystalline photonic band gap materials. Sci. Rep. 2015, 5, 13301. [Google Scholar] [CrossRef]

- Yan, X.; Li, B.; Li, L.-S. Colloidal Graphene Quantum Dots with Well-Defined Structures. Acc. Chem. Res. 2013, 46, 2254–2262. [Google Scholar] [CrossRef]

- Cooke, D.B.; Tian, Z. Modeling of Organic Thermoelectric Material Properties. In Thin Film and Flexible Thermoelectric Generators, Devices and Sensors; Skipidarov, S., Nikitin, M., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 241–258. [Google Scholar]

- Janssen, M. Statistics and scaling in disordered mesoscopic electron systems. Phys. Rep. 1998, 295, 1–91. [Google Scholar] [CrossRef]

- Stachurski, Z.H. On Structure and Properties of Amorphous Materials. Materials 2011, 4, 1564–1598. [Google Scholar] [CrossRef]

- Pantelides, S.T. The electronic structure of impurities and other point defects in semiconductors. Rev. Mod. Phys. 1978, 50, 797–858. [Google Scholar] [CrossRef]

- Huzayyin, A.; Boggs, S.; Ramprasad, R. An overview of impurity states and the basis for hole mobility in polyethylene. IEEE Electr. Insul. Mag. 2012, 28, 23–29. [Google Scholar] [CrossRef]

- Grimmeiss, H.G. Deep Level Impurities in Semiconductors. Annu. Rev. Mater. Res. 1977, 7, 341–376. [Google Scholar] [CrossRef]

- Wenderott, J.K.; Dong, B.X.; Green, P.F. Morphological design strategies to tailor out-of-plane charge transport in conjugated polymer systems for device applications. Phys. Chem. Chem. Phys. 2021, 23, 27076–27102. [Google Scholar] [CrossRef]

- Liu, H.; Liu, D.; Yang, J.; Gao, H.; Wu, Y. Flexible Electronics Based on Organic Semiconductors: From Patterned Assembly to Integrated Applications. Small 2023, 19, 2206938. [Google Scholar] [CrossRef]

- Abd Nasir, F.H.; Woon, K.L. Charge carrier trapping in organic semiconductors: Origins, impact and strategies for mitigation. Synth. Met. 2024, 307, 117661. [Google Scholar] [CrossRef]

- Xue, J.; Fujitsuka, M.; Tachikawa, T.; Bao, J.; Majima, T. Charge Trapping in Semiconductor Photocatalysts: A Time- and Space-Domain Perspective. J. Am. Chem. Soc. 2024, 146, 8787–8799. [Google Scholar] [CrossRef]

- Khanna, V.K. Physical understanding and technological control of carrier lifetimes in semiconductor materials and devices: A critique of conceptual development, state of the art and applications. Prog. Quantum Electron. 2005, 29, 59–163. [Google Scholar] [CrossRef]

- Kuik, M.; Wetzelaer, G.-J.A.H.; Nicolai, H.T.; Craciun, N.I.; De Leeuw, D.M.; Blom, P.W.M. 25th Anniversary Article: Charge Transport and Recombination in Polymer Light-Emitting Diodes. Adv. Mater. 2014, 26, 512–531. [Google Scholar] [CrossRef]

- Bemski, G. Recombination in Semiconductors. Proc. IRE 1958, 46, 990–1004. [Google Scholar] [CrossRef]

- Guo, X.; Waser, R. Electrical properties of the grain boundaries of oxygen ion conductors: Acceptor-doped zirconia and ceria. Prog. Mater. Sci. 2006, 51, 151–210. [Google Scholar] [CrossRef]

- Quirk, J.; Rothmann, M.; Li, W.; Abou-Ras, D.; McKenna, K.P. Grain boundaries in polycrystalline materials for energy applications: First principles modeling and electron microscopy. Appl. Phys. Rev. 2024, 11, 011308. [Google Scholar] [CrossRef]

- Waser, R.; Hagenbeck, R. Grain boundaries in dielectric and mixed-conducting ceramics. Acta Mater. 2000, 48, 797–825. [Google Scholar] [CrossRef]

- Greuter, F.; Blatter, G. Electrical properties of grain boundaries in polycrystalline compound semiconductors. Semicond. Sci. Technol. 1990, 5, 111. [Google Scholar] [CrossRef]

- Zhang, Y.; Conibeer, G.; Liu, S.; Zhang, J.; Guillemoles, J.-F. Review of the mechanisms for the phonon bottleneck effect in III–V semiconductors and their application for efficient hot carrier solar cells. Prog. Photovolt. Res. Appl. 2022, 30, 581–596. [Google Scholar] [CrossRef]

- Liao, J.-F.; Wu, W.-Q.; Jiang, Y.; Zhong, J.-X.; Wang, L.; Kuang, D.-B. Understanding of carrier dynamics, heterojunction merits and device physics: Towards designing efficient carrier transport layer-free perovskite solar cells. Chem. Soc. Rev. 2020, 49, 354–381. [Google Scholar] [CrossRef]

- Horowitz, G.; Hajlaoui, M.E. Grain size dependent mobility in polycrystalline organic field-effect transistors. Synth. Met. 2001, 122, 185–189. [Google Scholar] [CrossRef]

- Verlaak, S.; Arkhipov, V.; Heremans, P. Modeling of transport in polycrystalline organic semiconductor films. Appl. Phys. Lett. 2003, 82, 745–747. [Google Scholar] [CrossRef]

- Chen, J.H.; Tee, C.K.; Shtein, M.; Anthony, J.; Martin, D.C. Grain-boundary-limited charge transport in solution-processed 6,13 bis(tri-isopropylsilylethynyl) pentacene thin film transistors. J. Appl. Phys. 2008, 103, 114513. [Google Scholar] [CrossRef]

- Turnbull, D.; Hoffman, R.E. The effect of relative crystal and boundary orientations on grain boundary diffusion rates. Acta Metall. 1954, 2, 419–426. [Google Scholar] [CrossRef]

- Brandon, D.G.; Ralph, B.; Ranganathan, S.; Wald, M.S. A field ion microscope study of atomic configuration at grain boundaries. Acta Metall. 1964, 12, 813–821. [Google Scholar] [CrossRef]

- Merkle, K.L.; Smith, D.J. Atomic Structure of Symmetric Tilt Grain Boundaries in NiO. Phys. Rev. Lett. 1987, 59, 2887–2890. [Google Scholar] [CrossRef]

- Wolf, D.; Lutsko, J.F. On the geometrical relationship between tilt and twist grain boundaries. Z. Fur. Krist. Mater. 1989, 189, 239–262. [Google Scholar]

- Li, M.; Rogatch, M.; Chen, H.; Guo, X.; Tang, J. Supramolecular Design and Assembly Engineering toward High-Performance Organic Field-Effect Transistors. Acc. Mater. Res. 2024, 5, 505–517. [Google Scholar] [CrossRef]

- Shuai, Z.; Wang, L.; Li, Q. Evaluation of Charge Mobility in Organic Materials: From Localized to Delocalized Descriptions at a First-Principles Level. Adv. Mater. 2011, 23, 1145–1153. [Google Scholar] [CrossRef]

- Lan, X.; Chen, M.; Hudson, M.H.; Kamysbayev, V.; Wang, Y.; Guyot-Sionnest, P.; Talapin, D.V. Quantum dot solids showing state-resolved band-like transport. Nat. Mater. 2020, 19, 323–329. [Google Scholar] [CrossRef]

- Lee, J.-S.; Kovalenko, M.V.; Huang, J.; Chung, D.S.; Talapin, D.V. Band-like transport, high electron mobility and high photoconductivity in all-inorganic nanocrystal arrays. Nat. Nanotechnol. 2011, 6, 348–352. [Google Scholar] [CrossRef]

- Dong, R.; Han, P.; Arora, H.; Ballabio, M.; Karakus, M.; Zhang, Z.; Shekhar, C.; Adler, P.; Petkov, P.S.; Erbe, A.; et al. High-mobility band-like charge transport in a semiconducting two-dimensional metal–organic framework. Nat. Mater. 2018, 17, 1027–1032. [Google Scholar] [CrossRef]

- Alberi, K.; Fluegel, B.; Moutinho, H.; Dhere, R.G.; Li, J.V.; Mascarenhas, A. Measuring long-range carrier diffusion across multiple grains in polycrystalline semiconductors by photoluminescence imaging. Nat. Commun. 2013, 4, 2699. [Google Scholar] [CrossRef]

- Gao, Z.; Leng, C.; Zhao, H.; Wei, X.; Shi, H.; Xiao, Z. The Electrical Behaviors of Grain Boundaries in Polycrystalline Optoelectronic Materials. Adv. Mater. 2024, 36, 2304855. [Google Scholar] [CrossRef]

- Mataré, H.F. Carrier transport at grain boundaries in semiconductors. J. Appl. Phys. 1984, 56, 2605–2631. [Google Scholar] [CrossRef]

- Buscaglia, V.; Buscaglia, M.T.; Viviani, M.; Mitoseriu, L.; Nanni, P.; Trefiletti, V.; Piaggio, P.; Gregora, I.; Ostapchuk, T.; Pokorný, J.; et al. Grain size and grain boundary-related effects on the properties of nanocrystalline barium titanate ceramics. J. Eur. Ceram. Soc. 2006, 26, 2889–2898. [Google Scholar] [CrossRef]

- Reisinger, D.; Majewski, P.; Opel, M.; Alff, L.; Gross, R. Hall effect, magnetization, and conductivity of Fe3O4 epitaxial thin films. Appl. Phys. Lett. 2004, 85, 4980–4982. [Google Scholar] [CrossRef]

- Lotz, M.R.; Boll, M.; Østerberg, F.W.; Hansen, O.; Petersen, D.H. Mesoscopic current transport in two-dimensional materials with grain boundaries: Four-point probe resistance and Hall effect. J. Appl. Phys. 2016, 120, 134303. [Google Scholar] [CrossRef]

- Lim, H.; Lee, M.G.; Kim, J.H.; Adams, B.L.; Wagoner, R.H. Simulation of polycrystal deformation with grain and grain boundary effects. Int. J. Plast. 2011, 27, 1328–1354. [Google Scholar] [CrossRef]

- Choi, H.H.; Paterson, A.F.; Fusella, M.A.; Panidi, J.; Solomeshch, O.; Tessler, N.; Heeney, M.; Cho, K.; Anthopoulos, T.D.; Rand, B.P.; et al. Hall Effect in Polycrystalline Organic Semiconductors: The Effect of Grain Boundaries. Adv. Funct. Mater. 2020, 30, 1903617. [Google Scholar] [CrossRef]

- Müller, S.; Baumann, R.-P.; Geßner, T.; Weitz, R.T. Identification of grain boundaries as degradation site in n-channel organic field-effect transistors determined via conductive atomic force microscopy. Phys. Status Solidi (RRL)—Rapid Res. Lett. 2016, 10, 339–345. [Google Scholar] [CrossRef]

- Bolognesi, A.; Berliocchi, M.; Manenti, M.; Carlo, A.D.; Lugli, P.; Lmimouni, K.; Dufour, C. Effects of grain boundaries, field-dependent mobility, and interface trap States on the electrical Characteristics of pentacene TFT. IEEE Trans. Electron Devices 2004, 51, 1997–2003. [Google Scholar] [CrossRef]

- Weitz, R.T.; Amsharov, K.; Zschieschang, U.; Burghard, M.; Jansen, M.; Kelsch, M.; Rhamati, B.; van Aken, P.A.; Kern, K.; Klauk, H. The Importance of Grain Boundaries for the Time-Dependent Mobility Degradation in Organic Thin-Film Transistors. Chem. Mater. 2009, 21, 4949–4954. [Google Scholar] [CrossRef]

- Liu, P.; Wang, W.; Liu, S.; Yang, H.; Shao, Z. Fundamental Understanding of Photocurrent Hysteresis in Perovskite Solar Cells. Adv. Energy Mater. 2019, 9, 1803017. [Google Scholar] [CrossRef]

- Bercovici, D.; Ricard, Y. Grain-damage hysteresis and plate tectonic states. Phys. Earth Planet. Inter. 2016, 253, 31–47. [Google Scholar] [CrossRef]

- Castro-Méndez, A.-F.; Hidalgo, J.; Correa-Baena, J.-P. The Role of Grain Boundaries in Perovskite Solar Cells. Adv. Energy Mater. 2019, 9, 1901489. [Google Scholar] [CrossRef]

- Shao, Y.; Fang, Y.; Li, T.; Wang, Q.; Dong, Q.; Deng, Y.; Yuan, Y.; Wei, H.; Wang, M.; Gruverman, A.; et al. Grain boundary dominated ion migration in polycrystalline organic–inorganic halide perovskite films. Energy Environ. Sci. 2016, 9, 1752–1759. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, J.; Lawrie, B.J.; Kelley, K.P.; Ziatdinov, M.; Kalinin, S.V.; Ahmadi, M. Disentangling Electronic Transport and Hysteresis at Individual Grain Boundaries in Hybrid Perovskites via Automated Scanning Probe Microscopy. ACS Nano 2023, 17, 9647–9657. [Google Scholar] [CrossRef]

- Shen, Y.; Zhang, M.; He, S.; Bian, L.; Liu, J.; Chen, Z.; Xue, S.; Zhou, Y.; Yan, Y. Reliability issues of amorphous oxide semiconductor-based thin film transistors. J. Mater. Chem. C 2024, 12, 13707–13726. [Google Scholar] [CrossRef]

- Hao, Z.; Wu, Z.; Liu, S.; Tang, X.; Chen, J.; Liu, X. High-performance organic thin-film transistors: Principles and strategies. J. Mater. Chem. C 2024, 12, 9427–9454. [Google Scholar] [CrossRef]

- Yan, A.; Wang, C.; Yan, J.; Wang, Z.; Zhang, E.; Dong, Y.; Yan, Z.-Y.; Lu, T.; Cui, T.; Li, D.; et al. Thin-Film Transistors for Integrated Circuits: Fundamentals and Recent Progress. Adv. Funct. Mater. 2024, 34, 2304409. [Google Scholar] [CrossRef]

- Ma, L.-Y.; Soin, N.; Aidit, S.N.; Rezali, F.A.M.; Hatta, S.F.W.M. Recent advances in flexible solution-processed thin-film transistors for wearable electronics. Mater. Sci. Semicond. Process. 2023, 165, 107658. [Google Scholar] [CrossRef]

- Watanabe, T. Grain boundary design and control for high temperature materials. Mater. Sci. Eng. A 1993, 166, 11–28. [Google Scholar] [CrossRef]

- Langdon, T.G. The role of grain boundaries in high temperature deformation. Mater. Sci. Eng. A 1993, 166, 67–79. [Google Scholar] [CrossRef]

- Alexandreanu, B.; Sencer, B.H.; Thaveeprungsriporn, V.; Was, G.S. The effect of grain boundary character distribution on the high temperature deformation behavior of Ni–16Cr–9Fe alloys. Acta Mater. 2003, 51, 3831–3848. [Google Scholar] [CrossRef]

- Kim, D.; Ndikumana, J.; Lee, H.; Lee, S.; Yun, Y.; Park, J. Impact of Crystal Domain on Electrical Performance and Bending Durability of Flexible Organic Thin-Film Transistors with diF-TES-ADT Semiconductor. Electron. Mater. Lett. 2025, 21, 1–8. [Google Scholar] [CrossRef]

- He, Z.; Zhang, Z.; Asare-Yeboah, K.; Bi, S. Binary solvent engineering for small-molecular organic semiconductor crystallization. Mater. Adv. 2023, 4, 769–786. [Google Scholar] [CrossRef]

- Ayub, A.; Ans, M.; Gul, S.; Shawky, A.M.; Ayub, K.; Iqbal, J.; Hashmi, M.A.; Lakhani, A. Toward High-Performance Quinoxaline Based Non-fullerene Small Molecule Acceptors for Organic Solar Cells. Electron. Mater. Lett. 2023, 19, 38–54. [Google Scholar] [CrossRef]

- Hou, S.; Zhuang, X.; Fan, H.; Yu, J. Grain Boundary Control of Organic Semiconductors via Solvent Vapor Annealing for High-Sensitivity NO2 Detection. Sensors 2021, 21, 226. [Google Scholar] [CrossRef]

- Sun, L.; Li, T.; Zhou, J.; Li, W.; Wu, Z.; Niu, R.; Cheng, J.; Asare-Yeboah, K.; He, Z. A Green Binary Solvent Method to Control Organic Semiconductor Crystallization. ChemistrySelect 2023, 8, e202203927. [Google Scholar] [CrossRef]

- Bail, R.; Kang, J.W.; Kang, Y.J.; Chin, B.D. Binary Solvent Effects on Thermally Crosslinked Small Molecular Thin Films for Solution Processed Organic Light-Emitting Diodes. Electron. Mater. Lett. 2021, 17, 74–86. [Google Scholar] [CrossRef]

- Lee, Y.; Ho, D.; Valentini, F.; Earmme, T.; Marrocchi, A.; Vaccaro, L.; Kim, C. Improving the charge transport performance of solution-processed organic field-effect transistors using green solvent additives. J. Mater. Chem. C 2021, 9, 16506–16515. [Google Scholar] [CrossRef]

- Fo, W.-Z.; Xu, G.Y.; Dong, H.-J.; Liu, L.-N.; Li, Y.W.; Ding, L. Highly Efficient Binary Solvent Additive-Processed Organic Solar Cells by the Blade-Coating Method. Macromol. Chem. Phys. 2021, 222, 2100062. [Google Scholar] [CrossRef]

- Liu, R.; Xu, K. Solvent engineering for perovskite solar cells: A review. Micro Nano Lett. 2020, 15, 349–353. [Google Scholar] [CrossRef]

- Bharti, D.; Tiwari, S.P. Crystallinity and performance improvement in solution processed organic field-effect transistors due to structural dissimilarity of the additive solvent. Synth. Met. 2016, 215, 1–6. [Google Scholar] [CrossRef]

- Ye, L.; Zhang, S.; Ma, W.; Fan, B.; Guo, X.; Huang, Y.; Ade, H.; Hou, J. From Binary to Ternary Solvent: Morphology Fine-tuning of D/A Blends in PDPP3T-based Polymer Solar Cells. Adv. Mater. 2012, 24, 6335–6341. [Google Scholar] [CrossRef]

- Li, X.R.; Kjellander, B.K.C.; Anthony, J.E.; Bastiaansen, C.W.M.; Broer, D.J.; Gelinck, G.H. Azeotropic Binary Solvent Mixtures for Preparation of Organic Single Crystals. Adv. Funct. Mater. 2009, 19, 3610–3617. [Google Scholar] [CrossRef]

- Sánchez-Camargo, A.d.P.; Bueno, M.; Parada-Alfonso, F.; Cifuentes, A.; Ibáñez, E. Hansen solubility parameters for selection of green extraction solvents. TrAC Trends Anal. Chem. 2019, 118, 227–237. [Google Scholar] [CrossRef]

- Gao, J.; Wu, S.; Rogers, M.A. Harnessing Hansen solubility parameters to predict organogel formation. J. Mater. Chem. 2012, 22, 12651–12658. [Google Scholar] [CrossRef]

- Lindvig, T.; Michelsen, M.L.; Kontogeorgis, G.M. A Flory–Huggins model based on the Hansen solubility parameters. Fluid Phase Equilibria 2002, 203, 247–260. [Google Scholar] [CrossRef]

- Suzuki, I.; Hanna, J.-I.; Iino, H. High-speed blade-coating using liquid crystalline organic semiconductor Ph-BTBT-10. Appl. Phys. Express 2024, 17, 051007. [Google Scholar] [CrossRef]

- Hodsden, T.; Thorley, K.J.; Basu, A.; White, A.J.P.; Wang, C.; Mitchell, W.; Glöcklhofer, F.; Anthopoulos, T.D.; Heeney, M. The influence of alkyl group regiochemistry and backbone fluorination on the packing and transistor performance of N-cyanoimine functionalised indacenodithiophenes. Mater. Adv. 2021, 2, 1706–1714. [Google Scholar] [CrossRef]

- Chen, M.; Peng, B.; Huang, S.; Chan, P.K.L. Understanding the Meniscus-Guided Coating Parameters in Organic Field-Effect-Transistor Fabrications. Adv. Funct. Mater. 2020, 30, 1905963. [Google Scholar] [CrossRef]

- Li, Y.; Tao, R.; He, W.; Chang, C.; Zou, Z.; Zhang, Y.; Wang, D.; Wang, J.; Fan, Z.; Zhou, G.; et al. Realization of tunable artificial synapse through ambipolar charge trapping in organic transistor with pentacene/poly(α-methylstyrene) architecture. J. Appl. Phys. 2021, 129, 074903. [Google Scholar] [CrossRef]

- He, H.; He, W.; Mai, J.; Wang, J.; Zou, Z.; Wang, D.; Feng, J.; Zhang, A.; Fan, Z.; Wu, S.; et al. A flexible memory with low-voltage and high-operation speed using an Al2O3/poly(α-methylstyrene) gate stack on a muscovite substrate. J. Mater. Chem. C 2019, 7, 1913–1918. [Google Scholar] [CrossRef]

- Xu, W.C.; He, H.X.; Jing, X.S.; Wu, S.J.; Zhang, Z.; Gao, J.W.; Gao, X.S.; Zhou, G.F.; Lu, X.B.; Liu, J.M. High performance organic nonvolatile memory transistors based on HfO2 and poly(α-methylstyrene) electret hybrid charge-trapping layers. Appl. Phys. Lett. 2017, 111, 063302. [Google Scholar] [CrossRef]

- Chou, L.-H.; Chang, W.-C.; He, G.-Y.; Chiu, Y.-C.; Liu, C.-L. Controllable electrical performance of spray-coated semiconducting small molecule/insulating polymer blend thin film for organic field effect transistors application. React. Funct. Polym. 2016, 108, 130–136. [Google Scholar] [CrossRef]

- He, Z.; Bi, S.; Asare-Yeboah, K.; Chen, J. Study of Grain Boundary: From Crystallization Engineering to Machine Learning. Coatings 2025, 15, 164. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, S.; Jiang, T.; Chen, S.; Jia, R.; Xiao, Y.; Pan, J.; Jie, J.; Zhang, X. A floating-gate field-effect transistor memory device based on organic crystals with a built-in tunneling dielectric by a one-step growth strategy. Nanoscale 2024, 16, 3721–3728. [Google Scholar] [CrossRef]

- Gubanov, K.; Johnson, M.; Akay, M.; Wolz, B.C.; Shen, D.; Cheng, X.; Christiansen, S.; Fink, R.H. C8-BTBT-C8 Thin-Film Transistors Based on Micro-Contact Printed PEDOT:PSS/MWCNT Electrodes. Adv. Electron. Mater. 2023, 9, 2201233. [Google Scholar] [CrossRef]

- Jo, Y.; Lee, J.; Kim, C.; Jang, J.; Hwang, I.; Hong, J.; Lee, M.J. Engineered molecular stacking crystallinity of bar-coated TIPS-pentacene/polystyrene films for organic thin-film transistors. RSC Adv. 2023, 13, 2700–2706. [Google Scholar] [CrossRef]

- Tamayo, A.; Hofer, S.; Salzillo, T.; Ruzié, C.; Schweicher, G.; Resel, R.; Mas-Torrent, M. Mobility anisotropy in the herringbone structure of asymmetric Ph-BTBT-10 in solution sheared thin film transistors. J. Mater. Chem. C 2021, 9, 7186–7193. [Google Scholar] [CrossRef]

- Yang, Z.; Lin, S.; Liu, J.; Zheng, K.; Lu, G.; Ye, B.; Huang, J.; Zhang, Y.; Ye, Y.; Guo, T.; et al. Sharp phase-separated interface of 6, 13-bis (triisopropylsilylethynyl) pentacene/polystyrene blend films prepared by electrostatic spray deposition. Org. Elect. 2020, 78, 206–210. [Google Scholar]

- Li, J.; Tamayo, A.; Quintana, A.; Riera-Galindo, S.; Pfattner, R.; Gong, Y.; Mas-Torrent, M. Binder polymer influence on the electrical and UV response of organic field-effect transistors. J. Mater. Chem. C 2023, 11, 8178–8185. [Google Scholar] [CrossRef]

- Rahman, F.; Carbaugh, D.J.; Wright, J.T.; Rajan, P.; Pandya, S.G.; Kaya, S. A review of polymethyl methacrylate (PMMA) as a versatile lithographic resist—With emphasis on UV exposure. Microelectron. Eng. 2020, 224, 111238. [Google Scholar] [CrossRef]

- Fan, H.D.; Han, S.J.; Song, Z.H.; Yu, J.S.; Katz, H.E. Organic field-effect transistor gas sensor based on GO/PMMA hybrid dielectric for the enhancement of sensitivity and selectivity to ammonia. Org. Elect. 2019, 67, 247–252. [Google Scholar] [CrossRef]

- Hou, S.; Yu, J.; Zhuang, X.; Li, D.; Liu, Y.; Gao, Z.; Sun, T.; Wang, F.; Yu, X. Phase separation of P3HT/PMMA blend film formed semiconducting and dielectric layers in organic thin film transistors for high sensitivity NO2 detection. ACS Appl. Electron. Mater. 2019, 11, 44521–44527. [Google Scholar] [CrossRef]

- Xie, Q.; Wang, L.; Zhu, Y.; Sun, Q.; Wang, L. Highly sensitive NO2 sensors based on organic field effect transistors with Al2O3/PMMA bilayer dielectrics by sol-spin coating. Org. Elect. 2019, 74, 69–76. [Google Scholar] [CrossRef]

- Jung, S.; Albariqi, M.; Gruntz, G.; Al-Hathal, T.; Peinado, A.; Garcia-Caurel, E.; Nicolas, Y.; Toupance, T.; Bonnassieux, Y.; Horowitz, G. A TIPS-TPDO-tetraCN-Based n-Type Organic Field-Effect Transistor with a Cross-linked PMMA Polymer Gate Dielectric. ACS Appl. Mater. Interfaces 2016, 8, 14701–14708. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, D.; Wang, Y.; Wang, H.; Song, T.; Fu, C.; Yang, S.; Wei, J.; Liu, R.; Zou, B. Performance Enhancement of FET-Based Photodetector by Blending P3HT with PMMA. IEEE Photonics Technol. Lett. 2015, 27, 1535–1538. [Google Scholar] [CrossRef]

- Agrahari, K.; Chi, M.H.; Priya, S.L.; Cheng, Y.H.; Wang, Y.W. Low voltage driven P3HT/PS phototransistor for ultra-high power efficiency UV sensing. Org. Elect. 2024, 128, 107033. [Google Scholar] [CrossRef]

- He, Z.; Zhang, Z.; Bi, S.; Chen, J.; Li, D. Conjugated Polymer Controlled Morphology and Charge Transport of Small-Molecule Organic Semiconductors. Sci. Rep. 2020, 10, 4344. [Google Scholar] [CrossRef]

- Shin, H.; Park, J.; Choi, J.S. P-14: Electrical Characteristics of P3HT:TIPS-Pentacene Blend Organic Thin-Film Transistor under Light Irradiation. SID Symp. Dig. Tech. Pap. 2020, 51, 1362–1364. [Google Scholar] [CrossRef]

- Poelking, C.; Andrienko, D. Effect of polymorphism, regioregularity and paracrystallinity on charge transport in poly (3-hexylthiophene) [P3HT] nanofibers. Macromolecules 2013, 46, 8941–8956. [Google Scholar] [CrossRef]

- Nicho, M.E.; García-Escobar, C.H.; Arenas, M.C.; Altuzar-Coello, P.; Cruz-Silva, R.; Güizado-Rodríguez, M. Influence of P3HT concentration on morphological, optical and electrical properties of P3HT/PS and P3HT/PMMA binary blends. Mater. Sci. Eng. B 2011, 176, 1393–1400. [Google Scholar] [CrossRef]

- Benavides, C.M.; Biele, M.; Schmidt, O.; Brabec, C.J.; Tedde, S.F. TIPS Pentacene as a Beneficial Interlayer for Organic Photodetectors in Imaging Applications. IEEE Trans. Electron Devices 2018, 65, 1516–1522. [Google Scholar] [CrossRef]

- Ozorio, M.S.; Camacho, S.A.; Cordeiro, N.J.A.; Duarte, J.P.L.; Alves, N. Solvent Effect on Morphology and Optical Properties of Poly(3-hexylthiophene): TIPS-Pentacene Blends. J. Electron. Mater. 2018, 47, 1353–1361. [Google Scholar] [CrossRef]

- Ozorio, M.D.; Nogueira, G.L.; Morais, R.M.; Martin, C.D.; Constantino, C.J.L.; Alves, N. Poly(3-hexylthiophene): TIPS-pentacene blends aiming transistor applications. Thin Solid Film. 2016, 608, 97–101. [Google Scholar] [CrossRef]

- Mansouri, S.; Mir, L.E.; Al-Ghamdi, A.A.; Al-Hartomy, O.A.; Said, S.A.F.A.; Yakuphanoglu, F. Characterization and modeling of TIPS-pentacene-poly(3-hexyl) thiophene blend organic thin film transistor. Synth. Met. 2013, 185–186, 153–158. [Google Scholar] [CrossRef]

- Chen, J.; Shao, M.; Xiao, K.; He, Z.; Li, D.; Lokitz, B.S.; Hensley, D.K.; Kilbey, S.M.; Anthony, J.E.; Keum, J.K.; et al. Conjugated Polymer-Mediated Polymorphism of a High Performance, Small-Molecule Organic Semiconductor with Tuned Intermolecular Interactions, Enhanced Long-Range Order, and Charge Transport. Chem. Mater. 2013, 25, 4378–4386. [Google Scholar] [CrossRef]

- Lee, G.; Kim, H.; Lee, S.B.; Kim, D.; Lee, E.; Lee, S.K.; Lee, S.G. Tailored Uniaxial Alignment of Nanowires Based on Off-Center Spin-Coating for Flexible and Transparent Field-Effect Transistors. Nanomaterials 2022, 12, 1116. [Google Scholar] [CrossRef]

- Li, W.; Li, L.; Sun, Q.; Liu, X.; Kanehara, M.; Nakayama, T.; Jiu, J.; Sakamoto, K.; Minari, T. Direct fabrication of high-resolution and high-performance flexible electronics via surface-activation-localized electroless plating. Chem. Eng. J. 2021, 416, 127644. [Google Scholar] [CrossRef]

- Chen, Z.; Duan, S.; Zhang, X.; Geng, B.; Xiao, Y.; Jie, J.; Dong, H.; Li, L.; Hu, W. Organic Semiconductor Crystal Engineering for High-Resolution Layer-Controlled 2D Crystal Arrays. Adv. Mater. 2021, 34, 2104166. [Google Scholar] [CrossRef]

- Zhuang, J.-L.; Terfort, A.; Wöll, C. Formation of oriented and patterned films of metal–organic frameworks by liquid phase epitaxy: A review. Coord. Chem. Rev. 2016, 307, 391–424. [Google Scholar] [CrossRef]

- He, Z.; Chen, J.; Sun, Z.; Szulczewski, G.; Li, D. Air-flow navigated crystal growth for TIPS pentacene-based organic thin-film transistors. Org. Elect. 2012, 13, 1819–1826. [Google Scholar] [CrossRef]

- Lee, M.W.; Ryu, G.S.; Lee, Y.U.; Pearson, C.; Petty, M.C.; Song, C.K. Control of droplet morphology for inkjet-printed TIPS-pentacene transistors. Microelectron. Eng. 2012, 95, 1–4. [Google Scholar] [CrossRef]

- Kim, K.; Hong, J.; Hahm, S.G.; Rho, Y.; An, T.K.; Kim, S.H.; Park, C.E. Facile and Microcontrolled Blade Coating of Organic Semiconductor Blends for Uniaxial Crystal Alignment and Reliable Flexible Organic Field-Effect Transistors. ACS Appl. Mater. Interfaces 2019, 11, 13481–13490. [Google Scholar] [CrossRef]

- Kondo, M.; Kajitani, T.; Uemura, T.; Noda, Y.; Ishiwari, F.; Shoji, Y.; Araki, T.; Yoshimoto, S.; Fukushima, T.; Sekitani, T. Highly-ordered Triptycene Modifier Layer Based on Blade Coating for Ultraflexible Organic Transistors. Sci. Rep. 2019, 9, 9200. [Google Scholar] [CrossRef]

- Li, C.; Yin, J.; Chen, R.; Lv, X.; Feng, X.; Wu, Y.; Cao, J. Monoammonium Porphyrin for Blade-Coating Stable Large-Area Perovskite Solar Cells with >18% Efficiency. J. Am. Chem. Soc. 2019, 141, 6345–6351. [Google Scholar] [CrossRef]

- Wu, D.; Kaplan, M.; Ro, H.W.; Engmann, S.; Fischer, D.A.; DeLongchamp, D.M.; Richter, L.J.; Gann, E.; Thomsen, L.; McNeill, C.R.; et al. Blade Coating Aligned, High-Performance, Semiconducting-Polymer Transistors. Chem. Mater. 2018, 30, 1924–1936. [Google Scholar] [CrossRef]

- Lin, Y.Y.; Gundlach, D.J.; Nelson, S.F.; Jackson, T.N. Stacked pentacene layer organic thin-film transistors with improved characteristics. IEEE Electron Device Lett. 1997, 18, 606–608. [Google Scholar] [CrossRef]

- Gundlach, D.J.; Lin, Y.Y.; Jackson, T.N.; Nelson, S.F.; Schlom, D.G. Pentacene organic thin-film transistors—Molecular ordering and mobility. IEEE Electron Device Lett. 1997, 18, 87–89. [Google Scholar] [CrossRef]

- Brown, A.R.; Jarrett, C.P.; deLeeuw, D.M.; Matters, M. Field-effect transistors made from solution-processed organic semiconductors. Synth. Met. 1997, 88, 37–55. [Google Scholar] [CrossRef]

- Nelson, S.F.; Lin, Y.Y.; Gundlach, D.J.; Jackson, T.N. Temperature-independent transport in high-mobility pentacene transistors. Appl. Phys. Lett. 1998, 72, 1854–1856. [Google Scholar] [CrossRef]

- Gundlach, D.J.; Jackson, T.N.; Schlom, D.G.; Nelson, S.F. Solvent-induced phase transition in thermally evaporated pentacene films. Appl. Phys. Lett. 1999, 74, 3302–3304. [Google Scholar] [CrossRef]

- Anthony, J.E.; Brooks, J.S.; Eaton, D.L.; Parkin, S.R. Functionalized pentacene: Improved electronic properties from control of solid-state order. J. Am. Chem. Soc. 2001, 123, 9482–9483. [Google Scholar] [CrossRef]

- Brooks, J.S.; Eaton, D.L.; Anthony, J.E.; Parkin, S.R.; Brill, J.W.; Sushko, Y. Electronic and optical properties of functionalized pentacene compounds in the solid state. Org. Electron. 2001, 1, 301–306. [Google Scholar] [CrossRef]

- Knipp, D.; Street, R.A.; Völkel, A.; Ho, J. Pentacene thin film transistors on inorganic dielectrics: Morphology, structural properties, and electronic transport. J. Appl. Phys. 2003, 93, 347–355. [Google Scholar] [CrossRef]

- Mattheus, C.C.; Dros, A.B.; Baas, J.; Meetsma, A.; Boer, J.L.d.; Palstra, T.T.M. Polymorphism in pentacene. Acta Crystallogr. Sect. C 2001, 57, 939–941. [Google Scholar] [CrossRef]

- Chen, J.H.; Martin, D.C.; Anthony, J.E. Morphology and molecular orientation of thin-film bis(triisopropylsilylethynyl) pentacene. J. Mater. Res. 2007, 22, 1701–1709. [Google Scholar] [CrossRef]

- Mattheus, C.C.; Dros, A.B.; Baas, J.; Oostergetel, G.T.; Meetsma, A.; de Boer, J.L.; Palstra, T.T.M. Identification of polymorphs of pentacene. Synth. Met. 2003, 138, 475–481. [Google Scholar] [CrossRef]

- Lubert-Perquel, D.; Kim, D.K.; Robaschik, P.; Kay, C.W.M.; Heutz, S. Growth, morphology and structure of mixed pentacene films. J. Mater. Chem. C 2019, 7, 289–296. [Google Scholar] [CrossRef]

- Oehzelt, M.; Resel, R.; Suess, C.; Friedlein, R.; Salaneck, W.R. Crystallographic and morphological characterization of thin pentacene films on polycrystalline copper surfaces. J. Chem. Phys. 2006, 124, 054711. [Google Scholar] [CrossRef]

- Heringdorf, F.; Reuter, M.C.; Tromp, R.M. Growth dynamics of pentacene thin films. Nature 2001, 412, 517–520. [Google Scholar] [CrossRef]

- Edura, T.; Takahashi, H.; Nakata, M.; Tsutsui, K.; Itaka, K.; Koinuma, H.; Mizuno, J.; Wada, Y. Electrical characterization of single grain and single grain boundary of pentacene thin film by nano-scale electrode array. Curr. Appl. Phys. 2006, 6, 109–113. [Google Scholar] [CrossRef]

- Schön, J.H.; Kloc, C.; Batlogg, B. On the intrinsic limits of pentacene field-effect transistors. Org. Electron. 2000, 1, 57–64. [Google Scholar] [CrossRef]

- Minari, T.; Nemoto, T.; Isoda, S. Fabrication and characterization of single-grain organic field-effect transistor of pentacene. J. Appl. Phys. 2004, 96, 769–772. [Google Scholar] [CrossRef]

- Weis, M.; Gmucová, K.; Nádaždy, V.; Majková, E.; Haško, D.; Taguchi, D.; Manaka, T.; Iwamoto, M. Grain Boundary Effect on Charge Transport in Pentacene Thin Films. Jpn. J. Appl. Phys. 2011, 50, 04DK03. [Google Scholar] [CrossRef]

- Jin, S.H.; Jung, K.D.; Shin, H.; Park, B.-G.; Lee, J.D. Grain size effects on contact resistance of top-contact pentacene TFTs. Synth. Met. 2006, 156, 196–201. [Google Scholar] [CrossRef]

- He, Z.; Asare-Yeboah, K.; Zhang, Z.; Bi, S. Manipulate organic crystal morphology and charge transport. Org. Elect. 2022, 103, 106448. [Google Scholar] [CrossRef]

- Hao, Z.; Li, Y.; Deng, Y.; Chen, Z.; Liang, J.; Lu, X.; Zhang, J. High sensitivity flexible organic X-ray detectors with minor TIPS-pentacene/insulator polymer blend active layer. Org. Elect. 2024, 131, 107088. [Google Scholar] [CrossRef]

- Suzuki, T.; De Nicola, A.; Okada, T.; Matsui, H. Fully Atomistic Molecular Dynamics Simulation of a TIPS-Pentacene:Polystyrene Mixed Film Obtained via the Solution Process. Nanomaterials 2023, 13, 312. [Google Scholar] [CrossRef]

- He, Z.; Zhang, Z.; Bi, S. Tailoring the molecular weight of polymer additives for organic semiconductors. Mater. Adv. 2022, 3, 1953–1973. [Google Scholar] [CrossRef]

- Alanazi, F.; Eggeman, A.S.; Stavrou, K.; Danos, A.; Monkman, A.P.; Mendis, B.G. Quantifying Molecular Disorder in Tri-Isopropyl Silane (TIPS) Pentacene Using Variable Coherence Transmission Electron Microscopy. J. Phys. Chem. Lett. 2023, 14, 8183–8190. [Google Scholar] [CrossRef]

- Jiang, H.; Peng, B.; Liu, S.; Ren, J.; Yang, W.; Lin, C.; Wu, R.; Chen, H.; Li, H. Bending TIPS-pentacene single crystals: From morphology to transistor performance. J. Mater. Chem. C 2021, 9, 5621–5627. [Google Scholar] [CrossRef]

- He, Z.; Zhang, Z.; Bi, S.; Chen, J. Tuning charge transport in organic semiconductors with nanoparticles and hexamethyldisilazane. J. Nanoparticle Res. 2021, 23, 5. [Google Scholar] [CrossRef]

- Shin, S.I.; Kwon, J.H.; Kang, H.; Ju, B.K. Solution-processed 6,13-bis(triisopropylsilylethynyl) (TIPS) pentacene thin-film transistors with a polymer dielectric on a flexible substrate. Semicond. Sci. Technol. 2008, 23, 085009. [Google Scholar] [CrossRef]

- Kwon, J.H.; Seo, J.H.; Shin, S.I.; Kim, K.H.; Choi, D.H.; Kang, I.B.; Kang, H.; Ju, B.K. A 6,13-bis(Triisopropylsilylethynyl) pentacene thin-film transistor using a spun-on inorganic gate-dielectric. IEEE Trans. Electron Devices 2008, 55, 500–505. [Google Scholar] [CrossRef]

- Madec, M.B.; Crouch, D.; Llorente, G.R.; Whittle, T.J.; Geoghegan, M.; Yeates, S.G. Organic field effect transistors from ambient solution processed low molar mass semiconductor-insulator blends. J. Mater. Chem. 2008, 18, 3230–3236. [Google Scholar] [CrossRef]

- Lee, S.H.; Choi, M.H.; Han, S.H.; Choo, D.J.; Jang, J.; Kwon, S.K. High-performance thin-film transistor with 6,13-bis(triisopropylsilylethynyl) pentacene by inkjet printing. Org. Elect. 2008, 9, 721–726. [Google Scholar] [CrossRef]

- Kang, J.; Shin, N.; Jang, D.Y.; Prabhu, V.M.; Yoon, D.Y. Structure and properties of small molecule-polymer blend semiconductors for organic thin film transistors. J. Am. Chem. Soc. 2008, 130, 12273–12275. [Google Scholar] [CrossRef]

- He, Z.; Zhang, Z.; Asare-Yeboah, K.; Bi, S. Solvent Exchange in Controlling Semiconductor Morphology. Electron. Mater. Lett. 2022, 18, 501–518. [Google Scholar] [CrossRef]

- He, Z.; Zhang, Z.; Asare-Yeboah, K.; Bi, S. Poly(α-methylstyrene) polymer and small-molecule semiconductor blend with reduced crystal misorientation for organic thin film transistors. J. Mater. Sci. Mater. Electron. 2019, 30, 14335–14343. [Google Scholar] [CrossRef]

- He, Z.; Chen, J.; Li, D. Polymer Additive Controlled Morphology for High Performance Organic Thin Film Transistors. Soft Matter. 2019, 15, 5790–5803. [Google Scholar] [CrossRef]

- He, Z.; Zhang, Z.; Bi, S.; Asare-Yeboah, K.; Chen, J. Ultra-low misorientation angle in small-molecule semiconductor/polyethylene oxide blends for organic thin film transistors. J. Polym. Res. 2020, 27, 75. [Google Scholar] [CrossRef]

- Ryu, G.S.; Lee, M.W.; Jeong, S.H.; Song, C.K. Thermally Dried Ink-Jet Process for 6,13-Bis(triisopropylsilylethynyl)-Pentacene for High Mobility and High Uniformity on a Large Area Substrate. Jpn. J. Appl. Phys. 2012, 51, 051601. [Google Scholar] [CrossRef]

- Lee, S.G.; Lee, H.S.; Lee, S.; Kim, C.W.; Lee, W.H. Thickness-dependent electrical properties of soluble acene–polymer blend semiconductors. Org. Elect. 2015, 24, 113–119. [Google Scholar] [CrossRef]

- Naden, A.B.; Loos, J.; MacLaren, D.A. Structure–function relations in diF-TES-ADT blend organic field effect transistors studied by scanning probe microscopy. J. Mater. Chem. C 2014, 2, 245–255. [Google Scholar] [CrossRef]

- Li, R.; Ward, J.W.; Smilgies, D.-M.; Payne, M.M.; Anthony, J.E.; Jurchescu, O.D.; Amassian, A. Direct Structural Mapping of Organic Field-Effect Transistors Reveals Bottlenecks to Carrier Transport. Adv. Mater. 2012, 24, 5553–5558. [Google Scholar] [CrossRef]

- Zhang, X.; Deng, W.; Lu, B.; Fang, X.; Zhang, X.; Jie, J. Fast deposition of an ultrathin, highly crystalline organic semiconductor film for high-performance transistors. Nanoscale Horiz. 2020, 5, 1096–1105. [Google Scholar] [CrossRef]

- Kim, C.-H. Bias-stress effects in diF-TES-ADT field-effect transistors. Solid State Electron. 2019, 153, 23–26. [Google Scholar] [CrossRef]

- Salzillo, T.; D’Amico, F.; Montes, N.; Pfattner, R.; Mas-Torrent, M. Influence of polymer binder on the performance of diF-TES-ADT based organic field effect transistor. CrystEngComm 2021, 23, 1043–1051. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, M.; Zhang, D.; Wang, H.; Deng, W.; Shi, J.; Jie, J. Bilayer-passivated stable dif-TES-ADT organic thin-film transistors. Appl. Phys. Lett. 2021, 119, 183301. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, S.; Anthony, J.E.; Lim, S.; Nguyen, K.V.; Kim, S.B.; Jang, J.; Jang, H.W.; Lee, H.; Lee, W.H. Crystal Engineering Under Residual Solvent Evaporation: A Journey Into Crystallization Chronicles of Soluble Acenes. Small 2024, 20, 2405966. [Google Scholar] [CrossRef]

- Yu, L.; Portale, G.; Stingelin, N. Solution-processing of semiconducting organic small molecules: What we have learnt from 5,11-bis(triethylsilylethynyl)anthradithiophene. J. Mater. Chem. C 2021, 9, 10547–10556. [Google Scholar] [CrossRef]

- Rubinger, C.P.L.; Haneef, H.F.; Hewitt, C.; Carroll, D.; Anthony, J.E.; Jurchescu, O.D. Influence of solvent additives on the morphology and electrical properties of diF-TES ADT organic field-effect transistors. Org. Electron. 2019, 68, 205–211. [Google Scholar] [CrossRef]

- Ndikumana, J.; Kim, J.; Kim, J.Y.; Lee, D.; An, K. A review on 2,8-difluoro-5,11-bis(triethylsilylethynyl)anthradithiophene based organic thin film transistor. Flex. Print. Electron. 2023, 8, 023001. [Google Scholar] [CrossRef]

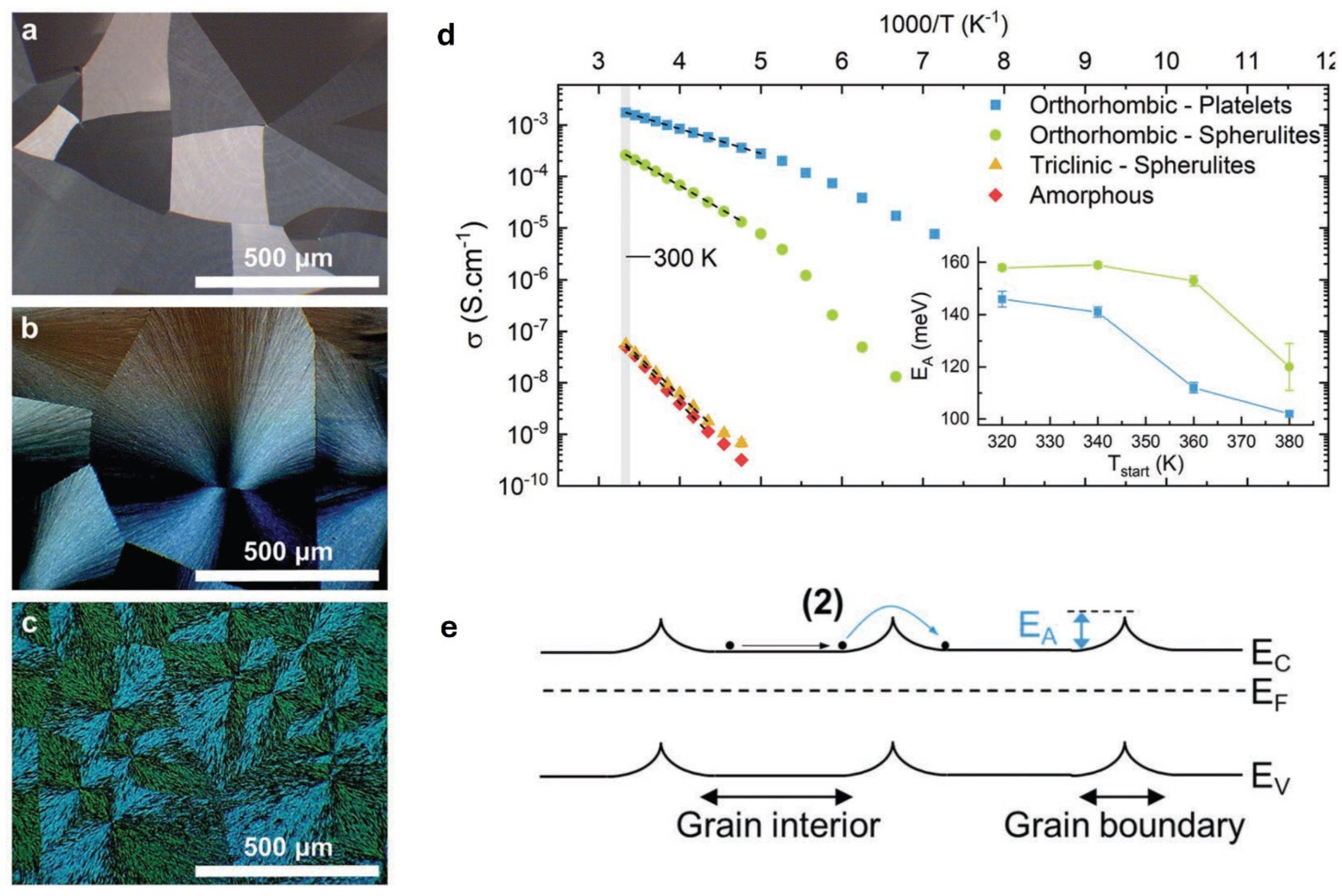

- Euvrard, J.; Gunawan, O.; Kahn, A.; Rand, B.P. From Amorphous to Polycrystalline Rubrene: Charge Transport in Organic Semiconductors Paralleled with Silicon. Adv. Funct. Mater. 2022, 32, 2206438. [Google Scholar] [CrossRef]

- Podzorov, V.; Menard, E.; Borissov, A.; Kiryukhin, V.; Rogers, J.A.; Gershenson, M.E. Intrinsic charge transport on the surface of organic semiconductors. Phys. Rev. Lett. 2004, 93, 086602. [Google Scholar] [CrossRef]

- Kafer, D.; Ruppel, L.; Witte, G.; Woll, C. Role of molecular conformations in rubrene thin film growth. Phys. Rev. Lett. 2005, 95, 166602. [Google Scholar] [CrossRef]

- Zeis, R.; Besnard, C.; Siegrist, T.; Schlockermann, C.; Chi, X.L.; Kloc, C. Field effect studies on rubrene and impurities of rubrene. Chem. Mater. 2006, 18, 244–248. [Google Scholar] [CrossRef]

- Foggiatto, A.L.; Takeichi, Y.; Ono, K.; Suga, H.; Takahashi, Y.; Fusella, M.A.; Dull, J.T.; Rand, B.P.; Kutsukake, K.; Sakurai, T. Study of local structure at crystalline rubrene grain boundaries via scanning transmission X-ray microscopy. Org. Electron. 2019, 74, 315–320. [Google Scholar] [CrossRef]

- Chapman, B.D.; Checco, A.; Pindak, R.; Siegrist, T.; Kloc, C. Dislocations and grain boundaries in semiconducting rubrene single-crystals. J. Cryst. Growth 2006, 290, 479–484. [Google Scholar] [CrossRef]

- Kim, J.J.; Bachevillier, S.; Arellano, D.L.G.; Cherniawski, B.P.; Burnett, E.K.; Stingelin, N.; Ayela, C.; Usluer, Ö.; Mannsfeld, S.C.B.; Wantz, G.; et al. Correlating Crystal Thickness, Surface Morphology, and Charge Transport in Pristine and Doped Rubrene Single Crystals. ACS Appl. Mater. Interfaces 2018, 10, 26745–26751. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, Z.; Asare-Yeboah, K.; Bi, S.; He, Z. Large-Dimensional Organic Semiconductor Crystals with Poly(butyl acrylate) Polymer for Solution-Processed Organic Thin Film Transistors. Electron. Mater. Lett. 2021, 17, 33–42. [Google Scholar] [CrossRef]

| Author | Semiconductor | Result Summary | Mobility | References |

|---|---|---|---|---|

| Edura et al. | Pentacene | Charge transport across single grains was nearly ten times higher than across grain boundaries due to lower resistance | 5 cm2/Vs | [183] |

| Schön et al. | Pentacene | Higher substrate temperatures led to larger grains, fewer boundaries, and improved charge mobility | 3.2 cm2/Vs | [164] |

| Minari et al. | Pentacene | Single crystals showed intrinsic polaron hopping, while polycrystalline films were dominated by extrinsic trap-limited transport | 2 cm2/Vs | [165] |

| Weis et al. | Pentacene | Smaller grain sizes increased defect concentration and reduced mobility, impacting sensitivity and performance | 4.3 cm2/Vs | [166] |

| Jin et al. | Pentacene | Larger grains reduced contact resistance and grain boundary trap density, leading to enhanced charge transport | 0.359 ± 0.002 cm2/Vs | [167] |

| He et al. | TIPS pentacene | Blending TIPS pentacene with PαMS, P3HT, and PEO enables tunable control over crystal alignment, grain width, and film uniformity via distinct mechanisms (amorphous confinement, π-π interaction, and crystallization competition, respectively). | 0.26 cm2/Vs | [130,181,183] |

| Sun et al. | TIPS pentacene | Incorporating PBA into TIPS pentacene enhanced crystal alignment and increased grain width by approximately fivefold | 0.11 cm2/Vs | [203] |

| Lee et al. | TIPS pentacene | Inkjet-printed TIPS pentacene films exhibited enhanced crystal alignment and charge mobility by aligning grain boundaries to reduce charge trapping | 0.44 cm2/Vs | [184] |

| Kim et al. | diF-TES-ADT | Chlorobenzene-processed films had higher initial mobility due to smaller, aligned grains but failed quickly under mechanical stress due to sharp grain boundaries. | 0.87 cm2/Vs | [94] |

| Rubinger et al. | diF-TES-ADT | Adding up to 8% dichlorobenzene to chlorobenzene improved crystallization and grain alignment in diF-TES-ADT films, increasing mobility, but excessive additive caused dewetting and performance degradation. | 0.34 cm2/Vs | [194] |

| Naden et al. | diF-TES-ADT | diF-TES-ADT/polymer blend transistors with continuous, well-aligned petal-like domains exhibited higher mobility and lower hysteresis, while disrupted domain connectivity and grain boundaries severely degraded charge transport performance. | 1.5 cm2/Vs | [186] |

| Li et al. | diF-TES-ADT | Misoriented grain boundaries, particularly those arising from crystalline texture transitions, severely limit charge transport, whereas promoting continuous grain alignment minimizes boundary-induced barriers and improves mobility. | Not reported | [187] |

| Salzillo et al. | diF-TES-ADT | Well-defined, low-density grain boundaries formed in PS-blended films enhance charge transport, while disordered, high-density grain boundaries in PMMA blends disrupt percolation pathways and reduce mobility. | 1.3 cm2/Vs | [190] |

| Foggiatto et al. | Rubrene | Rubrene spherulites show a wider grain boundary structure with higher RMS | 4 cm2/Vs | [200] |

| Chapman et al. | Rubrene | Small-angle grain boundaries and dislocation planes in rubrene single crystals degrade crystalline quality and likely limit charge transport. | 13 cm2/Vs | [201] |

| Kim et al. | Rubrene | Densely packed molecular step edges in thicker crystals act as grain boundary-like defects that disrupt in-plane transport and increase trap density, thereby reducing charge mobility. | 7.1 cm2/Vs | [202] |

| Euvrard et al. | Rubrene | Grain boundaries in polycrystalline rubrene films act as energy barriers that limit charge mobility, particularly in orthorhombic spherulitic morphologies, despite overall crystallinity. | 2 cm2/Vs | [196] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Z.; Asare-Yeboah, K.; Bi, S. Grain Boundary Engineering for High-Mobility Organic Semiconductors. Electronics 2025, 14, 3042. https://doi.org/10.3390/electronics14153042

He Z, Asare-Yeboah K, Bi S. Grain Boundary Engineering for High-Mobility Organic Semiconductors. Electronics. 2025; 14(15):3042. https://doi.org/10.3390/electronics14153042

Chicago/Turabian StyleHe, Zhengran, Kyeiwaa Asare-Yeboah, and Sheng Bi. 2025. "Grain Boundary Engineering for High-Mobility Organic Semiconductors" Electronics 14, no. 15: 3042. https://doi.org/10.3390/electronics14153042

APA StyleHe, Z., Asare-Yeboah, K., & Bi, S. (2025). Grain Boundary Engineering for High-Mobility Organic Semiconductors. Electronics, 14(15), 3042. https://doi.org/10.3390/electronics14153042