Development of a Pipeline-Cleaning Robot for Heat-Exchanger Tubes

Abstract

1. Introduction

- (1)

- The stability and adaptability of robot motion in confined pipelines are still limited, often resulting in slippage or jamming;

- (2)

- Due to variations in pipe diameter and spatial constraints, existing cleaning mechanisms often fail to reach and effectively clean the deep or branched regions of heat-exchanger tubes;

- (3)

- Many current systems lack real-time sensing and feedback control, making precise alignment and autonomous operation difficult to achieve.

2. Robot Structural Design

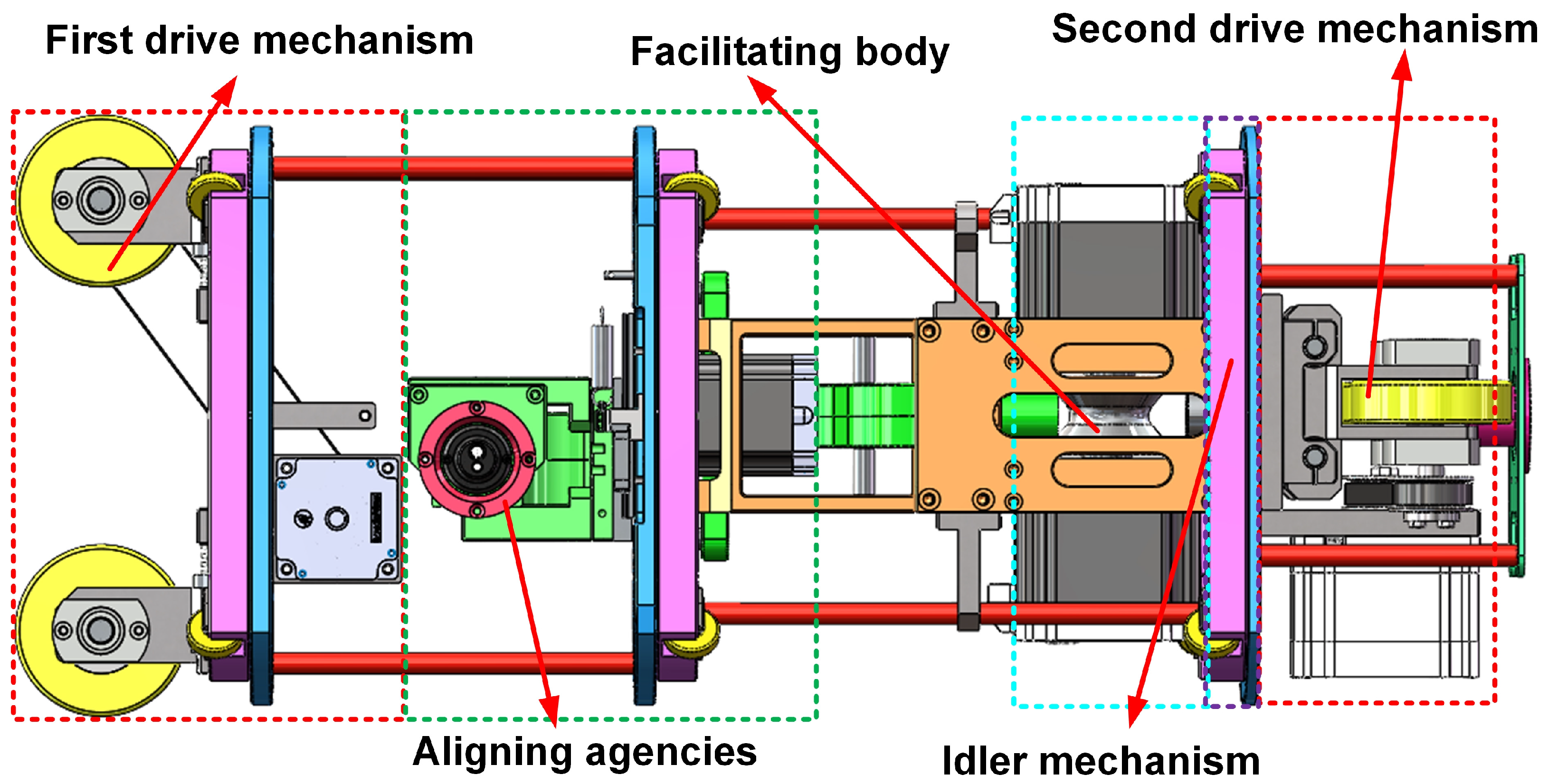

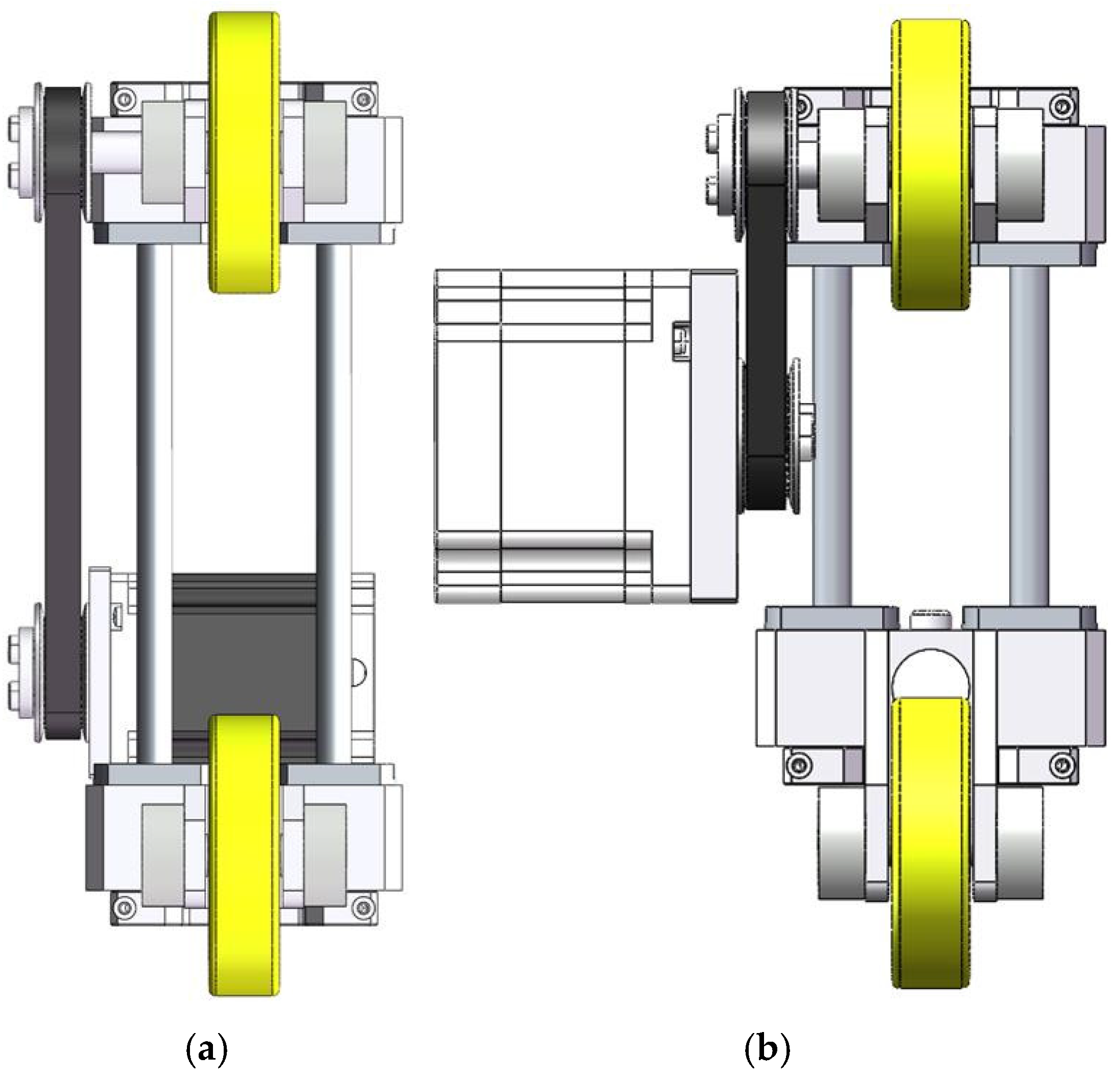

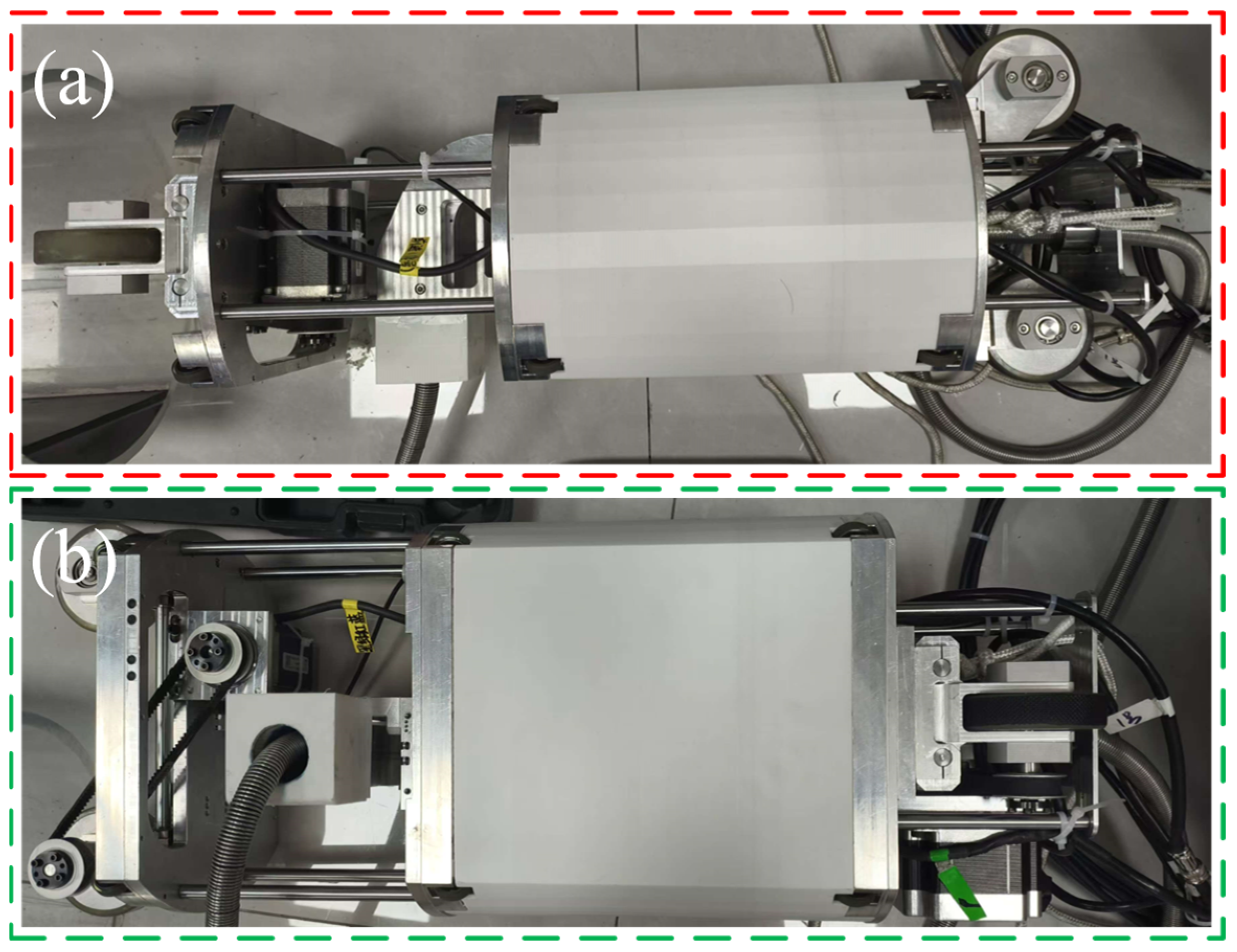

2.1. Mechanical Structure Design

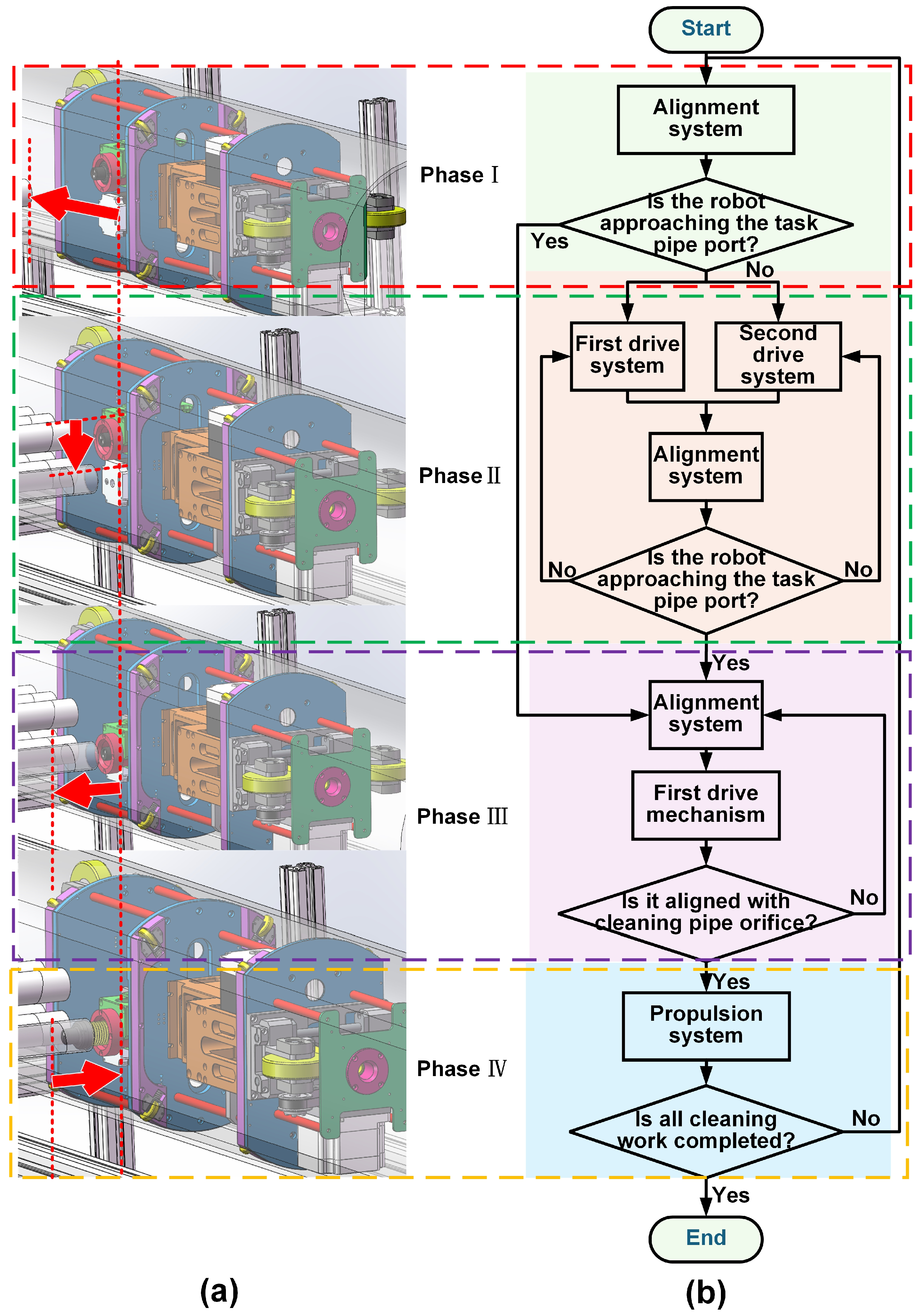

2.2. Working Principle

3. Kinematic Analysis

- Force (): Newton (N).

- Mass (): kilogram (kg).

- Acceleration (): meters per second squared (m/s2).

- Velocity (): meters per second (m/s).

- Torque (): Newton meter (N·m).

- Radius/diameter (, ): meter (m).

- Pressure (): Pascal (Pa).

- Area (): square meter (m2).

- Angular velocity (): revolutions per minute (rpm), unless otherwise stated.

- Friction coefficient (), efficiency (), and safety factor (): dimensionless.

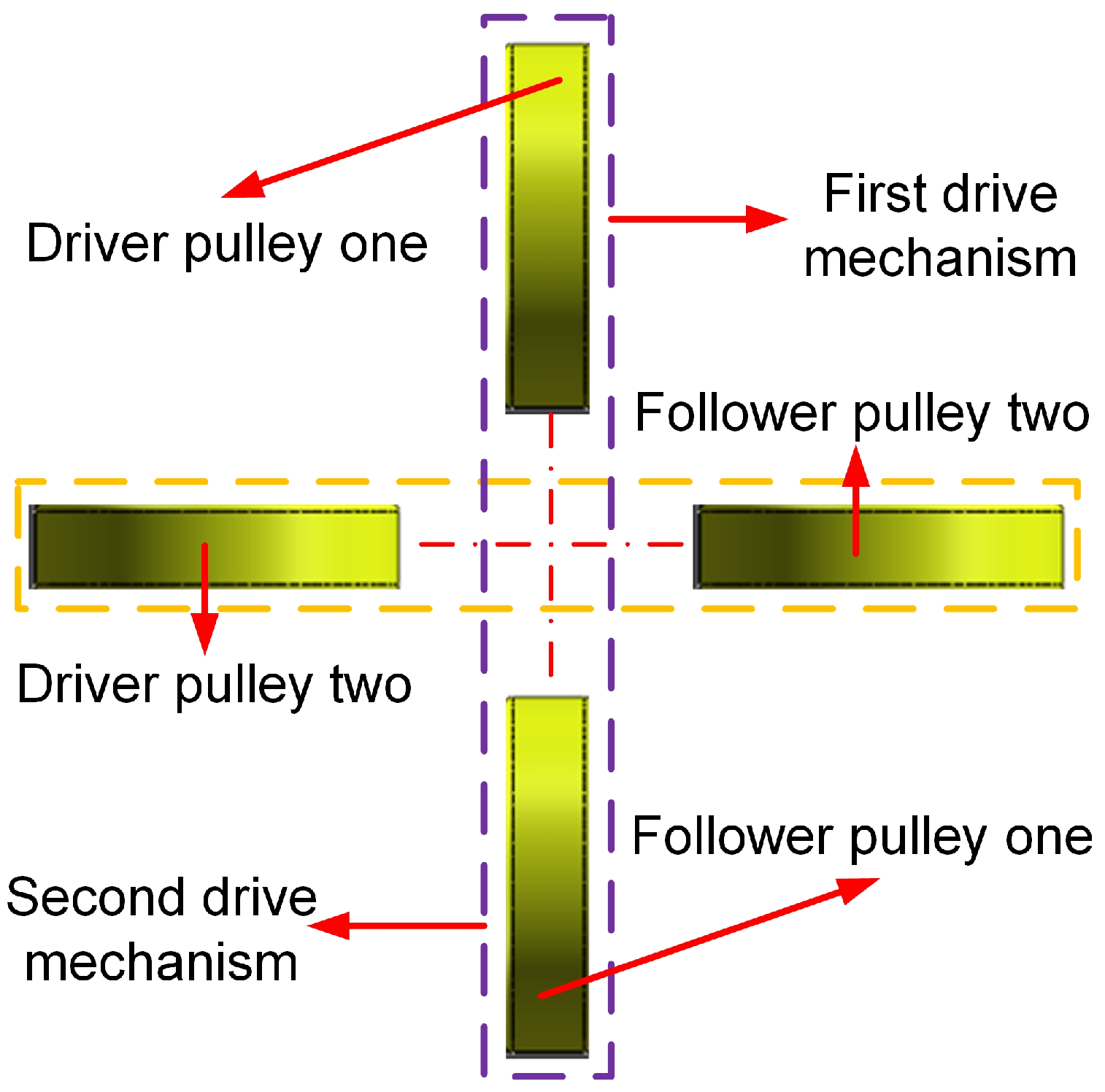

3.1. Drive-Mechanism Analysis

- is the friction coefficient between the wheel group and the inner wall of the pipeline (set as 0.35 in this study, based on typical engineering values for steel–rubber contact);

- is the total mass of the robot (approximately 25 kg, measured by weighing);

- is the gravitational acceleration (9.81 m/s2);

- is the inclination angle of the pipeline (default is 0°, but retained as a variable to account for extreme conditions);

- is the linear acceleration of the robot during startup or speed transitions (determined by actual control parameters).

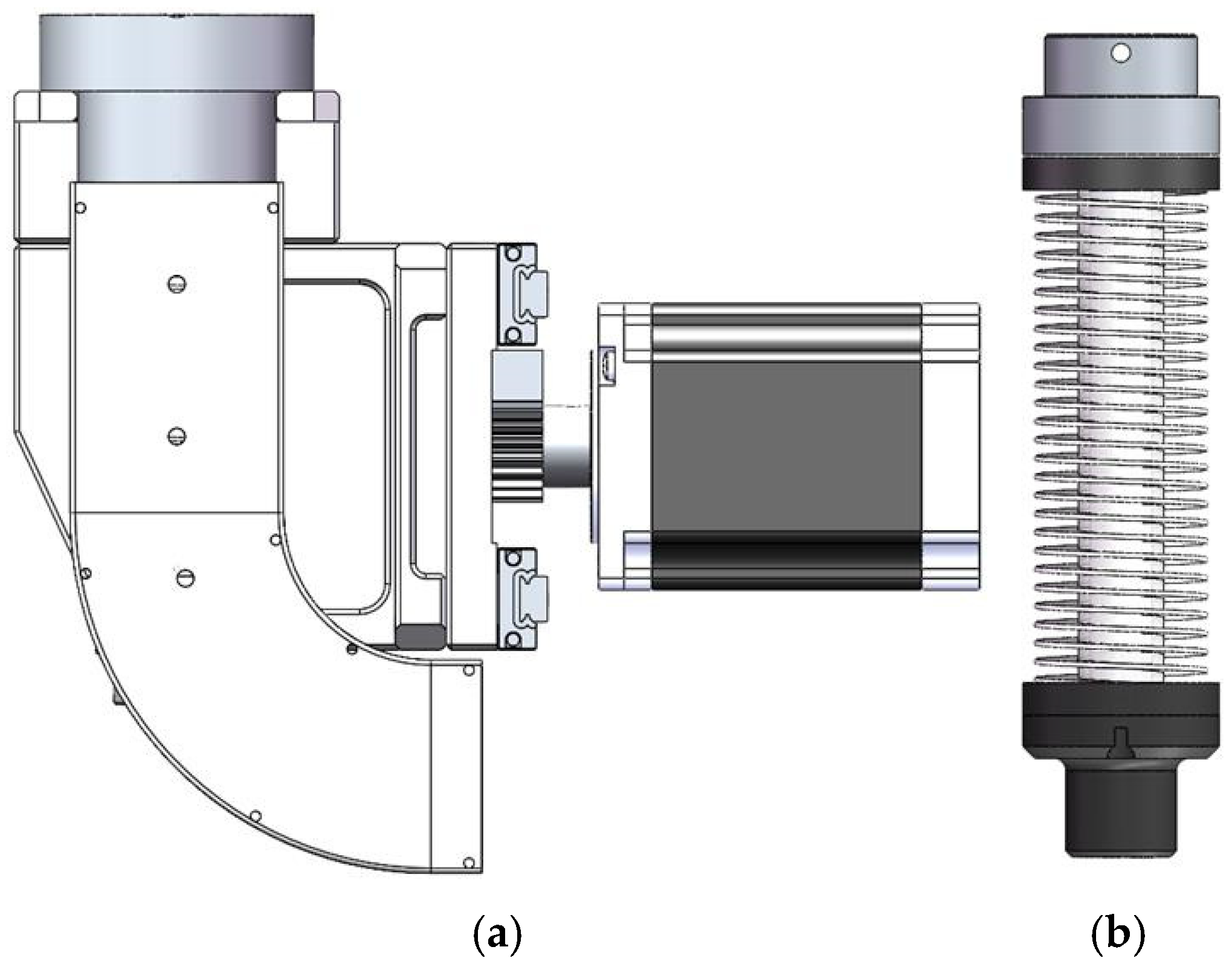

3.2. Propulsion Mechanism Analysis

3.3. Alignment Mechanism Analysis

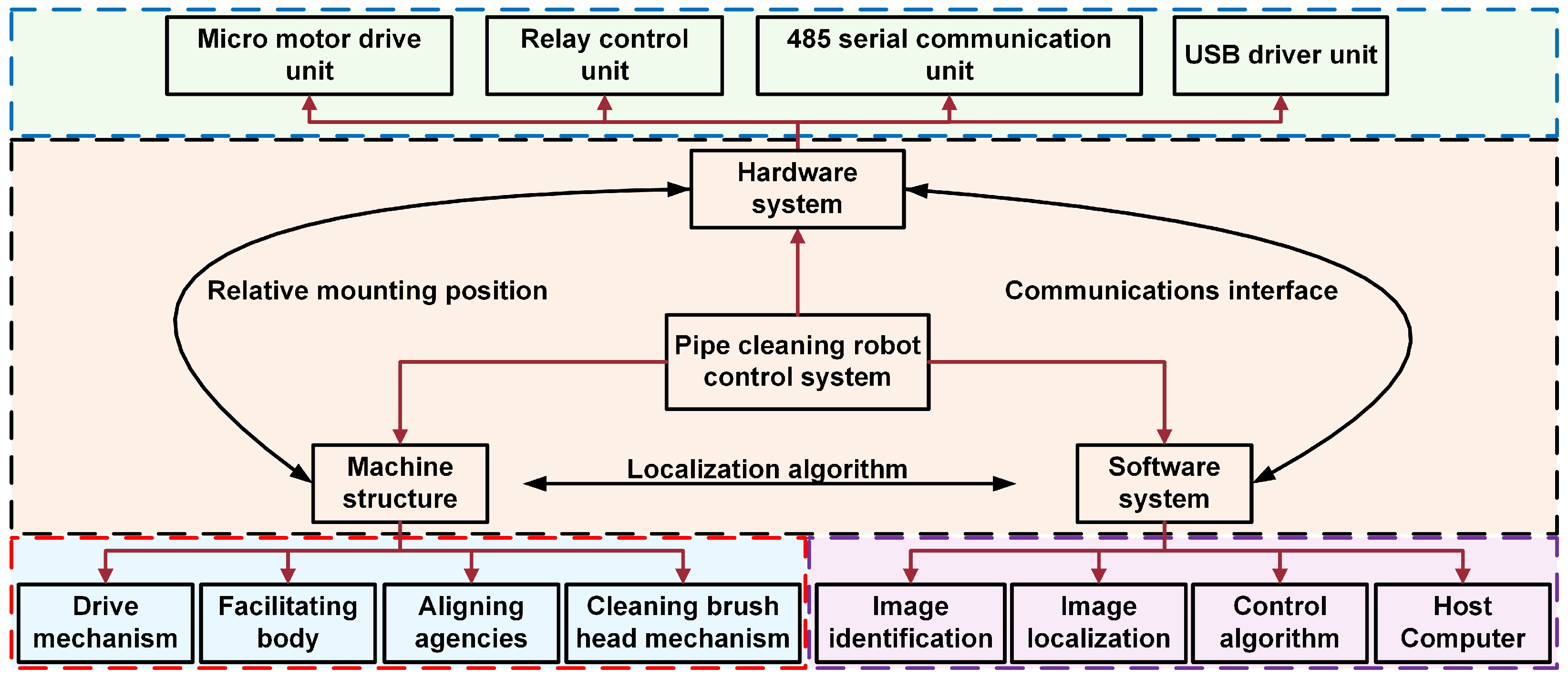

4. Control System Design

4.1. Overall Design of the Control System

- Modular control architecture with decoupled subsystems improves fault tolerance;

- Vision-based feedback dynamically corrects robot drift and localization errors inside the pipe;

- Independent and redundant circuit layouts for driving and control, including overload protection and physical limit switches;

- A state recognition and task-switching mechanism is embedded in the control logic to prevent malfunctions caused by abnormal data or environmental interference.

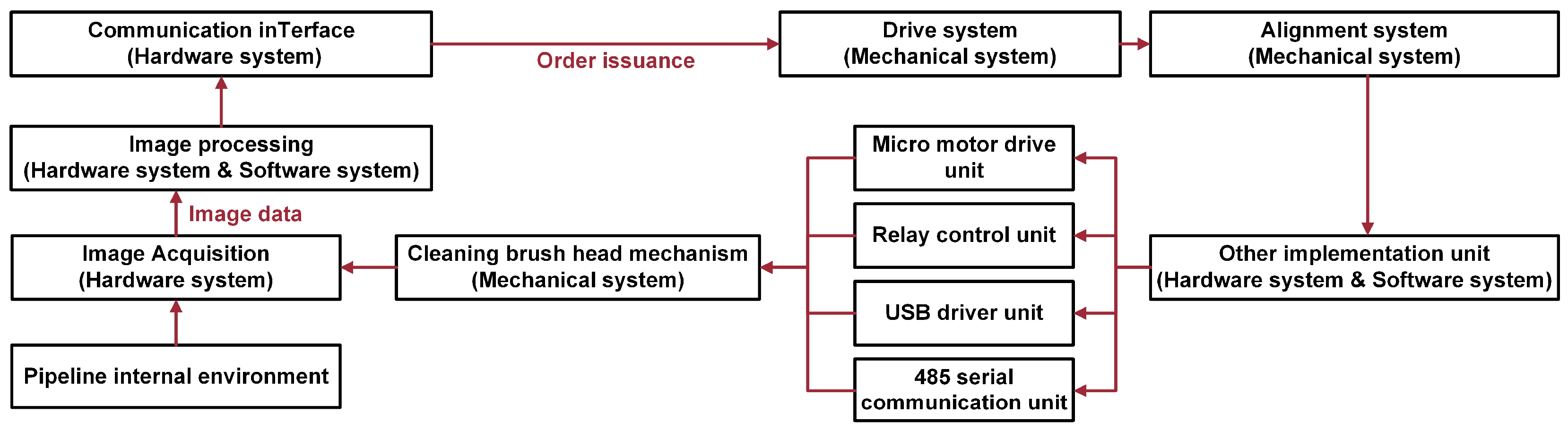

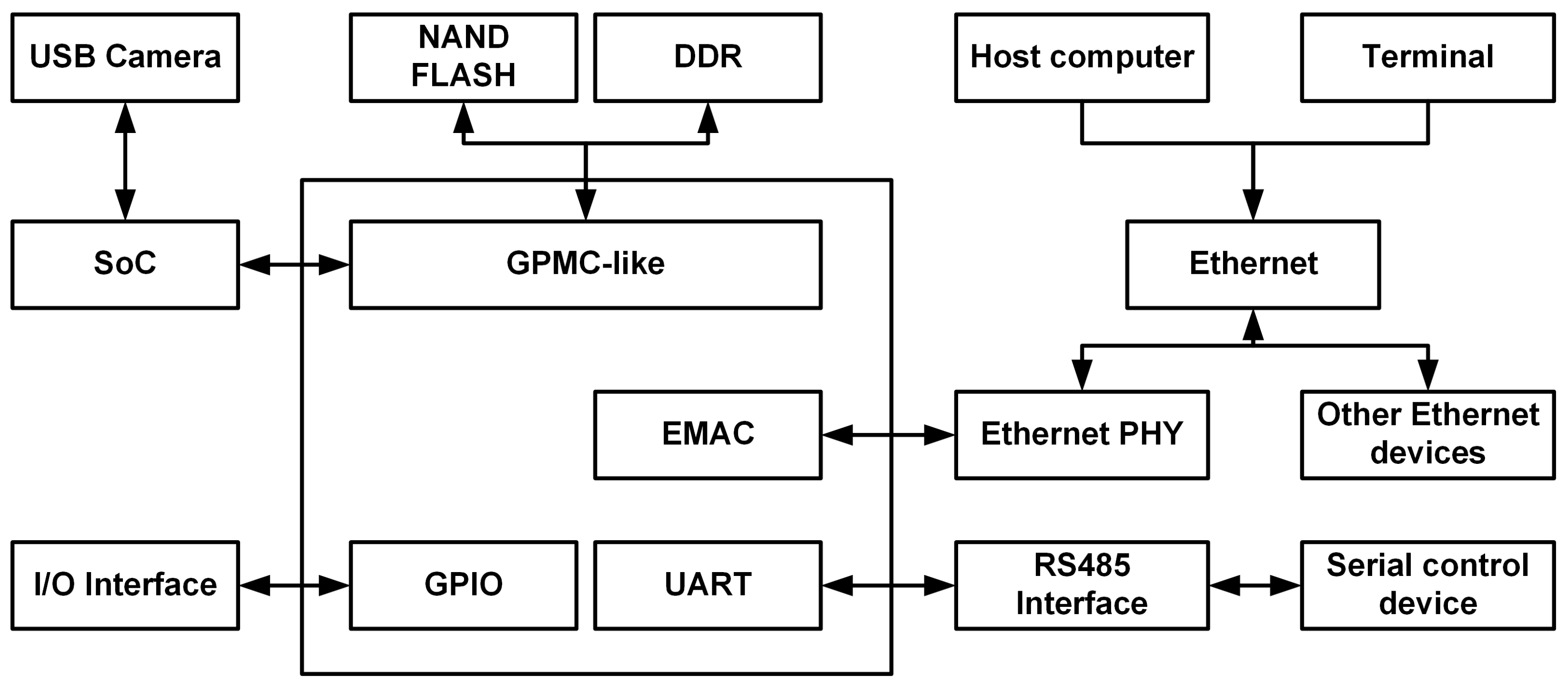

4.2. Hardware Design of the Control System

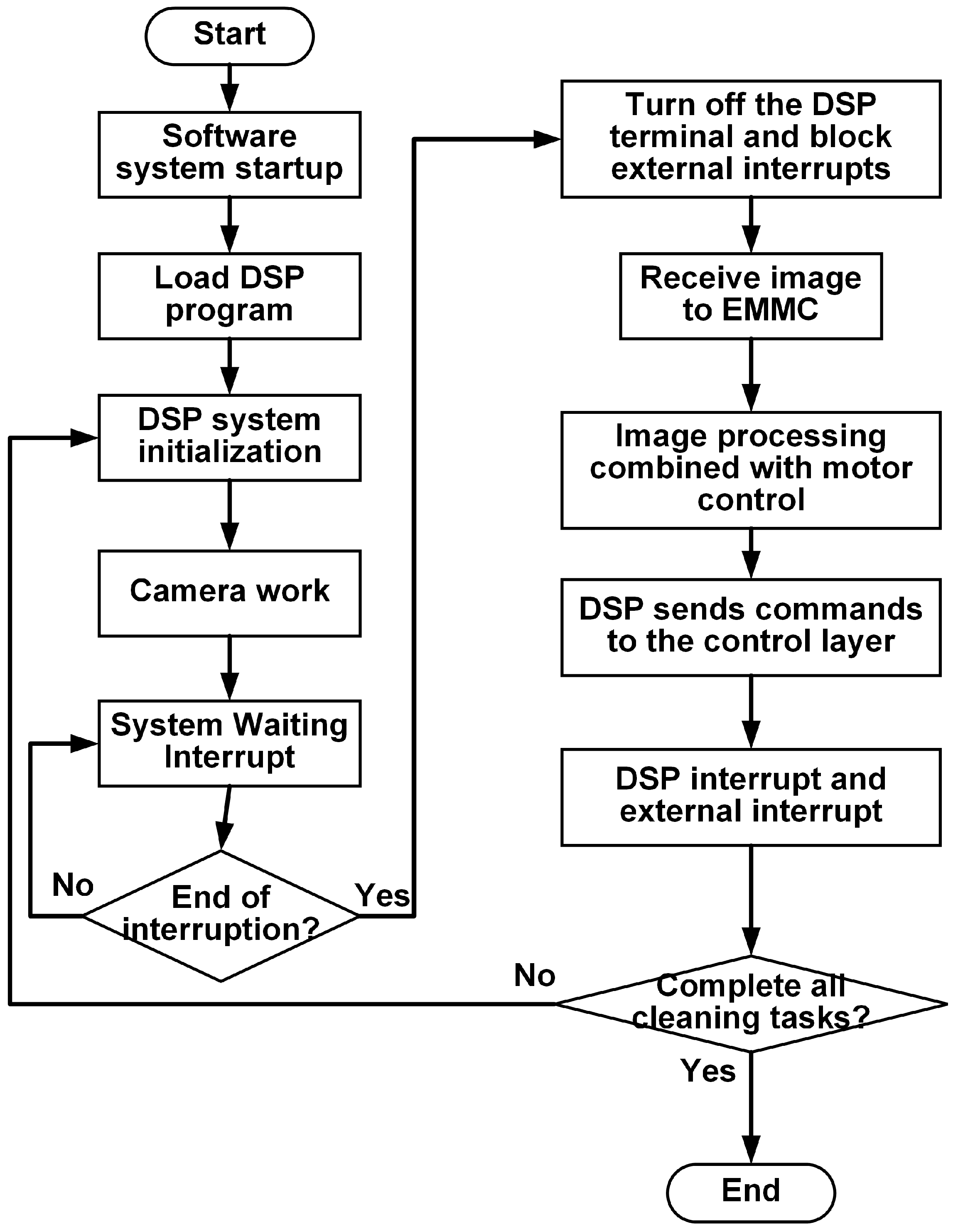

4.3. Software Design of the Control System

- (1)

- Image preprocessing: Grayscale conversion and bilateral filtering are applied to reduce noise while preserving edge features;

- (2)

- Feature extraction: Canny edge detection is performed, followed by morphological operations to enhance structural boundaries;

- (3)

- Geometric localization: Hough circle detection is employed to extract the centers of the brush head and the target sub-pipe for position recognition;

- (4)

- Deviation evaluation and control: The composite deviation is calculated from the center offset and compared with a threshold, . If , the system proceeds to the cleaning phase; otherwise, dual-channel PID controllers output horizontal and vertical correction commands iteratively.

| Algorithm 1 Visual-Guided Alignment Algorithm with Closed-Loop Control |

| Input: |

| Initial pipeline image |

| Alignment threshold |

| Maximum iterations |

| Output: |

| Motor control sequence |

| 1: Initialize: |

| 2: while and do |

| 3: Step 1: Image Processing |

| 4: Detect pipe center |

| 5: Detect brush head center |

| 6: Calculate deviations: |

| 7: Compute total deviation: |

| 8: Step 2: Horizontal Alignment |

| 9: if then |

| 10: Horizontal control |

| 11: if then |

| 12: |

| 13: else |

| 14: |

| 15: end if |

| 16: end if |

| 17: Step 3: Vertical Alignment |

| 18: if then |

| 19: Horizontal control |

| 20: if then |

| 21: |

| 22: else |

| 23: |

| 24: end if |

| 25: end if |

| 26: Update image: |

| 27: |

| 28: end while |

| 29: if then |

| 30: |

| 31: else |

| 32: |

| 33: Error recovery starts |

| 34: Reset actuators to default state |

| 35: Log current position and trigger fallback protocol |

| 36: Notify operator or retry alignment in next cycle |

| 37: end if |

5. Experimental Results and Discussion

5.1. Simulated Mobility Experiment for the Primary Pipeline to Be Cleaned

5.2. Simulated Cleaning Experiment for the Secondary Pipeline

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| SoC | System on Chip |

| UART | Universal Asynchronous Receiver/Transmitter |

| GPIO | General-Purpose Input/Output |

| EMAC | Ethernet Media Access Controller |

| DSP | Digital Signal Processor |

References

- Zhu, M.; Briot, S.; Chriette, A. Sensor-Based Design of a Delta Parallel Robot. Mechatronics 2022, 87, 102893. [Google Scholar] [CrossRef]

- Zhao, P.; Zhang, Y.; Guan, H.; Deng, X.; Chen, H. Design of a Single-Degree-of-Freedom Immersive Rehabilitation Device for Clustered Upper-Limb Motion. J. Mech. Robot. 2021, 13, 031006. [Google Scholar] [CrossRef]

- Zhu, M.; Huang, C.; Song, S.; Xu, S.; Gong, D. Vision-Admittance-Based Adaptive RBFNN Control with a SMC Robust Compensator for Collaborative Parallel Robots. J. Frankl. Inst. 2024, 361, 106538. [Google Scholar] [CrossRef]

- Huang, C.; Zhu, M.; Song, S.; Zhao, Y.; Jiang, J. Vision-Based Adaptive LT Sliding Mode Admittance Control for Collaborative Robots with Actuator Saturation. Robotica 2024, 42, 1986–2003. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Zhou, Q.; Feng, S.; Wang, X. Mechanism Design and Mechanical Analysis of Pipeline Inspection Robot. Ind. Robot. Int. J. Robot. Res. Appl. 2025, 52, 137–143. [Google Scholar] [CrossRef]

- John, B.; Shafeek, M. Pipe Inspection Robots: A Review. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Online, 9–13 May 2022; Volume 1272, p. 012016. [Google Scholar]

- Shao, L.; Wang, Y.; Guo, B.; Chen, X. A Review over State of the Art of In-Pipe Robot. In Proceedings of the 2015 IEEE Inter-national Conference on Mechatronics and Automation (ICMA), Beijing, China, 2–5 August 2015; pp. 2180–2185. [Google Scholar]

- Kahnamouei, J.T.; Moallem, M. A Comprehensive Review of In-Pipe Robots. Ocean Eng. 2023, 277, 114260. [Google Scholar] [CrossRef]

- Jang, H.; Kim, T.Y.; Lee, Y.C.; Kim, Y.S.; Kim, J.; Lee, H.Y.; Choi, H.R. A Review: Technological Trends and Development Direction of Pipeline Robot Systems. J. Intell. Robot. Syst. 2022, 105, 59. [Google Scholar] [CrossRef]

- Miyake, S.; Yoshida, K.; Sugano, S.; Kamezaki, M. Preliminary Design and Evaluation of a Ducted-Fan Type Pipeline Robot. ROBOMECH J. 2024, 11, 7. [Google Scholar] [CrossRef]

- Shen, Z.; Xie, M.; Song, Z.; Bao, D. Design and Performance Analysis of a Parallel Pipeline Robot. Electronics 2024, 13, 4848. [Google Scholar] [CrossRef]

- Zheng, T.; Wang, X.; Li, H.; Zhao, C.; Jiang, Z.; Huang, Q.; Ceccarelli, M. Design of a Robot for Inspecting the Multishape Pipeline Systems. IEEE/ASME Trans. Mechatron. 2022, 27, 4608–4618. [Google Scholar] [CrossRef]

- Song, S.; Zhao, M.; Gong, D.; Zhu, M. Convergence and Stability Analysis of Value Iteration Q-Learning under Non-Discounted Cost for Discrete-Time Optimal Control. Neurocomputing 2024, 606, 128370. [Google Scholar] [CrossRef]

- Song, S.; Gong, D.; Zhu, M.; Zhao, Y. Discrete-Time Optimal Control of State-Constrained Nonlinear Systems Using Approximate Dynamic Programming. Int. J. Robust Nonlinear Control 2025, 35, 858–871. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, M.; Du, L.; Bao, S.; Hu, Z.; Yuan, J. Design of a Magnetic Hemispherical Wheeled Pipeline Robot. In Proceedings of the 2024 IEEE International Conference on Mechatronics and Automation (ICMA), Tianjin, China, 4 August 2024; pp. 1671–1676. [Google Scholar]

- Helan Vidhya, T.; Deepak, G.L.; Amruth, K.V.; Ponnarasan, D. WALL E: A Robotic Duct Cleaning System. In Proceedings of the 2024 International Conference on Advances in Computing, Communication and Applied Informatics (ACCAI), Chennai, India, 9 May 2024; pp. 1–7. [Google Scholar]

- Momma, Y.; Hitomi, T.; Ito, F.; Nakamura, T. Square Duct Cleaning Machine Using a Multistage Planetary Gear Mechanism for Removing Grease. IEEE Access 2025, 13, 1962–1973. [Google Scholar] [CrossRef]

- Tanihira, H.; Tanaka, M. Motion Design of a Pipe Cleaning Snake Robot with a Long Brush. Adv. Robot. 2024, 38, 863–879. [Google Scholar] [CrossRef]

- Lee, K.; Kim, J.; Kim, K.; Park, J. Development of a Rotation Swab Pig Method for Cleaning Water Pipes. J. Korean Geosynth. Soc. 2024, 23, 63–75. [Google Scholar] [CrossRef]

- Liu, X.-Y.; Yang, J.-D.; Zhang, Y.; Zhang, X.-J.; Liu, H.-Y.; Duan, X.-H. Research on Automatic Pipe Cleaning Technology for Natural Gas Medium and Low Pressure Pipelines. J. Phys. Conf. Ser. 2024, 2834, 012153. [Google Scholar] [CrossRef]

- Tang, C.; Du, B.; Jiang, S.; Shao, Q.; Dong, X.; Liu, X.-J.; Zhao, H. A Pipeline Inspection Robot for Navigating Tubular Environments in the Sub-Centimeter Scale. Sci. Robot. 2022, 7, eabm8597. [Google Scholar] [CrossRef]

- Li, X.; Liu, L.; Huang, P.; Li, B.; Xing, Y.; Wu, Z. A Highly Adaptable Soft Pipeline Robot for Climbing Outside Millimeter-Sized Pipelines. Nano Energy 2025, 134, 110566. [Google Scholar] [CrossRef]

- Roh, S.-G.; Choi, H.R. Differential-Drive in-Pipe Robot for Moving inside Urban Gas Pipelines. IEEE Trans. Robot. 2005, 21, 1–17. [Google Scholar] [CrossRef]

- Kazeminasab, S.; Sadeghi, N.; Janfaza, V.; Razavi, M.; Ziyadidegan, S.; Banks, M.K. Localization, Mapping, Navigation, and Inspection Methods in In-Pipe Robots: A Review. IEEE Access 2021, 9, 162035–162058. [Google Scholar] [CrossRef]

- Li, Y.; Huang, X. Oil and Gas Pipeline Robot Localization Techniques: A Review. Proc. Inst. Mech. Eng. Part C: J. Mech. Eng. Sci. 2024, 238, 11049–11067. [Google Scholar] [CrossRef]

- Wang, W.; Gao, Z. A Variable Diameter Climbing Gait Design for a Snake Robot Based on the Bezier Curve. Int. J. Control Autom. Syst. 2024, 22, 3753–3761. [Google Scholar] [CrossRef]

- Han, L.; Ding, F.; Zhao, L.; Li, P.; Li, C.; Liu, M.; Ren, L.; Li, Y. Design and Motion Analysis of a Coal Mine Robot with Variable Wheel Diameter. Sci. Rep. 2025, 15, 6497. [Google Scholar] [CrossRef]

- Choi, H.R.; Roh, S. In-Pipe Robot with Active Steering Capability for Moving inside of Pipelines. In Bioinspiration and Robotics Walking and Climbing Robots; Intech Open Access Publisher: London, UK, 2007. [Google Scholar]

- Galajdová, A.; Virgala, I.; Kelemen, M.; Miková, L.; Lipták, T.; Kelemenová, T. Influence of Pipe Geometric Deviation on Bristled In-Pipe Mobile Robot Locomotion. Int. J. Adv. Robot. Syst. 2018, 15, 1729881418775808. [Google Scholar] [CrossRef]

- Rusu, C.; Tatar, M.O. Adapting Mechanisms for In-Pipe Inspection Robots: A Review. Appl. Sci. 2022, 12, 6191. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, G. In-Pipe Inspection Robot with Active Pipe-Diameter Adaptability and Automatic Tractive Force Adjusting. Mech. Mach. Theory 2007, 42, 1618–1631. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, F.; Wang, L. Soft Modular Pipe Robot Inspired by Earthworm for Adaptive Pipeline Internal Structure. Smart Mater. Struct. 2024, 33, 105019. [Google Scholar] [CrossRef]

- Mourik. Hydra Robotic Exchanger Cleaning Successful at Chemelot Site. Available online: https://www.mourik.com/news/hydra-robotic-exchanger-cleaning-successful-at-chemelot-site.html (accessed on 19 April 2025).

- Idrojet. Automatic Tube Bundle Cleaning System. Available online: https://www.idrojet.com/product/autojet-si-9305/ (accessed on 19 April 2025).

| Symbol | Description | Mathematical Definition |

|---|---|---|

| Initial image | RGB image matrix | |

| Alignment threshold | Position tolerance | |

| Max iterations | Positive integer | |

| Pipe center | Detected by Hough transform | |

| Brush head center | Feature matching coordinates | |

| Horizontal deviation | ||

| Vertical deviation | ||

| Total deviation | ||

| Iteration counter | ||

| Control commands | Set of motor commands | |

| PID() | Control function |

| Switching Case | Group 1 (s) | Group 2 (s) | Group 3 (s) | Mean (s) | Std Dev (s) |

|---|---|---|---|---|---|

| Tube 2 → 3 | 15 | 13 | 16 | 14.67 | 1.53 |

| Tube 3 → 4 | 14 | 12 | 11 | 12.33 | 1.53 |

| Tube 4 → 5 | 21 | 17 | 17 | 18.33 | 2.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Li, C.; Wang, G.; Li, L.; Wang, J.; Tan, J.; Wu, Y. Development of a Pipeline-Cleaning Robot for Heat-Exchanger Tubes. Electronics 2025, 14, 2321. https://doi.org/10.3390/electronics14122321

Liu Q, Li C, Wang G, Li L, Wang J, Tan J, Wu Y. Development of a Pipeline-Cleaning Robot for Heat-Exchanger Tubes. Electronics. 2025; 14(12):2321. https://doi.org/10.3390/electronics14122321

Chicago/Turabian StyleLiu, Qianwen, Canlin Li, Guangfei Wang, Lijuan Li, Jinrong Wang, Jianping Tan, and Yuxiang Wu. 2025. "Development of a Pipeline-Cleaning Robot for Heat-Exchanger Tubes" Electronics 14, no. 12: 2321. https://doi.org/10.3390/electronics14122321

APA StyleLiu, Q., Li, C., Wang, G., Li, L., Wang, J., Tan, J., & Wu, Y. (2025). Development of a Pipeline-Cleaning Robot for Heat-Exchanger Tubes. Electronics, 14(12), 2321. https://doi.org/10.3390/electronics14122321