Abstract

Wireless electric vehicle charging (WEVC) is rapidly advancing as an enabling technology for convenient electrified transportation. The trend toward high-power WEVC systems is accelerating, which not only enhances charging speed and user convenience but also introduces new and complex safety challenges. These challenges are particularly acute at the coupler level, where electrical, thermal, and magnetic risks often interact. This review offers a comprehensive analysis of safety management technologies that are specific to WEVC, with an exclusive focus on coupler-related risks. System-level and coupler-level hazards associated with high-power operation are first examined, followed by an in-depth discussion of recent progress in passive safety materials, such as insulation, thermal dissipation, and electromagnetic shielding. Active safety management strategies are also reviewed in detail, including foreign object detection, live body detection, misalignment detection, and multifunctional detection schemes that integrate these capabilities. Emphasis is placed on the ongoing rapid iteration of safety technologies as power levels increase and on the necessity for solutions that are comprehensive, precise, orderly, and reliable. This review concludes by highlighting future research directions, such as data-driven safety management, intelligent sensor integration, regulatory evolution, and user-centered system design, aiming to support the safe and scalable deployment of WEVC in next-generation mobility.

1. Introduction

The global transportation sector is undergoing a profound transformation under the dual pressures of electrification and automation. On the one hand, the urgency of addressing climate change has led to aggressive policy commitments toward carbon neutrality, with many countries setting targets to phase out internal combustion engine vehicles and increase the share of renewable energy [1,2,3]. The transportation sector, accounting for nearly one-quarter of global CO2 emissions, has become a focal point for decarbonization efforts [4]. Governments and regulatory agencies are incentivizing the adoption of electric vehicles (EVs) through subsidies, infrastructure investments, and emission regulations. On the other hand, autonomous driving technologies are advancing rapidly, enabling new paradigms of self-driving mobility services that demand minimal human intervention [5]. These two forces are converging to redefine the future of mobility.

In this evolving landscape, wireless electric vehicle charging (WEVC) is gaining momentum as a key enabler of next-generation EV infrastructure. Unlike conventional plug-in chargers, WEVC eliminates the need for manual cable connections, providing a hands-free, weather-resistant, and automated charging experience [6]. This not only improves user convenience but also addresses key limitations of plug-in systems, such as connector wear, vandalism risk, and operational downtime [7,8]. For autonomous EV fleets, WEVC is particularly critical, as it enables fully unattended charging without human intervention. Reports suggest that upcoming autonomous mobility platforms, such as Robotaxi, are being designed around wireless-only architectures—a trend that highlights the comparative advantage of WEVC in reliability, automation, and long-term maintainability [9].

Over recent decades, researchers have explored various wireless power transfer (WPT) technologies for electric vehicle applications. These can be broadly categorized into three types based on the physical coupling mechanism: capacitive coupling, which uses electric fields between conductive plates; microwave radiation, which transmits power via directed electromagnetic waves; and inductive coupling, which transfers energy through time-varying magnetic fields between coils [10]. While each method has unique advantages and limitations, inductive coupling based on magnetic fields has emerged as the foundational technology for WEVC, owing to its practical advantages in efficiency, misalignment tolerance, and, most importantly, scalability to high power levels required by modern EVs [11,12]. Accordingly, this review focuses exclusively on inductive coupling systems and their safety considerations.

While WEVC offers distinct advantages in user convenience, it also introduces new safety challenges—particularly as systems scale toward higher power levels. These challenges primarily stem from the high-frequency electromagnetic fields used for wireless power transfer, which can give rise to electrical stress, thermal buildup, and magnetic field leakage [13,14,15]. Such risks are especially concentrated in the power coupler—the contactless interface between the ground and vehicle units [16,17,18]. As a multi-physics interface, the coupler represents a confined region where electrical, thermal, and magnetic effects converge, making it a critical focus for system-level safety design.

Moreover, the trend toward high-power WEVC significantly amplifies these risks. Recent developments underscore this shift. For example, Oak Ridge National Laboratory has demonstrated a 100 kW single-phase WEVC system with 97% efficiency at a 5-inch air gap [19]; and the DOE project envisages a 500 kW wireless charging system for drayage trucks [20]. These examples illustrate that high-power WEVC is transitioning from lab-scale prototypes to commercial reality. However, these systems also pose intensified challenges in thermal management, electromagnetic compatibility, etc. A detailed analysis of this trend will be provided in Section 3.2.

In such systems, although real-time monitoring technologies—such as temperature and magnetic field sensors—are applied, monitoring alone is insufficient [21]. Ensuring safety requires strategies that combine passive protective materials and active control technologies to prevent, contain, and mitigate risks at the coupler level. A detailed analysis of these two types of measurements will be provided in Section 5 and Section 6, respectively.

It is also important to clarify how this review distinguishes itself from other recent works in the field. Over the past five years, a number of high-level reviews have addressed the development, performance, and future applications of WEVC systems, with some focusing on system efficiency, dynamic charging, or market prospects [22,23,24,25,26,27]. However, few have conducted a dedicated and systematic analysis of safety management technologies, especially with regard to high-power coupler-level risks and their mitigation. As practical deployment depends crucially on addressing these safety challenges, our review fills this gap, aiming to provide valuable guidance for both researchers and practitioners.

To be specific, this review provides a comprehensive overview of safety management technologies for WEVC systems, with a particular focus on coupler-level risks. Section 3 outlines system-level risk factors and introduces the high-power development trend. Section 4 analyzes coupler-level risks across electrical, thermal, and magnetic domains. Section 5 presents passive safety materials tailored to each type of risk. Section 6 covers active safety technologies, including foreign object detection, live object detection, and misalignment detection. Through this structure, this review aims to offer a clear understanding of the risk landscape, the technological countermeasures, and the future directions for the safe and scalable deployment of magnetic field-based WEVC systems.

2. Methodology

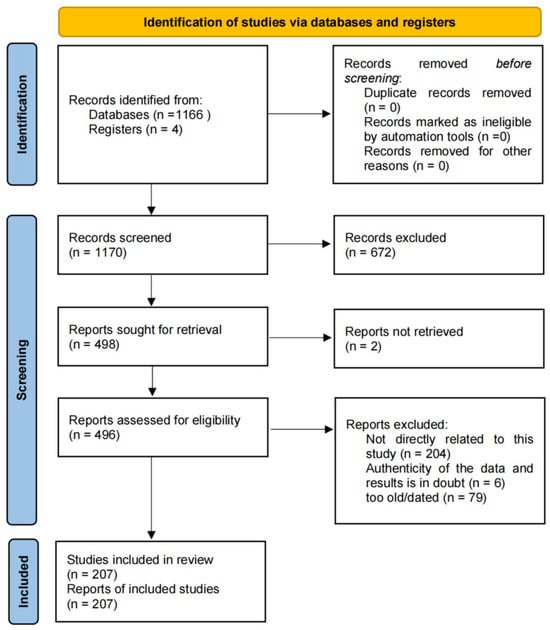

To systematically search and analyze the literature on safety management technologies for WEVC systems, a rigorous screening process was adopted, as illustrated in the preferred reporting items for systematic reviews and meta-analyses (PRISMA) flow diagram in Figure 1 [28]. Beyond the automatic filtering of duplicates, the relevance and quality of each study were also manually assessed. Only publications directly addressing WEVC safety were considered, with screening based on titles and abstracts. For quality assurance, we prioritized peer-reviewed journal articles, leading conference papers, key industry standards (such as SAE, IEC, ISO), and important patents from top WEVC enterprises (e.g., WiTricity). Studies with questionable authenticity or those lacking methodological rigor were excluded. Generally, only studies from the past ten years were included, except for older works that have remained highly cited and influential in recent years. Notably, over 80% of the included studies were published within the last five years, ensuring both timeliness and authority in the final selection.

Figure 1.

PRISMA flow diagram.

3. Risks Associated with WEVC Systems

3.1. Overview of System-Level Risks

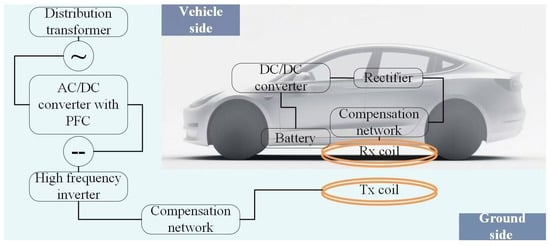

As shown in Figure 2, a typical inductive-coupling-based WEVC system consists of multiple power electronic stages. On the ground side, the system begins with an AC/DC converter with integrated power factor correction (PFC), which rectifies and conditions the grid-side input [29]. This is followed by a high-frequency inverter that generates an alternating current centered around the standardized 85 kHz band [30]. The output is delivered through a compensation network to the transmitting (Tx) coil, which serves as the primary side of the magnetic link [31]. On the vehicle side, the receiving (Rx) coil captures the magnetic flux and transfers the energy through its own compensation network, followed by a high-frequency rectifier and a DC/DC converter that regulates the output for battery charging [32,33]. Together, the Tx and Rx coils form the magnetic coupler—a contactless interface that enables efficient energy transfer between the ground and vehicle.

Figure 2.

Structure of a WEVC system.

From a system-level perspective, WEVC systems share many risk factors with other high-power electronic infrastructures such as plug-in EV chargers, centralized photovoltaic inverters, and data center power supplies [34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49]. These shared risks include overvoltage and overcurrent stress during conversion [34,35,36], thermal buildup in power components [37,38,39], electromagnetic interference (EMI) [40,41,42], long-term component degradation (especially in capacitors and semiconductors) [43,44,45], and battery-related hazards such as thermal runaway, overcharging, and cell imbalance [46,47,48,49]. These risks are relatively well studied and are typically mitigated through circuit protection, thermal management, and control strategies. In contrast, the magnetic coupler introduces a distinct set of risks that are unique to WPT. These include magnetic field leakage that may exceed human exposure limits, eddy current heating in nearby conductive objects, misalignment-induced power loss and localized heating, resonance-related instability in the presence of parasitic interactions, etc.

What makes these risks particularly critical is that they are not only unique to wireless systems and less comprehensively addressed in the existing literature and standards, but also have the potential to cause harm not only to system components but also to human health—especially in scenarios involving prolonged exposure or unintended field interactions [50,51,52]. Moreover, they often involve coupled multi-physics processes—specifically electromagnetic, thermal, and mechanical interactions—which can lead to complex and sometimes unpredictable failure modes [53,54,55]. These characteristics make the safety of the magnetic coupler a central concern in the reliable and scalable deployment of wireless charging technology.

3.2. Trend Toward High-Power WEVC

As reflected in Figure 3, WEVC systems are experiencing a clear and accelerating trend toward higher power levels [39,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76]. Since 2015, prototype systems have evolved from designs below 20 kW to recent demonstrations exceeding 200 kW. This progression is largely driven by the demand for faster charging and compatibility with larger EVs and the goal of achieving performance comparable to plug-in fast charging. The dotted curve illustrates the upward shift in power capability, while the shaded region captures the increasing ambition in terms of system power density and coil design complexity.

Figure 3.

Summary of power level and power density of WEVC prototypes [39,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76].

However, as system power increases, so too does the intensity of the alternating magnetic field required to sustain efficient energy transfer, which significantly amplifies the risks associated with the magnetic coupler. These risks manifest across multiple physical domains. Electrically, higher voltages and currents raise the likelihood of insulation breakdown, partial discharge, and component overstress, particularly within the compensation networks and rectification stages [77,78,79]. Thermally, increased power transfer leads to greater losses in coils, ferrite materials, and surrounding conductors, intensifying local heating and challenging thermal management strategies [80,81,82]. Magnetically, stronger fields exacerbate leakage flux, increase the coupling sensitivity to misalignment, and elevate the risk of unintended interactions with nearby objects and materials [83,84,85].

These interrelated effects highlight that as WEVC systems scale in power, coupler-related risks do not increase linearly—they become more complex, more tightly coupled across physical domains, and more difficult to predict or contain using conventional design practices. This underscores the need for a systematic, multi-physics risk analysis framework. Accordingly, the next section will examine these risks in greater depth, categorized into three primary domains: electrical, thermal, and magnetic. Each domain reflects a distinct aspect of the coupler’s vulnerability under high-power operation, and together, they form the foundation for understanding and mitigating safety challenges in advanced WEVC systems.

4. Investigation of Coupler-Level Risks

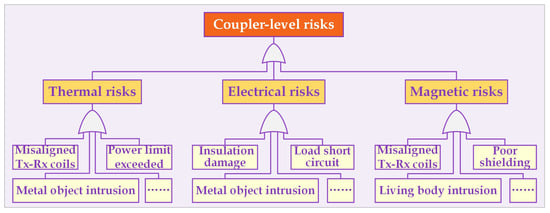

The magnetic coupler—comprising the Tx and Rx coils as well as their associated core and shielding structures—forms the key functional part of inductive-coupling-based WEVC systems. The coupler not only enables contactless power delivery but also becomes the principal area where multiple physical risks accumulate. These risks are driven by high voltage, high current, and high-frequency excitation, and they are further magnified by the increasing power levels and spatial misalignments associated with real-world deployments. As illustrated in Figure 4, the coupler-level risks can be categorized into three interdependent domains: thermal, electrical, and magnetic. Each domain has distinct failure mechanisms but shares a high degree of interaction with the others, leading to complex, multi-physics risk behaviors.

Figure 4.

Risk tree of magnetic coupler.

4.1. Electrical Risks

Electrical risks at the coupler level mainly originate from insulation degradation, turn-to-turn faults, load-side short circuits, metal object (MO) intrusion, and leakage current. These are driven by the high voltage and fast-switching phenomena intrinsic to resonant WPT, especially when operating at or above 85 kHz.

The insulation of Litz wires used in coupler windings is particularly susceptible to degradation under thermal cycling, mechanical vibration, and elevated ambient humidity. Over time, these factors may lead to partial discharge or insulation breakdown, eventually causing inter-turn short circuits [86,87]. Once such a fault occurs, the local current density can spike dramatically, producing intense localized heating, often far exceeding the thermal limits of ferrite cores and polymeric insulation [88,89,90]. At higher power levels, the magnitude of these fault currents increases significantly, accelerating damage propagation and reducing the time window for safe shutdown [91]. Load-side short circuits represent another critical scenario. In the event of a battery-side failure or rectifier malfunction, the receiving side of the coupler may draw excessive current from the Tx coil. This surge not only stresses the power electronics but also causes a rapid rise in coil temperature [92]. Simulation studies have shown that with a fivefold increase in primary current, the ferrite core temperature can exceed 250 °C within 35 s, surpassing the Curie point and causing an irreversible loss of magnetic permeability [93]. If the system fails to detect and shut down within 16 s, the heat accumulation may also compromise the shielding structure and lead to open-flame events. In addition, the intrusion of MOs—especially high-conductivity material—can unintentionally create electrical bridges between adjacent windings or between coil terminals and ground [94]. These low-impedance paths may not trigger immediate shutdown but can initiate silent degradation processes that evolve into full-scale electrical faults. Despite the implementation of circuit-level overcurrent protection, many of these risks are concentrated within the coupler itself and are not easily detected through standard electrical diagnostics [93,95]. Furthermore, the higher the power level of WEVC systems, the larger the danger zone for MOs [96]. Another increasingly prominent issue in high-power systems is leakage current. As the power transfer level increases, so does the alternating magnetic field strength, which can induce significant displacement currents through parasitic capacitances between the coil and ground [97,98]. These paths may include structural metal near the vehicle underbody, shielding layers, or even the human body in extreme scenarios [99,100]. In some cases, high-frequency common-mode currents generated by asymmetrical excitation can also flow through unintended return paths, posing risks of electric shock or interference with control electronics [101].

4.2. Thermal Risks

Thermal risks are among the most critical challenges in the magnetic coupler. The coupler structure involves multiple heat-generating components, including Litz-wire coils with resistive losses, ferrite cores with hysteresis and eddy current losses, and aluminum shielding plates that absorb stray magnetic fields via induced eddy currents. Among them, the Litz coils are generally the dominant source of heat, often contributing over 50% of the total thermal loss in typical mid- to high-power configurations [15,102,103,104].

These losses exhibit different scaling relationships with respect to coil current. Specifically, resistive losses in the Litz wires are basically proportional to the square of the current, and the same goes for shielding losses, and magnetic core losses scale approximately with I2 or higher depending on frequency and waveform distortion [93]. As power levels increase, the required current also increases, possibly leading to superlinear escalation of thermal stress, which makes high-power systems not only more prone to overheating but also more difficult to cool effectively.

Under ideal alignment, these losses can be effectively managed through conventional thermal design techniques. However, when the transmitting and receiving coils become misaligned—a common scenario in real-world deployments—the system becomes highly sensitive to flux imbalance, which increases reactive power and circulating current. This, in turn, disproportionately amplifies power loss in the coils and cores, leading to a rapid temperature rise [71]. Experimental and simulation studies have shown that in a 6.6 kW system, a lateral misalignment of 100 mm caused the coupler surface temperature to exceed 100 °C in less than 30 min, surpassing SAE J2954’s [50] highest thermal risk rating [37,105]. The standard defines four risk levels: 65 °C (Level 1, risk of igniting low-flashpoint materials), 73 °C (Level 2, skin burn threshold), 80 °C (Level 3, metal ignition), and 90 °C (Level 4, non-metal ignition) [37].

A distinct category of thermal risk arises from MO intrusion. When conductive materials such as bolts, coins, or aluminum sheets are accidentally placed near the magnetic coupler, they intercept fringe magnetic fields and act as secondary heating loads via induced eddy currents [106]. The heating rate depends on the object’s material, geometry, orientation, and position relative to the magnetic field gradient [107]. For example, graphite objects are particularly hazardous, with heating rates exceeding 200 °C/min due to their high resistivity and magnetic susceptibility. Cylindrical objects such as cans or bolts typically heat faster than flat ones because of their smaller surface-area-to-volume ratio, which limits heat dissipation [108,109,110]. The spatial distribution of thermal risk is also non-uniform. In double-D coil structures, simulation and experimental studies have shown that objects placed 10–15 cm beyond the visible edge of the coil can still reach ignition temperatures within minutes [93]. It should be noted that this phenomenon is observed using a low-power 6 kW WEVC prototype. For those systems with higher power, the risky area for Mos is definitely larger. Therefore, the foreign object detection (FOD) zone must be significantly larger than the physical coil boundary. For high-power systems using double-D coils, it is recommended that the detection area be expanded by at least 135% in the x-direction and up to 200% in the y-direction to ensure adequate coverage [93]. Infrared imaging of physical prototypes confirms these findings [93].

Another important consideration is the thermal coupling between the coil and surrounding materials. In many designs, the coil is embedded in polymeric housings or encapsulated in resin. These materials often have low thermal conductivity, which can trap heat and delay dissipation. Moreover, thermal gradients within the coupler can induce mechanical stress, leading to delamination, cracked ferrite tiles, or insulation fatigue over time [111]. These degradation mechanisms are difficult to detect externally but can significantly reduce the lifetime and reliability of the system.

4.3. Magnetic Risks

Magnetic risks associated with couplers primarily arise from the unintended spread of alternating magnetic fields beyond the intended energy transfer zone. While these fields are crucial for power transmission, their uncontrolled expansion into the environment raises numerous safety and electromagnetic compatibility issues. These concerns include biological exposure, interference with nearby electronics, thermal induction in foreign materials, and coupling with structural elements of vehicles or ground infrastructure. As system power levels increase, these risks become more pronounced in both spatial extent and field intensity [112].

One significant risk is the exposure of living organisms to leakage fields. According to the ICNIRP guidelines, the magnetic flux density at 85 kHz should not exceed 27 μT in accessible areas, a threshold adopted by the SAE J2954 and GB/T 38775 [51] standards. However, recent studies indicate that this limit is often exceeded in higher-power systems. For example, a 100 kW system recorded flux densities over 35 μT at 1 m from the coupler center under lateral misalignment conditions [54]. In some cases, the 27 μT contour can reach over 1.2 m from the coil center, especially with off-center vehicle parking [54].

Field leakage poses risks not only to human health but also to biological sensors, medical implants, and nearby electronic systems. Magnetic flux densities exceeding 20 μT can interfere with magnetic compasses, MEMS gyroscopes, and low-frequency communication systems [113,114]. Additionally, the field environment is dynamic: vehicle approach, coil misalignment, power ramp-up, and environmental reflections can cause transient spikes in field intensity, which are difficult to predict and often undetected by conventional monitoring systems [115,116,117].

Magnetic risks also arise from unintended coupling with nearby conductive or ferromagnetic materials. Structural components such as EV chassis, battery enclosures, or rebar in the ground can act as “parasitic receivers” of magnetic flux, forming closed-loop paths that absorb energy and re-radiate it unpredictably [118]. In extreme cases, these materials may heat up due to eddy current losses, posing localized thermal hazards similar to foreign object heating. Simulation studies show that a steel plate 15 cm below the transmitting coil can experience local flux densities exceeding 0.3 T, leading to temperature rises over 50 °C within minutes [119]. This parasitic coupling is challenging to model due to the complex and variable geometry of real-world installations.

The magnetic saturation of ferrite cores is another indirect but significant risk. In fault scenarios such as load-side short circuits or turn-to-turn coil faults, the magnetic flux density in the core can exceed the saturation threshold (typically 0.4–0.5 T), causing a sharp drop in permeability. This not only reduces power transfer efficiency but also increases magnetic flux leakage, degrading shielding performance and increasing external exposure. Saturation is often accompanied by increased core losses and localized heating, which contribute to thermal risks [120].

5. Passive Safety Materials for Coupler

5.1. Insulating Material

Effective insulation is fundamental for the passive safety of magnetic couplers in WEVC systems. Insulation primarily serves to prevent electrical breakdown, short-circuiting, and hazardous leakage currents, both inside the coil windings and between the coil and its environment. The main insulation targets in magnetic couplers are (1) strand-to-strand insulation within Litz wires and (2) wire-to-wire or wire-to-ground insulation between turns and the coupler structure.

For strand-to-strand insulation, each fine wire within Litz wire is typically coated with enamel such as polyimide or polyester, and sometimes further wrapped or taped, which suppresses circulating currents and reduces the risk of internal short circuits, directly impacting system safety and AC loss performance [121,122,123,124,125,126]. For wire-to-wire and wire-to-ground insulation, various approaches are applied. Resin impregnation and potting with materials like epoxy, polyester, polyurethane, or polyurea are widely used to encapsulate coils, enhancing dielectric and mechanical integrity; the addition of advanced fillers such as AlN nanoparticles can further improve thermal conductivity while maintaining insulation performance [121,122,124,125,127]. Slot liners and tapes, made from materials such as Nomex, PET, or mica-based papers, are commonly used to physically separate coils from housings or other components, and additional taping or extrusion layers, such as polyimide, are adopted for high-voltage or harsh environments [121,123,124,125]. Surface coatings and nanocomposite materials are also being developed to provide improved dielectric strength for compact high-power systems [122,127].

As WEVC systems advance toward higher power and voltage levels, insulation challenges will intensify: increased voltage raises the risk of the partial discharge and aging of insulation materials, making the careful selection and engineering of both internal and external insulating materials critical for safety and long-term reliability [128,129,130].

5.2. Thermal Dissipation Material

The purpose of thermal dissipation in WEVC systems is to keep the magnetic coupler and its materials within safe temperature limits, directly impacting system reliability and safety. The coupler components, Litz wire and ferrite cores, are sensitive to excessive heat, which can alter magnetic properties and potentially cause failures or safety hazards. Therefore, effective thermal dissipation materials are essential for WEVC.

Most current WEVC systems use passive thermal management. This approach employs thermally conductive materials, such as specialty epoxies, aluminum backplates, and, more recently, phase-change materials (PCMs), to absorb transient heat loads. For example, filling the pad with epoxy efficiently transfers heat from the coil and core to an aluminum plate, which then dissipates heat to the environment [39,131]. PCM has also been embedded around ferrite bars in concrete-embedded dynamic charging pads, helping to buffer temperature spikes, while non-metallic fiberglass reinforcement avoids the eddy current losses associated with steel rebar [132,133]. These passive approaches are favored for their simplicity and reliability, especially in low- and mid-power systems.

However, as WEVC systems move to higher power levels, passive dissipation alone may not be sufficient. Active cooling methods, such as forced air or integrated liquid cooling, are increasingly being adopted to manage greater losses and higher thermal loads [134,135]. Liquid-cooled assemblies have already shown effectiveness in keeping multi-phase coupler temperatures within safe limits at power levels up to hundreds of kilowatts, a trend that follows the evolution of high-power wired charging infrastructure [136]. As power ratings increase, so do the thermal safety challenges, making advanced thermal management an essential part of future high-power WEVC system design. Notably, the long-term aging of thermal interface materials, such as thermal greases, adhesives, and phase-change materials, tends to accelerate under high-power, high-temperature, and repeated thermal cycling conditions. This can lead to drying, cracking, or delamination at material interfaces, resulting in reduced heat transfer efficiency and the formation of local hotspots. Over years of operation, such aging effects may cause the initial thermal safety margins to erode, potentially making previously safe designs inadequate for long-term reliability. These risks highlight the importance of robust material selection, regular maintenance, and life-cycle assessment as power levels continue to rise.

5.3. Shielding Material

The purpose of shielding in the magnetic coupler of WEVC systems is to ensure user and environmental safety by confining stray electromagnetic fields and minimizing electromagnetic interference (EMI) beyond the designated power transfer region. Effective shielding is essential not only to comply with international standards such as the ICNIRP guidelines but also to mitigate risks such as inadvertent human exposure and interference with in-vehicle electronics. The safety performance of a WEVC coupler is closely tied to the material properties of its shielding: magnetic permeability and electrical conductivity both influence the shield’s ability to suppress leakage fields and withstand operational stresses at high power and frequency.

Recent progress in shielding materials for WEVC couplers can be broadly categorized into four main types, as summarized in Table 1. Metallic shields, typically made from aluminum or copper in the form of plates, rings, or mesh, are widely adopted for their high conductivity and strong eddy current shielding effect. These metallic structures are simple and robust, but they can suffer from significant losses and heating at high frequencies, especially under high-power operation [137,138,139,140,141]. For instance, Ref. [137] provides a systematic review of aluminum shielding in wireless charging systems, highlighting that aluminum sheets can effectively suppress high-frequency electromagnetic leakage, but the shield’s thickness and conductivity significantly influence both losses and weight. Experimental results in [139] demonstrate that in a 7 kW system, replacing a conventional aluminum shield with a hybrid structure (aluminum plate plus copper ring) reduced shield loss by 21% while maintaining EMF below ICNIRP limits; specifically, the shield resistance was reduced from 85 mΩ (aluminum ring) to 48 mΩ (copper ring) without compromising shielding effectiveness.

Table 1.

Shielding materials and technologies for WEVC couplers.

Ferrite-based shields, either in the form of bars or plates, are valued for their high permeability and low core loss at WEVC operating frequencies, providing efficient magnetic flux guidance and low leakage. However, they are better combined with metals, viz., dual-layer shields [142,143,144,145,146,147]. In [142], various ferrite arrangements are compared, showing that increasing the width of ferrite bars at the coil corners can raise the coupling coefficient to 0.293 (an approximate 17% increase over conventional bar arrangements) while significantly reducing total losses compared to a solid ferrite plate. However, from a shielding perspective, the use of ferrite bars exposes the aluminum plate more directly to the magnetic field, which necessitates a more complex and bulky aluminum shield to achieve the same level of electromagnetic containment. The quantitative study in [144] investigates high-power (50 kW) systems and reveals that for circular pads, aluminum shielding minimizes magnetic leakage, while for double-D pads, ferrite shielding is superior. Finite element analysis indicates that the size of the Rx coil has a much greater impact on leakage field than the Tx coil, and large ferrite shields can keep leakage under the 15 μT safety threshold even under significant misalignment.

Composite and multilayer shields, which combine ferrites, nanocrystalline ribbons, and metallic foils, offer significant weight reduction and reduced cost while maintaining strong shielding performance. The integration of nanocrystalline materials can further increase saturation flux density and reduce core volume [148,149,150,151]. For example, Ref. [149] compares four coupler types (no shield, conventional ferrite, optimized ferrite, and ferrite plus alnico) in a 100 mm air gap. Results show that the conventional ferrite design significantly increases the coupling coefficient but also raises magnetic flux density, necessitating shield optimization for EMI safety. In [151], a ferrite–nanocrystalline hybrid shield in a low-power MCRWPT system raises transmission efficiency from 40.38% (no shield) to 69.17%, while reducing shielding weight by 63.1% compared to full ferrite shielding. The hybrid approach delivers leakage suppression nearly as effective as full ferrite, but at lower cost and weight, achieving an optimal trade-off for large-scale deployment.

Cancel coil shields represent another promising approach: by arranging shorted Litz-wire loops, passive windings, or reverse loops at the shield’s outer boundary, these designs generate local canceling magnetic fields that suppress EMF emission while minimizing shield losses. This method is especially attractive for light-weight, flexible, or high-frequency applications [118,146,152,153]. However, the ability to cancel magnetic fields might be insufficient once the power level reaches up to tens of kilowatts. In [118], an MHz-range high-frequency self-resonant coil system utilizes an integrated ferrite–aluminum–PTFE layered shield. By optimizing ferrite and PTFE thickness, the system achieves 92.3% DC-DC efficiency and a volumetric power density of 7.1 kW/dm3 in a 6.6 kW demonstrator, with shielded coil pad thicknesses of only 11.4 mm (transmitter) and 7.4 mm (receiver). In [153], a ferrite-less, shorted Litz-wire shield is proposed and benchmarked against traditional aluminum + ferrite and aluminum-only shields. At 100 W and 86.9 kHz, the Litz-wire design attains 77.76% efficiency—higher than aluminum-only (73.66%) and comparable to aluminum + ferrite (77.25%)—while being 40% lighter than ferrite-based designs. The Litz-wire shield reduces EMF leakage by approximately 75% in both vertical and lateral directions and is particularly suitable for weight- and flexibility-critical applications such as UAVs and wearable devices.

In summary, the selection and optimization of shielding material and structure are crucial for the electromagnetic safety of WEVC couplers. As system power increases, so do the challenges of effective shielding, thermal management, and maintaining system reliability. Advanced shield designs—employing composite materials, optimized geometries, and innovative cancel coil arrangements—are essential for enabling safe, efficient, and reliable operation in next-generation high-power WEVC systems.

6. Active Safety Management Technologies

6.1. Foreign Object Detection

Foreign object detection (FOD) constitutes a critical component of active safety management in WEVC systems, particularly as charging power levels and system complexity continue to escalate. The primary objective of FOD is to identify and address safety risks posed by conductive or magnetic FOs such as coins, bolts, tools, or metallic debris that may inadvertently enter the charging zone. Over the past decade, diverse FOD methodologies have emerged, which can be broadly categorized into three groups: physical sensing, self-sensing, and electromagnetic (EM) sensing. As illustrated in Table 2, these approaches exhibit distinct advantages and limitations in terms of cost, reliability, localization capability, and compatibility with high-power applications.

Table 2.

Comparison of FOD methods for WEVC.

Physical sensing techniques primarily rely on external sensors, including infrared thermography, millimeter-wave radar, and cameras, to monitor temperature variations, target reflection characteristics, or visual appearances within the charging area [154]. These systems typically enable FO localization and operate independently of WEVC operating frequencies, theoretically allowing the detection of both metallic and non-metallic objects [18,155,156,157]. Key advantages include intuitive detection mechanisms and strong localization capabilities, coupled with high reliability. However, significant drawbacks include elevated costs, sensitivity to environmental conditions, and the need for complex system integration. While prevalent in safety-critical applications, these limitations hinder widespread adoption in commercial WEVC systems where cost-effectiveness is paramount.

Self-sensing methods utilize the real-time monitoring of system operating parameters—such as the input/output power, coil Q-factor, resonant frequency, phase differences, and harmonic components—to detect FO intrusion [158,159,160,161]. For instance, FO presence typically increases system losses, reduces the Q-factor, and shifts resonant frequencies. These hardware-free solutions offer minimal cost, making them suitable for low-power applications with simple structures, such as smartphone charging under the Qi standard [162]. Fundamental limitations, however, include constrained sensitivity and localization resolution. In high-power WEVC systems, subtle signal variations caused by small FOs often become obscured by primary circuit energy fluctuations and load disturbances, leading to missed detections or false alarms [163]. Additionally, these methods struggle to distinguish between foreign objects, EV misalignment, and load variations.

EM sensing has emerged as the dominant FOD strategy for high-power WEVC systems in recent years. This approach deploys passive or active sensing coils near primary power transfer coils to detect voltage or impedance changes caused by electromagnetic field disturbances from foreign objects [164,165,166,167]. Modern EM sensing architectures incorporate innovations such as multi-coil arrays, non-overlapping/symmetric topologies, and signal decoupling with vector decomposition, significantly improving blind zone coverage, misalignment tolerance, and localization resolution [168,169,170,171,172,173,174]. Compared to alternatives, EM sensing balances moderate cost, high reliability, strong compatibility with high-frequency/high-power operation, and FO localization capabilities. Detection targets can now be as small as a paperclip, with the corresponding voltage change exceeding 150 mV in a stable and repeatable manner, which is more than sufficient for reliable FOD operation. Nevertheless, performance remains highly dependent on coil design and calibration, while requiring sophisticated signal processing algorithms to differentiate FO signals from system noise and alignment-related interference.

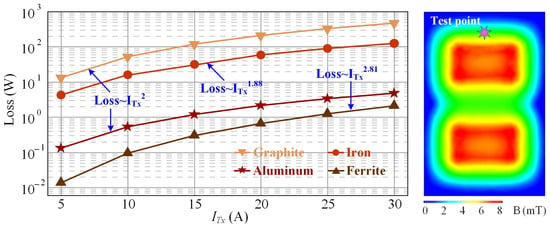

Contemporary research emphasizes that FOD systems should prioritize risk assessment over binary detection, focusing on whether an FO poses sufficient thermal hazard rather than merely confirming its presence. Experimental and simulation studies demonstrate substantial variations in power dissipation and temperature rise depending on FO material composition, dimensions, and spatial positioning, as reflected in Figure 5 [93]. Physical testing alone cannot comprehensively address all risk scenarios, driving the adoption of high-fidelity simulations and digital twin technologies to predict and quantify thermal risks under diverse FO intrusion conditions. Furthermore, systematic definitions of FO parameters—including material types (metallic vs. non-metallic, magnetic vs. non-magnetic), geometric configurations, and multi-object interactions—remain critical for practical FOD implementation [93].

Figure 5.

Loss of a can-shaped FO versus current in Tx coils located in DD coils.

State-of-the-art EM sensing systems now achieve blind zone elimination, high-precision localization, and robust detection against severe vehicle misalignment. However, three major challenges persist: firstly, enhancing detection coverage and risk discrimination accuracy for multi-material/multi-morphology FOs without increasing system complexity or cost; secondly, establishing standardized simulation and experimental protocols for systematic FO risk assessment to guide FOD parameter optimization and response strategies; and thirdly, achieving the deep integration of FOD systems with real-time thermal monitoring, autonomous charging management, and adaptive control to form closed-loop safety architectures encompassing detection–assessment–response cycles.

EM sensing currently represents the most viable FOD solution for high-power WEVC applications, which effectively balances cost, reliability, and multifunctional capabilities. Future development should focus on EM-based architectures enhanced by refined risk modeling and multi-source data fusion, transitioning from pure FOD toward risk-centric active safety management frameworks. Key implementation priorities might include the co-design of sensing coils and power transfer systems to minimize interference, development of machine learning algorithms for FO recognition under dynamic operating conditions, and international standardization of FO risk classification and testing methodologies. This evolution will require close collaboration between academic researchers, automotive engineers, and regulatory bodies to ensure the safe deployment of next-generation wireless charging infrastructure.

6.2. Live Body Detection

Live body detection (LBD) technologies aim to identify the presence of humans or animals before or during their intrusion into the hazardous charging region, thereby enabling rapid intervention and risk mitigation. As summarized in Table 3, current LBD methods can be broadly categorized into (i) sensor-based detection and (ii) capacitive detection approaches, with several further subdivisions.

Table 3.

Comparison of LBD methods for WEVC.

Sensor-based LBD methods encompass millimeter-wave radar, passive infrared (PIR) sensors, ultrasonic sensors, and thermal imaging. Millimeter-wave radar systems exploit Doppler and range information to distinguish moving living objects by analyzing their motion states through advanced signal processing (e.g., 2D-FFT), enabling both detection and classification prior to entry into the charging area [175,176]. These systems offer high reliability, robust performance under adverse environmental conditions, and real-time operation but come with relatively high cost and integration complexity. PIR and ultrasonic sensors, widely used in mobile rescue robots and surveillance systems, detect body heat and motion, respectively, and can trigger alarms or activate cameras when motion is detected [177,178,179,180]. While they are cost-effective and easy to deploy, their detection coverage is limited, and they may suffer from false positives or reduced accuracy in cluttered or outdoor environments. Thermal imaging, sometimes combined with deep learning for object recognition, can effectively distinguish living bodies from non-threatening objects such as plastics or cardboard [181]. However, these systems require significant computational resources and are sensitive to ambient temperature variations.

Capacitive-based LBD methods employ comb-shaped or multi-comb capacitor structures to sense changes in the local dielectric environment above the charging pad [182,183]. When a living object approaches, the effective capacitance changes due to the high permittivity of biological tissue, and this is detected through variations in differential output voltage or resonant circuit behavior. These methods can be cost-effective and readily integrated with existing coil structures, but their detection range is often limited to the immediate vicinity of the charging pad, making pre-entry detection challenging. Recent advances such as symmetrical but structurally different comb capacitor arrays and self-resonant detection coils have improved sensitivity and allowed for real-time discrimination between living and metal objects, even under high-power operation and significant coil misalignment [183,184]. Importantly, capacitive methods are generally immune to electromagnetic interference from 85 kHz WPT operation, which is critical for high-power WEVC environments.

As shown in Table 3, sensor-based approaches generally offer superior pre-entry detection capability and adaptability to complex environments but at higher system cost and integration effort. In contrast, capacitive methods, while more cost-effective and easier to integrate, are typically limited to detection within or very near the charging region. For high-power WEVC, where early intervention is crucial, the integration of millimeter-wave radar or advanced sensor fusion may be necessary to achieve the desired safety level.

6.3. Misalignment Detection

Effective misalignment detection is essential for WEVC safety and efficiency, as misalignment between Tx and Rx coils can significantly reduce efficiency and introduce thermal and electromagnetic hazards [185,186]. Misalignment typically includes lateral and longitudinal offsets as well as yaw angle, as illustrated in Figure 6. To address this issue, various detection methods have been developed, which can be classified into five main categories: GPS-based, camera-based, RFID/UWB-based, magnetic sensor-based, and detection coil-based. Table 4 provides a comparative overview of these approaches in terms of cost, reliability, precision, ability to detect multi-type misalignment, and integration potential with EV sensors.

Figure 6.

Misalignments between Tx and Rx coils.

Table 4.

Comparison of misalignment detection methods for WEVC.

GPS-based methods use satellite positioning to estimate the vehicle’s location relative to the charging pad. They are low in cost and easy to integrate with existing EV systems, but their precision is poor (≥10 cm), limited to horizontal offsets, and susceptible to environmental signal strength [187]. Camera-based approaches detect visual cues or parking lines, achieving cm-level precision and strong integration potential with ADAS, though their reliability is affected by lighting and occlusion [188]. RFID/UWB-based methods use tag-reader triangulation, offering cm-level precision and moderate integration, but come with higher cost and can suffer from electromagnetic interference [189,190].

Magnetic sensor-based methods (e.g., GMR or Hall sensors) directly sense the magnetic field distribution, providing high reliability and good precision (cm-level), but with limited integration in standard EV sensor suites [191,192]. Detection coil-based methods represent the state of the art: by measuring induced voltages in auxiliary coils around the Rx coil, these systems can simultaneously detect lateral, longitudinal, and yaw misalignments with excellent precision (≤2 cm/1.5°) and high reliability [185,193]. Advanced, data-driven strategies such as ACPR-ResNet further improve performance, achieving 95.2% accuracy for horizontal misalignment and 91.7% for yaw angle [185].

As summarized in Table 4, only magnetic sensor- and detection coil-based methods fundamentally address the core technical requirement in WEVC: aligning the magnetic center of the coils. Due to manufacturing and winding tolerances, the magnetic center may not perfectly coincide with the geometric center [185]. Thus, only these magnetic field-based methods, which directly sense the magnetic coupling, can ensure that alignment targets the true energy transfer path, making them the most technically appropriate for WEVC safety. In contrast, GPS, camera, and RFID/UWB approaches are generally limited to geometric alignment and might be less reliable for true coupling optimization. Future work should explore hybrid approaches to leverage the strengths of magnetic field-based detection with EV sensors used in autonomous driving.

6.4. Multifunctional Detection

As WEVC systems advance toward higher power levels and stricter safety requirements, multifunctional detection schemes that integrate FOD, LBD, and misalignment detection into a unified architecture are attracting increasing attention. Multifunctional detection methods can generally be classified into three categories: sensor fusion approaches, hybrid detector arrays, and vision-based or AI-enhanced solutions.

Sensor fusion approaches combine signals from different physical principles, such as magnetic, electric, and ultrasonic sensors, to achieve comprehensive risk coverage. For example, recent studies have demonstrated systems that monitor impedance changes for metal detection and capacitive or ultrasonic signals for LBD, often using a shared processing platform [194,195]. This design reduces hardware redundancy and improves detection robustness under harsh or varying environmental conditions. Although the initial integration cost may be elevated, sharing analog front-ends and signal processing units significantly reduces system complexity and long-term maintenance costs [195,196]. These systems often utilize simple PCB-based sensors, making them cost-effective for integration or retrofitting, but direct integration with existing EV sensors for autonomous driving remains limited due to the differences in sensing modalities.

Hybrid detector arrays, as proposed in [195], integrate both inductive coils and capacitive plates into a single PCB to detect metal and living objects within the same physical unit. With an adaptive excitation and detection algorithm, these arrays operate as simplified impedance analyzers, distinguishing metal from living objects based on their impact on the LC network of the sensing unit. This approach results in lower system complexity, since only one sensing unit and one signal processing chain are needed for both FOD and LBD, which lowers costs and enhances sensitivity, especially for weak signals at detection boundaries or blind spots. However, performance may decrease for very small objects or those at the periphery of the detection area, so multi-frequency excitation is often employed to address these limitations.

Vision-based and AI-enhanced multifunctional detection solutions are gaining popularity, particularly those utilizing real-time thermal imaging and deep learning. For instance, a system employing a single thermal camera and a convolutional autoencoder can simultaneously detect metallic and living objects by their thermal signatures, regardless of material [156]. AI-based systems can adapt to new object types through software updates rather than hardware changes, and although the initial hardware cost might be higher, the reduced sensor count and versatility can deliver substantial long-term cost and reliability benefits. Importantly, this method aligns well with the sensor suites already present in autonomous vehicles, which frequently include thermal or visual cameras for perception, allowing for more seamless integration and additional cost savings [156,197]. The development of multifunctional detection thus reflects an evolution from physically diverse sensor fusion and hybrid arrays toward flexible, software-defined solutions that leverage shared hardware platforms and intelligent algorithms.

7. Future Perspectives

As WEVC technology moves into the era of high-power and high-frequency operation, the increase in power levels is expected to trigger a rapid wave of technological iteration in safety management. This coming phase will be characterized by the urgent need to develop solutions that are comprehensive, precise, orderly, and reliable. Higher power levels not only intensify existing coupler-level risks but also introduce new, more complex safety challenges. To address these issues, future research should prioritize the development of advanced materials with adaptive or self-healing capabilities for insulation, heat dissipation, and EM shielding, ensuring that material performance remains robust under increasingly demanding operational conditions. The incorporation of nano-engineered composites, phase-change materials, and flexible shielding architectures will likely play a critical role, but their integration into mass production and real-world WEVC systems remains an open challenge that requires systematic, cross-disciplinary validation.

On the active safety management front, the march toward high-power WEVC will accelerate the convergence of multifunctional detection technologies and intelligent system control. As outlined in this review, integrating FOD, LBD, and misalignment detection within unified hardware and software architectures is becoming increasingly feasible and desirable. Future systems will rely on sensor fusion, drawing from electromagnetic, acoustic, thermal, and vision-based sources, all processed by real-time analytics. The growing computational capability in modern EVs, especially those featuring autonomous driving modules, makes it possible to deploy deep learning and edge AI for adaptive and context-aware safety management. These intelligent systems will be capable of identifying a wide range of threats, even under dynamic and unpredictable operating environments. However, the adoption of such advanced safety technologies brings new challenges in cybersecurity and system resilience, particularly as WEVC infrastructure becomes more interconnected and data-driven.

Moreover, the regulatory landscape and standardization efforts will also need to keep pace with this rapid technological evolution. Current standards, such as SAE J2954, provide a baseline but do not yet fully address the complexities of multifunctional detection, interoperability, and fail-safe operation under real-world, high-power conditions. The next generation of standards must be developed through close collaboration among industry, academia, and regulators, with a focus on harmonizing safety requirements and accelerating the translation of technological advances into practice. Conversely, some of the recent international guidelines are already ahead of current research and industrial practice. For example, the 2020 ICNIRP recommendations have introduced stricter limits for electromagnetic field exposure, including more rigorous thresholds for both magnetic field strength and specific absorption rate (SAR). However, these updated limits have not yet been fully addressed in the academic literature or widely implemented in the context of wireless power transfer. Bridging this gap will require more systematic SAR-based assessment, as well as new compliance strategies, to ensure that future research and applications align with the latest safety standards and effectively protect public health.

Another very important direction is the deeper integration of WEVC safety management with broader EV system architectures. Traditionally, the data generated by WEVC systems has been used primarily for operational monitoring and control, but safety management itself is also evolving to become increasingly data-driven. In this context, the intelligence collected and processed by advanced WEVC safety technologies can support not only risk mitigation but also predictive maintenance, operational optimization, and insurance modeling. Ensuring secure, private, and scalable data management will be essential in this context.

Finally, user experience must remain at the forefront of future development. As WEVC might become a routine part of daily mobility, safety systems should operate reliably and transparently, minimizing user intervention and seamlessly adapting to changing environments. Advances in invisible sensing, self-diagnosing materials, and AI-driven predictive analytics are expected to create a new paradigm where safety is actively maintained in the background, enabling users to benefit from a secure and convenient charging experience without extra burden.

Despite these promising directions, several practical constraints must be acknowledged. The high cost of magnetic materials and intelligent sensing hardware remains a significant barrier to the large-scale deployment of WEVC systems, especially in the EV charging market. Given that WEVC systems naturally require more components than conductive charging systems, the overall cost is typically higher. However, rather than viewing wireless and conductive charging as competitors, it is more constructive to recognize that charging infrastructure is a broad ecosystem and WEVC can play a valuable role within it, even if it does not become the dominant solution. Moreover, the regulatory and certification processes for new safety technologies in WEVC have already proven to be lengthy and often lag behind technological advances, which has delayed real-world adoption. Field deployments may also encounter unforeseen challenges, such as electromagnetic compatibility issues, variability in installation environments, and maintenance difficulties, which can lead to performance degradation or system failures.

In summary, only by advancing comprehensively, precisely, in an orderly manner, and with strong reliability can the industry keep pace with this evolution and ensure the safe, large-scale adoption of WEVC for the future of electric transportation.

8. Conclusions

This review has systematically explored the landscape of safety management technologies for WEVC, with particular emphasis on the complex risks arising at the coupler level considering the trend of high-power operation. We analyzed electrical, thermal, and magnetic hazards and evaluated both passive and active safety solutions, highlighting the growing importance of multifunctional detection strategies that combine FOD, LBD, and misalignment monitoring within integrated, intelligent systems. As WEVC advances toward higher power and broader deployment, it is clear that a rapid period of technological iteration is underway, requiring the field to innovate with comprehensive coverage, precision, order, and reliability. Success in this new phase will depend on coordinated advances in materials, sensor integration, AI-powered analytics, and the evolution of regulatory standards. By meeting these challenges, the industry can provide safe, reliable, and user-friendly WEVC solutions that support the widespread electrification and automation of transportation.

Author Contributions

Conceptualization, S.N. and L.J.; investigation, Q.J. and Y.H.; writing—original draft preparation, S.N., Q.J. and Y.H.; writing—review and editing, C.Y. and L.J.; visualization, S.N. and Q.J.; supervision, L.J. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the Jiangyin-SUSTech Joint Research Grant under Project OR2404021.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Li, D.; Leung, M.-F.; Tang, J.; Wang, Y.; Hu, J.; Wang, S. Generative Self-Supervised Learning for Cyberattack-Resilient EV Charging Demand Forecasting. IEEE Trans. Intell. Transp. Syst. 2025, 1–10. [Google Scholar] [CrossRef]

- Jamil, U.; Alva, R.J.; Ahmed, S.; Jin, Y.-F. Artificial intelligence-driven optimal charging strategy for electric vehicles and impacts on electric power grid. Electronics 2025, 14, 1471. [Google Scholar] [CrossRef]

- Jia, C.; He, H.; Zhou, J.; Li, J.; Wei, Z.; Li, K. A novel health-aware deep reinforcement learning energy management for fuel cell bus incorporating offline high-quality experience. Energy 2023, 282, 128928. [Google Scholar] [CrossRef]

- Zhang, C.; Niu, S.; Jian, L. Vehicle position measurement and misalignment-effect-eliminated metal object detection for wireless EV charging system: A dual-purpose design of sensing coils. In Proceedings of the 2021 IEEE 5th Conference on Energy Internet and Energy System Integration (EI2), Guangzhou, China, 27–29 October 2020; pp. 591–596. [Google Scholar]

- Phan, D.; Bab-Hadiashar, A.; Fayyazi, M.; Hoseinnezhad, R.; Jazar, R.N.; Khayyam, H. Interval type 2 fuzzy logic control for energy management of hybrid electric autonomous vehicles. IEEE Trans. Intell. Veh. 2021, 6, 210–220. [Google Scholar] [CrossRef]

- Niu, S.; Xu, H.; Sun, Z.; Shao, Z.; Jian, L. The state-of-the-arts of wireless electric vehicle charging via magnetic resonance: Principles, standards and core technologies. Renew. Sustain. Energy Rev. 2019, 114, 109302. [Google Scholar] [CrossRef]

- Niu, S.; Lyu, R.; Lyu, J.; Chau, K.T.; Liu, W.; Jian, L. Optimal resonant condition for maximum output power in tightly coupled WPT systems considering harmonics. IEEE Trans. Power Electron. 2025, 40, 152–156. [Google Scholar] [CrossRef]

- Yang, C.; Song, B.; Xie, Y.; Tang, X. Online Parallel estimation of mechanical parameters for PMSM drives via a network of interconnected extended sliding-mode observers. IEEE Trans. Power Electron. 2021, 36, 11818–11834. [Google Scholar] [CrossRef]

- Alvarez, S. Tesla Robotaxi Cybercab Wireless Charging Speed Teased. Available online: https://www.teslarati.com/tesla-robotaxi-cybercab-wireless-charging-speed-teased/ (accessed on 25 April 2025).

- Li, S.; Xia, K.; Li, T.; Lu, S.; Xia, J.; Liu, Z. A novel comb-shaped coupler for hybrid inductive and capacitive wireless power transfer system. IEEE Trans. Power Electron. 2025, 40, 4787–4792. [Google Scholar] [CrossRef]

- Niu, S.; Zhao, Q.; Chen, H.; Yu, H.; Niu, S.; Jian, L. Underwater wireless charging system of unmanned surface vehicles with high power, large misalignment tolerance and light weight: Analysis, design and optimization. Energies 2022, 15, 9529. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, F.; Liu, H. Indirect control strategy of secondary charging voltage and current and transient analysis of LCC-S WPT system. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 2364–2376. [Google Scholar] [CrossRef]

- Niu, S.; Yu, H.; Jian, L. Thermal behavior analysis of wireless electric vehicle charging system under various misalignment conditions. In Proceedings of the 2020 IEEE 4th Conference on Energy Internet and Energy System Integration (EI2), Wuhan, China, 30 October–1 November 2020; pp. 607–612. [Google Scholar]

- Yang, C.; Song, B.; Xie, Y.; Lu, S.; Tang, X. Stable simultaneous inertia and disturbance torque identification for SPMSM drive systems subject to mismatched rotor flux linkage. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 2445–2462. [Google Scholar] [CrossRef]

- Kim, S.; Amirpour, M.; Dharmakeerthi, T.; Barsari, V.Z.; Covic, G.; Bickerton, S.; Thrimawithana, D. Thermal Evaluation of an Inductive Power Transfer Pad for Charging Electric Vehicles. IEEE Trans. Ind. Electron. 2022, 69, 314–322. [Google Scholar] [CrossRef]

- Tiemann, M.; Saifo, M.; Clemens, M.; Schmuelling, B. Magnetic and thermal coupled field analysis of wireless charging systems for electric vehicles. IEEE Trans. Magn. 2019, 55, 1–4. [Google Scholar] [CrossRef]

- Rasekh, N.; Dabiri, S.; Rasekh, N.; Mirsalim, M.; Bahiraei, M. Thermal analysis and electromagnetic characteristics of three single-sided flux pads for wireless power transfer. J. Clean. Prod. 2020, 243, 118561. [Google Scholar] [CrossRef]

- Tian, Y.; Li, Z.; Lin, Y.; Xiang, L.; Li, X.; Shao, Y.; Tian, J. Metal object detection for electric vehicle inductive power transfer systems based on hyperspectral imaging. Measurement 2021, 168, 108493. [Google Scholar] [CrossRef]

- Pries, J.; Galigekere, V.P.; Onar, O.C.; Su, G.-J.; Wiles, R.; Seiber, L.; Wilkins, J.; Anwar, S.; Zou, S. Coil Power Density Optimization and Trade-off Study for a 100 kW Electric Vehicle IPT Wireless Charging System. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; pp. 1196–1201. [Google Scholar]

- Ideanomics. “First Planned Deployment of 500kW Inductive Charger to Power Electric Trucks in Cold Climates,” GlobeNewswire News Room, 16 January 2024. Available online: https://www.globenewswire.com/news-release/2024/01/16/2809713/0/en/First-Planned-Deployment-of-500kW-Inductive-Charger-to-Power-Electric-Trucks-in-Cold-Climates.html (accessed on 25 April 2025).

- Yang, C.; Song, B.; Xie, Y.; Zheng, S.; Tang, X. Adaptive identification of nonlinear friction and load torque for PMSM drives via a parallel-observer-based network with model compensation. IEEE Trans. Power Electron. 2023, 38, 5875–5897. [Google Scholar] [CrossRef]

- Mahesh, A.; Chokkalingam, B.; Mihet-Popa, L. Inductive wireless power transfer charging for electric vehicles–a review. IEEE Access 2021, 9, 137667–137713. [Google Scholar] [CrossRef]

- Amjad, M.; Farooq-i-Azam, M.; Ni, Q.; Dong, M.; Ansari, E.A. Wireless charging systems for electric vehicles. Renew. Sustain. Energy Rev. 2022, 167, 112730. [Google Scholar] [CrossRef]

- Tan, Z.; Liu, F.; Chan, H.K.; Gao, H.O. Transportation systems management considering dynamic wireless charging electric vehicles: Review and prospects. Transp. Res. Part E Logist. Transp. Rev. 2022, 163, 102761. [Google Scholar] [CrossRef]

- Ramakrishnan, V.; Savio, D.A.; Balaji, C.; Rajamanickam, N.; Kotb, H.; Elrashidi, A.; Nureldeen, W. A comprehensive review on efficiency enhancement of wireless charging system for the electric vehicles applications. IEEE Access 2024, 12, 46967–46994. [Google Scholar] [CrossRef]

- Tenllado, I.C.; Cabrera, A.T.; Lin, Z. Simultaneous wireless power and data transfer for electric vehicle charging: A review. IEEE Trans. Transp. Electrif. 2024, 10, 4542–4570. [Google Scholar] [CrossRef]

- Sagar, A.; Kashyap, A.; Azimi Nasab, M.; Padmanaban, S.; Bertoluzzo, M.; Kumar, A.; Blaabjerg, F. A comprehensive review of the recent development of wireless power transfer technologies for electric vehicle charging systems. IEEE Access 2023, 11, 83703–83751. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Zhao, Q.; Niu, S.; Shao, Z.; Jian, L. Hull-compatible underwater IPT system with enhanced electromagnetic–thermal performance for USVs. Energies 2025, 18, 237. [Google Scholar] [CrossRef]

- Liu, W.; Chau, K.T.; Lee, C.H.T.; Han, W.; Tian, X.; Lam, W.H. Full-range soft-switching pulse frequency modulated wireless power transfer. IEEE Trans. Power Electron. 2020, 35, 6533–6547. [Google Scholar] [CrossRef]

- Zhu, Q.; Han, H.; Su, M.; Hu, A.P. A 3D wireless charging cube with externally enhanced magnetic field for extended range of wireless power transfer. Wirel. Power Transf. 2019, 6, 67–76. [Google Scholar] [CrossRef]

- Jia, C.; Zhou, J.; He, H.; Li, J.; Wei, Z.; Li, K.; Shi, M. A novel energy management strategy for hybrid electric bus with fuel cell health and battery thermal-and health-constrained awareness. Energy 2023, 271, 127105. [Google Scholar] [CrossRef]

- Xiong, R.; Yang, R.; Chen, Z.; Shen, W.; Sun, F. Online fault diagnosis of external short circuit for lithium-ion battery pack. IEEE Trans. Ind. Electron. 2020, 67, 1081–1091. [Google Scholar] [CrossRef]

- Filipova-Petrakieva, S.K.; Shopov, Y.M. Overvoltages protection in electrical devices and transient analysis by Duhamel’s principle. In Proceedings of the 2019 11th Electrical Engineering Faculty Conference (BulEF), Varna, Bulgaria, 11–14 September 2019; pp. 1–6. [Google Scholar]

- Pozo, N.; Prócel, L.-M.; Trojman, L. All-GaN integrated overcurrent protection circuit using only enhancement-mode p-GaN devices. In Proceedings of the 2024 37th SBC/SBMicro/IEEE Symposium on Integrated Circuits and Systems Design (SBCCI), Joao Pessoa, Brazil, 2–6 September 2024; pp. 1–5. [Google Scholar]

- Zhang, K.; Wang, Z.; Wang, T.; Du, Z.; Xiao, F.; Yang, H.; Tang, A. Optimal connecting nodes planning based on the risk assessment of power systems. In Proceedings of the 2020 IEEE 4th Conference on Energy Internet and Energy System Integration (EI2), Wuhan, China, 30 October–1 November 2020; pp. 1796–1800. [Google Scholar]

- Niu, S.; Yu, H.; Niu, S.; Jian, L. Power loss analysis and thermal assessment on wireless electric vehicle charging technology: The over-temperature risk of ground assembly needs attention. Appl. Energy 2020, 275, 115344. [Google Scholar] [CrossRef]

- Mou, W.; Lu, M. Safety assessment of wireless chargers for electric vehicles considering thermal characteristics. Radiat. Prot. Dosim. 2023, 200, 187–200. [Google Scholar] [CrossRef]

- Aydin, E.; Barua, H.; Aktas, A.; Mohammad, M.; Onar, O.C.; Ozpineci, B. Thermal Analysis of a 100 kW Polyphase Wireless Power Transfer System. In Proceedings of the 2024 IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 25–29 February 2024; pp. 1927–1931. [Google Scholar]

- Jia, C.; He, H.; Zhou, J.; Li, K.; Li, J.; Wei, Z. A performance degradation prediction model for PEMFC based on bi-directional long short-term memory and multi-head self-attention mechanism. Int. J. Hydrogen Energy 2024, 60, 133–146. [Google Scholar] [CrossRef]

- Das, M.; Jeong, S.; Sim, B.; Lee, S.; Hong, S.; Kim, Y.; Kim, J. Study of series-series topology for suppressing electromagnetic interference (EMI) for digital TV wireless power transfer (WPT) systems. In Proceedings of the 2018 IEEE Electrical Design of Advanced Packaging and Systems Symposium (EDAPS), Chandigarh, India, 16–18 December 2018; pp. 1–3. [Google Scholar]

- Okada, R.; Ota, R.; Hoshi, N. Radiated EMI reduction and efficiency improvement in WPT systems with passive auxiliary circuits for soft-switching. In Proceedings of the 2023 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Chiang Mai, Thailand, 28 November–1 December 2023; pp. 1–3. [Google Scholar]

- Rezaei, M.A.; Fathollahi, A.; Akbari, E.; Saki, M.; Khorgami, E.; Teimouri, A.R.; Chronopoulos, A.T.; Mosavi, A. Reliability calculation improvement of electrolytic capacitor banks used in energy storage applications based on internal capacitor faults and degradation. IEEE Access 2024, 12, 13146–13164. [Google Scholar] [CrossRef]

- Cui, S.; Riaz, S.; Wang, K. Study on lifetime decline prediction of Lithium-ion capacitors. Energies 2023, 16, 7557. [Google Scholar] [CrossRef]

- Roy, S.; Hanif, A.; Khan, F. Aging detection and state of health estimation of live power semiconductor devices using SSTDR embedded PWM sequence. IEEE Trans. Power Electron. 2021, 36, 4991–5005. [Google Scholar] [CrossRef]

- Jia, C.; Zhou, J.; He, H.; Li, J.; Wei, Z.; Li, K. Health-conscious deep reinforcement learning energy management for fuel cell buses integrating environmental and look-ahead road information. Energy 2024, 290, 130146. [Google Scholar] [CrossRef]

- Shen, H.; Wang, H.; Li, M.; Li, C.; Zhang, Y.; Li, Y.; Yang, X.; Feng, X.; Ouyang, M. Thermal runaway characteristics and gas composition analysis of lithium-ion batteries with different LFP and NCM cathode materials under inert atmosphere. Electronics 2023, 12, 1603. [Google Scholar] [CrossRef]

- Jia, C.; Liu, W.; He, H.; Chau, K. Deep reinforcement learning-based energy management strategy for fuel cell buses integrating future road information and cabin comfort control. Energy Convers. Manag. 2024, 321, 119032. [Google Scholar] [CrossRef]

- Jia, C.; He, H.; Zhou, J.; Li, J.; Wei, Z.; Li, K. Learning-based model predictive energy management for fuel cell hybrid electric bus with health-aware control. Appl. Energy 2024, 355, 122228. [Google Scholar] [CrossRef]

- SAE J2954; Wireless Power Transfer for Light-Duty Plug-In/Electric Vehicles and Alignment Methodology. SAE International: Warrendale, PA, USA, 2020.

- GB/T 38775; Electric Vehicle Wireless Power Transfer. Standardization Administration of China—SAC: Beijing, China, 2020.

- IEC 61980; Electric Vehicle Wireless Power Transfer Systems. International Electrotechnical Commission—IEC: Geneva, Switzerland, 2020.

- Yang, C.; Song, B.; Xie, Y.; Lu, S.; Tang, X. Speed-controller-independent mechanical parameter identification in SPMSM drive achieved via signal injection. IEEE Trans. Ind. Electron. 2023, 70, 1282–1297. [Google Scholar] [CrossRef]

- Zhang, B.; Carlson, R.B.; Smart, J.G.; Dufek, E.J.; Liaw, B. Challenges of future high power wireless power transfer for light-duty electric vehicles—Technology and risk management. eTransportation 2019, 2, 100012. [Google Scholar] [CrossRef]

- Rayan, B.A.; Subramaniam, U.; Balamurugan, S. Wireless power transfer in electric vehicles: A review on compensation topologies, coil structures, and safety aspects. Energies 2023, 16, 3084. [Google Scholar] [CrossRef]

- Lu, F.; Zhang, H.; Hofmann, H.; Mi, C. A high efficiency 3.3 kW loosely-coupled wireless power transfer system without magnetic material. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015; pp. 2282–2286. [Google Scholar]

- Miller, J.M.; Daga, A. Elements of wireless power transfer essential to high power charging of heavy duty vehicles. IEEE Trans. Transp. Electrific. 2015, 1, 26–39. [Google Scholar] [CrossRef]

- Zeng, H.; Yang, S.; Peng, F.Z. Design consideration and comparison of wireless power transfer via harmonic current for PHEV and EV wireless charging. IEEE Trans. Power Electron. 2017, 32, 5943–5952. [Google Scholar] [CrossRef]

- Bi, Z.; Kan, T.; Mi, C.C.; Zhang, Y.; Zhao, Z.; Keoleian, G.A. A review of wireless power transfer for electric vehicles: Prospects to enhance sustainable mobility. Appl. Energy 2016, 179, 413–425. [Google Scholar] [CrossRef]

- Choi, Y.; Kwak, B.; Kim, M. 4kW magnetic resonance wireless power transfer system. In Proceedings of the 2016 IEEE International Conference on Power System Technology (POWERCON), Wollongong, NSW, Australia, 28 September–1 October 2016; pp. 1–3. [Google Scholar]

- Bojarski, M.; Asa, E.; Colak, K.; Czarkowski, D. A 25 kW industrial prototype wireless electric vehicle charger. In Proceedings of the 2016 IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 20–24 March 2016; pp. 1756–1761. [Google Scholar]

- Bosshard, R. Multi-Objective Optimization of Inductive Power Transfer Systems for EV Charging. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2015. [Google Scholar]

- Dai, Z.; Wang, J.; Long, M.; Huang, H. A witricity-based high-power device for wireless charging of electric vehicles. Energies 2017, 10, 323. [Google Scholar] [CrossRef]

- Mohamed, A.A.S.; An, S.; Mohammed, O. Coil design optimization of power pad in IPT system for electric vehicle applications. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar] [CrossRef]

- Kusaka, K.; Kusui, R.; Itoh, J.; Sato, D.; Obayashi, S.; Ishida, M. A 22 kW-85 kHz three-phase wireless power transfer system with 12 coils. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 3340–3347. [Google Scholar]

- Deng, Q.; Sun, P.; Hu, W.; Czarkowski, D.; Kazimierczuk, M.K.; Zhou, H. Modular parallel multi-inverter system for high-power inductive power transfer. IEEE Trans. Power Electron. 2019, 34, 9422–9434. [Google Scholar] [CrossRef]

- Ji, B.; Hata, K.; Imura, T.; Hori, Y.; Shimada, S.; Kawasaki, O. Wireless power transfer system design with power management strategy control for lunar rover. IEEJ J. Ind. Appl. 2020, 9, 392–400. [Google Scholar] [CrossRef]

- Shi, W.; Dong, J.; Soeiro, T.B.; Riekerk, C.; Grazian, F.; Yu, G.; Bauer, P. Design of a highly efficient 20-kW inductive power transfer system with improved misalignment performance. IEEE Trans. Transp. Electrif. 2022, 8, 2384–2399. [Google Scholar] [CrossRef]

- Ramezani, A.; Narimani, M. A modular coil design for high-power wireless EV charging. In Proceedings of the IEEE Annual Conference of the Industrial Electronics Society (IECON), Toronto, ON, Canada, 13–16 October 2021; pp. 1–5. [Google Scholar]

- Ibrahim, A.U.; Zhong, W.; Xu, M.D. A 50-kW three-channel wireless power transfer system with low stray magnetic field. IEEE Trans. Power Electron. 2021, 36, 9941–9954. [Google Scholar] [CrossRef]

- Lawton, P.A.J.; Lin, F.J.; Covic, G.A. Magnetic design considerations for high-power wireless charging systems. IEEE Trans. Power Electron. 2022, 37, 9972–9982. [Google Scholar] [CrossRef]

- Liu, X.; Chen, G.; Su, D.; Wu, X.; Gong, W.; Ren, F. A 100 kW magnetic coupled wireless power transfer system for electrical vehicles. In Proceedings of the 2022 IEEE 4th International Conference on Power, Intelligent Computing and Systems (ICPICS), Shenyang, China, 14–16 July 2023; pp. 48–52. [Google Scholar]

- Park, J.U.; Oh, J.M.; Bok, Y.H.; Lee, I.O. 22 kW high-efficiency IPT system for wireless charging of electric vehicles. J. Power Electron. 2023, 23, 374–386. [Google Scholar] [CrossRef]

- Subudhi, P.S.; Padmanaban, S.; Blaabjerg, F.; Kothari, D.P. Design and implementation of a PV-fed grid-integrated wireless electric vehicle battery charger present in a residential environment. IEEE J. Emerg. Sel. Topics Ind. Electron. 2023, 4, 78–86. [Google Scholar] [CrossRef]

- Elbracht, L.; Lin, F.J.; Parspour, N.; Covic, G.A.; Patrick, A.J.L. Input voltage range optimization of a high power wireless power transfer system for constant power output. In Proceedings of the 2024 IEEE Wireless Power Technology Conference and Expo (WPTCE), Kyoto, Japan, 8–11 May 2024; pp. 582–587. [Google Scholar]