Modelling and Simulation of a New π-Gate AlGaN/GaN HEMT with High Voltage Withstand and High RF Performance

Abstract

1. Introduction

2. Theoretical Approach and Modelling

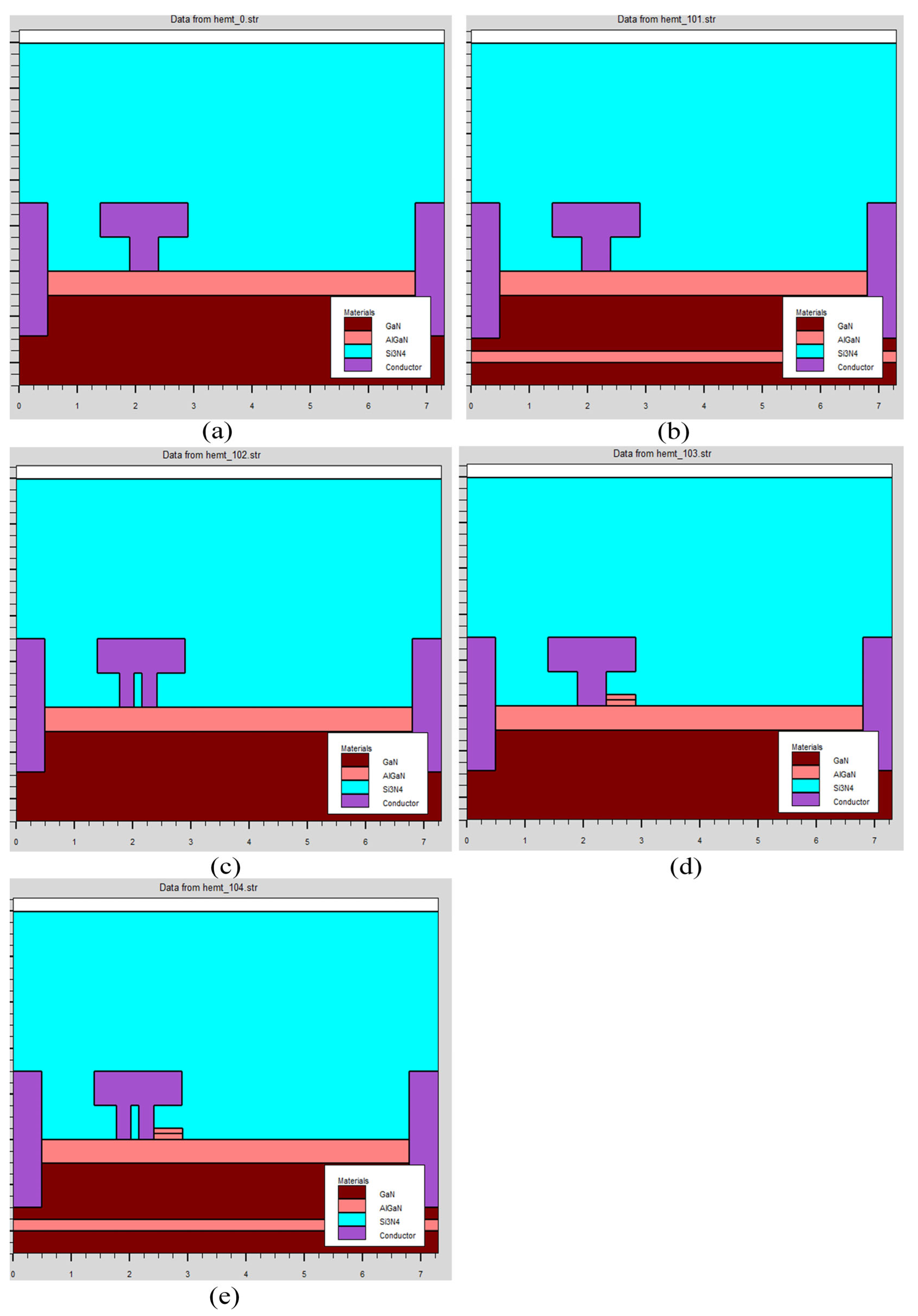

2.1. Device Structure and Theoretical Approach

2.2. Physical Modelling

3. Results and Discussions

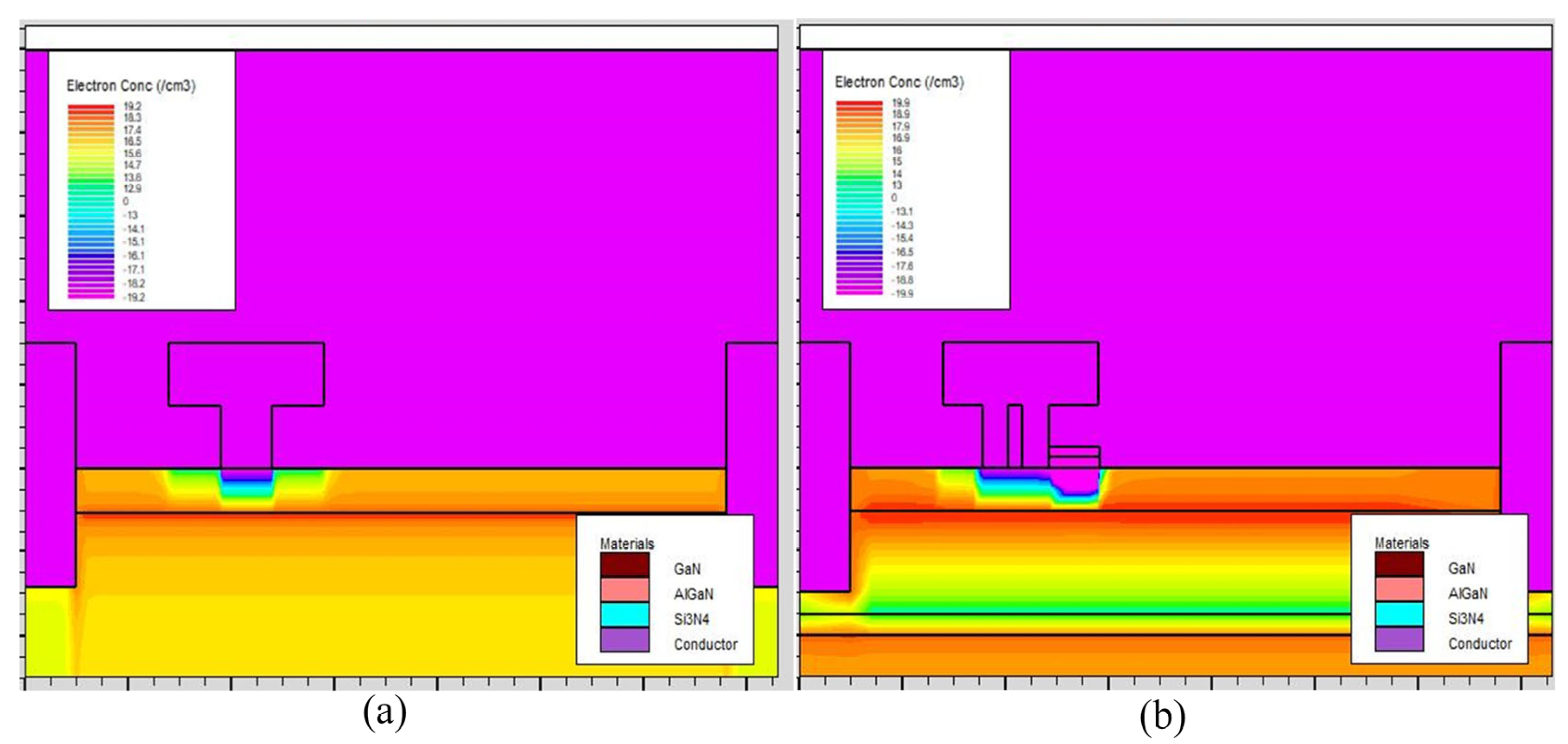

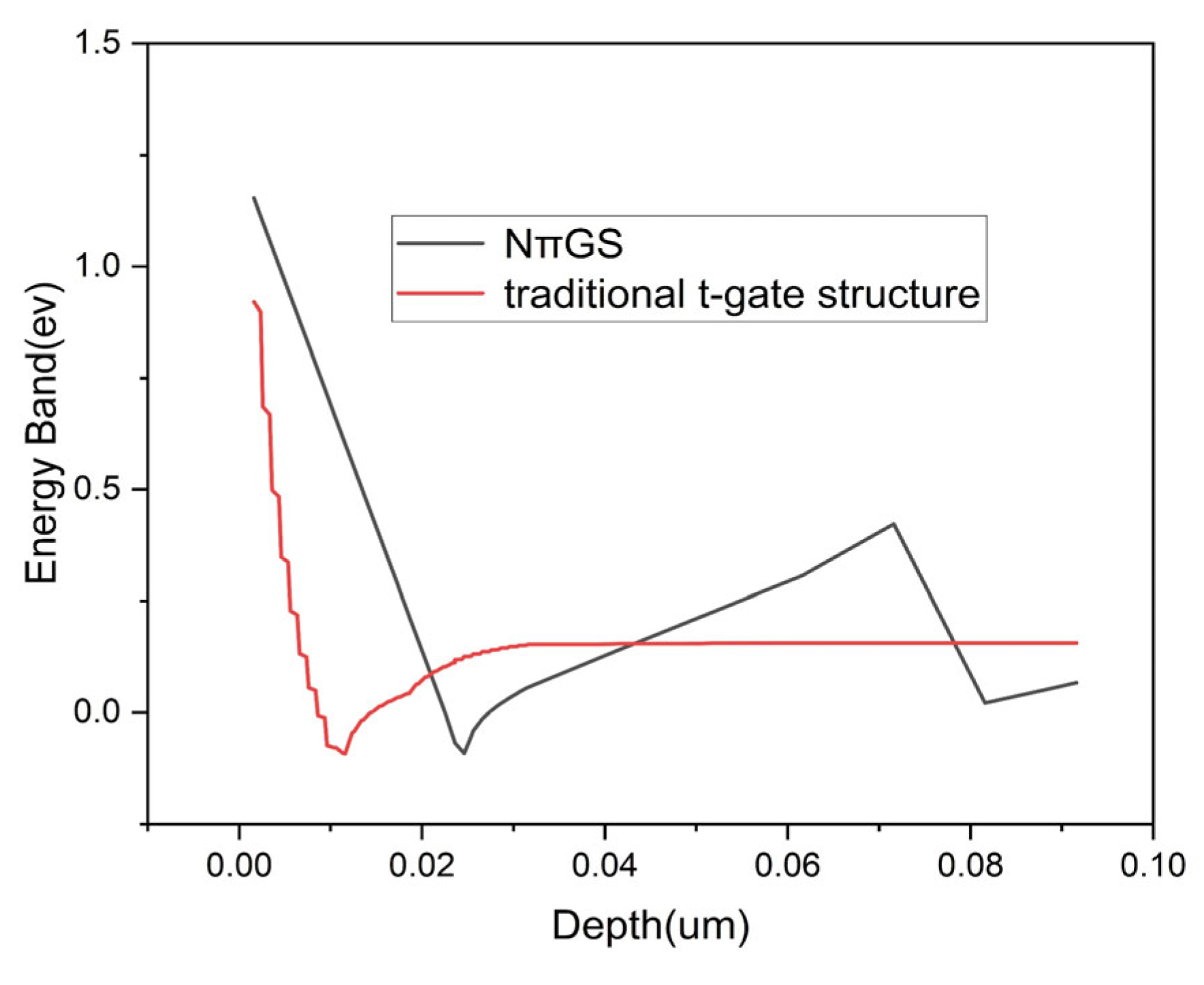

3.1. Device Characteristics

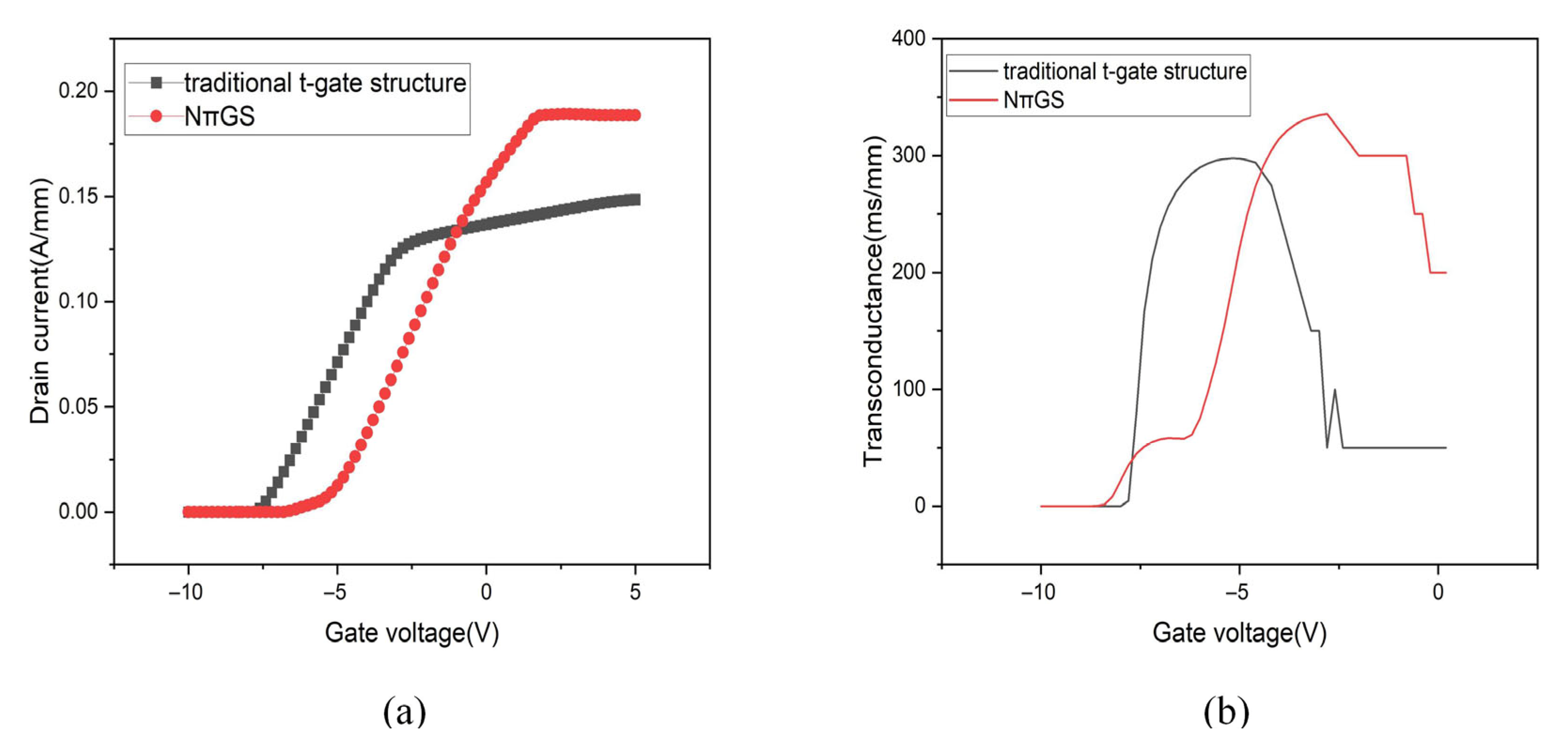

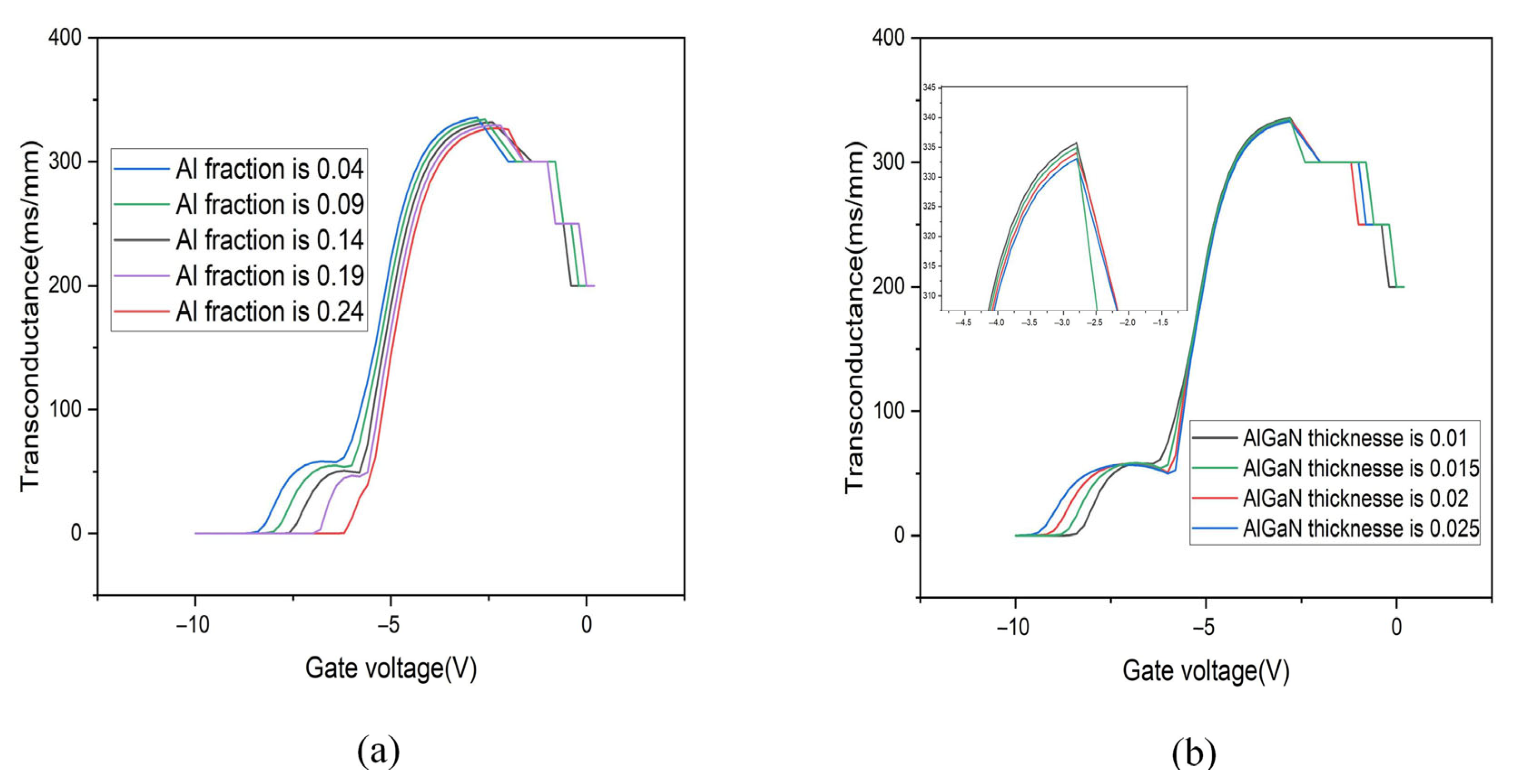

3.2. Transfer Characteristics

3.3. Output Characteristics

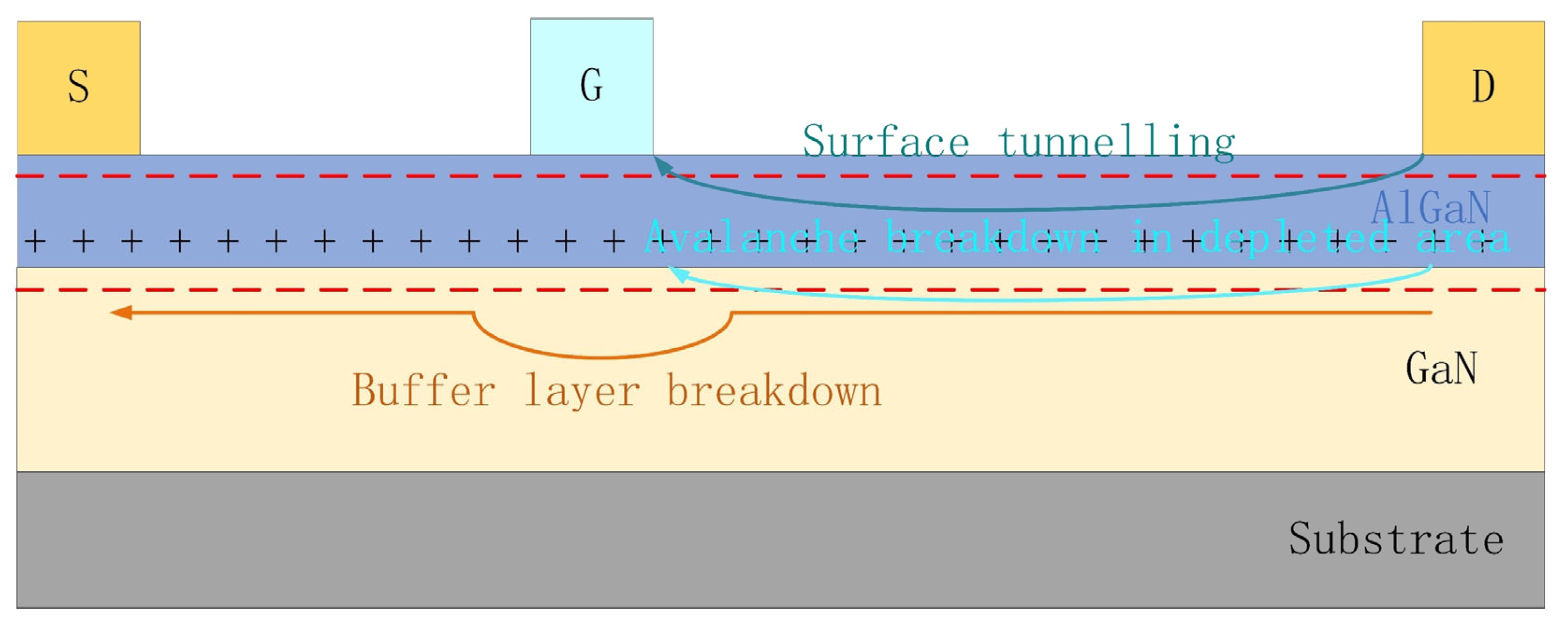

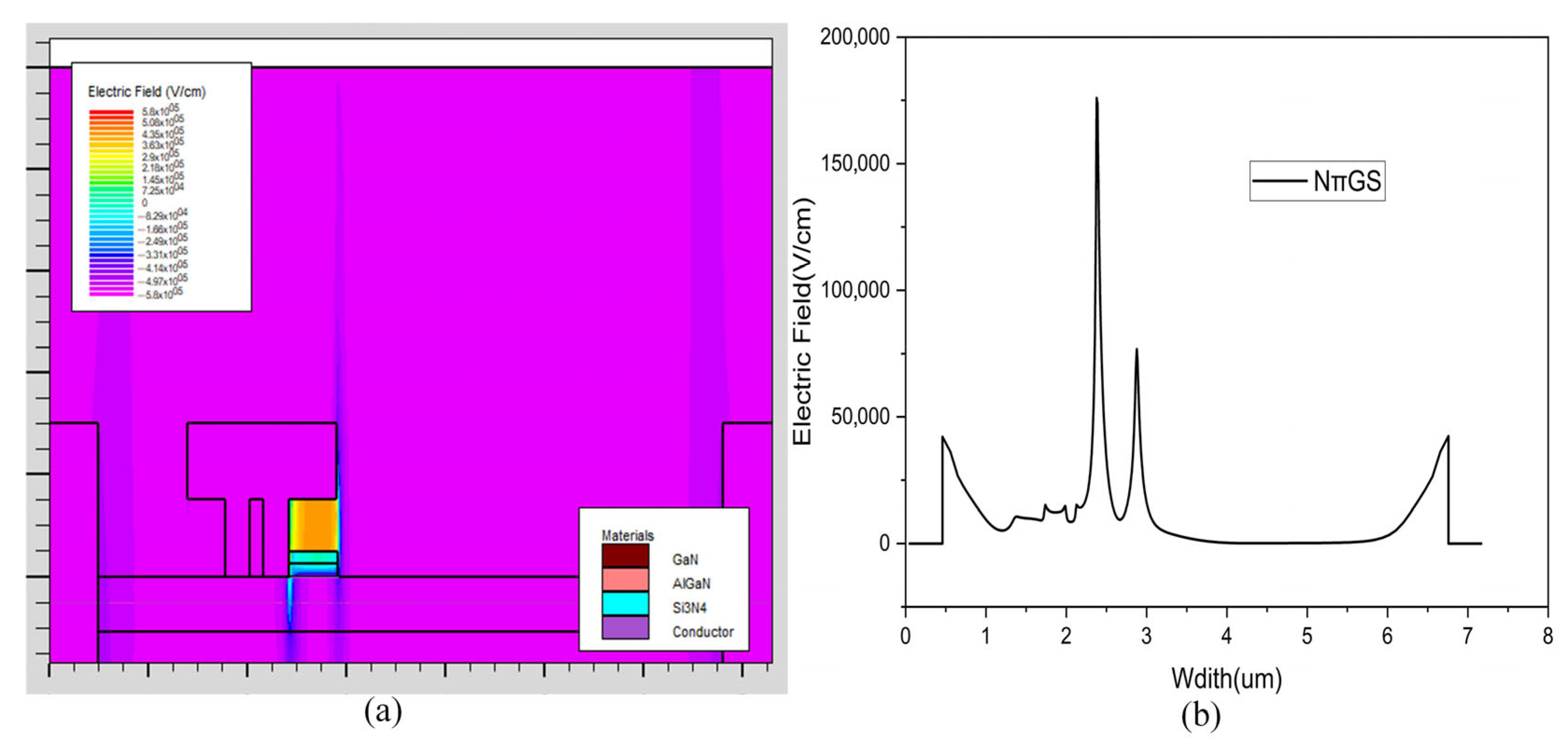

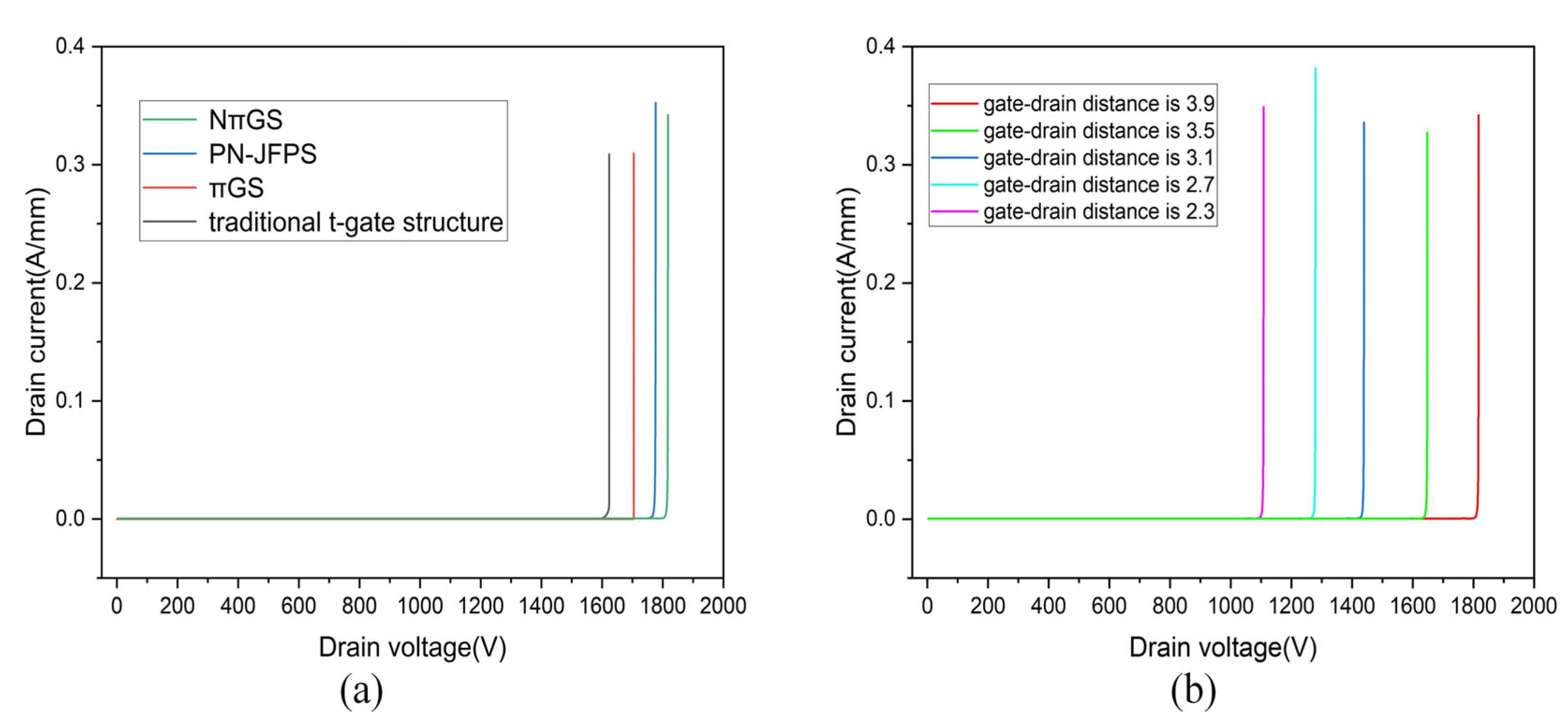

3.4. Breakdown Characteristics

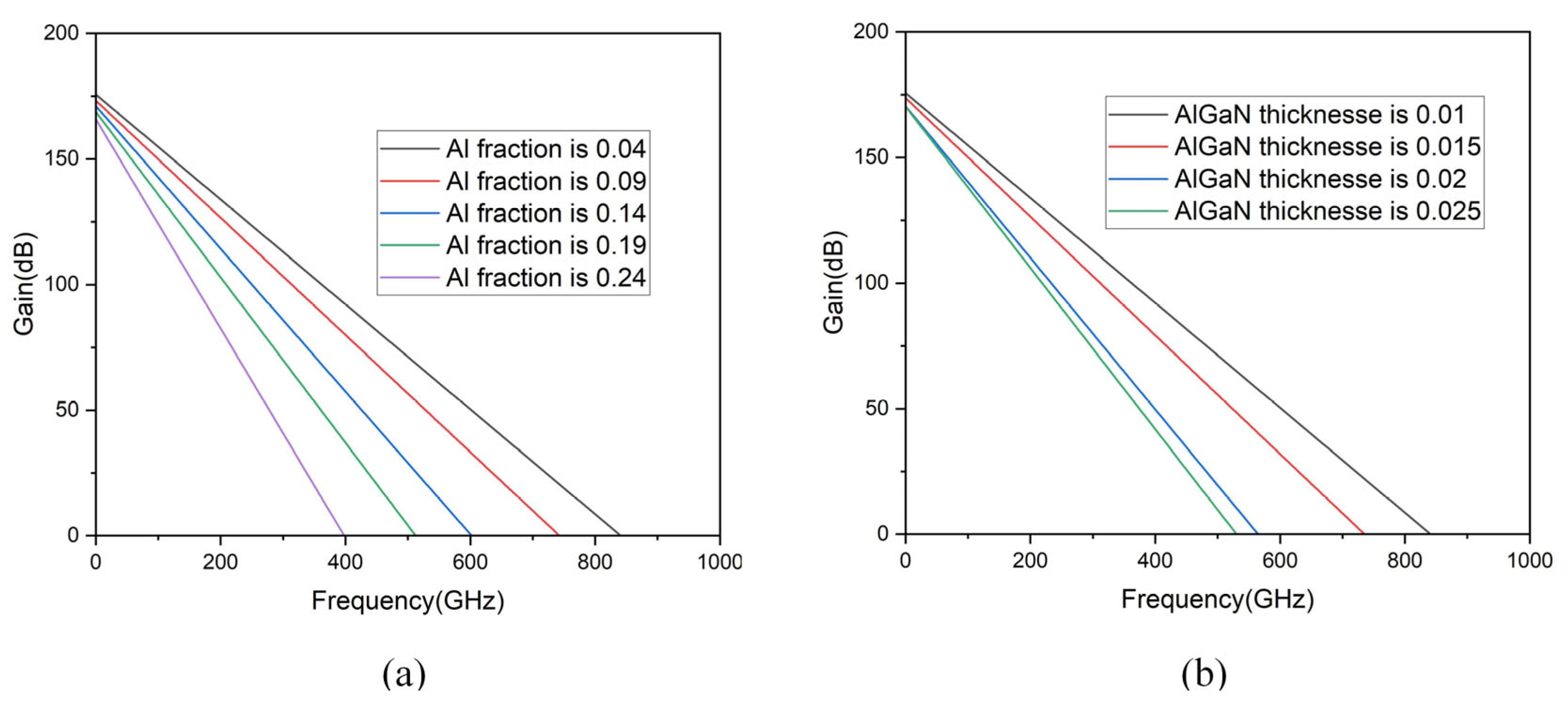

3.5. RF Characteristics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mukherjee, K.; Darracq, F.; Curutchet, A.; Malbert, N.; Labat, N. TCAD simulation capabilities towards gate leakage current analysis of advanced AlGaN/GaN HEMT devices. Microelectron. Reliab. 2017, 76, 350–356. [Google Scholar] [CrossRef]

- Ghaffari, M.; Orouji, A.A. Dual trench AlGaN/GaN HEMT on SiC substrate: A novel device to improve the breakdown voltage and high power performance. Physica E 2016, 80, 108–114. [Google Scholar] [CrossRef]

- Sriramadasu, K.S.; Hsin, Y.-M. An AlGaN-GaN HEMT with p-GaN Extended Gate for Improvements on Current Dispersion and Breakdown Characteristics. ECS J. Solid State Sci. Technol. 2024, 13, 015004. [Google Scholar] [CrossRef]

- Li, J.; Yin, Y.; Zeng, N.; Liao, F.; Lian, M.; Zhang, X.; Zhang, K.; Zhang, Y.; Li, J. A dual-gate and Γ-type field plate GaN base E-HEMT with high breakdown voltage on simulation investigation. Semicond. Sci. Technol. 2021, 36, 095036. [Google Scholar] [CrossRef]

- Xu, K.; Wang, H.Y.; Chen, E.L.; Sun, S.X.; Wang, H.L.; Mei, H.Y. Improvement of DC and RF characteristics for a novel AlGaAs/InGaAs HEMT with decreased single event effect. J. Ovonic Res. 2024, 20, 395–403. [Google Scholar] [CrossRef]

- Lee, D.S.; Liu, Z.; Palacios, T. GaN high electron mobility transistors for sub-millimeter wave applications. Jpn. J. Appl. Phys. 2014, 53, 100212. [Google Scholar] [CrossRef]

- Wu, S.; Hao, Y.; Ma, X.; Yang, L.; Mi, M.; Zhang, M.; Wu, M.; Lu, Y.; Zhang, H.; Yi, C. A Millimeter-Wave AlGaN/GaN HEMT Fabricated With Transitional-Recessed-Gate Technology for High-Gain and High-Linearity Applications. IEEE Electron Device Lett. 2019, 40, 846–849. [Google Scholar] [CrossRef]

- Dubey, S.K.; Islam, A. Effect of high-k dielectric HfO2 on performance of AlGaN/GaN based MOSHEMT for RF applications. Microsyst. Technol. 2023, 30, 163–175. [Google Scholar] [CrossRef]

- Lu, Y.; Ma, X.; Yang, L.; Hou, B.; Mi, M.; Zhang, M.; Zheng, J.; Zhang, H.; Hao, Y. High RF Performance AlGaN/GaN HEMT Fabricated by Recess-Arrayed Ohmic Contact Technology. IEEE Electron Device Lett. 2018, 39, 811–814. [Google Scholar] [CrossRef]

- Kharei, P.; Baidya, A.; Maity, N.P.; Ghosh, A.; Zonunmawii, M. Novel double deck gate field plate structure on a normally-off AlGaN/GaN HEMT- An extensive analysis. Micro Nanostructures 2024, 192, 207874. [Google Scholar] [CrossRef]

- Meneghesso, G.; Meneghini, M.; Zanoni, E. Breakdown mechanisms in AlGaN/GaN HEMTs: An overview. Jpn. J. Appl. Phys. 2014, 53, 100211. [Google Scholar] [CrossRef]

- Peng, Z.; Liu, H.; Yu, H.; Li, L.; Chang, K.C. Constructing drain surrounded double gate structure in AlGaN/GaN HEMT for boosting breakdown voltage. RSC Adv. 2024, 14, 22238–22243. [Google Scholar] [CrossRef] [PubMed]

- Pal, P.; Pratap, Y.; Kabra, S. TCAD Simulation of Novel Recess Gate Common Drain Dual Channel AlGaN/GaN HEMT for Small Signal Performance. IETE Tech. Rev. 2024, 41, 621–631. [Google Scholar] [CrossRef]

- Lee, H.-J.; Lee, C.-C.; Pan, H.-R.; Kuan, C.-H. Optimization of Contact Resistance and DC Characteristics for AlGaN/GaN HEMTs Utilizing Sub-10 nm Nanohole Etching. Electronics 2024, 13, 2490. [Google Scholar] [CrossRef]

- Saito, W.; Takada, Y.; Kuraguchi, M.; Tsuda, K.; Omura, I.; Ogura, T.; Ohashi, H. High breakdown voltage AlGaN-GaN power-HEMT design and high current density switching behavior. IEEE Trans. Electron Devices 2003, 50, 2528–2531. [Google Scholar] [CrossRef]

- Dora, Y.; Chakraborty, A.; McCarthy, L.; Keller, S.; Denbaars, S.P.; Mishra, U.K. High Breakdown Voltage Achieved on AlGaN/GaN HEMTs With Integrated Slant Field Plates. IEEE Electron Device Lett. 2006, 27, 713–715. [Google Scholar] [CrossRef]

- Wen, Z.; Xu, Y.; Chen, Y.; Tao, H.; Ren, C.; Lu, H.; Wang, Z.; Zheng, W.; Zhang, B.; Chen, T.; et al. A Quasi-Physical Compact Large-Signal Model for AlGaN/GaN HEMTs. IEEE Trans. Microw. Theory Tech. 2017, 65, 5113–5122. [Google Scholar] [CrossRef]

- Qu, A.; Xie, Z.; Wang, Y.; Hu, G.; Tan, C.-K. Effect of Acceptor-Type Traps in GaN Buffer Layer on Current Collapse of ε-Ga2O3/GaN HEMTs. J. Electron. Mater. 2025, 54, 3086–3096. [Google Scholar] [CrossRef]

- Du, J.; Liu, D.; Bai, Z.; Liu, Y.; Yu, Q. Design of high breakdown voltage GaN-based vertical HFETs with p-GaN island structure for power applications. Superlattices Microstruct. 2015, 85, 690–696. [Google Scholar] [CrossRef]

- Wang, H.; Wei, J.; Xie, R.; Liu, C.; Tang, G.; Chen, K.J. Maximizing the Performance of 650-V p-GaN Gate HEMTs: Dynamic RON Characterization and Circuit Design Considerations. IEEE Trans. Power Electron. 2017, 32, 5539–5549. [Google Scholar] [CrossRef]

- Yu, Q.; Shi, C.; Yang, L.; Lu, H.; Zhang, M.; Zou, X.; Wu, M.; Hou, B.; Gao, W.; Wu, S.; et al. Improved DC and RF Characteristics of GaN-Based Double-Channel HEMTs by Ultra-Thin AlN Back Barrier Layer. Micromachines 2024, 15, 1220. [Google Scholar] [CrossRef] [PubMed]

- Natarajan, R.; Murugapandiyan, P.; Vigneshwari, N.; Mohanbabu, A.; Ravi, S. Investigation of different buffer layer impact on AlN/GaN/AlGaN HEMT using silicon carbide substrate for high-speed RF applications. Micro Nanostructures 2024, 189, 207815. [Google Scholar] [CrossRef]

- Sun, S.; Zhang, Y.; Si, Y.; Xiong, J.; Luo, X. Improvement of Breakdown Characteristic for a Novel GaN HEMT with Enhanced Resistance Single-Event Transient Effect. J. Electron. Mater. 2024, 54, 784–791. [Google Scholar] [CrossRef]

- Uren, M.J.; Moreke, J.; Kuball, M. Buffer Design to Minimize Current Collapse in GaN/AlGaN HFETs. IEEE Trans. Electron Devices 2012, 59, 3327–3333. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, Q.; Du, J. Simulation design of a high-breakdown-voltage p-GaN-gate GaN HEMT with a hybrid AlGaN buffer layer for power electronics applications. J. Comput. Electron. 2020, 19, 1527–1537. [Google Scholar] [CrossRef]

- Xing, H.; Dora, Y.; Chini, A.; Heikman, S.; Keller, S.; Mishra, U.K. High Breakdown Voltage AlGaN–GaN HEMTs Achieved by Multiple Field Plates. IEEE Electron Device Lett. 2004, 25, 161–163. [Google Scholar] [CrossRef]

- Tsatsulnikov, A.F.; Lundin, V.W.; Zavarin, E.E.; Yagovkina, M.A.; Sakharov, A.V.; Usov, S.O.; Zemlyakov, V.E.; Egorkin, V.I.; Bulashevich, K.A.; Karpov, S.Y.; et al. effect of the parameters of AlN/GaN/AlGaN and AlN/GaN/InAlN heterostructures with a two-dimensional electron gas on their electrical properties and the characteristics of transistors on their basis. Semiconductors 2016, 50, 1383–1389. [Google Scholar] [CrossRef]

- Neha; Kumari, V.; Gupta, M.; Saxena, M. TCAD-Based Optimization of Field Plate Length & Passivation Layer of AlGaN/GaN HEMT for Higher Cut-Off Frequency & Breakdown Voltage. IETE Tech. Rev. 2020, 39, 63–71. [Google Scholar] [CrossRef]

- Yu, H.; Lisesivdin, S.B.; Bolukbas, B.; Kelekci, O.; Ozturk, M.K.; Ozcelik, S.; Caliskan, D.; Ozturk, M.; Cakmak, H.; Demirel, P.; et al. Improvement of breakdown characteristics in AlGaN/GaN/AlxGa1−xN HEMT based on a grading AlxGa1−xN buffer layer. Phys. Status Solidi A 2010, 207, 2593–2596. [Google Scholar] [CrossRef]

- Hanawa, H.; Horio, K. Increase in breakdown voltage of AlGaN/GaN HEMTs with a high-k dielectric layer. Phys. Status Solidi A 2014, 211, 784–787. [Google Scholar] [CrossRef]

- Jiang, Y.; Du, F.; Wang, P.; He, J.; Wen, K.; Deng, C.; Zhang, Y.; Li, M.; Wang, X.; Wang, Z.; et al. Gate Leakage suppression and breakdown improvement of InAlN/GaN MIS-HEMTs with N2O surface treatment. J. Alloys Compd. 2025, 1024, 179922. [Google Scholar] [CrossRef]

- Cheng, J.; Wang, Q.; Liu, Y.; Ding, G.; Zhang, M.; Yi, B.; Huang, H.; Yang, H. Study on a p-GaN HEMT with composite passivation and composite barrier layers. Semicond. Sci. Technol. 2024, 39, 085004. [Google Scholar] [CrossRef]

- Langpoklakpam, C.; Hsiao, Y.-K.; Yi Chang, E.; Lin, C.-H.; Kuo, H.-C. Analysis of breakdown voltage for GaN MIS-HEMT with various composite field plate configurations and passivation layers. Solid-State Electron. 2024, 216, 108930. [Google Scholar] [CrossRef]

- Cui, A.; Zhang, J.; Ren, Z.; Zhou, H.; Wang, D.; Wu, Y.; Lei, Y.; Zhang, J.; Hao, Y. Microwave power performance analysis of hydrogen terminated diamond MOSFET. Diam. Relat. Mater. 2021, 118, 108538. [Google Scholar] [CrossRef]

- Sun, H.; Liu, M.; Liu, P.; Lin, X.; Cui, X.; Chen, J.; Chen, D. Performance optimization of lateral AlGaN/GaN HEMTs with cap gate on 150-mm silicon substrate. Solid-State Electron. 2017, 130, 28–32. [Google Scholar] [CrossRef]

- Luo, S.; Liu, X.; Jiang, X. Effect of Source–Drain Opposite Side Gate on the AlGaN/GaN High Electron Mobility Transistor Devices. Phys. Status Solidi A 2023, 220, 2300375. [Google Scholar] [CrossRef]

- Wang, P.; Deng, C.; Cheng, H.; Cheng, W.; Du, F.; Tang, C.; Geng, C.; Tao, N.; Wang, Q.; Yu, H. Simulation of High Breakdown Voltage, Improved Current Collapse Suppression, and Enhanced Frequency Response AlGaN/GaN HEMT Using A Double Floating Field Plate. Crystals 2023, 13, 110. [Google Scholar] [CrossRef]

- Li, M.; Zhao, Z.B.; Fan, L.B. Effect of spin-orbit coupling on the wave vector and spin dependent transmission probability for the GaN/AlGaN/GaN heterostructure. Phys. Scr. 2015, 90, 015806. [Google Scholar] [CrossRef]

- Wang, W.K.; Li, Y.J.; Lin, C.K.; Chan, Y.J.; Chen, G.T.; Chyi, J.I. Low Damage, Cl2-Based Gate Recess Etching for 0.3-μm Gate-Length AlGaN/GaN HEMT Fabrication. IEEE Electron Device Lett. 2004, 25, 52–54. [Google Scholar] [CrossRef]

- Niu, D.; Wang, Q.; Li, W.; Chen, C.; Xu, J.; Jiang, L.; Feng, C.; Xiao, H.; Wang, Q.; Xu, X.; et al. Hybrid-gate structure designed for high-performance normally-off p-GaN high-electron-mobility transistor. Jpn. J. Appl. Phys. 2020, 59, 111001. [Google Scholar] [CrossRef]

- Jebalin, I.B.K.; Franklin, S.A.; Nirmal, D. Revolutionizing Fe doped back barrier AlGaN/GaN HEMTs: Unveiling the remarkable 1700V breakdown voltage milestone. Microelectron. J. 2024, 147, 106158. [Google Scholar] [CrossRef]

- Chung, J.W.; Hoke, W.E.; Chumbes, E.M.; Palacios, T. AlGaN/GaN HEMT With 300-GHz fmax. IEEE Electron Device Lett. 2010, 31, 195–197. [Google Scholar] [CrossRef]

| Parameter Name | Value | Unit |

|---|---|---|

| Source length/height | 0.5/0.12 | μm |

| Drain length/height | 0.5/0.12 | μm |

| Gate length | 1.5/0.25 | μm |

| Gate height | 0.03/0.03 | μm |

| gap between the two pillars | 0.14 | μm |

| distance from Gate to Drain | 3.9 | μm |

| AlGaN layer length/height | 7.3/0.022 | μm |

| GaN layer length/height | 7.3/0.048 | μm |

| AlGaN back-barrier layer length/height | 7.3/0.01 | μm |

| PN-junction field plate length/height | 0.5/0.01 | μm |

| Structure Type | Bv (V) | Fₜ (GHz) | Year |

|---|---|---|---|

| NπGS | 1817 | 834 | 2025 |

| ITGS-DOSS | 1661 | 625 | 2023 |

| two-step D-FP with G-FP | 1700 | / | 2024 |

| Gate field plate | 1590 | 400 | 2017 |

| Gate field plate with Diamond substrate | 2000 | 90 | 2021 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, J.; Liu, X.; Lu, C.; Yang, D.; Yuan, W. Modelling and Simulation of a New π-Gate AlGaN/GaN HEMT with High Voltage Withstand and High RF Performance. Electronics 2025, 14, 2947. https://doi.org/10.3390/electronics14152947

Yao J, Liu X, Lu C, Yang D, Yuan W. Modelling and Simulation of a New π-Gate AlGaN/GaN HEMT with High Voltage Withstand and High RF Performance. Electronics. 2025; 14(15):2947. https://doi.org/10.3390/electronics14152947

Chicago/Turabian StyleYao, Jun, Xianyun Liu, Chenglong Lu, Di Yang, and Wulong Yuan. 2025. "Modelling and Simulation of a New π-Gate AlGaN/GaN HEMT with High Voltage Withstand and High RF Performance" Electronics 14, no. 15: 2947. https://doi.org/10.3390/electronics14152947

APA StyleYao, J., Liu, X., Lu, C., Yang, D., & Yuan, W. (2025). Modelling and Simulation of a New π-Gate AlGaN/GaN HEMT with High Voltage Withstand and High RF Performance. Electronics, 14(15), 2947. https://doi.org/10.3390/electronics14152947