Broken Wire Detection Based on TDFWNet and Its Application in the FAST Project

Abstract

1. Introduction

2. Theory and Methods

2.1. Time-Domain Feature Analysis

2.2. Convolutional Neural Network

2.3. Dynamic Time Warping

3. Time-Domain Feature Weighted Network

3.1. Dataset Preparation

3.2. FCDTW Data Augmentation

3.3. Model Architecture and Evaluation

4. Engineering Application

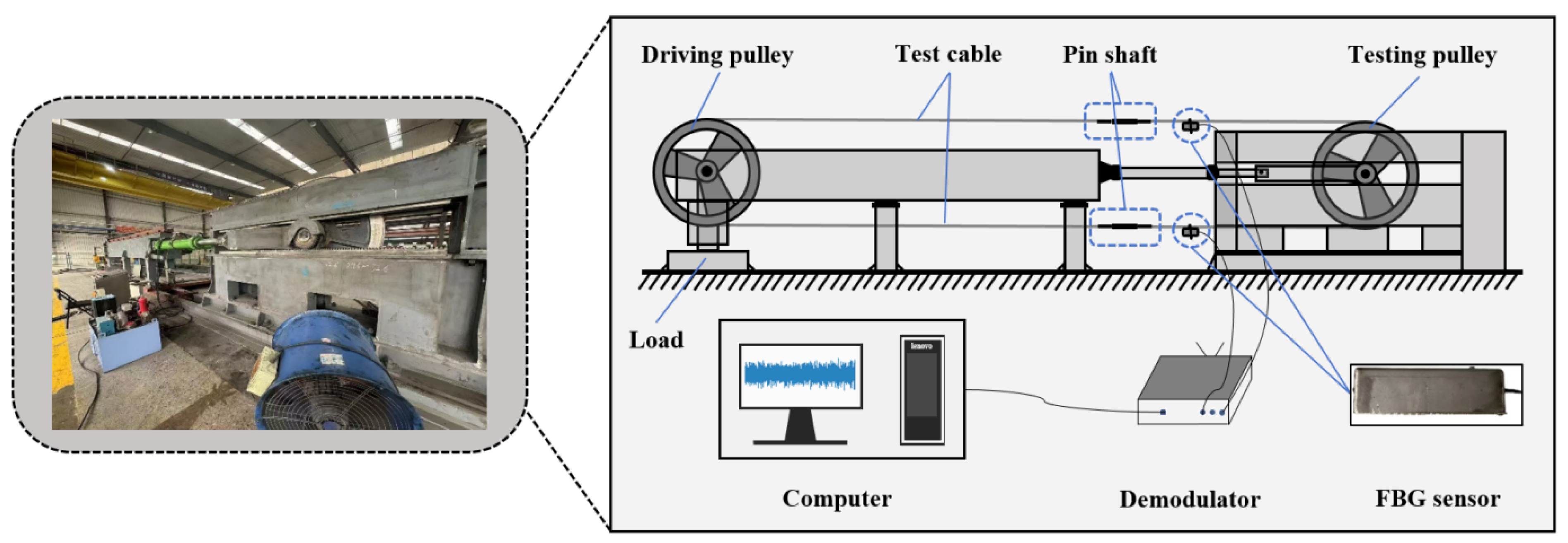

4.1. Structure of the Drive Cable and Fatigue Test Design

4.2. Detection Method and Data Acquisition

4.3. Results of Bending Fatigue Testing

5. Conclusions

- A data augmentation method based on FCDTW was developed in this study. Compared with other data augmentation methods such as DTW, GAN, and VAE, FCDTW outperforms these methods in terms of feature preservation, clustering compactness, and class separability. The augmented data generated by FCDTW have higher quality, which is more conducive to enhancing the wire breakage signal recognition capability of the model.

- The proposed TDFWNet model demonstrated excellent classification performance during both the training and testing phases. After 10 training experiments, TDFWNet achieved an average precision of 98.5%, an average recall of 97.2%, an average F1 score of 97.9%, and an average accuracy of 91.5%. These metrics are 1.5%, 2.0%, 1.8%, and 16.6% higher, respectively, than those of the CNN model constructed by Liu et al., which fully proves its reliability and stability.

- The wire breakage detection method proposed in this study has shown good stability and practicability in the long-term fatigue testing of FAST drive cables. During three bending fatigue tests, a total of 27 suspected wire breakage signals (4, 5, and 18 in each test, respectively) were detected, which is highly consistent with the results of the wire breakage inspection after the fatigue tests (a total of 28 wire breakages, with 5, 7, and 16 in each test, respectively). This indicates that the method can effectively support wire breakage detection requirements in practical engineering applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| TDFWNet | Time-Domain Feature Weighted Network |

| FAST | Five-hundred-meter Aperture Spherical radio Telescope |

| CNN | Convolutional Neural Network |

| FCDTW | Feature-Constrained Dynamic Time Warping |

| FBG | Fiber Bragg grating |

| AE | Acoustic emission |

| DTW | Dynamic Time Warping |

| GAN | Generative Adversarial Network |

| VAE | Variational Autoencoder |

References

- Li, P.; Tian, J.; Zhou, Z.; Wang, W. Detection of Internal Wire Broken in Mining Wire Ropes Based on WOA–VMD and PSO–LSSVM Algorithms. Axioms 2023, 12, 995. [Google Scholar] [CrossRef]

- Liu, S.; Sun, H.; Jiang, X.; Kang, Y. A Review of Wire Rope Detection Methods, Sensors and Signal Processing Techniques. J. Nondestruct. Eval. 2020, 39, 85. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, E.; Jia, F. Study on bending fatigue failure behaviors of end-fixed wire ropes. Eng. Fail. Anal. 2022, 135, 106172. [Google Scholar] [CrossRef]

- Hao, P.; Yu, C.; Feng, T.; Zhang, Z.; Qin, M.; Zhao, X.; He, H.; Yao, X. PM fiber based sensing tapes with automated 45 degrees birefringence axis alignment for distributed force/pressure sensing. Opt. Express 2020, 28, 18829–18842. [Google Scholar] [CrossRef]

- Li, X.; Ren, W.; Bi, K. FBG force-testing ring for bridge cable force monitoring and temperature compensation. Sens. Actuator A Phys. 2015, 223, 105–113. [Google Scholar] [CrossRef]

- Wang, X.; Guo, Z.; Huang, Y.; Xiong, L.; Yao, D.; Dong, W. Design of flexible sensor for wind pressure monitoring of stay cables. Meas. Sci. Technol. 2024, 35, 045109. [Google Scholar] [CrossRef]

- Liu, S.; Sun, Y.; Jiang, X.; Kang, Y. A new MFL imaging and quantitative nondestructive evaluation method in wire rope defect detection. Mech. Syst. Signal Process. 2022, 163, 108156. [Google Scholar] [CrossRef]

- Ni, Y.; Zhang, Q.; Xin, R. Magnetic flux detection and identification of Bridge cable metal area loss damage. Measurement 2021, 167, 108443. [Google Scholar] [CrossRef]

- Zhang, J.; Peng, F.; Chen, J. Quantitative Detection of Wire Rope Based on Three-Dimensional Magnetic Flux Leakage Color Imaging Technology. IEEE Access 2020, 8, 104165–104174. [Google Scholar] [CrossRef]

- Zhang, H.; Li, H.; Zhou, J.; Tong, K.; Xia, R. A multi-dimensional evaluation of wire breakage in bridge cable based on self-magnetic flux leakage signal. J. Magn. Magn. Mater. 2023, 566, 170321. [Google Scholar] [CrossRef]

- Paweł, M.; Maciej, R.; Jerzy, K. Analysis of the resolution of the passive magnetic method on the example of nondestructive testing of steel wire ropes. J. Magn. Magn. Mater. 2024, 589, 171607. [Google Scholar]

- Zhao, S.; Li, G.; Wang, C. Bridge cable damage identification based on acoustic emission technology: A comprehensive review. Measurement 2024, 237, 115195. [Google Scholar] [CrossRef]

- Li, S.; Feng, J.; Liu, Z.; Xu, B.; Wu, G. Spatial propagation characteristics of acoustic emission signals in parallel steel wire cables. Measurement 2024, 226, 114138. [Google Scholar] [CrossRef]

- Hou, J.; Wang, C.; Li, S.; Jiang, N.; Xu, B.; Wu, G. Study on propagation mechanism and attenuation law of acoustic emission waves for damage of prestressed steel strands. Measurement 2023, 219, 113240. [Google Scholar] [CrossRef]

- Li, G.; Zhao, Z.; Li, Y.; Li, Y.; Lee, C. Preprocessing Acoustic Emission Signal of Broken Wires in Bridge Cables. Appl. Sci. 2022, 12, 6727. [Google Scholar] [CrossRef]

- Li, S.; Hou, S.; Wu, G.; Wang, H.; Jiang, N. Sheath-outside AE monitoring method for multiple sources of damage to cables considering the effect of an HDPE sheath on AE propagation. Measurement 2024, 227, 114244. [Google Scholar] [CrossRef]

- Li, S.; Liu, Z.; Xia, L.; Wang, Y.; Feng, H. Wire breaking localization of parallel steel wire bundle using acoustic emission tests and finite element analysis. Struct. Control Health Monit. 2020, 28, e2681. [Google Scholar] [CrossRef]

- Yu, W.; Luo, X.; Qin, H. An experimental study on monitoring the wire breakage signal of a zip wire using FBG sensors. Adv. Lasers Optoelectron. 2023, 60, 94–100. [Google Scholar]

- Xue, S.; Sun, Y.; Su, T.; Zhao, X. Deep reference autoencoder convolutional neural network for damage identification in parallel steel wire cables. Structures 2023, 57, 105316. [Google Scholar] [CrossRef]

- Han, J.; Zhang, Y.; Feng, Z.; Zhao, L. Research on Intelligent Identification Algorithm for Steel Wire Rope Damage Based on Residual Network. Appl. Sci. 2024, 14, 3753. [Google Scholar] [CrossRef]

- Liu, S.; Liu, Y.; Shan, L.; Wang, Q.; Sun, Y.; He, L. Hybrid Conditional Kernel SVM for Wire Rope Defect Recognition. IEEE Trans. Ind. Inform. 2024, 20, 6234–6244. [Google Scholar] [CrossRef]

- Feng, J.; Gao, K.; Gao, W.; Liao, Y.; Wu, G. Machine learning-based bridge cable damage detection under stochastic effects of corrosion and fire. Eng. Struct. 2022, 264, 114421. [Google Scholar] [CrossRef]

- Qin, Y.; Gao, G.; Lian, M.; Liu, Y. Wire Rope Fault Diagnosis Based on Wavelet Analysis and Support Vector Machine (SVM). Adv. Mat. Res. 2014, 3255, 1396–1399. [Google Scholar] [CrossRef]

- Wang, X.; Cao, Q.; Jin, S.; Chen, C.; Feng, S. Research on Detection Method of Transmission Line Strand Breakage Based on Improved YOLOv8 Network Model. IEEE Access 2024, 12, 168197–168212. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, Z.; Shi, S.; Dong, Z.; Zhao, L.; Jing, L.; Tan, J. A quantitative identification method based on CWT and CNN for external and inner broken wires of steel wire ropes. Heliyon 2022, 8, e11623. [Google Scholar] [CrossRef]

- Zhu, W.; Liu, R.; Jiang, P.; Huang, J. Cable Broken Wire Signal Recognition Based on Convolutional Neural Network. Electronics 2023, 12, 2138. [Google Scholar] [CrossRef]

- Liu, R.; Zhu, W.; Shan, D.; Liang, S. Steel wire fracture detection using fibre bragg grating vibration sensors and a convolutional neural network. Measurement 2025, 244, 116560. [Google Scholar] [CrossRef]

- Zhu, W.; Liu, G.; Qin, H.; Liu, R. Development of fiber Bragg grating vibration sensor for bidirectional monitoring of thin rod cantilever beam. Measurement 2025, 242, 115979. [Google Scholar] [CrossRef]

- Zhu, W.; Qin, H.; Li, J.; Ou, J. Monitoring Cable Force of FAST Project Based on Fiber Bragg Grating Sensor External Installed on Anchorage Zone. J. Mech. Eng. 2017, 53, 23–30. [Google Scholar] [CrossRef]

- Wang, Y.; You, R.; Ren, L. A fibre Bragg grating accelerometer with temperature insensitivity for cable force monitoring of FAST. Measurement 2024, 225, 114031. [Google Scholar] [CrossRef]

- Kang, J.; Zhu, X.; Shen, L.; Li, M. Fault diagnosis of a wave energy converter gearbox based on an Adam optimized CNN-LSTM algorithm. Renew. Energy 2024, 231, 121022. [Google Scholar] [CrossRef]

- Jeong, J.; Koo, G. AdaLo: Adaptive learning rate optimizer with loss for classification. Inf. Sci. 2025, 690, 121607. [Google Scholar] [CrossRef]

- Niu, Y.; Xing, X.; Jia, Z.; Liu, R.; Xin, M. Implicit local–global feature extraction for diffusion sequence recommendation. Eng. Appl. Artif. Intell. 2025, 139, 109471. [Google Scholar] [CrossRef]

- Kumar, P.; Laha, S.; Kumaraswamidhas, L. Assessment of rolling element bearing degradation based on Dynamic Time Warping, kernel ridge regression and support vector regression. Appl. Acoust. 2023, 208, 109389. [Google Scholar] [CrossRef]

- Shi, J.; Zhang, W.; Zhao, Y. ANN Prediction Model of Concrete Fatigue Life Based on GRW-DBA Data Augmentation. Appl. Sci. 2023, 13, 1227. [Google Scholar] [CrossRef]

- Tony, C.; Rong, M. Theoretical Foundations of t-SNE for Visualizing High-Dimensional Clustered Data. J. Mach. Learn. Res. 2021, 23, 2022. [Google Scholar]

- GB/T 20118-2017; Steel Wire Ropes for General Purposes. China National Standards: Shenzhen, China, 2017.

- GB/T 12347-2008; Steel Wire Ropes—Bending Fatigue Testing. China National Standards: Shenzhen, China, 2008.

- Jia, Z.; Dang, S.; Yu, D.; Fan, W. Cantilever vibration sensor based on Fiber Bragg Grating temperature compensation. Opt. Fiber Technol. 2023, 75, 103183. [Google Scholar] [CrossRef]

| Name | Dimension of Output Value | |

|---|---|---|

| Convolution | Conv1D | (None, 198, 32) |

| MaxPooling1D | (None, 99, 32) | |

| Conv1D_1 | (None, 97, 64) | |

| Dropout | (None, 97, 64) | |

| MaxPooling1D_1 | (None, 48, 64) | |

| Conv1D_2 | (None, 46, 128) | |

| Dropout_1 | (None, 46, 128) | |

| MaxPooling1D_2 | (None, 23, 128) | |

| Conv1D_3 | (None, 21, 256) | |

| Dropout_2 | (None, 21, 256) | |

| MaxPooling1D_3 | (None, 10, 256) | |

| Flatten | Flatten | (None, 2560) |

| Dense | Dense | (None, 256) |

| Dense_1 | (None, 128) | |

| Dense_2 | (None, 200) |

| Time-Domain Features | Minimum Value | Lower Quartile | Upper Quartile | Maximum Value |

|---|---|---|---|---|

| Waveform factor | 1.443633 | 1.529352 | 1.720721 | 1.894116 |

| Kurtosis | 4.654313 | 6.279180 | 9.748393 | 14.907855 |

| Pulse factor | 4.219765 | 5.473978 | 7.184436 | 9.000339 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, W.; Zhong, Z.; Cheng, S.; Li, Q.; Yao, R.; Li, H. Broken Wire Detection Based on TDFWNet and Its Application in the FAST Project. Electronics 2025, 14, 2544. https://doi.org/10.3390/electronics14132544

Zhu W, Zhong Z, Cheng S, Li Q, Yao R, Li H. Broken Wire Detection Based on TDFWNet and Its Application in the FAST Project. Electronics. 2025; 14(13):2544. https://doi.org/10.3390/electronics14132544

Chicago/Turabian StyleZhu, Wanxu, Zixu Zhong, Sha Cheng, Qingwei Li, Rui Yao, and Hui Li. 2025. "Broken Wire Detection Based on TDFWNet and Its Application in the FAST Project" Electronics 14, no. 13: 2544. https://doi.org/10.3390/electronics14132544

APA StyleZhu, W., Zhong, Z., Cheng, S., Li, Q., Yao, R., & Li, H. (2025). Broken Wire Detection Based on TDFWNet and Its Application in the FAST Project. Electronics, 14(13), 2544. https://doi.org/10.3390/electronics14132544