Review of Research on Ceramic Surface Defect Detection Based on Deep Learning

Abstract

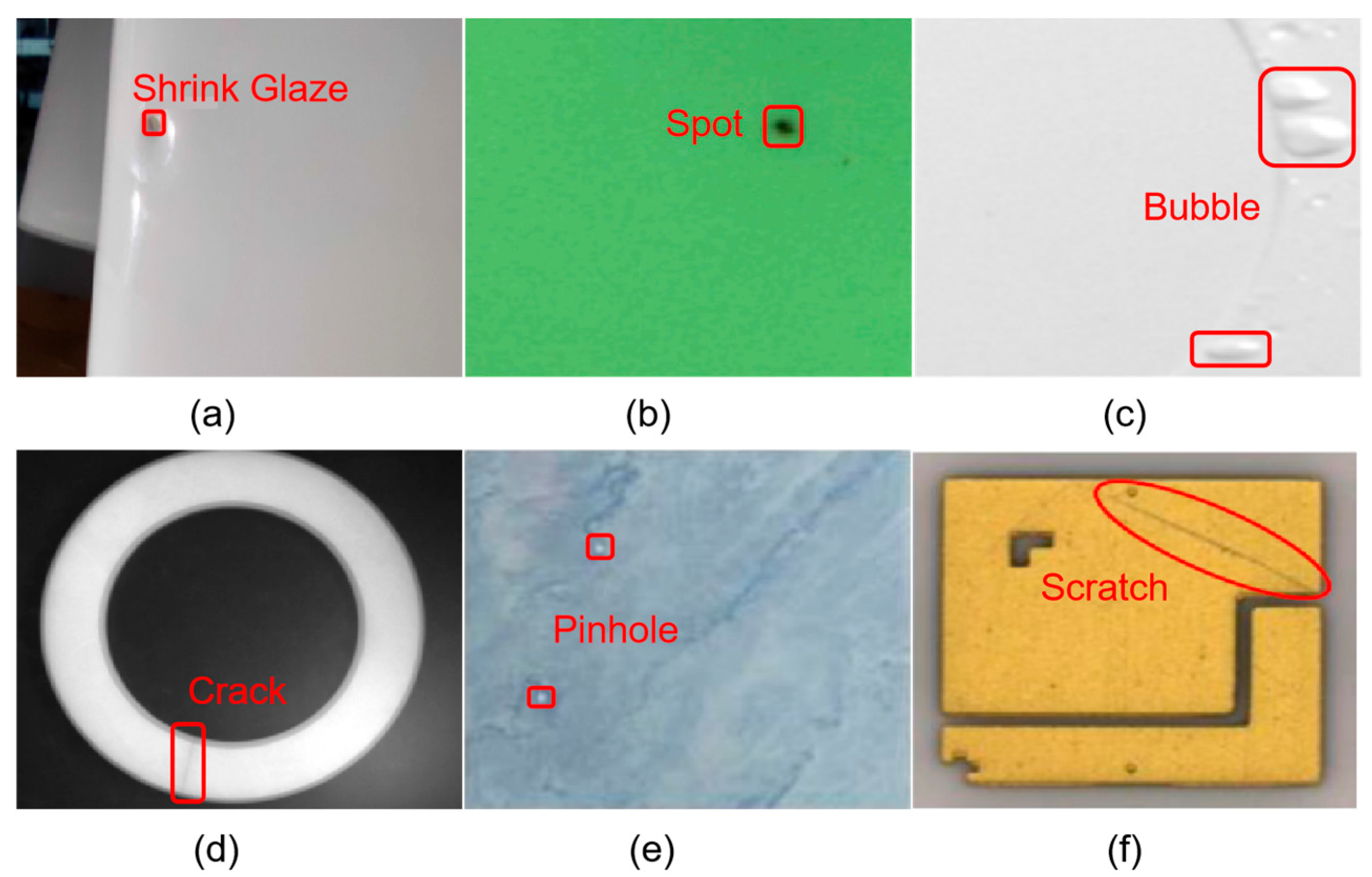

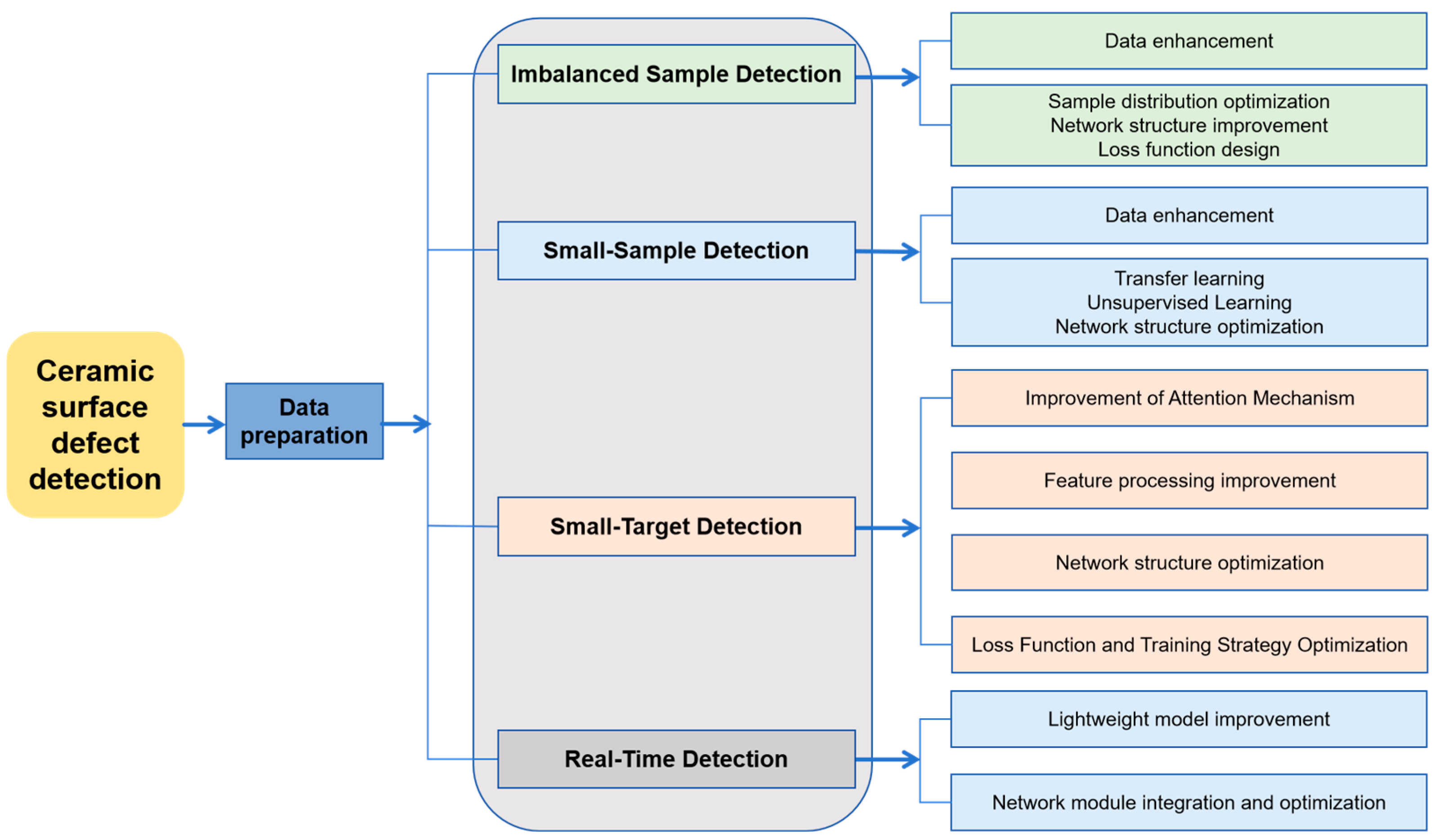

1. Introduction

2. Data Preparation

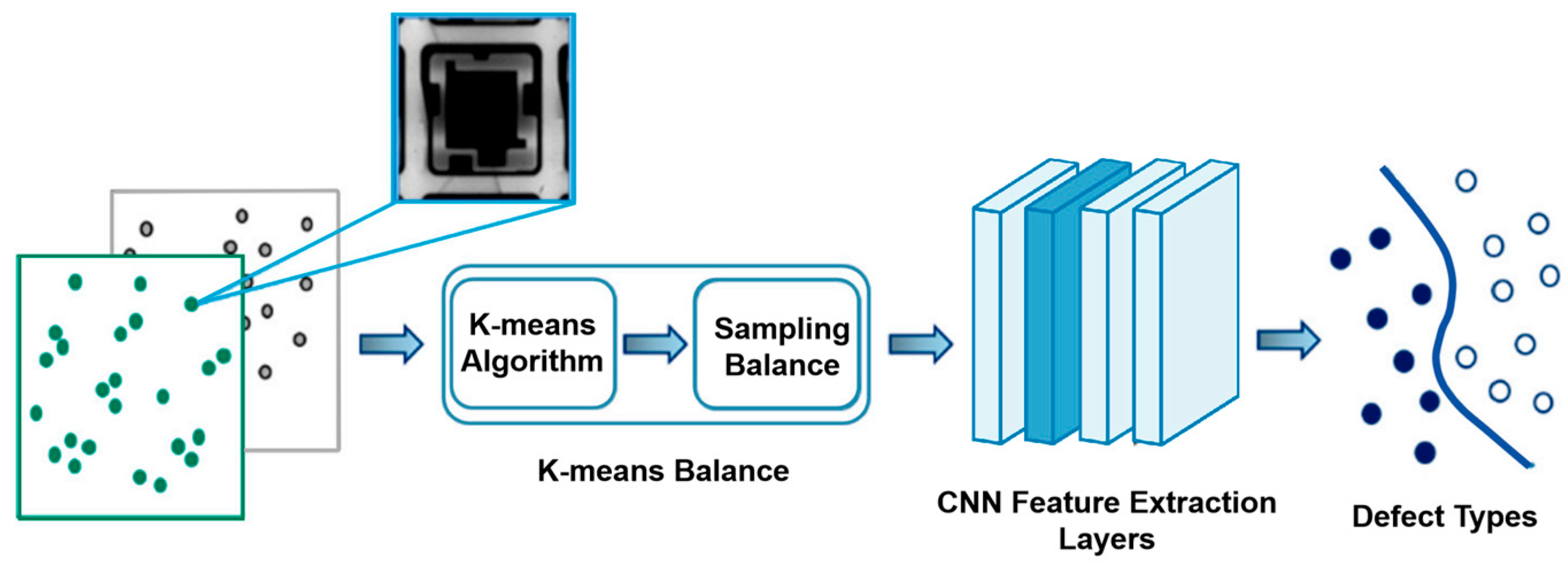

3. Detection Methods for Imbalanced Samples in Ceramic Surface Defects

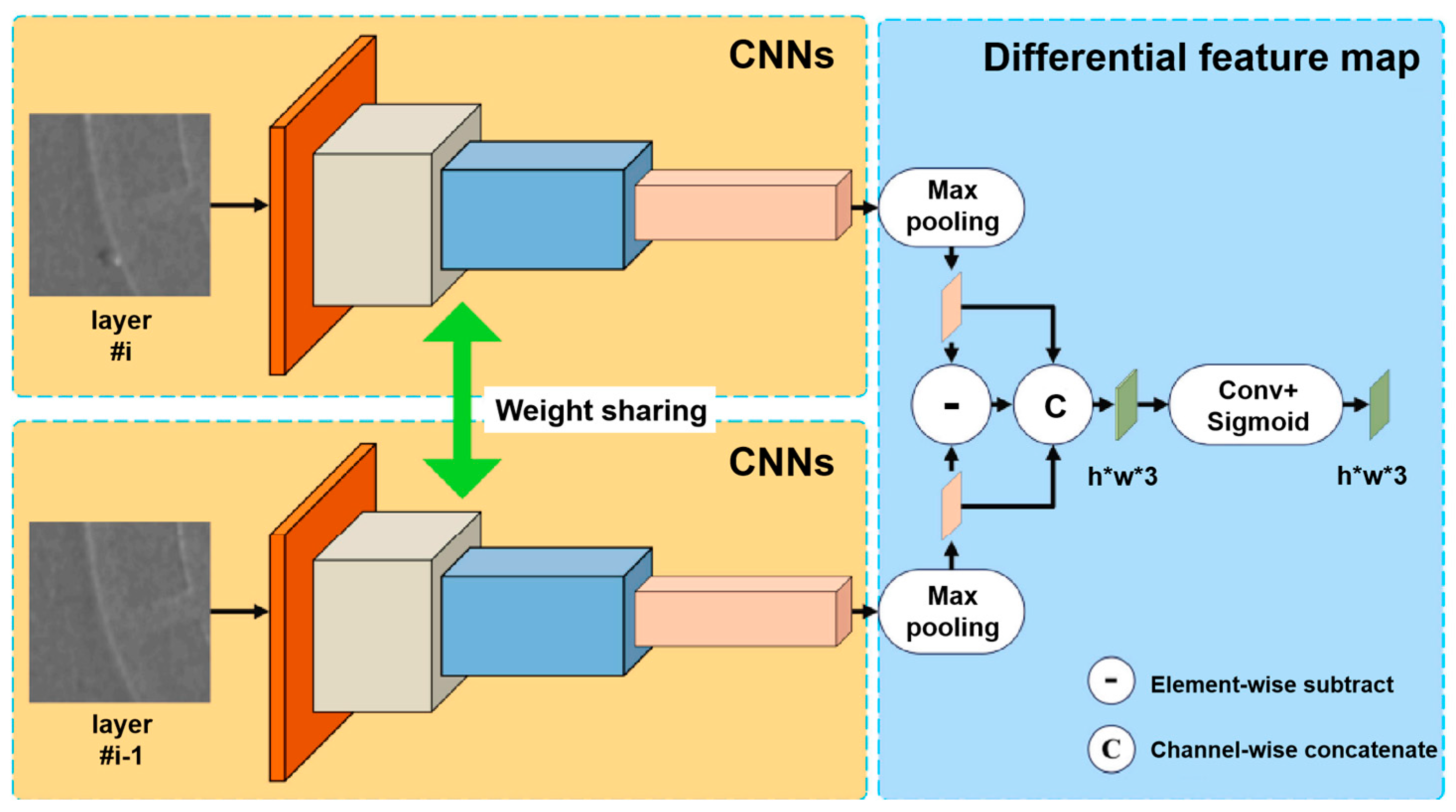

4. Detection Methods for Small Samples in Ceramic Surface Defects

4.1. Data Augmentation Methods

4.2. Methods Based on Transfer Learning, Unsupervised Learning, and Network Structure Optimization

5. Detection Methods for Small Targets in Ceramic Surface Defects

5.1. Network Structure Optimization

5.2. Feature Processing Improvement

5.3. Attention-Mechanism Improvement

5.4. Loss Function and Training Strategy Optimization

6. Real-Time Detection Methods for Ceramic Surface Defects

6.1. Lightweight Model Improvement

6.2. Network Module Integration and Optimization

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Boch, P.; Nièpce, J.-C. Ceramic Materials: Processes, Properties, and Applications; John Wiley & Sons: New York, NY, USA, 2010. [Google Scholar]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Otitoju, T.A.; Okoye, P.U.; Chen, G.; Li, Y.; Okoye, M.O.; Li, S. Advanced ceramic components: Materials, fabrication, and applications. J. Ind. Eng. Chem. 2020, 85, 34–65. [Google Scholar] [CrossRef]

- Singer, F. Industrial Ceramics; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Hang, J.; Sun, H.; Yu, X.; Rodríguez-Andina, J.J.; Yang, X. Surface defect detection in sanitary ceramics based on lightweight object detection network. IEEE Open J. Ind. Electron. Soc. 2022, 3, 473–483. [Google Scholar] [CrossRef]

- Pan, H.; Li, G.; Feng, H.; Li, Q.; Sun, P.; Ye, S. Surface defect detection of ceramic disc based on improved YOLOv5s. Heliyon 2024, 10, e33016. [Google Scholar] [CrossRef]

- Jia, X.; Li, S.; Wang, T.; Liu, B.; Cui, C.; Li, W.; Wang, G. High-Performance Defect Detection Methods for Real-Time Monitoring of Ceramic Additive Manufacturing Process Based on Small-Scale Datasets. Processes 2024, 12, 633. [Google Scholar] [CrossRef]

- Guan, S.; Wang, X.; Wang, J.; Yu, Z.; Wang, X.; Zhang, C.; Zhang, L. Ceramic ring defect detection based on improved YOLOv5. In Proceedings of the 2022 3rd International Conference on Computer Vision, Image and Deep Learning & International Conference on Computer Engineering and Applications (CVIDL & ICCEA), Changchun, China, 20–22 May 2022; IEEE: Washington, DC, USA, 2022; pp. 115–118. [Google Scholar]

- Zhao, Z.Q.; Zheng, P.; Xu, S.T.; Wu, X. Object detection with deep learning: A review. IEEE Trans. Neural Netw. Learn. Systems 2019, 30, 3212–3232. [Google Scholar] [CrossRef]

- Huang, C.Y.; Lin, I.C.; Liu, Y.L. Applying deep learning to Construct a defect detection system for ceramic Substrates. Appl. Sci. 2022, 12, 2269. [Google Scholar] [CrossRef]

- Zheng, X.; Zheng, S.; Kong, Y.; Chen, J. Recent advances in surface defect inspection of industrial products using deep learning techniques. Int. J. Adv. Manuf. Technol. 2021, 113, 35–58. [Google Scholar] [CrossRef]

- Saberironaghi, A.; Ren, J.; El-Gindy, M. Defect detection methods for industrial products using deep learning techniques: A review. Algorithms 2023, 16, 95. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, M.X.; Chen, Y.S.; Ping, E.X.; Fang, Y.; Lv, Y.L.; Gao, Y. Review of surface defect detection methods based on machine vision. Mod. Manuf. Eng. 2023, 4, 143–156. [Google Scholar]

- Birlutiu, A.; Burlacu, A.; Kadar, M.; Onita, D. Defect Detection in porcelain industry based on deep learning techniques. In Proceedings of the 2017 19th International Symposium on Symbolic and Numeric Algorithms for Scientific Computing (SYNASC), Timisoara, Romania, 21–24 September 2017; IEEE: Washington, DC, USA, 2017; pp. 263–270. [Google Scholar]

- Mariyadi, B.; Fitriyani, N.; Sahroni, T.R. 2D detection model of defect on the surface of ceramic tile by an artificial neural network. J. Phys. Conf. Series. 2021, 1764, 012176. [Google Scholar] [CrossRef]

- Dang, D.Z.; Su, B.Y.; Wang, Y.W.; Ao, W.K.; Ni, Y.Q. A pencil lead break-triggered, adversarial autoencoder-based approach for rapid and robust rail damage detection. Eng. Appl. Artif. Intell. 2025, 150, 110637. [Google Scholar] [CrossRef]

- He, S.; Ao, W.K.; Ni, Y.Q. A unified label noise-tolerant framework of deep learning-based fault diagnosis via a bounded neural network. IEEE Trans. Instrum. Meas. 2024, 73, 3513515. [Google Scholar] [CrossRef]

- Alexandropoulos, S.A.N.; Kotsiantis, S.B.; Vrahatis, M.N. Data preprocessing in predictive data mining. Knowl. Eng. Rev. 2019, 34, e1. [Google Scholar] [CrossRef]

- Zelaya, C.V.G. Towards explaining the effects of data preprocessing on machine learning. In Proceedings of the 2019 IEEE 35th International Conference on Data Engineering (ICDE), Macao, China, 8–11 April 2019; IEEE: Washington, DC, USA, 2019; pp. 2086–2090. [Google Scholar]

- Maharana, K.; Mondal, S.; Nemade, B. A review: Data pre-processing and data augmentation techniques. Glob. Transit. Proc. 2022, 3, 91–99. [Google Scholar] [CrossRef]

- Tian, Y.; Zhu, F. Application of Computer Vision Algorithm in Ceramic Surface Texture Analysis and Prediction. Intell. Syst. Appl. 2025, 25, 200482. [Google Scholar] [CrossRef]

- Ghosh, K.; Bellinger, C.; Corizzo, R.; Branco, P.; Krawczyk, B.; Japkowicz, N. The class imbalance problem in deep learning. Mach. Learn. 2024, 113, 4845–4901. [Google Scholar] [CrossRef]

- Huang, Y.P.; Su, C.M.; Basanta, H.; Tsai, Y.L. Imbalance modelling for defect detection in ceramic substrate by using convolutional neural network. Processes 2021, 9, 1678. [Google Scholar] [CrossRef]

- Wu, L.Y. Application of Surface Defect Detection Algorithm for Daily Ceramic Cupsbased on YOLOv8. Master’s Thesis, Jingdezhen Ceramic University, Jingdezhen, China, 2024. [Google Scholar]

- He, Y.; Cai, C.; Chen, G.; Hu, J.; Hu, S.; Fu, J. PFEI-Net: A profound feature exploration and interaction network for ceramic substrate surface defect detection. Expert Syst. Appl. 2025, 263, 125741. [Google Scholar] [CrossRef]

- Carvalho, R.; Morgado, A.C.; Gonçalves, J.; Kumar, A.; Rolo, A.G.E.S.; Carreira, R.; Soares, F. Computer-Aided Visual Inspection of Glass-Coated Tableware Ceramics for Multi-Class Defect Detection. Appl. Sci. 2023, 13, 11708. [Google Scholar] [CrossRef]

- Ye, X.F.; Chen, M.; Li, H.; Cao, Y.; Wang, X.B. Channel and spatial joint attention based defect detection method in complex texture ceramic tile. Appl. Res. Comput. 2024, 41, 944–950. [Google Scholar]

- Cao, T.; Song, K.; Xu, L.; Feng, H.; Yan, Y.; Guo, J. Balanced multi-scale target score network for ceramic tile surface defect detection. Measurement 2024, 224, 113914. [Google Scholar] [CrossRef]

- Bansal, M.A.; Sharma, D.R.; Kathuria, D.M. A systematic review on data scarcity problem in deep learning: Solution and applications. ACM Comput. Surv. 2022, 54 (Suppl. S10), 1–29. [Google Scholar] [CrossRef]

- Cumbajin, E.; Rodrigues, N.; Costa, P.; Miragaia, R.; Frazão, L.; Costa, N.; Pereira, A. A real-time automated defect detection system for ceramic pieces manufacturing process based on computer vision with deep learning. Sensors 2023, 24, 232. [Google Scholar] [CrossRef]

- Niu, J.; Chen, Y.; Yu, X.; Li, Z.; Gao, H. Data Augmentation on Defect Detection of Sanitary Ceramics. In Proceedings of the IECON 2020 the 46th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 18–21 October 2020; IEEE: Washington, DC, USA, 2020; pp. 5317–5322. [Google Scholar]

- Chu, J.L.; Liang, D.; Xi, Y.L.; Ye, M.J. Surface inspection of annular ceramic metal coating based on small sample data augmentation and deep learning. Signal Image Video Process. 2025, 19, 46. [Google Scholar] [CrossRef]

- Wang, J.G.; Sun, F.Z.; Yuan, Z.L.; Sun, D.F. Tile surface defect detection algorithm based on improved Faster RCNN. J. Nanjing Tech. Univ. Nat. Sci. Ed. 2025, 47, 49–55. [Google Scholar]

- Wang, X.; Guan, S.Q.; Liu, T.; Zhang, L.B.; Wang, J.G.; Yu, Z.J. Ceramic Ring Defect Detection Algorithm Based on Improved YOLOv5. Light Ind. Mach. 2023, 41, 66–71. [Google Scholar]

- Tang, S.Z. Research on Surface Defect Detection Algorithm of Metal-Plated Ceramic Filter Based on Machine Vision. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2022. [Google Scholar]

- Zhang, Z.P. Key Technology Research of Ceramic Surface Defect Detection Based on Computer Vision. Master’s Thesis, Yanshan University, Qinhuangdao, China, 2023. [Google Scholar]

- Li, Z.H.; Chen, X.D.; Huang, J.S.; Wu, L.; Lian, Y.Q. Defect Detection of Texture Tile Using Improved YOLOv3. Laser Optoelectron. Prog. 2022, 59, 294–302. [Google Scholar]

- Li, Z.H.; Chen, X.D.; Lian, Y.Q. Surface defect detection of ceramic tiles based on convolutional autoencoder network. Mod. Comput. 2021, 27, 109–114. [Google Scholar]

- Niu, Z.; Zhong, G.; Yu, H. A review on the attention mechanism of deep learning. Neurocomputing 2021, 452, 48–62. [Google Scholar] [CrossRef]

- Teng, B.W. Defect Detection of Sanitary Ceramics Based on Deep Learning. Master’s Thesis, General Institute of Mechanical Science Research, Beijing, China, 2021. [Google Scholar]

- Chen, W.; Zou, B.; Yang, G.; Zheng, Q.; Lei, T.; Huang, C.; Li, L. A real-time detection system for multiscale surface defects of 3D printed ceramic parts based on deep learning. Ceram. Int. 2024, 50, 13101–13112. [Google Scholar] [CrossRef]

- Lei, Z.T.; Zhu, X.L.; Sun, J.; Ma, H.T.; Liang, L.; You, Z.G. YOLOv5 ceramic film defect detection method incorporating coordinate attention and adaptive features. Electron. Meas. Technol. 2023, 46, 133–137. [Google Scholar]

- Ding, W.L.; Zhang, Z.P.; Lei, Z.Q.; Sun, P. Deep learning ceramic surface defect detection algorithm research. J. Electron. Meas. Instrum. 2023, 37, 161–169. [Google Scholar]

- Sun, P.; Hua, C.; Ding, W.; Hua, C.; Liu, P.; Lei, Z. Ceramic tableware surface defect detection based on deep learning. Eng. Appl. Artif. Intell. 2025, 141, 109723. [Google Scholar] [CrossRef]

- Cao, C.; Wang, B.; Zhang, W.; Zeng, X.; Yan, X.; Feng, Z.; Wu, Z. An improved faster R-CNN for small object detection. IEEE Access 2019, 7, 106838–106846. [Google Scholar] [CrossRef]

- Zhu, Y.; Song, H. Improved Small Defect Detection on Ceramic Surfaces with YOLOv8. In Proceedings of the 2024 39th Youth Academic Annual Conference of Chinese Association of Automation (YAC), Dalian, China, 7–9 June 2024; IEEE: Washington, DC, USA, 2024; pp. 1879–1884. [Google Scholar]

- Han, L. Ceramic Surface Defect Detection Based on Deep Learning. Master’s Thesis, Shenyang University of Aeronautics and Astronautics, Shenyang, China, 2022. [Google Scholar]

- Chen, W.; Zou, B.; Zheng, Q.; Huang, C.; Li, L.; Liu, J. Research on anti-interference detection of 3D-printed ceramics surface defects based on deep learning. Ceram. Int. 2023, 49, 22479–22491. [Google Scholar] [CrossRef]

- Dong, G.; Wang, Y.; Liu, S.; Wu, N.; Kong, X.; Chen, X.; Wang, Z. A New Method for Rapid Detection of Surface Defects on Complex Textured Tiles. J. Nondestruct. Eval. 2025, 44, 3. [Google Scholar] [CrossRef]

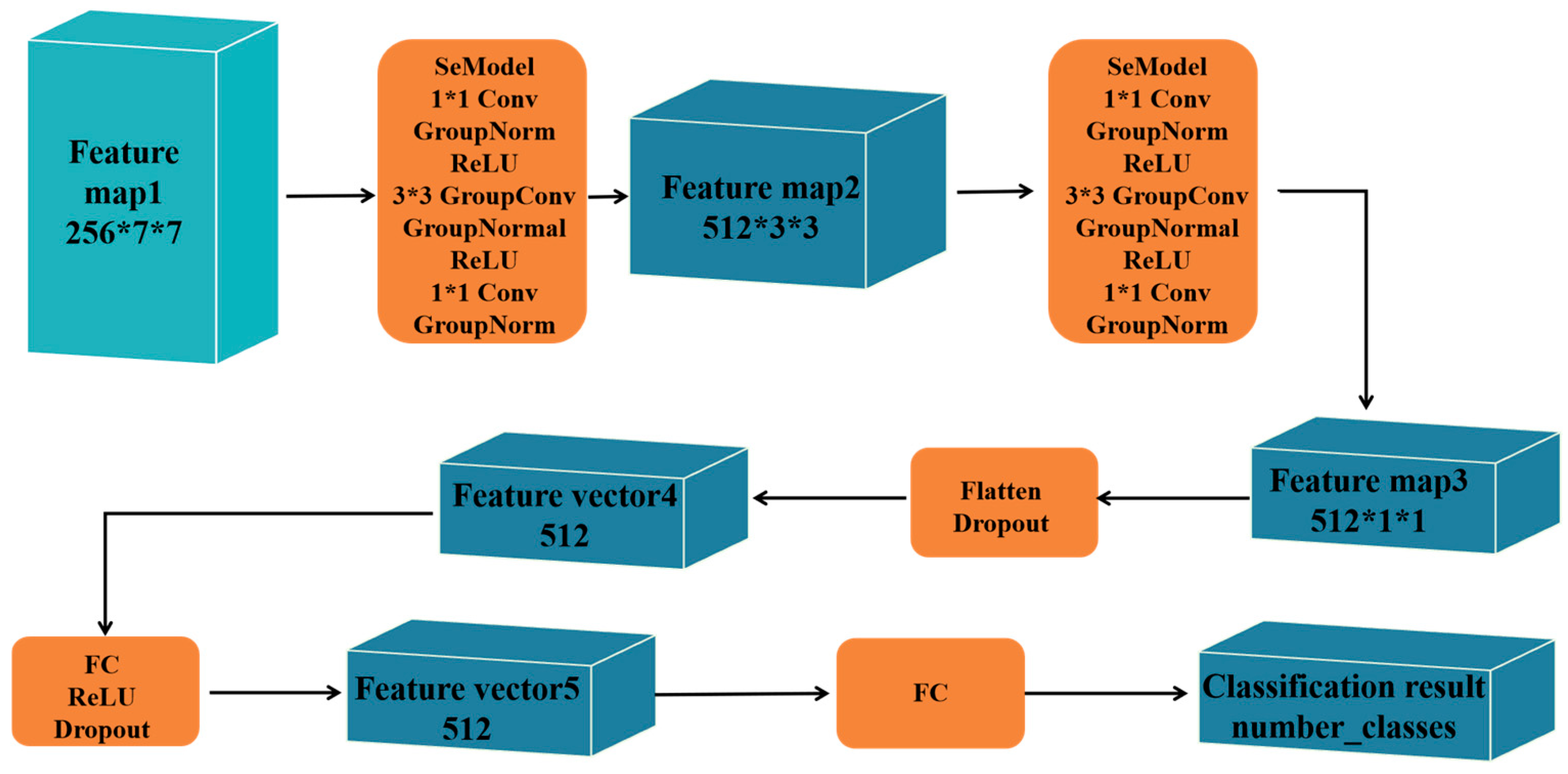

- Man, Y.J.; Wang, X.; Sun, D.Y.; Deng, N.D.; Wu, S.X. 2Defect Detection of Metallized-Ceramic Rings Based on Fusion of Object Detection and Image Classification Networks. Laser Optoelectron. Prog. 2023, 60, 167–175. [Google Scholar]

- Liu, Y.; Qiu, W.; Fu, K.; Chen, X.; Wu, L.; Sun, M. An improved YOLOv8 model and mask convolutional autoencoder for multi-scale defect detection of ceramic tiles. Measurement 2025, 248, 116847. [Google Scholar] [CrossRef]

- Guo, M.H.; Xu, T.X.; Liu, J.J.; Liu, Z.N.; Jiang, P.T.; Mu, T.J.; Hu, S.M. Attention mechanisms in computer vision: A survey. Comput. Vis. Media 2022, 8, 331–368. [Google Scholar] [CrossRef]

- Pan, J.J.; Zeng, C.; Zhang, J.; Li, Z.Y.; Geng, X.N. Ceramic Surface Defect Detection Algorithm Based on Improved YOLOv5. Mod. Inf. Technol. 2024, 8, 70–75. [Google Scholar]

- An, D.; Hu, R.H.; Wang, L.Y.; Sao, M.; Li, X.R.; Liu, Z.T. Ceramic Bearing Surface Defect Detection Method Based on Transformer. Modul. Mach. Tool Autom. Manuf. Tech. 2024, 2, 160–163+168. [Google Scholar]

- Tang, Y.X. Research on Low Temperature Co-Fired Ceramic Hole Filling Defects Detection Technology Based on Machine Vision. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2023. [Google Scholar]

- Chen, W.; Zou, B.; Huang, C.; Yang, J.; Li, L.; Liu, J.; Wang, X. The defect detection of 3D-printed ceramic curved surface parts with low contrast based on deep learning. Ceram. Int. 2023, 49, 2881–2893. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, S.; Wang, Y.; Huan, W. Review of research on lightweight convolutional neural networks. In Proceedings of the 2020 IEEE 5th Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 12–14 June 2020; IEEE: Washington, DC, USA, 2020; pp. 1713–1720. [Google Scholar]

- Wang, Z. Research on Defects Detection of Direct Bounding Copper Based on Faster R-CNN. Master’s Thesis, Xiangtan University, Xiangtan, China, 2020. [Google Scholar]

- Wang, S.Q.; Dun, W.C.; Huang, J.F.; Wang, N.T. Ceramic Tile Surface Defect Detection Based on YOLOv5. Packag. Eng. 2022, 43, 217–224. [Google Scholar]

- Ma, C.K.; Wu, Y.H.; Fu, H.Q.; Ye, N. Real-Time Defect Detection System for Advanced Ceramic Parts Based on Deep Learning. J. Nanjing Univ. Aeronaut. Astronaut. Nat. Sci. Ed. 2021, 53, 726–734. [Google Scholar]

- Yang, M.Y. Research on Defect Detection and Size Measurement Technology of Ceramic Medicine Bottle. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2022. [Google Scholar]

| Problem | Improvement Methods | Advantages | Disadvantages | Future Research Directions |

|---|---|---|---|---|

| Imbalanced sample detection problem | Data augmentation, clustering sampling, and loss function optimization | Improved minority class recognition and overall accuracy | Limited performance under extreme imbalance | Synthetic data generation and intelligent resampling |

| Small-sample detection problem | GAN-based augmentation, pre-training, unsupervised learning, and structure design | Reduced overfitting and better generalization and accuracy | Poor robustness and challenges in complex environments | Semi/self-supervised learning and novel augmentation |

| Small-target-detection problem | Attention mechanisms, multi-scale feature fusion, and network optimization | Enhanced feature representation and better detection | High computational cost and long training time | Lightweight attention and new loss functions |

| Real-time detection problem | Lightweight networks, module optimization, and simplified structures | Faster detection with acceptable accuracy | Accuracy may drop in complex scenarios | Efficient architecture design and algorithm optimization |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhang, L.; Zhao, X.; Tang, B.; Yang, W. Review of Research on Ceramic Surface Defect Detection Based on Deep Learning. Electronics 2025, 14, 2365. https://doi.org/10.3390/electronics14122365

Wang Y, Zhang L, Zhao X, Tang B, Yang W. Review of Research on Ceramic Surface Defect Detection Based on Deep Learning. Electronics. 2025; 14(12):2365. https://doi.org/10.3390/electronics14122365

Chicago/Turabian StyleWang, Yu, Long Zhang, Xinjie Zhao, Binghui Tang, and Weidong Yang. 2025. "Review of Research on Ceramic Surface Defect Detection Based on Deep Learning" Electronics 14, no. 12: 2365. https://doi.org/10.3390/electronics14122365

APA StyleWang, Y., Zhang, L., Zhao, X., Tang, B., & Yang, W. (2025). Review of Research on Ceramic Surface Defect Detection Based on Deep Learning. Electronics, 14(12), 2365. https://doi.org/10.3390/electronics14122365